www.vineyardmagazine.co.uk

VINEYARD

Kelsey Media, The Granary, Downs Court

Yalding Hill, Yalding, Maidstone, Kent, ME18 6AL 01959 541444

EDITORIAL

Editor: Rebecca Farmer vineyard.ed@kelsey.co.uk

GRAPHIC DESIGN

Jo Legg

Flair Creative Design jo.legg@flair-design.co.uk

ADVERTISING & MARKETING

Jamie McGrorty 01303 233883 jamie.mcgrorty@kelsey.co.uk

PHOTOGRAPHER

Martin Apps www.countrywidephotographic.co.uk

MANAGEMENT

DIVISIONAL MANAGING DIRECTOR: Steve Kendall

PUBLISHER: Jamie McGrorty

RETAIL DIRECTOR: Steve Brown

SUBSCRIPTION MARKETING MANAGER:

Claire Aspinall

PRINT PRODUCTION MANAGER: Kelly Orriss

DISTRIBUTION

Distribution in Great Britain: Seymour Distribution Limited

2 East Poultry Avenue, London EC1A 9PT Tel: 020 7429 4000 www.seymour.co.uk

Distribution in Northern Ireland and the Republic of Ireland:

Newspread

Tel: +353 23 886 3850

Kelsey Media 2023 © all rights reserved. Kelsey Media is a trading name of Kelsey Publishing Ltd. Reproduction in whole or in part is forbidden except with permission in writing from the publishers. Note to contributors: articles submitted for consideration by the editor must be the original work of the author and not previously published. Where photographs are included, which are not the property of the contributor, permission to reproduce them must have been obtained from the owner of the copyright. The editor cannot guarantee a personal response to all letters and emails received. The views expressed in the magazine are not necessarily those of the Editor or the Publisher. Kelsey Publishing Ltd accepts no liability for products and services offered by third parties.

Kelsey Media takes your personal data very seriously. For more information of our privacy policy, please visit Kelsey Media takes your personal data very seriously. For more information of our privacy policy, please visit https://www.kelsey.co.uk/privacy-policy/ . If at any point you have any queries regarding Kelsey’s data policy you can email our Data Protection Officer at dpo@kelsey.co.uk.

Features

The art of wine

Shoreham village near Sevenoaks in Kent is quaint and beautiful a landscape painters idyll. This month

When fungus attacks

Grapevine Trunk Diseases are a huge global problem. They can devastate a vineyard – leading to a decline in vine quality and lower yields through the loss of vigour or entire vines. 36

Vineyard visits The Mount Vineyard. 26 42

Fast track to the best equipment

Core Equipment supplies and installs a complete range of winemaking equipment to top wineries across England and Wales, increasingly as part of a consultancy-led, projectbased approach.

Keep going all day Electric secateurs help reduce the risk of

Grapevine Trunk Disease.

This is the exact time registered by Roger Bannister when he became the first man to run a mile in under four minutes. How is this related to wine?

Links to public transport is a valid concern for many tourists and a puzzle for many vineyards and thus the subject of the ‘final mile’ is a recurring topic for many vineyards across England and Wales. Talking to Jo Smith of the Wine Garden of England this month emphasised this point to me. This was further reinforced when I visited The Mount Vineyard; there cannot be many vineyards located just 13 minutes walk from a train station.

The peace and tranquillity of a vineyard is one of its greatest attractions for tourists and also one of its difficulties. On site accommodation may provide some vineyards with part of the solution but this is not suitable for every site nor is it a solution for every visitor. In the large wine regions of the world car free options for visiting vineyards are woven into the fabric of the tourism industry and I am sure that vineyards in England and Wales will continue to work on this question of the ‘final mile’ sharing between them any milestones that make the overall solution closer at hand. Afterall, Chris Chattaway and Chris Brasher provided the pace that allowed Roger Bannister to achieve the time registered above on 6 May 1954. Since then well over 1000 athletes have recorded times below four minutes for a mile. Reaching beyond a seemingly set limit is not always simple or easy but English and Welsh vineyards and wineries have proved consistently that when working together for a common goal even the impossible becomes possible. For proof we need look no further than the gold medals and awards that have been achieved.

It seems fitting for this column to reach the finishing line by noting that in 1956 Chris Brasher received an Olympic Gold medal in the Steeplechase and it was recently announced that Woodchester Valley won a Master medal at the Global Sauvignon Blanc Masters 2022. Congratulations from all at Vineyard Magazine!

Lyme Bay Winery has released a trio of single vineyard wines as part of its ambitious project to further demonstrate the UK’s unique potential for still wines.

Sourced exclusively from Martin’s Lane Estate and Crows Lane Vineyard in Essex, James Lambert, MD and winemaker at Lyme Bay Winery is aiming to illustrate the diversity of the terroir and the superb potential for winemaking within specific UK regions.

“Alongside other producers, we want to help demonstrate that we can produce something truly special and consistently so. With the right clones and the right grapes, in the right places, the UK is uniquely positioned to produce world class still wines,” commented James Lambert.

The three wines are from the 2020 vintage and come from a selection of outstanding vineyard sites that were chosen due to their distinct characteristics.

Lyme Bay Martin’s Lane Pinot Noir is a deep ruby colour with a ripe cherry, dark chocolate and cedar nose. On the palate the dark fruit dominates the palate with cherries, blackcurrant and some lighter raspberry, underpinned by toasty vanilla and subtle spice.

Lyme Bay Martin’s Lane Chardonnay has notes of toasted almonds, ripe fruit and a smoky edge. On the palate it is a truly classic style of Chardonnay, focussing on richness and body. Red apple and lemon citrus underpin a

long buttery and almond finish.

Lyme Bay Crows Lane Pinot Noir has gorgeous notes of black cherry, blackcurrant, and smoke. On the palate it displays a complex array of fruit including damsons, mulberry and raspberry, underpinned by toasty vanilla and spice.

Sarah Massey winemaker at Lyme Bay Winery commented: “2020 was a beautiful, long, hot summer which enabled the grapes to give us outstanding ripeness, resulting in the intensity of flavour and body for both the Pinot Noir and Chardonnay.”

She continued: “Both the Pinot Noirs went through small batch fermentations with manual pigéage, every eight hours, to gently maximise the extraction of colour, flavour, and structure. The Chardonnay went through full malolactic fermentation and extended fine lees ageing for ten months in French oak, with regular bâtonnage to accentuate the natural weight and ripe fruit, creating a complex and textural style of Chardonnay. The individual parcels of grapes showed such great potential, as well as their own unique character. The phenolic ripeness was there as well as the sugar levels, it just made them perfect to showcase our first Single Vineyard expressions that truly represent a sense of place that those blocks uniquely showed in 2020.”

James Lambert concluded: “Since 2015

we’ve been looking to demonstrate what the potential for English still wines is. We do that through a relentless search of pockets of land owned by growers who share the same passion as we do, looking for the highest degrees of potential ripeness and wines that can really showcase the terroir. What we’ve been able to do with these single vineyard releases is focus in and look at specific blocks within vineyards to find something special. This is certainly a long-term project and alongside other still wine producers, we want the UK to increasingly be seen as a benchmark for growing the highest quality, cool climate still wines.”

Just over 2,000 bottles of these wines are available and the individual RRPs are: £35 for single vineyard Chardonnay and £40 for each single vineyard Pinot Noir from Lyme Bay Winery. The wines will also be in a selection of high-end retailers.

We specialise in the supply and construction of steel framed buildings. We have a wealth of knowledge and experience in the wine and fruit production sector to complete your new facility Based in the heart of Sussex, covering the South East. Sussex builders since at least 1605.

vine

GPS planting

Forma offer all aspects of steel framed construction and cladding together with groundworks and electrical fit out if required.

• SITE SELECTION & SITE ASSESSMENT: Correct choice of site is vital in the UK’s northerly winegrowing climate.

• VINEYARD DESIGN: Design of your trellis system and density of plantation is offered as a standard part of our service.

• PRE-PLANTATION ADVICE: All advice and organisation of soil & site preparation works.

• GRAPEVINE SUPPLY: All vines sourced through one partner nursery, proven vine establishment over many years.

• VARIETIES, CLONES, ROOTSTOCKS: All combinations created to suit your vineyard site and target wine styles.

• PLANTING: Planted by GPS guided machine, accurate to within 8mm.

• TRELLIS MATERIALS: We supply everything, sourced direct from the factory to ensure lowest possible prices!

YOUR VINEYARD WILL BE IN THE GROUND FOR 40 YEARS. GET IT RIGHT FIRST TIME, WITH DUNCAN MCNEILL AND

WE HAVE 50 YEARS COMBINED EXPERIENCE IN VINEYARD MANAGEMENT. YOUR VINEYARD WILL BE IN THE GROUND FOR MANY YEARS. GET IT RIGHT FIRST TIME, WITH DUNCAN MCNEILL AND VOLKER SCHEU OF VINES DIRECT LTD.

CONTACT DUNCAN MCNEILL ON 07972 668370 OR EMAIL

Known for its Bordeaux, Pinot Noir and Champagne wines, France is one of the largest wine producers in the world.

However, like many countries, it has seen its wine production affected by climate change.

The French viticultural sector has now been put under the spotlight by researchers investigating what its winegrowers are doing to mitigate climate change.

Led by scientists at Scotland’s Rural College (SRUC), the research investigated what motivates French winegrowers to adopt and use specific management practices to enhance soil carbon sequestration (SCS) – which mitigates climate change by increasing the carbon sink function of soils. It also looked at what prevents them from using these practices in their vineyards.

More than 500 winegrowers were surveyed about their use of six SCS practices: applying organic amendments; using biochar – a charcoal produced from plant matter; returning pruning residues to the soil; no-tillage; cover cropping; and introducing

or preserving hedges in the vineyard.

The survey also investigated ways of overcoming barriers to adoption and winegrowers' perception of agri-environment measures.

Researchers found the overall adoption rate of SCS practices was high with nearly all the 506 respondents adopting at least one practice and only two not using any at all.

Most winegrowers – 91% – return pruning residues to the soil and 73% use organic amendments and cover cropping. More than half the respondents (57%) maintain hedges in their vineyard, while just under half (48%) practice no-till viticulture. However, only very few winegrowers (2%) use biochar amendments in their vineyard.

The main reason for the adoption of these practices was biophysical – to overcome degradation of the soil caused by conventional management. Biophysical and technical barriers – such as soil type, vineyard size and access to adequate equipment – were cited as reasons for

not adopting SCS practices.

The study found that agri-environment schemes, which offer financial support to encourage the adoption of SCS practices such as cover cropping, no-tillage and maintenance of hedges, are a useful policy instruments to increase uptake. However, they need to be supplemented by communication and education schemes to underline the greenhouse gas mitigation potential of SCS practices.

The research was funded by the Natural Environment Research Council (NERC) as part of the Soils-R-GGREAT project and published in the Frontiers in Sustainable Food Systems journal.

Early season fertilisation in viticulture is challenging with a need to balance off-take from the previous year with vine vigour and soil type; each factor influencing the decisions that need to be made in the vineyard.

OvinAlp, the French manufacturer has developed organic options in two unique pelletised formulations that improve soil fertility, organic matter, and early season nutrition. This sustainable source of

For more information on OvinAlp, please contact your usual Agrii agronomist, the customer services team on 0845 607 3322 or email info@agrii.co.uk

nutrients provides nitrogen, potassium and phosphorous as well as trace elements. OvinAlp’s products are also a source of natural humic precursors and organic matter which improve soil cation exchange capacity (CEC), soil structure and soil water management.

The main blends of OvinAlp are:

MV100 is cold corked to preserve microbial life. While providing humus, it stimulates biological activity – a major issue in the fertility of cultivated soils. OvinAlp improves soil-plant exchanges while enhancing soil nutrient reserves by making them more mobile in the rhizosphere. The microbes living within MV100 help reduce nitrogen volatilisation in winter and improve mineralisation in spring. Its high content of dry matter (80%) and organic matter (60%) make this an easily applied alternative to compost to improve soil water retention and nutrient availability. The nutritional analysis of OvinAlp is 2-1-2 (N-P-K), with trace elements.

SKOR is derived from the MV100 formulation but supplemented with major elements of organic or mineral origin for added fertilisation. SKOR is particularly suitable for sandy, low vigour and organic sites where the extra nitrogen (N) will benefit the vines, helping improve cane vigour and leaf quality. High potassium (K) and magnesium (Mg) are also present, which helps replace annual nutrient crop off-take after each year’s harvest. The nutritional analysis of SKOR is 5-2-8-4 (N-P-K-Mg) and trace elements.

Global real estate consultancy Knight Frank has signed an agreement to join Wine Garden of England as their first property partner. In the new partnership, the organisation will work primarily with Knight Frank’s viticulture team, which is focused on supporting vineyard managers and wine producers who make quality still and sparkling wine from grapes grown in Britain.

As part of its services to the expanding wine sector across England, Knight Frank has been advising many leading UK vineyard and wine businesses across the country with land identification, purchase, sale and business consultancy matters for over a decade. The consultancy also identifies land that is suitable for viticulture using its in-house geospatial vineyard mapping software. This technology assesses important variables such as soil type, altitude, frost risk, slope direction, gradient and road access to ensure the land can produce quality wine grapes. The viticulture team will then help buyers to negotiate with landowners to buy or rent land.

Knight Frank supports vineyards and wineries looking to diversify and upscale

their businesses. Its placemaking-led diversification service enables wine producers to increase the quality and quantity of footfall to their site. The viticulture team is also able to provide advice on sales and investment in vineyard land and wine businesses.

Ed Mansel Lewis, Partner and Head of Viticulture at Knight Frank, said: “We are thrilled to have been appointed as Wine Garden of England’s first property partner. The organisation is doing an excellent job in growing the wine industry in Kent and we are looking forward to supporting them and their members on their exciting journey, with a variety of services tailored to their individual needs.’’

Jo Smith, Brand Manager at Wine Garden of England, added: “Our members are delighted to be working at ground level with such an esteemed land agent as Knight Frank. We are looking forward to contributing to shaping the infrastructure of the English wine industry to enable strong and sustainable growth for the future.”

Knight Frank will join Wine Garden of England's three existing industry partners, Crowe Accountants, NFU Mutual and Cripps

in supporting the wine industry in Kent. Wine Garden of England is a collaboration of eight Kent wine producers who are collectively responsible for around 80% of the county's wine production. They work together to encourage visitors to their estates and to grow wine tourism to Kent as a whole.

Gwinllan Conwy Vineyard in Wales have an innovative project that utilises raw wool in the under vine area.

The project has drawn attention to the ways in which vineyards are striving to reduce the amount of sprays they use. Recent research published by NIAB (See December 2022 edition of Vineyard magazine) has reinforced the importance of weed control in vineyards with vines suffering from significant yield losses where no weed control was

undertaken. Fleece has several advantages besides weed suppression. One advantage is that as it breaks down the wool will naturally feed the soil and is also a natural deterrent to slugs and snails. One of the words that springs to mind in relation to this project is sustainability. Not just in terms of vine and soil health but also in that it is a collaborative project by two local businesses working together –Gwinllan Conwy Vineyard & Wool and Vine.

From vineyard establishment through to post-harvest management, our dedicated agronomists are able to ensure that you maximise your yields of top quality fruit, whilst satisfying the ever more complex demands of legislation, protocols and consumer expectation. Contact us for more information.

“Working closely with our growers, we use integrated pest management to optimise fruit quality and yield.”

Penny Meadmore Viticultural Consultant for Agrovista UK

THE cost efficient & effective solution for frost protection in fruit orchards & vineyards – sustainable & reliable!

VOEN Covering Systems | Matt Foster | 07887 747917 | mattfoster.mgf@gmail.com

t: 0115 939 0202

e: enquiries@agrovista.co.uk

@AgrovistaFruit

@AgrovistaUK

www.agrovista

Ov is the main active principle in OvinAlp, obtained through solid biofermentation of the organic matter under the action of microbial flora naturally present in the sheep manure for 12 months. This allows enrichment of the product into stable humus while guaranteeing complete sanitation and unbeatable sanitary quality.

For more information, please contact your usual Agrii agronomist, our Customer Services Team on 0845 607 3322 or email fruit.solutions@agrii.co.uk

www.agrii.co.uk

Agrii is the sole distributor of OvinAlp fertiliser in the UK.OvinAlp in the Alpes-de-Haute-Provence, close to Sisteron: a high-tech factory in the heart of the mountains, close to flocks of sheep

@VineyardMagGB vineyard.ed@kelsey.co.uk

Dear Editor

I have a suggestion for a fun feature. Dogs in viticulture – there are loads! I bring my dog to the office and I know others who take their dogs round on visits too so you could include other aspects of the industry rather than just vineyards. I can even think of some winery dogs.

It is a practical thought worth noting that agricultural industries can be solitary at times so there are lots of benefits to staff welfare for having a dog around. On a commercial side, being dog-friendly as a tourist attraction is a bonus and lots of vineyards have public footpaths through too, (and they make great brand ambassadors!).

VineWorks

So this is not just an idea for a fun feature, but also a practical reminder of the benefits of looking beyond the human element.

Cherry Constable, Head of Retail and Kara the Greyhound, Comfort Control Officer, VineWorks

Envelope

Editor: Thank you for your letter. It is a good point and on my travels I too have met many a vineyard and winery dog. Vineyard Magazine will run this feature in the April edition and if any readers have some pictures they would like to be included please send a high resolution photo, the name of your dog and the name of your vineyard/winery/business to vineyard.ed@kelsey.co.uk

Dear Editor

I have a small newly planted vineyard in Suffolk and managed to take a couple of nice photos. Scott Chapman, Goose Hall Vineyard

#Kubota invests in #Chouette, the leading company in France in precision vineyard management solutions. This is a strategic step for Kubota to face global issues in agriculture and to become a total solution provider in the wine industry: https://bit.ly/Kubota-Chouette

We started selling Speidel tanks 27 years ago for the simple reason that we learned by experience that there are wine tanks and there are Wine Tanks

See our ‘Just a tank?’ blog online at vigoltd/wine to read about the Speidel effect, the range and Sustainability.

Due to the international demand for Speidel tanks, ordering early is essential

The majority of Speidel tanks are manufactured to order due to the bespoke requirements of the winery. If you require tanks in time for harvest, we recommend you contact us by the middle of March to avoid disappointment.

Vigo, part of the Call us on 01404 892 100

E-mail: sales@vigoltd.com

Quantor energy efficient chilling systems installed by us

Reduce power consumption & operational costs during wine/cellar temperature control

Quantor temperature control units include utilities to save energy and reduce CO2 footprints by means of higher efficiency and optional heat-recovery features (e.g., reversible via heat-pump for producing hot water). Please call us for more information.

creative packaging from rawlings Rawlings offer a bespoke container design service as well as a range of standard wine bottles. Call 0117 960 4141, email hello@rawlingsbristol.co.uk or visit www.rawlingsbristol.co.uk

We wouldn’t be where we are today, 39 years on, without the support we offer

Our renowned engineering team now includes 9 engineers to provide installation; bespoke applications; and the servicing/ repairs of equipment supplied by us. Services include fabrication, electrical/electronic (incl. PLC programming) engineering and more.

www.vigoltd.com

@VigoLtd

BASET (The Britain-Australia Society Education Trust) provides young people with life changing opportunities to develop new skills, broaden their horizons and realise their potential through its Endeavour Career Skills Award Programme.

The two talented students selected this year are the second year BSc Viticulture and Oenology students David Cole and Natasha Sousa Rompante. They will undertake a career skills placement on the Hungerford Hill estate, one of the Hunter Valley’s great success stories. From their humble

beginnings in the 1960s the Hungerford Hill estate has grown over the past 50 years to incorporate the award-winning Sweetwater vineyard as well as the famous Dalwood vineyard, which is considered the birthplace of Australian wine and the country’s oldest continually operating vineyard. The students will be important ambassadors for Plumpton College and the UK Wine Industry.

The placement will last for four weeks and involve full-time work time in the vineyard and the winery during vintage, including harvesting and fruit intake,

pressing/crushing and fermentation management, along with a range of other winery and vineyard-related tasks required by the winery and vineyard. This will allow students to compare and contrast practices and challenges in the UK wine industry with those in a well-established significant Australian wine region and richly contextualise their studies and previous experience. Furthermore, students will be exposed to different ways of working and thinking and some significant opportunities to innovate and, importantly, bring this knowledge back to the UK wine industry.

wine division has been fortunate to receive two BASET

Endeavour Awards to fund two students’ trips to Australia during the

With preparations for this year’s Vineyard & Winery show well underway, Vineyard magazine are pleased to announce that NFU Mutual have agreed to become a major sponsor of what has quickly become recognised as the main event in the calendar for the viticultural industry. “NFU Mutual have exhibited at the show since our first event in 2021 so we are very pleased that they have been able to increase their support in this way,” comments Jamie McGrorty, publisher of Vineyard magazine.

NFU Mutual are joined by the same five sponsors that supported the show in 2022, who have all renewed their support for this year’s show on 22 November 2023. These five being machinery dealers Vitifruit Equipment; label manufacturers Royton Labels; agronomy specialists Hutchinsons; wine making suppliers Berlin Packaging; and winery advisors Core Equipment.

“NFU Mutual is delighted to be sponsoring the 2023 Vineyard & Winery Show in support of the UK’s growing Viticulture sector,” said Colin Campbell, Regional Manager South East at NFU Mutual. "We’re committed to supporting vineyard owners, grape-growers and winemakers throughout Britain. As WineGB’s exclusive insurance partner, we’re passionate about delivering insurance and risk management solutions that meet the needs of those operating within the viticulture sector.”

Colin continued: “We have extensive experience in supporting our

To

customers through every stage of the production process, from grapegrowing and winemaking to manufacturing and selling. The future is bright for British viticulture and at NFU Mutual we’re proud to be a part of the industry at such an exciting time. We look forward to meeting many of our customers at the Vineyard & Winery show this November – and some new faces too! We wish everyone a successful year ahead.”

“Thank you so much to all our sponsors, because without them it would be very difficult to host the quality event that the Vineyard & Winery Show has become,” concluded Jamie.

Now one of the UK’s leading vineyard agronomy companies, Hutchinsons was keen to sign up as a sponsor of The Vineyard Show for the third year running.

Head of Marketing Nick Rainsley explained that the show has provided an opportunity not just to support the industry and allow Hutchinsons’ experts to share up-to-date knowledge and information but to take the time to meet and chat to new growers within a thriving sector.

Hutchinsons has a dedicated, full-time team of vineyard specialists, including Chris Cooper and Rob Saunders, two highly experienced and well respected vineyard agronomists who contribute to Vineyard each month.

“Along with advice, Hutchinsons supplies crop protection products, nutrition and all the sundry products and services needed to manage a vine crop and to do so successfully,” Nick said. “We offer nutrition mapping and management plus soil health and soil management on organic and conventional vineyards, which is critical. Our unique healthy soils assessment looks not just at the chemical make-up of the soil but at its physical attributes to produce a comprehensive guide to how the grower can improve it.”

MARCH 2023 | VINEYARD 18 22 NOVEMBER 2023

support,” he said. “They expect more, and we are here to deliver more.

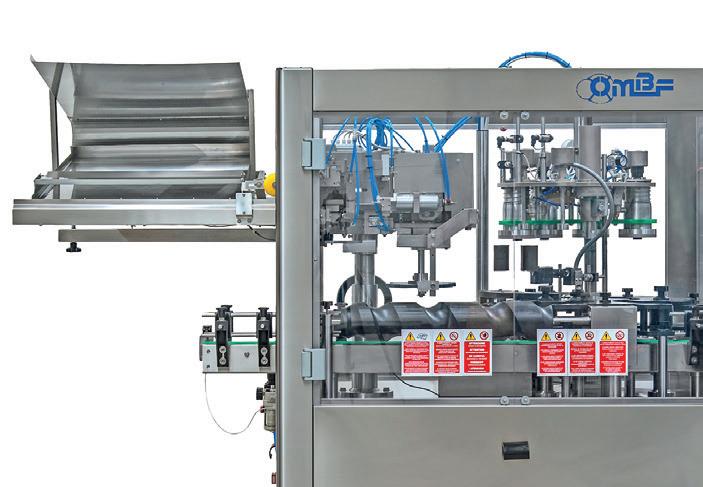

Featured extensively in this month’s edition of Vineyard, leading distributors for winery equipment in the UK, Core Equipment, supply high quality products, including pneumatic grape presses, tanks, fermentation control systems and more from industry trusted manufacturers guaranteed to support evolving businesses.

At every stage of the order process, the Core team are on hand to support and help. Each project is assigned a project manager to ensure that equipment is delivered and installed as smoothly as possible, whilst the Core service team work closely with customers during installation and on an ongoing basis.

Jonathan Chaplin, Managing Director of Core Equipment explained: “As the UK’s leading supplier for winery equipment, we wanted to build on the successes from last year’s Vineyard & Winery Show and so we are really pleased to renew our sponsorship for the 2023 event. The UK wine market is experiencing phenomenal growth at present and the Vineyard & Winery Show is right at the heart of this, connecting all sectors of the wine market. Our presence as a main sponsor of the event reflects our position in the industry as a key distributor for winery equipment and it was therefore an obvious decision to attend. The Vineyard & Winery Show is a great way to celebrate the end of harvest and allows us to speak to wine producers on how we can support their growing requirements. We are looking forward to welcoming old and new customers onto our stand at this year’s event”.

Machinery dealer Vitifruit Equipment supplies a broad range of outdoor equipment for vineyards across the UK and takes pride in providing a bespoke service based on each customer’s needs.

“We stock entry level, but still high quality, equipment for new or smaller growers but we can also provide state-of-the-art machinery from big name manufacturers for larger vineyards,” explained Richard Witt, joint owner of the Edenbridge based business.

“As an example, we stock sprayers from MM and Zupan which cost a few thousand pounds and are ideal for smaller vineyards, but we can also supply the Lipco recirculation sprayer that recycles any liquid that drips off the vines, saving up to 40% of chemical costs and eliminating drift.

“As well as sprayers, Vitifruit supplies mowers, inter-vine cultivators and de-leafers as well as smaller items such as secateurs and tying machines,” said Richard. “Everything apart from tractors – and in most cases we can offer products across a broad price spectrum.”

Vitifruit, which Richard set up in 2010 with partner David Sayell, also offers repairs, servicing and machinery hire, looking after customers all over the country. David Wood, the third member of the team, leads on the workshop side of the business.

Richard explained why Vitifruit have been a major sponsor since the first year of The Vineyard & Winery Show. “The company has been with Vineyard Magazine since its inception, and David (Sayell) writes an article every month, so we feel a strong affinity with the magazine and want to be continue to support in whatever ways we can.

“The idea of an industry specific show for English wines and vineyards under one roof has worked a treat – and very necessary at a time when there is so much happening in the sector. It also takes place at a perfect time of the year when people are less busy.”

Sponsoring The Vineyard & Winery Show for the third year running, Berlin Packaging’s Mark Crumpton brings a particular understanding of the industry to his role with the company, having obtained a Masters Degree in wine making from Plumpton College.

Given its long standing history, it is no surprise that in 1955

Berlin Packaging – then H Erben Ltd – supplied pressing and bottling machinery to Sir Guy Salisbury-Jones, who planted the first commercial vineyard in the UK for a hundred years. More recent developments include setting up a supplier partnership with Laffort, which allows the company to offer oenological supplies, filtration kits, processing aids and additives alongside tanks, bottling equipment and closures.

Berlin Packaging has its own UK laboratory and offers technical support to all its customers. “We see ourselves as very customercentric and we make sure we listen and respond to their requests. We offer other support including stockholding, logistics and credit accounts and we can also print straight onto glass,” explained Mark.

“It’s exciting to see the increasingly professional approach being taken by UK wine growers and makers and their determination to produce high quality wines, and our aim is to supply them with the right products and the right bottles to help them do that. The industry is going through astonishing growth and has a great future.

“The Vineyard & Winery Show has become a great way to celebrate that and bring the various industry players together as a source of ideas and expertise from which all the visitors can draw. We are pleased to have sponsored this event from the start and proud to be doing so for a third year in a row.”

Established in 1984 and based in Royston near Cambridge, Royston Labels is a privately owned company boasting a state-of-the-art production facility and a team of 80 dedicated employees. The engine at the heart of our business is a technical team focused on developing new products and market innovations to enhance our clients’ packaging and brands. Royston produce over 400 million labels per year and their award winning team of experts have become well respected in the UK industry.

Combining their knowledge of traditional print technologies with the latest in digital innovations, ensures clients always receive the most cost effective, high quality packaging solutions available. Head of Sales Glyn Scriven comments: “From the initial brief to printing the final label, we pride ourselves on the outstanding quality, production, and service we deliver, while supporting our clients through their packaging journey.

“We also pride ourselves on putting sustainable solutions first, our strategy is based around reducing, reusing, and recycling. We ensure our team have widespread knowledge and experience of the complete supply chain and recycling process and can advise customers on the most practical solutions. We work with our recycling partners to ensure all production waste is reutilised, including the waste matrix, glassine, and PET liners, inks, and rags. During 2021 alone, we saved 83 trees, recycled 55.77 tonnes of waste from the waste matrix as well as recycling 12 tonnes of glassine liner.”

“Royston Labels are very pleased and proud to be a main sponsor of the new Vineyard & Winery show,” commended Glyn Scriven. “I have been involved with the UK wine industry for over a decade and so I am very excited about the new Vineyard & Winery show and the opportunities that it will bring for the industry,” Glyn added.

Jo Smith has been Brand Manager at the Wine Garden of England since August 2021 but her career in and around wine has taken many different directions.

Originally part of the team at The London Wine Fair back in 1995 and more recently covering Kentish wines for BBC Radio Kent as a monthly slot with Julia George. “I found out about The Wine Garden of England when I was doing an interview with Patrick McGrath at Domaine Evremond. It sounded like the perfect job and I thought it was a shame someone was already doing it,” said Jo. So when the job became available she was happy to apply for the position of Brand Manager. Jo Smith has also worked as a tour guide at Kingscote Vineyard and “it made me realise how much I love talking to people face to face about wine and how it is made. Understanding the job of a tour guide has been really helpful in this role,” she said.

The Wine Garden of England has eight members Balfour, Biddenden, Chapel Down, Domaine Evremond, Gusbourne, Simpsons, Squerryes and the newest member Westwell. According to Jo Smith: “Each of the vineyards are part of a brand within a brand.” Every vineyard in the group is unique and as such

no one venue is similar to any other. “One of the things we love about the wine Garden of England is that people can visit three or four vineyards in a day and have very different experiences,” she added.

The Group is working hard at raising the profile of the brand by attending events with the aim of increasing awareness of the Wine Garden of England amongst consumers. “The wine industry would recognise us a lot more at the moment than consumers so this is a major goal; get to the consumers,” said Jo. Within the scope of this goal a fantastic handbook has been produced which will be available at targeted venues around the county. This concept of multiple vineyards encompassed within a single brand image is not without challenges. “The brand itself represents some very strong brands that are all very different and we don’t represent the wine making aspect of what they do we represent their tourism offering,” said Jo. The commitment to increasing wine tourism in Kent requires “re-writing the rulebook”. Each member of the group works very hard for the collective whole. Every six weeks Jo meets with the Partners Group which comprises all the owners of the

estates “which means I have eight bosses,” she said smiling. The group has a Chairperson and this role changes every two years. Currently this role is filled by Henry Warde of Squerryes Court. “It is quite a time consuming job to take on and the chairperson has to think about the requirements of Wine Garden of England so the estate in the chair needs to be quite selfless.” The second group that meets is the Operations Group with the marketing and operations managers within the estates meeting together with Jo as Chairperson every four weeks. “As you can imagine in the first group we have a lot of bold ideas and innovative suggestions,” said Jo. The operations group undertakes the technical and practical side of some of these suggestions. “As a group we have become very friendly and members are all really generous with both their time and their venues,” said Jo. The common goal is to bring more people through the cellar doors of all the venues and one way to do this is by training the staff at the individual estates. “The staff are trained to talk to customers and say have you tried…they are only a few miles away,” she explained.

There are criteria for estates to join the group. One of the first criteria is that there must be a comfortable indoor wine tasting room. Each member can decide how that criterion is met. There are other requirements too, and being part of a group that meets regularly takes time and commitment “you must see Wine Garden of England as a priority, in a separate way to your own brand,” said Jo. There are requirements that exist to ensure that everyone is able to contribute fairly to the operation of the group. Generosity is a large part of the ethos and this is not always suitable for everyone. Being part of the group brings both tangible and intangible benefits “people like to see brands like this working together,” said Jo. There is a joining fee but “you get to be part of a collaborative organisation within the English Wine industry and as a group we have so much more power to increase wine tourism to all the estates,” Jo added.

“Looking around the world in terms of international tourism English Wine is young and it will take effort and work to educate the tourism industry about Kent as a destination,” she said. “Wine Garden of England is all about getting people to the estates it is not about selling the wines; they do that themselves,” Jo explained. The target is to see the overall wine tourism figures grow so collaboration with the tourism industry is important. This can have several levels; “companies such as ‘Winerist’ and ‘Smooth Red’ are very wine focussed travel agents, good at moving people around vineyards on an international basis, so it is important to get England some destination recognition,” said Jo.

Jo has worked with ‘Visit Kent’ highlighting the wines to a group of tour operators from Oregon and hosted a tutored tasting with a wine from each estate. Jo then spoke about what it was like to visit the estate. “It was a real eye opener for these tour operators who just didn’t know that we had any sort of wine industry especially not one where you can visit the vineyards,” she said.

Tourism companies have started to pop up who take people around local vineyards on coaches. “We also work with a company, www. ukelectricbike.com who have electric bikes that can be hired for tours,” Jo said. “The most difficult thing is that final mile from the train station to the vineyards,” said Jo. “I don’t know if anyone has solved it yet, but we are working with WineGB and local councils such as Ashford borough council to try and find solutions.”

10 June 2023 at Balfour Winery

11.30am - 6pm Tickets are £20 which include a sample from each of the seven producers:

• Balfour • Biddenden • Chapel Down

• Gusbourne • Simpsons • Squerryes

• Westwell

There are also vineyard and winery tours and masterclasses with Clive Barlow. All tickets can be purchased by visiting: www.winegardenofengland.co.uk

“One thing we do very well is attending and organising events; bringing all the brands together as a group of collaborative vineyards,” said Jo. On 10 June 2023 at Balfour Estate, Tonbridge The Wine Garden of England will hold ‘The Wine Garden of England Summer Celebration.’ The idea is to bring all eight producers together and showcase their wines to the public. Wine masterclasses will also available on the day hosted by Clive Barlow MW. The event will really allow the public to engage with all the wines from the group in an amazing environment with live music and food. Our meeting took place in the wonderful restaurant at Balfour Estate and Richard Balfour Lynn kindly allowed us to look at the amazing space that is currently under construction that will be completed and in use

on 10 June. The views from the area where the masterclasses are being held will be spectacular and there will be free transport from the nearest station to bring the visitors to the event. The inaugural event took place at Squerryes Court and had an attendance of 1,000. Ticket prices for the 2023 event are £20 and it promises to be a fantastic event for all in attendance.

The objectives for Wine Garden of England are both vast and varied and could seem overwhelming but Jo is quick to point out “we don’t have to do everything all at once,” this pragmatic approach to a daunting task will help Wine Garden of England achieve both its long and short term goals.

“What’s in a name? That which we call a rose by any other name would smell just as sweet.” Shakespeare used this line in Romeo and Juliet to suggest that the naming of things is irrelevant. But is it?

I have selected three wines this week that use carefully chosen words to convey a deep sense of understanding about the wine in the bottle. Each winery uses different words as prompts to deliver information and instruction.

I find it both fascinating and extremely astute that the subliminal use of words brings confidence and legitimacy to purchasing a bottle of wine. The trick is to use words that make sense and are not boastful or overreaching but also convey a degree of excitement and desirability. This is a considerable challenge. My chosen trio imparts so much more than just a name with their deft use of words and spot-on imagery.

2018 Simpsons Wine Estate, Flint Fields Blanc de Noirs Brut

£42.00 www.thefinestbubble.com www.oxfordwine.co.uk

£41.99 www.tivoliwines.co.uk

I usually pride myself on writing up new releases, better still, previews, but this wine is all but sold out. Ruth Simpson proudly informed me that 2018 Flint Fields won the 2022 Champagne and Sparkling Wine World Championships –Best in Class English Blanc de Noirs and Overall Best English Sparkling Wine.

It is safe to say that this is a spectacular drop, of that there is no doubt, combining the remarkable depth of fruit found in the

2018 vintage with Pinot Clone 115 bringing untold luxury to the fore. But you already know that every wine on this page is a superstar, and this one won its position in this article because of the sensational name Flint Fields.

These two words are factual, dramatic, textural, commanding and evocative. They sum up not only a place but a flavour and an attitude, and this wine lives up to all of these stunning images.

£29.75,

www.bridevalleyvineyard.com

There are no rules when naming a wine brand, but it certainly helps when you live in a place with an idyllic name. Litton Cheney Vineyard might have been a quaint moniker, but Bride Valley Vineyard is downright perfect.

As the Dorset AONB website reports, ‘The sweeping broad profile of the Bride Valley marks a transition from the intimate pastures of the West Dorset landscape to the broader chalk and coastal landscapes to the east.’ Now that description even sounds tasty! Dorset Crémant then doubles down and conveys even more of a picturesque and yet languid image of an unrushed, sparkling, soothing brew, and it is!

This wine is one of the country’s most carefully judged and enchanting sparkling wines. In addition, I tasted the very first sample of 2020 Bride Valley Chardonnay (£20.50) the other day, and it is a triumph. If you were in any doubt about the paradise that is Bride Valley, then this crystalline beauty will enchant your palate like no other.

£15.00 www.stophamvineyard.co.uk

While Stopham is a hamlet near Pulborough in West Sussex, and its place name makes perfect sense on its label, the sages at this superb winery have decided to write a motto or a mission statement on the label to accompany their locational name. ‘Passion, precision, craft, sustainability’ are the four words encircling the Stopham brand. What would you come up with if you were challenged to think of four words that sum up your winery mantra? I believe Stopham has nailed it, signalling emotion, accuracy, skill and responsibility.

I tasted this bottle only five days after it was bottled on 12 January this year, and it blew me away. I have been a fan of this wine since I wrote up the 2014 vintage, and it has always managed to bring a magical quality and silky texture to the Pinot Blanc grape. There is an intensity of flavour here coupled with a lightness of touch. Usually, Pinot Blanc enjoys putting on weight while the sun shines, and they can often become too chubby for my tastes, but there is a degree of dynamism here that is electrifying. It is sure to blossom even more throughout the next couple of years, too, so be sure to secure your stock.

Driving through the historic streets it is possible to see glimpses of the large white cross on the hillside above the village which serves as a memorial to the fallen in World War I and subsequently World War II. Like many coastal areas Shoreham Village suffered great hardship during World War II as German bombers would drop on these areas any remaining bombs they had left before returning across the sea to mainland Europe. Travelling through the peaceful village with a population of about 2,000 on a beautiful sunny day this tragic history seems a strange mixture of near and yet far away.

The Mount Vineyard is hidden from view by a beautiful brick entranceway. At first there is no sign of the 10 acres under vine – but the first parcel of vines soon becomes apparent. A lovely sight of sheep grazing in amongst the vines greeted us the day of our visit.

Estate Manager Will Lewis later pointed out that the mixed flock includes the Romney breed. The sheep have been grazing the estate in winter for about three years and are one of many ways the estate has improved its green credentials.

Simon and Sarah Greenwood live in the main house on the site built by the owner of a local paper mill in 1869. Directly attached to the main house is a courtyard restaurant with a retractable roof. Feeling like a sophisticated and modern space it still manages to hold onto the charm of the past. With a little imagination on a day which had an outside temperature near to freezing it was possible to contemplate sitting there on a summers evening drinking wine made from grapes that surround the restaurant whilst savouring the aroma of delicious wood fired pizza. In the depths of winter however with the roof firmly in place the

restaurant is cosy and warm and still has that lovely aroma of wood fired pizza.

Back in 2011 Simon who still works in finance in the city was looking to move outside of London and into a rural community. Having grown up in Rutland, the smallest county in England Simon once again wanted to enjoy the countryside. “I was addicted to looking at property websites,” he joked. Just 40 minutes train journey from Victoria Station Mount Estate was planted with 2,500 vines between 2004 and 2006 and was put up for sale in 2011. Simon saw the opportunity he had been looking for and purchased the estate. Simon explained: “Very quickly I fell in love with the concept of growing and producing something.” Initially with little experience Simon sort expert help in the form of VineWorks who helped increase the planted area by a further two acres adding Chardonnay to the selection of

vines along with more Bacchus vines. There are now eight varieties planted with Pinot Noir, Rondo, Regent, Bacchus, Seyval Blanc, Phoenix, Siegerrebe and Chardonnay.

The estate totals 104 acres with four plots of vines planted at roughly 1,200 vines per acre totalling 10 acres under vines. “My first vintage was 2012 and I found myself becoming very aware of weather patterns,” explained Simon. Since this first vintage Simon has quickly gained a large degree of vineyard experience but there have been other changes too. Simon met Sarah who also works in the financial sector and the couple now have two children. The couple got married at the vineyard in 2019 and the events team are able to offer other couples the opportunity to hold their special day at The Mount Vineyard.

Weddings are only a small part of the events held at the vineyard with outdoor cinema and music events also taking place. Simon was keen to point out that the connection to the term ‘vineyard’ in the name The Mount Vineyard was very important and as such the vineyard offers a viticulture course that takes place on five separate days throughout the year. The course covers aspects of vineyard management and harvest including pruning. On the day of the visit Will Lewis pointed out a section of vines that had been left specifically unpruned for those on the course. Will said: “At first I was nervous about the prospect but it was a really positive experience.” The package is a popular gift but there are also those who wish to join the course with the prospect of adding to their skill set.

Sarah is very motivated by the idea of environmental sustainability and the business was recognised with a ‘Green Business Award’ at Sevenoaks Business Awards 2022. Apart from the sheep in the vineyard there are other not quite so obvious sustainable practices on the estate for example the restaurant uses a biomass boiler and solar thermal panels have also

The estate totals 104 acres with four plots of vines planted at roughly 1,200 vines per acre totalling 10 acres under vinesSimon and Sarah Greenwood

<< been incorporated into the energy generation processes on the estate. One future plan is to install electric car charging points in the spacious car park adjoining the Ten Acres Shop which stocks all the various wines alongside other specialist items such as truffle oil and chocolate from local producers. The vineyard already benefits from excellent public transport links with a train station just 13 minutes walk away. Where many vineyards struggle with car free access the Victorian expansion of the railways brought people to this part of Kent and today it is easy for people to arrive by train at the vineyard. “People dress up for the tastings and can often be seen walking from the train station,” said Sarah.

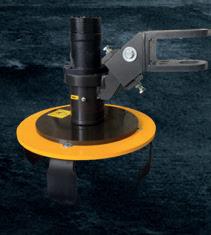

This link to the Victorian penchant for travel leads to a discussion about climate. Simon explained that the vineyard has its own valley microclimate and in the summer it is possible for the estate to be around 2°C warmer than the surrounding area so the Victorian visitor (and the modern visitor) would definitely have enjoyed their summer vacation spot. Conversely the vineyard is extremely prone to frost, suffering as many as 10 frost nights in just one season. “Bougies are effective but are very labour intensive,” explained Will and the vineyard also uses a Frost Buster supplied by N P Seymour. “Between Plot One and Plot Three there is only a distance of 300 metres but the weather stations show the temperature can differ by 1°C,” said Will. The early Chardonnay can be particularly vulnerable but where there has been frost damage the second shoots on the Seyval have proven more fruitful than the other varieties. Simon explained that there is a plan to install a sprinkler system across the entire vineyard. After some research it was decided that heated wires were unsuitable for the site owing to the high wind chill factor experienced in the vineyard and therefore the sprinkler system was the best option.

There is 10 inches of soil before you reach chalk and “a slightly alkaline ph of 7.0-7.5 can mean the vines struggle to access the manganese and magnesium they need but the soil is generally nitrogen rich,” said Will. Historically the vineyard has had significant disease pressure from downy and powdery mildew so

The vineyard has its own valley microclimate and in the summer it is possible for the estate to be around 2°C warmer than the surrounding area

inputs are purchased upfront for the whole season from Agrii with John Buchan as the independent vineyard advisor. Will explained that whilst canopy management to relieve disease pressure is very important in recent years it has been possible to tighten the spray windows so that applications are made at exactly the right time. The number of varieties that are present in the vineyard can make this complicated though as some plots have been planted with half a row of Bacchus and half a row of Pinot Noir. “The timings of applications for these varieties differ with the Bacchus suffering disease pressure earlier,” explained Will. This slightly unorthodox vineyard layout also presents challenges at harvest. The estate has three full time employees who supervise the harvest which is done by volunteers.

Harvest figures vary but in a good year 25 tonnes of fruit are picked usually across five days with 60-70 volunteers per day. Many of the volunteers return year on year to take part and each day finishes with pizza and wine in the courtyard restaurant. “We use the white chalk that football referees use to indicate where in the row the pickers should stop as the varieties change mid row,” Will said with a smile.

The estate has very little problem with pests although the red varieties are netted to prevent predation by birds but there does not seem to be a major threat in the area. Simon pointed to the fact that there are a number of birds of prey in the area which provide enough protection for the grapes and only one of the four plots has ever suffered from deer damage.

The fruit is sent to Litmus Wines in Dorking and the 25,000 bottles produced are all used by the estate. One of the label designs for The Mount Vineyard features a large key in the design. Simon explained: “When I bought the house I found a box of keys some of them were modern and some were intricate and old. Some of the locks were possibly part of old outbuildings that were no longer on the estate <<

Harvest figures vary but in a good year 25 tonnes of fruit are picked usually across five days with 60-70 volunteers per day

and some were keys to doors that are still part of the house. Keys denote all sorts of ideas and possibilities and I wanted to capture this in the label design.” Celebrating the birth of their first child Ellie, Simon and Sarah released a 2017 Rosé with a special label and other labels are now part of The Mount Vineyard offering. The estate produces a still Bacchus and a Pinot Blanc alongside traditional method sparkling. Recently both the Sparkling Red (2015) and Sparkling White (2016) were awarded silver medals at the ‘IEWA 2022’. The production of a sparkling red is a break from the norm and can be quite controversial but Simon pointed out that: “By the time it received the award the sparkling red was already sold out.”

Just a short walk from the vineyard sits a lovely local village pub. The pub dating from the 15th Century was previously part of a large chain and had not seen much investment so in 2020 Simon and Sarah decided to purchase the pub and after a refit covering a period of two years the pub reopened with the name The Samuel Palmer. “This is the name of a local landscape artist who was featured at the Royal Academy,” said Sarah. “The interior design of the pub has been influenced by his painting and the walls of the pub are adorned by pictures of the artist himself alongside his thoughtful depictions of the local scenery. “There is a walk that starts and ends in the village ‘The Landscape of the Landscape Artist,’ added Simon. The pub has a lovely atmosphere and there is the possibility that in the future it could offer guest rooms but for now Sarah and Ellie really enjoy their trips to the Samuel Palmer.

Sarah who grew up in Ireland admitted that living on the estate is fantastic and that her dad who is a horticulturist always enjoys his visits and makes useful suggestions during his stay.

There are significant possibilities for the

businesses to have unusual synergies. Starting small, all the wreaths used for decoration on the estate make use of the prunings from the vines but other synergies present themselves. The orchard apples are used in the pub and restaurant menus. There is also a walnut grove however although the grapes don’t tend to suffer from pests protecting the walnuts from predators such as squirrels has proved a challenge as anyone who has one of these beautiful but prone trees will tell you. There is also a recently planted hazelnut grove that has been pre inoculated to provide truffles. “We will be

able to produce and use the truffle oil in the restaurant and pub,” explained Simon. This fascinating and unusual project will take seven years to mature but the ability to use locally sourced ingredients has become a part of the ethos at The Mount Vineyard and it will be interesting to see both this project and others develop. At The Mount Vineyard the artistry of wine dovetails with culinary creativity and like the picture perfect backdrop is constantly evolving whether depicted on canvas or captured and bottled. Each presents a past moment in time that can be enjoyed into the future.

Winzer-Service Messe, Karlsruhe is a substantial trade fair, but just shy of the periodic massive international ones as occasionally encountered around Europe and as such it had a bit of a 'local feel' to it.

Karlsruhe is about an hours drive away from the Freytag vine nursery and it was an easy decision to take the day to visit it.

My colleagues had a few areas of interest that they wanted to investigate, so arrived primed up and ready to fire off the questions. My idea being to take a slightly back step view on goods and services, amble around, and listen in on matters when they interested me, or to generally see what inspired me.

From the first door way and at the first stand they started in on the questions. This could be a long day as after all there was probably a reason why the show goes on for three days.

Nurseries take up quite a lot space, and require a lot of tractor attentions. A drone might require more frequent charging of its power supply, but the large modern ones have a payload greater than I had imagined. There are also efficiencies in their manoeuvrability, covering the ground well and then landing to reload etc and to then carry on. All without having to consider an impact on the soil. This ability being almost invaluable after heavy rain.

As an older person this type of technical advance (allowing from now to many years in the future an increase in better management strategies) I find almost mind boggling. For younger people this is but a simple bit of work kit, where if it's use is viable, then you put one to use.

In my early days I worked with a plough, with a Fordson Dexta, vineyard narrow, and I got to plough under vines that had never seen the use of herbicide. I heard from the old man across the road that as a child he used to sit on the shoulder of the oxen, as his Father ploughed the vines, and that was back in the early 1930's.

I can still drive a tractor, though that one should be in a museum, but I don't ever expect to programme a drone.

From now on I might be taking a 'slightly back step in life'...however the Karlsruhe trade fair days are fascinating, and so very progressive.

There are some very large bits of kit here. What I think that I have noticed though, is within that insidious increase in size, comes an increase in weight.

By that I mean to say that within the vineyard there are implications of soil compaction issues.

No worries though as all that needs doing is to build a bigger, and better, form of cultivator for soil issues...

Except that surely cannot always be right; doing nothing detrimental to the soil in the first place must be a better option? However that does not

appear to be where some place their values.

Bigger is better, where big is beautiful...and in all of the technology and the thinking, possibly our needs in meeting requirements in production all err towards increase.

Thus more growth might produce more grapes, and with this probably more leaves, leading to machines that strip away those leaves, and possibly on two rows simultaneously.

With this front mounted bit of kit, why not add something to the side of the tractor, a mid mounted...something, or indeed behind lies an excellent opportunity...say for a cultivator and perhaps a seed drill.

Where is it all going to stop? After all, isn't this modern interpretation of 'get as much done in a single passage' form of management, the cleanest, most 'bio' and efficient way that could be operated? How big and complicated is it going to get?

Another aspect to events such as this are the social interactions, all very valuable as we are generally social animals at heart. There is often much to be learnt from such encounters.

I was very happy to cross paths with several of my previous work colleagues, but also other contacts and including some with strong connections to the UK.

Paul, ex EMR, was there. He now being known by many for his good work with Clemens, and his visits to the Vineyard Magazine's show in Kent.

Ernst, who for many years co-ordinated the activities of vineyard planting operations in conjunction with James of VineWorks, he was there with the company that handles Hadley posts in Germany. Ernst has not been in the UK for a few years due to a mix of Covid-19 and business re-structuring/ semi retirement, (as he never sits still.) However he remembers his time there with delight and had a hundred questions for me.

Naturally a glass or two lubricated the occasion, and it brought to mind the efforts of Volker Freytag of Rebschule Freytag, who funds a stand at the Kent show.

These shows are not all a simple 'hard nosed business' drive, in some attempt to increase sales. However in building the service of supply there are many occasions of valuable times together. I'm very aware that Volker is always happy to support and offer good wines for a tasting, all in the interests of sharing knowledge and starting a good debate.

There are I feel many good UK relevant companies and occasions that happen over this way, here in the Pfalz. For those with a little more international view on matters, it might be of interest to learn of "Weincampus Neustadt", the local wine school, holding an 'Information Day' around their upcoming courses in wine related matters on 19 April –Details available at weincampus-neustadt.de

Increasing yields while culturally reducing frost damage are two important priorities for growers, and the way vines are pruned and trained plays a significant part in this.

Many approaches to training vines are used worldwide, but the most popular in the UK is the Vertical Shoot Position (aka Guyot) system.

Tying canes down flat onto the fruiting wire has traditionally been the standard approach, favoured for its simplicity and ease of management. There are however, inherent risks with this method, not least from the increased likelihood of more significant frost damage occurring to any buds in contact with the galvanised wire, which conducts cold along its length.

Laying canes flat also encourages the inherent apical dominance of the vine’s distal bud, prompting it to burst into leaf earlier than other buds, potentially resulting in uneven crop development throughout the season. Indeed, before vines were cultivated by humans, they evolved to be freeloaders, climbing over trees and shrubs to get leaves into sunlight, without investing valuable carbohydrates into fully structural trunks and stems.

This evolutionary pressure accentuated a trait called acrotony, defined as increased vigour of the branches arising from dormant buds according to their position on the stem, progressing from the proximal (close to the main stem) to the distal (furthest away from the main stem).

The effect of pronounced acrotony is that the final bud on a cane is usually the most vigorous and first to break, leading to uneven cane growth and ripening.

Tying canes flat to the fruiting wire does little to balance the vigour of buds along the cane, but arching them can help reduce

apical dominance, promote more even sap distribution and improve the evenness of bud burst along its length, while potentially reducing frost risk.

A variation of the Guyot system was developed in Germany, named ‘Pendelbogen’ which literally translates as ‘pendulous bow’. This is descriptive of the final effect, where arching canes in a double Guyot resembles a McDonalds ‘M’.

This is most often achieved by installing a second fruiting wire around 10cm above the first, arching the cane over the upper wire and attaching the end to the lower. This is quick to do, provides a well secured, stable cane with three attachment points, and is easier to pull out at the end of the season than would be the case where canes are wound around a flat fruiting wire.

There is a narrow window of opportunity to install the second fruiting wire, however, which lies after pruning is complete, but while canes are still pliable, and most importantly before buds start to swell and become susceptible to damage.

There are four main benefits to bowing canes:

1. Reduce risk of frost damage associated with a cane tied or wound around a single wire

2. Overcome acrotony, leading to more even bud break

3. Increase the total length of cane laid down by around 20%, and with it, additional buds, so the approach is particularly suited to vigorous sites and varieties

4. Increase the depth of the fruiting zone from top to bottom, from say 30cm to 40cm, which should benefit overall yield potential, providing growers manage crops appropriately through to harvest.

The disadvantages are that with greater bud

critical and for varieties such as Siegerrebe, or situations where the internodal distances are small, a second fruiting wire will be more of a hinderance than an advantage.

Finally, for those with vines still to prune over the next few weeks, it is worth remembering the basics, such as trying to avoid pruning in wet weather, when the risk of grapevine trunk disease infection is greater.

Pruning when sap starts to run in February and March may help reduce wounds suffering from GTD infections, but where large cuts (>25 mm) are needed, if re-structuring, it is beneficial to apply a wound protectant.

When planning the amount of cane to leave, it is generally better to be conservative when removing material. We all remember the frosts of 2020, so this may mean allowing more buds, and adopting cultural methods to delay bud burst, plus mitigating frost damage through methods such as leaving sacrificial canes, or delaying tying down, especially on frost-prone sites.

Sort out any natural frost drainage before bud burst begins too. As the saying goes, plan for the worst and hope for the best.

VineWorks, like all other UK vine importers, buy our vines from Europe. In our case they’re from nurseries in France and Germany. Some other winemaking regions have established their own nurseries within their countries, but disease pressure makes a UK nursery nigh impossible, not to mention the lack of consistent high temperatures throughout the growing season.

The process of importing vines has become an ever-lengthening spiral of complexity since Brexit. Each year, the import restrictions increase and criteria for phytosanitary certificates evolve. However, our nurseries’ processes for managing healthy vines have not changed at all. In fact, the reason we have been using these nurseries for more than a decade is precisely because of their attention to plant health, graft quality and understanding of our market. The nurseries have mostly delivered good quality, healthy plants. If there are any issues, they quickly acknowledge and resolve them. That’s what you get when you work with generational family businesses.

I was lucky enough to spend Christmas in Burgundy and relished the opportunity to subject my family to a nursery inspection!

Pépinières Guillaume kindly hosted a comprehensive tour of their facilities: hot water treatment processes, quality checks, (usually around 50% of vines are discarded as they don’t reach the required standard) and finally cold storage and packing.

Hot water treatment is the process where vines are dipped in a tank of water and subjected to near 50°C for a period of time to kill any nasties on the vine. At this nursery having clean, quality vines is crucial. Owner, Francois Guillaume said: “There is a control from FranceAgrimer, (the French authorities in charge of the nursery control) in the mother block of rootstock and scion that we use to make plants. In Pépinières

Guillaume, we are adding to their control, an auto-control that ensures we use clean material. This auto-control is based on observation and control of possible symptoms of diseases and we make random samples to send for virus and bacteria analysis.”

Francois does offer up a warning, however. “It is very important to notice the difference between serious diseases like Fanleaf, Leafroll, Flavescence Dorée and less preventable diseases that a healthy plant can manage by itself if it is well planted. Agrobacterium is one of these, for example. You will find it everywhere, but if the plants are correctly managed, agrobacterium will never be a problem.”

VineWorks also imports vines from Pépinières Tourette, another French nursery that follows hot water treatment protocols and has supplied many of the vines that are planted in the UK today. They have contributed to earlier articles about vine importation. Pépinières Tourette also sells vines to Canada – the process for importing vines is very different and they are at around twice the price of the vines we buy. Vines bound for Canada must have all the soil washed off the roots before they leave France. This is a colossal task that uses a lot of water and costs a considerable amount more. A process that would further increase the already high costs of vineyard establishment in the UK.

All our PiWi vines are sourced from Rebschule Freytag in Germany. They have been

instrumental in the breeding and perfecting of PiWi varieties and supply vines all over the world. Volker Freytag is the current custodian of the nursery which has been running for over 70 years. Volker believes that hot water treatment will not be necessary for vines leaving Germany for the UK: “All our propagation areas are visually inspected annually to exclude diseases. All these measures are controlled and recognised by a state authority in Germany. In addition, wood samples are taken at regular intervals and serological tests are carried out in the laboratory with regard to viral diseases. Thus, every mother plant is serologically tested in the laboratory and by visual inspection. All propagation plots used are tested by a state laboratory for virustransmitting nematodes; only disease-free plots are used for the production of mother blocks.” He adds that “a wide network of monitoring stations, organised by state entomologists, ensures the control of diseases and vectors. Fortunately, Germany is considered free of “Flavescence Dorée” and “Xylella fastidiosa”, and their vectors, so no hot water treatments are necessary!”

Ultimately the decision whether to hot water treat vines from Germany will be in the hands of the Animal and Plant Health Authority (APHA). APHA decides how vines are imported into the UK and the WineGB Vine Importers group is working closely with them to keep on top of any changes in the future.

More than 3500 units sold worldwide ! Frostbusters -

We offer several solutions !

hectares

We are the biggest producer of frost protection machines in the world and our turnover increases year after year. During the last 50 years, we have been the only company that introduced new effective solutions to fight frost.

We have the biggest range of frost protection machines in the world, so we can always offer you the best solution and we continue to invest in research for better solutions and better results.

UK Importer:

NP Seymour - Cranbrook - Kent TN17 2PT

Tel: 01580 712200 - www.npseymour.co.uk

Email: hello@npseymour.co.uk

Agrofrost (Belgium)

Contact: Patrik Stynen

Tel.: 01580 291565 or mobile +32 495 517689

Email: info@agrofrost.be

Find out all about it on our website: www.agrofrost.eu

Grapevine Trunk Diseases (GTD) are a huge global problem. They can devastate a vineyard – leading to a decline in vine quality and lower yields through the loss of vigour or entire vines. GTDs are caused by a range of pathogenic fungi entering the vine through open wounds, normally pruning cuts.

This is a cyclical process, as spores on existing cankerous wood on old vines are re-dispersed by the elements, insects and even on pruning shears to infect new pruning wounds on young, healthy plants. The problem is compounded by the diseases being asymptomatic in the early stages, so by the time it is identified it may already be too late. The fungus will progressively kill the spurs, cordons and then trunks of the vine.

A family of diseases are caused by the GTD fungi, with nearly 100 species of pathogen having been identified as potential culprits causing damage to vineyards. It is unlikely that there will be a single ‘magic bullet’ found to treat such a complex problem, although research continues globally.

Now believed to be in itself a family of diseases, esca appears on grapevines usually over five years old, although younger vines may already be infected. The first symptoms can include dark red or yellow stripes on leaves, depending on the cultivar, usually seen in the summer. They will eventually become necrotic.

The so-called “black goo” may also be present within the wood, causing brown staining. After cutting a cross-section of the trunk or spurs, a shiny tar-like substance may ooze from the wound instead of healthy clear sap. Black goo may be visible externally at the graft union. Upon further progression of the disease, the whole vine can die. Sometimes this can happen without any visible warning signs on the leaves.

Caused by the Eutypa lata fungus. Diseased vines may present yellowed leaves, stunted

shoots with dead edges and a distinctive cupped appearance. Cankerous dead wood will show the path of the infection through the vine. On the trunk, the bark will fall off to expose the stained brown wood. Grape bunches may ripen unevenly and have fewer, smaller berries. Where the infection is severe, the berries will not set at all. Infected grapevines will see a decline in productivity and eventually die.

Another fungal infection that mainly grows in mature wood, Botrosphaeria dieback is caused by fungi within the family Botryosphaeriaceae. The trunk may show wedge-shaped lesions when cut in crosssection, and ‘dead arm’ dieback can occur. Budburst may be delayed and infected shoots have a stunted appearance when they develop.

Guarding against the fungal spores that cause GTD is difficult, but some measures can be taken to decrease the likelihood of infection. For example, it is best to prune in dry conditions when spores are less likely to have been dispersed. Pruning late can also help, as the rising sap will help to displace spores on the cuts.

When pruning, the advice is to avoid larger wounds over 15mm when possible. If they must be made, use a wound paint or treatment to protect the area. Dispose of pruning waste to lower the risk of spore transfer, leading to the infection of young, healthy plants in the vineyard. Burning the prunings will lower but not eradicate the risk. Pulverising them may be the better option, leaving them to break down completely on healthy soil.

Recent research has is shedding new light on exactly how the families of GTD fungi

cause damage. This mechanism has not previously been properly understood. The research is being undertaken by a group that includes Professor Barry Goodell, Professor of Microbiology at the University of Massachusetts. He has an extensive background in the fungal degradation of wood.

“Our research group has been developing an understanding of how certain fungi use very small molecules produced by the fungus (fungal metabolites) to bind, or chelate, metals like iron,” Professor Goodell told Vineyard Magazine. “Some types of fungal metabolite will change the state of iron molecules as part of the chelation process to make the iron very reactive. Once the iron is in this reactive state the fungi also generate oxygen radicals which react with that iron. This reaction (and oxygen radical reaction) causes extensive damage to wood cell walls. We call that damage “wood decay”.

“With the GTD work, we expanded our hypothesis of how the fungi cause wood to decay to also demonstrate that the fungi involved in GTD behaved similarly, and we demonstrated how the same types of oxygen

radicals were produced in the GTD system.”