THE HARD WORK BEHIND “GOING WITH THE FLOW”

Toro’s full line of all-electric and hybrid mowers and vehicles were engineered to help reduce engine exhaust emissions, noise pollution and be more efficient, easy to use and easy to maintain. All without compromising power, precision, comfort or reliability. And with fuel prices soaring, Toro will continue to invest in golf’s future in a sustainable way.

@smithturf

#Reelmaster #Greensmaster #Workman #ToroLynx #ToroInfinity

TChristopher C. Sykes

he saying goes that ‘The days are long, but the years are short.’ This rings more true the older I get as time only continues to speed up. Most of my regrets are simply not spending more time with family and friends as those opportunities are precious.

One such opportunity is coming up in a matter of weeks with the 57th Annual Tennessee Turfgrass Conference and Tradeshow. I am very much looking forward to spending a few days with some of my closest friends and colleagues in Murfreesboro on January 9th – 11th.

The Education and Tradeshow Committees have put together another outstanding program for the 2023 Show. The educational programming is some of the best you will find as there is something for everyone. The new trade show format provides the ideal platform for networking and getting caught up on the latest and greatest from our vendor partners. We will have an opportunity to celebrate some of our peers at the Awards Luncheon and have some fun at the TTA Top Golf Championship. It is going to truly be a special event.

Most of all is simply spending time with my brothers and sisters from across the green industry.

Looking forward to seeing you all in a few weeks!

Chris Sykes

TTA President

Harrisburg , Arkansas

Michael Crawford

On behalf of all the East Tennessee GCSA Board Members, THANK YOU to all the host courses and their staff for allowing us to have our monthly meetings this past year!

We had great attendance at each meeting. I want to give a BIG shout out to the men and women who spend countless hours providing perfect playing conditions on a daily basis – every course we played was in fantastic shape. I also want to thank our special guest speakers that graciously gave their time amidst their already busy schedules, sharing their experiences and offering up valuable insight in our ever-changing industry.

I want to extend our heartfelt appreciation to Chuck James and the staff at The Virginian Golf Club for being our host for the annual Research and Scholarship Tournament this past fall. We had beautiful weather, and it was a treat for us all to be able to play this course. Lastly, I want to thank our many vendor partners for their donations to help make this event a success. What an honor it is to be able to give back to the University of Tennessee Turf Program through this tournament.

Lastly, please mark your calendar and save the date for the upcoming Tennessee Turfgrass Conference January 9-11 in Murfreesboro. This is a great opportunity to network and gain valuable industry-specific information to further your success in turf. I’m looking forward to seeing you there!

Michael Crawford ETGCSA President

TVSFMA has established an “Excellence in Sports Turf” award to recognize the efforts of sports field managers in the region who maintain high quality athletic field surfaces. Our next recipient of this award is

Head Baseball Coach of Dickson County High School Dickson, TN

Tell us about yourself and the turfgrass you manage.

Shelby Rye Field – 419 bermudagrass overseeded with rye. I also mow 10 properties and raise fescue hay on a 180-acre farm.

What led you to turfgrass management?

I grew up on a farm and coach baseball. I have no choice but to learn what to do to maintain the field.

What is most rewarding about the position?

The finished product with smiling faces from those playing on the field. What is most challenging about the position?

Limited resources, money, and time.

What is your favorite “tool” in your turf maintenance toolbox?

My mind. I am constantly looking for ways to improve with the limited resources I have.

What tool would you most like to add to your turf maintenance toolbox?

A reel mower. Why do you do it?

I was born into a farming family. I enjoy working with the different dirt and grasses. It’s in my blood.

Congratulations to Coach Parker, the staff, and players of Dickson County High School!

Check us out at www.tvstma.org for more information on the award, membership in our organization, and Meeting dates and locations.

Randall

Sales & Marketing

615-708-5219 randall@csfsod.com

mkyates@live.com

JANUARY 9 – 11, 2023 EMBASSY SUITES • MURFREESBORO, TN

Since 1965, the Tennessee Turfgrass Association has held strong to its core mission: To promote the turfgrass industry through education, scholarship and research. We invite you to join us at this year’s conference and trade show at the Embassy Suites Hotel in Murfreesboro. This year’s conference features an excellent education program and an expanded tradeshow floor, plus our annual awards recognitions with keynote speaker Danny Bader! This is a conference you will not want to miss!

Tennessee Turfgrass Association’s annual Conference and Trade Show has historically been a favorite event for members. A worldclass education lineup, along with certifications, networking, and award recognition rounds out full lineup of events and workshops that are essential for turfgrass professionals.

We were proud to return to an in-person event in January 2022, and we anticipate a great turnout once again for our 2023 gathering. Be sure to register early and make plans to join us!

Please complete the registration form on page 16 and return it along with a check for all fees payable to The Tennessee Turfgrass Association. Additional copies of the form may be made as needed. Members are encouraged to email a copy of the registration form to The TTA and then mail the original with a check. Please keep a copy of the completed registration form for your confirmation. Everyone is encouraged to register early.

The TTA has reserved a block of rooms at The Embassy Suites Hotel in Murfreesboro, TN until December 3. After December 3, reservations will be subject to availability and regular rates. The room rate is $169. Please call 615-890-4464 and reference the Tennessee Turfgrass Association room block to get the group rate or use the group code TRF.

Our knowledge of the industry and collabora�on of premier turf experts gives us an edge. We are commi�ed to providing our customers with the total experience from selec�on to the final product.

The Embassy Suites Hotel in Murfreesboro is located at 1200 Conference Center Boulevard, Murfreesboro, TN 37129. From I-24 East or West take exit 76 Medical Center Parkway. Head north on Medical Center Parkway, hotel is located on the right. It is located 29 miles (35 minutes) from the Nashville airport (BNA). You may reach the hotel by calling 615-890-4464.

Applications for pesticide points have been submitted to Tennessee, Kentucky, Georgia, South Carolina, Alabama and Mississippi.

This program has been submitted for GCSAA continuing education.

For more information, call The Association office at 615-928-7001, email info@ttaonline.org

MONDAY, JANUARY 9th, 2023

8:00 AM – 5:00 PM

Embassy Suites • 1200 Conference Center Blvd Murfreesboro, TN 37129

You must pre-register for this session. The last day to register will be on December 10.

Learn all you need for the Category 3 exam required to be a certified applicator in TN. At the end of the session, all individuals have the opportunity to take the exam.

The registration fees for this session are $175. These fees include instruction, materials, lunch and the exam.

Please complete the registration form on page 16 and return it along with a check for all fees payable to The Tennessee Turfgrass Association. You can also pay online. You must pre-register for this session no later than December 10.

For more information, call The Association office at 615-928-7001, email info@ttaonline.org

Don’t miss your opportunity to exhibit your products and services at the trade show. Complete the form on page 18 and return to TTA!

Park and

JANUARY 9 – 11, 2023 • EMBASSY SUITES •

TUESDAY, JANUARY 10, 2023

TIME Turfgrass Deep Dives 7:00

MONDAY, JANUARY 9, 2023

Welcome & Opening Remarks

The Mission of TTA Chris Sykes, TTA President

The Vital Nature of Vision…Always Commit to Better Days Ahead Danny Bader

Training for the Tennessee Department of Agriculture Pesticide Certification Exam

Dr. Darrell Hensley University of Tennessee 8:10 –

Learn all you need for the Category 3 and Category 7 Exams required to be a certified application in TN

7:30 AM Prayer and Fellowship Scott Lehman, In His Grip Golf Ministries 8:00 –8:15 AM 2022 Rounds for Research Update Paul Carter, CGCS, Bear Trace at Harrison Bay 8:15 –10:15 AM Shade Management for Sports Fields, Golf Courses, & Lawns Drs. John Sorochan and John Stier, Univ. of Tennessee 10:15 –10:30 AM BREAK 10:30 AM –12:30

What’s New in Pest Management? Drs. Jim Brosnan and Brandon Horvath, Univ. of Tennessee 12:30 –4:30 PM Lunch and Fun on the Trade Show Floor 6:00 –9:00 PM Top Golf Event Transportation Provided

WEDNESDAY, JANUARY 11, 2023

Supply Chain Roundtable

Austin Lanzerone, Barenburg

Bob McLean as contact

Dr. Jeff Marvin, PBI Gordon

Jonathan Huff, Nouryon

Jim Moon, Harrell’s

Boyd Montgomery

Jeff Wyatt as contact

Take the Exam to Become a Certified Applications in TN

Dr. Darrell Hensley University of TN

8:00 –8:45 AM Course Renovations: Lessons Learned Gil Hanse Will Misenheimer Clayton Peele Lucas Sykes Sand Selection for Sports Turf Adam Thoms, PhD Iowa State University Equipment Managers Workshop If the turf is the canvas, the mower is the paintbrush. Learn how to properly configure mowers to optimize turfgrass quality and reduce pest invasion Irrigation Technology Workshop TBD Adam Porteneir, Nashville SC Eric Holland, Precision Turf 10:30 –10:45 AM BREAK 10:45 –11:45 AM The Road to Winged Foot Steve Rabideau Winged Foot Branding Your Facility Jeff Mondor Aerflo 11:45 AM –12:00 PM TGCSA Update TVSFMA Update 12:00 PM Adjourn

Please complete the registration

form and return it along with a check for all fees payable to The Tennessee Turfgrass Association. Additional copies of the form may be made as needed. Members are encouraged to email a copy of the registration form to The TT A and then mail the original with a check. Please keep a copy of the completed registration form for your confirmation.

*Registrants from the same facility are eligible for discounted full conference registration fees if 2 individuals are registered at the full conference price. **You must choose which day will be attended in advance.

Company Name

Representative to Contact:

Mailing Address

City/State/Zip

Phone Email

January 9 -11, 2023

Embassy Suites Hotel Murfreesboro, TN

Submission of this registration form to the Tennessee Turfgrass Association constitutes your commitment to serve as an exhibi tor and your agreement to pay exhibitor fee.

urfgrass producers from all over the world descend on Nashville, TN when TPI hosts its 2023 International Education Conference next February 20 – 22, 2023. Each year, TPI brings together sod and seed producers, equipment manufacturers, suppliers, educators, and others for education, networking, and seeing the latest advancements in turfgrass production. “We’re excited to bring our conference to the Gaylord Opryland Resort and Convention Center in Nashville next year” says TPI’s Executive Director Dr. Casey Reynolds. TPI’s 2023 conference will include Monday tours and optional activities around Nashville, a singer-songwriter showcase Monday for conference attendees, one and a half days of education, and exhibit hall time with vendors. “We’ve got a great education program lined up and always enjoy seeing old friend and meeting new ones. We invite anyone with an interest in turfgrass production to join us in Nashville next February.”

You can find more information on the 2023 TPI International Education Conference, including information on how to register, at www.TurfgrassSod.org/Events.

9:00 am –4:00 pm

6:00 pm –7:00 pm

7:00 pm –8:00 pm

8:00 pm –11:00 pm

Monday, February 20, 2023

Optional Activities

Women in Turf Reception Sponsored by Turf Producers Association, Barenbrug, and Brouwer Kesmac

President’s Reception

The Lawn Institute Fundraiser: Songwriters Showcase Sponsored by Magnum

Tuesday, February 21, 2023

9:00 am –10:00 am

10:10 am –11:00 am

Opening Keynote –How To Keep Your Top Talent From Becoming Someone Else’s – Lisa Ryan

Marketing Session Clutch Marketing

11:10 am –12:00 pm GPS on the Farm Jing Zhang, PhD and Jerome Maleski, PhD

12:00 am –1:30 pm

1:45 pm –2:35 pm

2:45 pm –3:45 pm

4:00 pm –5:00 pm

5:30 pm –9:00 pm

7:30 am –8:30 am

Annual Business Meeting and Lunch TPI Board Members

Sod Checkoff Discussion Casey Reynolds , PhD

Your Mental Health Matters: Managing Stress in Turbulent Times Nabil El-Ghoroury, PhD

New TPI Board Member Show & Tell Eric Hjort, Tater Farms and Adam Russell, MVP Genetics

Sponsor Showcase Reception

Wednesday, February 22, 2023

Inspirational Prayer Message Brett Boesch

7:30 am –9:00 am Sponsor Showcase

9:00 am –10:00 am

10:10 am –11:00 am

11:10 am –12:00 pm

Business Succession Planning Lance Woodberry

TPI Member Panel Discussion on Labor Randy Jasperson, Jasperson Sod Farm and Gordon Millar, Ren Hen Turf Farm

TPI Innovation Series and Closing Remarks Sarah Nolte, Blue Grass Enterprises, Inc., Scott DeBuck, New Lawn Sod Farm, Inc., and Graham Simmons, Woerner Farms

Join TPI at the Gaylord Opryland Resort & Convention Center in Nashville, Tennessee, on February 20 – 22, 2023, for the International Education Conference! !e conference education is packed with great sessions to help you grow your business, including the two featured here. !e following two pages share more Conference highlights and the Conference Schedule. Watch for even more exciting highlights to come!

The raging war for talent combined with a shrinking candidate pool makes is critical for organizational leaders to figure out how to keep their top employees from leaving. Creating a workplace culture that works means implementing new ideas and effective ways of engaging with team members. With an engaged workforce, employees work harder, have fewer safety incidents, and are more loyal to and profitable for their employer. During this Opening Keynote presentation by Lisa Ryan, you will explore a six-step process that gives you the tools you need and can use immediately. You will learn from the content, share with each other, and discuss the best practices to create a workplace culture that attracts and retains the very top employees while increasing profitability and productivity, and reducing downtime.

A dynamic, engaging speaker, Lisa Ryan is President and Founder of Grategy®, a Cleveland-based firm specializing in employee engagement, retention, and recognition using gratitude strategies (Grategies) for personal and professional development. Lisa has more than 20 years of experience in marketing, training, and sales. She has worked in a variety of industries, including manufacturing, healthcare, and executive recruiting.

Lisa’s work experience and research in employee engagement and cultural transformation give her a unique perspective for retaining top talent. An active member of The National Speakers Association, Lisa has been featured in Speaker Magazine as an expert advisor, writes articles for several newsletters and online publications, and speaks regularly for several colleges and universities.

The past two and a half years have seen tremendous and unpredictable changes. Between the pandemic, the fragility of the supply chain, quickly rising inflation, extreme weather, and more, people are getting more and more stressed. This session, presented by Nabil El-Ghoroury, PhD, CAE, will provide you with evidence-based stress management strategies to help you cope with these challenges and more. The session will start with an overview of how stress can affect both your mind and body. You will learn numerous self-care and wellness strategies that can help you manage your stress. You will learn the types of symptoms that might indicate the need for formal assistance from licensed professionals. The goal of this session is to arm you with techniques to help you manage your stress during turbulent times.

Nabil El-Ghoroury, PhD, CAE, is a licensed psychologist and principal at Executive Therapy & Consulting, where he conducts telehealth psychotherapy to leaders and executives in over 30 states and speaks to associations and businesses. His topics of expertise include stress management and self-care for the CEO, transforming work culture, and health disparities in autism. He is bilingual (English/Spanish) and has spoken on five continents. He earned his PhD in clinical psychology from Binghamton University and is licensed in Ohio and Virginia.

By Madison Johnson, FWF Masters student,

Dr. Andrea Ludwig, Associate Professor, Department of Biosystems Engineering and Soil Science, and Dr.

Sharon Jean-Philippe

, Professor, Forestry, Wildlife and Fisheries Department, The University of Tennessee

This article was originally published in Tennessee GreenTimes, Winter 2023. It is reprinted with the authors’ permission.

Riparian buffers, or riparian forests, are unique ecosystems that act as transitional parts of the landscape occurring between land and water (Figure 1) and that are typically bordered with a mixture of woody (Figure 2) and herbaceous vegetation (Figure 3). These riparian areas provide their buffer as a first line of defense in mitigating against anthropogenic impacts resulting from residential, commercial and/or agricultural activities (Figure 4). A healthy riparian forest provides essential ecosystem services to both the aquatic and terrestrial communities around them, such as erosion prevention, pollution reduction, and increased habitat biodiversity (Figure 5).

Multiple issues confound efforts to successfully establish healthy riparian buffers in urban areas in Tennessee and nationwide, ranging from lack of public education to challenges in finding landowners willing to install riparian features and habitat. These challenges are made more difficult by increased development, harmful residential and agricultural management practices, and spread of invasive plant species (Figure 6). In response to these challenges, Tennessee’s Community Riparian Restoration Program (CRRP) is funded by the Tennessee Division of Forestry and operated through the University of Tennessee Institute of Agriculture. This partnership serves as a multidisciplinary initiative that is focused on driving community involvement in riparian restoration through participation in applied research efforts.

The CRRP team’s aim is to foster a sense of stewardship for riparian forests and waterways among Tennesseans through four main objectives:

1) Community Education

2) Community Involvement in Restoration

3) Development and Dissemination of Watershed Materials

4) Research and Analysis of Watershed and Forest Health

Each of these objectives is essential for providing the resources needed to facilitate riparian restoration projects across Tennessee. Currently, the CRRP team are centering efforts in ten counties in East Tennessee, but the program will be expanding into Middle and West Tennessee during the next few years. Understanding each objective helps to detail the scope of these efforts.

Although we may not consciously think about their purpose and function, streams, and waterways contribute a valuable role to sustaining the health and resilience of our communities. Whether you own a home next to a creek or small tributary stream, take a walk on a greenway, or enjoy outdoor recreation activities such as kayaking & fishing, the quality of the riparian forests in your regional environment is something that has profound daily impacts on our lives. Unfortunately, many people may not recognize what a riparian buffer is or what a healthy riparian buffer looks like (Figure 7). The public may not be aware of the many pressures that challenge riparian buffer health. In addition, it is often daunting for the public to identify what resources are available to help interested stakeholders to improve and repair their degraded riparian buffer habitats. These problems can be especially difficult navigate for landowners trying to manage streamside properties. Landowners often want to care for their stream yet may not know where or how to get started.

Through Community Education outreach and programming, the CRRP addresses these issues by developing educational workshops for landowners, schools, neighborhoods, as well as anyone who wants to learn how to care for riparian forests in their area. These hands-on, interactive sessions are focused on identifying signs of an unhealthy stream and riparian forest, invasive plant identification and removal (Figure 8), and resources and demonstrations of Best Practices for bank re-vegetation (Figure 9). Our goal with this objective is to empower individuals by providing the knowledge they will need to take small steps towards healthier waterways in their neighborhoods.

Planting trees is a great way to improve the health and sustainability of our cities and neighborhoods. Trees provide ecosystem services that contribute to improved human and biological system health, and that sustain community well-being with enhanced experiences. In riparian systems, planting trees for biodiversity, tree and shrub regeneration, and bank stabilization provides farreaching beneficial effects. We will be partnering with community groups and public citizens on projects that will target sections of streams in Tennessee that are prioritized for restoration. Prioritization will be based upon a variety of factors associated with watershed quality and community demographics.

Figure 1. An example of healthy riparian habitat as the stream enters bordering woods. Figure 2. A seedling sycamore (Platanus occidentalis) establishes its roots to stabilize the moist soil next to a riparian waterway. Figure 3. Native herbaceous perennials can be encouraged or restored in impacted riparian habitats to increase biodiversity and enhance community partner experience with their landscape. Figure 4. Undergraduate student volunteer Jessie Loewen takes notes along a stretch of urban/waterway intersection where the stream has become contained within a channel. Figure 5. An American green tree frog (Hyla cinerea) “hides” in plain sight along an east TN stream.

Figure 6. Undergraduate student volunteer Katherine Ballard works to cut and remove invasive plant materials from an impacted riparian habitat. Figure 7. A native Lobelia cardinalis adds a pop of color to a sun-dappled riparian shoreline. Figure 8. Undergraduate student volunteer Jamie Pretorius prepares to flag native and invasive plant species along a section of riparian steam. Figure 9. Lobelia siphilitica, another native lobelia species.

For example, high priority areas will include watersheds that display characteristics of systems contributing to lower downstream water quality. Features in this category often include high impervious cover and heavily managed, vegetated areas like agricultural fields and suburban lawns. Other impacted watersheds have low forest cover or highly erodible soils. Other restoration priority areas will address habitats within low-income urban, suburban, and rural community areas that are often challenged by limited green space and reduced forest cover.

Our goal is to empower community members to take ownership of their waterways and forests, and to become stewards of their riparian forests long after these trees are planted. To help meet that goal, the CRRP will facilitate communication and planning with local watershed organizations, stormwater departments, landowners, and volunteer groups, and provide planting plans, and help coordinate events.

This state-wide program is providing ready access to new and existing public resources that are related to riparian forest health. At our website riparian.utk.edu, we are creating a public database and interactive map that will showcase common problems impacting riparian forests in different watersheds in Tennessee. Information about current and future restoration and monitoring efforts will be available. In coming months, our leadership team (Figure 10) will also be creating tutorials and guides for riparian forest management packed with information on native plant selection and identification of invasive species. We are also excited to share progress updates and educational posts, as well as network with community members and organizations through Instagram & Facebook social media.

To accomplish this objective, our team will initiate projects that will be designed to help identify the functional role that vegetation contributes to stream health, identify specific problems facing riparian forests in Tennessee, and track progression of mitigation in impacted systems following restoration activities. Success depends upon long-term documentation of benefits resulting from the methods that are deployed to support peer-reviewed research. For example, our team is actively assessing vegetation composition and stream temperature data on 45 impacted sites located across the most developed counties in East Tennessee (Figure 11). Most of these sites are privately owned, and partnerships will allow helpful insights into management practices available to private landowners. We will also be able to document the prevalence of invasive species and inadequate buffer widths that are occurring across these sites. The data we get will be used to inform future efforts and design modifications.

Community will always be our greatest resource in our efforts to restore and maintain the biodiversity and habitat around our waterways. Our mission for riparian restoration is to cultivate the knowledge and skills that individuals need to protect riparian forests in their neighborhoods. We are excited to be a partner in initiatives that we are forming between the CRRP and diverse groups of interested people across Tennessee who all are working toward a common goal.

This work and its impact on Tennessee’s ecological habitats and the state’s riparian systems would not be possible without the help of our community partners, local and state leaders, and volunteers. We appreciate the support and expertise shared through our partnership with the Tennessee Division of Forestry, and Tennessee Stormwater Association, and the Knox County Stormwater Department cooperators. We would like to particularly credit the hard work and help of our UT undergraduate student volunteers: Katherine Ballard, Jessie Loewen, Jamie Pretorius; and Sam Neary, our undergraduate research assistant, who were all vital members of our project team.

José Javier Vargas Almodóvar

Research Associate II Turf & Ornamental Weed Science

The University of Tennessee 2431 Joe Johnson Drive

• 252 Ellington Plant Sci. Bldg. Knoxville, TN 37996 (865) 974-7379 • jvargas@utk.edu tnturfgrassweeds.org • @UTweedwhisperer

Jim Brosnan, Ph.D.

Associate Professor, Turfgrass Weed Science

The University of Tennessee 2431 Joe Johnson Drive

• 252 Ellington Plant Sci. Bldg. Knoxville, TN 37996-4561 (865) 974-8603 • jbrosnan@utk.edu tnturfgrassweeds.org • @UTturfweeds

Frank Hale, Ph.D. Professor, Entomology and Plant Pathology

The University of Tennessee 5201 Marchant Drive • Nashville, TN 37211-5201 (615) 832-6802 • fahale@utk.edu ag.tennessee.edu/spp

Tom Samples, Ph.D. Professor, Turfgrass Extension

The University of Tennessee 2431 Joe Johnson Drive

• 252 Ellington Plant Sci. Bldg. Knoxville, TN 37996-4561 (865) 974-2595 • tsamples@utk.edu turf.utk.edu • @tnturfman

John Stier, Ph.D.

Associate Dean, The University of Tennessee 2621 Morgan Circle • 126 Morgan Hall Knoxville, TN 37996-4561 (865) 974-7493 • jstier1@utk.edu turf.utk.edu • @Drjohnstier

Greg Breeden

Extension Specialist, The University of Tennessee 2431 Center Drive • 252 Ellington Plant Sci. Bldg. Knoxville, TN 37996-4561 (865) 974-7208 • gbreeden@utk.edu tnturfgrassweeds.org • @gbreeden1

Kyley Dickson, Ph.D.

Associate Director, Center for Athletic Field Safety Turfgrass Management & Physiology (865) 974-6730 • kdickso1@utk.edu @DicksonTurf

Brandon Horvath, Ph.D.

Associate Professor, Turfgrass Science The University of Tennessee 252 Ellington Plant Sci. Bldg. • 2431 Joe Johnson Drive Knoxville, TN 37996 (865) 974-2975 • bhorvath@utk.edu turf.utk.edu • @UTturfpath

John Sorochan, Ph.D.

Professor, Turfgrass Science The University of Tennessee 2431 Joe Johnson Drive • 363 Ellington Plant Sci. Bldg. Knoxville, TN 37996-4561 (865) 974-7324 • sorochan@utk.edu turf.utk.edu • @sorochan

Alan Windham, Ph.D.

Professor, Entomology and Plant Pathology The University of Tennessee 5201 Marchant Drive • Nashville, TN 37211-5201 (615) 832-6802 • https://ag.tennessee.edu/spp/ @UTPlantDoc

By Kim Brown, UT Extension

TheTurf Circle has had a long history at the West Tennessee AgResearch and Education Center (WTREC). The demonstration site dates back to before the 1980s. However, the circle has had multiple locations throughout its history. It found its way to its current site in approximately 1991 after the completion of the current WTREC building. Through the years, multiple people have managed the circle and it has become a major part of the UT Gardens in Jackson.

In March of 2022, discussion of a total renovation started, and plans were developed to renovate the turf circle. The focus of this renovation was to bring in the major sod growers in West TN to showcase improved varieties and grasses that are available to homeowners in the area. This location is to give a place for homeowners to come and see varieties that they can choose from to pick the grass that they would like most in their yard.

April 27, 2022, the renovation of the turf circle started by removing the grasses that were previously there. Herbicides were applied to terminate the remaining grasses. The area was later tilled and any grasses that emerged were also treated to help prepare the area for new grasses. In May of 2022, Jackson Sand delivered 120 tons of a peat/sand mixture to improve the area and create an approximate 1% slope from the inside of the circle to the outside. This was done to decrease water from pooling on the circle. The new soil was tilled in to help ensure proper drainage of the soil.

After preparing the area, there was still an area on the south side of the circle that continued to hold water. A drain was added to assist with drainage in June of 2022. Once the soil was prepped and ready, the circle was measured and flagged to delineate the different areas for sod to be installed. Soil samples were taken prior to the installation of the sod to help ensure success of the new grasses.

On June 20, 2022, grasses were delivered from McCurdy Sod Farms and Tri-Turf Sod Farms. With help from the West TN AgResearch and Education Center staff and interns, the new varieties were installed successfully. Because the area received a limited amount of rainfall, the circle was irrigated to help the grasses successfully be established.

The first grasses installed on June 20th were Innovation® Zoysia, Palisades Zoysia, Meyer Zoysia, Tifway 419 Bermuda, TIFTUF Bermuda, and Latitude 36® Bermuda.

On June 30, 2022, Winstead Sod Farms’ grasses arrived and were installed. The grasses that were installed on this day were Zeon Zoysia and Tahoma 31 Bermuda. After installation all of the grasses were top-dressed with sand from Jackson Sand.

The grasses were ready for their first cut on July 5, 2022. Once this project was underway, there were requests to show a seeded variety that might be available to homeowners as well. On July 6, 2022, Dune Bermuda was sowed on one piece of the circle.

This fall, a Fescue variety will be planted on a section of the circle to give homeowners an idea of how that variety does in our growing conditions.

By Max Schlossberg, Ph.D.

Accurate and uniform distribution is the essence of effective turfgrass fertilization, and broadcast application of granular fertilizer via spreader is the most common method used. Spreader calibration entails the measuring and establishment of fertilizer output from a spreader operating over a known area.

Regardless of which book, article, website, or fact sheet you are reading, the first step of spreader calibration is determining the granular fertilizer or amendment application rate in lbs product per 1000 sq. ft. (M). For pesticides, lime, or amendments, this is typically best achieved by following label or soil test recommendations. For nutrient recommendations provided in a specific soil test report; e.g., a recommendation of 2 lbs K2O per M, the fertilizer grade will be required to scale the fertilizer application rate. This is achieved by inserting the recommended nutrient delivery rate into the numerator and inserting the decimal form of the percent nutrient contained in the fertilizer into the denominator (Figure 1).

It is crucial that the percent nutrient contained within the fertilizer, reported as a percentage by mass either in the fertilizer grade or guaranteed analysis, be included in its decimal form. In this example, the desired K-Mag fertilizer (0-0-22) application rate is 2 divided by 0.22, or 9.1 lbs K-Mag fertilizer (0-0-22) per M. Insert this value into the ‘Desired fert/amend application rate (lbs/M)’ slot of the rotary spreader calibration equation (Figure 2).

The next step in my rotary spreader calibration method is measuring the fertilizer specific treatment swath. It diverges from more commonly recommended approaches, but sensibly addresses a

poignant question: Why does fertilizer application by a rotary spreader sometimes leave stripe artifacts (Figure 3)?

The answer(s) is one or both of the following:

1. Successive spreader passes, back and forth across the target area, were made too far apart.

2. When operated in the traditional back and forth manner, an asymmetric distribution of fertilizer from the spreader prevailed across the treatment swath; i.e., one side heavier than the other.

The opportunity for the first of these issues will certainly arise, while that for the second may or may not. The first reason stripe artifacts occur isn’t surprising given the only thing exceeding the number of approaches used to determine ‘the specific distance to maintain between passes’ is the number of ways to reference it. Such crafty monikers include: treatment band/swath/width, distribution band/swath/width, effective spacing, and effective swath width, among others. Over the 25 years I’ve instructed turfgrass students on this topic, I’ve consistently used ‘distance to be maintained between pass centers (feet)’ in my rotary spreader calibration equation (Figure 2). Perhaps this intuitive, straightforward terminology is what deters widescale adoption, but I can dare to dream and will continue using it.

The second step of my rotary spreader calibration method has practitioners assess the right-to-left symmetry of the treatment distribution as well as its swath in feet. Thus, successful completion should resolve both the above-mentioned causes of striping artifacts. The outcome of the asymmetry test determines whether a 100% or 200% overlap should be employed during the ultimate granular product application but does not influence determination of the distance to maintain between passes (feet).

Measuring the treatment swath is a critical step of rotary spreader calibration as explained by Mr. Lance Walheim of the National Gardening Association:

‘To use a broadcast spreader properly, you need to know how wide a band the spreader covers. If the directions that came with the spreader don’t indicate the width, put some fertilizer in the spreader and run the spreader over a short stretch of lawn to find out.’

Word, Mr. Walheim! Determining the treatment swath in feet is by no means a ‘separate’ or ‘optional’ step in the procedure. The treatment swath (feet) will vary by product, and in some cases by walking speed too, but is required for every unique combination of rotary spreader model and granular product to be applied. Mr. Walheim further states; ‘don’t measure the coverage on concrete unless you plan to sweep up the fertilizer.’

His middle name is ‘Butta’ because he’s on a roll! When the ultimate destination of the product is maintained turfgrass, this should be measured on maintained turfgrass. Measuring the treatment swath on smooth pavement increases spreader travel rate, boosts speed of the impellor disc rotation, and exaggerates the treatment swath; further contributing to stripe artifact by way of Issue #1. It will also extend the time needed to complete the spreader calibration task due to sweeping requirements.

Excepting the clean, dry rotary spreader and granular product to be applied, Figure 4 comprehensively depicts all the equipment required to calibrate a rotary spreader. No future surprises, it’s all there in full! Step 2 requires each of the two clean rectangular tarps be spread approximately 15 inches apart on an eligible, representative turfgrass system. Next, examine the rotary spreader and ensure the metal screen is set in position (Figure 5). Open the hopper gate and examine the gate openings on the hopper bottom. They should be approximately one-third open (Figure 6).

If not, shut the hopper gate and follow the spreader instructions to adjust the hopper gate openings to an approximately one-third open position. Close the hopper gate, tighten the adjustment knob (for good measure), and carefully fill the hopper with 10 lbs of the desired granular product.

Next, the intended applicator positions the spreader 20 feet away from the tarps (Figure 7) and begins walking at a safe yet briskly consistent pace toward the gap between the tarps. Once up to speed, and no less than 15 feet from the leading edge of both tarps, the applicator should firmly swing open the hopper gate lever while directing the spreader straight through the gap between the tarps (Figure 8). Once aligned with the trailing edge of the tarps, the applicator can close the hopper gate lever. This process should be repeated, always travelling in the original

direction, until a measurable quantity of granules is visible on both tarps.

At this time, a measuring tape is used to determine the treatment swath in feet. The outer edge of granules on the tarp should not be considered the boundary of the treatment swath. Rather, it should be used as a guide to locate the outer edge of granules in the turfgrass (along the leading edge of each tarp). The boundary of granules in the turfgrass is what should be used for measurement. If the granules bounced across the tarp, then the outer edge of granules in the turfgrass will rest closer to the gap than the outer edge of granules on the tarp. Place a pin flag to denote the boundary, then repeat using the leading edge of the granules on the other tarp as a guide to locate the outer edge of granules in the turfgrass.

Once set, measure the distance between the two pin flags in feet (Figure 9), and record as the treatment swath. Then retrieve the pin flags and measuring tape. To complete Step 2, divide the treatment swath by two. For example, the treatment swath depicted in Figure 9 is 18 feet. One half the treatment swath is the distance to be maintained between pass centers, or 9 feet in this example. Yes, meeting a 100% overlap goal is just that easy (Figure 10).

Ubiquitous alternatives to the above method are inextricably elaborate, yet poorly supported by experimentally-derived fertilizer distribution from commercial, walk-behind rotary spreaders. Given a treatment swath measuring 18 feet, enter the value of 9 feet into the ‘Distance to be maintained between passes (feet)’ slot of the rotary spreader calibration equation (Figure 11).

Many refer to this method as ‘spreading wheel-to-wheel’ and consider their view of it to be much simpler than mine. Sure, spreading wheel-to-wheel is a simplistic way of saying your next pass center will be made at the edge of where your last pass distributed fertilizer. Conceptually, the wheel-to-wheel directive would indeed amount to a 9-foot distance maintained between pass centers for the Figure 10 example. However, as simple as a directive that may be to one employee, it may prove operationally problematic for another.

As an assistant superintendent who trained teammates to calibrate a rotary spreader for their use, I felt comfortable identifying the finite distance to maintain between subsequent passes. Effective communicators give directions that are not open to interpretation. Likewise, when critical precision is ultimately required of the planned granular treatment, practitioners can use measuring tape and alternating-colored pin flags to ensure that 9-foot distance is in fact maintained between passes (Figure 12). Without belaboring it further, trust me when I say I’ve collected a lot of data, acquired even more, and run a hundred simulations. All other inanely-complex distribution sampling, plotting, and midpoint calculating steps will not prove more reliable a method as maintaining half the total treatment swath between passes, period. The more diligent the operator is about determining and maintaining this half the treatment swath distance between passes, the more successful the outcome.

Now that you are convinced of that, grab one of the two clean buckets and carefully lift the corners of one tarp to collect all the granules along the middle of one edge. Position the bucket accordingly and transfer all granules into it, then set that granuleladen bucket safely aside on a stable surface. Repeat the process on the second tarp using the second clean bucket. If the mass of granules in each bucket resides within the operating range of your balance, then carefully determine each mass and record. Alternatively, the volume of granules collected from each tarp can be

measured by transferring the granules into a graduated cylinder. Gently tap the filled cylinder to facilitate consistent settling and a uniform bulk density, then carefully determine each volume and record. This information will be used momentarily.

The next step is to mark out a practice run length on representative turfgrass. The length of the practice run should be no less than 25 ft but need not exceed 60 ft. I’ve noticed some industry YouTube videos encourage their subjects to determine the practice run length by dividing 1000 sq. ft. by the number of feet the spreader treatment swath is wide. These folks then go on to present a simplified equation, where the practice run target mass equals the desired fertilizer/amendment rate in lbs per M. Yet the spreader treatment swath width is never again mentioned.

So, allow me to briefly support my characterization of this recommendation as highly-suspect, or ‘sus’ as PSU students sometimes say. First, accurate balances and proportional properties of multiplication facilitate precise calibration at reduced scale, i.e., we don’t have to treat 1000 sq. ft. (M) in each practice run to calibrate our rotary spreader to lbs per M.

Second, using a practice run length equal to 1000 divided by the treatment swath width, for the purpose of setting the practice run target mass equal to the desired fertilizer/ amendment rate, presumes the treatment swath width distance will be maintained as the distance between pass centers.

And while a 0% overlap approach proves adequate when operating a drop spreader, expectations of further versatility are misguided. While all turfgrass scientists may not agree whether rotary spreaders apply granules in a semi-circular, triangular, or trapezoidal distribution across the swath width, I’m pretty certain none are betting the perfectly-rectangular horse.

Getting back on topic, next use paint or pin flags to mark at least one 25- to 60-foot practice run over representative turfgrass. Employ of a calibration kit (Figure 13) facilitates reuse of a single practice run as many times as necessary. If a calibration kit is not available, multiple practice run lengths will be required and any number will be treated by the product at a rate less or greater than the desired application rate. Frankly, it depends on how close your first hopper gate setting guess comes to delivering the target mass.

You will employ pin flags to avoid double treating practice run lengths. If calibrating your rotary spreader to apply a desired rate of pesticide, then you could really use a calibration kit! Otherwise, the area receiving product from iterative practice runs must be accurately described in pesticide application records; and treated areas may not be re-treated in a manner prohibited by the label.

Again, one can never be certain how many practice runs will be required, but the number typically exceeds one.

Before I get too far ahead of myself, let’s suppose several practice runs 25 feet in length will be marked in the representative turfgrass area. Insert this value into the ‘Length of practice run (feet)’ slot of the rotary spreader calibration equation and solve for ‘Target lbs fertilizer applied in practice run.’ The resulting target fertilizer mass to be applied over a 25-foot practice run is 2.05 lbs K-Mag (Figure 11). We have now completed over half the rotary spreader calibration steps. A remaining task is committing to either 100 or 200% overlap. Committing to 200% overlap is the more admirable option but requires twice as many traversing passes when making the planned granular treatment. The information I use in the decision rule, and encourage the readers to use as well, is the right-to-left distribution of granules as determined by the tarp collections.

13

If the masses or volumes of granules collected from the adjacent tarps were identical (or nearly), then a 100% overlap will suffice in preventing stripe artifacts. This means the calculated ‘practice run target mass= 2.05 lbs KMag fertilizer)’ should be employed in the final step (#4).

If the masses or volumes of granules collected from the adjacent tarps were dissimilar; then you may have options for resolving this issue. If your rotary spreader has a distribution adjustment cone between the hopper and impellor disc, then you can consult the spreader manual and follow the instructions they provide for centering the distribution swath. That’s your Option #2. Using two tarps, this will prove a time-consuming and iterative process without assurance of rewarding outcome. Using eight to sixteen ‘cake pans’ or ‘egg cartons’ spread across pavement to iteratively center the treatment swath defers a notable sweeping commitment, and is without question the most ludicrously impractical suggestion I have typed this year. If you agree, or your rotary spreader does not feature a distribution adjustment cone, then consider Option #1: Calculate the ‘asymmetry ratio’ by dividing the bigger tarp collection value by the smaller. When employing 100% overlap, the extent to which this asymmetry ratio exceeds 4/3 (1.33) correlates directly to the likelihood of striping by way of Issue #2. Thus, to prevent stripe artifacts, practitioners are suggested to employ a 200% overlap when the asymmetry ratio exceeds 1.33. This means the ‘as calculated’ practice run target mass is then further divided by 2, which makes sense given twice as many passes will ultimately be made across the treatment area.

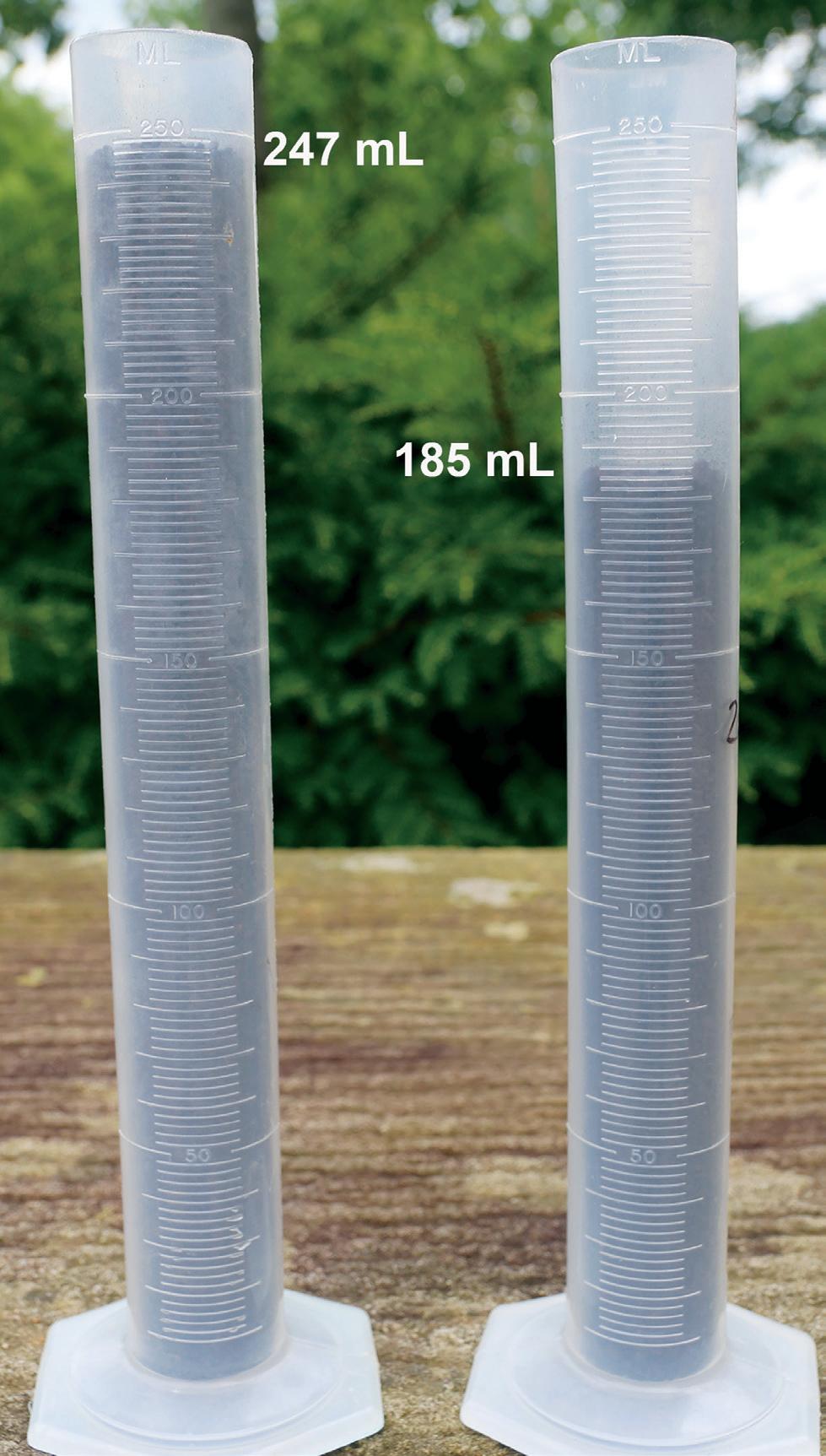

In our example, 247 mL of fertilizer was collected from one tarp and 185 mL collected from the other (Figure 14); resulting in an asymmetry ratio of 247/185= 1.34. Thus a 200% overlap should be employed, making 2.05∕2= 1.025 lbs K-Mag the ‘practice run target mass (lbs fertilizer)’ goal of the final step.

Now it is time to iteratively confirm the hopper gate setting satisfies the desired application rate. There are three general ways to do this, selection of the most ideal method will depend on your specific rotary spreader and available ancillary equipment.

I. Volume replacement procedure (good for large, mounted, or tractor-drawn spreaders)

STEP 1. Set the spreader on a (suspected) desirable setting, making sure spreader is off (closed).

STEP 2. Fill the spreader hopper full, or to a clearly marked and repeatable level, with your fertilizer.

STEP 3. With the spreader, begin walking at a typical and constant rate and open the hopper gate at the marked/ flagged starting point, continue over the practice run length, and close the spreader at the appropriate end point.

STEP 4. Return the spreader to the scale vicinity.

STEP 5. Tare a bucket, fill it with the fertilizer material, and weigh and record the material mass.

STEP 6. Use the fertilizer in the bucket to refill the spreader hopper to the original level (Step 2).

STEP 7. Weigh the fertilizer remaining in the bucket.

STEP 8. By subtraction, determine the mass of fertilizer spread while walking. This is fertilizer mass applied per linear distance (at previously walked speed, NOT ANY speed).

STEP 9. Determine if more or less than the target mass was applied, adjust the hopper gate setting accordingly, and repeat.

II. Indirect mass (or remainder) procedure (good for small spreaders that can easily be emptied)

STEP 1. Set the spreader on a (suspected) desirable setting, making sure spreader is off (closed).

STEP 1. Tare a bucket and fill it with the fertilizer material, then weigh & record the material mass.

STEP 3. Carefully, transfer all the fertilizer to the spreader hopper.

STEP 4. Begin walking at a typical and constant rate with the spreader, open the hopper gate at the marked/flagged starting point, continue over the practice run length, and close the spreader at the appropriate end point.

STEP 5. Carefully transfer the fertilizer remaining inside the spreader hopper to the original tared bucket.

STEP 6. Weigh the fertilizer in the bucket and record its mass.

STEP 7. The difference in fertilizer mass, from before walking the practice run to after, is the fertilizer mass applied per linear distance (at previously walked speed, NOT ANY speed).

STEP 8. Determine if more or less than the target mass was applied, adjust the hopper gate setting accordingly, and repeat.

III. Direct mass measurement (best, but REQUIRES a PENN PRO calibration kit)

STEP 1. Set the spreader on a (suspected) desirable setting, making sure spreader is off (closed).

STEP 2. Install the enclosure kit PROPERLY (covering the spinning rotor plate/impellor disc).

STEP 3. Remove and empty collection pan, place pan on balance, tare to zero, return pan to kit enclosure.

STEP 4. Fill the spreader with an ample quantity of your fertilizer.

STEP 5. Begin walking at a typical and constant rate with the spreader, open the hopper gate at the marked/flagged starting point, continue over the practice run length, and close the spreader at the appropriate end point.

STEP 6. Carefully collect all the material into the detachable collection pan, ensuring all prills have been collected from the calibration kit enclosure! Failure to recover all fertilizer from the kit will result in improper calibration.

STEP 7. Detach collection pan and weigh. This is the fertilizer mass applied per linear distance (at previously walked speed, NOT ANY speed).

STEP 8. Determine if more or less than the target mass was applied, adjust the hopper gate setting accordingly, and repeat.

Review: When is using a 200% overlap (spreading at ½ rate in two perpendicular directions) appropriate?

1. When the rotary spreader distribution is skew, or heavier on one side than the other; i.e., the asymmetry ratio exceeds 1.33.

2. When applying seed (or a seed/amendment blend) to a bed prepared for turfgrass establishment.

3. When spreading fert./amend. on a windy day.

4. When the desired application rate (lbs fert./amend. per M) exceeds the maximum rate of delivery by the spreader. For instance, when you seek to apply 35 lbs pelletized limestone / M but can only apply 19 lbs pelletized limestone / M with the hopper gate wide-open (and at your typical walking speed). In this event, do not slow down your walking speed to achieve a 35 lbs pelletized limestone / M rate! Instead, maintain your original walking speed (and treatment swath) and calibrate the spreader to apply ½ the original rate (½ of 35), or 17.5 lbs pelletized limestone / M. Apply the 35 lbs pelletized limestone / M by making two perpendicular passes over your target area.