Plain and Coated Aluminium

Plain and Coated Aluminium

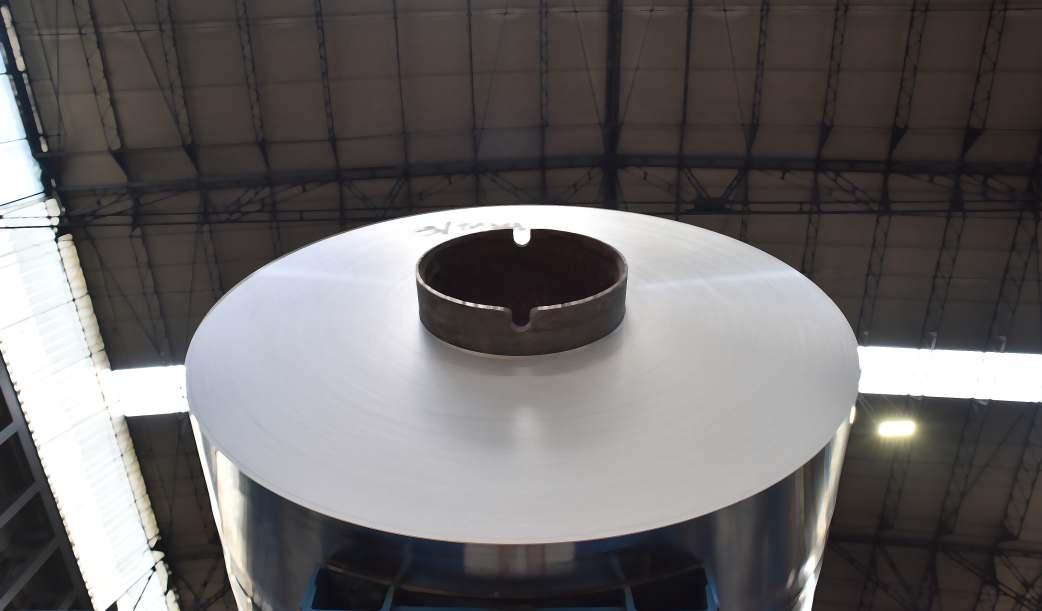

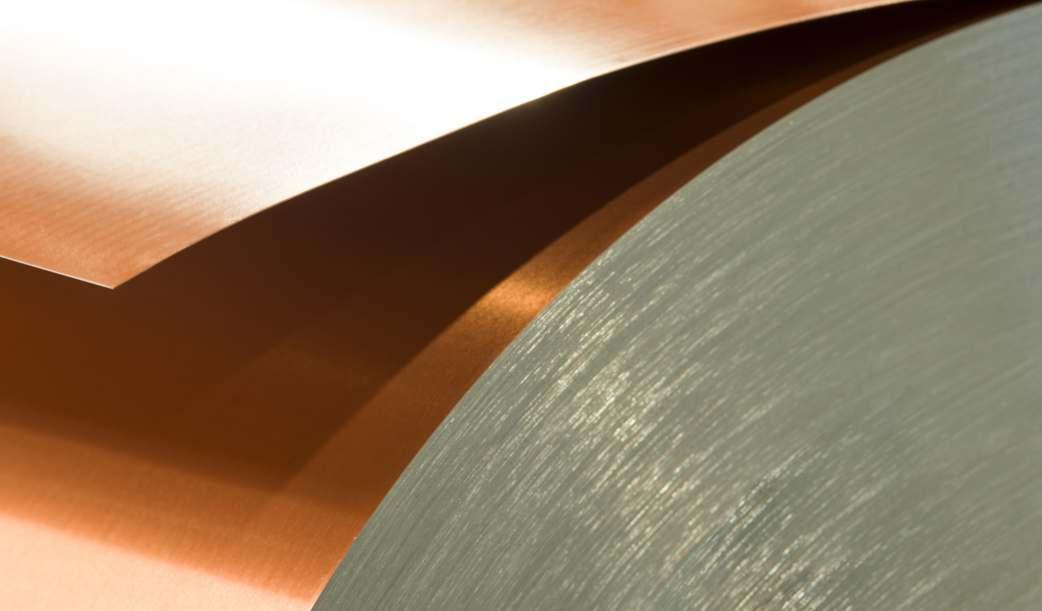

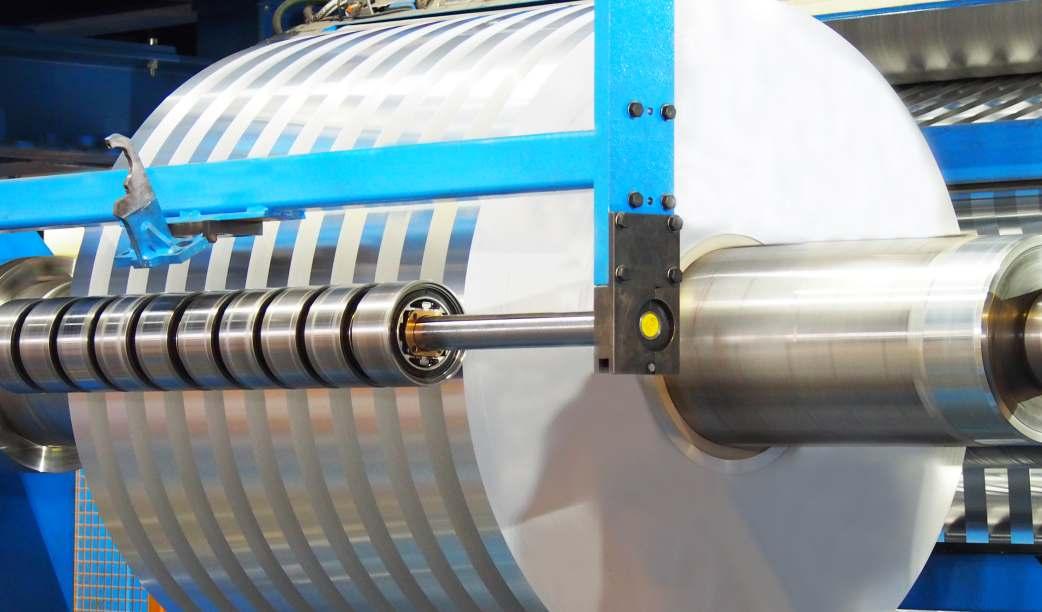

Laminazione Sottile Group is a worldwide supplier of plain and lacquered aluminium coils and sheets, exporting to over70countries.

Continuous reasearch and innovation, quality assurance, financial solidity, commitment towards sustainability: theseareourkeystobeareliablepartner

LaminazioneSottileGroupisspecializedinaluminiumtransformation. The Group’s production goes from the foundry to the manufacture of bare and lacquered aluminium semisfordifferentindustrialapplications,downtofinishedproductsforthefoodindustry

Our Business Units work in a highly sustainable integrated cycle, to meet the needs of a dynamic andconstantlyevolvingmarket.

- rigid packaging - semirigid packaging - flexible packaging - HVAC-R - building - aerospace - automotive - technical applications

SURFACE FINISHING SURFACE TREATMENT LACQUERING

THICKNESS TOLERANCE

STRIP WIDTH RANGE

STRIP INSIDE DIAMETER

STRIP OUTSIDE DIAMETER

SHEET LENGTH RANGE SHEET WIDTH RANGE

3XXX • 5XXX • 8XXX

from 0,15 to 0,50 mm

icrons mill finish - bright roughness Ra<0,10 m conversion treatment chemical degreasing and/or available in any colour, upon request according to EN standard or better from 20 to 1250 mm

150 • 200 • 300 • 400 • 500 mm from 590 to 1180 mm from 400 to 1900 mm from 400 to 1250

Foil coated on one or both sides, meeting all the European and national food laws and regulations. Coating could be realized with BPA N.I.A. (“Bisphenol A - Not Intentionally Added”) and free of PVC.

THICKNESS

SURFACE FINISHING SURFACE TREATMENT LACQUERING

THICKNESS TOLERANCE

STRIP WIDTH RANGE

STRIP INSIDE DIAMETER

STRIP OUTSIDE DIAMETER

1XXX • 3XXX • 5XXX • 8XXX from 0,030 to 0,40 mm mill finish available in any colour, upon request chemical degreasing • cleaning (grade A • no smell) according to EN standard or better from 35 to 1700 mm

70 • 75 • 150 • 200 • 300 mm from 590 to 1075 mm

Coated aluminium laminated with polypropylene film through sterilizable glue to manufacture containers for aggressive food Suitable to a retort process with a long shelflife

ADVANTAGES

High corrosion resistance

Suitable for sterilization and retorting processes

Polypropylene film and Glue developed to guarantee the perfect adhesion of the laminate during the manufacturing process

STRATIGRAPHY

Polypropylene film

Surface pre-treatment

Aluminium

Glue Outside epoxy gold/white lacquer

SURFACE FINISHING*

SURFACE TREATMENT LACQUERING

THICKNESS TOLERANCE

STRIP WIDTH RANGE

STRIP INSIDE DIAMETER

STRIP OUTSIDE DIAMETER

1XXX • 8XXX from 0,010 to 0,05 mm matt • bright thermal degreasing • chemical degreasing if > 0,05 mm available in any colour, upon request according to EN standard or better from 590 to 1075 mm 70 • 76 • 150 mm from 450 to 800 mm

*under 0,025 mm one side matt one side bright / from 0,025 to 0,04 mm both sides bright

Lacquered, coloured or printed aluminium foil, to manufacture processed cheese packaging, from 25g up to 500g portion. Foil is suitable for any packaging machine and customizablewithlogo

SHELL 10-20 µm |

primer / print Aluminium heat sealing non corrosion lacquer

LID 10-20 µm |

heat sealing lacquer Aluminium protective non corrosion lacquer

TEAR TAPE 45 µm | opp

opp Adhesive (Red Colour) heat sealing lacquer

triangular square round rectangular tear tape

Porosity Test and Electrochemical Impedance Spectroscopy (EIS) prove that our foil has a corrosion resistance 1000 timeshigherthantheaveragemarketmaterial

Finstock

THICKNESS

SURFACE FINISHING SURFACE TREATMENT LACQUERING

THICKNESS TOLERANCE

STRIP WIDTH RANGE

STRIP INSIDE DIAMETER

STRIP OUTSIDE DIAMETER

1XXX • 3XXX • 5XXX • 8XXX from 0,09 to 0,4 mm mill finish Degreasing and / or conversion treatment according to EN standard or better available in any colour, upon request from 20 to 1700 mm 150 • 200 • 300 • 400 • 500 mm from 590 to 1800 mm

Coated aluminium with a new hygroscopic lacquer ideal for the manufactureofenergyrecoveryrotors.

Aluminium

Reduction of the 15% of Energy consumption

Good solvent resistance

Good adhesion on the aluminium surface Selective adsorption of water moisture with the exclusion of pollutants (Molecular Sieve)

Good resistance against corrosion caused by humid environment

Total absence of Silica Gel (source of bad smell caused by bacteria growth)

No risk of coating pulverization

Chance to add biocide additive to the formulation

Coated aluminium with a new high performance adsorbing hydrophilic lacquer to manufactureadiabaticheatexchangers.

STRATIGRAPHY

TMHydrafins Lacquer

Primer

Surface pre-treatment

Aluminium

Surface pre-treatment

Primer

TMHydrafins Lacquer

Adsorbing hydrophilic behaviour preservation even after ageing

Superior corrosion resistance

Excellent mechanical properties in the deep drawing process

FIN

New innovative coated aluminium with high performance hydrophilic lacquer to supply manufacturersofaluminiumfinsforheatexchangers

STRATIGRAPHY

Bluefin

Primer

Surface pre-treatment

Aluminium

Surface pre-treatment

Primer

Bluefin

excellent hydrophilic performance

Corrosion resistance

UV Resistance

Suitable for indirect food contact

Available with antimicrobial additive

Coated aluminium to manufacture alu fins for heat exchangers. Aluminium is varnished with a nanotech-based lacquer, specifically developed to guarantee high performance in veryaggressiveenvironments.

High hydrophobic surface

Nano-tech

Aluminium

Nano-tech

Corrosion resistance

UV Resistance

Self-Cleaning properties

High oleophobic surface

Excellent mechanical properties in the deep drawing process

Italcoat supplies coated aluminium with a new high performance super hydrophobic lacquertomanufacturersofalufinsforheatexchangers

Super Hydrophobic lacquer

Surface pre-treatment

Aluminium

Surface pre-treatment

Super Hydrophobic lacquer

excellent hydrophobic performance

Corrosion resistant

Excellent mechanical properties in the deep drawing process

Available with antimicrobial additive

Laminazione Sottile Group produces flat aluminium, coated with antimicrobial lacquer to beused in HVAC-R systems. This innovative product halts the growth of bacteria,mouldandfungi.

Antimicrobial

Surface pre-treatment

Aluminium

Surface pre-treatment Antimicrobial

ASTM G21–13

Antimicrobial effect according to the following standards: ASTM E2180 ISO 22196:2011

Corrosion resistance

UV Resistance

flat and embossed aluminium, coated with antimicrobial lacquer to be used in foamed panels for air ventilation ducting systems. This innovative product halts the growth of bacteria,mouldandfungi.

Antimicrobial

Surface pre-treatment

Aluminium

Surface pre-treatment Back Gold

ASTM G21–13

Antimicrobial effect according to the following standards: ASTM E2180 ISO 22196:2011

Corrosion resistance

UV Resistance

THICKNESS

SURFACE FINISHING SURFACE TREATMENT LACQUERING

THICKNESS TOLERANCE

STRIP WIDTH RANGE

STRIP INSIDE DIAMETER

STRIP OUTSIDE DIAMETER

SHEET LENGHT RANGE

SHEET WIDTH RANGE

1XXX • 3XXX • 5XXX

from 0,01 to 4 mm mill finish, EDT, brushed, lubricated Degreasing and / or conversion treatment available in any colour, upon request according to UNI EN 485 from 20 to 1700 mm 500 mm max 1700 max 6000 mm max 1500 mm

Laminazione Sottile Group produces embossed and flat aluminium, laminated with polyethylene film and coloured glue, to be used in the manufacturing of acousticandthermalshieldsfortheautomotiveindustry

Aluminium Polyethylene film

Coloured Glue

SURFACE FINISHING SURFACE TREATMENT LACQUERING

THICKNESS TOLERANCE

STRIP WIDTH RANGE

STRIP INSIDE DIAMETER

STRIP OUTSIDE DIAMETER

SHEET LENGHT RANGE

SHEET WIDTH RANGE

1XXX • 3XXX • 5XXX • 8XXX from 0,03 to 5 mm mill finish • bright Degreasing and / or conversion treatment available in any colour, upon request according to EN standard or better from 16 to 1250 mm

70 • 75 • 150 • 200 • 300 • 400 • 500 • 600 mm from 590 to 1180 mm from 400 to 5000 mm from 400 to 1250 mm

SURFACE FINISHING SURFACE TREATMENT LACQUERING

THICKNESS TOLERANCE

STRIP WIDTH RANGE

STRIP INSIDE DIAMETER

STRIP OUTSIDE DIAMETER

SHEET LENGHT RANGE

SHEET WIDTH RANGE

1XXX • 3XXX • 5XXX • 8XXX from 0,03 to 5 mm mill finish • bright Degreasing and / or conversion treatment available in any colour, upon request according to EN standard or better from 16 to 1250 mm

70 • 75 • 150 • 200 • 300 • 400 • 500 • 600 mm from 590 to 1800 mm from 400 to 5000 mm from 400 to 1250 mm

Laminazione Sottile Group has developed specific aluminium coils coated with adhesive lines accordining to AMS A 81596. The product meets the needs of Honeycombproducers:afasterandmoreefficientproductionprocess. Sheets cutting coated aluminium with adhesive lines

Hot pressing Slices cutting

Laminazione Sottile Group Honeycomb producers

Aluminium foil can be supplied to produce honeycomb panels with these cells dimensions: 18,00mm 17,00mm 9,52mm 6,35mm | | |

We work very hard to reduce our plant’s environmental impact, through

in processes and, technologies,resourceoptimizationandacontinuousmonitoringprogram.

Yet, we are investing focus on the objective of reducing energy consumption, increasing the use ofrenewablesources,aswellasreducingwaterusage,wasteproductionandemissions.

Laminazione Sottile Group commitment to a durable and sustainable development expresses itself in the balance between the company growth and the respect for environment and employees, as well as in the relationshipwithlocalinstitutional, socialandeconomicpartners.

innovations

Laminazione Sottile Group commitment to a durable and sustainable development expresses itself in the balance between the company growth and the respect for environment and employees, as well as in the relationshipwithlocalinstitutional, socialandeconomicpartners.

innovations

wwwlaminazionesottilecom enquiries@laminazionesottilecom

Sign Up for our newsletter

wwwlaminazionesottilecom

enquiries@laminazionesottilecom