As an Oklahoma native, Cole Niblett understands first-hand the water challenges that face his state. He’s dedicated to shaping communities across Oklahoma by improving the water and wastewater infrastructure that helps supply safe, reliable water resources to residents in every corner of the state.

Cole Niblett, PE Oklahoma Water Team Leader

Craig Kelman & Associates is both honored and thrilled that we have been selected as the new o cial publishing partner of OWEA for The Splash magazine, commencing July 2024.

As a publishing partner to nearly 100 professional associations across the United States, Canada, and the Caribbean, our organization brings extensive experience in publishing print and digital content across various industries on a multitude of platforms. Since our inception in 1980, we have been dedicated to delivering high-quality association communications including magazines, newsletters, directories, websites, and helping manage dynamic and robust social media presences.

Our expertise spans a diverse array of industries such as healthcare, engineering, public works, education, transportation, and real estate, among others. We are excited to apply this breadth of experience to enhance the communication e orts of the Oklahoma Water Environment Association (OWEA) and its members.

The dedicated team here at Kelman, led by Managing Editor Mathias Leiendecker (mathias@kelman.ca) and Marketing Manager Chad Morrison (chad@kelman.ca), is committed to meeting the evolving communication needs of OWEA. We are eager to engage with the companies and individuals who will utilize the pages of The Splash to disseminate their vital messages and reach you, their target audience.

We invite you to experience the refreshed look of The Splash magazine in its latest edition and appreciate your warm welcome to the communications team. Thank you for allowing us to play a significant role in your ongoing engagement and outreach e orts.

ENGINEERING

Water/Wastewater

Groundwater Systems

Civil/Electrical/I&C

Hydraulic Modeling/Master Planning

Value Engineering

DESIGN

New Construction

Refit/Rehabilitation

Assessments/Studies

PROJECT/ CONSTRUCTION MANAGEMENT Inspection Design Build Services MUNICIPAL,

Iam excited to write this letter to kick o our revitalized publication! Many exciting things are happening in OWEA and we have high hopes that The Splash will keep all of you up to date on what is happening now and what we have planned for the future. I have the opportunity to step into this role at a great time, bene tting from the hard work of previous presidents and other Board members.

This past May, through continued partnership with APWAOK, we held our largest conference to date. We are thankful to our membership for providing a robust technical agenda addressing the challenges faced in our industry. We look forward to a wonderful event in Norman in 2025 and a possible new venue in Tulsa in 2026. Our Conference Planning Committee is already looking at alternative ways to ensure that we can continue to grow the conference each year.

OWEA’s annual business meeting was held at the conference and included welcoming some new OWEA o cers to the organization as well as saying goodbye to past o cers as their time on the board came to an end. John Bannen nished up his tenure on the OWEA presidential cycle, though he is no longer an o cer I have no doubt he is going to continue to be an active member and chairperson for several of our committees. Shawn Glen decided to step back from Treasurer duties after several years of diligent work, but I know plans to continue to support

“MANY EXCITING THINGS ARE HAPPENING IN OWEA AND WE HAVE HIGH HOPES THAT THE SPLASH WILL KEEP ALL OF YOU UP TO DATE ON WHAT IS HAPPENING NOW AND WHAT WE HAVE PLANNED FOR THE FUTURE.”

the organization. We are so appreciative of all the hard work and the time these two put into our organization. With these changes, we welcome our new o cers, Crystal Kowalik as Vice President, and Joy Kotey as Treasurer.

In June, we hosted the WEF Residuals and Biosolids Conference in Oklahoma City. This was a great opportunity to showcase Oklahoma and the great work that is

happening here. Conference attendees were invited to attend the Friends of Biosolids Event held at RiverSport OKC as well as to tour Midwest City’s Modern Composting Facility and Edmond’s Aerobic Digestion and Dewatering Facility. We look forward to hosting other specialty conferences in the future. We will provide a recap of the event in the next issue of The Splash this fall.

“THE BOARD HAS CONTINUED TO WORK BEHIND THE SCENES EVERY YEAR TO PUSH THE OBJECTIVES OF THIS PLAN FORWARD AND, THOUGH IT HAS TAKEN A FEW YEARS, AS EXHIBITED BY OUR CONFERENCE TURNOUT THIS YEAR, PEOPLE ARE READY TO DIVE BACK IN, WITH EVEN MORE GUSTO THAN BEFORE.”

OWEA has several events planned throughout the next year. The rst was a training event held for board and committee members in Oklahoma City in August. This training intended to help give volunteers a better understanding of the organization, what we do, who we are, and why we do it. This was a great way to help people see how to get involved and get them excited about the organization. I was overwhelmed when I stepped onto the Board two years ago and didn’t have an in-depth knowledge of who OWEA was and what they did, so I think this will be a great initiative. We hope to continue these

trainings annually as we continue to grow. Contact me at erowland@brokenarrowok.gov, if you’d like more information about this training.

We also are working on plans to have an awards banquet. We hope this banquet will allow us to have more dedicated awards and allow us more time to honor the awardees.

Finally, we have a new Women in Water Community that hosted its rst event at our conference with a great turnout. They are excited to plan more events throughout the year to draw women together and create community.

These are just a few of the numerous events we are working on over the next few months. Be sure to also visit owea.org for the latest information.

OWEA’s Strategic Plan includes values of Leadership, Stewardship, Collaboration, Integrity, and Passion. The Board has continued to work behind the scenes every year to push the objectives of this plan forward. As exhibited by our conference turnout this year, people are ready to dive back in, with even more gusto than before. I have been given a great springboard to jump forward from to continue moving these values forward.

The WEF House of Delegates (HOD) has been doing a lot of exciting things this year, but before I dive into that, let me explain a bit about what the House of Delegates is and what we do.

The WEF House of Delegates is the deliberative and representational body of WEF, consisting of delegates from each member association and twelve delegates-at-large, which represent underrepresented constituencies. We advise the Board of Trustees on strategic direction and policy development, and we are the primary conduit of information between WEF and the member associations. Basically, we are a simpli ed version of a House of Representatives.

The House of Delegates is in the process of change, which is both exciting and di cult at the same time. We are currently developing our own Strategic Plan, which will be HOD-centered and focused on how we can better serve our member associations, constituencies, and WEF. In addition to that, we are also working on several initiatives regarding helping member associations with their delegate selection and workforce development programs. Hopefully you have seen invites for the WEF HOD Member Association Spotlight Webinar, which has allowed member associations to share special projects, topics, initiatives, and more with other member associations. We also just nished up with our in-person WEFMAX Conferences, which took place

“WE ARE CURRENTLY DEVELOPING OUR OWN STRATEGIC PLAN, WHICH WILL BE HOD-CENTERED AND FOCUSED ON HOW WE CAN BETTER SERVE OUR MEMBER ASSOCIATIONS, CONSTITUENCIES, AND WEF.”

in Alexandria, Virginia, Park City, Utah, and St. Petersburg, Florida. These are amazing events that allow member association leaders to learn and exchange ideas, hence the WEF Member Association Exchange. Even more exciting is that next year OWEA will be hosting WEFMAX April 2-4, 2025 in Oklahoma City. We encourage all to attend! More information to follow.

The overall goal of the HOD is to become more of a resource to the member associations and we are very excited about the opportunity to grow in that

direction and increase communication and transparency. With WEFTEC around the corner, we will be revealing our work groups and new delegate leaders to the community and jumping into our new initiatives with two feet. Speaking of WEFTEC, registration is open, and it is going to be a fantastic time in New Orleans. Hotels are going quickly so be sure to reserve your spot soon! New Orleans, October 5-9, 2024. Happy rst edition of The Splash magazine! We will be back for more updates in subsequent issues.

The number is tiny. But its impact is massive.

Introducing XBAT, a cutting-edge technology that is poised to transform water and wastewater treatment. Conceived and developed by Carollo Engineers, XBAT combines suspended ion exchange and softening to remove organics and anions, resulting in a minimal waste brine (only 0.8% of total feed water flow). This revolutionary technology will empower more communities to embrace potable reuse, obtain sustainable reductions in disinfection byproducts, and achieve effective nutrient management. Efficient, sustainable, and cost-effective technology that removes organics, nutrients, and salinity—that’s Carollo Innovation.

800.523.5826 / carollo.com

he current Strategic Plan of the Oklahoma Water Environment Association (OWEA) was updated and adopted ve years ago. Since that time, we have endured a pandemic, rapid in ation, and a shift in the state of the workforce in our sector. However, much of what is in our Strategic Plan still holds for the organization. Our mission, vision, and organizational values remain. While we haven’t met all our Strategic Intentions or goals found in that plan, the organization continues to engage the water workforce and we are looking for young minds to move the organization forward. The water sector is faced with an entirely new set of challenges that we must tackle in the years to come. With the revitalized magazine and newly formed Women in Water Community, we look forward to the coming years and those who will drive the next set of initiatives for the organization forward.

While we don’t intend to update our Strategic Plan immediately it will be interesting to review the new WEF Strategic Plan when it is complete. We will examine how we can better align with WEF’s strategic initiatives and begin to implement those goals in Oklahoma.

There is not currently an article/publicfacing narrative on the WEF Strategic Plan. They are nalizing several action plan speci cs in mid-July, so hopefully, there will be more ‘meat on the bones’ after mid-July.

That said, we can say that the WEF Strategic Plan was an intensive board and member-wide e ort. WEF surveyed its

“THE ORGANIZATION CONTINUES TO ENGAGE THE WATER WORKFORCE AND WE ARE LOOKING FOR YOUNG MINDS TO MOVE THE ORGANIZATION FORWARD.”

membership to gauge value and interest in current and potential WEF o erings. Public-facing visibility of the sector as it relates to water workforce development and collaboration with like-minded organizations rose to the top in terms of priorities. Circular Water Economy emerged as a key to making a unique impact through WEF’s work. That has led WEF to develop the Circular Water Economy Summit and a big e ort at bringing in new stakeholders such as industrial and corporations that have not traditionally been a part of the wastewater space even though they’re actively using water technologies on-site or in their work.

Diversifying WEF’s member o erings beyond hosting an excellent annual WEFTEC, which is geographically bound to participants, is also a focus of the Strategic Plan, to strengthen the global water community and enhance WEF’s relevance to its members and the general public.

Essentially, it goes back to WEF can’t try to be all things to all people. Almost three years into the plan WEF is still working to let go of things that don’t laser-focus on the articulated mission and vision and build on existing successes. One of WEF’s goals is that MAs consider WEF’s Strategic Plan moving forward, in so far as WEF and MAs are essential for mutual organizational success, but also the working relationship between WEF and MAs might empower both to scale up and down various programs, successes, and practices. In particular, MAs who have adapted InFLOW programs to meet their needs, or the WEFTEC Student Design Competition that grew out of an MA competition years ago. The Strategic Plan re ects an appetite from leadership and members for trying new things and shaking things up – of course, all with an eye toward impact, inclusion, and excellence. Let’s go!

JOINT TECHNICAL CONFERENCE + TRADE SHOW

MAY 6-8, 2024 | RENAISSANCE TULSA HOTEL AND CONVENTION CENTER

Join us in celebrating a great 2024 APWAOK/OWEA Joint Technical Conference and Trade Show event held in May at the Tulsa Renaissance Hotel! It was our largest yet with over 580 people attending. Vendors were over owing the exhibit space. We also received a record number of abstracts. Thanks so much to our speakers – we could not host a terri c conference without your involvement. Our Conference Planning Committee is already looking at alternative ways to accommodate our growing conference.

As part of the conference, we held our Annual Water Taste Contest. The City of Broken Arrow, the City of Tulsa, the City of Norman, and the City of Midwest City participated. It was a close call between these utilities, but ultimately our judges chose the City of Norman as this year’s winner. Congratulations Norman!

Our WEF/OWEA awards and recipients were:

The Hat eld Award for operators of wastewater treatment facilities for outstanding performance and professionalism –Awarded to Mr. Tom Vogt from the City of Midwest City WWTP.

The Burke Safety Award to encourage an active and e ective safety program in municipal and industrial wastewater facilities –Awarded to the Chickasaw Wastewater Treatment Plant in Bartlesville, OK.

The Bedell Award for Outstanding Member Association Service –Awarded to Mr. Michael Taylor.

The Lab Analyst Award for outstanding performance, professionalism, and contributions to the water quality analysis profession – Awarded to Ms. Linda Lake at the Lawton WWTP.

Our OWEA awards and recipients were:

2024 Past President – Mr. Andy Doer inger at STV

The Lifetime Achievement Award – Mr. Rusty Whisenhunt the Lawton Public Utilities Director

The Outgoing WEF Delegate Award – Alexie Kindrick at Tetra Tech.

We appreciate all of the work that you have done and continue to do for the Oklahoma water/wastewater sector

Remember to save the date and make plans to attend the 2025 Conference scheduled for May 19-21 at Embassy Suites in Norman. Find out more by visiting owea.org.

ReWa looks to remote alarm noti cation software to improve e ciency and avert problems

Greenville County, South Carolina, encompasses an area of approximately 795 square miles with a population of over 500,000. The water and wastewater infrastructure servicing the county is intricate and robust and includes over 350 miles of pipes connecting the community, and providing for future growth and development.

For almost 100 years, Renewable Water Resources (ReWa) has been responsible for the county’s wastewater infrastructure and manages eight water resource recovery facilities (WRRF). This oversight includes purifying more than 40 million gallons of water per day from homes, businesses, and industries. ReWa operates 83 pump stations and nine water treatment facilities. Each facility contains a self-su cient water treatment process with onsite power generation and sometimes thousands of gauges, ow meters, and storage tanks depending on the facility size.

“For almost 100 years, Renewable Water Resources (ReWa) has been responsible for the county’s wastewater infrastructure and manages eight water resource recovery facilities (WRRF).”

Since 2002, ReWa has relied on AVEVA’s System Platform SCADA system integrated with WIN-911 remote alarm noti cation software to monitor and alert the team about any abnormal operating conditions. This involved a complicated process of the SCADA system calling a mobile phone; operators would then stop work, answer the call, input a unique identi cation number, and then enter an acknowledgment. This process could take up to

one minute. While this doesn’t seem very long, this is critical time lost during possible emergencies. Additionally, since these alarm noti cations were transmitted via cell phones if the operator was in a part of the facility without good (cell) service, the call might break up and the entire identi cation input process would have to be repeated.

In 2020 ReWa, WIN-911, and MR Systems, the systems integration company with whom ReWa partners to implement technology, identi ed opportunities to improve the WRRF alarming systems by deploying the more streamlined, technologically advanced WIN-911 mobile solution. Tony Jones, ReWa business analyst, reached out to Ed Noyes, application engineer with MR Systems. Jones worked

closely with Noyes, who listened to Jones’ concerns and designed a system that met ReWa’s high-security requirements, improved the ease and e ciency with which operators can monitor and action SCADA alarms, and deployed a proactive monitoring system to notify ReWa technology personnel in the event of a system issue.

The WIN-911 mobile app enables more e cient plant operations by giving operators the ability to monitor and act on SCADA alarms via mobile devices with redundant voice and text callouts as needed. Additionally, it complements ReWa’s mission of supporting wastewater treatment through the use of innovative solutions, promoting operational e ciency, and reinforcing the core values of safety and unity.

WIN-911 provides the teams with faster response times, which is critical since many alarms involve lost power. In these situations, every minute counts to get an alarm message to the team. This could mean the di erence between restarting the generator or experiencing an over ow.

The types of alarms that WIN-911 monitors include critical functions - pumps, UV disinfecting systems, generators, and utility power - that can stop a process and result in a sewer over ow or discharged untreated water. To ensure the systems’ integrities are not compromised, it’s critical to use the most secure architecture possible. To that end, Noyes and the MR Systems team implemented the highest security levels o ered

WIN-911 running in a distributed landscape across 8 WRRF’s (Water Resource Recovery Facilities) with a Centralized Mobile Hub leveraging the most secure implementation offered by the WIN-911 Application

Mauldin Rd. WRRF

WIN-911 (R2)

Inter-Component Encryption

Voice Call-outs use POTS

Hot Backup Redundant Failover System

Durbin Ck. WRRF

WIN-911 (R2) Inter-Component Encryption

Voice Call-outs use VOIP

DMZ Network

Lower Reed WRRF

WIN-911 (R2) Inter-Component Encryption

Voice Call-outs use POTS

Hot Backup Redundant Failover System

WIN-911 Mobile Hub (R2) Inter-Component Encryption

Gilder WRRF

WIN-911 (R2) Inter-Component Encryption

Voice Call-outs use VOIP

Pelham WRRF

WIN-911 (R2) Inter-Component Encryption

Voice Call-outs use POTS

George’s Ck. WRRF

WIN-911 (R2) Inter-Component Encryption

Voice Call-outs use POTS

Piedmont WRRF

WIN-911 (R2) Inter-Component Encryption

Voice Call-outs use POTS

Marietta WRRF

WIN-911 (R2) Inter-Component Encryption

Voice Call-outs use VOIP

All WIN-911 Components now use the same System Account for Local Authentication

Proactive System Monitoring

Custom Built Monitoring Solutions that detects whether or not both Wonderware & WIN-911 are running and communicating successfully and notifies designated personnel in the event of an issue.

The intricate and upgraded system monitoring the eight WRRFs meets ReWa’s high security requirements, improves the ease and e ciency with which operators can monitor and action SCADA alarms, and deploys a proactive monitoring system to notify ReWa technology personnel in the event of a system issue.

by WIN-911 in the form of intercomponent encryption in conjunction with a custom-built proactive monitoring system that detects if WIN-911 and AVEVA are communicating and noti es designated personnel of any issues. Additionally, WIN911’s integration with the SCADA system o ers ReWa another layer of security.

This proactive and perpetual monitoring routinely averts problems. However, if any of the equipment is not operating properly, WIN-911 Interactive alerts the ReWa team via mobile app, phone call, email, or text. One such instance occurred when the team received an alarm related to a power outage at one of the WRRFs.

A newly installed generator did not automatically start during a power failure and WIN-911 alerted the technology sta who then began a dialogue with the operations team via the mobile

app’s chat feature. Because of this early and real-time intervention, ReWa assessed the problem and determined that the generator wasn’t properly wired, avoiding additional problems that an extended power loss would have caused.

“Prior to this upgrade, ReWa functioned in a reactive mode and waited until the WIN-911 software noti ed the operations team there was an issue. Now, we have completely changed this mindset and become more e cient. The IT team knows there is a system problem long before the operations team,” added Jones.

Named a Utility of the Future by the National Association of Clean Water Agencies, ReWa is committed to enhancing the area’s quality of life through the quality of its waterways. Using advanced technology like the AVEVA System Platform integrated with the WIN-911 mobile app remote alarm noti cation software helps ensure this.

Joy Kotey, P.E., and John Bannen, City of Oklahoma City, and Michael Graves, P.E., STV, Inc.

The Oklahoma City Water Utilities Trust (OCWUT) is the state’s largest provider of drinking water, wastewater, and solid waste management services. In the wastewater system, OCWUT maintains more than 3,000 miles of wastewater lines that carry commercial and industrial waste to one of four wastewater treatment plants (WWTPs) before discharge. The North Canadian WWTP was constructed in 1981 and is the largest WWTP for Oklahoma City and has a rated capacity of 80 MGD. The Deer Creek WWTP was constructed in 1981 and has a

Facility/Location

Deer Creek WWTP

Sludge Holding Tank

Dewatering Building

rated capacity of 15 MGD. The Chisholm Creek WWTP was constructed in 1978 and has a rated capacity of 10 MGD. The South Canadian WWTP was constructed in 1986 and has a rated capacity of 6 MGD. The collection system includes over 80 lift stations, including the Witcher Lift Station, which was constructed in 1978 and has a capacity of 80 MGD. These facilities generate biosolids and odors which pose signi cant short and long-term operational challenges. Additionally, OCWUT has been facing increasing community complaints

Key Issues

High H2S and other RSCs, fugitive odors with no current foul air collection

about odors in the vicinity of the plants, particularly the Deer Creek WWTP due to the rapid growth of residential development in the area. OCWUT set forth to determine the odor sources responsible for such community complaints, assess the current biosolids and odor equipment at the WWTPs, and determine immediate and long-term solutions to reduce or eliminate these odor sources. OCWUT tasked STV Infrastructure (STV) and Black & Veatch Corporation (BV) to provide a comprehensive Biosolids and Odor Management Plan to assess short-term

High H2S and other RSCs, impacting operators, equipment and, likely, o site odors

Solids Handling Chemical Scrubber Poor H2S removal at time of testing, very poor RSC removal, both possibly contributing to odors

Stacking Pad

Chisholm Creek WWTP

Primary Clari ers

Sludge Holding Tanks

North Canadian WWTP

Screen, Aerated Grit and Dewatering Buildings

In uent Flume

Sludge Holding Tanks

Stacking Pad

Witcher LS/Equalization Basins

Manholes near Lift Station

Equalization Basins

High triethylamine (2 ppm) could contribute to both site and land application odors

High H2S and other RSCs result in short media life

Relatively high H2S expected to lead to short media life in roughing (1st stage) adsorber

Ine ective capture, high H2S require opened door for operator safety, but leads to fugitives odors

Very high H2S, likely contributing to o site odors

Relatively high H2S measured outside of tanks indicate poor capture and likely fugitive odors

Very high triethylamine (11 ppm) could contribute to both site and land application odors

Generally moderate H2S, but unusually high ambient measurements near one manhole, likely an odor source

Unusually high ambient H2S spike in response to a wet weather event, likely contributes to o site odors

needs and provide recommendations for long-term management of biosolids and odors at each of these facilities.

In June 2020, STV and BV performed a condition and capacity assessment of biosolids and odor control processes and equipment at the North Canadian WWTP, Deer Creek WWTP, Chisholm Creek WWTP, and Witcher Lift Station. The South Canadian WWTP was removed from this assessment due to an ongoing expansion project that included biosolids and odor control improvements. Important considerations during the assessments included available historical performance data, current regulatory criteria for wastewater treatment facilities, visual condition and age of plant components and equipment, discussions with operations sta regarding current odor mitigation activities, and federal regulations and industry trends that may have future impacts on biosolids management. To identify alternatives for sludge stabilization and odor mitigation, various samples were collected at multiple locations at each facility. Solids samples collected

included waste sludge, dewatered cake, and stabilized biosolids. Odor sampling included the evaluation of both liquid and vapor phase parameters, as well as hydrogen sul de (H2S) measurements.

The summary of key odor issues identi ed during the assessments is shown in Figure 1.

Based on prioritization and recommendations provided after the completion of the condition and capacity assessments, a detailed design commenced for short-term improvements at the Deer Creek WWTP. The Deer Creek WWTP was originally constructed in 1982 as a twostage nitri cation process consisting of a combination of biological treatment systems including rotating biological contactors (RBCs) and an activated sludge system for nitri cation. The WWTP has undergone several upgrades and improvements and currently has a rated capacity of 15 MGD. The relevant process areas that produce biosolids and odors include FEBs, bar screens at the main lift station, grit removal, and primary and secondary clari ers.

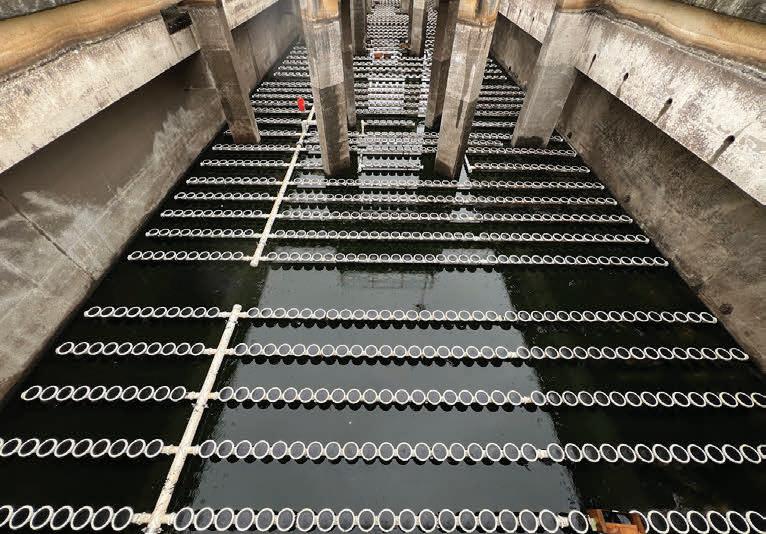

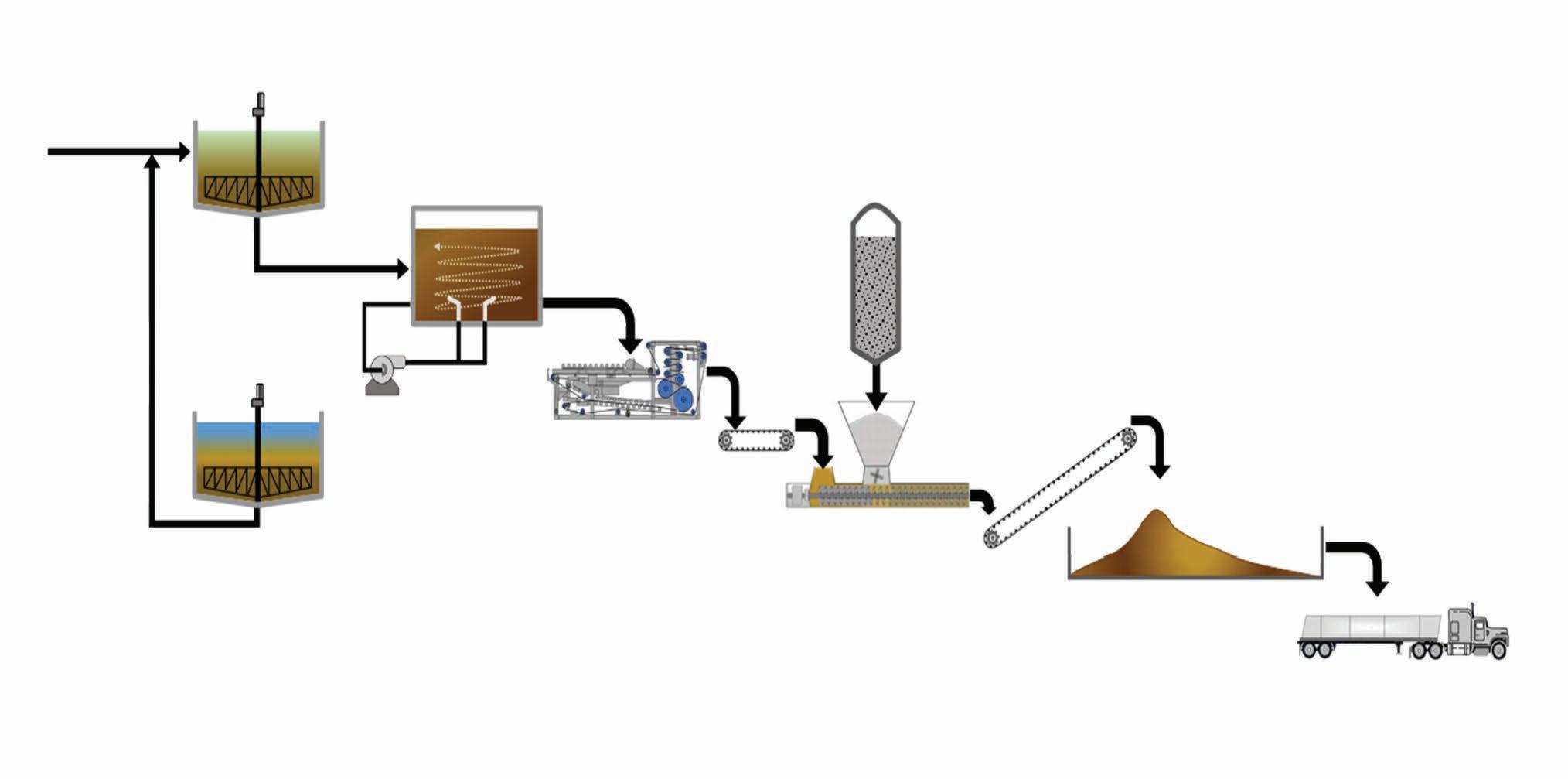

The sludge handling facilities include sludge holding tanks, mechanical

dewatering with belt lter presses, and a lime stabilization system. Waste sludge is pumped from primary and secondary clari ers to the mixed sludge holding tanks. Waste-activated sludge (WAS) from the secondary clari ers is co-settled in the primary clari ers. Blended sludge is pumped to the dewatering building and pressed using belt lter presses (BFPs). The presses are operated as needed to provide operational volume in the sludge holding tanks. Polymer is added before the presses for sludge conditioning and improved dewatering. Lime is added and blended with the dewatered cake solids to increase pH and comply with Class B requirements. The lime-stabilized solids are either sent to directly to the land application or transported to the North Canadian WWTP for storage before disposal.

The solids process ow diagram for the Deer Creek WWTP is shown in Figure 2.

Existing odor control infrastructure at the Deer Creek WWTP includes a chemical scrubber utilizing sodium hydroxide and sodium hypochlorite to treat exhausts from both the sludge holding tanks and belt lter presses in the dewatering building.

Throughput Capacity

Performance (% TS)

Energy Demand

Polymer Demand

Washwater Demand

Capture E ciency

O&M Labor Requirements

Odor Containment

Operations Familiarity

Suitable for High H2S

H2S Removal

Odor Removal

Ease of O&M

Footprint

Capital Cost

O&M Cost

Established Technology

The dispersion fan is not operated routinely, and the scrubber has some non-functioning gauges and a broken drain. Air ow is poor due to bio growth on the scrubber’s internal media. The scrubber achieves moderate hydrogen sul de removal but poor removal of mercaptan and sulfur compounds. Plant operators also noted that lime from the solid’s stabilization

A comparison of odor control technologies is shown in Figure 4. Parameter

process can enter the odor control unit through the BFP exhaust.

Technology assessments were performed for both solids management and odor control improvements at the Deer Creek WWTP. Solids management technology assessments focused on the following categories: sludge

storage tank aeration, solids dewatering, solids stabilization, and storage pad covers. For sludge storage tank aeration, the addition of positive displacement blowers and coarse-bubble di users was recommended to mix the sludge and create an aerobic environment in the tanks. For solids dewatering, belt lter presses, screw presses, rotary presses, and centrifuges were evaluated. Ultimately, replacement of the existing belt lter presses was recommended, as well as gravity zone covers and hard piping to capture ltrate and reduce odors. For solids stabilization, Schwing Bioset and BCR CleanB were evaluated. For vaporization systems, modi cation of the existing system at the Flow Equalization Basins (FEBs) was recommended. Additionally, a new canopy and vaporization system were recommended for the solids stacking pad.

A comparison of solids dewatering technologies is shown in Figure 3.

Odor control technology assessments focused on the following categories: vapor phase treatment, vaporization systems, liquid phase treatment, and H2S monitoring. For vapor phase treatment, the technology screening initially yielded two potential technologies for the treatment of contained foul air: bio trickling lters (BTFs) and catalyst scrubbers. However, it was ultimately decided that only BTFs would be further evaluated due to their long-standing history as an established, non-proprietary technology. For liquid phase treatment, chemical injection was proposed for plant sludge streams to reduce odor potential. Bench scale testing was performed by USP Technologies to determine the e cacy of injecting hydrogen peroxide into the sludge stream. For H2S monitoring, the Envirosuite and DiCom fence line monitoring systems were evaluated. The existing Envirosuite system at the Deer Creek WWTP was considered in this evaluation.

The following recommendations were provided for improvements for the Deer Creek WWTP: bio trickling lters for the primary clari ers, sludge storage tank, and dewatering building, peroxide chemical injection before sludge dewatering, lime stabilization with Schwing Bioset, and a cover and vaporization system for the solids stacking pad. However, due to budget constraints and future projects slated for the WWTP, the items were prioritized using value engineering and phased into shortterm and long-term improvement projects.

The ultimate improvements and phased improvements after value engineering and prioritization are shown in Figures 5 and 6.

The short-term improvements project for the Deer Creek WWTP includes the following items: replacement of the belt lter presses, replacement of the lime system, replacement of the dewatered solids conveyor, installation of a new dewatered solids stacking pad cover, vaporization system modi cations at the

solids stacking pad, installation of a new biological trickling lter, installation of a new hydrogen peroxide dosing system for dewatering, improvements to the sludge holding tanks, electrical and ventilation improvements for the dewatering building, and installation of a new electrical building. This project is currently in detailed design.

The short-term improvements project at the Deer Creek WWTP will be bid in Fall 2024, with a bid award anticipated in Winter 2024 and construction commencing in early 2025.

97th Annual Technical Exhibition & Conference

Ernest N. Morial Convention Center

New Orleans, Louisiana USA

Conference: October 5-9, 2024

Exhibition: October 7-9, 2024

At WEFTEC, you can transform those connections into real-world collaboration. Here’s why you should be there.

At WEFTEC, you can:

• Connect with passionate water professionals from across the country and around the globe.

• Deepen your knowledge through technical sessions and interactive learning exchanges.

• Explore the latest innovations and technologies while engaging with vendors and technical experts.

• Access a diverse range of equipment suppliers conveniently gathered in one location.

• Earn Continuing Education Credits (CEUs and Professional Development Hours (PDHs).

• Cultivate your career prospects by networking with peers and potential employers.

• Experience the thrill of Operations Challenge rsthand.

Be part of the energy and excitement at the water sector’s premier event and leave inspired!

Register at www.weftec.org/register.

See You in New Orleans, October 5-9.

As an attendee, you’ll have access to… EDUCATIONAL CONTENT

Whether you’re looking to drill down into speci c topics in wastewater treatment, nd solutions around zero liquid discharge, or stay updated on collection system trends, WEFTEC o ers valuable learning opportunities for anyone working in the water sector. Check out the Schedule at a Glance, Technical Sessions, Workshops, and Facility Tours.

With over 800 exhibitors on site, WEFTEC showcases the latest innovations, technologies, and solutions in water quality management. In the nearly sold-out exhibit hall, you’ll get hands-on experience with the latest technologies and engage in a directory with the supplier teams to solve your most challenging issues.

From the exhilarating Operations Challenge Competition to the prestigious WEF Awards Ceremony, WEFTEC o ers a diverse range of unique events that entertain, inspire, and educate.

From Continuing Education Credits to our A nity groups, you’ll immerse yourself in a dynamic environment where creativity thrives, and collaboration ourishes. Attendees also earn continuing education credits, gain insights into career advancement opportunities, and stay informed about the latest job trends in the water sector.

10-12

Oklahoma Municipal League Annual Conference Tulsa, Oklahoma

SEPTEMBER

10-12

Oka’ Institute at East Central University hosts OKA CON ’24 Ada, Oklahoma

SEPTEMBER

16-18

SEPTEMBER

13-15

OCTOBER

Oklahoma Floodplain Managers Association Annual Conference Durant, Oklahoma

Southwest Section AWWA Annual Conference Norman, Oklahoma

19-20

NOVEMBER

Oklahoma Governor’s Water Conference Embassy Suites, Norman, Oklahoma

Find out about OWRB hosted Floodplain Management training by visiting their website.

Find out about ODEQ Operator Renewal Trainings throughout the state (availability may be limited) by visiting their website.

TBD (January 2025) – OWEA Awards event

April 2-4, 2025– WEF MAX in Oklahoma City

28 AUGUST Sponsored eShowCase: From Activated Sludge to Granular Sludge: An Overview of Time – Based Biological Treatment Technologies 2:00-2:45 pm Eastern

5 OCTOBER

WEFTEC 2024 Ernest N. Morial Convention Center | New Orleans, Louisiana

11 FEBRUARY

WEF/AWWA Utility Management 2025 Hilton Anatole | Dallas, Texas

OWEA is looking for technical papers for future issues of The Splash. We want to highlight people, projects, and facilities in the State of Oklahoma. Please contact Joshua Muskopf at joshua.muskopf@stantec.com for more information or to submit your white paper for consideration. Thank you so much for your contribution to The Splash!

The Splash is made possible by the companies below who convey their important messages on our pages. We thank them for their support of OWEA and its publication and encourage you to contact them when making your purchasing decisions. To make it easier to contact these companies, we have included the page number of their advertisement, their phone number, and, where applicable, their website.

Splashing in a pool, tossing a water balloon—water is one of life’s great pleasures.

Most of us never think about how water gets to us or where it goes when it swirls down the drain. Luckily, we don’t have to. Pumps, treatment plants, and pipes bring us clean water and remove wastewater.

But our water systems are aging. They need investment so they can continue to deliver life’s most precious resource. All day, every day.

Water—Essential. Reliable. Invaluable.