2 minute read

News

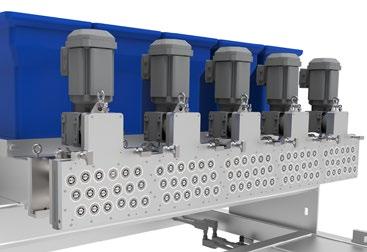

Reading Bakery Systems introduces new rotating die

Reading Bakery Systems (RBS) designed a new 18-nozzle rotating die for increased throughput capacity. Depending on the size of the finished snack product, it increases throughput capacity by up to 33% on the same size production line when compared to the 12-nozzle die that has been available to the industry for 40 years, RBS details. The rotating nozzle die creates wound shapes spirally while continuously extruding a rope of dough, which is then cut into twisted pretzel and stick products. The number of rotations made © Reading Bakery Systems and the speed of the extrusion can be controlled independently – to increase the range of product that can be made in terms of shapes and textures. The new design has incorporated gear-driven nozzles constructed of stainless steel with internal nozzle inserts made of FDA-approved sanitary plastics. These new components utilize a food-grade semi-solid lubricant, instead of gear oil. The rotating nozzle die mounts directly onto all standard RBS low-pressure extruders, expanding these systems’ flexibility. +++

Groundbreaking ceremony for new KEMPF plant

KEMPF held the groundbreaking ceremony to announce the official start of the construction of its new plant. Spanning around 21,000 sqm, the facility will house an upgraded production area, logistics and administration offices. The expansion will also include new staff member hires, with the total number of employees estimated to reach 200. There are plans for the production area to be set up with highly-automated, new technologies. The project is designed to source its electricity from a 2,100 kWp photovoltaic system that will be installed.The plant is scheduled to be ready by the end of 2023, and the relocation to be complete in the first quarter of 2024. Guido Kempf, the company’s CEO, commented on the start of the expansion project: “The construction of our new plant is an important milestone in our company’s history. The step is well-considered. In the current political and economic situation, the plans have certainly been called into question once again. But, in the family, we agreed to stay true to the motto ‘Standing still is a step back’ and we would like to take the courageous step.” +++

KEMPF ©

DSM highlights new solutions at FiE 2022

Royal DSM introduces its latest developments at this year’s Food ingredients Europe (FiE), held December 6-8, 2022, in Paris. Among the new launches, DSM showcases Panamore® Xtense, a label-friendly lipase and a more sustainable alternative to the common emulsifier, DATEM. The new solution helps bread producers maintain dough stability and improve volume and shape in more challenging applications like wholewheat, frozen dough and while using flours or varying quality, DSM explains. A breakfast cookie is among the highlights, formulated to aid digestion while providing an energy boost and containing reduced acrylamide levels, DSM says. New additions to its plant-based portfolio are also presented in Paris. +++

MECATHERM launches patisserie know-how sharing series

Loïc Le Denmat, a patisserie expert at MECATHERM, is preparing a series of knowledge-sharing videos, called ‘Ask Loïc’. Each episode will be focusing on a unique product, including muffins to madeleines. The first video will become available soon, MECATHERM said. “He will share his passion, knowledge, and expertise with you. Through each unique episode, you will discover the secrets of baking pâtisseries on an industrial scale and the keys to achieving product quality and industrial performance,” the company detailed. +++