British Gypsum has made further progress towards its goal of being carbon neutral by 2050, thanks to the introduction of Hydrotreated Vegetable Oil (HVO) fuelled vehicles to its UK fleet.

This additional investment in low-emission vehicles reflects British Gypsum’s ongoing commitment to significantly reducing its impact on the environment, putting it on course to achieving its pledge of net zero carbon emissions by 2050.

British Gypsum has started to convert its HGV fleet from diesel to HVO and is expected to use approximately 75000 litres of fuel per week. This means that around 40% of the company’s UK fleet will now operate on HVO fuel, with a further 10% using Liquefied Natural Gas (LNG). The use of multi-fuelled vehicles at this scale is expected to reduce British Gypsum’s carbon emissions by approximately 70%, year on year.

To support the implementation of HVO vehicles, British Gypsum has made several upgrades to

site infrastructure, including an HVO refuelling point in Robertsbridge and a new fuel island capable of delivering 110,000 litres a week at its Distribution Centre in Gotham.

HVO is an emerging ‘drop-in’ fuel replacement for diesel, and is manufactured at refineries from waste materials such as cooking oils and other waste streams that are not fit for human consumption. The British Gypsum vehicles are using Green D+ HVO, which is an EN15940 fuel - recognised by almost all major engine manufacturers as it leaves no carbon deposits, and also has a cleaning effect on engines. It’s becoming more ubiquitous due to its wealth of environmentally-friendly benefits, including reducing greenhouse gas emissions by up to 90%.

To reach net zero in 2050, global net human-caused emissions of carbon dioxide need to fall by about 45% from 2010 levels by 2030. In October 2021, more than a third of businesses across all industries reported taking at least one action to reduce emissions.

Contractor and developer Real has been appointed to construct 92 quality & affordable homes in the London Borough of Sutton Town Centre.

The new homes at Beech Tree Place will be delivered as part of the broader revitalisation of the Town Centre and will respond to Sutton residents’ desire to deliver sustainable, quality led projects which protect heritage & promote sustainability in a changing commercial environment. Real will dedicate its work to support the broader ambitions of Sutton council and residents, by working

sympathetically and proactively to ensure the successful delivery of these affordable homes.

Attention to sustainable energy will be at the heart of the project, including modern installations, like air source heat pumps to provide heating and hot water. The development will be gas free and follow exemplar design methodology.

Beech Tree Place residents will benefit from a new communal rear garden, an open green roof-top and internal communal spaces to socialise and meet.

Sutton Council, along with its construction partners have paid particular attention to the heritage of the neighbouring Grade II listed, St. Nicholas Church and have begun the much anticipated process of opening up the gyratory to a more welcoming and accessible public realm design.

Mark Unsworth, Regional Director of Real LSE, said: “We are pleased to be working with the London Borough of Sutton on this project to deliver modern, spacious & affordable housing for Sutton residents. We are proud to be supporting the borough’s

York Against Cancer are pleased to announce that Lodestone Projects have been appointed to construct the brandnew Leveson Centre, a support centre for people living with cancer, at the York Community Stadium, with work commencing this week.

Project Management company Turner & Townsend have been managing the contractor tender process which was sent out in the summer. Two companies were shortlisted with Lodestone Projects coming out on top after careful assessment. The tender criteria was based on Quality, time management & Cost which were all successfully met through Lodestone Projects detailed proposal.

James Gilyead, Director at Turner & Townsend commented; ‘‘Turner & Townsend are delighted to be working with York Against Cancer to help to produce an outstanding cancer support centre, we are proud to be involved in such a meaningful scheme that will see true benefit to its users. Having appointed Lodestone Projects as the principal contractor, we are confident that their experience, innovative thinking and attention to detail will bring exactly what York Against Cancer are looking for’.

Lodestone Projects experience of fitting-out similar sized units includes the University of Leeds Clothworkers Central, Skipton Building Society branches across the UK and Fibre Extrusion Technology CAT A & B refurbishment.

Josh Donnelly, Managing Director at Lodestone Projects says “I am very proud and appreciative that Lodestone Projects have

been trusted with the delivery of the new Leveson Centre.

York Against Cancer is an important and life changing organisation which is truly making a difference to people’s lives. This will be a game changer for the region, with amazing people providing world class support and care for those who need it. We are absolutely delighted to be part of a fantastic team delivering this much needed facility.

wider regeneration goals, particularly at a time when affordable housing is needed due to the cost of living crisis and increasing rental prices.”

Cllr David Bartolucci, Lead Member for Housing, London Borough of Sutton, said: “The London Borough of Sutton is committed to maintaining and improving its council estates, so we can continue providing quality homes for our existing residents and the broader community. We are therefore pleased to have selected Real LSE to deliver the Beech Tree Place scheme.

“Real LSE are vigilant to the present challenges in the construction industry and are engaging with residents and Sutton Council on how we ensure the resident co-design scheme is fulfilled to the highest standard.

“We look forward to working with them and Beech Tree Place residents, in order to deliver and provide 92 ‘exemplar’ homes for local people.”

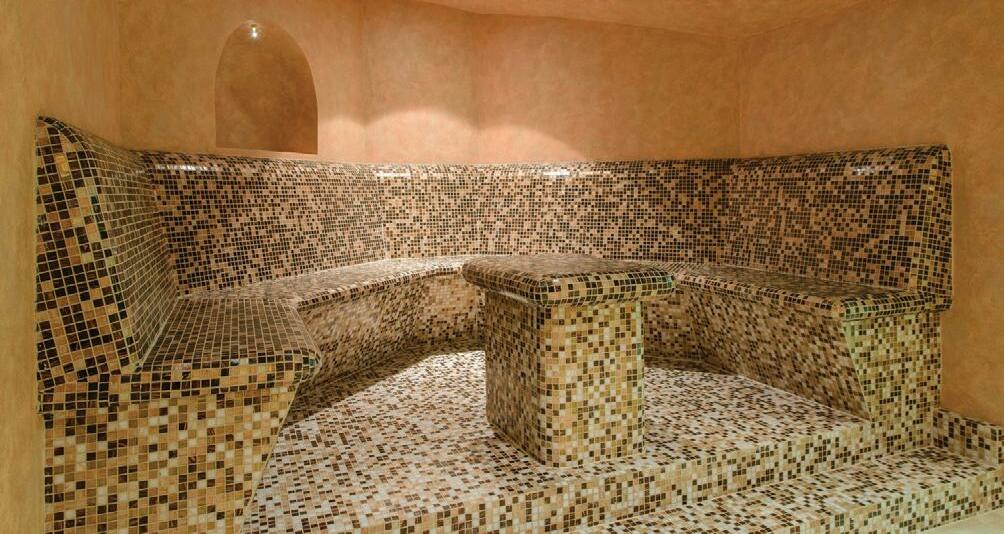

The Leveson Centre has been designed by Award Winning Leeds Architect and Interior Design firm, Fuse Studios. Fuse’s design concept fits the brief supplied by the charity which was ‘…to implement a design that can be a force for good. To create a space where anyone will feel at home a retreat, a sanctuary, an area to escape to where you can tackle one of life’s toughest challenges.’

CEO of York Against Cancer, Julie Russell, said; ‘With the contractors now on site, we are looking forward to having the development complete so we can welcome everyone into the new Centre, this really is a huge milestone for both the charity and the region, and we can’t wait to open the doors.”

If you would like to support York Against Cancer in the work they do to help cancer patients and their families across Yorkshire, you can do so by donating to them here: https://www.justgiving.com/ campaign/YorkAgainstCancer

Willmott Dixon Interiors has been appointed to deliver a new biomedical research and development facility in central Oxford.

The fit-out and refurbishment specialist contractor will redevelop two former retail warehouse assets on Botley Road into c.65,000 sq. ft of world-class laboratory and creative office space.

Known as Inventa, the redevelopment is being delivered on behalf of a joint venture between property developer, Mission Street, and BentallGreenOak, a global real estate investment management advisor, which acquired the property in 2021.

Willmott Dixon Interiors will reuse and extend the existing structure of the two warehouse buildings, adding a new internal floor and a colonnade to the north elevation.

The additional floorspace will enable the creation of a new reception area and a combination of sustainable new spaces for market-leading life science companies. They include enhanced common areas and meeting rooms, new collaboration and circulation spaces, breakout areas and café provision, as well as a new cycle centre and shower facilities.

The building fabric will also be substantially upgraded, including a new façade, while new mechanical and electrical services will also be installed.

Externally a cycle and pedestrian route and a newly landscaped car park will create a revitalised visitor experience, with landscaping at the rear of the building doubling as an area for flood mitigation.

Inventa is expected to be complete in summer 2023.

Morrison Data Services (MDS), part of M Group Services’ Energy Division, is proud to announce it has secured a contract extension with EDF. The relationship between MDS and EDF ensures the continued rollout of EDF’s smart meters across the UK.

This rollout is part of the government’s Smart Meter Implementation Programme (SIMP) which helps consumers in the UK manage their energy consumption leading to a more efficient service across the grid as dependency and demand increases.

The initial contract was first signed in 2015 and to date, MDS has installed hundreds of thousands of smart meters

for their client. The two-year extension will see these installations continue until the end of 2024 with the opportunity to extend the contract again.

David Dale, Director of Installation Services at MDS, said: “This contract extension, with one of M Group Services’ key strategic partners, is testament to our people’s hard work across the contract. The trust shown in MDS by EDF shows our reliability and dedication as a business.”

M Group Services’ Energy Division provides a range of services including, metering services, regulated data management, national meter reading, energy theft detection & resolution and smart metering support services.

A CGI of Inventa, a new biomedical research and development facility that is being created in central Oxford.

The latest market report from international property and construction consultancy Gleeds reveals that rising labour and materials prices continue to threaten growth in the construction sector. Over three quarters of contractors questioned said they had seen further increases to labour rates in the preceding quarter, and nearly 70% reported continuing volatility in materials prices.

The ongoing escalation of costs was cited as the biggest threat to the industry, with 77% of contractors believing that growth is suffering as a result and around a third of all respondents warning that recession will do further damage going into 2023. Issues around availability of labour also persist, with 60% of contractor respondents experiencing problems, however almost half of all of those quizzed were optimistic

that concerns around the availability of materials were beginning to settle.

Gleeds CEO Graham Harle said of the survey, “Our report reveals that spiralling costs of materials and labour show no signs of abating, although there is some hope that availability of both is stabilising compared to the previous quarter. It seems inevitable that the turbulent political backdrop will impact investor confidence, and the prospect of a recession has led to predictions of a decrease in tender opportunities going into Q4.

HM Revenue and Customs (HMRC) is urging contractors in a wide range of roles across the construction sector not to get caught out by unscrupulous promoters of tax avoidance schemes.

Tax avoidance is when people bend the rules of the tax system to try to pay less than they should. But those who join avoidance schemes then end up having to pay the tax due in the first place – as well as interest and potentially penalties. That is on top of the fees or margin they have already paid for joining the scheme.

HMRC wants to stop people being drawn into such schemes and also to help them leave tax avoidance schemes if they believe they might be caught up in one. HMRC is working with construction firms to give them the tools to educate the contractors who work for them on the risks of using tax avoidance schemes.

This is because each of us is responsible under UK law for paying the correct amount of tax.

This still applies if contractors have appointed someone else to deal with their tax affairs or have been given bad advice – the ultimate responsibility and risk rests with the individual.

HMRC is urging contractors, agency workers or those who work through an umbrella company to check how they are paid to make sure they’re not caught out. They can use the interactive risk checker to see whether their current contract could involve tax avoidance.

To find out how to spot the signs, report avoidance, or get help leaving or reporting a tax avoidance scheme, HMRC wants contractors to:

Recognise...tax avoidance. Learn how to spot the signs, understand how these schemes operate, and know the risks.

Understand...how umbrella companies work. If you work through an ‘umbrella company’ - here’s what you need to know about how they should operate.

The consultancy’s report also found that a massive 91% of respondents believe the government should be doing more to support retrofitting measures and energy performance, with 64% of noncontractors and 47% of contractors reporting that clients themselves are giving greater consideration to both on projects. Meanwhile, 82% and 69% respectively said that projects are also increasingly incorporating futureproofing measures such as flexibility for change of use or easy renewal of components.

Check...your pay and contract arrangements. Looking at your payslip is a useful way to check for signs that you may be involved in a tax avoidance scheme.

Get help...if you think you’re already in a tax avoidance scheme and don’t know how to get out.

For further information read Tax avoidance: getting out of an avoidance scheme.

HMRC publishes Spotlights about tax avoidance schemes on GOV.UK that warn people about what they should look out for. Spotlight 60 published in August 2022 specifically warns about noncompliant umbrella companies and what to look out for.

Productivity remains high, though and the teamwork we’ve seen on projects to combat these challenges has continued to increase, with over 80% of those we surveyed experiencing greater collaboration on schemes.

Local suppliers have been involved in two Linden Homes launch events for the forthcoming Langham Meadows location in Langham.

Vistry Group held an information day for prospective purchasers on Saturday 3 September at Langham Community Centre, with refreshments provided by Frinton Golf Club.

A second event, when the first homes were released for sale, was also held at the centre on Saturday 24 September, and also involved the golf club’s catering team.

Golf club catering manager James Oxley said: “It was nice to be involved in a community event.

“I live close to Langham and have a good relationship with those in the village.

“It is a lovely area, and we took our children to school here.

“We work at the community centre a lot to provide catering for events like this.

“We provided tea, coffee and fresh juices as well as homemade cakes and cookies.

We had also been looking forward to catering for the launch of the first homes for sale in phase one of Langham Meadows later in the month which was equally successful.

Vistry is building 20 new properties under the Linden Homes brand in phase one at Langham Meadows, including a choice of threebedroom houses which will be completed in time to meet the Help to Buy construction deadline at the end of December this year.

Welcome to our Editor’s Products of the Year, where you will find carefully selected companies, chosen for their product innovations and quality. Throughout the feature you will find information on these companies. Please also visit their websites for further information and enquiries.

At Door Controls Direct we are continually applying our expert knowledge, quality products, and exceptional value to provide product solutions to the FM and building industry to keep people safe and secure. We have been trading for 25 years but our history of supplying architectural ironmongery dates back over 100 years. Our recently published product catalogue makes the procurement of our door hardware even easier.

Providing our customers with access to trusted and reliable branded products and information, supported by guidance from our technical team of industry experts is the foundation which Door Controls Direct has built itself upon and to this day is our passion. Being able to engage with our customers directly allows us to offer a premium service and quality products at a competitive price.

Our company has gone from strength to strength, and we would especially like to thank you, our customers, for your continued loyalty and for allowing us to keep you at the heart of all our decisions.

For more information on our products and services, you can visit our website: https://doorcontrolsdirect.co.uk/ or contact our sales team on 01305 263300 sales@doorcontrolsdirect.co.uk

UK welfare manufacturer, Boss Cabins is delighted that its sustainable solarpowered Deep Green range of site welfare has been recognised by Construction UK Magazine in their round-up of the year’s best products.

Deep Green has had a phenomenal 2022 with the welfare cabins’ solar performance outstripping all expectations. With over 500 Deep Green units now in the field, extensive data gathered from the units’ on-board remote access telemetry system has demonstrated that almost all these units have functioned almost entirely without the generators running at all. With no generator usage, fuel consumption and costs for Deep Green users have plummeted. And more importantly, zero generator run-time means zero CO2 emissions at the point of use meaning these cabins can be a largescale contributor to helping construction companies and other welfare users achieving Net Zero targets on site.

As well as being proven in practice on worksites all over the country, the fuel cand carbon saving properties of the Deep Green range have been analysed and verified by independent industry assessors Carbon Footprint Ltd. Their in-use Energy Saving Assessment concluded using that a Deep Green welfare unit in place of a standard one

could save up to 3400 litres of fuel each year on operation and servicing and reduce CO2 emissions by 8.4 tonnes.

In addition, Deep Green was recognised by judges at this year’s Showman’s Show winning Boss Cabins a Highly Commended Award in the Green Suppliers and Innovations category.

As well as solar technology, Deep Green units incorporate a unique patented rain harvesting and grey water recycling system which sees sterilised rainwater used for hand-washing and then re-used to flush the toilets. They are also fitted with a patented Infinity generator that needs servicing 10x less than the industry standard. In addition, the telemetry system monitors water, waste and fuel levels remotely meaning service visits can be planned precisely when they are needed with no wasted trips. Together, these innovations significantly reduce the need for service visits and their associated environmental and financial costs.

Deep Green cabins are built from stainless steel with a guaranteed lifetime of 25 years and are 97.2% recyclable at end of life.

Boss Cabins’ Managing Director, James Kearsey, says: “We’ve had a fantastic response from the major players in the construction and infrastructure sectors. They recognise how our Deep Green 2030 range gives the welfare industry a product that truly reduces environmental impact while not sacrificing any of the performance you need or expect from a high-spec welfare cabin.

Even better, this success in removing carbon from the cabins’ operations can easily be monitored and reported for the purpose of ESG scoring, investor reports etc. using the SolarTrack remote telemetry system. Users get 24 hour remote access to transparent information showing exactly what their energy usage is and what source it derives from.

The Deep Green 2030 range includes mobile and static welfare units plus portable toilet solutions. For information contact Boss Cabins Sustainable Welfare Team 01778 300475, sales@bosscabins.co.uk, www.bosscabins.co.uk

and Remediation Tax Relief is one of the best kept secrets in the UK construction and building industries.

It is available to recover costs of carrying out remediation work prior to receiving planning permission to render the land useable for new developments.

Qualifying criteria are few. You must be a registered UK corporate entity and the owner of the land. You cannot claim if you own the land and caused the contamination. From this point most costs associated with the clean-up measures, disposal of waste and making good the finished projects form the basis for cost evaluation and submission of the claim.

Known contaminated land can be claimed for. Derelict land that

has remained unused from the earlier of 1st April 1998 or date of acquisition can also form the basis of a claim, especially if it has suffered tipping and illegal waste disposal over the years.

Since Land Remediation must

construction works begin, it is advised to consider remediation

All contributory costs should be identified and recorded. These are wide and include your own company costs of

contractors, suppliers, travel and subsistence costs, surveys, tests, disposal and replacement

Generally, brown field sites and land that has existing buildings will be contaminated, especially where older buildings

are suspected of containing asbestos in any form. Used land can contain old foundations, utility services, hydrocarbon and chemicals whatever. If remediation surveys discover radon gas emissions, Japanese Knotweed and any other invasive plant species and contaminants deposited through earlier occupier activities, these too can be included in remediation costs. Where buildings contain asbestos, costs of removal and either demolition or insitu encapsulation and sealing of the asbestos elements is a claimable cost.

The definition of what is contaminated land is peculiar to land remediation relief legislation and is broader than for planning purposes as in Environmental Protection Act 1990. It is beneficial to know land remediation relief is available before purchase of land. This reduces possible uncertainty and risk.

MCS Corporate urges its clients to consider all possible sites for development and planning. We can give early assurance of a likely claim and work with you to identify, prepare and submit claims as the remediation proceeds. Contact T: +44 (0)1926 512475 E: charlotte@mcs-corporate.com W: www.mcs-corporate.com

To qualify for Land Remediation Tax Relief your company must have incurred costs on cleaning up land or buildings considered to be in a contaminated state. The scope of costs allowed is generous.

You must be registered as a limited company in the UK and be the owner of the land or building at the time of the remediation work. In addition, the land or building must be owned either as a freehold or longer-term leasehold.

Common examples of qualifying contamination:

• Asbestos

• Ground and landfill gases

• Japanese Knotweed

• Sulphate contamination in soil and concrete

• Arsenic

• Removal of redundant utility services and concrete foundations

Qualifying costs can include surveys, excavations, soil and groundwater treatments, staff costs, materials and subcontractor costs. Claims can be made for categories of derelict land. This can be advised with relevance to time periods when land could be considered for derelict status.

Regardless of the industry you operate within, if you’ve acquired land or buildings in a contaminated or derelict state for intended commercial use, you could claim.

Astra Lumos is an exclusive and bespoke lighting and electrical solutions company. They have been installing high-end lighting designs integrated with control systems since 2014 and although they have been doing lighting design alongside this, until their rebrand, they haven’t advertised this fact. With their new name and branding they are making waves and their existing clients have really got behind them.

Do you know how lighting can affect colours, mood or even energy of a room? Have you thought about a bespoke lighting design for your next project or are you just assuming the architect or M&E company will take care of it? Are you tired of looking into your garden at night and seeing nothing but abyss?

Based in the Cotswolds but serving clients nationally, Astra Lumos offer bespoke lighting and electrical designs with the huge benefit of being able to install the designs. Historically Astra Lumos would be given a design which would have quite a few “flaws,” due to the lack of installation experience by the designer. David Ritchie (one of the directors at Astra Lumos) is now chief designer, having worked on-site since the age of 18. With nearly two decades of on the tools experience, Astra Lumos are confident their designs are able to overcome the “usual pitfalls” of a traditional lighting and electrical design.

Lighting can completely change the ambience of a room and affect all aspects of the space. From altering the colours of the soft furnishings, to changing the energy of the room, lighting is a hugely important aspect of interior and exterior design.

Light added to your garden is a great way to ‘extend’ the space from your home to the outside, creating an additional ‘room.’

As Astra Lumos put it, “The right lighting can illuminate your garden, adding a soft glow which brings to life an almost ethereal and magical space you can enjoy well into the night. From creating a safe path through the garden to highlighting textures and features, lighting can add both beauty and function to your outdoor space.”

• Design led installations – we have the capabilities to consult and advise on design, whilst also completing the installation. This means you will not be left with a design that can’t be installed, and we help to engineer designs that have installation in mind, whether this be sympathy to the architecture, or designing for install time or minimal damage.

• Consultants able to diagnose issues with installations by others – often we are called in to help clients where previous installers have failed.

• Research & Development – unlike other installers, we have an R&D department where we are able to bring custom designed solutions for unique problems.

Astra Lumos is Latin for star light, hence the name choice. Just as starlight beautifies the night sky, our stunning lighting solutions can really amplify the beauty of your garden and home.

With over 50 years of experience, ELA Container is one of the leading suppliers of high-quality and flexible room modules. The German family-owned company with over 1,200 employees and 20 locations worldwide has also become an important player in the UK since market entry in 2018.

The ELA UK office and production facility is located in Scunthorpe. Due to the well-established distribution network, the containers are quickly delivered to customers in all areas of the UK. A comprehensive stock of fully equipped containers and on-site assembly ensures fast and ready-to-occupancy delivery.

The ELA UK sales team on the stand at UK Construction Week 2022 in Birmingham.

ELA Container is represented in Scunthorpe with a twostorey office building.

With a wide product range of multifunctional rooms, ELA containers create optimal conditions. Whether as an office, changing room, recreation room, accommodation, storage container, workshop or sanitary area. Thanks to the modular design and stackability of the units, any project can be built on a small footprint. For example, a large container building suitable for 400 individuals was installed in Central London with over 80 containers across four floors.

At this year’s UK Construction Week in Birmingham, the UK team was represented with its own exhibition stand and as event sponsor. It was shown that there is a massive change in the building industry increasingly towards large and open spaces. ELA creates those spaces where people like to stay, improving the overall wellbeing.

More information at www.ela-container.co.uk

GEZE UK has demonstrated its commitment to supporting customers with technical advice and product guidance with the recent appointment of Ian Prince, who joins the renowned manufacturer of door and window control systems as Area Sales Manager for supply and fit of automatic doors covering the East Midlands and East of England.

Ian will be focusing on building strong business relationships with customers supporting them by analysing their requirements and proposing technical solutions from the company’s extensive range of automatic operators.

With a strong track record of B2B sales and over 20 years’ experience in account management and business development across 5 different industries Ian brings with him a wealth of knowledge to assist customers make the right choices for their projects.

Ian has a BA (Hons) Degree in Marketing, is ADSA accredited and has won the Yellow Pages award for performance several times.

Said Ian ‘I am delighted to join GEZE UK, they are an industry-leading company that offer a complete service of design, supply and fit of automatic doors.

Andy Iredale, National Sales Manager for Automatic Doors and Window Technology added ‘It’s great to have Ian join the team; he has vast experience across several sectors and will be a great asset to the company. He will be an important part of the company’s continued growth.’

For more information about GEZE UK’s comprehensive range of automatic and manual door and window control products visit www.geze.co.uk

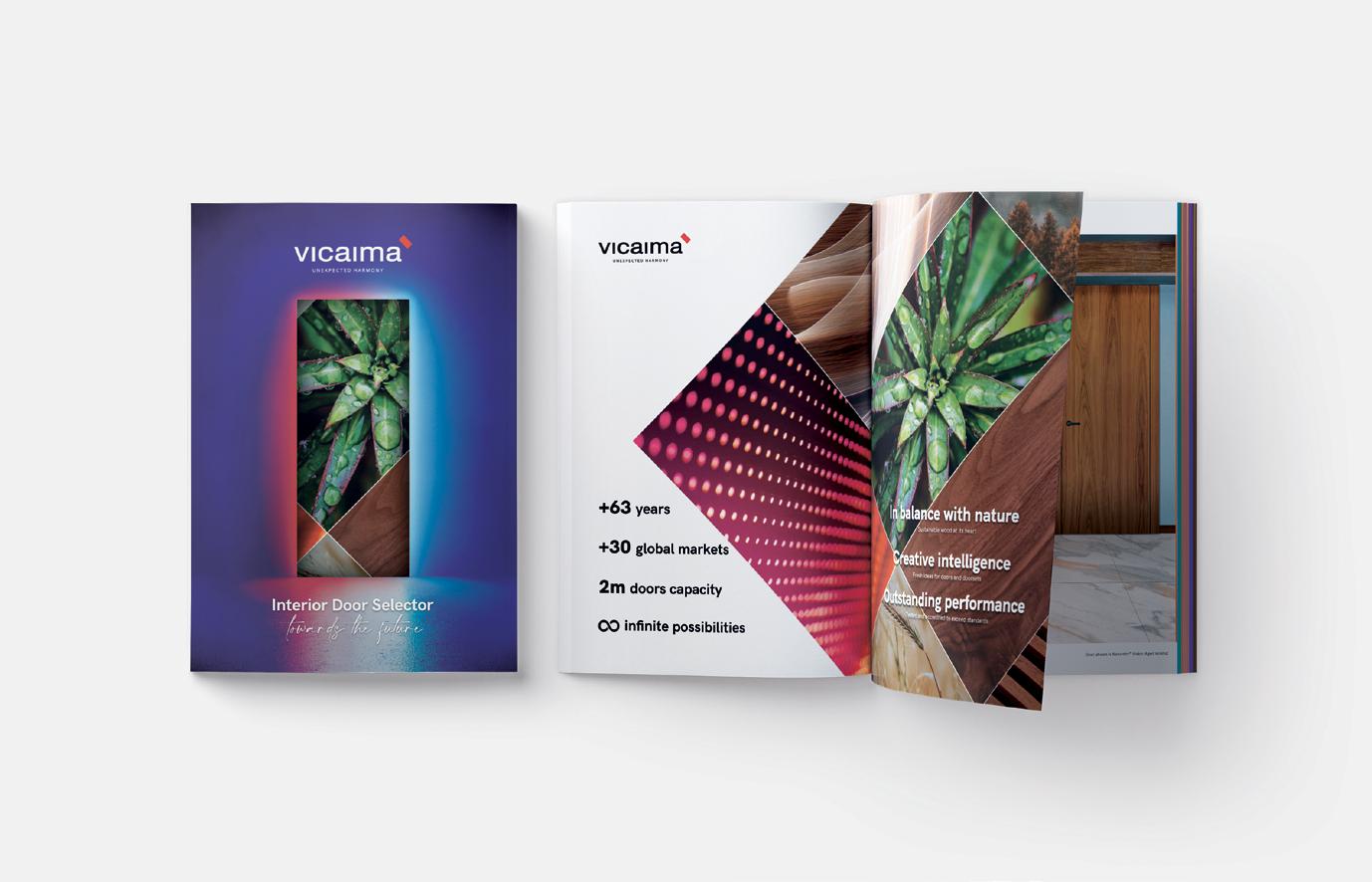

As the construction industry gets ready to welcome a new year with a fresh set of challenges and opportunities, 2023 heralds the dawn of changing trends and possibilities in the world of interior timber doors and door sets. Ever one to embrace innovation and seen as a true manufacturing trailblazer, Vicaima bring design, performance and quality solutions to the interiors arena. With this in mind, the launch their latest incarnation of the perennially popular Interior Door Selector (IDS) has been much anticipated.

In recognition of changing specifier preferences, Vicaima is largely moving away from conventional paper-based brochures, towards digital catalogues.

This is not only environmentally friendly, but also enables a more dynamic user experience. New products and useful information can be updated instantly and at the same time enabling links to other resources such as technical data, so that specifiers can be fully equipped to make an informed decision about their next project.

Bigger than ever! This latest brochure contains over 150 pages to inspire professionals who are looking to transform modern living space. From economy options which are ideal for affordable homes in the current cost of living crises, to ground-braking quality designs that create an instant wow factor and set the standard for twenty twenties living!

Although best known for fresh ideas in veneer, foil, laminates and paint lacquered finishes, Vicaima are also opening a window to the future with their new Infinity Range, where digital and precision imagery can re-imagine stone, metal and other surface features, in a way that hitherto was the stuff of dreams!

Of course, innovative doors from Vicaima are not confined to aesthetics alone. With fire safety, security, acoustics, and thermal efficiency very much in the minds of specifiers and regulators. Vicaima Door kit and set solutions build on a framework of rigorous testing and superior constructional cores. Among recent additions to what is already a comprehensive performance range, comes VCP 60 from Vicaima. This in-house developed core, which is thirdparty accredited under the BM TRADA Q-Mark scheme; provides a one-hour FD60S rated door, but with a considerable cost saving over conventional products, thereby improving safety while keeping budgets on track.

What to look out for in the latest Vicaima IDS

There are a great many new products to be found in this latest issue, among which look out for:

• Naturdor Vision – A new range where real wood veneers are taken to new heights, with tones such as Rich Mocha and Fresh Bamboo

• New Economy Veneer Range – Cost effective options such as Red Oak and Walnut Crown EV give that luxury look for less

• Dekordor 3D - Two new colour tones are added to this highly tactile and durable finish range, with Cloud White and Pale Oak

• Visual Sensations - A touch of Scotland comes to this popular foil collection, with the introduction of Highland.

• Vicaima Wardrobes – Flexible configurations to match Vicaima’ s many door finish options.

• Infinity – Endless Possibilities to be explored. Pushing the boundaries of interior design

To download a copy of the Vicaima Interior Door Selector or for further inspiration, Visit www.vicaima.com, contact info@vicaima.com, or Tel: +44 (0) 1793 532333

In the search for the most cost-effective materials in the building, construction, and infrastructure sectors, the fire, smoke, and toxicity (FST) properties of materials are often considered too late. Here, Eric Moussiaux, VP technology at Exel Composites, explains why it’s important to understand the standards, select the right tests, and choose composites that deliver the best FST performance.

Whether it’s windows, doors or curtainwall profiles, interior or exterior cladding, or even railway cable trays, the fire, smoke and toxicity properties of materials should be considered early in the journey of any new project. Fail to do this and by the time you come to consider the FST properties, you’ll already be on the backfoot, potentially having to overspend to acquire a material that meets all your needs. In extreme cases, not considering the FST properties of a material early on could result in businesses having to discard or offload materials they’ve already purchased or make costly adjustments to tooling investments.

Part of the problem stems from the historic discrepancy in fire standards across Europe, which weren’t unified until about two decades ago. Whether it was Germany’s Musterbauordnung (national model building code), France’s safety commissions, Spain’s onus on local authorities, or the UK’s devolved enforcement, there was little harmony in fire safety. Some of these rules were prescriptive — requiring structures to meet specific fire tests — others were

based on performance testing, where the regulation only set out how a building or structure is expected to perform, not how it should be designed. Ultimately, it was clear that fragmentation was creating trade barriers, and hampering business.

In 2000, the European Union introduced the Euroclass system, or EN135011. This system classifies the reaction to fire of construction and building materials, based on three main factors: combustibility, smoke production and the production of flaming droplets or particles. Combustibility achieves a classification from A1-F with A1 being the least combustible; smoke production ranges from S1 to S3, with S1 producing the least smoke emissions; and flaming droplet production ranges from D0 to D2, with D0 demonstrating no dripping. So, for example a material classified as B-s2,d0 would be one with limited combustibility, that produces smoke at a quantity and speed that is of an average intensity, and produces no flaming droplets during combustion.

However, the use of defined tests can be a limiting factor. In a recent project, Exel Composites worked with a customer in Germany to develop a composite cabletray for use on embankments at the side of German railroad tracks. Hot summers can cause the desiccated grass to catch fire from sparks generated by the brakes of a passing train. The resulting bush fire can expose the underside of the elevated cable trays to fire, so it’s essential that the tray can continue to protect the cables inside it.

There is a danger that choosing a simple, well-known test in such specifications, can be less relevant to the real-world application and add unnecessary difficulty. One such test is the UL 94 vertical test in which a small sample — 25 mm wide by 100 mm in length — is lit at the bottom with a 20 mm flame. Picture it like holding a matchstick from the top and lighting it from the bottom; the flame will quickly reach and burn your fingers.

In this scenario, the specified bushfire test is much more appropriate. Here, a normalized quantity of hay is lit under the tray. The tray must then withstand the fire until it stops, without causing structural damage or allowing the internal temperature to rise high enough to damage the cables inside. The difference is that one material composition might fail the UL 94 test dramatically, while surviving the bushfire test with flying colors.

As well as selecting appropriate FST tests, specifying engineers must ensure that the composites they choose are not hazardous to health.

Many composites contain flame retardant additives, which reduce or delay the combustion process using substances such as aluminum trihydrate (ATH), which give off far less toxic smoke when burned compared to traditional halogenated additives.

However, the associated filler material leaves less room for reinforcing fibers, which can affect structural performance. The answer is to work with a composites partner that understands the complex manufacturing and pultrusion techniques to produce composites that deliver both structural and FST performance.

The takeaway here for anyone working in the building, construction, or infrastructure sector is to consider FST requirements early, understand the standards, select the right tests, and choose composites that deliver consistent, high-quality results.

To find out more about composites for building, construction, and infrastructure applications, visit exelcomposites.com

Eric Moussiaux

Eric Moussiaux

Established in 1979 by MD Derek Ward, the Envirograf® brand quickly evolved to become a leading force in passive fire products. Having developed fire retardant and fire stopping products for numerous scenarios, the company’s reputation as an innovator and developer is widely recognised with many products unique to Envorgraf®.

From Intumescent paints that provide over 60 minutes protection on timber, steel and plasterboard, to intumescent seals and electrical fire protection, the vast range of products enjoys widespread international demand.

Mr Ward says that, when it comes to passive fire protection, every risk must be considered to ensure that loss of life and property are kept to a minimum. While many people are aware of the importance of fire barriers in preventing or delaying the spread of fire, they do not always consider the implications when breaching the fire barrier, for example, to allow electrical wires or other services to pass through a wall, floor or ceiling. That is why a range of Envirograf® intumescent products has been designed, to safeguard the integrity of fire barriers by swelling to seal such gaps should the worst happen and fire break out.

One of Envirograf’s strengths is the ability to adapt to the constantly evolving needs of their customers. Following a number of enquiries, they recently introduced of a new variant to the versatile and popular FIROBLOK® range of fire sleeves; a new version designed to be inserted into hollow plasterboard or lath and plaster ceilings and walls, that sits flush with the surface.

Another common enquiry relates to the use of metal back boxes in hollow plasterboard walls. In recent months the company has received an increasing number of calls asking how they can maintain fire separation capabilities when installing metal back boxes in plasterboard walls. Fortunately, Envirograf® have an extensive range of tried and tested expanding intumescent gaskets and linings that are ideal for a wide range of standard electrical boxes. They are lightweight, flexible and can be trimmed to size to fit most socket boxes.

Sister company, EnviroEcoWall Panels has been established to manufacture one of Mr Ward’s latest innovations, a pre-engineered, insulated, load bearing panel system designed to form a fireproof building envelope. This unique system combines structure and insulation into one prefabricated, thermally efficient component. Not only are EnviroEcoWall Panels protected from fire by Envirograf’s intumescent coatings, the buildings are also designed to cope with flooding as they are constructed on a unique metal sub-frame that can carry the structure from 150mm to any height off the ground and can be raised to a new level at a later date in 300mm intervals.

Additionally, the system reduces build time, minimises waste on site and doesn’t require the significant amount of water consumption associated with more traditional construction methods.

Using the same high-spec system, the company recently introduced a range of smaller garden office buildings as a unique and cost-effective way to gain extra work or leisure space at home. In addition to standard models, the company offers a bespoke design service.

For more details you can call 01304 842555 or email sales@envirograf.com

Because pipes, cables, ventilation ducts and other services sometimes need to pass through a hollow plasterboard or lath & plaster ceiling we have introduced new variants of our successful FIROBLOK® range of fire protection sleeves.

Designed specifically for plasterboard or lath & plaster ceilings, these new products have a metal encasement under the reinforced foiled cloth which also serves as a hinge, enabling the sleeve to open up for fitting around existing services. Once, fitted, the adhesive tag is peeled off to seal the two halves together.

Fixing tabs are used to secure the sleeve with screws or toggle bolts as appropriate.

Following the growth in popularity of using metal back boxes in hollow plasterboard walls, we fire tested various combinations of metal boxes, extenders and gaskets in a hollow plasterboard partition wall to ensure that fire integrity of the wall was maintained. Some boxes were mounted flush with the face of the plasterboard and others were set back.

Kirk Smith of Allegion UK discusses fire door neglect and how to spot the potential faults that could be compromising your fire safety procedures.

Purpose built to compartmentalise fire and smoke, fire doors are recognised as a critical element of passive fire protection and exist in practically every building where we work, sleep and live. Such is their importance; they are acknowledged by several professional bodies and are a legal requirement in non-domestic premises and houses in multiple occupation (HMOs).

Day to day we use them without a thought, yet fire doors consist of much more than a simple piece of furniture. A fire door is a complete door assembly, comprising of a doorset fit with a door frame, leaf, essential hardware, edge seals and integral panels. In the event of a fire, not one of these elements can fail, and so to meet the necessary standards, a fire doorset must pass one or more of a series of standardised tests, confirming its certification and FD ratings.

So why can fire doors experience failure in critical moments? Between neglect, misspecification and a misunderstanding

of their significance, 75% of fire doors fail to meet the required standard, as has been revealed by the Fire Door Inspection Scheme (FDIS). To combat this, a conscious effort is needed, with more attention given to fire doors and their components. Once installed, simple checks can help ensure a fire door is safe to fulfil its role, but where should you start when spotting a door’s potential faults?

Upon operation, a fire door calls upon its many elements - all of which must function in tandem to ensure the door is effective in a fire situation. Generally, there are eight core areas to consider when conducting regular risk assessments and spotting potential faults. Kirk Smith of Allegion UK explains more:

“When opening or closing a door, our hands instinctively reach out for the handle. Should it be absent, or even loose, it could affect whether a door can be opened in an emergency. Because of this, a handle should always remain installed on a fire door and its screws tight. Bolt-through fixings pass right

through the door and the lock or latch case and will strengthen the installation of handles by preventing the screws from moving or becoming loose. Check whether the handle operates smoothly and returns freely to a horizontal position after use, too. Finally, if the fire door in question is on an escape route, it must open in the direction of travel, without the use of a key. Keep it simple, but effective.”

“Hinges are a necessary pivot action fixing that provides the movement to a door. A standard height fire door requires the installation of three hinges minimum, with intumescent pads fitted. A door standing over 2.2 metres will require four hinges. This will prevent the door from warping in a fire due to its weight, and so should you see a fire door only hung on two hinges, it must be changed. Again, screws must be fitted securely, and the hinges themselves must be free of metal fragments and oil leakage as this could indicate signs of wear. When it comes to certification, check for CE or BS EN 1935 marks. Hinges may be hidden somewhat, but they can never be overlooked.”

“To form an effective barrier against fire, a fire door must close fully. Locks and latches help to keep doors held shut and so must be fixed firmly and working correctly. Upon inspection, it’s important to check whether the latch engages fully into the strike plate and whether the door can be held firmly in place without rattling. Failure to do so may indicate faulty or damaged hardware. Like hinges, check for metal dust deposits - typically located on the latch bolt or strike plate - as this could also show wear or damage.”

“Door closers facilitate the operation of a fire door and must be UKCA and CE marked and tested to EN 1154. When opened, a fire door should fully engage into the door frame every time, shutting tight by use of its own selfclosing device. When conducting checks, the trick is to open a door to 5° or 75mm, and upon letting it go, it should close and engage the latch successfully. Failing to do so could indicate the door closer has been incorrectly installed or damaged and, therefore, needs adjustments or replacing. Adjustments can be made to the closing power and speed of door closers, and in busy environments such as schools and hospitals, a prolonged closing action is useful, giving people extra time to pass through the doorway.”

“Buildings with high footfall may benefit from approved, electromagnetic hold-open devices tested to BS EN 1155, which permit open fire doors that automatically release to close in the event of a fire. Naturally, these systems are more complex and regular maintenance is mandatory, so it’s vital to spot any potential faults, such as the door straining against its self-closing device upon operation.

an electromagnetic hold-open device not release the door when a fire alarm is activated, a problem has occurred and must be resolved immediately.”

“Exit devices are designed to provide safe and effective escape through a doorway with minimum effort. All panic and emergency exit devices must be functioning correctly, with fixings on the operating device, bolts and strikes tightly fit. Emergency exit devices and panic exit devices should be tested to BS EN 179 and BS EN 1125 respectively, as well as UKCA and CE marked. Aside from their mechanical operation, it’s critical to keep emergency exits clear and without obstruction - assisting a quick escape when called upon.”

“When rated FD30 or FD60, a fire door is certified to resist smoke and fire for 30 or 60 minutes, respectively. For this to remain true, a doorset must be fitted with intumescent seals which, in the event of a fire, expand significantly to close the gap between the door and its frame. Intumescent seals should track continuously around the frame or door leaf and must remain in good condition, intact and undamaged.

If you can see excessive gaps between the side of the door and the frame, a fire door may be ineffective. A maximum gap of 3mm is recommended around all fire doors and can be assessed with simple gap tester tools.

“Although not a mechanical element of a fire door, signage plays an important role in fire door safety and must be considered when checking for faults. Providing quick and key information in an emergency, ‘Fire Door Keep Shut’ signage must be fitted to both sides of a fire door. Additionally, ‘Automatic Fire Door Keep Clear’ signs must appear on fire doors with hold open devices and ‘Fire Door Keep Locked’ signs must be fitted to doors without self-closing devices – which can commonly be found in storerooms and cupboards.”

A complete and functional fire door is a prerequisite for fire safety and regular maintenance periods are required to ensure they retain their standard while in operation. The first step is to understand the various components of a fire doorset and the potential faults to look out for when evaluating its condition. Should any doubt linger, it’s crucial to seek out professional advice immediately. Checks can save lives but where action is an obligation, knowing what to look out for is only half of the responsibility.

“Should

Sales Director sees 300% increase in fuel security enquiries following the red diesel ban.

MHM Group, the UK-wide distributor of leading hireto-hire solar and diesel equipment, has launched a range of high security fuel storage and management systems in line with a 300% increase in security enquiries this year.

Concern around the security of fuel storage tanks has risen dramatically following the red diesel ban in April 2022, which means that the white fuel now found in storage containers can be stolen and decantated directly into cars.

In addition, the rising fuel cost crisis affecting the UK has led to a proportion of drivers turning to theft, with forecourts reporting a 39% increase in stolen fuel since January.

To that end, the MHM Group’s multipurpose, fuel storage containers that can be paired with generators or heaters, have been launched as a new product offering in response to the crisis.

To combat fuel theft, the tanks consist of a two-part locking system which can also be monitored virtually with the latest telematics solution so that customers can track their fuel level remotely. Users can set phone or email alerts when the tank is being used.

MHM Sales Director Brad Ireland, who has nearly a decade of experience in the storage container industry said, “We believe this increase in queries is due to the recent

rise in fuel costs, as well as the red diesel ban in April. Red dye allowed law enforcement to identify and quickly prosecute illegal usage, but with the construction, demolition and other industries making the change to white diesel, there is no way of differentiating or spotting the stolen diesel.

“We are delighted to launch our latest product range of fuel storage tanks to the hireto-hire industry.

“To meaningfully address the fuel theft crisis, we have included a range of products in our secure fuel storage fleet, including the SteelCube tanks that can be paired with generators or heaters.

“Our ready-to-rent tanks have the option of an all-new tracking solution which sets us apart from others in the market.

“We can provide our customers with innovative and integrated solutions that monitor their fuel safely, as well as increase business efficiencies by producing less waste.”

The MHM Group has grown from a small family business into an industry-leading enterprise with a total of nine depots across the UK and Ireland.

Brad added, “The team have worked hard to ensure that our specialist tanks are robust and reliable and readily available across the UK, so our customers have peace of mind that they are receiving the best product possible.

We look forward to seeing where this initiative will take us and will continue to develop products that meet the needs of our clients.”

Red dye allowed law enforcement to identify and quickly prosecute illegal usage, but with the construction, demolition and other industries making the change to white diesel, there is no way of differentiating or spotting the stolen diesel.

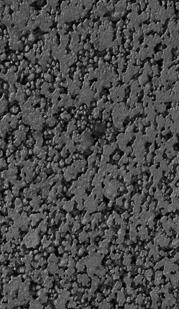

Construction is one of many contributors to particulate pollution. A result of operating diesel-powered machinery, demolition and construction, research suggests that building works are responsible for 18% of the UK’s PM10 emissions, and this has been found to be a staggering 30% in London (Impact on Urban Health). To protect the neighbourhoods surrounding construction sites, operators must comply with strict environmental permits and choose the right air quality monitor that both satisfies their permit requirements, but also works flexibly and in line with construction activities.

This is where the Monitoring Certification Scheme (MCERTS) becomes an important factor. MCERTS certifies the data quality coming from monitoring equipment of emissions into air, land, and water. Certified pollution monitors are a non-negotiable for regulatory and safety purposes, like EarthSense’s Zephyr® air quality monitor, which has been approved as compliant with MCERTS performance standards for indicative monitoring of particulate matter (PM2.5 and PM10).

Taking this into account, EarthSense has taken an alternative approach to monitoring dust emissions as its new construction suite covers all angles of air quality monitoring. The suite starts with the Zephyr® monitor, offering MCERTS data quality for simultaneous PM2.5 and PM10 monitoring to meet local permit requirements. With live measurements of NO, NO2, O3, SO2, CO, H2S, CO2, TVOC (key gaseous pollutants) together with wind speed and direction, the Zephyr® can help provide a detailed understanding of air quality across sites, delivering the data needed to protect the local community and on-site staff from exposure to harmful pollutants.

To ensure all dust monitoring locations are covered, including those where monitoring dust emissions may be challenging, the suite offers a level of flexibility due to the various power options for the Zephyr®. Choose from using a solar panel, connect to mains power, or run for up to three months on an external battery source – no longer do monitoring locations become compromised due to a lack of power. The flexibility also provides a range of options

as sites transition through different stages of development. Walk-away confidence is another important consideration during equipment installation, and EarthSense’s Companion App provides an intuitive way to check the status of instruments. Using a phone or tablet, professionals can now connect to Zephyr® monitors via Bluetooth and check functional statuses, making it quick and easy to check operation, even if units are out of reach.

Once Zephyr® networks are up and running, air quality data is automatically transmitted to EarthSense’s data application, MyAir®. Within the app, configurable air pollution alerts can be set up and sent via email or SMS, enabling onsite managers to know where and when to act immediately.

EarthSense’s air quality service is providing the basis for safer practices across the world. It might be for the simplicity of connecting to a Zephyr® network, or for its MCERTS certified data quality, EarthSense have trusted solutions for construction, consultants, local authorities and more.

Find out more by signing up to EarthSense’s webinar: www. earthsense.co.uk/mcerts-webinar.

Construction professionals can now quickly and easily access the web app and use dust data for regulatory reasons, be it for traceability to evidence compliance with local policies, responding to local complaints, impact assessments or reporting compliance with dust management plans.

So, the first thing I do when I wake up is get some caffeine into the system to get my brain working and then check my phone to see if there have been any late-night messages come in. This mainly comes from working in a rail environment where lots happens at night so it’s indoctrinated in me to see if there is anything urgent that needs attending as soon as I wake up, this could be lost shifts, an HSE incident or simply to see the nights’ progress reports.

I head to work early so I can get through my emails before people start coming in as typically my day is meeting-heavy. The main day-to-day tasks of my role, however, is to serve our team and be there to do whatever they need in terms of support, direction, or guidance.

I spend a lot of time talking to everyone about what’s happening in their world, where we are doing things right, where we could be doing things better, and then working on improving them.

I like to move quickly on everything I do and being good at communicating the pertinent information to the relevant people quickly is key to being successful in this role as it keeps momentum.

The best part about my role is having the opportunity to build a team the way I believe it should be built; on honesty, integrity, and a strong delivery ethic. If you say you’re going to do something then do it! I love developing people and giving them autonomy, enabling them to grow in a safe environment and the real reward comes from seeing people succeed in their roles and be totally self-sufficient.

When I was young, I actually started out wanting to be an architect, I loved drawing and creating things, taking my ideas and imagination and putting them on paper.

As I grew older, I realised I wanted more than just to create the idea I wanted to build it too. So, I found interest in civil and structural engineering. I completed my Masters in this field and went into a graduate scheme with a Rail company (Tube Lines), a very successful JV between Amey and Bechtel.

The graduate scheme taught me so much about the rail construction industry, and just how vast it was in terms of different roles, disciplines, systems, and history. You can have a whole career in rail and not cover everything.

I developed my engineering skill set with London Underground and quickly realised how my real fulfilment came from managing people, fixing problems and making decisions, and owning them too, whether they are right or wrong.

Once I knew this is what made me happy, I moved around different disciplines such as signalling, communications, and now mechanical and electrical to test myself in different arenas and still see if I can achieve the same outcomes.

Have you always aspired to become a Director in this industry?

I suppose the short answer to this question is yes. The reason is that I love autonomy in a job, I like to be the person where the buck stops. I enjoy the responsibility and the challenge that comes from making big decisions based on lots of complexity and quite often a lot of moving parts. That’s the challenge and is what makes my job fun.

We are currently working on several projects for London Underground through various clients, bringing the knowledge of our vastly experienced rail team to a more Commercial Environment. One of the particular projects we are working on is Paddington Square.

This is a four-level extension to the Bakerloo Line including all mechanical and electrical fit-out and HV Transformer Room installation.

However, our focus for the future is within the HS2 space. We believe that as a company we have a considerable offering to this major infrastructure organisation, we want to bring our well-established delivery reputation to the private sector and apply that drive to the rail environment spearheaded by our experienced rail delivery team.

There are lots of opportunities out there but we are being selective about the projects we are targeting as we want to be considerate of project suitability to ensure we are the right choice for the client.

Why is it important to ensure that there are more equal opportunities in the rail and engineering industry provided for all?

This importance stems from the benefits that diversity provides. Rail and construction has typically been a maledominated industry for a long time. It is getting better but slowly and we need to move this on quicker to ensure the industry survives.

best part about

is having the opportunity to build a team the way I believe it should be built; on honesty, integrity, and a strong delivery ethic. If you say you’re going to do something then do it! I love developing people and giving them autonomy, enabling them to grow in a safe environment and the real reward comes from seeing people succeed in their roles and be totally selfsufficient.

The perception of rail and construction is half of the problem, I don’t believe that young students at school understand just how vast the industry is and you can pretty much do every profession out there within the environment. We need to provide that education of available opportunity back to the next generation so they can harvest that excitement and grow a want for a career in rail.

I have three daughters and I desperately want to see them succeed in a career in rail because there are so many routes and

paths, they can take to a career that makes them happy. However, I recognise there isn’t an abundance of women in rail so how do we change this? I feel (and I may be wrong here) there is a misconception that there are no opportunities for young women in the industry, I think the problem is the opposite, I think there are lots of companies looking to offer these opportunities but the number of young women who want to come into the industry is low.

So, the important question for me is how do we convince these young women to want a career in rail?

What one piece of advice would you give to anyone out there that wants to get into this industry?

The advice I would give is to not be put off by any perception of rail or construction but to make your own judgement by speaking to different people in different organisations and at all levels to understand how broad the spectrum of career opportunities there are available to everyone.

Or even better try a job in rail, you may just find your calling...

- Stacy Benson, Director at Lonsdale RailThe

my role

Sustainability has become one of the construction sector’s main concerns.

Architects and designers are increasingly looking for eco-efficient materials and solutions that ensure quality and comfort, without harming the environment. Cork - which combines sustainability and performance – meets these requirements since it offers tremendous potential for construction, urban rehabilitation and large-scale public works.

An increasing proportion of the world’s population lives in cities. Big or small, old or new, cities have become our natural environment. According to the United Nations, around 55% of the world's population currently live in urban areas, and this percentage is estimated to increase to 68% over the coming decades*.

Cork - as a natural renewable raw material that reduces greenhouse gases - is increasingly used in the field of sustainable and eco-efficient construction, primarily due to its thermal insulation properties and capacity to control acoustics and vibrations. Studies indicate that for every ton of cork produced, the cork oak forest can sequester up to 73 tons of CO2, thereby helping reduce the Global Warming Potential**.

But nature is just the starting point. In order to protect the future we also need to rethink the way that we look at waste. Amorim Cork Composites is helping build a circular future, by transforming materials that were previously considered to be waste into new business opportunities.

The combination of cork granules with surplus production from other industries

has made it possible to create a diversified portfolio of acoustic insulation and vibration control solutions, thereby enhancing the natural characteristics of this raw material.

Cork-based acoustic blanket in the new premises of the eMedia group

A diversified portfolio of sound insulation and vibration control solutions is based on a mixture of cork granules and various polymers. The cork-based material, Acousticork by Amorim, ensures longlasting performance with stable material properties, throughout the product's lifetime.

These were the principal reasons for choosing the cork-based Acousticork underscreed, for eMedia Investments’ new headquarters. The solution ensures impact noise insulation, while offering maximum comfort to users.

Located in the city of Johannesburg, South Africa, the building houses the offices and studios of the various radio and television channels of the media group - which owns the eNCA news channel.

Applied during the construction process in the floor between the structural slab and the screed, an underscreed significantly reduces the propagation of impact noise through the building’s structural elements

© eMedia Investments, all rights reserved © Asia Alliance International,

and improves its sound insulation – an essential characteristic for a television studio. In addition to limiting heat loss, it also improves the building’s overall thermal performance, offering journalists and other employees the best working conditions and comfort.

Designed to fill the spaces between the concrete slabs, Amorim Expandacork expansion joints absorb expansions and contractions caused by temperature variations in different construction materials. These joint-filling products enable the structures to move without causing damage. They guarantee longterm sustainability and high technical performance for buildings and large public works.

Taoyuan International Airport in Taipei City, Taiwan is being expanded through the construction of a new passenger terminal, which is expected to open to the public in 2026.

Amorim Expandacork was chosen for the expansion joints of Terminal 3’s buildings and other infrastructures. It is a corkbased solution for expansion joints that guarantees excellent performance and low maintenance.

Use of Amorim Expandacork expansion joints makes a positive contribution to the contraction and expansion of the construction elements, preventing cracks and reducing the preventive maintenance ratio.

For further information visit: www.amorimcorkcomposites.com

*Source: https://unhabitat.org/sites/ default/files/2020/10/wcr_2020_ report.pdf

**Source: https://www.apcor.pt/wpcontent/uploads/2015/10/Brochura_ Ambiente__EN.pdf

Kier has been appointed by NHS Ayrshire & Arran to deliver Foxgrove, a mental health facility at Ayrshire Central Hospital in Irvine. It will be the first medium secure adolescent inpatient service for young people in Scotland and has been procured through The Health Facilities Scotland Framework.

Foxgrove will be an inpatient unit for children aged 12-18 years who have

complex difficulties and need a high level of care. This means that young people in the facility will be cared for nearer to home and will receive appropriate care, treatment, therapies, security and on-going education.

The new unit will comprise of 12 en-suite bedrooms, a dining area, recreational areas including a gym and sports barn, external relaxation and horticultural areas, therapy and education space, as well as staff areas

including accommodation. Externally, there are numerous areas for patient therapies. The building is a timber frame with rendered insulation panels and facing brick forming the envelope with a Kalzip roof.

Phil McDowell, regional director at Kier Construction North & Scotland said: “This is such an important project, and the first of its kind in Scotland. We’re proud to be working with NHS Ayrshire & Arran to deliver a key

A major scheme to replace the A533 Expressway bridge has reached a key milestone after the new bridge was lifted into position.

The 67m steel structure was built off-site at a compound close to the side of the M56 and was moved into place over the weekend.

Using a self-propelled modular transporter (SPMT), the bridge was slowly transported down the embankment, along the carriageway of the motorway and into position.

The M56 between junctions 11 and 12 was closed over the weekend to allow for the work to be carried out.

Stewart Jones, National Highways’ Regional Delivery Director, said: “Installing a bridge of this size in a single weekend was hugely ambitious. Our team worked around the clock to make sure it was a success, and I’m pleased to say the motorway was reopened for traffic ahead of schedule, late on Sunday night. I’d like to thank everyone who planned ahead for their journeys over the weekend. Reduced traffic volumes on the M56 meant delays were significantly lower than forecast.”

The existing A533 Expressway bridge was also closed while the bridge was installed.

Chris Buckley, AmeySRM Project Manager, said: “It was an absolute priority for us to minimise disruption to the local

community over the weekend. Our team ensured a safe crossing point for any pedestrians or cyclists who were passing through. We’re extremely grateful for local support over the last 10 months.

“To celebrate this important milestone, we teamed up with SRM’s Strong Foundations grant to donate £25,000 to charities and community groups. We were honoured to have some of these join us at our recent ‘topping out’ ceremony.”

Phoenix Community Archery Club in Runcorn was awarded £3,000 to build a new platform providing all-weather access for wheelchair users.

First Knutsford Scout Group also received £3,000 to help build their new scout hut and Huyton Asphalt received £3,000 on behalf of the Bobby Colleran Trust.

National Highways made use of the weekend closures to also carry out additional work – reducing the need for more closures in the future.

As well as removing narrow lanes from the M56, they also installed three new manholes and a 4m deep drain. They also carried out structural surveys, installed infrastructure for new power and phone cables, and completed general maintenance work.

The next project milestone will be removing the old bridge which is expected to happen spring 2023.

strand of the Scottish Government’s Mental Health Strategy (2017-2027). During the construction of the building, we’ll also be focusing on leaving a lasting legacy in the local community, working with local supply chain partners and providing employment and apprenticeship opportunities.”

Caroline Cameron, Director for North Ayrshire Health and Social Care Partnership, said: “This is fantastic news and is a real milestone in this national project which is being taken forward in Ayrshire and will benefit young people around the country.

“Currently, there are no facilities in Scotland to care for this most challenging and vulnerable group of patients. This means that children are referred to secure adolescent mental health facilities in England, or in some cases, the child may be cared for in an adult inpatient setting. This places significant additional pressure and stress on the child, as well as their families.

Foxgrove will without doubt improve the outcomes for young people who are seriously unwell and pose a risk to themselves. Scottish adolescents with complex mental health needs will be able to access the health care, education and support services they need in an appropriate, modern environment bespoke to their needs and aspirations. It is great news for young people throughout Scotland, as well as their families and carers.

Mental Wellbeing Minister Kevin Stewart said: “I am pleased that the Scottish Government has been able to provide funding of over £16 million to allow this national facility to be built for young people with complex needs and mental health conditions.

“This will help ensure children and teenagers are being given care in the most appropriate setting for their needs. I look forward to seeing how the build progresses and develops.”

Building work on 33 units at the iconic Botany Bay site in Chorley will deliver 405,000 sq ft of industrial and commercial space.

Construction work on a new £26m industrial and commercial park at the historic 21-acre Botany Bay site in Chorley will start this month.

When complete, the scheme will deliver 33 units for light industrial and commercial use across 405,000 sq ft and a drive-thru food outlet.

FI Real Estate Management (FIREM) received planning permission for the development from Chorley Borough Council in July and the development will be the largest ever built by its construction arm, FI Construction.

FIREM manages assets totalling more than £1bn and founder and managing director, Tim Knowles said the Botany Bay development was one of the most important in the company’s 40-year history.

Tim said: “We want to create the highest quality industrial and commercial space for local businesses and those from further afield looking to make Lancashire their home.

“Botany Bay is an iconic location and the development will be built in two phases. The construction costs for phase one will be £26m and the fit out costs will add an estimated 10 per cent to the total bill. We’ve already significantly grown our FI Construction arm to deliver it. We’re also fully committed to provided further training and employment opportunities to local people as well as seeking new supply chain partners from across Lancashire to ensure FIREM’s investment benefits the local economy.”

The company employs 300 people across the Group and plans to add another 100 as part of its growth strategy.

Once complete, the new development will provide units specifically designed for light industrial use. Unit sizes will range from 1,000 sq ft reaching 164,000 sq ft.

FIREM’s Botany Bay development forms part of its growing pipeline of new build projects across the UK, totalling 5m sq ft over the next four years. It sits within FIREM’s already extensive UK portfolio of commercial property which now exceeds 10m sq ft.

Work has begun on a substantial housing development in Carterton in Oxfordshire that will see 200 homes provided for people to live in the area.

Platform Housing Group have begun work at the site at Milestone Road which has been provided by West Oxfordshire District Council and will be developed by United Living. It represents the group’s largest site in the area to date and the continuation of their strong start of their strategic partnership with Homes England.

Over the next four years, the new homes will be made available through Platform’s different affordable options. 105 of the homes will be available to rent, 12 as rent to buy and 83 through the increasingly popular shared ownership scheme. This allows people to purchase a share of their home and then pay a rent on the rest

with the option to increase that share up to 100%.

Amongst those visiting the site was MP for Witney and West Oxford Robert Courts who said, “It was a pleasure to visit the site in Carterton which will provide much needed affordable homes for local people. It was encouraging to see work getting underway and useful to learn more about how this development will benefit local people and the wider area in Carterton. I look forward to following progress closely.”

Group Chief Executive of Platform Elizabeth Froude said, “It’s been fantastic to see the site today where we’ll be able to provide much needed affordable housing for the area. We look forward to offering people real opportunities to live in the area and even buy a home that is quality and

Outpost Management announced that its latest build to rent development, Enclave: Croydon, has reached its maximum height. Standing at 158m, the development is Europe’s tallest modular building and now becomes the tallest building in Croydon, and one of the tallest buildings in London.

Due to open in late 2023, Enclave: Croydon will feature 817 rental homes across a 50-storey tower in the heart of Croydon.

Employing the latest modular construction techniques, the development, being delivered by developer and contractor Tide Construction and its volumetric modular company Vision Modular Systems, is set to complete with an estimated construction time of only 30 months - using the Vision Modular Systems construction methodology typically saves 40% - 50% on construction programmes compared to traditional methods.

affordable. With 200 different homes, we are delighted to be offering such a large site for our partners at West Oxfordshire District Council who have been fully committed to these options to help with the growth of the area. I’d also like to thank our developers United Living and Homes England for their help in delivering this development.”

Carl Rylett Cabinet Member for Planning and Sustainable Development at West Oxfordshire District Council said, “It’s good to see this site come forward for development; affordable housing is greatly needed in West Oxfordshire. We identified the site through the Council’s Local Plan, and granted planning permission in 2020. We are fully committed as a council to bringing forward sites for affordable housing development, and this development will make a real difference to the community.”

Neil Farmery, Construction Director, United Living New Homes, said: “We are delighted to have started building work at Milestone Road. Working collaboratively with Platform Housing Group, we look forward to delivering high-quality, affordable new homes that will provide a welcome housing boost to the local community.”

Celebrating the topping out onsite, Troy Tomasik, Outpost Management founder and CEO, said: “We’re excited to have reached this important construction milestone on Europe’s tallest modular building. The speed and precision of its construction is testament to the hard-work and dedication of our construction and development teams. Enclave: Croydon will offer one of the highest amenity provisions in the U.K., equipping residents to be more productive, healthy, and social, and we can’t wait to welcome them to their new homes next year.”