2022 | NORTHWEST

THE OFFICIAL PUBLICATION OF THE NORTHWEST CHAPTER OF THE NORTH AMERICAN SOCIETY FOR TRENCHLESS TECHNOLOGY

AUTOMATED AND INTELLIGENT ANOMALY DETECTION IN SEWER PIPELINES FALL/WINTER PM #40065075

HYDRO EXCAVATORS BUILT FOR THE REAL WORLD

The Vac•Con line of vacuum excavators is designed for simple, powerful, effective soft digging operations all day long — no matter how tough the job.

Contractors and municipalities alike will discover that the Hydrovac Family of Products by Vac-Con is built to exceed their demands. Learn more at www.vac-con.com

Proudly serving Canada since 1986, our dealers offer a full line of Vac-Con products. Visit us online to locate a dealer near you.

X-Cavator CXT Hydrovac Truck

X-Cavator CXT Hydrovac Truck

More Support

Better Availability

Easier To Own

brandt.ca 1-888-227-2638

Brandt provides 24/7/365 customer support to keep your operation productive and profitable no matter what comes your way.

With more in-stock inventory available, Brandt ensures you have access to the machines you need exactly when you need them.

Brandt makes ownership easy with flexible in-house financing options to suit the needs of your business. Ditch Witch directional drills pack performance and unrivalled power into a tough line-up of exceptional, easy to own machines. HERE’S THE DRILL.

ONLINE

IN THIS ISSUE: MESSAGE FROM THE NASTT-NW CHAIR ....................... 6 MESSAGE FROM NASTT 8 ADVERTISER PRODUCT & SERVICE CENTRE 30 DEPARTMENTS: THE OFFICIAL PUBLICATION OF THE NORTHWEST CHAPTER OF THE NORTH AMERICAN SOCIETY FOR TRENCHLESS TECHNOLOGY 2022 | NORTHWEST ON THE COVER: Esplanade Riel By Wade Kehler https://stock.adobe.com/ca 2022 | NORTHWEST THE OFFICIAL PUBLICATION OF THE NORTHWEST CHAPTER OF THE NORTH AMERICAN SOCIETY FOR TRENCHLESS TECHNOLOGY AUTOMATED AND INTELLIGENT ANOMALY DETECTION IN SEWER PIPELINES FALL/WINTER PM #40065075 www.kelman.ca Managing Editor: Marc Lagace Design/Layout: Dani Goulet Marketing Manager: Chad Morrison Advertising Coordinator: Stefanie Hagidiakow ©2022 Craig Kelman & Associates Ltd. All rights reserved. The contents of this publication, which does not necessarily reflect the opinion of the publisher or the association, may not be reproduced by any means, in whole or in part, without the prior written consent of the Northwest Chapter of the North American Society for Trenchless Technology. NASTT-NW BOARD OF DIRECTORS CHAIR SHANE COOPER Company PAST CHAIR BEN CAMPBELL Neptune Coring VICE-CHAIR GEORGE BONTAS Aegion Corporation TREASURER KEITH MOGGACH Royal Building Products SECRETARY RAVEN SHARMA City of Selkirk DIRECTOR ALI BAYAT University of Alberta DIRECTOR CHAOSHI HU EPCOR DIRECTOR CRAIG PASS Associated Engineering MAGAZINE COMMITTEE CARLIE PITTMAN Associated Engineering Return undeliverable Canadian addresses to: lauren@kelman.ca Publication Mail Agreement #40065075 13 21 NASTT-NW. COM VIEW US

7 NO-DIG SHOW 2023 IN PORTLAND, OR 9 NO-DIG NORTH – TORONTO, ON 11 CALL FOR MAGAZINE SUBMISSIONS 13 OLD SCHOOL, BUT EFFECTIVE: CONSTRUCTION OF THE SEMPLE AVENUE TRUNK SEWER UTILIZING TWO-PASS TUNNELLING 19 DIGITAL AECOM LAUNCHES NEW PIPEINSIGHTS AI PLATFORM 20 MUNICIPAL & PUBLIC UTILITY SCHOLARSHIP PROGRAM 21 AUTOMATED AND INTELLIGENT ANOMALY DETECTION IN SEWER PIPELINES NASTT-NW.COM | 5

t has been an extremely busy design and construction season throughout the Northwest Chapter, and I do hope our members got to enjoy at least a bit of summer with their families and loved ones doing what they love to do outside the office!

Of course, as summer turns to fall, No-Dig North 2022 is right around the corner! The event is being held at the Beanfield Centre in downtown Toronto from October 17-19, 2022, and will feature the largest number of exhibitors and exhibitor space for a No-Dig North event to date! Come join us for our 2022 AGM (location and date TBD), take in paper presentations from leading industry professionals, explore the exhibition hall, and see what is new in trenchless! Come share your knowledge,

learn and network with exhibitors, attendees, speakers and Municipal Scholarship winners! The program and technical committees have been working tirelessly along with NASTT to put on a world class event, so come on out and see what No-Dig North is all about! Visit nodignorth.ca for more information on the event and host hotels.

While on the topic, our NASTT-NW chapter will be the host chapter for No-Dig North 2023 in Edmonton. We will be looking for motivated volunteers to

join our program and technical committees, as well as volunteer your time at the show moderating sessions. If you wish to increase your profile in the industry and would like to volunteer, please reach out to me (shane.cooper@aecom.com). I would be happy to have you on the team!

I would also like to welcome the Canadian Underground Infrastructure Innovation Centre (CUIIC) to our own backyard!

Headed by Dr. Ali Bayat at the University of Alberta, CUIIC’s mission is to address current and future challenges related to sustainable underground infrastructure and trenchless construction through research and stakeholder collaboration, to facilitate industry innovation, collaboration, and research across Canada, and to promote excellence in education and train the next generation of leaders and industry professionals. For more information on CUIIC or to become a member, please visit cuiic.ca

The Right Choice

Would you like to become more involved in the NASTT-NW chapter? Board positions will be opening up in 2023 with elections in the early spring. If you are interested, speak to a current board member, or reach out to me directly! Look for Call for Nominations e-mails in late 2022 or 2023 and consider running for election.

Finally, I would like to wish all our members health, success and happiness as 2022 wraps up and turns to another promising year!

6 | NASTT-NW JOURNAL | Fall/Winter 2022 BACK TO CONTENTS MESSAGE FROM THE NW CHAIR SHARING OUR KNOWLEDGE

I 1-866-976-2626 www.ivisconstructioninc.com The Right People, The Right Equipment,

Servicing the Underground Infrastructure Since 1996 • Secondary Utility Locates/GPR • High pressure flushing/vacuum • CCTV (camera) inspections of sewer lines • Lift Stations-maintenance & refurbishing • Hydro excavating utilities, piles, trenching • High Rail Unit for hydrovac, flushing, vacuum • Relining of sewer lines, storm lines, laterals, T-liners, manholes and lift stations and potable water lines Residential • Commercial • Municipalities • Industrial

Shane Cooper NASTT-NW Chair

“If you wish to increase your profile in the industry and would like to volunteer, please reach out to me. I would be happy to have you on the team!”

IN-PERSON EVENTS ARE BACK AND BETTER THAN EVER!

t feels like we are embarking on a fresh start now that restrictions are lifting across North America. We are excited as we look forward to the future! We’re riding high on the success of the NASTT 2022 No-Dig Show held earlier this year in Minneapolis. We hosted over 1,700 attendees and more sponsors than ever before. The trenchless industry is ready to be back to in person with networking and education leading the way.

In the coming months we have many events planned to bring the underground infrastructure community together. This fall we hope you will join us in Toronto for the 2022 No-Dig North conference, October 17-19. No-Dig North is hosted by the Canadian Chapters of NASTT and offers two full days of training, education and networking. This is a must-attend

event for trenchless training and networking in Canada. Visit nodignorth.ca for details!

Be sure to mark your calendars and save the date for the NASTT 2023 No-Dig Show in Portland, OR, April 30 – May 4. The city of Portland is a perfect location for our industry to come together to celebrate and educate with the theme, Green Above, Green Below. It is important that our industry is a steward of our precious natural resources, and we welcome the opportunity to provide a forum to learn about the latest in innovative trenchless products and services. Learn more at nastt.org/no-dig-show

If you or your company has attended a NASTT Conference (National or Regional), you may leave that conference wondering how you could get more involved. I ask that you consider getting engaged in one of the many NASTT committees that focus on wide variety of topics. Everything from Publications Committee, Good Practice Course Committee, No Dig Planning Committee with many others for you to consider. With education as our goal and striving to provide valuable, accessible learning tools to our community, one of the things of which we are most proud at NASTT is that we have been able to grow. In keeping with our mission of education and training, we are offering our Good Practices Courses in a live, virtual format throughout the year. For the latest information on upcoming events, visit our website at nastt.org/training/events

For more information on our organization, committees, and member benefits, visit our website at nastt.org and please feel free to contact us at info@nastt.org

We look forward to seeing you at a regional or national conference or training event soon!

I 8 | NASTT-NW JOURNAL | Fall/Winter 2022 BACK TO CONTENTS MESSAGE FROM NASTT

“Be

sure to mark your calendars and save the date for the NASTT 2023 No-Dig Show in Portland, OR, April 30 – May 4.”

Building Better Communities

Associated Engineering specializes in trenchless design and construction. We provide communities with sustainable and resilient solutions. Our expertise includes horizontal directional drilling, micro-tunnelling, slip-lining, direct pipe, cased crossings, and pipe rehabilitation technologies.

www.ae.ca

10 | NASTT-NW JOURNAL | Fall/Winter 2022 BACK TO CONTENTS

Call

www.precisecrossings.com Spruce Grove, Alberta | P. (780) 962.6882 | Toll Free. (866) 962.6882 experienced in all types and sizes of crossings Environmental Sensitive Area Crossings Rivers | Creeks | Ravines certificate of recognition latest technology in navigation systems committed to safety and to our environment equipped with 110,000 lbs to 440,000 lbs capacity drills NASTT-NW.COM | 11BACK TO CONTENTS

for Submissions If you would like to submit your project paper or other content and photos for an upcoming issue of this Northwest Chapter magazine, please contact Shane Cooper (shane.cooper@aecom.com) or Carlie Pittman (pittmanc@ae.ca). Editorial submissions for the Northwest Trenchless Journal are welcome and due for our next publication by April 3, 2023.

® HANDS-FREE TECHNOLOGY KEEP YOUR CREW SAFE WITH THE SOLUTION THAT CHANGES HOW EXIT-SIDE WORK GETS DONE: TONGHAND ® SAFE. PRECISE. PRODUCTIVE. ACCESS TONGHAND ® VIDEO & DETAILS 12 | NASTT-NW JOURNAL | Fall/Winter 2022 BACK TO CONTENTS formadrain.com | 1-888-337-6764 Eliminate the costs and hassles associated with traditional CIPP methods. Opt for FORMADRAIN’s trenchless CIPP solutions for laterals and spot repairs of pipes up to 48" in diameter. Join us at the No-Dig North show in Toronto, Booth #413. ai165705395233_FORMA-20660-PubMagTrenchlessTechCanada-DemiPage-HR-2.pdf 1 2022-07-05 16:45

Minnesota

OLD SCHOOL, BUT EFFECTIVE:

Construction of the Semple Avenue Trunk Sewer Utilizing Two-Pass Tunnelling Methods

Jordan Thompson, AECOM, Winnipeg, Manitoba, Canada Marvin McDonald, AECOM, Winnipeg, Manitoba, Canada Jurgen Friesen, City of Winnipeg, Winnipeg, Manitoba, Canada Kas Zurek, City of Winnipeg, Winnipeg, Manitoba, Canada

ABSTRACT

The Semple Avenue Trunk Sewer was constructed to provide combined sewer relief for the Jefferson East Combined Sewer District in Winnipeg, Manitoba, Canada. The land drainage sewer (LDS) trunk relieves hydraulic load on the combined sewer system, reducing risk of basement flooding and combined sewer overflows to the nearby Red River. The trunk is the launch point for future sewer separation contracts in the district.

Construction included approximately 400 m (1,312') of 1,800 mm (72") LDS and 1,140 m (3,740') of 2,100 mm (84") LDS, associated lateral sewer stubs, catch basins, and manholes. The project is located in a densely treed, mature residential neighbourhood.

The subsurface stratigraphy along the alignment generally comprises of mixed upper complex soils (sand, silt and clay) overlying glacio-lacustrine clay, and glacial till deposits. A geotechnical investigation was undertaken during the design phase and a Geotechnical Baseline Report (GBR) was produced to set clear baselines for conditions that were anticipated to be encountered during construction.

The project specifications stipulated long drive tunnels to minimize disruption of the neighbourhood. Two trenchless construction methods were tendered competitively, including single-pass tunnelling with pipe jacking, and two-pass tunnelling with a grouted in place carrier pipe. The successful proponent utilized a two-pass TBM tunnelling method with

rib and lagging primary support and a Centrifugally Cast, Fiberglass-Reinforced, Polymer Mortar Pipe (CCFRPMP) carrier. The tunnel was constructed in a single drive of approximately 1,540 m (5,052") over the course of approximately five months.

INTRODUCTION

The Jefferson East Combined Sewer District represents an area of 475 hectares (1175 acres) of predominantly residential area in a mature neighbourhood in Winnipeg, Manitoba, Canada. AECOM developed the conceptual basement flooding relief and pollution abatement plan in 2009 and has been engaged in the implementation of the program since 2011.

The scope of construction work was segmented into ten (10) separate construction contracts; each providing relief to various catchments within the Jefferson East Combined Sewer District. Contracts one (1) through three (3) provided relief to catchments east of Main Street. Contracts four (4) through ten (10) will provide complete separation of the combined sewer system west of Main Street. An overview of contracts four (4) through ten (10) is shown in Figure 1.

The Semple Avenue Trunk Sewer was predominantly constructed under Contract 5, shown in orange above, to provide combined sewer relief to the Jefferson East Combined Sewer District. The new land drainage sewer (LDS) trunk relieves hydraulic load on the combined sewer system, reducing risk of basement flooding and combined sewer overflows

to the nearby Red River. The trunk is the launch point for future sewer separation contracts in the district.

Construction included approximately 400 m (1,312') of 1,800 mm (72") LDS and 1,140 m (3,740') of 2,100 mm (84") LDS, associated lateral sewer stubs, catch basins, and manholes.

SITE CONTRAINTS AND CHALLENGES

The area for construction of the new trunk sewer is a largely residential, mature neighbourhood located in north Winnipeg. The trunk spans approximately 1,540 m (5,052") along Semple Avenue and crosses eight intersections including Main Street. Several constraints and challenges were identified during the detailed design phase including:

• Impact on Existing Mature Trees

• Utility Density (Buried and Overhead)

• Noise

• Vibration

• Construction Footprint

• Traffic Disruption

• Close Vertical Proximity of Existing Combined Sewer Trunks (less than 150 millimetres)

Given the compact and well-established nature of the neighbourhood, minimizing the impact on homeowners was the top priority when reviewing potential construction technologies, monitoring requirements and mitigation measures. Trenchless construction methods were identified early in the design phase as the only acceptable method of construction that would be suitable to the area. The Semple Avenue right of way includes a large canopy of mature elm trees

Minneapolis,

NASTT-NW.COM | 13BACK TO CONTENTS

Semple

(shown in Figure 2) that are highly valued by the neighbourhood and the City of Winnipeg. Trenchless construction would allow work to occur without the need to remove trees. In addition to the tree lined boulevards, overhead power lines (shown in Figure 3) and extensive buried utilities precluded traditional open cut construction methods in the Semple Avenue right of way.

The impact of noise caused by construction was also evaluated. The City of Winnipeg Neighbourhood Liveability By-law places restrictions on noise associated with construction projects. Construction projects in Winnipeg must adhere to the requirements of the bylaw, which includes limiting construction activities to regular working day hours. Given the nature of trenchless construction and the desire to allow for the possibility of 24-hour construction, the City of Winnipeg granted exemptions to the by-law for activities deemed critical and necessary to tunnelling operations. Additional restrictions were placed on activities undertaken outside of the time periods allowed for in the by-law to ensure that the impact of noise on the neighbourhood was minimized. The restrictions included:

4 through 10.

• Only equipment deemed critical for tunnelling operations would be allowed to operate outside of regular working hours,

• Equipment must meet stringent noise output requirements, and

• Sound attenuation barriers and devices would be required if the equipment did not satisfy the noise output requirements. Baseline sound measurements of the neighbourhood were to be recorded and acoustic monitoring of construction would be implemented to confirm conformance with the specified maximum noise levels. Construction methods that are likely to impart major vibrations, including but not limited to driving sheet piles, would not be suitable to the area due to the proximity of homes and other infrastructure. The proposed construction schedule also overlapped with the coldest months of winter, which meant that frozen ground would exacerbate the potential for large vibrations. A Vibration Monitoring Plan was to be undertaken by the contractor to document the impact of potential vibrations caused by construction. The plan included:

• Pre-construction surveys of nearby buildings and structures,

14 | NASTT-NW JOURNAL | Fall/Winter 2022 BACK TO CONTENTS

Figure 1: Jefferson East Combined Sewer Relief

– Contracts

Figure 2: Semple Avenue – Tree Canopy.

Figure 3: Semple Avenue – Overhead Utilities.

Construction of the

Avenue Trunk Sewer Utilizing Two-Pass Tunneling Methods

• The supply and installation of vibration monitoring systems,

• Daily vibration monitoring reports, and

• Post-construction surveys of affected buildings and structures, as required. Semple Avenue spans approximately 1.5 km (0.9 mi) intersecting eight roads in the project area including Main Street, the primary arterial link between downtown Winnipeg and north Winnipeg. Several of the intersecting streets serve as public transit and school bus routes. Semple Avenue is a narrow two-lane street with limited space for lay-down areas. Block to block distances are approximately 200 m (656') on center, therefore minimum tunnelling drive lengths of 200 m (656') were required to minimize mid-block construction during tunnelling activities and to minimize the impact on traffic in the area.

The alignment of the proposed trunk crosses under several active sewer and water utilities including watermains and combined sewers. While the new pipe is generally much deeper than the surrounding utilities (5.5 m (18') to obvert), clearance for several deeper combined sewers ranged from 0 mm (0") to 500 mm (19.7") depending on TBM size and amount of overcut required. Utilities deemed close enough to be obstacles would require temporary relocation or bypass pumping, whereas utilities not deemed to be obstacles but at risk of damage due to subsidence of the tunnel below would require monitoring. A surface and subsurface monitoring plan was included in the contract that required that all major combined sewers and watermains along the alignment be monitored for settlement by means of surface and subsurface monitoring points.

GEOTECHNICAL CONSIDERATIONS

Winnipeg is located beneath what was once glacial Lake Agassiz and lies in a flood plain at the confluence of the Red and Assiniboine rivers, which influences both the geotechnical and hydrological characteristics of the region. The shallow bedrock geology of the Winnipeg area generally comprises of carbonate rock of the Selkirk and Fort Garry Members belonging to the Red River Formation. The Red River Formation consists of alternating layers of limestome and dolomite with basal shale layers. The overlaying surficial soils generally comprise of upper complex deposits, glacio-lacustrine clays, and glacial till soils of varying thickness and compositions. The glacial till soils were laid down by the advancing and retreating glacial ice masses. The glacio-lacustrine soils are a product of fine materials deposited through suspension within the glacial lakes.

Geotechnical Investigation

Geotechnical investigations completed under the previous construction contracts provided initial geotechnical information for the project. A new geotechnical investigation was undertaken in 2019 along the length of the Semple Avenue Trunk Sewer to supplement the existing information and determine the subsurface conditions.

A hydro excavation investigation was completed at seventeen proposed test hole locations to a maximum depth of 3.1 m (10.2") to assess the presence of buried utilities or other obstructions. One proposed test hole was discarded due to the presence of underground and aboveground utilities. The 16 remaining test holes were drilled adjacent to the alignment of the trunk. Six test holes were drilled into the deeper glacial

till and ten shallower test holes were drilled into the overlaying surficial soils. Samples collection from the drilling program were tested to determine moisture contents, grain size distribution, Atterberg limits, undrained shear strength, bulk unit weight, permeability, consolidation, swell, and electrochemical properties. An overview of the test hole program is shown in Figure 4.

A Geotechnical Data Report (GDR) was prepared to summarize the results of the geotechnical investigation. A Geotechnical Baseline Report (GBR) was prepared to detail baseline conditions for the proposed tunnelling and shaft construction work. The GDR and GBR were intended to be used in parallel to provide the contractor with:

• Clear baselines for subsurface conditions anticipated to the encountered during construction, • A single contractual interpretation for bidders to utilize when preparing bids, and

• To assist in evaluating the requirements for excavation, temporary support, groundwater control, and ground movement for the shaft and tunnel construction. Any claims related to a change of subsurface conditions during construction would be reviewed and evaluated against the baselines established in the GBR.

Historic Waterways

Winnipeg was once home to approximately 16 major streams and twenty small creeks that existed prior to the arrival of the first European settlers in the area. Many of these waterways have been drained, filled, entombed, or re-routed over time to allow for construction of infrastructure, roadways, neighbourhoods and buildings as the city

NASTT-NW.COM | 15BACK TO CONTENTS

Figure 4: Extent of Geotechnical Test Holes along Semple Avenue between McKenzie Street and Scotia Street.

the Semple Avenue Trunk Sewer Utilizing Two-Pass Tunneling Methods

grew and developed over the 20th century. While detailed records of these waterways are scarce; a review of historical maps, articles and geological information revealed the presence of a historic waterway in the project area named Inkster’s Creek that appeared to cross the alignment of the proposed trunk between Main Street and Scotia Street. The presence of Inkster’s Creek was verified by survey, as there was an approximate 2.5 m (8.2") change in the roadway elevation and topographic contours in the area follow the shape of a likely former waterway. Houses were constructed the former creek in the early 1950s, indicating that the creek has been backfilled for at least 70 years. The location of the former creek is shown in Figure 5.

Particular attention was paid to collecting additional geotechnical information in this area to determine if there were any changes in subsurface conditions that would differ from the relatively consistent material overserved along the majority of the trunk, such as alluvial soils deposits that could impact the selection of tunnelling methods. Further, the change in ground elevation reduced the overburden thickness above the proposed trunk, which would need to be considered during design and construction. The geotechnical investigation revealed that there were no significant anomalies in subsurface conditions that would negatively impact tunnel construction.

TRENCHLESS CONSTRUCTION TECHNOLOGIES

Two trenchless construction technologies were selected as viable options for the project: • Single-Pass Tunnelling with Pipe Jacking

• Two-Pass Tunnelling with Grouted in Place Carrier Pipe

The selection of these technologies was based on a balance of cost, technical requirements of the contract, and the ability to minimize disruption to the neighbourhood. It also allowed for a wide range of proponents located locally and from across Canada to pre-qualify and bid on the project.

Despite limiting allowable tunnelling methods to two primary technologies, innovation and creativity were encouraged during the procurement process. The intent was to allow for a wide range of technical approaches to the means and methods including various laydown and working areas, shaft construction techniques, pipe materials, and drive lengths. Proponents were also permitted to upsize pipe diameters, should that be of benefit to the contractor’s means and methods.

PROCUREMENT Pre-Qualification

A Request for Qualifications (RFQ) was issued in November 2019 to identify experienced and capable proponents to successfully execute the work. To qualify, the proponents were required to address the following:

1) Project Understanding:

• Demonstrate an understanding of project objectives, key issues, and risks.

• Describe the propose approach for dealing with site constraints, access limitations and traffic movements.

• Describe proposed methods of mitigating deviations in the Neighbourhood Livability By-Law (working hours, noise, etc.).

2) Proposed Tunnelling Method:

• Describe the proposed tunnelling method(s).

• Describe the proposed number of drives, shafts, and any pipe upsizing.

• Describe methods for dealing with potential obstructions.

• Describe proposed method of shaft construction.

3) Proposed Tunnelling Equipment:

• Tunnel boring machine (TBM).

• Spoil removal equipment.

• Slurry separation equipment (if required).

4) Past Project Experience (three examples per proponent, subcontractor, or key personnel):

• Minimum drive lengths of 400 m (1,312"),

• At least one drive length equal to or exceeding 600 m (1,969"), and

• Include the installation of pipes with a minimum internal diameter of 1,800 mm (70.87"), with one example including pipes with a minimum internal diameter of 2,100 mm (82.68").

Six contractors were deemed pre-qualified to bid on the project for the single-pass method, and three contractors for the twopass method.

Construction Tender

The project was tendered in January 2020 and closed in February 2020. A total of responsive bids were received ranging from $17,971,800.00 to over $32,000,000. Bids received included construction methods of microtunnelling with pipe jacking, conventional open face TBM with pipe jacking, and two-pass tunnelling with GRP liner.

McNally Construction Ltd. (McNally) of Hamilton, Ontario, Canada was awarded the construction contract in May 2020. The proposed method was a two-pass tunnelling system.

CONSTRUCTION

Mobilization:

Construction commenced in August 2020 with site mobilization and the installation of all surface, subsurface and utility monitoring points. The contractor arranged for direct connection to the local power grid, rather than using conventional diesel generators, to meet acceptable noise levels in accordance with the contract specifications and the City of Winnipeg Neighbourhood Livability By-Law.

16 | NASTT-NW JOURNAL | Fall/Winter 2022 BACK TO CONTENTS

Figure 5: Historical Location of Inkster’s Creek with Reference to the Trunk Sewer.

Construction of

Hydrogeological Investigation:

A hydrogeological investigation was undertaken by the contractor prior to the commencement of shaft construction to assess the feasibility of bedrock depressurization as a means of relieving hydrostatic pressure from the underlying bedrock aquifer at the base of the excavation. A test well was drilled, and a pumping test was completed to determine the required pumping rates and predicted radius of influence of the pumping. It was concluded that due to the low hydraulic conductivity of the glacial till, an adequate factor of safety against basal heave was attainable without the need for depressurization of the bedrock aquifer.

Tunnelling Activities:

The means and methods of tunnelling proposed by the contractor consisted of the following:

• Two-Pass Tunnelling with Grouted in Place Carrier Pipe.

• TBM: 112" Rotary Lovat TBM.

• Primary Tunnel Support: Steel ribs and timber lagging.

• Locomotive conveyed spoil removal system.

• A single tunnel drive of 1,542 m (5,059"). The proposed extent of tunnelling is shown in Figure 6.

The tunnel launch shaft was constructed at the intersection of Semple Avenue and McKenzie Street. The shaft consisted of conventional steel soldier piles with timber lagging excavated to a depth of approximately 9 m (29.5"). The steel soldier piles were pre-drilled prior to installation to mitigate the potential for vibrations. Photos of the launch shaft are shown in Figure 7.

Vibration monitoring systems were installed prior to the construction of all shafts on the project. Baseline vibration measurements were recorded for one week prior to the commencement of excavation and were maintained for the duration of construction until shafts were backfilled, and shoring removed. While there was a noted increase in vibrations during certain activities such as the movement of larger equipment on site, the measured vibrations did not exceed the allowable thresholds. In instances where vibrations were approaching the thresholds, work was temporarily stopped on site to modify means and methods to reduce vibrations to an acceptable level.

Tunnelling commenced in November 2020. Production rates ranged from

approximately 15–19 m (49.2–62.3") per day during peak production. Tunnelling continued through a cold Winnipeg winter, where temperatures dropped as low as -38.8°C (-37.8°F). Tunnelling was completed five months later in April 2021. Photos of the TBM during installation at the launch shaft, completed tunnel section, and TBM at breakthrough in the reception shaft are shown in Figure 8.

Carrier Pipe Installation:

The carrier pipe consisted of approximately 400 m (1,312') of 1,800 m (72") and 1,140 m (3,740') of 2,100 millimetre (84") CCFRPMP supplied by HOBAS. The pipe segments were installed using a rail mounted cantilever boom pipe carrier, shown in Figure 9.

An intermediate shaft was installed at the location of the size change at Andrews Street. Carrier pipe installation was

completed in May 2021. The carrier pipe was grouted in place using cellular concrete grout in June 2021. Figure 10 includes photos of the grouted in place pipe at the launch shaft and the interior of the pipe.

Appurtenances and Restoration:

All existing on street drainage was connected to the new sewer trunk upon the completion of grouting activities. LDS stubs were trenchlessly installed at Andrews Street and McKenzie Street to push the

NASTT-NW.COM | 17BACK TO CONTENTS

Figure 7: Tunnel Launch Shaft.

Figure 8: TBM install at the Launch Shaft, Completed Tunnel Section, and Breakthrough at the Reception Shaft.

Figure 6: Extent of Tunneling on Semple Avenue from McKenzie Street to Scotia Street.

Figure 9: Cross-Sectional View of Carrier Pipe Installation.

location connections under future contracts out of the Semple Avenue right-of-way and minimize future on-street excavations. 3,658 mm (12”) precast concrete box manholes were installed on the trunk at McKenzie Street, Andrews Street, and Scotia Street. Substantial Performance of the contract was achieved in October 2021. Restorations were largely complete by the end of October 2021.

SUMMARY

The Semple Trunk Sewer was constructed to provide combined sewer relief for the Jefferson East Combined Sewer District in Winnipeg, thereby reducing the risk of basement flooding and combined sewer overflows to the nearby Red River. Construction commenced in the Summer of 2020 and was successfully completed in the fall of 2021.

The successful proponent utilized a twopass TBM tunnelling method with rib and lagging primary support and a CCFRPMP carrier pipe. The tunnel was constructed in a single drive of approximately 1,540 m (5052") over the course of approximately five months.

The location of the project presented unique challenges in terms of executing a relatively large construction project in a compact residential neighbourhood. Project constraints, challenges, and potential impacts on the surrounding neighbourhood were identified early in the design process and mitigations were developed and included in the project specifications.

The mitigations put in place during construction included the requirement for long tunnel drive lengths, vibration monitoring, noise mitigation, and subsurface utility monitoring. These mitigations allowed construction to occur over a footprint of approximately 1.5 km (0.9 mi) with minimal disruption to the neighbourhood. Clear and consistent communication between AECOM, the contractor, the City of Winnipeg, as well as homeowners, schools, and businesses in the area was vital to ensuring that project objectives were met.

The procurement methods encouraged industry to be creative, utilize innovation and allowed for proponents to consider a variety of technical approaches in their

means and methods to achieve the desired end result of a safe and successful sewer installation. The flexible approach in procurement resulted in a competitive, open market, and cost-effective means of tendering the project with a wide range of high-quality proponents. Bids ranged from approximately $17,400,000 to over $32,000,000. The project was successfully completed on budget.

18 | NASTT-NW JOURNAL | Fall/Winter 2022 BACK TO CONTENTS

Figure 10: Carrier Pipe at Launch Shaft and Interior.

Construction of the Semple Avenue Trunk Sewer Utilizing Two-Pass Tunneling Methods We look back on 40 years of experience with AVN technology, 1,500 machines built, with up to 4 meters inner diameter, and countless successfully completed pipe jacking projects by our customers. With service from North America and reliable tunnelling technology we do our best to continue the joint success story. herrenknecht.com/en/avn TRUSTFUL PARTNERSHIP IN MICROTUNNELLING AVN MACHINE 22-08-30_013_ID22037_enAz_AVN_NW Trenchless Journal_7x4_RZfo 22-08-30_013_ID22037_enAz_AVN_NW Trenchless Journal_7x4_RZfo.indd 1 30.08.22 12:01

DIGITAL AECOM LAUNCHES NEW PIPEINSIGHTS AI PLATFORM

Digital AECOM is pleased to introduce its new artificial intelligence (AI) and machine learning (ML) technology designed to improve the speed and accuracy of sewer inspection programs. PipeInsights is the latest in Digital AECOM’s growing range of software offerings and helps clients rapidly deliver superior rehabilitation and maintenance activities for sewer systems. PipeInsights augments conventional CCTV inspections using advanced machine learning and computer vision algorithms to provide automated defect detection and suggest optimal maintenance decisions.

The PipeInsights platform significantly reduces the previously manual processing and QA/QC time, provides a more consistent approach to condition assessment and treatment selection as well as enhancing the overall understanding of the health of your sewer system.

By seamlessly integrating CCTV footage and results into a convenient interface, PipeInsights enables users to manage multiple sewer projects or programs simultaneously, while providing defensible structural and operational rehabilitation or replacement options based on AECOM’s significant worldwide sewer management program experience.

To date, PipeInsights has been used on real-world CCTV inspections and captured images of hundreds of thousands of

defects as it continues to learn. This secure, cloud-based platform enables access to inspections from any computer or mobile device, allowing users to visualize and share the health of their systems from the office or out in the field.

To sign up for a free 30-day trial or to book a demo, please contact Shane Cooper (shane.cooper@aecom.com) or visit https://pipeinsights.com

Developing the most cost-effective rehab strategy requires accurate condition information. That’s why we’ve developed a tool that processes CCTV inspection data more effectively, providing engineers with insight they need to make decisions faster than ever before.

NASTT-NW.COM | 19BACK TO CONTENTS

pipeinsights.com

Improve the speed and accuracy of pipe inspection programs

AUTOMATED AND INTELLIGENT ANOMALY DETECTION IN SEWER PIPELINES

Khalid Kaddoura, AECOM, 1150 Morrison Drive, Ottawa, ON Jeff Atherton, AECOM, 5090 Explorer Drive, Mississauga, ON

ABSTRACT

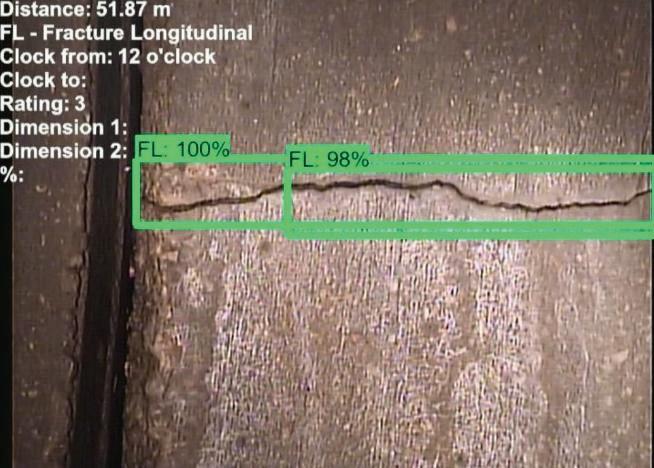

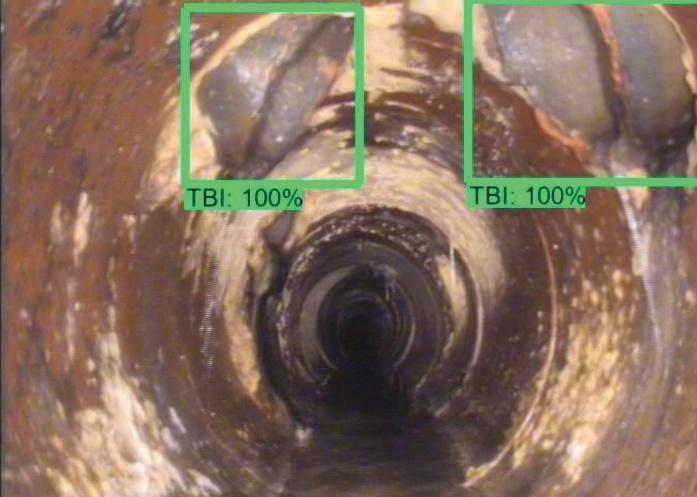

Sewer pipelines are inspected using the closed-circuit television (CCTV) camera. As the inspector controls the video camera through the pipe, they will look for different types of defects/anomalies, including structural, operational, construction features, and miscellaneous defects. Based on the National Association for Sewer Service Companies (NASSCO) standard, there are 224 different defects/ sub-defects which can occur within a given inspection. Given the significant number of defects/sub-defects, assigning defect codes and their corresponding severities are prone to subjectivity and hence may impact the overall accuracy of the inspection interpretations. Inaccurate interpretations could mislead decision-makers while selecting the proper intervention actions to sustain critical sewers. To expedite the overall inspection process and enhance the interpretation accuracy, this paper presents research aimed at utilizing an artificial intelligence and computer vision tool to detect and classify defects in accordance to existing standards. The smart and automated tool relies on enormous data obtained from the City of Toronto, multiyear program to build a reliable database. The initial results of the prototype showed promising detection and classification capabilities of defects and sub-defects including CC, FL, DAE, TB, TBI, and OBI. The average accuracy achieved for the six anomalies was 85%, where the maximum and minimum accuracy levels were 94%

and 75%. This tool, once completed, will elevate the sewer inspection process by speeding up the inspection validation, enhancing accuracy, and maintaining consistency. Thereby, assisting in making proper decisions when selecting the required intervention actions.

INTRODUCTION

Sewers are one of the most important infrastructure components in any city or municipality. According to the US Cybersecurity and Infrastructure Security Agency (CISA) (2020) and Canada Government (2020), these assets are considered a critical infrastructure. Sewer components are designed to transport sewage from laterals, mains, to treatment plants or disposal areas. As the medium is considered a hazardous material, enhancing sewer networks performance is essential to avoid sudden collapses or sewage exfiltration.

One of the first steps in maintaining these assets is by conducting regular inspections in which practitioners can then assign interventions based on the existing condition of the asset. There are a number of sewer inspection techniques that can be utilized in sewer assessment, including laser profilers and sonars. If these sensors are applied in an inspection, they are mostly combined in one float or crawler with a CCTV camera, and called a “multisensor” inspection. These sensors provide numeral information of some defects that practitioners may have difficulty to precisely quantify using CCTV alone including,

settled deposits, wall loss, deformation, etc. Generally, the indirect and direct costs associated with these sensors are costly when compared to a CCTV method. Based on a survey that was performed in Thomson et al. (2004), 100% of the respondents stated that CCTV is the main method of assessing their sewer pipelines.

In CCTV inspection, cameras are mounted on top of a float or crawler where operators are able to remotely control its movement. The camera is able to record the condition of the inner surface of the pipeline and can only supply information above the flow-line. Therefore, defects (anomalies) that exist below the flow-line will not be captured by a CCTV inspection alone. The data obtained from a CCTV video can show evidence of defects including settled deposits, deformation, joint defects, cracks, leaks, and many others.

In North America, the most widely used Technical Guide for visual inspection of sewer pipes is called the Pipeline Assessment Certification Program (PACP), which is published by the North American Sewer Service Companies (NASSCO). The guide provides a standardization to organize distress and defect codes to help practitioners interpret visual observations. Based on the severity of the defect, a grade is assigned to the defect and an overall Internal Condition Grade (ICG) is concluded. This ICG plays a major role in deciding the required intervention action to restore the condition of the pipe. The PACP classifies the observations into four

NASTT-NW.COM | 21BACK TO CONTENTS

Orlando, Florida

different families which are subdivided into more than 200 sub-defects and modifiers:

• Structural defects – These defects impact the structural integrity of the asset. They may have modifiers and can be represented as point or continues defects. The severity of the defect may vary depending on the type of the defect and its value.

• Operational defects – These defects impact the operation of the conveyance system. They may have modifiers and can be represented as point or continuous defects. The severity of the defect may vary depending on the defect type and its value.

• Construction features – These observations describe the multiple features that can be observed in a pipe environment, including taps, seal material, etc.

• Miscellaneous – These observations include general features and defects that are not included in PACP. Further requirements by PACP can be found in NASSCO’s PACP latest version (NASSCO 2015).

The typical process of reviewing inspection videos is to manually code and grade inspections based on the recorded observations and in accordance to PACP. Generally, the duration of each video is approximately 10 to 15 minutes (the duration may vary depending on the length of the pipe, the speed of the camera, and the number of codes recorded). Since any sewer inspection program may include miles of inspected sewers, the manual inspection procedure is time consuming and hence costly. Further, the interpretation of the sewer severity and type is subjective as it is dependent on the experience of the practitioner evaluating the videos (Kaddoura 2015). In an effort to enhance the existing process, an automated smart inspection assessment tool is required to automatically detect and classify sewer inspection anomalies in accordance to PACP. This automated tool will help in:

• Increasing the productivity of sewer inspection assessment;

• Decreasing the resources needed and hence the direct and indirect costs;

• Enhancing the accuracy of the assessment by decreasing the subjectivity of the code and severity assignment;

• Limiting intervention false assignments due to inaccurate interpretations;

• Maintaining consistency in the assessment process; and Encouraging the application of innovative and smart tools in infrastructure assessment.

The following article provides some of the recent research achieved in the domain of sewer defect detection.

LITERATURE REVEW – IN SUMMARY

Automated sewer inspection methodologies in the past leveraged image processing techniques in evaluating and quantifying observations. Some of the researchers who deployed this type of application are Mashford et al. (2010), Su et al. (2011), Halfawy and Hengmeechai (2014), Su and Yang (2015); Kaddoura (2015), and Hawari et al. (2018). While these tools provided an automated process in the evaluation, it assessed few numbers of sewer defects; in fact, some of the models required user inputs to complete the evaluation process. Given the technological advancement in soft computing, recent studies utilized deep learning algorithms to detect and classify sewer anomalies. In recent applications of

the convolutional neural network (CNN), Kumar et al. (2018) detected two types of operational defects (roots and deposits) and one type of structural defects (cracks). Their model approximately achieved 86% defect detection and classification. Cheng and Wang (2018) proposed a model that utilized a faster region-based CNN to detect cracks, deposits, infiltration and roots with a detection accuracy of 83%. Meijer et al. (2019) utilized the CNN model to classify 12 defects which were claimed to be the widely observed defects in sewer pipeline inspection. Further Yin et al. (2020) used the CNN model to detect six types of defects including broken, hole, deposits, crack, fracture and roots. The accuracy of the proposed model was approximately 85.37%.

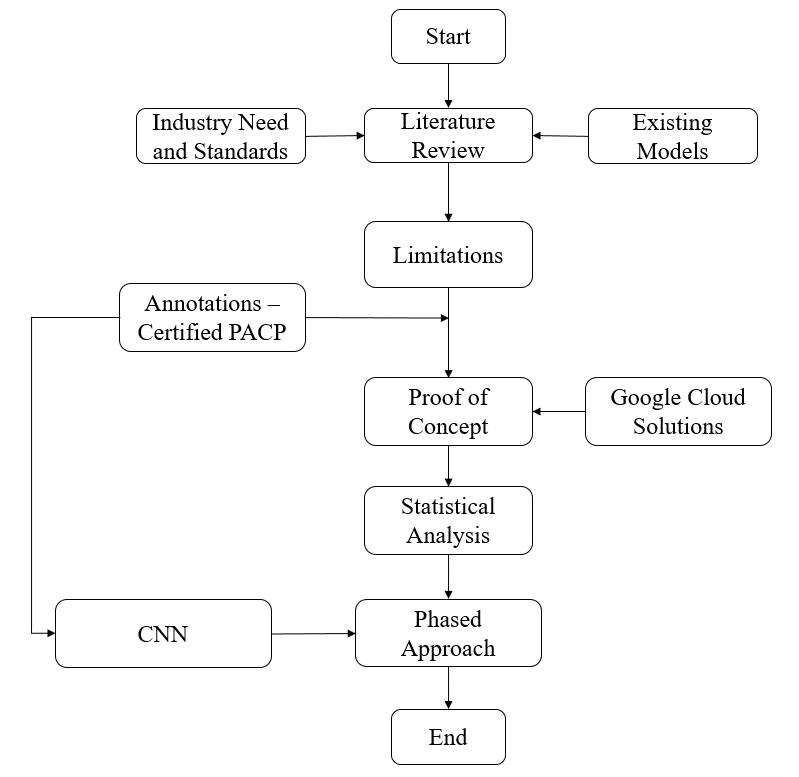

While there have been efforts devoted to intelligently and automatically detect and classify sewer defects, some of the existing deep-learning models had the following limitations:

• Did not rely on a huge dataset that can reduce false recalls and be applicable on larger scales;

• Focused on group defects rather than the PACP modifiers and descriptors;

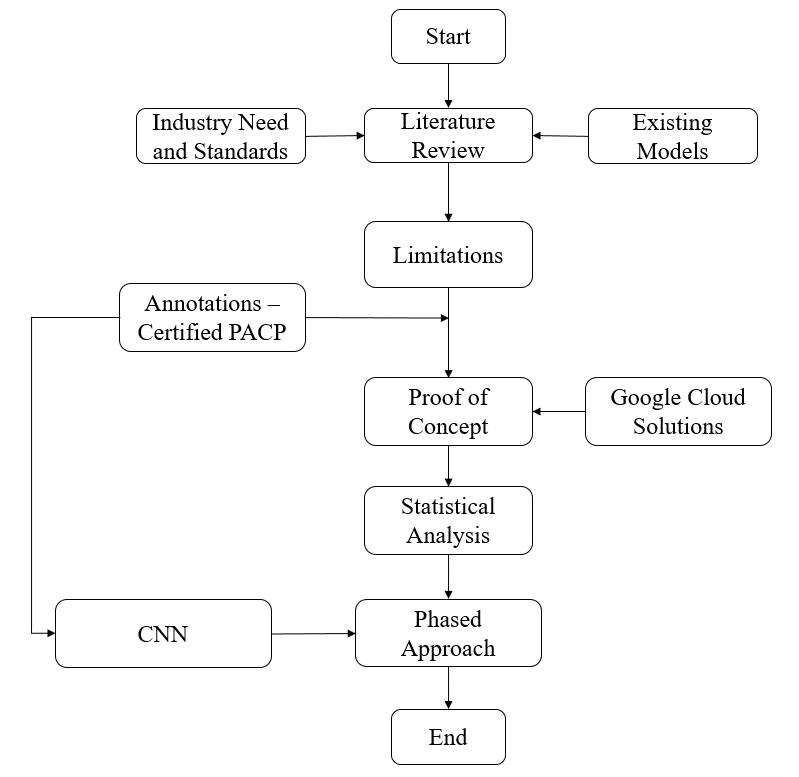

Figure 1: Research Methodology AUTOMATED AND INTELLIGENT ANOMALY DETECTION IN SEWER PIPELINES 22 | NASTT-NW JOURNAL | Fall/Winter 2022 BACK TO CONTENTS

• Trained images and frames were not annotated by certified practitioners;

• Were based on a fewer number of defects; therefore, their application is limited; and

• Did not take into considerations the minimum requirements that PACP suggest so that it can actually be applicable in the industry. Therefore, this paper’s main objective is to utilize machine learning (ML) to smartly and automatically detect and classify defects in accordance to the PACP standard. This model aims to reduce human interventions while aligning with the industry need of standardization and NASSCO requirements.

RESEARCH METHDOLOGY

This initiative started when a team from AECOM Canada participated in AECOM x Google Hack-a-thon to prove the applicability of deep-learning tools in sewer assessment applications (Figure 1). The proof of concept was based on a number of defects representing structural and operational groups which were annotated by certified PACP engineers. Based on the results of the proof of concept, the team proceeded with scaling the tool to include additional defects and in accordance to NASSCO’s PACP coding system.

The smart and automated sewer inspection detection and classification is mainly based on the application of the CNN technique as the main deep-learning tool. Since this approach requires a huge dataset to each modifier and descriptor, some statistical analyses were conducted to determine the most frequently observed defects in a dataset representing a decade of sewer inspection program in Canada and the US. This approach’s main aim is to firstly identify those defects that are included in PACP but have not been observed or were statistically insignificant in the inspected pipes. This group of defects will not be prioritized in the first phases of the model development, as opposed to defects that were statistically significant, frequently observed in multiple sewer material types, and impact the overall performance of the sewer.

CASE STUDY

The main dataset used in training the model were based on the city of Toronto’s sewer inspection program. The dataset included more than one-million observations collected from a decade of

inspections and thousands of hours of videos. Toronto is Canada’s largest city and the fourth largest city in North America. The sewer system in the city consists of approximately 3,730 km of sanitary, 1,411 km of combined, and 401 km of trunk sewers. There are approximately 507,500 sewer service connections and 87 wastewater pumping stations. Sewer inspection in the city of Toronto is completed through sewer inspection programs. AECOM has been responsible for the city’s inspection program for more than a decade. Approximately, 800 km of sewers are inspected annually by qualified contractors and reviewed by certified engineers. The majority of the sewer system is made of clay and concrete pipes.

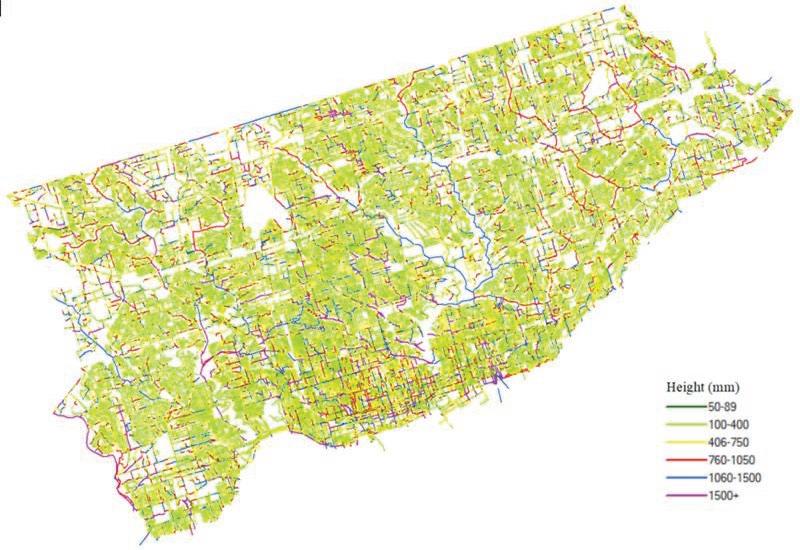

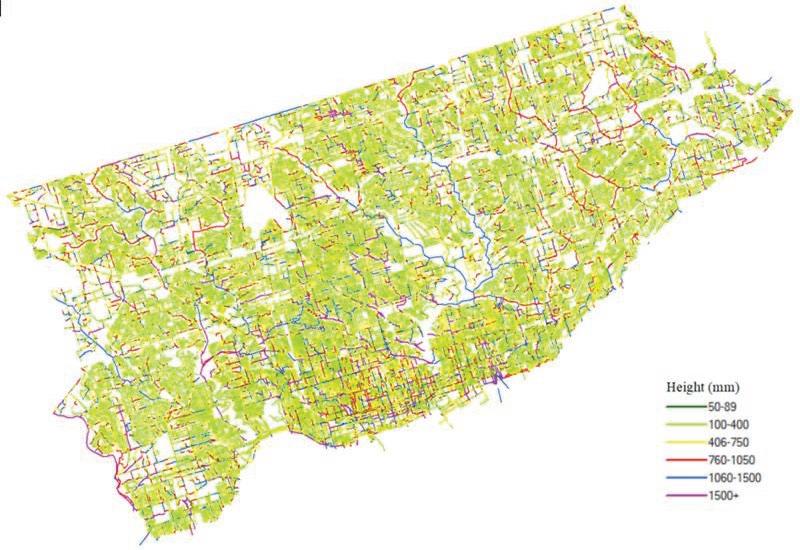

Brick sewers are still observed in multiple locations across the City. Figure 2 shows a Geographic Information System (GIS) map of the city’s sewer network. The figure shows segments with pipe ranges between 50 mm and greater than 1,500 mm.

Figure 3 displays the four different defect groups that were observed in more than twenty material types (for the material type abbreviation definitions, refer to NASSCO 2015). In Toronto, the majority of sewers are made of concrete pipes (CP), reinforced concrete pipes (RCP), and vitrified clay pipes (VCP). This is evident from Figure 3 as most of the codes were observed in these specific material types. Generally, the distribution of the four defect groups is almost similar for these materials.

Figure

Figure

2: City

of Toronto Sewer

Network

Figure

3: Defect Group by Material Type NASTT-NW.COM | 23BACK TO CONTENTS

Further, the figure shows that the most recorded observations are in the miscellaneous defect group followed by the construction features defects. These two groups shared approximately 69% of the total observations. The frequency of the structural defects was approximately half of the recorded operational defects.

RESULTS

While the frequency of observations was the major criteria in selecting the defects, the type and severity of the defect on the overall performance of the sewer was also taken into consideration. This approach assisted the researchers in prioritizing the defects during the defect detection and classification model development.

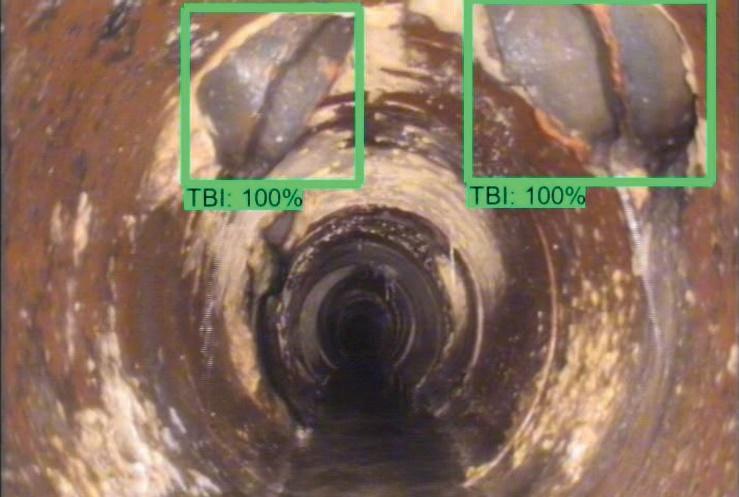

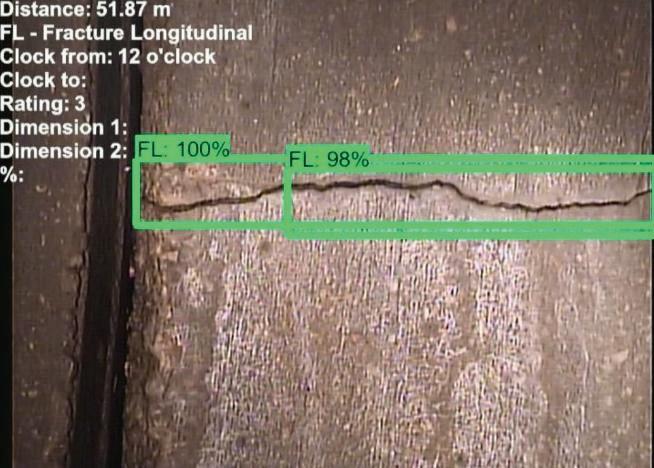

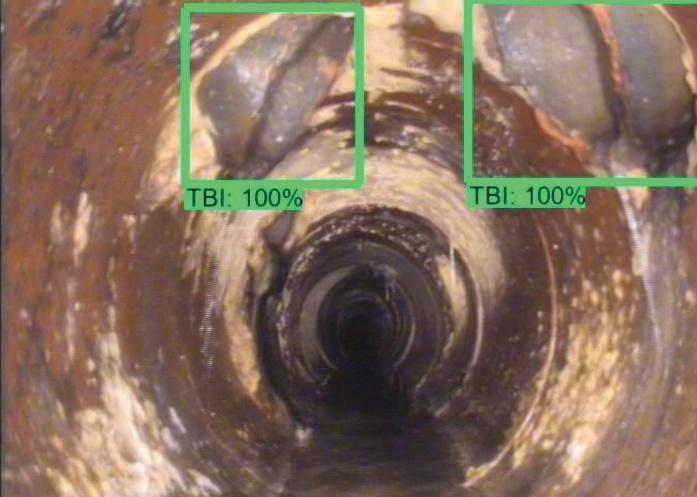

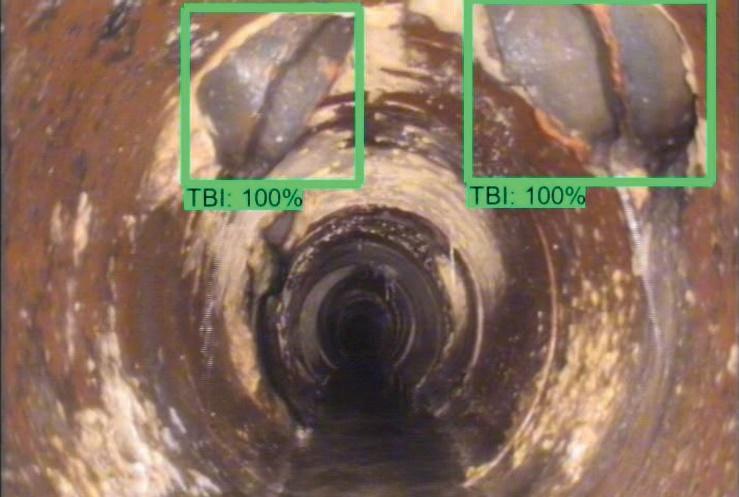

The result section focuses on the detection and classification of the six anomalies that were identified during the defect prioritization step. These anomalies are the Circumferential Crack (CC), Attached Deposits-Encrustation (DAE), Longitudinal Fracture (FL), ObstructionIntruding (OBI), Tap Break-in (TB), and Tap-Intruding (TBI). These six defects represented the three major defect groups which are the structural, operational, and construction features.

Each defect was initially trained by using more than 100 annotations, to present the results in this paper. A number of annotations were set aside to test the models. Where the outputs of the models were not sufficiently adequate, automated augmentation techniques (flipping, rotation, and color transformation) were deployed to increase the number of trained annotations. This approach reduced the time to search for the available anomalies in the database. More annotations and model improvements are still in progress. The initial results are illustrated in Figure 4.

For each defect, a confusion matrix was prepared in order to calculate the accuracy. The True Positive (TP), True Negative (TN), False Positive (FP) and False Negative (FN) were determined. The accuracy was calculated using Equation 1 and the results are shown in Figure 5.

Equation 1

The average accuracy of the six models was 85% with the maximum value being 94% and minimum value being 75%. The lowest Figure 5: Accuracy of the Detection and Classification Models

Figure 4: Defect Detection and Classification Sample Results

AUTOMATED AND INTELLIGENT ANOMALY DETECTION IN

SEWER

PIPELINES 24 | NASTT-NW JOURNAL | Fall/Winter 2022 BACK TO CONTENTS

accuracy percentages were observed in the CC and DAE while the highest accuracy percentages were observed in the OBI, TB and TBI defect codes. Few points were observed upon reviewing the outputs, which reduced the accuracy of the models are as follows:

• Some of the joints and Longitudinal Crack defects (CL) were identified as CC;

• In locations where illumination was intense, the settled deposits were identified as DAE;

• Few sewer breaks were classified as TBI; and

• A number of TB were detected and classified as TBI.

CONCLUSIONS

Inspecting sewers is an essential first step for any future maintenance activities. The most commonly used method for inspecting sewers is by using a CCTV crawler or float to record the internal condition of the pipes. Operators control the CCTV crawler or float while also identifying and recording anomalies. The observations are coded in accordance to NASSCO’s PACP which consists of more than 200 codes and modifiers. Ultimately, the regular method and approach of evaluating and identifying the defects is slow, prone to subjectivity, and errors. In an effort to increase the productivity levels and enhance the overall accuracy of inspection, an AI tool is developed and implemented on a number of defect codes. Since PACP consists of more than 200 codes, a phased approach was followed to firstly tackle defects that are frequently observed in sewers and impact the overall performance of the pipes. The initial group of defects in the initial phases consisted of six different defects (i.e., CC, FL, DAE, OBI, TB and TBI).

A CNN tool was deployed in order to train the six different defects. Anomalies were annotated by certified PACP engineers and fed into the CNN model. Each defect was trained using more than 100 annotations. Image augmentation was utilized when the model supplied low accuracies. Overall, the accuracy percentage of the initial deployment of this tool was on average 85%. The highest and lowest accuracies were observed in OBI and CC, respectively. While the initial results provided acceptable level of accuracy, this smart and automated tool will be expanded

to include a number of structural, operational, construction features and miscellaneous codes. Each defect will be trained on more than 5,000 annotations so that the accuracy and precision levels are increased. Once the complete model is developed, this tool is expected to aid different stakeholders in the sewer asset management domain. The overall benefits of this tool are increased productivity, reduced errors, and enhanced accuracy.

REFERENCES

• Cheng, J. C., & Wang, M. (2018). Automated detection of sewer pipe defects in closed-circuit television images using deep learning techniques. Automation in Construction, 95, 155-171.

• Hawari, A., Alamin, M., Alkadour, F., Elmasry, M., & Zayed, T. (2018). Automated defect detection tool for closed circuit television (cctv) inspected sewer pipelines. Automation in Construction, 89, 99-109.

Proven Technology for Underground Construction

•

Reliable technology and expertise for

•

•

•

•

Discover the world of MAPEI:

Technology

construction

NASTT-NW.COM | 25BACK TO CONTENTS Our commitment is the detail that makes the difference.

underground

Alkali-free set accelerators and admixtures for shotcrete

Products for mechanized tunneling

Products for grouting and consolidation

Products for the repair, protection and coating of concrete

Products for waterproofing

Underground

Team utt.mapei.com hq.utt@utt.mapei.com 1-800-426-2734 (1-800-42-MAPEI)

NOTE: COLORS VIEWED ON-SCREEN ARE INTENDED FOR VISUAL REFERENCE ONLY AND MAY NOT MATCH THE FINAL PRINTED PRODUCT. 1144 E. Newport Center Dr. Deerfield Beach, FL 33442 FileName:22-1649_CA_Ad_Resize_NorthWest_Trenchless_Journal_UTT_CA-EN Job#: 22-1649 Artist: Simon Tremblay Email: stremblay@mapei.com Date: April 4, 2022 3:08 PM Page Size: 4,625" x 7" Number of Pages: 1 Bleed: No Amount: Colors: CMYK Process INFO SPECS 22-1649_CA_Ad_Resize_NorthWest_Trenchless_Journal_UTT_CA-EN.indd 1 2022-04-06 14:10:44

• Kaddoura, K. (2015). Automated sewer inspection analysis and condition assessment (Doctoral dissertation, Concordia University).

• Mashford, J., M. Rahilly, P. Davis, and S. Burn. 2010. “A morphological approach to pipe image interpretation based on segmentation by support vector machine.” Automation in Cosntruction, 19 (7): 875–883. https:// doi.org/10.1016/j.autcon.2010.06.001.

• Meijer, D., L. Scholten, F. Clemens, and A. Knobbe. 2019. “A defect classification methodology for sewer image sets with convolutional neural networks.” Automation in Construction, 104 (Aug): 281–298. https://doi .org/10.1016/j.autcon.2019.04.013.

• Sinha, S. K., and P. W. Fieguth. 2006. “Segmentation of buried concrete pipe images.” Automation in Construction, 15 (1): 47–57. https://doi.org/10.1016/j. autcon.2005.02.007

• Su, T. C. 2015. “Segmentation of crack and open joint in sewer pipelines based on CCTV inspection images.”

In Proc., Int. Conf. on Circuits and Systems (CAS 2015). Red Hook, NY: Curran Associates.

• Su, T. C., and M. D. Yang. 2015. “Application of morphological segmentation to leaking defect detection in sewer pipelines.” In Proc., 2015 AASRI Int. Conf. on Circuits and Systems, 8686–8704. Paris: Atlantis Press.

• Su, T. C., M. D. Yang, T. Wu, and J. Lin. 2011. “Morphological segmentation based on edge detection for sewer pipe defects on CCTV images.” Expert Syst. Appl. 38 (10): 13094–13114. https:// doi.org/10.1016/j .eswa.2011.04.116.

• Yin, X., Chen, Y., Bouferguene, A., Zaman, H., Al-Hussein, M., & Kurach, L. (2020). “A deep learning-based framework for an automated defect detection system for sewer pipes.” Automation in Construction, 109, 102967.

• CISA. (2020). “Critical Infrastructure Sectors”. From <www.cisa.gov/criticalinfrastructure-sectors>

• Thomson, J., Hayward, P., Hazelden, G., Morisson, R., Sangster, T., Williams,

D., et al. (2004). “An Examination of Innovative Methods used in the Inspection of Wastewater Systems.” VA and IWA Publishing.

• NASSCO. (2015). Pipeline Assessment Certification Program. NASSCO, Frederick, MD.

• Kumar, S. S., Abraham, D. M., Jahanshahi, M. R., Iseley, T., & Starr, J. (2018). “Automated defect classification in sewer closed circuit television inspections using deep convolutional neural networks.” Automation in Construction, 91, 273-283.

• Cheng, J. C., & Wang, M. (2018). “Automated detection of sewer pipe defects in closed-circuit television images using deep learning techniques.” Automation in Construction, 95, 155-171.

• Meijer, D., Scholten, L., Clemens, F., & Knobbe, A. (2019). “A defect classification methodology for sewer image sets with convolutional neural networks.” Automation in Construction, 104, 281-298.

AUTOMATED AND INTELLIGENT ANOMALY DETECTION IN SEWER PIPELINES 26 | NASTT-NW JOURNAL | Fall/Winter 2022 BACK TO CONTENTS • UV Cured Liner 6”-66” • UV Cured Spot Repair Materials • Liner Handling Machines • UV Curing Systems and Trucks • Cutter Systems and Trucks • Custom Cans and Hardware • Engineering Support • Service and Support • Truck and Equipment Rental You need a PARTNER Not just a MANUFACTURER 605-558-1020 - INFO@omegauvpipe.com - www.omegauvpipe.com LINER COMPANY OMEGA See us at No-Dig North, Booth #823, 10/17-10/19. See You There!

Our concern for the environment is more than just talk

This publication is printed on Forest Stewardship Council® (FSC® ) certified paper with vegetable oil-based inks. Please do your part for the environment by reusing and recycling. NASTT-NW.COM | 27BACK TO CONTENTS

to

print and electronic communication operating hand-in-hand,

can

that

is

INTERACTIVE EDITION VISIT US ONLINE. HTTPS://NASTT.ORG/RESOURCES/REGIONAL-CHAPTER-MAGAZINES TRENCHLESS JOURNAL AVAILABLE ONLINE A USER-FRIENDLY, INTERACTIVE FORMAT THAT INCLUDES: 1. Active hyper-links to all websites and emails contained in the publication 2. Active links to the specific stories from the front cover and contents page 3. Active links to advertiser websites from their ads brandt.ca 1-888-227-2638 FULL-SIZE POWER WITHOUT THE FULL-SIZE FOOTPRINT NEEDFAST,FLEXIBLEFINANCING?WE DELIVER. CallTOLLFREE:1-855-711-4545orvisitbrandtfinance.com UnparalleledPower Withits155hpCumminsB4.5StageV dieselengine,32,000lbsofthrust/pullback and4,200ft-lbsofrotationaltorque,even solidrockdoesn’tstand chance. SuperiorProductivity TheAT32featuresincreaseddrillpipe capacity,nowallowing450ft.ofall-terrain pipeor600ft.ofdirtpipewithareversible pipeboxon-board,increasingproductivity. UnrivaledSupport Bestofall,thesemachinesarebackedby Brandt;thebesttrained,mostcommitted, 24/7/365after-salessupportinthebusiness with fullservicelocationsnationwide. Burstingattheseamswithpower,theDitchWitchAT32isthenextgenerationofall-terrain drilling,packingperformanceandstrengthintoasleekpackage. 2022 | NORTHWEST THE OFFICIAL PUBLICATION OF THE NORTHWEST CHAPTER OFTHE NORTH AMERICAN SOCIETY FOR TRENCHLESS TECHNOLOGY AUTOMATED AND INTELLIGENT ANOMALY DETECTION IN SEWER PIPELINES FALL/WINTER PM #40065075 FREE

print advertisers With

you

take advantage of the fact

Trenchless Journal

available online in a highly interactive format. THE OFFICIAL PUBLICATION OF THE NORTHWEST CHAPTER OF THE NORTH AMERICAN SOCIETY FOR TRENCHLESS TECHNOLOGY 28 | NASTT-NW JOURNAL | Fall/Winter 2022 BACK TO CONTENTS

Use Paper Responsibly

Today’s forest industry is working hard to become one of the greenest industries on earth.

Paper is an essential part of human civilization. While we all use and depend upon electronic communications, it is easy to ignore that it comes at an environmental cost. Worldwide spam email traffic creates greenhouse gases equivalent to burning two billion gallons of gasoline yearly, with numbers rising. More than $55 billion in toxic e-waste material is thrown away every year in the US alone, with a recycling rate of only 20% compared to 64.7% for paper.

No industry is perfect. But the paper industry has made, and continues to make, huge investments in environmental responsibility. Specifying and buying paper from certified sources ensures the continuation and growth of carbon absorbing forests. Using paper with appropriate amounts of recycled fibre helps preserve forests, conserve energy, and maximize fibre usage through paper lifecycles.

NASTT-NW.COM | 29BACK TO CONTENTS

COMPANY NAME PAGE PHONE WEBSITE/EMAIL

AECOM Canada

Engineering

Brandt Tractor Ltd.

Direct Horizontal Drilling

Noise Control

FORMADRAIN Inc

Herrenknecht Tunnelling Systems Canada Inc.

Insituform Technologies

IVIS Inc.

LaValley Industries

204-928-9252 www.aecom.com

780-451-7666 www.ae.ca

888-2BRANDT www.brandttractor.com

780-960-6037 www.directhorizontal.com

403-392-1029 www.environmental-noise-control.com

888-337-6764 www.formadrain.com

253-447-2300 www.herrenknecht.com

800-234-2992 www.insituform.com

780-476-2626 www.ivisinc.com

218-444-3030 www.lavalleyindustries.com

MAPEI Canada 25 800-426-2734 www.mapei.ca

Michael Byrne Mfg

Michels Canada

Muddruckers Inc

Omega Liner Company, Inc.

Precise Crossings Ltd.

Vac-Con, Inc.

419-525-1214 www.byrnegroup.com

780-955-2120 www.michelscanada.com

204-992-6833 www.muddruckers.ca

605-558-1020 www.omegauvpipe.com

866-962-6882 www.precisecrossings.com

904-252-6027 www.vac-con.com

ADVERTISER PRODUCT & SERVICE CENTRE Chad Morrison • 1-866-985-9788 • chad@kelman.ca To reach the targeted readership of the NASTT-NW Journal please contact Chad: The NW Trenchless Journal is made possible by the companies below who convey their important messages on our pages. We thank them for their support of NASTT-NW and its publication and encourage you to contact them when making your purchasing decisions. To make it easier to contact these companies, we have included the page number of their advertisement, their phone number, and, where applicable, their website.

19

Associated

10

4

31

Environmental

27

12

18

3

6

12

10

32

8

26

11

2

30 | NASTT-NW JOURNAL | Fall/Winter 2022 BACK TO CONTENTS

Edmonton (780) 960.6037 www.directhorizontal.com Trenchless solutions from the sharpest minds in the business!

An Energy & Infrastructure Contractor www.MichelsCanada.com Michels builds and maintains the world under your feet. Our construction and maintenance services can be delivered in many alternative delivery formats, including Design Build, CMAR, RFQ-RFP, and Traditional Bid/Build. • Tunneling and Microtunneling • Horizontal Directional Drilling • Direct Pipe® • Cured-in-place pipe (CIPP) • Spray-in-place pipe (SIPP) • Sliplining - FRP & GRP BOOTH 525 Visit Us October 17-19, 2022 NASTT's No-Dig North Show

X-Cavator CXT Hydrovac Truck

X-Cavator CXT Hydrovac Truck

Figure

Figure