Conquer your engineering and construction challenges with our design-build solutions

EXPLORE OUR SOLUTIONS

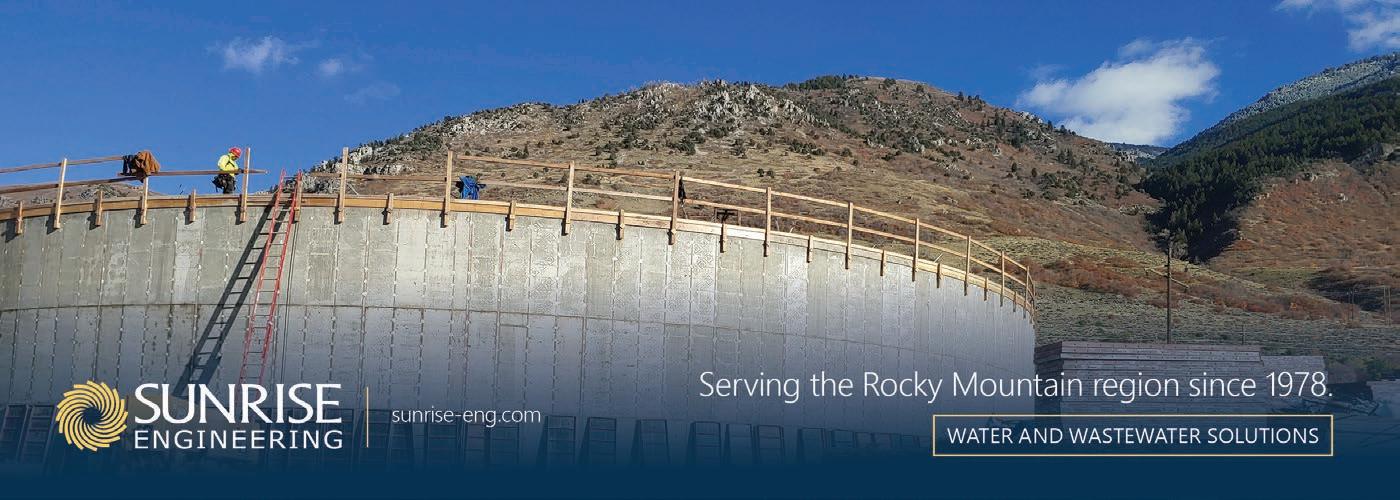

Colorado Springs Utilities EW Bailey WTP El Paso County, CO

Conquer your engineering and construction challenges with our design-build solutions

EXPLORE OUR SOLUTIONS

Colorado Springs Utilities EW Bailey WTP El Paso County, CO

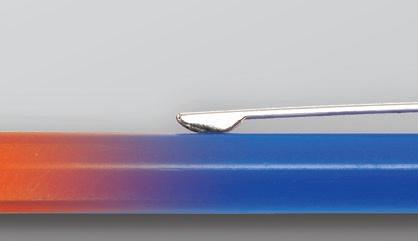

Orthos has repeatedly demonstrated a long track record of granular media filtration applications, and with our Centurion™ monolithic design repeatedly responds to utilities’ demands of resiliency, reliability, and permanency. scan for more info

clear reasons to choose orthos

Never once, ever, had a monolithic underdrain failure. RESILIENCY

Repeatable results through excellent distribution and broad operational range reliability

At 25 years, nozzles are simply replaced, not the entire underdrain life cycle savings

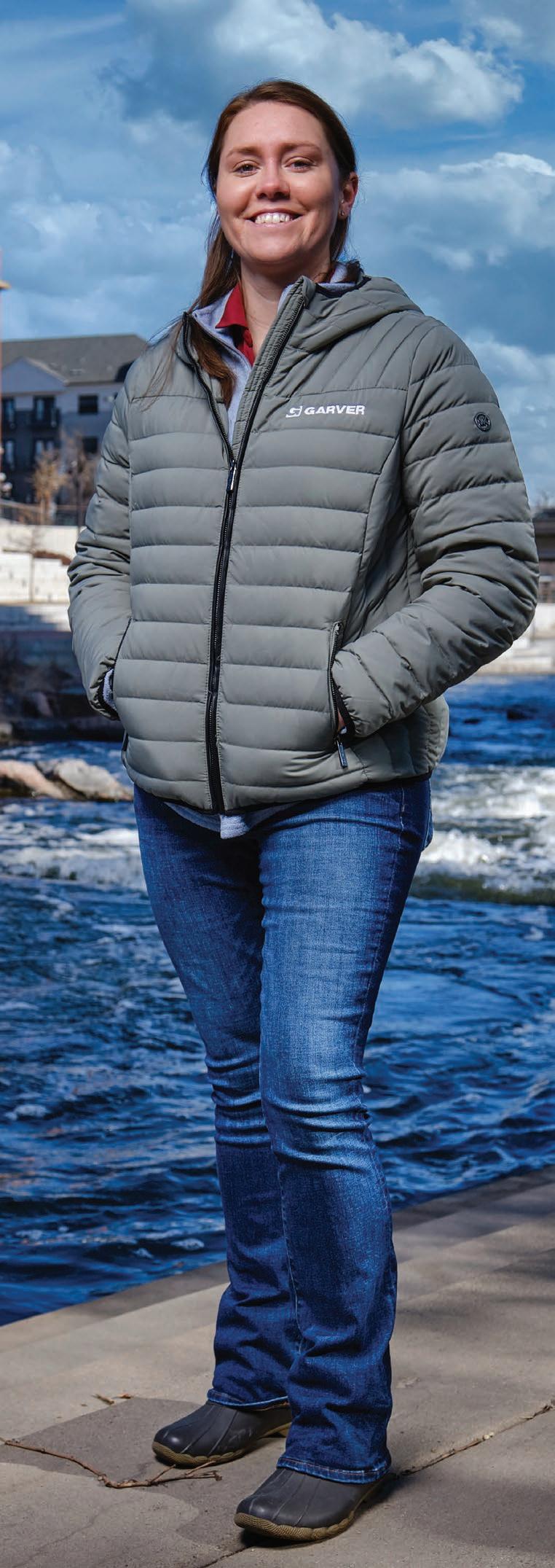

Project Manager Jessica Johnson is passionate about securing and protecting public water supplies in Colorado for generations to come. And, with the backing of a nationwide firm with over 100 years of service, she’s well equipped to meet the toughest challenges facing utilities and communities and protect this vital resource.

Rocky Mountain Water Magazine Group

The following volunteers support RMSAWWA and RMWEA with content collection, management, editing, and reviewing the magazine.

BLAIR CORNING bcorning@englewoodco.gov

ANDREW DUGAN andrew.dugan@waterwrites.co

KARI LARESE klarese@highlandsranch.org

RMSAWWA Communications Committee

KARI LARESE, Chair klarese@hrwater.org

ERIN RIDOLFO, eNewsletter Editor eridolfo@rmsawwa.org

RMWEA Communications Committee

ELIZABETH DEWAARD, Co-Chair edewaard@englewoodco.gov

JORI NELSON, Co-Chair jori.nelson@hdrinc.com

NATALIE COOK, eNewsletter Reviewer ncook@auroragov.org

ANDREW DUGAN, eNewsletter Reviewer andrew.dugan@waterwrites.co

ROCKY MOUNTAIN

Designing Resilient Water Systems in the Face of Climate Change: Addressing Droughts, Wildfires, and Water Quality Challenges

Colorado’s Commitment to Sustainable Landscapes Partnering for Progress: CE Corps and La Jara Collaborate on Water System Improvements

Tel: 866-985-9780 Fax: 866-985-9799 info@kelman.ca www.kelman.ca

Managing Editor: Mathias Leiendecker

Marketing Manager: Chad Morrison

Design/Layout: Jackie Magat

Advertising Coordinator: Sabrina Simmonds

FROM THE RMWEA PRESIDENT

Clay Rahn, RMWEA President, Senior Water/Wastewater Project Manager, HDR, Inc.

Spring is in the air! The sight of budding green leaves, colorful flowers, and warmer days are just around the corner. We will soon be able to enjoy a hike in nature without having to bundle up; Or a jog along one of the Rocky Mountain region’s numerous river trails without the worry of slipping on ice; Or enjoy that dinner on an outdoor restaurant patio with the whole family. Spring is a time of renewal, rebirth, and even a refreshment of sorts! It plays right into a major initiative that is in the works for RMWEA: A refreshment of our Vision, Mission, Values (VMV), and Strategic Plan (SP).

A little perspective: The VMV has not been updated since the 2016 Summer Planning meeting in Salida and the SP was last published in 2021. Typically, a hard look (as a minimum) at both should be completed every three to five years. Thus, now is the time to update the SP and maybe we are a little overdue on the VMV.

Action: I am excited to share with you that our recent Winter Planning event held on March 6 served as our official kickoff for the exercise of refreshing RMWEA’s VMV and SP. We began with a morning session consisting of just the Executive Board (a smaller group) to analyze the current VMV/SP and offer changes that are consistent with who RMWEA will be in 2025. You might be asking, “Why just the Executive Board?” Typically, a smaller group (usually an executive board or similar for most organizations) is ideal, otherwise, the conversations can go in too many directions and consensus can become impossible. So, after a four-hour long morning session, we opened the afternoon

Spring is a time of renewal, rebirth, and even a refreshment of sorts! It plays right into a major initiative that is in the works for RMWEA: A refreshment of our Vision, Mission, Values (VMV), and Strategic Plan (SP).

session for the larger group (including RMWEA leaders of all sorts) to get input on the Executive Board’s overall direction with the VMV/SP.

Remember, Winter Planning served as just the kickoff for the refreshment. Several more meetings will be held in the coming months before we are ready to roll out the new VMV and SP. Our goal is to have them published for all to see by the Rocky Mountain Water Conference in Keystone. It is a lofty goal, so please have grace with us if we need time beyond the late August conference.

Additionally, I would like to extend a special thank you to Simon Watson (Black & Veatch), Manon Fisher (Brown and Caldwell), Muzit Kiflai (Metro Water Recovery), and Stephanie Segler (Black & Veatch) for all their help and expertise in leading this effort. Simon helped the California Water Environment Association (CWEA) work through their VMV and SP, which made him our ideal candidate to facilitate this effort at RMWEA’s Winter Planning. Manon, through her professional expertise, helped to plant this idea as the main focus for Winter Planning in the first

place when we met for lunch back in August. Muzit has extensive relevant experience in her career working through VMVs and SPs, as well as facilitating groups, so she too was ideal for this task. I very much appreciate Stephanie’s support in bringing everyone and everything together to make this happen.

Switching gears, and as an aside, you may have noticed that my place of employment has changed to HDR. First, let me stress that I absolutely enjoyed my nearly two years with the City of Westminster and learned a great deal about a wide variety of topics that I never would have been exposed to while working in private consulting. Previously, I worked for HDR from 2015 to 2023, so I am very excited to return to the family I got to know so well over almost eight years! However, I will miss my Westminster family a great deal, but I look forward to seeing many of them regularly going forth!

Finally, I cannot express how excited I am to refresh the VMV and SP. I think this will serve RMWEA well for years to come! As always, thank you for allowing me to serve all of you during my time as President.

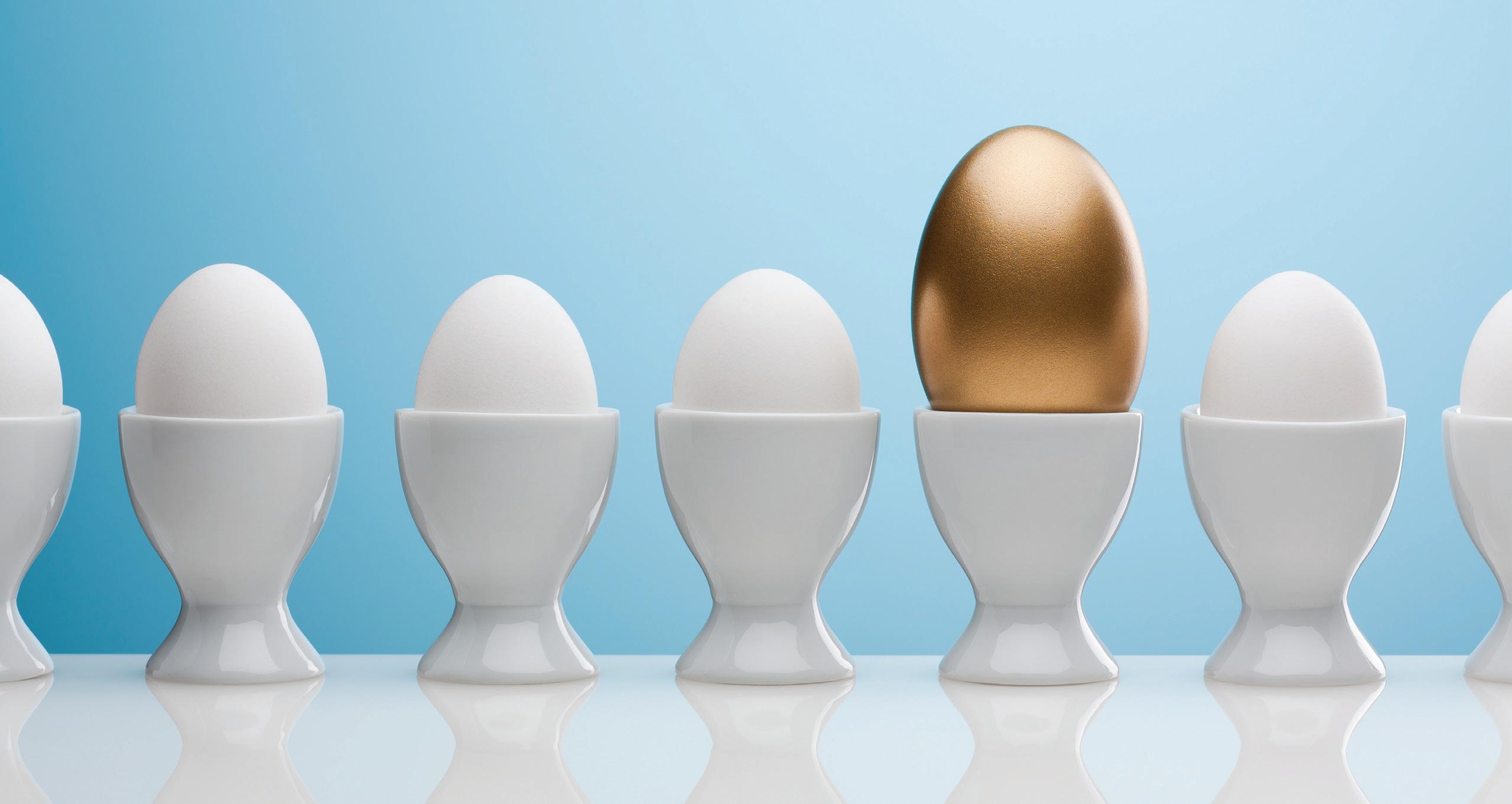

As you would expect from Lakeside, our Raptor® Multi-Rake Bar Screen is an efficient, proven screen technology for rapid removal of inorganic solids in municipal and industrial applications. But what sets it apart is the simple fact that ours is built to Lakeside’s renowned standards and features superior quality. As with everything we do, our Raptor Multi-Rake Bar Screen is well-engineered, designed for optimum performance and durability, and is manufactured in the USA. That’s important on a lot of levels. When critical decisions are made on design and specifications, stand out with the Lakeside Raptor Multi-Rake Bar Screen, the gold standard of the industry.

Speak to one of our experts at 630.837.5640, email us at sales@lakeside-equipment.com or visit lakeside-equipment.com for more product information.

FROM THE RMSAWWA CHAIR

Stephanie Elliott, RMSAWWA Chair, Senior Project Manager, Stantec

Spring in the Rocky Mountains! It’s that time of year when the weather can be as irregular as my golf swing. One day, the sun is shining with temperatures in the 60s and the next, a fresh blanket of snow might dust the peaks. Personally, I’m rooting for more of those sunny days – with just enough rain or snow to nourish the gardens, yards, and, of course, the golf courses. I’m ready to shake off the winter dust on my clubs and get back out there, even if it means hacking my way through the first few rounds of the season.

Beyond the lighthearted weather flukes, the unpredictable patterns we’re seeing now are starting to feel like the new normal. As I write this, Southern California is grappling with the most devastating wildfire in the state’s history, while much of the country is enduring a polar vortex, bringing bitterly cold temperatures, snow, and ice. These extreme events highlight a broader issue central to this edition of Rocky Mountain Water: Climate Resilience and Sustainability.

Building a resilient and sustainable water sector takes collaboration and creativity. We, as water professionals, have been tasked with one central mission: protecting public health by ensuring access to clean, safe water. This is no simple job, especially as the challenges of climate change and sustainability grow ever more complex. Climate resilience – the ability to prepare for, respond to, and recover from the impacts of climate change – now intersects with the timeless goal of sustainability, which ensures that water resources are used in

ways that support long-term ecological and community health. The pressure on water systems has never been greater. From droughts to flooding, unpredictable weather patterns to rising temperatures, the water sector must adapt quickly. But to meet these challenges and safeguard our future, collaboration, and creativity will be key.

Building a resilient and sustainable water sector is not a task that can be accomplished in isolation. It requires ongoing collaboration among utilities, policymakers, and engineers – and a strong dose of creativity to come up with innovative solutions. We all play a role in shaping the water systems of tomorrow. For example, utility operations bring valuable insights into their specific water challenges. Policymakers are essential for developing the regulations, funding, and support needed to implement lasting change. Engineers, with their expertise in water infrastructure, can develop and deploy new technologies that both conserve water and protect systems from climate-related disruptions. This cross-sector collaboration will be crucial in creating frameworks that allow water systems to adapt to the changing climate. These frameworks must be flexible and dynamic – ready to respond to immediate needs while also anticipating future challenges.

However, we must also recognize that creating a more resilient and sustainable water sector will not happen without continued attention to the workforce issue. A significant hurdle in achieving a resilient and sustainable water sector is the ongoing workforce challenge.

As the sector faces increasing demands, especially with the added pressures of climate change, it’s essential to build and retain a skilled workforce capable of addressing these complex issues. The challenges are large, but so too is the potential for a brighter, more sustainable water sector now and into the future.

The RMSAWWA Committees such as the Colorado Water Utility Council, the Strategic Workforce Committee, and the Risk and Resiliency Committee play an important role in facilitating the kind of collaboration necessary to build a more resilient and sustainable water sector. These committees serve as forums for collaborative innovation. They allow professionals to exchange knowledge and best practices, discuss emerging issues, and devise creative solutions. The result is a more unified, informed water sector that is better equipped to tackle the challenges posed by climate change and sustainability. By getting involved in these committees, whether through sharing expertise, presenting ideas, or collaborating on new projects, water professionals can make a tangible impact on the future of water management. It’s through these forums that solutions emerge, making it easier for the sector to innovate and build adaptive systems that are more climateresilient and sustainable.

If you would like to learn more about how to get involved with RMSAWWA, please don’t hesitate to visit the website at www.rmsawwa.org or connect with me by emailing chair@rmsawwa.org. Additionally, please visit redcross.org for ways to support the fire relief effort.

Shannon Harney, Engineer II, South Platte Renew

South Platte Renew (SPR) is the third largest water resource recovery facility (WRRF) in Colorado and daily treats 20 million gallons of wastewater and converts it to clean water returned to the South Platte River, biosolids used as fertilizer on farms in eastern Colorado and renewable natural gas that’s reinjected into the local utility’s pipeline. SPR serves 300,000 people in the cities of Littleton and Englewood as well as 19 other connector districts. While SPR is beneficially reusing several resources through the treatment process, there is a desire to increase the facility’s overall sustainability and environmental footprint by optimizing overall energy usage at the facility.

Beginning in 2021, SPR started to take actionable steps to become better environmental stewards and find ways to optimize and reduce the overall energy usage at the plant. From August 2021 to October 2022, SPR participated in the Strategic Energy Management (SEM) Cohort facilitated by Cascade Energy and funded by Xcel Energy which provides energy management consulting services to WRRFs. This cohort involved several SPR staff and activities such as monthly webinars to increase knowledge and a plant-wide audit to identify energy-saving opportunities. Some of the projects and initiatives implemented during the cohort include turning down the pumping rates at several pump stations, increasing wet well levels to reduce pumping energy, and installing ammonia-based aeration control in the Solids Contact Tanks. From these initiatives, SPR saved over 500,000 kWh in energy usage and $34,000 in avoided energy costs in 2022 compared to 2021 baselines. The cohort also increased awareness and knowledge at SPR of energy-saving practices and further increased the desire to explore more energy-efficient treatment options.

To build upon the success of the SEM cohort and develop a more robust and permanent energy program, SPR enlisted consulting services from Hazen and Sawyer to develop an Energy Management Master Plan (EMMP). The EMMP was completed in March of 2023 and developed an energy usage baseline, identified over 20 energy-saving opportunities on the plant, outlined a roadmap to energy neutrality, and created the groundwork for a long-standing energy program. SPR has now taken the recommendations from the EMMP and is in the process of developing a plant-wide Energy Program that will establish guidelines, procedures, and workflows to integrate energy efficiency into all SPR business processes. This includes energy tracking procedures, sustainable procurement policies, and the utilization of energy data to impact capital planning and asset management assessments.

There is a desire to increase the facility’s overall sustainability and environmental footprint by optimizing overall energy usage at the facility.

SPR has executed several of the initiatives outlined in the EMMP to start taking steps toward more energy-efficient operations. A resource usage dashboard was created in PowerBI that allows staff to track and observe any changes in energy usage at the plant and dive into specific process areas. The dashboard is used to track changes in usage compared to baseline values as well as identify the major energy users at the plant to direct efforts and resources towards where it will make the biggest difference. The dashboard also includes water usage, waste production, and renewable

Safe for the operator. Safe for the environment. Simple to use.

Vita-D-Chlor offers environmentally responsible Vitamin C dechlorination that works with a variety of equipment. Reach out to our specialists to get answers to your dechlorination questions.

Solutions in Vitamin C dechlorination for over 20years!

SPR hopes to develop a longstanding sustainable and effective approach to energy management and to strive for energy efficiency without compromising the integrity or quality of the water being treated.

natural gas production to evaluate the plant at a higher level of sustainability and resource usage.

Another initiative that has been completed since the completion of the EMMP is a Digester Heating Demand Study. During the EMMP it was found that the largest energy user on the plant site when considering both electrical energy and natural gas is the Digester Complex. This process is crucial to solids treatment at SPR and requires the solids to be heated to almost 100 degrees F for about 30 days which requires a significant amount of natural gas. This study evaluated the efficiency of the heating system in the digester to understand the balance between the heating demand needed for adequate treatment and the supply of natural gas. The goal was to identify opportunities to improve efficiencies and reduce natural gas usage. The study found that the treatment demand and natural gas supply are actually relatively similar and there are no major inefficiencies in the heating system. This highlights how much energy is really required for advanced wastewater treatment and why it is so vital to explore diverse energy production options.

SPR continues to implement the initiatives identified in the EMMP and use the roadmap developed to establish a plant-wide Energy Program. SPR hopes to develop a longstanding sustainable and effective approach to energy management and to strive for energy efficiency without compromising the integrity or quality of the water being treated.

Shannon Harney is an Engineer II at South Platte Renew, she works on the development and implementation of the facility’s Asset Management Program as well as serves as a project engineer on several capital projects and pilots. She also works on the development of several plant-wide programs including Safety, Energy and Sustainability, and the Analytical Instrumentation Program. Shannon has her bachelors in Environmental Engineering with minors in Sustainable Watersheds and Global Environmental Sustainability from Colorado State University.

The effects of climate change are increasingly felt across the globe through increasing temperatures and extreme weather events. The Western United States especially has experienced frequent drought and catastrophic wildfire events, intensified by increased temperatures and decreased precipitation and snowpack levels. When designing resilient drinking water treatment systems, it is crucial to consider the effects of climate change on water availability, location of infrastructure, and changes in historical source water quality.

Prolonged droughts can significantly impact drinking water quality and distribution. These effects range from reduced source water quality to increased water age in distribution systems due to water conservation measures. Common issues include higher turbidity, pathogen concerns, challenges in managing disinfection byproducts (DBPs), and taste and odor complaints. As lake, reservoir, and stream volumes decrease, several risks emerge. Reduced dilution from wastewater and industrial sources can lead to higher contaminant concentrations. Additionally, lower water volumes can promote algal growth due to warmer, stagnant conditions and increased nutrients, causing taste and odor problems and contributing to DBP formation. Regions experiencing prolonged drought followed by heavy rainfall are susceptible to increased mobilization of accumulated sediments, leading to sudden increases in organic carbon concentrations in source water. Cyclic drought and precipitation

events can fundamentally change how nutrients cycle within the watershed which in turn, influences water quality over extended periods. Water conservation measures, while beneficial for reducing consumption, can increase residence time in distribution systems, raising the potential for DBP formation in chlorinated systems.

WILDFIRE

While wildfires can directly threaten treatment facilities and distribution structures, many of their impacts emerge during subsequent heavy rainfall or snowmelt runoff events and can persist for years after the event. Ash, the primary product of wildfires, is highly mobile via wind and water in the days and weeks following a fire. Forest biomass is thought to act as a sink for regional pollution, carrying large quantities of metallic components, minerals, and inorganic species that risk contaminating drinking water sources. Commonly reported contaminants following wildfires include elevated nitrogen and phosphorus from ash.

Wildfires increase the risk of soil erosion due to the loss of plant roots and heat-induced soil hydrophobicity, leading to greater sediment transport. Runoff during storm or snowmelt events transports significant quantities of sediment and ash, increasing dissolved organic carbon and previously mentioned contaminants in water supplies. In the months and years following a wildfire, the altered hydrological processes, such as reduced evaporative losses due to lack of vegetation, increase the precipitation reaching the ground and contributing to runoff.

Many utilities and water providers are proactively addressing the challenges posed by extreme weather and source water quality variability fueled by climate change. This involves identifying opportunities to diversify water supply portfolios or building new infrastructure to improve resilience, mitigating risks from watershed to tap. Conducting a thorough evaluation of system susceptibility to climate-related risks helps identify unique needs, ensuring improved system reliability as droughts, wildfires, and floods continue to challenge our water providers.

Climate change increasingly threatens utilities, particularly through drought and wildfires impacting water supply and quality in the Western United States. Recognizing these risks, utilities’ forward thinking on climate resilience, showcases how utilities can mitigate growing risks to drinking water. A focus on resiliency and sustainability in design and construction can help water providers minimize negative environmental impacts, maximize social and economic benefits, gain stakeholder and public support, and enhance resiliency to both current and future climate change impacts on our watersheds.

Tim Rynders, P.E., PMP, is CDM Smith’s Climate Resilience discipline leader for drinking water. He can be contacted at rynderst@cdmsmith.com.

Chris Cerreta, P.E., is an environmental engineer in Denver, CO with a focus on water treatment and conveyance. He can be contacted at cerretacl@cdmsmith.com.

Alexa Gardner is a climate-focused environmental engineer in Denver, CO. She can be contacted at gardnerar@cdmsmith.com.

In today’s complex landscape of natural hazards, stringent regulations, and evolving water challenges, resilient water and wastewater utilities aren’t just safeguarding infrastructure—they’re protecting public health and shaping our water future. From proactive assessments and strategic planning to emergency preparation and management, Carollo partners with utilities to build resilience into the fabric of their organizations, because true resilience is about protecting what matters most. It goes beyond addressing vulnerabilities and maintaining essential services to sustain the health and well-being of the public, our communities, and the environment we all share.

800.523.5826 / carollo.com

olorado is leading the charge in promoting sustainable landscapes through innovative initiatives that address water scarcity and enhance climate resilience. Programs like the Turf Replacement Program (HB22-1151) and the Prohibit Landscape Practices for Water Conservation Act (SB24-005) have made water-wise landscaping a cornerstone of the state’s efforts. These programs focus on replacing high-wateruse turf with sustainable alternatives, conserving resources while maintaining functionality and aesthetic appeal. In 2021, two nonprofit organizations, Western Resource Advocates and WaterNow Alliance, partnered with three Colorado communities – Broomfield, Westminster, and Greeley – to implement large-scale turf replacement projects.

These efforts targeted prominent public spaces, replacing non-essential bluegrass turf with native grasses and drought-resistant plants. The goals were to conserve water, address challenges, assess resource needs, and establish funding strategies that could serve as a model for other communities. Future case studies from these projects will be published by Western Resource Advocates.

In Greeley, an innovative project has emerged from this initiative: a collaboration between the University of Northern Colorado (UNC) and the City of Greeley’s

water conservation team. Together, they are transforming a 3.4-acre plot of land near 11th Avenue and West 20th Street into a drought-resilient landscape. This prominent corner, serving as a gateway to UNC’s central campus and home to the iconic bronze bear sculpture, holds historical and practical significance. In September 1960, the City of Greeley donated this land to UNC as a park-like landscape. Now, more than 60 years later, it is being revitalized into a sustainable and functional space that honors its original purpose while addressing contemporary environmental challenges.

“In September 1960, the City of Greeley donated this land to UNC as a park-like landscape. Now, more than 60 years later, it is being revitalized into a sustainable and functional space that honors its original purpose while addressing contemporary environmental challenges.”

The project gained additional momentum in the spring of 2022 when students from UNC’s Leadership and Community Building class chose it as their final assignment. Student organizations like Earth Guardians and LEAF also embraced the project, providing invaluable input. Through surveys, students shared ideas for the space, including educational and recreational features, seating and hammock areas, enhanced walkways for connectivity, and opportunities for student art displays to foster engagement.

The transformation of the 3.4-acre site began around Thanksgiving 2024, with crews leveling the hill to create a new patio, pathway, and irrigation system. In spring 2025, drought-resistant grass will be planted, requiring about a year to establish and another one to two years to fully mature. This timeline reflects the importance of patience and long-term planning in achieving sustainable landscaping goals. By replacing traditional bluegrass with drought-tolerant grasses, the project is expected to save approximately two million gallons of water annually, showcasing the profound impact thoughtful landscape design can have on water conservation.

Additionally, the adjacent corner will feature the new College of Osteopathic Medicine, which will incorporate native grasses and mirror the sustainability concepts outlined in the original project.

This project represents a significant milestone for Greeley and UNC while providing a replicable blueprint for other schools and cities. Demonstrating how large-scale turf replacement and sustainable landscaping can save water, reduce maintenance costs, and enhance community spaces, it highlights

the potential for partnerships to drive innovation and inspire broader change. By 2025, the drought-resilient landscape will not only save millions of gallons of water annually but also create a welcoming, sustainable space for UNC students, staff, and visitors. As Colorado faces the challenges of climate change and water scarcity, initiatives like this exemplify the state’s commitment to building resilient, water-wise communities that benefit both people and the environment.

Additional details about Greeley’s case study or native landscape can be followed at:

• unco.edu/news

• westernresourceadvocates.org

• waternow.org

• coloradonativegrass.org

Dena Egenhoff is the Water Conservation Manager with the City of Greeley. She is also the Co-Chair of the RMSAWWA Conservation Committee. She can be reached at dena.egenhoff@greeleygov.com or 970-350-9846.

Most see a water tower.

We see a thirst-quenching drink.

Report (PER) that outlines solutions to strengthen their water infrastructure and positions the town for funding opportunities to make these upgrades a reality.

La Jara’s water distribution system is the backbone of the community, delivering safe and reliable water to more than 700 residents, businesses, and essential services like schools

In the heart of Colorado’s San Luis Valley, the Town of La Jara has long demonstrated resilience in managing its essential services. Like many small towns, La Jara faces unique challenges in maintaining its water distribution system and balancing aging infrastructure with the growing needs of its community. To ensure the town’s water system could continue to support its residents well into the future, La Jara partnered with Community Engineering Corps (CE Corps) to assess the system and develop a roadmap for targeted improvements.

CE Corps, a joint initiative of the American Society of Civil Engineers (ASCE), the American Water Works Association (AWWA), and Engineers Without Borders USA (EWB-USA), connects underserved communities with volunteer engineering expertise. Through this collaboration, La Jara received a Preliminary Engineering

and care facilities. Like many systems of its era, La Jara’s infrastructure includes materials and designs that were appropriate at the time of construction but now require updates to meet modern standards and ensure long-term reliability.

One of the system’s key challenges is its limited storage capacity. The town’s current tank provides 60,000 gallons of storage, which has served the community well but cannot meet the future needs of both daily

use and fire protection. As La Jara plans for the future, ensuring adequate storage to support growth and emergency response is a priority.

Another area for improvement is the network of distribution pipes. The system includes segments of older pipe material, some of which are prone to breaks and require frequent repairs. While these repairs have been managed effectively by the town’s staff, updating this infrastructure can reduce maintenance costs and improve reliability for residents.

These challenges are not unique to La Jara but are shared by many small towns across the region. What sets La Jara apart is its proactive approach in seeking solutions and partnerships to address these needs.

Through the support of CE Corps volunteers Ashley Waldron and Taylor Gertig, as well

“These challenges are not unique to La Jara but are shared by many small towns across the region. What sets La Jara apart is its proactive approach in seeking solutions and partnerships to address these needs.”

as contributions from students at the University of Colorado Boulder, La Jara embarked on a detailed evaluation of its water system. The team worked closely with the town’s leadership to assess the system’s current performance, identify opportunities for improvement, and develop practical solutions tailored to La Jara’s specific needs and resources.

The culmination of this effort was the development of a PER which serves to outline the town’s water system challenges and presents actionable recommendations for upgrades. Beyond technical details, the PER serves as a critical tool for securing

funding through organizations like the Rural Community Assistance Corporation (RCAC).

The PER proposed a series of targeted improvements to enhance La Jara’s water system, ensuring it can continue to serve the community effectively:

1. Increased Storage Capacity:

A larger storage tank, with a capacity of approximately 450,000 gallons, was recommended to meet both daily demands and fire flow requirements. This improvement would provide La Jara with the flexibility and resilience

“The

partnership between CE Corps and La Jara highlights the power of collaboration in solving infrastructure challenges. By combining local knowledge with engineering expertise, the project created a roadmap for progress that will have lasting benefits for the community.” needed to support growth and respond to emergencies.

2. Modernized Distribution System:

Replacing aging pipe segments with durable materials, such as PVC, was suggested to reduce maintenance needs and improve the system’s overall performance.

3. Improved Disinfection Redundancy:

Enhancing the disinfection system would ensure water quality remains consistent during periods of high demand or maintenance, providing an additional layer of reliability for residents. These recommendations are designed to build on the strong foundation already established by La Jara’s team, addressing current needs while planning for future demands.

bringing CE Corps to your town, visit www.communityengineeringcorps.org.

With the PER complete, La Jara is wellpositioned to pursue funding and begin implementing the recommended upgrades. These improvements will help ensure the town’s water system continues to meet the needs of its residents while enhancing reliability, safety, and resilience.

CE Corps: Supporting Communities Through Engineering Community Engineering Corps was created to help communities like La Jara address infrastructure challenges by connecting them with volunteer engineering expertise. Since its inception, CE Corps has supported communities across the country by providing pro bono technical services and fostering collaborations that empower local leaders.

What makes CE Corps unique is its ability to deliver high-quality engineering solutions while prioritizing community input and participation. For towns like La Jara, this partnership represents an opportunity to access professional expertise and create a clear path forward, even with limited local resources.

CE Corps welcomes volunteers from diverse engineering disciplines, as well as students and technical professionals, to join its mission of supporting communities. To learn more about getting involved or

The partnership between CE Corps and La Jara highlights the power of collaboration in solving infrastructure challenges. By combining local knowledge with engineering expertise, the project created a roadmap for progress that will have lasting benefits for the community.

As La Jara moves forward with the next phase of its water system upgrades, CE Corps is proud to have played a role in supporting the town’s efforts. This project serves as an example of how proactive

leadership, paired with community partnerships, can create meaningful and sustainable change.

Ashley Waldron is the Director of Water & Wastewater Operations for the Special Districts managed by Shea Properties, including Meridian Metropolitan District. She has more than 10 years of experience in the water treatment field, spanning research, consulting, and utility operations, with expertise in master planning, process optimization, siting studies, piloting, and design.

Taylor Gertig is a Project Manager at Plummer Associates and specializes in water treatment and infrastructure projects. Her work includes the planning, design, and implementation of treatment and distribution system projects that meet the needs of clients and communities. Taylor is passionate about providing sustainable quality drinking water to communities.

Water is essential to life, yet every day our waterways are faced with significant threats that challenge our ability to provide clean water for our communities. With over a century of water treatment experience, our experts offer a trusted, commonsense approach to address water quality issues proactively and provide solutions that bolster resilience in the face of uncertainty and change.

From Wyoming to New Mexico, we are committed to your success in protecting the Rocky Mountain region’s most precious resource.

There are nearly 400,000 house fires in the U.S. each year, and water that flows from hydrants is our best defense. Most of us never think about how water gets to us. Luckily, we don’t have to. Pumps, treatment plants, and pipes bring us clean water and carry away wastewater. All day, every day

But our water systems are aging. They need investment to continue delivering life’s most essential resource. Water—Essential. Reliable. Invaluable.

100%

COLLABORATIVE DELIVERY

Through Haskell’s in-house craft labor team, we build water treatment facilities with integrity, excellence, and a commitment to exceeding expectations. The key to our self-perform resources is strategic deployment across the U.S. with ample capacity to get the job done anywhere at any time. Let’s create something extraordinary together.

Design-Build | CM/GC | CMAR | Progressive Design-Build | Preconstruction Services

Scan to learn more about our commitment to you. We Create Things That Matter.

Dustin Ensminger, Water and Sewer Operator, Jorgensen Associates

Nothing lasts forever, including water meters, regardless of which types or manufacturers of meters are used. Every utility should have a meter replacement program with an established schedule based on age, consumption, accuracy, expected battery life, a combination of these, or some other formula. Routine meter replacement is a prudent practice to achieve maximum useful meter life without sacrificing accuracy, which equates to lost revenue.

There aren’t enough pages in this publication to discuss all the considerations or variables for a meter replacement program, so this article focuses on mechanical meters and presents a few factors related to meter manufacturers, materials, and register types to mull over for those beginning or continuing meter replacement programs.

There is a vast array of meter manufacturers on the market, and each claims to be better than the next. Choosing between them can be challenging. Keep in mind the goal is to have a meter that remains accurate for years to come. Additionally, with any mass-produced product, there may be some manufacturing issues.

Routine meter replacement is a prudent practice to achieve maximum useful meter life without sacrificing accuracy, which equates to lost revenue.

If that occurs, you’ll want to ensure the meter manufacturer is willing to identify and address the problem and make it right. This should include consideration for the labor resources you allocated to address the problem, not just the cost of the parts or meter to correct the issue.

Public entities are often bound by purchasing laws or guidelines that sometimes require purchases based on the lowest bid. This can lead to problems, such as subpar meters, meters by multiple manufacturers installed in your system, and less staff familiarity with each meter. If this sounds familiar, look to set or update your specifications to ensure you are getting a meter that meets your immediate and future needs, not just the lowest-cost meter. To avoid subpar meters, specify meter specifications over and above the minimum AWWA standard. For example, meters supporting a higher minimum flow rate indicate a larger measuring chamber resulting in better long-term accuracy. Meters with lower extended low-flow accuracy register smaller leaks. Also, while most mechanical meter accuracy warranties are

limited by a similar number of years, the number of gallons of flow can vary. Consider specifying published warranty parameters. There are some genuine benefits to ensuring meter manufacturers stay competitive with pricing by publicly bidding on meter purchases, but there are some drawbacks to consider. Although it can be a scary proposition to enter a long-term relationship with a meter manufacturer, there are also several advantages, including:

• Familiarity with product – Your staff will become very familiar with the design and function of the meters.

• Pricing – There is always the potential to negotiate pricing. However, the more meters you plan to install and replace, the more leverage you will have in negotiating lower costs.

• Contract – In some cases, multiple-year contracts for pricing can be established, which significantly helps with budget estimates.

• Staging for automatic meter reading/advanced metering infrastructure (AMR/AMI) – Some manufacturers offer the potential to move to their AMR/AMI system with little effort.

• Support and training – Manufacturers are typically more responsive to your needs, including support and training, when they are your approved manufacturer.

Meters can be made from many different materials. It will be up to your utility to determine what works best for your system as long as the meters meet or exceed industry standards. Manufacturers make variations of the same meter, so consider the cost benefits of mixing different materials. For instance, if your utility has traditionally installed brass meters, including the lid and register shroud, there can be savings gained by switching to a composite lid and shroud. Nearly all the meter components can be specified, so work with your manufacturer to identify areas that do not compromise meter performance but reduce costs.

If considering moving to a different material or manufacturer not previously used, complete a pilot test with the meters. Note any issues with installation, reinstallation, or otherwise.

Different materials and manufacturers have different dimensions, even if the lay length is the same. This could result in clearance issues when the meter is replaced. That turns a relatively quick replacement into a lengthier and more costly process, especially if damage or alterations to the installation are needed. The reinstallation of a meter is something you should also consider. Although your utility may not have the practice of regularly reinstalling a meter in different locations, there are several other reasons why a meter may be reinstalled at the same place. Take note if the meter is difficult to install during reinstallation. Some softer materials used for the threaded meter ends may tend to slightly distort after installation. This can result in the inability to tighten the swivel couplings onto the meter by hand, making for a frustrating and more time-consuming installation.

Lastly, double-check that maximum and continuous flow rates are not impacted by different manufacturers and materials. Even meters produced by the same manufacturer may be affected if an alternative material is used.

Registers typically come in two forms: 1) a register that cannot integrate with AMR/AMI; and 2) a register that allows for the migration to AMI in the future. These registers typically have a wire attached to the register, which allows for a radio to be installed. Deciding to convert to an AMR/AMI system is a significant decision for any utility. The pros and cons are well documented, with many resources available to review. If your utility has yet to commit to AMR/ AMI, you should consider if this is a viable option within the next several years. If your utility is considering a conversion, it will be less expensive to install meters with a register able to connect to a radio now versus paying the additional labor and cost of the register to retrofit at a future date. The reason is that the register is the most expensive part of the meter. Even more costly is the labor to revisit a meter to replace the register in the future with a compatible register. Nobody likes to pay twice for something, so making this decision now can save the cost and waste of replacing the register in the future. If you choose to do this, consider specifying a universal connector versus a proprietary connection to allow for AMR/AMI radio options. Not specifying a universal connector could mean cutting and splicing wires to utilize a different manufacturer’s radio. This splice can be the source of problems in the future, including radios functioning sporadically or not at all.

Many registers are now available with a digital display which can provide additional functionality and even store historical read information. However, consideration should be given to using these because some of the displays are powered by a battery which means the useful life of the battery must be given thought. Stocking replacement meters for several months could mean impacting the life of the battery. Additionally, if also using an AMR/AMI radio, there are now two batteries to contend with. The concern of when to replace the meter could then shift from the accuracy of the meter to when the battery will fail.

As mentioned at the onset, there are many variables to consider for your meter replacement program. Hopefully, this article helped you evaluate some options you may not have previously considered or will be the start of future conversations about different ways to administer a water system’s meter change-out program.

Dustin Ensminger is a licensed water and wastewater professional with over 26 years of experience working in municipal water and wastewater systems in AZ, OR, WA, CA, and WY. He can be reached at dansmngr@gmail.com, densminger@jorgeng.com or 307-231-6352.

• Water/Wastewater Treatment

• Water/Wastewater Infrastructure Planning, Design and Rehabilitation

• Special District Engineering and Consulting Services

• Groundwater Wells

• Construction Management

Providing sustainable solutions for clients, communities, and the environment Contact: Jerry Peña | 215 Union Blvd, Suite 500, Lakewood, CO 80228 (720) 744-2233 | kennedyjenks.com

Our concern for the environment is more than just talk

WASTEWATER PUMPING SYSTEM WITH BUILT-IN INTELLIGENCE

Achieve clog-free, energy-efficient wastewater pumping with Flygt Concertor.

Using advanced software functionality and state-of-the-art hardware, Concertor protects against unscheduled downtime and creates significant energy savings for your pump station.

Adaptive pump performance finds the most efficient operating point each duty cycle, while self-cleaning functionalities clear potential blockages. Integrated intelligence also makes setup and operation quick and easy.

A scalable system

Start with Concertor

Concertor N is a trouble-free, energy-efficient pump for on/off operation. Clog detection, pump cleaning, and soft start increase pump system reliability and lower operating costs.

Add Gateway

Concertor DP leverages your

Add MultiSmart® powered by Nexicon®

Concertor DP leverages your plant’s existing process control algorithms while simplifying the adjustment of performance parameters and providing redundancy as an on/off control.

Concertor with MultiSmart powered by Nexicon comes preprogrammed with wastewater pumping logic for lowest total cost of ownership. Continuous operational analysis minimizes energy use, and built-in sump and pipe cleaning reduce maintenance callouts.

Reduces O&M Costs & Capital Expenses

Very Low Life Cycle Cost

Helps Protect the Environment

Prevents Corrosion

Rapid Trenchless Installation

As a result of the impervious nature of the SpectraShield Liner System, infiltration and ex-filtration is eliminated in structures. Operating and maintenance expenses are reduced, plant capacity is preserved, and plant expansion requirements may be delayed or eliminated.

As a result of the long life and competitive installation cost, the life cycle cost for the SpectraShield Liner System is very low. In many cases the ROI is under 24 months.

Groundwater entering the system is reduced, allowing more to percolate to the aquifer. Reduced pumping requirements reduce energy use reducing the carbon footprint. SSOs (Sewer System Overflows) are reduced as infiltration is reduced.

The Spectrashield Liner System provides a protective barrier that prevents H2S and moisture from reaching the surface of the structure.

The SpectraShield Liner System can be installed in a typical 7 foot deep manhole in about an hour without any excavation. The manhole may be returned to service immediately upon completion of the installation. An average sized pump station or wet well application takes about 2 days from start to finish. The pump station or wet well may be returned to service immediately upon completion of the installation.

Flexibility

Long Life

Versatile Experience

Cost competitive

The multi-layer SpectraShield Liner System is flexible, allowing it to handle the stresses associated with structure settling, traffic loading, and freeze thaw cycles.

The SpectraShield Liner System has a design life of 100 years and comes with a 10 year manufacturer warranty. The first structures lined in 1993 are still in place, and in good condition.

The SpectraShield Liner System may be used in a variety of structures, such as; manholes, lift stations, wetwells, large diameter pipes, box culverts, headworks, grit chambers, weirs, and package WWTPs.

Since 1993, in-house applicators, and trained certified licensees, have applied the SpectraShield Liner System in over 121,000 structures. Over 12 million square feet of the SpectraShield Liner System have been applied.

The SpectraShield Liner System installation cost is very competitive with all other liners and coatings.

A.D. Norford and Dan Freedman, Metro Water Recovery, Becky Luna, Darrell Buhman, and Tyler Dougherty, Carollo Engineers, Inc.

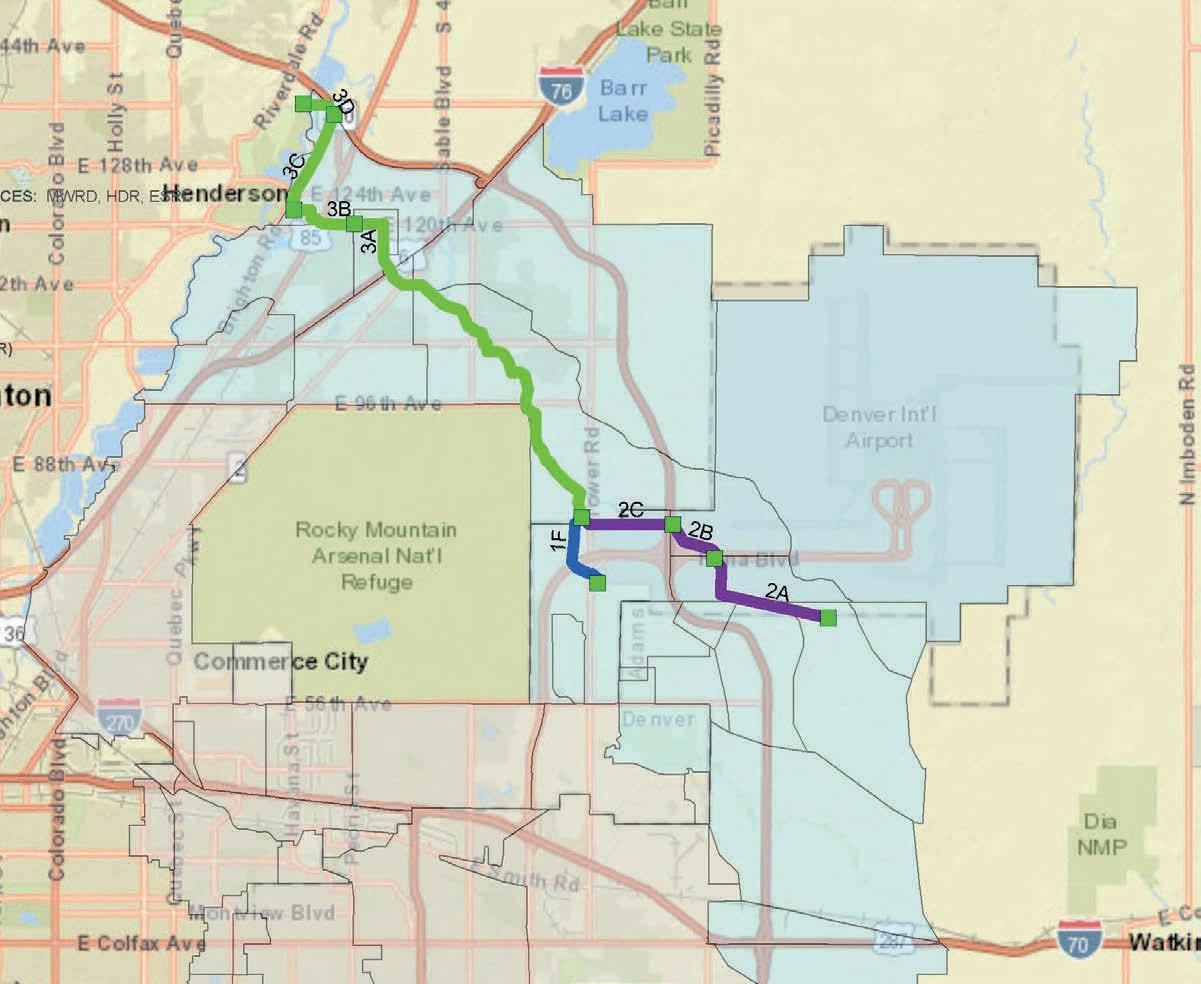

Metro Water Recovery (Metro) will take energy generation to a new level as it moves from cogeneration to pipeline injection of renewable natural gas (RNG) at its Robert W. Hite Treatment Facility (RWHTF) in Denver, Colorado.

Metro is the largest water and resource recovery agency in the Rocky Mountain West, serving approximately 2.2 million people in an 817-square-mile service area. As an industry leader, Metro has produced electricity and heat through cogeneration for nearly 40 years.

As Metro strives to identify the most sustainable, cost-effective, and efficient solutions to the complex challenges of resource recovery, a collaborative study with Carollo Engineers, Inc. (Carollo) highlighted the benefits of RNG for pipeline injection.

Metro’s cogeneration system at the RWHTF went online in 1985, allowing methane generated from the treatment process to

supply as much as 40% of the energy needed at the facility while providing a source of heat for the anaerobic digestion process.

After nearly four decades, the cogeneration system has reached the end of its useful life, prompting Metro to explore alternate biogas use options. The study, completed in 2021, evaluated whether to replace the cogeneration system or install biogas upgrading equipment to generate RNG for pipeline injection into Xcel Energy’s natural gas pipeline. Ultimately, RNG was selected as the solution with the most social, environmental, and financial benefits.

Metro and Carollo began design in 2022 for an RNG pipeline injection system and a boiler mechanical facility to replace the heat currently supplied by the cogeneration system to the digesters and facility buildings. As the project moved into design, the team faced the important decision of selecting the most appropriate biogas upgrading technology.

Project

$62.4 million

$316,000 to $589,000

Operating

Operating Temperature

System Inputs

Waste Streams

Footprint

Operational Complexity

Constructability and Sequencing

212 degrees F

Hot water supply

Compressed air

Potable water

Waste stream

Tail gas

One skid: 66 feet wide, 66 feet long, 47 feet tall

Overall: 4,400 sq ft

Additional hot water and heat recovery systems to maintain and operate

Combination of skid-mounted equipment located outdoor and within enclosures and a Boiler Mechanical Facility

$64.5 million

to $748,000

Ambient

Lubrication oil

Compressed air

Make-up water

Water blowdown

Tail gas

Two skids: 22 feet wide, 133 feet long, 48 feet tall

Overall: 5,800 sq ft

Additional stage of compression

Combination of skid-mounted equipment located outdoor and within enclosures and a Boiler Mechanical Facility

Safety System requires glycol solution at 266 degrees F System operates at 150 psi

Sustainability

Experience

Lower net GHG emissions

2 U.S. Installations

Redundancy A single treatment train

Higher net GHG emissions

9 U.S. installations

Two, 50% treatment trains

Notes: (1) Based on 2,000 to 3,000 scfm biogas flow; includes net heat demand from the amine system assuming heat recovery is used; includes costs associated with product gas compressors. (2) A 1.9 percent difference in methane recovery equates to approximately $6 million over 20-year life ($300,000/year).

A comparison of the two biogas upgrading technologies favored amine upgrading due to slightly higher methane capture, higher purity tail gas stream, lower greenhouse gas emissions, and the ability to recover a significant portion of the heat input.

Due to cost-effectiveness at lower flow rates, most water resource recovery facilities (WRRF) in the United States use membrane or pressure swing absorption technologies to separate methane and carbon dioxide in the biogas. Due to Metro’s higher biogas flow rate of 3,000 standard cubic feet per minute, amine wash and water wash systems could also be considered. While less common at WRRFs in the United States, these technologies offer capital, layout, and operating cost benefits at large biogas flow rates.

The design team determined that both amine and water wash upgrading systems could reliably produce RNG that meets the natural gas utility’s requirements. After comparing the two approaches, Metro ultimately chose the amine upgrading system.

Benefits of the amine system over the water wash include a slightly higher methane capture, higher purity tail gas stream, lower greenhouse gas emissions, and the ability to recover a significant portion of the heat input.

In an amine upgrading system, carbon dioxide is solubilized into an amine solution at high temperatures, separating it from the methane gas. Up to 90% of the heat required by the amine upgrading system can be recovered and used elsewhere on site. However, the recoverable heat is considered “low grade” (not hot enough to be usable for digesters or building heat applications).

To utilize heat recovery, Metro and Carollo evaluated industrial water-to-water heat pumps that would upgrade the recovered

heat to make it usable in the digestion process, which represents the most significant heat demand at the RWHTF.

While the heat pump system will have a significant electrical demand, its energy output was estimated at more than five times its input. Compared to solely using natural gas for digester heating, the heat pumps will directly offset approximately $1.5 million in annual natural gas usage in the boilers and reduce greenhouse gas emissions by 30%.

The construction manager at-risk contractor, Molz Construction, Inc., developed the heat pump system’s capital cost. The total construction cost for the heat recovery system, including the building it is housed in, was estimated at $9.2 million. Anticipated Inflation Reduction Act funding would reduce the capital cost to approximately $6.4 million. The heat recovery system should pay for itself in 15 years. With Inflation Reduction Act funding, that estimate drops to 10 years.

Once complete, Metro’s biogas upgrading system will be the second-largest RNG system in the United States and the first installation of an amine upgrading system at a WRRF in the country.

Construction for the Biogas Utilization Project is already underway, with work initiated on the boiler mechanical facility that will provide heat to the digesters, the amine upgrading system, and other buildings at the RWHTF. Metro plans to start demolition of the cogeneration facility and begin construction of the amine upgrading and heat recovery systems by January 2027.

Injection of RNG into Xcel Energy’s natural gas pipeline is anticipated by mid-2028, completing Metro’s transition from cogeneration to RNG.

$8,000,000

$6,000,000

$4,000,000

$2,000,000

$0

($2,000,000)

($4,000,000)

($6,000,000)

($8,000,000)

($10,000,000)

An evaluation of the 20-year net present value of the heat recovery system shows a 15-year payback, which may be reduced to 10 years with anticipated Inflation Reduction Act funding.

A.D. Norford has over 20 years of wastewater design and construction experience. He has managed over $500 million of projects on the RWHTF, serving the greater Denver Metropolitan area in liquids, solids and biogas streams. A.D. is the Metro Project Manager for the RWHTF Biogas Utilization Project.

Becky Luna is nationally recognized throughout the industry for her expertise in the beneficial use of biogas. With 25 years of experience at Carollo focused on wastewater planning, design, and construction, her areas of expertise include process evaluation, nutrient optimization, solids treatment, and biogas utilization and design.

Over his 21-year career, Darrell Buhman’s expertise encompasses cogeneration and digester gas conditioning systems, boilers, plant process heating systems, process heat recovery, cooling towers, and gas handling. As a subject matter expert at Carollo, Darrell has designed

and analyzed numerous boiler systems and wastewater plant heat loops across the country and is Carollo’s primary heat recovery and cogeneration expert.

Tyler Dougherty has 11 years of experience with Carollo. As the company’s sustainability lead, Tyler has been instrumental in evaluating sustainable and cost-effective options for biogas reuse and energy efficiency projects. His expertise extends to the design and construction of biogas upgrading systems, with a focus on renewable natural gas injection.

Dan Freedman has 15 years of experience in the water industry, spanning consulting and public utility roles. As the Director of Technology & Innovation at Metro Water Recovery, he leads efforts in process optimization and innovative solutions to environmental challenges. He served as Metro’s Technical Manager for the RWHTF Biogas Utilization Project, supporting renewable energy and sustainability in wastewater treatment.

Rotary Lobe Pumps Macerating Technology

PROTECTS PUMPS AND SYSTEMS. SOLIDS REDUCTION CONSTANTLY IMPROVED.

+ Consistent Macerating Results

+ Adjustable Maceration

+ Compact, Space-Saving Design

+ Long Service Life

+ Energy Efficient

+ Ease of Maintenance (MIP ® )

+ Large Selection of Component Materials

Megan McDowell, Senior Communications Specialist, AWWA

The global business events sector is a substantial economic driver, generating more than $1.15 trillion in direct spending and supporting 10.9 million jobs. With this economic impact comes a responsibility to address the industry’s environmental footprint. The American Water Works Association (AWWA) recognizes this responsibility and is taking significant steps toward hosting more sustainable events, with its flagship Annual Conference and Exposition (ACE) leading the charge.

In 2023, AWWA launched a dedicated effort to integrate sustainability and social responsibility into its events, starting with ACE24 in Anaheim, California. Guided by the Events Industry Council (EIC) framework and in partnership with Colorado-based sustainability consultant

Honeycomb Strategies (HCS), AWWA established comprehensive sustainability policies and plans, earning the EIC Foundations Level Certificate in August last year.

This achievement laid the groundwork for ACE25 – hosted in AWWA’s headquarter city Denver, Colorado – to further elevate AWWA’s commitment to environmental and social responsibility. This year’s conference will take place June 8-11, 2025, and integrate sustainable practices that minimize its environmental footprint while maximizing its positive social impact.

“AWWA’s ACE sustainability initiative reflects our dedication to the future of water,” said AWWA CEO David LaFrance. “This effort is interwoven within our organization’s long-term vision for a sustainable water future, as embodied

in the Water 2050 initiative – it is a collaborative effort to envision and create a future where water is sustainable, secure, affordable and resilient.”

By implementing sustainable practices at ACE25, AWWA is demonstrating its commitment to the Water 2050 goals and inspiring the water community to take collective action.

Some of the ways ACE25 is reducing its environmental footprint include:

• Waste reduction: Building on ACE24’s success in diverting 21% of waste from landfills, ACE25 aims to increase this rate through comprehensive waste management strategies, including promoting reusable and recyclable materials and partnering with local organizations for material donation and composting programs.

AWWA’s ACE sustainability initiative reflects our dedication to the future of water. This effort is interwoven within our organization’s long-term vision for a sustainable water future, as embodied in the Water 2050 initiative – it is a collaborative effort to envision and create a future where water is sustainable, secure, affordable and resilient.

• Energy efficiency: ACE25 will prioritize energy-efficient practices to minimize its carbon footprint. Collaborating with the Colorado Convention Center and local partners, AWWA will utilize renewable energy sources and implement energysaving measures.

• Water conservation: As a leading organization in the water sector, AWWA recognizes the critical importance of water conservation. ACE25 will continue to implement water-efficient practices throughout the event, including promoting the use of reusable water bottles, encouraging use of permanent filland-go stations, and educating attendees and exhibitors about water conservation.

• Sustainable sourcing: From conference materials to booths, ACE25 will improve its sustainable sourcing practices, procuring materials made from recycled and renewable resources whenever possible. AWWA will prioritize vendors and suppliers who share the Association’s commitment to sustainability, ensuring that the event’s supply chain reflects its environmental values.

• Community engagement: ACE25 aims to positively impact the local Denver community, engaging with local organizations and businesses to support their sustainable programs and the nearby workforce.

AWWA recognizes that sustainability is a collective effort, and ACE25 will actively engage attendees, exhibitors, sponsors, partners and the broader water community in its efforts.

Conference attendees can expect sustainable practices embedded in their ACE25 experience, including:

• Carbon footprint offset program: Attendees will have the opportunity to offset their travel-related carbon emissions through the Voluntary Carbon Offset Dashboard.

• Public transportation and ridesharing: AWWA will encourage the use of public transportation and ridesharing options to reduce traffic congestion and emissions.

• Sustainable food and beverage options: ACE25 will spotlight smart sourcing within the menus, minimizing transportation and supporting local businesses.

Exhibitors at ACE25 are also encouraged to demonstrate their commitment to sustainability by taking the AWWA ACE Exhibitor Sustainability Pledge (www.awwa. org/ace-exhibitor-sustainability-pledge/). This pledge outlines specific actions exhibitors can take to reduce their environmental impact, such as:

• Using reusable or recyclable booth materials.

• Reducing paper consumption and opting for digital alternatives.

• Creating sustainable promotional items.

• Minimizing waste generation and properly disposing of materials.

• Prioritizing energy efficiency in booth design and operation.

By taking the pledge, exhibitors not only document their contributions to the overall sustainability of ACE25 but

also showcase their leadership in environmental responsibility.

With the Foundations Level Certificate under its belt, AWWA will work closely with EIC, third-party auditor Alliance for Audited Media (AAM), and Honeycomb Strategies (HCS), to conduct a full logistics audit on the ACE25. AWWA aims for ACE25 to achieve a Bronze, Silver, Gold or Platinum certification level award within the EIC Sustainable Event Standards (SES) framework.

“Sustainability isn’t just a buzzword, it is a responsibility – especially for industries with a large footprint like the business events sector,” said AWWA Director of Conferences and Events Joanne Gaglia. “AWWA is committed to leading by example, and this effort is one of the ways we’re walking the walk.”

To learn more about ACE25 and to register for the conference, visit awwa.org/ACE. For more information about the ACE25 sustainability initiative, visit https://ace.awwa.org/Attend/ Sustainability-Impact.

Megan McDowell is the Senior Communications Specialist for the American Water Works Association in Denver, CO. She believes everyone should understand the profound impact water has on our lives and does so through storytelling, focusing on solutions that protect the world’s most vital resource. She can be contacted at mmcdowell@awwa.org

Biochemical Oxygen Demand

Total Suspended Solids

Ammonia-Nitrogen

Nitrate and Nitrite Nitrogen

Kjeldahl-Nitrogen (TKN)

E-Coli, Total Coliform

Metals by ICP-MS and ICP-OES

SOC/VOC

Biosolids-503 Regs/Fecal Coliform

NPDES Requirements

DMRQA Study Participant

Organic Contaminants (SOC/VOC)

DBP (THM/HAA, TOC/ALK)

Inorganic Contaminants (Metals)

Nitrate and Nitrite Nitrogen

Copper and Lead

Total Coliform

Fluoride

Metals by ICP-MS and ICP-OES

Compliance Auto-Ship Bottle Program

VISITONEOFOURCONVENIENTLOCATIONS FOR MODERNDAYTECHNOLOGYAND OLD-FASHIONED SERVICE!

Commerce Cit y Laboratory 10411 Heinz Way Commerce City, CO 80640

Lakewood S ervice Cent er

610 Garrison St. Unit E Lakewood, CO 80215 303.659.2313 www.coloradolab.com info@coloradolab.com

Contact us

Kari Larese, Communications Manager, Highlands Ranch Water

Just south of Denver is a water and wastewater provider whose name, until recently, didn’t clearly define who they are and who they serve. In a community of more than 35,000 homes and businesses, imagine trying to engage with an audience who doesn’t know who’s talking. How can you prioritize resiliency and sustainability when no one knows who you are?

Centennial Water and Sanitation District was established in 1981 to serve the master planned community of Highlands Ranch, Colorado. The name Centennial Water was chosen from the district’s location in the Centennial State, and because a popular TV miniseries from the 1970s called Centennial was filmed in the community. Thus, the water and wastewater provider adopted a name with no clear link to the community it served.

Two decades later in 2001, the City of Centennial, located just north of Highlands Ranch, incorporated and took the same name as its neighboring, but unrelated, water district. Therein lies the challenge Centennial Water was facing: their name was inadvertently linked to a neighboring community they didn’t serve. This misalignment created confusion among customers and stakeholders,

impacting public perception and trust. A name isn’t just a label; it’s an identity that communicates purpose, builds credibility, and aligns with organizational values and missions.

Fast forward to 2025 and you have a water and wastewater provider serving the master planned community of Highlands Ranch that has nearly reached build-out. The focus has undergone a complete transformation, shifting from supporting a growing community to prioritizing long-term sustainability, and strengthening connections with customers and stakeholders.

This past January, Centennial Water announced it was changing its name to Highlands Ranch Water. The name reflects the district’s commitment to the communities it serves. The rebrand refreshes the district’s image and reinforces its dedication to sustainability, innovation and customer service, demonstrating it is deeply connected to its mission of providing safe, sustainable and reliable water and wastewater utility services to customers with superior quality and value.

“Changing our name to better reflect the customers we serve is more than a rebrand,

it’s a renewed commitment to our role as an integral part of this community,” said General Manager Sam Calkins. “We are excited to begin this next chapter as Highlands Ranch Water, dedicated to safeguarding the public health and well-being of the more than 100,000 customers in our service area.”

The new name reflects the interconnectedness of water and wastewater and the district’s approach to managing all water as a valuable and essential resource. Whether water is treated and pumped out to homes and businesses, or wastewater is treated and returned to the South Platte River, managing the community’s water

Changing our name to better reflect the customers we serve is more than a rebrand, it’s a renewed commitment to our role as an integral part of this community. We are excited to begin this next chapter as Highlands Ranch Water, dedicated to safeguarding the public health and well-being of the more than 100,000 customers in our service area.

supply while protecting the environment is a responsibility the district tackles every single day.

Highlands Ranch Water has implemented several initiatives to prioritize long-term sustainability and resiliency. These include investing in infrastructure upgrades to reduce reliance on groundwater sources, implementing programs and offering resources to encourage water conservation among residents and businesses, and partnering with customers, stakeholders, and community partners to educate and increase awareness about our most vital resource.

To strengthen ties with customers, Highlands Ranch Water plans to increase its outreach efforts and presence in the community. This includes sponsoring the local race series, partnering with the newly opened Highlands Ranch Senior Center to educate and inform older adults in the community, and hosting booths at

community events. The district is partnering with a local brewery to host conservationrelated events throughout the year aimed at educating residents about the critical role Highlands Ranch Water plays in public health and environmental stewardship.

“It’s time for the next chapter of Highlands Ranch Water,” said Calkins. “We are prioritizing our customers and making it easier for you to get to know us. We will be doing more education and outreach with customers than ever before, to deepen the understanding of the vital services we deliver.

Our new name will serve as a bridge, fostering trust and confidence among employees, customers, and stakeholders while highlighting our proactive commitment to long-term reliability.”

Kari Larese is the Communications Manager for Highlands Ranch Water, formerly Centennial Water and Sanitation District. She is passionate about the water industry and enjoys learning from and collaborating with other industry professionals.

It’s time for the next chapter of Highlands Ranch Water. We are prioritizing our customers and making it easier for you to get to know us. We will be doing more education and outreach with customers than ever before, to deepen the understanding of the vital services we deliver.

Behind

Jay Adams, Denver Water

An old proverb says, “It takes a village to raise a child.”

It also takes a village of people with a variety of skills to bring water from the mountains and send it to customers’ taps.

Denver Water’s industrial controls team taps into the skills of IT professionals to ensure a safe, reliable water supply for 1.5 million people in the Denver Water service area.

“People may not think about how computers and IT help get water to their faucet, but we use a variety of industrial controls across Denver Water,” said Brian

Marshall, an industrial controls technician at Denver Water.

The team designs, builds, and maintains computer and networking systems that help operate and monitor various operational processes used in the delivery and treatment of water.

“Think of industrial control systems like the thermostat in your home. When you push buttons on the thermostat controller, it sends a signal with instructions to the air conditioner or furnace in your house to send out heat or cool air,” said Drake Dennert, IT manager at Denver Water.

Denver Water’s industrial controls team taps into the skills of IT professionals to ensure a safe, reliable water supply for 1.5 million people in the Denver Water service area.

There’s a

lot of work that goes on behind the scenes to keep all of these computer systems running. Our job starts with creating the programming for the system. We also design, build, and install many of the components. We also do all of the maintenance, upgrades, and repairs if there’s ever an issue with the equipment.

Using industrial controls allows Denver Water to operate and monitor various processes efficiently to ensure a safe and secure water treatment and delivery system.

“There’s a lot of work that goes on behind the scenes to keep all of these computer systems running,” said Zach Carlson, an industrial controls engineer at Denver Water.

“Our job starts with creating the programming for the system. We also design, build, and install many of the components. We also do all of the maintenance, upgrades, and repairs if there’s ever an issue with the equipment.”

Each day for the industrial controls team is different.

Team members can find themselves working anywhere in Denver Water’s system, from the utility’s main administration building near downtown Denver, to its water treatment facilities, pump stations, reservoirs – even its operations at Denver International Airport.

The group is also responsible for managing Denver Water’s radio communications systems, which was what attracted Marshall to the organization after he spent time in Afghanistan while serving in the US Army.

“My military background showed me a lot of different avenues of work that can be done, and it definitely leads into leadership experience and working with a vast group of people,” Marshall said.

“Coming into Denver Water, I really found a place of camaraderie that’s similar to working in the military.”

Team members also enjoy working around new computer systems and technologies. Working on industrial controls systems requires knowledge in programming, networking and electronics, while also being a mechanic who can troubleshoot problems.

“I am extremely proud of the work we do here,” Carlson said.

“I take the job very seriously and I take a lot of pride in the fact that I am helping to deliver the water that I drink, that my wife drinks, and that all of my friends and family drink.”

Jay is a content producer who loves telling a good story. He has a news background as a multimedia journalist, producing stories and videos about employees, projects and water industry news.

Adams worked as a broadcast news producer at KCNC-TV in Denver before joining the Denver Water team in 2013.

He earned his bachelor’s and master’s degrees from Iowa State University, where he got his start reporting the news for the campus TV station. His passion for water comes from growing up on a lake in Minnesota and spending his summers sailing and water skiing. Jay is an avid skier, snowboarder and mountain biker who loves teaching his two daughters about all Colorado has to offer and the importance of water in the West.

Alex Sofranko, DEI Committee

Diversity, Equity, and Inclusion (DEI) observance days and months provide opportunities to celebrate the unique identities, experiences, and contributions of various communities. These observances, such as Black History Month in February or LGBTQ+ Pride Month in June, encourage reflection, learning, and growth. Recognizing these events fosters a greater understanding of the diverse groups that make up our society, helping to break down barriers, reduce prejudice, and promote inclusivity. By highlighting these observances, we not only honor individuals’ histories and struggles but also acknowledge the ongoing work needed to create a more equitable and just society.

In the workplace, recognizing DEI observance days can help create an inclusive culture where everyone feels valued and understood. When employees see their identities represented and celebrated, it fosters a sense of belonging and psychological safety. It also demonstrates that the organization is committed to diversity, ensuring people of all backgrounds feel respected and supported.

These observances can be used as learning opportunities, where employees can engage in discussions, attend training, or participate in activities that increase awareness of different cultures, experiences, and challenges.

To incorporate DEI recognition in the workplace, companies can take several actions. Organizing educational events, workshops, or webinars on the significance of these observance months can help employees deepen their understanding of different communities. Displaying symbols of recognition (e.g., rainbow flags for Pride Month or cultural displays during Hispanic Heritage Month) can visually affirm an organization’s commitment to diversity. Additionally, incorporating inclusive language in communications and offering space for open dialogue or employee resource groups centered around these topics can support ongoing DEI efforts. By making these observances an integral part of the workplace culture, organizations not only contribute to a more inclusive environment but also enrich employees’ experiences and growth.

If you are interested in learning more about certain DEI observances or in helping out on the Rocky Mountain AWWA DEI Committee, please contact Alex Sofranko (asofranko@pwsd.org) or Victor Sam (victor.sam@stantec.com).

January

February

March

National Mentoring Month

Martin Luther King Jr. Day

Black History Month

National Youth Leadership Month

Women’s History Month

Gender Equality Month

Developmental Disabilities Awareness Month

International Women’s Day

April

May

June