BUILDING INFORMAL

Informality is everywhere since the first human settlement. It is an obsession for generations of architects through the ages. Informality intrigues by dealing with other rules than the formal city, but what is defining informality? What are the rules of this settlement, which seems outside of the classic order of things?

The frame of the Reality Studio is an opportunity to explore the question of informality, to experience it, for real. We, as architecture students, were interested by this kind of human organisation, the challenges of it, the place and the role of the architect in it. The profession of architect has an ambiguous relation between its questionable work ethic of only serving clients demands and its role in informal settlements potentially helping the other 90%.

The upgrading of slums is a recurrent question often addressed.

The common conclusion is the underlining difficulty of upgrading slums with its economical dilemmas and the interference of many decisions makers. We took the opportunity of the Reality Studio as a challenge to give a concrete answer to the issue of upgrading slums. Our aim: “Improve the living conditions in informal settlements by implementing a new and sustainable method of construction: Rammed earth.” We think that architects have the ideas and the tools to answer this kind of question.

We also think that it is in the ethic of the architect to answer to this kind of problematic. By answering, we also mean convincing and we decided to build a prototype on site to validate our concept. We built this project as a manifesto for a practice-based research as a key of knowledge transmission and teaching. We are militating in favour of the tool of the prototype for this kind of problematic. Our site of action: Emmaus Blessed School in Obunga, Kisumu, Kenya.

Léon Bührer Reality Studio June 2018 Marine Kerboua RAM-UP OBUNGA Chalmers 3 Reality Studio June 2018

08 11The Emmaus Blessed School 14The Reality Studio 18What is Informality? 24The Challenges of Informality 26Build permanent The Context Kisumu, Kenya 20A few words about Obunga 62 64The Wooden Formwork 72The Earth Ramming V. Works 94Experience the Prototype 96Financial Analysis 98Process Improvements Findings The Bricks Foundations 91The Day of Celebration 95Reactions to the Prototype VI. Build Informal 22Earth construction in Obunga Intro II. I.

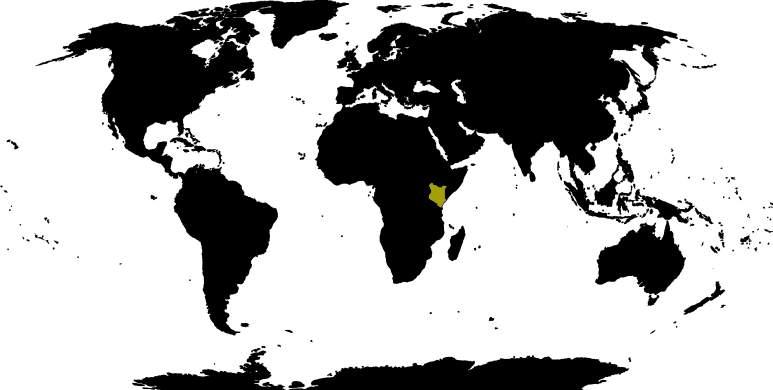

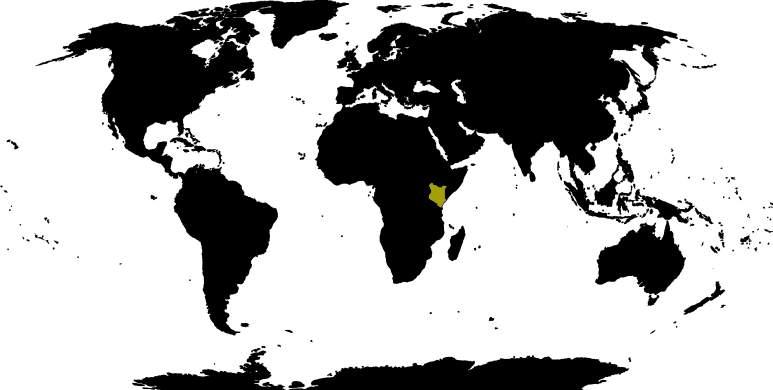

THE CONTEXT KISUMU, KENYA

Kisumu is the third biggest city of Kenya (after Nairobi the capital and Mombasa on the east coast) and it is situated almost exactly on the equator. The temperature is constantly high all over the year. The protection against the sun is one of the issues. Kisumu borders the Lake Victoria, well-known to be the biggest lake of Africa. The lake is a big resource providing opportunities for a big fishing industry. However, lately pollution of the lake, water hyacinth infestation and overfishing have reduced the amount of fish caught.

The population is estimated to be about 500,000 with 60 % of the urban population living in slums (ten different ones) at the fringe of the urban fabric. The major ethnic group in Kisumu are the Luo’s thereby Luo is the most spoken language in Kisumu (the official languages of Kenya are English and Kiswahili). Most of the people are speaking English, there is no problems to communicate with the population. We also noticed that there is a big community of Indians in Kenya, that owns many hardware shops and restaurants.

Kenya is situated on the East Africa region. The country has lately suffered from recurrent drought and during the two rain seasons there is risk of flooding (March to June and October to November).

Climate change is moving forwards and we experienced the unusually early rain season during our stay. The main environmental issues for Kenya are water pollution and degradation of water quality due to urban and industrial waste as well as increased use of pesticides and fertilisers. Deforestation, soil erosion and desertification are other problems in need of attention. Deforestation is causing a decrease of water resources and is increasing the drought risk. Just as we arrived at the end of February, a ban on logging was issued by Kenya’s Deputy President William Ruto for the next three months. This ban had a serious repercussion on the price of timber in Kenya.

TABLE OF CONTENTS 30 32Why rammed earth in Obunga? 36Our concept III. Hypothesis 42Planning of the wall 50The local participation 54The materials for the recipe Prototype What is Rammed Earth? 34Our method 48Construction timeline IV. 106 The bigger scale The concept of step by step VII. Upgrade Emmaus Rammed earth as a solution Personal inputs What is next? Conclusion Applying the findings The upgrading project VIII. 46Our partners 58Earth testing 107 108 110 Where we failed 44Financing the prototype Experience of Kenya 114 115 116 118 119 6 Ram-up Obunga Intro. INTRO. 8 Ram-up Obunga Intro.

60 % 500,000 inhabitants in Kisumu Part of the population living in slums in Kisumu.

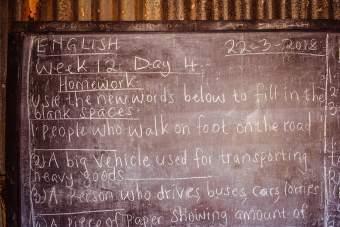

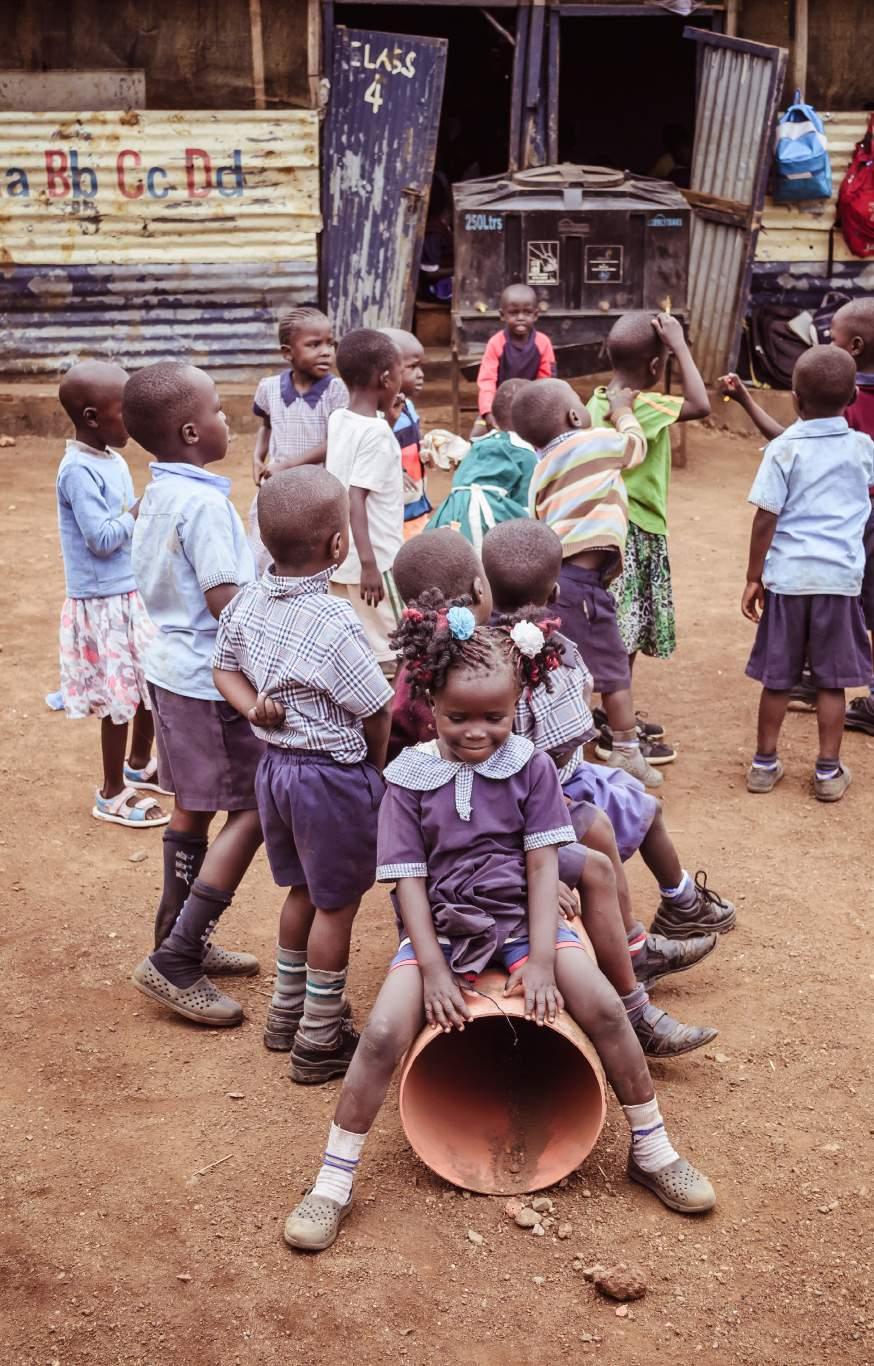

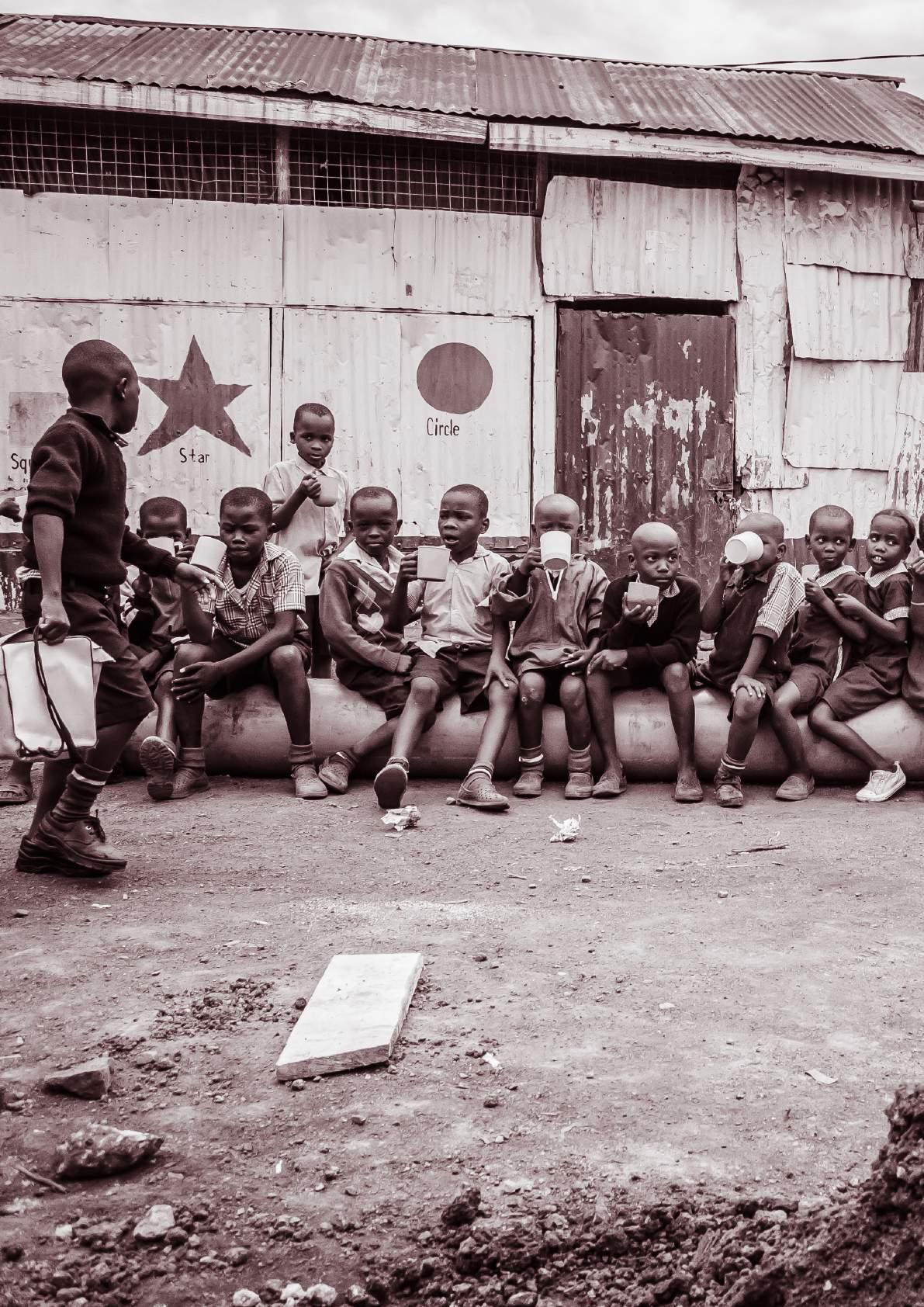

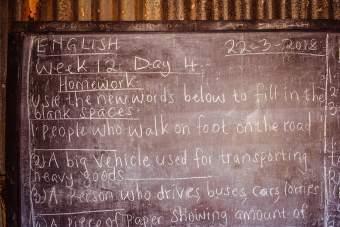

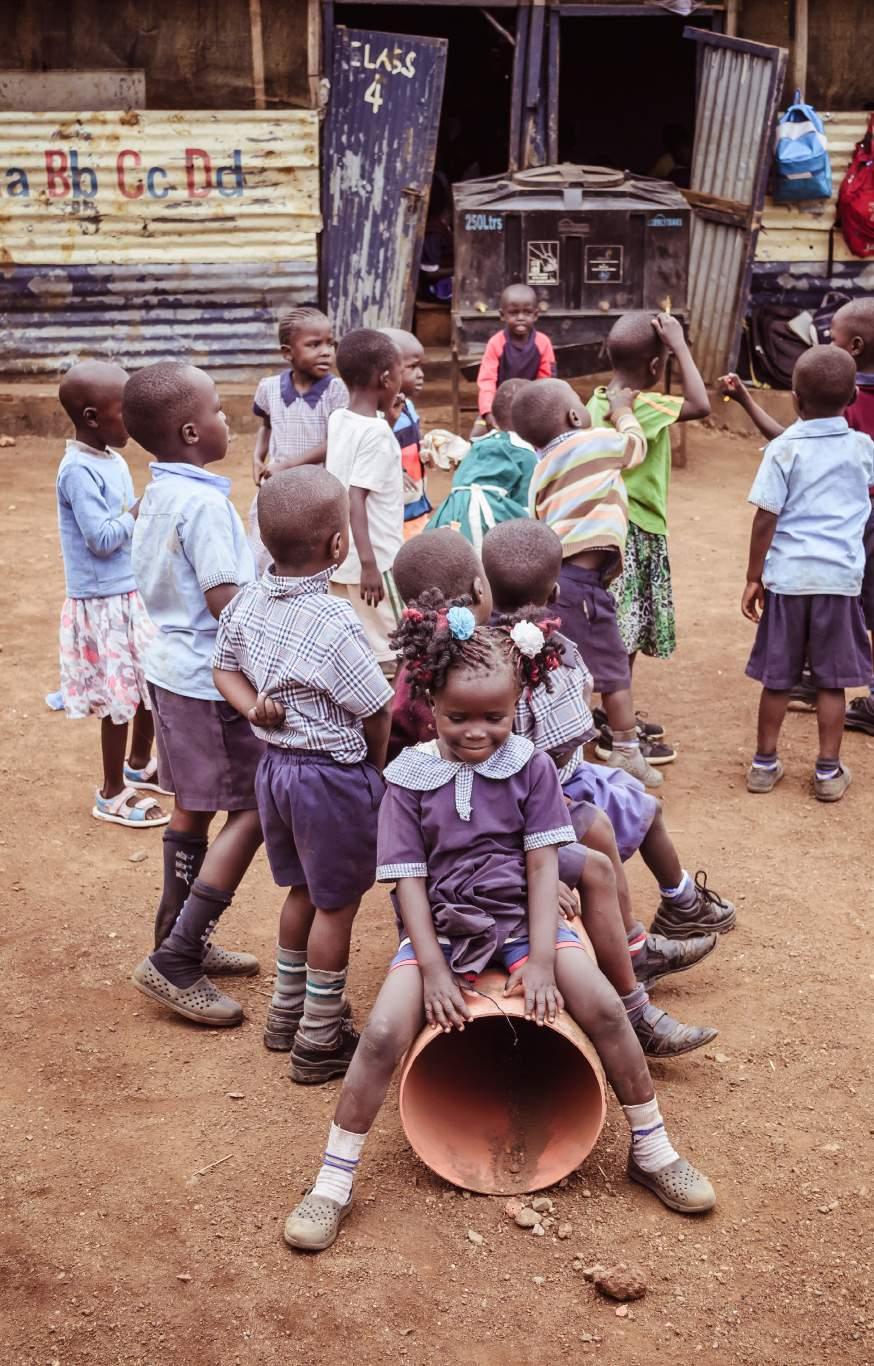

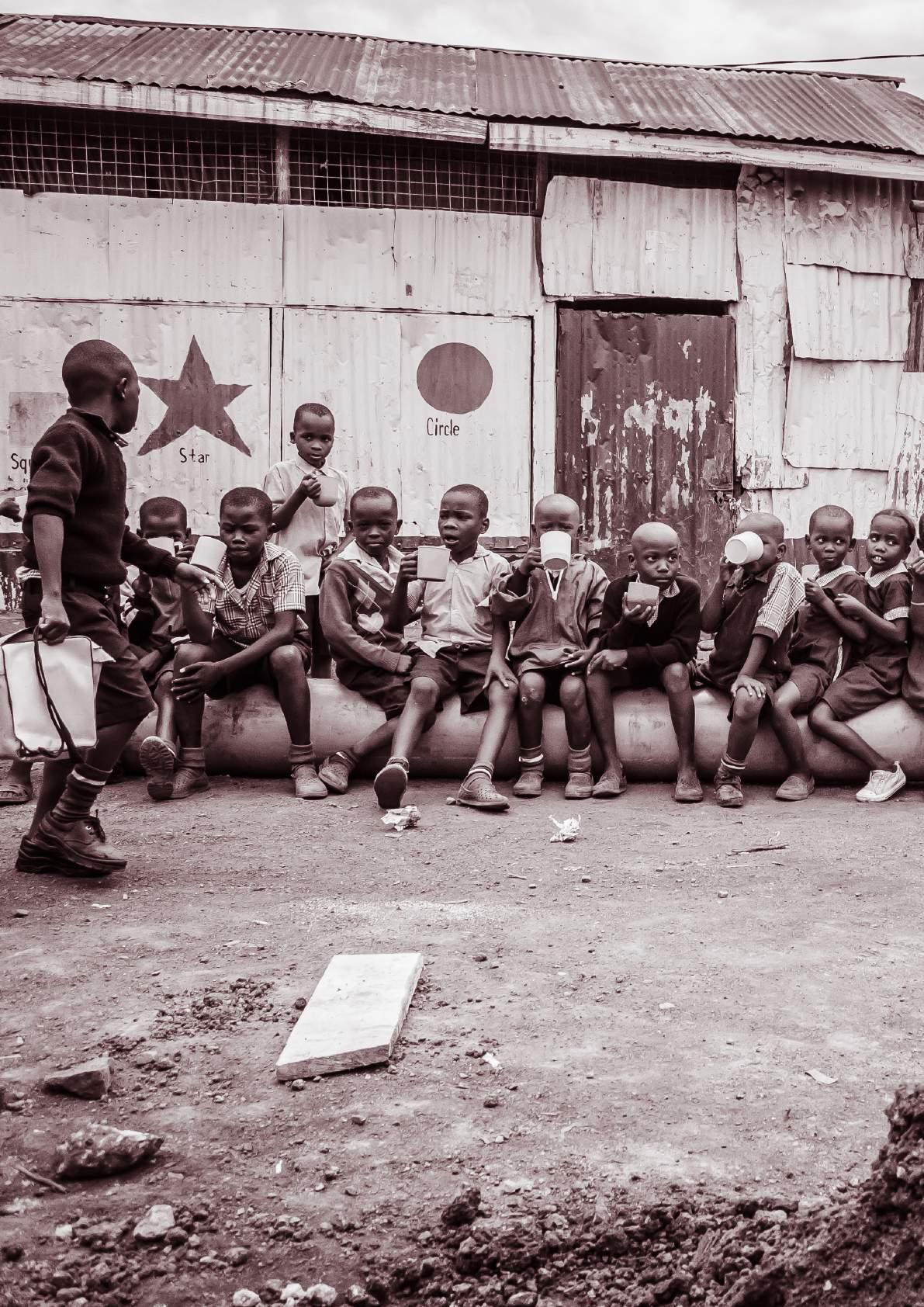

THE EMMAUS BLESSED SCHOOL

Our story with the Emmaus Blessed School started on a Tuesday, the 6th of March 2018. We had a common visit of primary schools in the informal settlement of Obunga with all of the students from Reality Studio 2018 This school particularly interested us. The school is a private initiative open for everyone, depending on donations and welcoming orphans for free. We directly appreciated the mood of the school. We visited them again and met the headteacher Kennedy Oriko and the financial director, Samson Oduor, who explained us how they run the school. We received an explanation of their needs. We saw the necessity of further improvements and were impressed by the work already done by those two men. After falling in love with the place, we also fell in love with the stakeholders. It was the beginning of our engagement with the Emmaus Blessed School of Obunga.

The Emmaus Blessed School is a primary school situated in the informal settlement of Obunga in Kisumu. Its particularity is to welcome orphans from Obunga and is providing them education, food but also a roof. Kennedy, the headteacher of the school is not drawing a line between his professional and private live. He is welcoming orphans at his own home close to the school offering them shelter. The school is a part of the “Green Life Widows & Orphans Foundation” and take care of widows by providing support and a job (they are in charge of the feeding program of the school and are cooking for the children).

When children finish the primary school, they are sent to secondary school with the support of the school, which is paying the school fees for the “vulnerable children” (meaning the orphans). The school stay also open for them after school to provide space for working and further studying.

THEIR GOAL

The Emmaus School in numbers:

10 grades from nursery class to grade 8th

130 pupils

50 orphans

12 secondary pupils helped out

10 teachers

185 m2 of classrooms

15 children per class of 15 m2 in average

15 widows helping with the feeding programm

30 %

Percentage of the population infected with HIV in Kisumu.

Kenya underwent a period of colonisation by the British and obtained its independence in 1963. Today, Kenya is a republic with an elected president (Uhuru Kenyatta in 2013). Kenya is the regional hub for trade and finance in East Africa. The country’s economy is slowed down by a high level of corruption and the reliance on primary goods with prices remaining low.

The main part of the population is Christian with 45 % being protestant and 33 % Roman Catholic. Out of the remaining part of the population 10 % are Muslims, 10 % have indigenous beliefs and 2 % other beliefs. The christianism replaced the Luo beliefs and its way of life. Polygamy is not longer common and the traditional round buildings made from mud can be seen only sporadically in the countryside. The religion, mostly Christian, is ubiquitous at school. The school follows a system of 8-4-4 and it is supposed to be free (at least for the 8 years of primary) but there is not enough public schools and most of the children have to pay to be educated. The rate of literacy is increasing in Kenya with 72% of literacy of adults but 84% of attendance in primary schools.

Concerning the health situation, the major issues in the area are the high prevalence of HIV/AIDS and malaria (Kisumu District has the highest infection rate in the country with 29% of the population being affected). The AIDS pandemic remains the biggest threat in Kenya, resulting in a growing population of orphaned children most often themselves suffering from the disease.

9 Reality Studio June 2018 Kenya Kisumu Obunga 10 Ram-up Obunga Intro.

11 Reality Studio June 2018

“To ensure that every child in Kisumu, and every Orphan can access education for free no matter what their background, class, disability, and gender, is.”

12

Ram-up Obunga

Intro.

THE REALITY STUDIO

The Reality Studio is an educational platform for joint knowledge production and education between the Maseno University and Jaramogi Oginga Odinga University of Science and Technology (JOOUST) in Kenya and Chalmers University of Technology in Sweden, in collaboration with other organisations, associations and authorities in both countries.

The visionary and long-term goal of the studio is to increase health and enrich quality of everyday life. The goal of the studio is to find new design and planning strategies for urban areas, villages, neighbourhoods, built environment, architectural heritage conservation and transformation.

Extract from the presentation of the studio available on: https:// student.portal.chalmers.se/en/)

The studio is situated in the second semester of the Master programme Architecture and Planning Beyond Sustainability (MPDSD) at Chalmers University of Technology, Gothenburg, Sweden. The students have backgrounds in design, architecture, urban design and planning. The studio includes a field study of two months in Kisumu, Kenya.

6 st March

First visit of Emmaus Blessed School.

26 th February Leaving Gothenburg, flying to Nairobi.

12st March

Second visit of Emmaus Blessed School.

14st March Group formation.

We are two students, Marine and Léon, from the Reality Studio 2018, working on this project. We are not from Sweden but we both chose Chalmers for a one year Erasmus exchange without thinking that this experience in a cold country would lead us to Kenya! We are both interested in sustainable building techniques and earth lovers. We like to get our hands dirty and build in one to one scale.

Marine - Hi! I am Marine Kerboua, architecture student from France at the Ecole nationale supérieure d’architecture de Paris-Belleville (ENSAPB). As a French food lover, I acclimatized really well with local food and my new “crêpe” is chapati!

Léon - Hello! I am Léon Bührer, am from Bern in Switzerland and pursuing my studies at the Ecole Polytechnique Fédérale de Lausanne (EPFL). After an unusual cold winter in Sweden, really enjoy the warm climate and culture in Kenya!

13 Reality Studio June 2018 14 Ram-up Obunga Intro.

1st March Leaving Nairobi to Kisumu.

EXPLORATION 15 Reality Studio June 2018 16 st March Project formulation. 20 st March Decision to do a rammed earth prototype. 23rd March Start of the construction. 7st April End of the construction. 9 st April Exhibition in Kisumu. 10 st April Leaving Kisumu for holidays. 16 st April Return to Gothenburg. 23rd April Presentation in Chalmers. 25th May Final presentation in Gothenburg. CONSTRUCTION SPREADING

16 Ram-up Obunga Build informal.

The Reality Studio students with Maasai in Maasai Mara Reserve.

WHAT IS INFORMALITY?

What is an informal settlement?

An informal settlement, also called “slum”, is difficult to define.

The most common definition is the one from UN-HABITAT:

“Informal settlements are residential areas where

1) inhabitants have no security of tenure vis-à-vis the land or dwellings they inhabit, with modalities ranging from squatting to informal rental housing.

2) The neighbourhoods usually lack, or are cut off from, basic services and city infrastructure.

3) The housing may not comply with current planning and building regulations, and is often situated in geographically and environmentally hazardous areas.1

The two concepts formality and informality go hand in hand. Tom J. C. Anyamba states that one of the two concepts cannot exist without the other, they define each other, and that these spatial categorisations are social constructions meaning “space is neutral but acquires a given meaning or category according to specific circumstances”.2 Slums are present all over the world with differences in terms of longevity, reasons to exist or size. We are used to them and their constant fight to stay but architects do not intervene much in this informality. For some, the question is fascinating and they are studying their organisation, the way they are working and the link with the formal. Each informal settlement has its own rules and it is necessary to study them to understand them. The Reality Studio is pushing students in another context and we chose the context of Obunga, one of the informal settlements of Kisumu to start our research.

BUILD INFORMAL.

In Obunga, we had difficulties to read the definition of an informal settlement through our visits. If informal means illegal, it is not the case in Obunga. Landlords own titles of property and many people are renting out their plot. It is also organized in a certain way. Roads and paths are clearly traced. During one of our first visits, the sewage system was under construction and the headteacher of Emmaus Blessed School explained us how is working the request for a building permit. A minority? Slums gather 60% of the population of Kisumu. What is informal when it represents more than half of the population?

A way for politicians to close their eyes?

Theses questions interested us early on in the analysis. The reality was far from our preconceived ideas and learning the rules was our first objective before starting. We started by defining informality by its challenges, which are really interesting architectural issues. We taught, as many architects before us, about upgrading the living situation in slums but how to do that? How can the upgrading of such a settlement be planned economically, when it is already crowded in certain areas? How could it be made affordable, sustainable? We began by researching, what previous studies and projects where doing in that field. We found master plans of slums as upgrading but without financial questions. How to finance it? Who? When? How to build little by little to follow the arriving of founds? At this moment we found our question: “How to upgrade informal settlement by the introduction of a new and sustainable building technique which is rammed earth?” In this report, we will try to explain the keys of definition of the informal settlement of Obunga through the rules we discovered and faced during the project.

A FEW WORDS ABOUT OBUNGA

How can the upgrading of such a settlement be planned economically, when it is already crowded in certain areas? How could it be made affordable, sustainable?

Obunga is one of the informal settlements of Kisumu, which counts ten different one. Obunga is situated in the north-western part of Kisumu and it houses around 20 000 inhabitants (but a counting is really difficult in this area). The average of the population is young. Most of them are aspiring to build their own house in the countryside when they are retired. The border of Obunga with the city centre is clearly articulated through a highway. The asphalt road is transformed into a mud road. The concrete that qualify the downtown is moving to metal sheet and mud. The main road, Pamba road, is going trough Obunga starting from the “junction”. From either side, little businesses are open on the street, mostly little cabins selling vegetables, meat, telecommunication, groceries, small dried fish, chapati and others food specialities. Sometimes some more special services can be found like a cinema or a street vendor selling ice creams. Typical shop on the

18 Ram-up Obunga Build informal.

1 UN-Habitat, The Challenge of Slums, 2003.

19 Reality Studio June 2018

2 Tom J. C. Anyamba, Diverse Informalities: Spatial Transformations in Nairobi a Study of Nairobi's Urban Process, 2008.

The main street of Obunga during the works for the new sewage system.

20 Ram-up Obunga Build informal.

side of the main road in Obunga selling meat.

The settlement is characterized by the density of many small buildings, especially close to the main road. Further away, the houses are more detached and green areas are present. There is no comprehensive sewage system but tap water is available in some places. The roads are mud roads and are almost impassable in periods of heavy rain. Humans are crossing animals all the time in the main artery of Obunga. The houses are mostly done with corrugated iron and cheap wood. Some of them are made from earth with the method wattle and daub. A minority of buildings are built with concrete or bricks.

Obunga counts quiet many schools but most of them are private and have fees. There is one private hospital in Obunga (that we visited when we were injured by the metal sheet) and some community services like a information centre. The main way of transportation (of people and goods) is the motorcycle locally called boda-boda. Tuktuk are also used to move heavier loads.

The mood of the area is generally happy and alive when the sun is up. Our crossing of the settlement as “mzungu” (white people) did not got unnoticed and we were pursued by the call “Mzungo, how are you? I am fine, thank you!”

EARTH CONSTRUCTION IN OBUNGA

“Mzungo, how are you? I am fine, thank you!”

WATTLE AND DAUB

Is the maybe most common and easy way to build with earth. The technique dates back, at least in Europe to the first humans who became sedentary after they gave up their nomadic lifestyle as gatherer and hunters. In northern Europe many examples of the technique can still be seen in the old medieval city centres where houses were mostly built with the German Fachwerkhaus typology. In this technique a timber frame built from massive wood gets filled in with a weaved wooden structure made from branches covered with a mud, straw and cow dung mixture. Thanks to the massive timber frame structure those buildings can reach the height of several stories. In Kenya the wattle and daub technique is used in its more original way not only as a infill but as the main structural part of the buildings. Traditionally in Kenya the Luo and the Maasai huts can be found, as main examples of earth houses. The Maasai being semi nomadic people, their huts from wattle and daub are easier and faster to build. The Luo hut which is traditionally round but after British colonisation became rectangular is more durable and has a practical lifespan of one human lifetime. This because after the death of the house owner (the women) the house is getting destroyed. Because of those particularities the Luo earth houses almost never have a second story. In Kisumu the earth buildings that can be found are “modernised” or post-colonial versions of the Luo hut. They usually have a rectangular floor-plan. The main structure is made from wooden poles rammed into the earth and smaller sticks woven in between those. They are then covered and filled in with a more or less sophisticated mix of soil, straw, cow dung and stones. If it can be afforded the outside as well as the inside are then plastered with a cement plaster. The roofs are mostly done with a round wood structure from young eucalyptus trees covered with corrugated iron sheets.

Compared to the widespread iron sheet constructions the wattle and daub technique keeps the room temperature low. For economic, fire hazard and because the British forbid it thatched roofs are almost non-existent, even though they would further cool down the rooms. This way of building is widespread, rather easy to build and has a kind of collective knowledge base. One would think the cultural heritage of it would be an advantage but since the colonisation and with western society is model to strive for, the wattle and daub buildings became the social status of a poor man’s housing.

The maybe biggest problem of wattle and daub is the earlier mentioned socio-cultural stigma that sticks to it. If the people could they would build with bricks and concrete. As soon as they can afford it locals are plastering their earth walls with cement to protect the wall and hiding the fact of it being a mud wall. In fact, they are by doing that even damaging the wall, because the cement is trapping humidity inside the wall and is rather badly sticking to mud. A better alternative would be a lime plaster. This is though a rather unknown material and a bit more expensive than cement. Another problem with the technique is that it uses wood and wood currently is a scarce and expensive material. The cheapest wood in Kenya is the invasive species eucalyptus, as it is the fastest growing tree it is an important cash-crop for local farmers. In other countries of the region already limited the cultivation of blue gum eucalyptus like Rwanda where the newly planting is completely banned. This because eucalyptus has an especially high water consumption what is endangering water levels in the catchment areas of the big rivers. Also has the eucalyptus invasive properties and is replacing native species. Thirdly the eucalyptus is decreasing the soil quality and interrupting the nutrition cycle. Another problem with the wattle and daub technique is the fact that it can be attacked and destroyed by termites or water damage either by flooding or heavy rain fall.

THE CHALLENGES OF

During our second meeting the 12th of March with Kennedy, we exchanged ideas about the necessities of the school. From a new shelf to a new library, the needs are various and the scope of scales is broad. We established a list of potential projects and analyse it afterwards. We catched the challenges that are facing the school and crossed it with the opportunities offered by the context of the Reality Studio.

21 Reality Studio June 2018

Study visit of Obunga with the students of the Reality Studio.

22

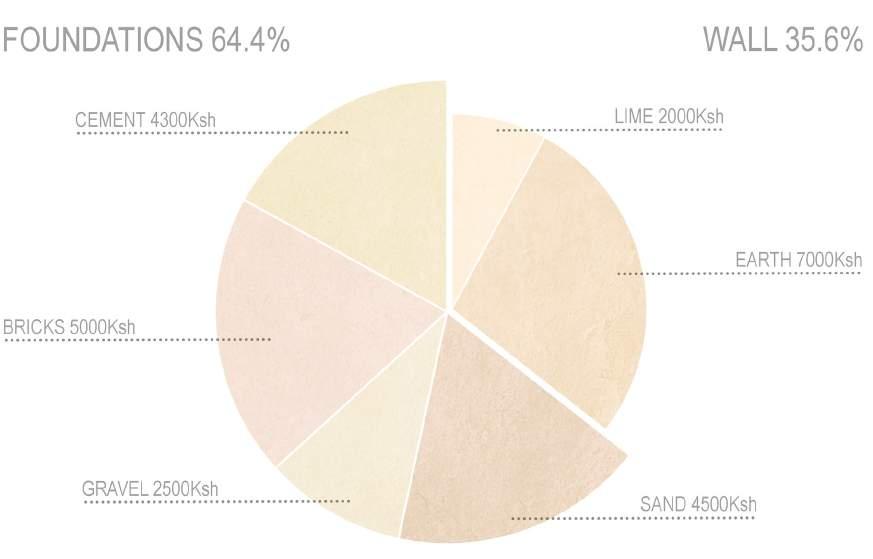

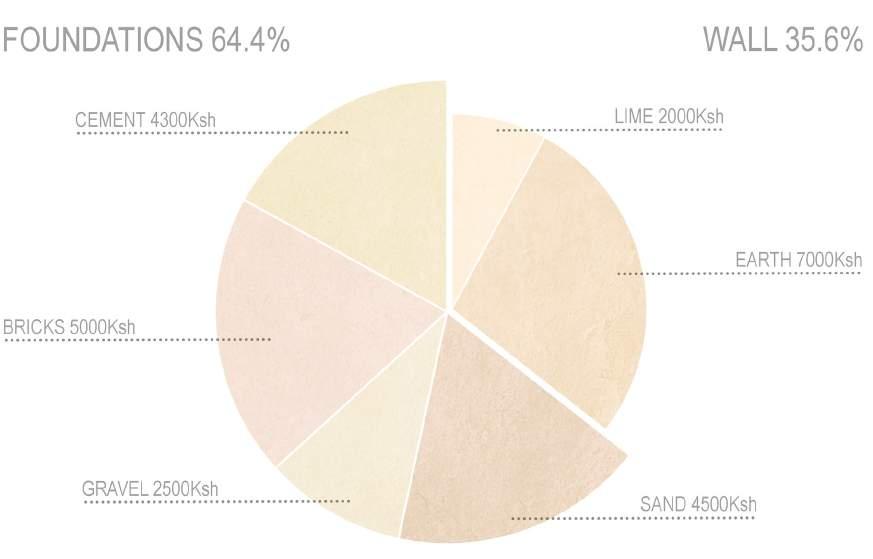

Build

Ram-up Obunga

informal.

23 Reality Studio June 2018

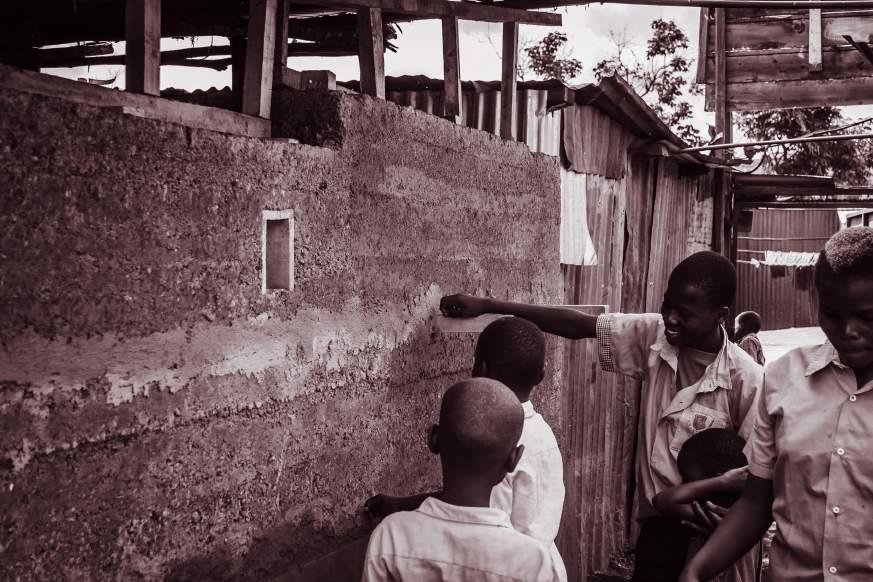

Earth construction completed with rocks in Obunga. The photo shows the damage on the wall caused by rain.

Earth building made by wattle and daub technique damaged by the rain. At the foreground, piles of earth from previous houses recently destroyed to rent out easier the land.

24 Ram-up Obunga Build informal.

INFORMALITY

EMMAUS BLESSED SCHOOL A new library Improvement of the furnitures Classroom upgrading Repairings Home clothes Courtyard planning A new orphanage Toilet upgrading Adults education program First aid shelter Locked cupboard for books PRIORITY Nikola & Oskar’s project of school furnitures Klara & Nicolas’s project of a community center School books School uniforms

THE NEEDS:

Add a second storey to the classrooms

A new library for pupils and secondary students

Better office spaces

Upgrading of the toilet situation

Planning of the courtyard as a playground

Add storage to expand their capacity

Include a farming program in the plot behind

We analysed each of them and classified them: the ones we have the tools to answer and the others. In this category, we prioritized the needs and identified the opportunities Finally we arrived with the issue of the classroom upgrading, one of the most urgent issues, where we have the tools to respond and who offers us a challenging problematic.

The classrooms are currently made from metal sheet assembled by Kennedy himself with some help. Everything is handmade. Already deteriorated after only three years, it needs to be redone. Metal sheet is a very cheap and easy material to build with, but the heat inside the classroom is unbearable and the edges of the metal sheet as well as the nails are hurting the kids. It is not a safe and comfortable environment to learn. We saw this issue as a priority.

The visions of Kennedy are bigger and he also wishes to add a second floor to the school. Obviously the challenges are numerous. The cost of the construction is essential. The materials used have to be cheaply available and healthy for the children. We have added the criteria of sustainability and durability The price of the workforce is also an important factor. The planning has also to consider a time-scale perspective depending on funding. Finally, the material used and the process are the keys to success.

BUILD PERMANENT

During our exploration we discovered a first aspect of the informal settlement: permanence Or rather the non-permanence. Nonpermanent is a legal term to define informal settlements. Slums are mostly built by non-permanent materials to not require a building permit. Even if the material used are not durable, the people are staying permanently, for years. The constructions are constantly redone at the same place using the same cheap materials resulting in a loss of money doing it again each time. This is resulting in the paradox of being obliged by the financial situation to build cheaply with not durable materials for a permanent stay.

The reality of an informal settlement is everything but permanent or persistent. After the first weeks, we decided to work with a school to implement our vision which is: “Improve the living conditions and awareness about sustainability in the informal settlement of Obunga, Kisumu.” Education as a key for development needs a permanent framework. Teaching needs a safe and permanent place to exist and persist. That is not currently the case in the classrooms being basically overheated boxes built with nails and metal sheets. The material and the technique became the key to answer the challenges and we came up with the idea of rammed earth

Extract from the Building Code of the Republic of Kenya (2009 Edition):

BB76.1

a) In these Regulations temporary buildings shall mean any building for which a permit is issued on a temporary basis and is: i. required only for a short time; ii. constructed of short lived materials; or iii. constructed as a contractors shed required in connection with the erection of permanent buildings.

OUR VISION

As we understood from the Building code of the Republic of Kenya and through discussions with the population, workers and other people in relation with Obunga, we did a classification of what is considered as permanent in informal settlement:

Non-permanent houses - mud/metal sheet house with thatched roof.

Semi-permanent houses - “mud house” with metal sheet roof.

Permanent houses - Fired bricks/adobe bricks/CSEB Bricks/stone/concrete houses or houses with some cement.

In legal terms, we found that earth (as metal sheet) is one of the material considered as semi-permanent because it can be torn down easily. It is a material currently used (in minority) in the informal settlement with the technique of wattle and daub. Durability goes hand in hand with permanency, so how to play within the rules? At this moment we started to think about the material of earth and how to build with it in a durable way.

horizontally, and any boarding less than 16mm in thickness, or in the case of feather edge boarding less than 16mm in thickness at the thicker edge of the board;

ii. sheets of fibre building board (except super hard-board as defined in BS 1142: 1953), wood chipboard or compressed straw;

iii. wood-wool building slabs;

iv. plywood, except plywood suitable for external use;

v. plaster board;

vii. lime or gypsum plaster on wood or metal lath;

viii. cement plaster not exceeding 40mm in thickness on wood or metal lath;

ix. sheet iron or steel which is not galvanized, painted or otherwise protected by a bituminous or other not less suitable coating;

x. organic-based felt;

xi. canvas or cloth;

xii. palm leaves or matting;

b) unprotected softwood boarding, so far as it is used wholly or principally for the construction of the weather-resisting part of the roof of a building;

c) any other combustible material. This material is also answering our other criteria.

b) The Authority may, in its discretion, include any other building constructed on land held on licence.

BB76.2

Short lived materials mean any building materials which are, in the absence of special care, liable to rapid deterioration or are otherwise unsuitable for use in the construction of permanent buildings: a) so are as they are used wholly or principally for the construction of the weather-resisting part of a roof or external wall of a building: i. tongued and grooved boarding fixed

25 Reality Studio June 2018

Presentation of the project of the prototype to Kennedy

26

Obunga Build informal.

in his office.

Ram-up

27 Reality Studio June 2018

“Improve the living conditions in informal settlements by introducing a new and sustainable method of construction: Rammed earth”

Rammed earth is an old earth building technique used since several thousand years. Appearing for the first time in ancient China, the technique spread over the hole globe, but got forgotten over the curse of the last 200 years due to the innovations of the industrialisation. Recently the construction method became more and more popular, in the western world, thanks to experts like David Easton or Martin Rauch. Thanks to its low carbon footprint, which manly comes from eventual transport and low water usage, the technology is a viable alternative to the commonly used, industrialized techniques.

When building with rammed earth a formwork similar to one used to cast concrete is needed. Instead of pouring a viscous liquid into the formwork with rammed earth a sieved rather dry mix of soil is put in layers into the formwork. The layers of about 10-15cm are compressed by ramming them down either manually with a wooden or metal rammer or with a pneumatic rammer. There is either a formwork put in place for the hole wall section or a smaller one is making “bricks” of rammed earth.

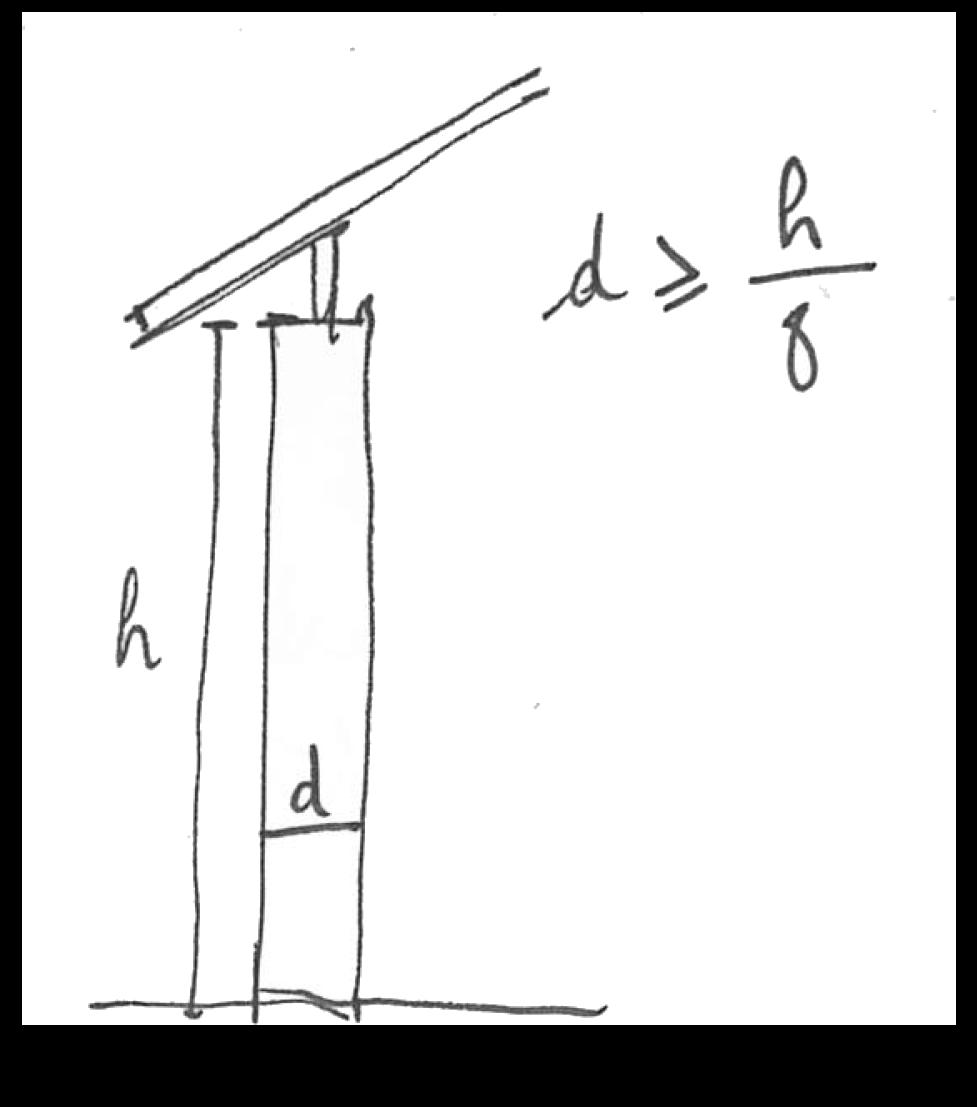

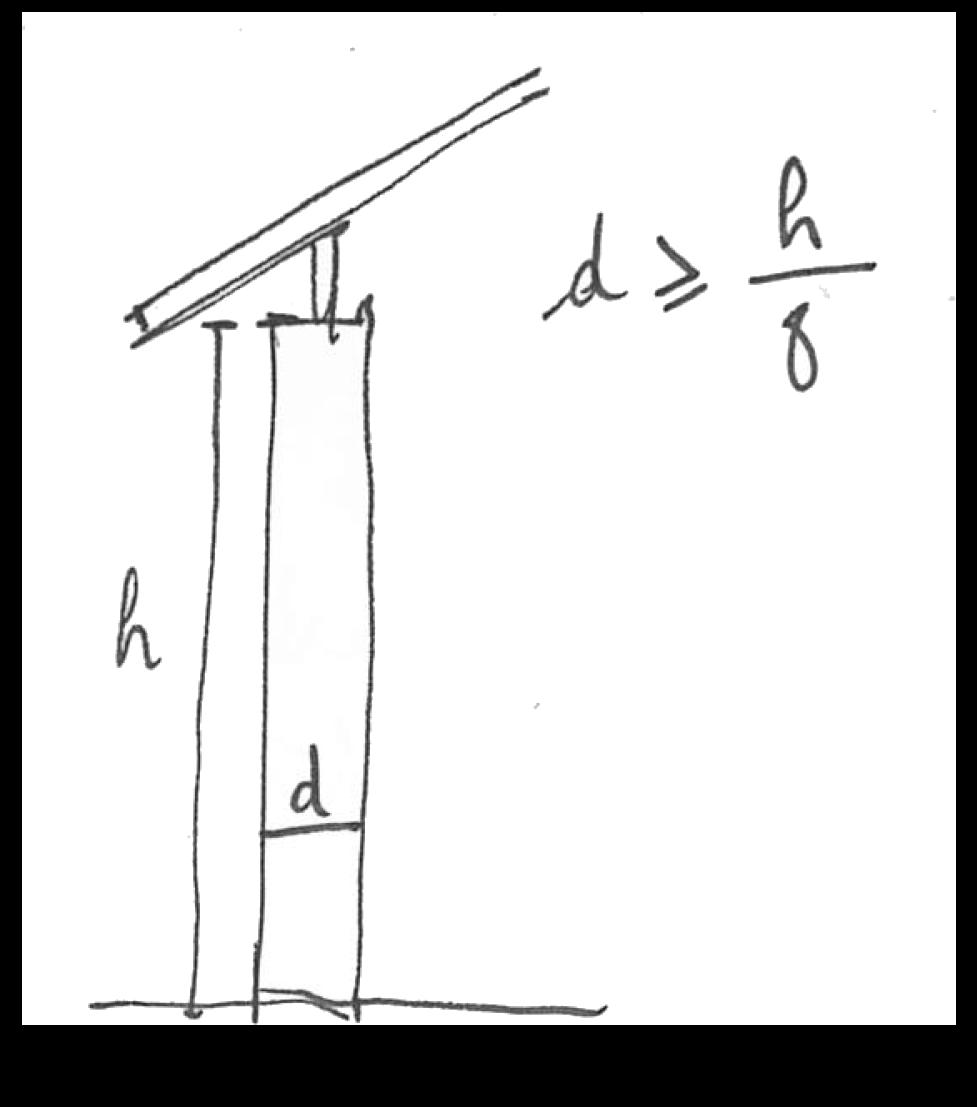

This process of successively ramming down layers is making the technique very labour intensive. There exist though industrialized versions of the process where rammed earth is prefabricated, cut into pieces and then stacked up like bricks on site. The soil used for rammed earth has to be free of organic matter and consist of about 70% sand and gravel 15% silt and 15% clay. When rammed the soil mix needs to have the right amount of moisture for the biggest possible compression. Rammed earth walls can be stabilized with cement or lime but can also perform structurally without stabilizers. Unstabilized walls have a minimum thickness of 35cm. The presumably tallest rammed earth building stands in Weilburg, Germany, and has 6 floors.

HYPOTHESIS.

Prefabricated facade elements of the Ornithological station in Sempach, Switzerland by mlzd Architekten. Builders: Lehm Ton Erde Schweiz GmbH.

Source: http://www.lehmtonerde.at/

WHY RAMMED EARTH IN OBUNGA?

Old city of Sana’a, Yemen. Rammed earth is an old method of building used all over the world. Multy-storey buildings are possible as shown in this picture.

Source: https://commons.wikimedia.org/

Traditional rammed earth construction in north Africa.

Source: https://i.pinimg.com/

BUILD SAFE DURABLE SUSTAINABLE PERMANENT ECONOMICAL

Rammed earth has a lot of advantages especially compared to the currently wide spread of iron sheet sheds in Obunga and other informal settlements. The high mass of a rammed earth wall is giving it great thermic properties, to regulate the room temperature by taking up heat during the day and realising it during the night and by insulating the rooms. This is an especially useful aspect of rammed earth since the climate in Obunga is very hot. Inside the widely spread iron sheet constructions its gets extremely hot over the course of the day. Ideally the main part of a rammed earth wall, the soil, can be sourced for free on site but in the context of an informal settlement this is not always possible. Still the material is local and transportation distances are short. The tools like the formwork and the rammer are reusable lowering the overall costs with every construction. Rammed earth has a low carbon footprint, most of the CO2 emissions are caused by the rather short transports and the foundations. Rammed earth is also ecological sustainable because of its durability. If executed correctly a rammed earth wall can stand a lot longer than an iron sheet construction or a building built with the local wattle and daub earth construction technique. Rammed earth has also great structural capabilities and can support buildings several floors high. An important part why rammed earth should be used is also because it puts the financial investment into the labour and not the materials. This keeps the money in the pocket of the community as the salary of the workers most likely is spent again in the local economy. In that way the money spent does not go to big industrial companies benefiting only a few but is kept inside the informal settlement. Currently earth constructions in Kenya and elsewhere have the socio-cultural stigma being a poor-man housing. The preferred building material of the local population is concrete and bricks. With the western world as an example, the material earth is not desirable anymore. Rammed earth can challenge that as it has the strength and appearance similar to concrete. Legal advantages of rammed earth over other permanent construction methods are also a very important point. One craftsman we met remembered to have seen the technique somewhere on the countryside once, but he was the only one who ever has heard of it. We think that rammed earth is an opportunity to upgrade the living conditions in informal settlements and it is a solution for the issues facing informal settlements.

30 Ram-up Obunga Hypothesis.

WHAT IS RAMMED EARTH?

31 Reality Studio June 2018

32 Ram-up

Recently the construction method became more and more popular, in the western world, thanks to experts like David Easton or Martin Rauch.

Obunga Hypothesis.

ADVANTAGES:

MATERIAL Local and cheap (could be sourced on site).

TOOLS Formwork reusable many times.

CHILDREN FRIENDLY Participation possible and safe construction site.

GOOD ROOM CLIMATE Good insulation and thermal regulation (mass).

WORKER FRIENDLY Low tech solution with a material that has no toxic properties.

PROMOTION OF CRAFTSMANSHIP Works realised by local craftsman and not big industry.

AESTHETICS Can overcome the stigma of earth construction as a construction material of the poor.

SUSTAINABLE AND ECO-FRIENDLY An earth wall has a long durability and small ecological footprint.

DISADVANTAGES:

MANUAL LABOUR Physically hard work.

FOUNDATIONS Need of good foundations (expensive).

WATER DAMAGES Constructions can be damaged by heavy rain if not protected properly.

MATERIAL Construction depending on the quality of the soil.

TRANSPORTATION COST High price of material transport if they are not sourced on site.

TIME Long construction time

CONSTRUCTION SITE SIZE Big quantities of material that have to be stored somewhere.

KNOWLEDGE Expertise based essentially on literature, few experts around to ask.

THE RESEARCH LOOP

The method chosen for the introduction of rammed earth in Obunga is the construction of a prototype in the community. The prototype should be a practical example of the technique, which we are trying to promote. As no one knows about the technique locally, the only way of efficiently promote it, is by presenting it to the community in reality. Therefore, an accessible site that can be seen by many persons has to be chosen. Another important point of our method is to give the local stakeholders the means and knowledge to continue to spread the technology, because a show case without the knowledge to replicate it would be useless. Therefore, we included different local stakeholders in the building process, especially the local mason we worked with over the whole course of the construction. This network built around the prototype is a way to strengthen it and its promotional purpose. Another way to facilitate the spreading of the technique was by handing over the tools necessary for the construction to a local partner, cutting down construction costs. By constructing ourselves a prototype in an informal settlement this is giving us insight in challenges and particularities of the context in which we are trying to introduce rammed earth. Informations and experiences from the construction of the prototype can then help us again to improve the process and give these findings back to the community once the prototype is built.

We are militating for the use of prototypes as a key of communication and proof of concept. We are also in favour of practice-based research. At the centre of our research stands a activist approach towards slum upgrading in a “Do it yourself” way. We are using the findings of our prototype to plan a concrete upgrading project based on its analysis. By handing over the plans for this upgrading project to the community we show what could be possible with the technique and we are giving them a concrete example with which they can advocate for and advertise the technology themselves further on. We are using the findings from, but also the network of the prototype for the general upgrading. The outcomes of the prototype are coming all over its life. One of the aims is also to follow it, monitor it and continue to learn from it. The prototype and the eventual future ones are feeding the research to be more and more powerful.

33 Reality Studio June 2018

34 Ram-up Obunga Hypothesis.

OUR METHOD

35 Reality Studio June 2018 D E S I G N B U I L D I N G PROTOTYPE PROJECT RESEARCH F E E D B A C K P L A N N I N G M O N I T O R I N G Participative design Create partnership Link stakeholders Materials search Craftsman support Participative building Convincing process Learn from experience Problematize research Learn from the fails Based on research Using network Participative design Back to research Monitoring building Apply bigger Multiply example

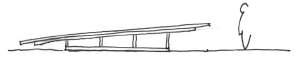

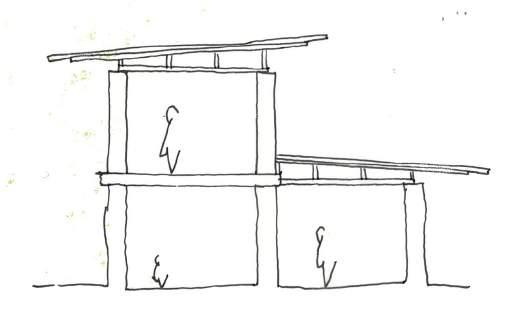

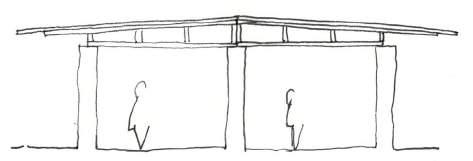

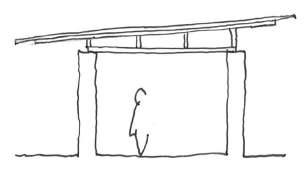

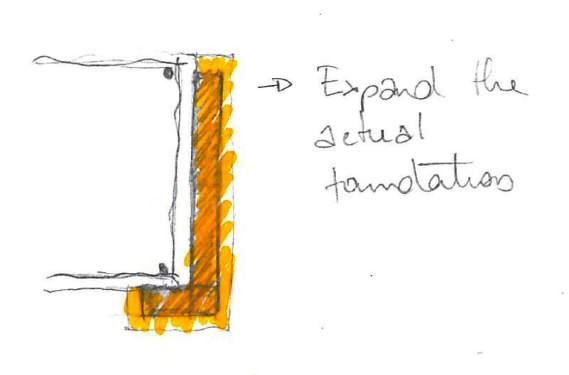

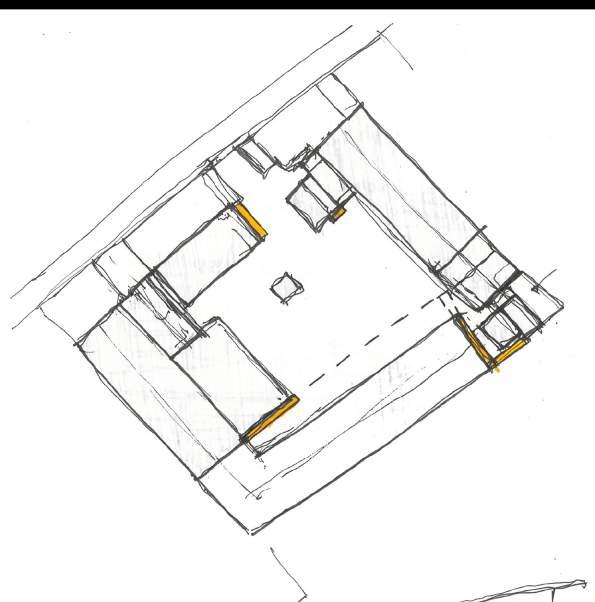

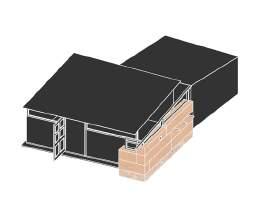

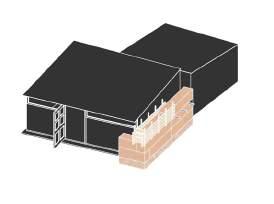

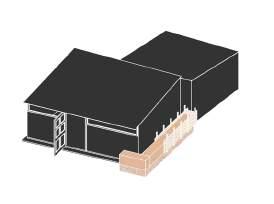

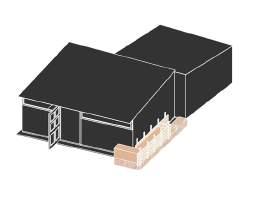

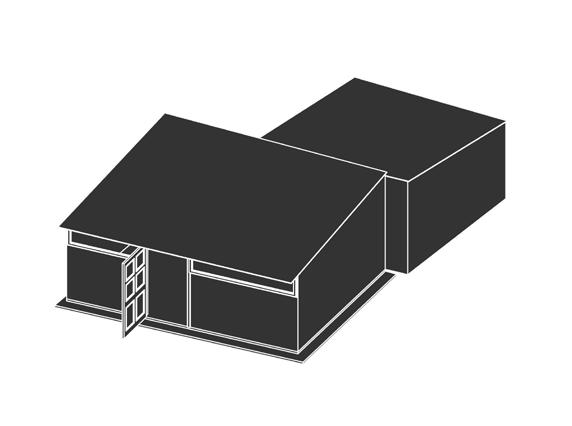

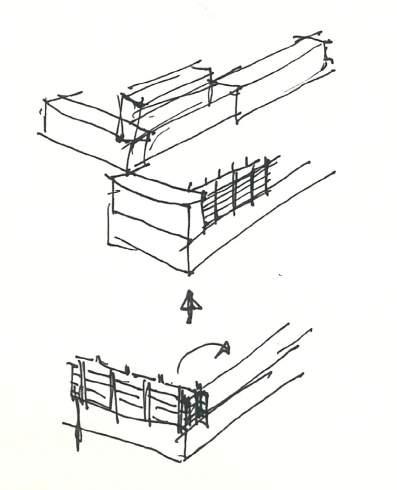

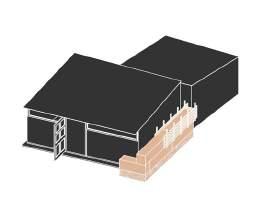

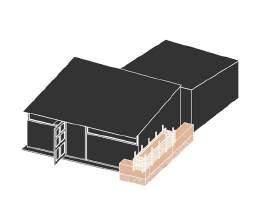

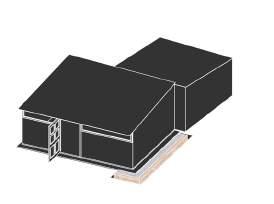

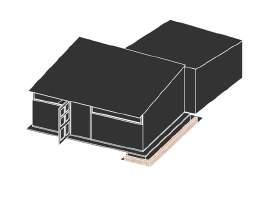

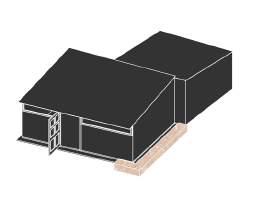

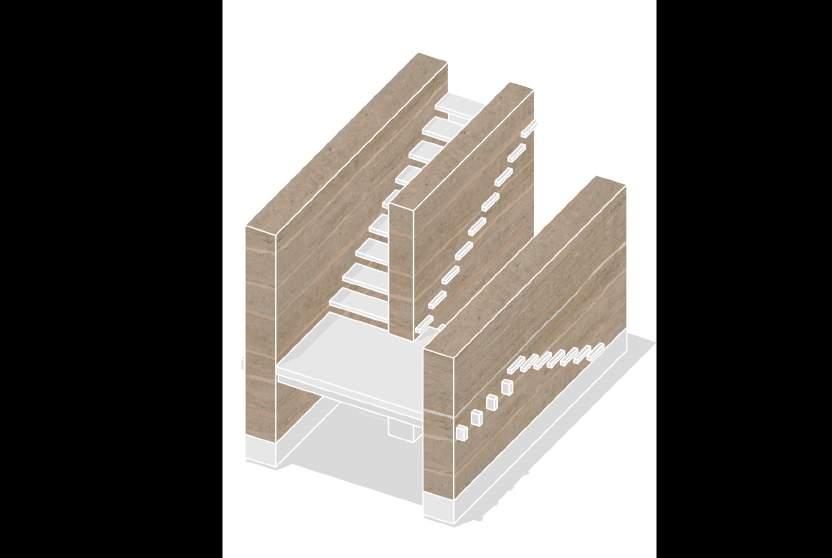

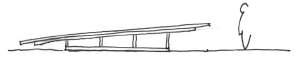

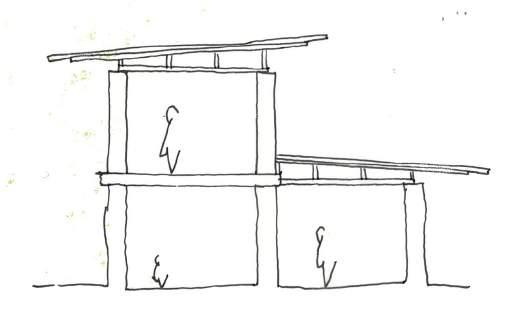

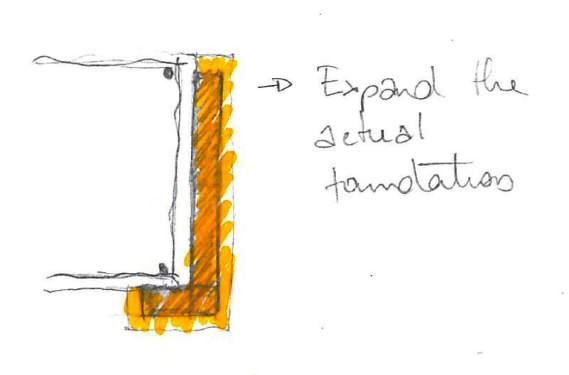

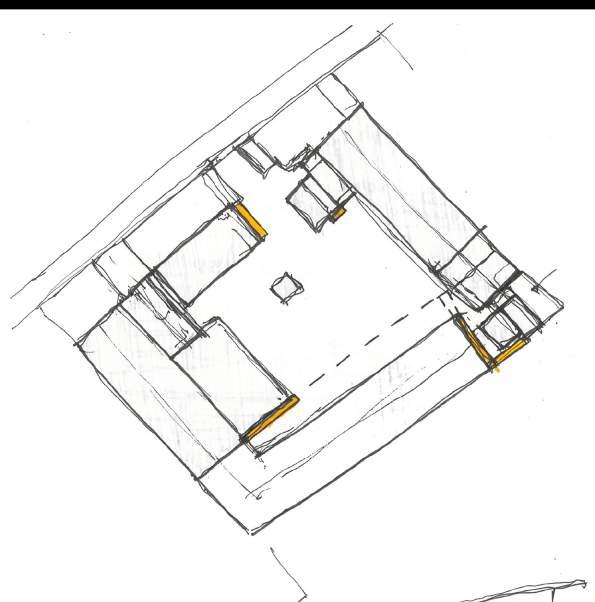

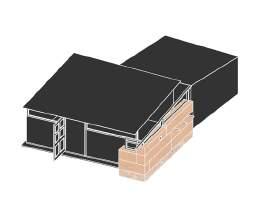

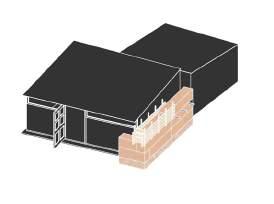

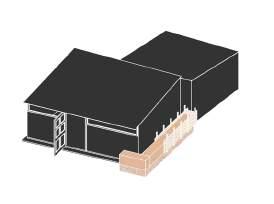

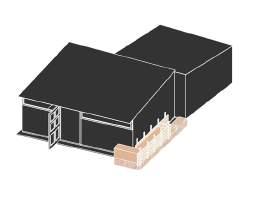

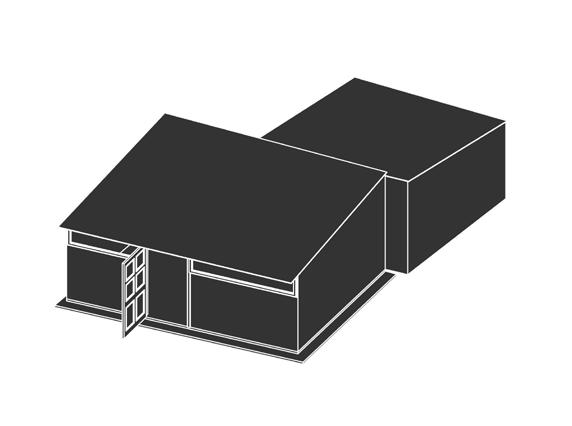

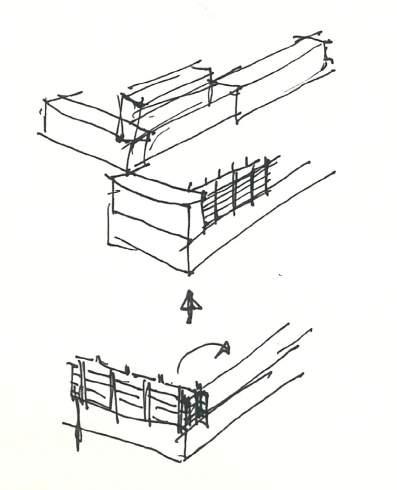

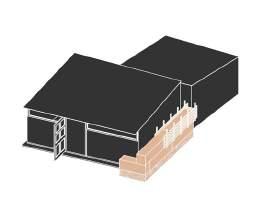

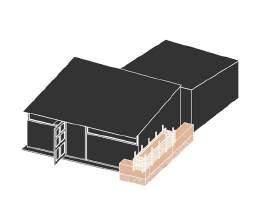

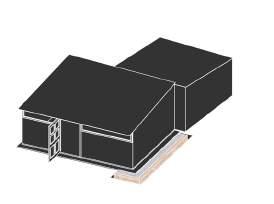

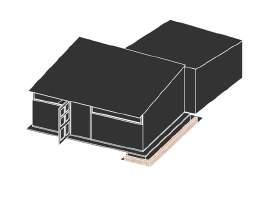

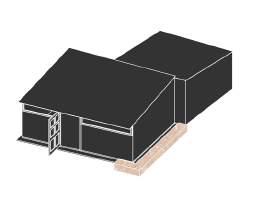

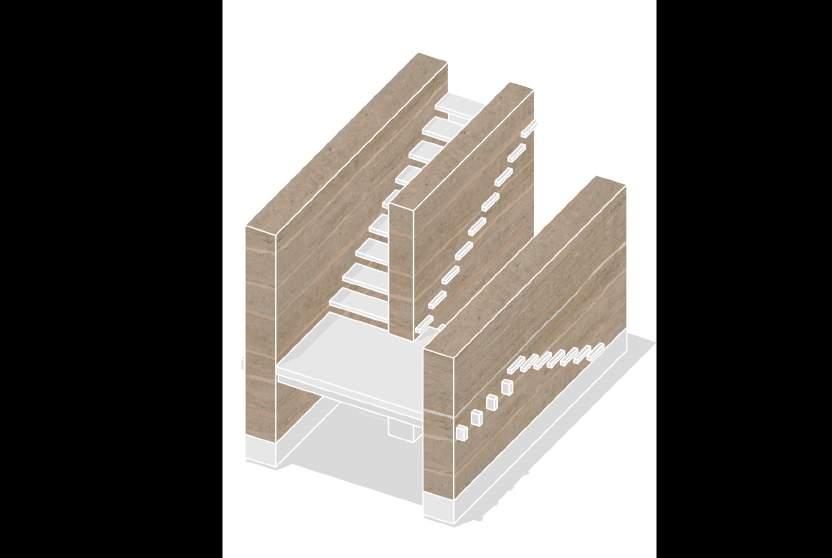

36 Ram-up Obunga Hypothesis. OUR CONCEPT Existing situation The most common organisation in informal settlements is to build on the borders of the land thus the construction are really close to each other. Close neighbours 1 2 3 Building around The first step of the upgrading is to build the first walls on the exterior of a room. If possible keeping up the activities inside. Finish the square For this step, the previous walls have to be demolished and the previous roof kept to be put in place later on again. Replace the roof The roof could be put in place again. The metal sheet knocked down from the walls could be reused for the extension of the roof to protect the wall from rainfall. In this concept we are keeping the same size of each room but it is also possible to benefit from the upgrading to extend the room surface.

Upgrading slums face many issues. The kind of material used, is a problematic issue, as we have seen before but also the price of the upgrading is one of the main issues. The renovations done by private owners in Obunga are being done little by little. When they can afford reparations, they fix one part, then another. They can not save money for a complete upgrading, because they have to fix different parts and continue during this time, to live in their house. One problematic, especially for the scale of the Emmaus Blessed School, is to follow the arriving of funds for the upgrading. The works have to be done in several steps, when the money is coming. The challenge of the school is also that it is already very crowded and they cannot afford to close the school or parts of it during the time of the construction works. This is another argument to manage the upgrading step by step. We developed a form of upgrading achievable in several steps and allowing to keep up the teaching during the construction works. The new walls are been built next to the previous ones, before being torn down. Thereby we minimize the time of moving the children. It could even be done without moving the children at all, if the last steps are done during the three last days of the week, when the children have no teaching in the classrooms (the Fridays are used for sports outside the school).

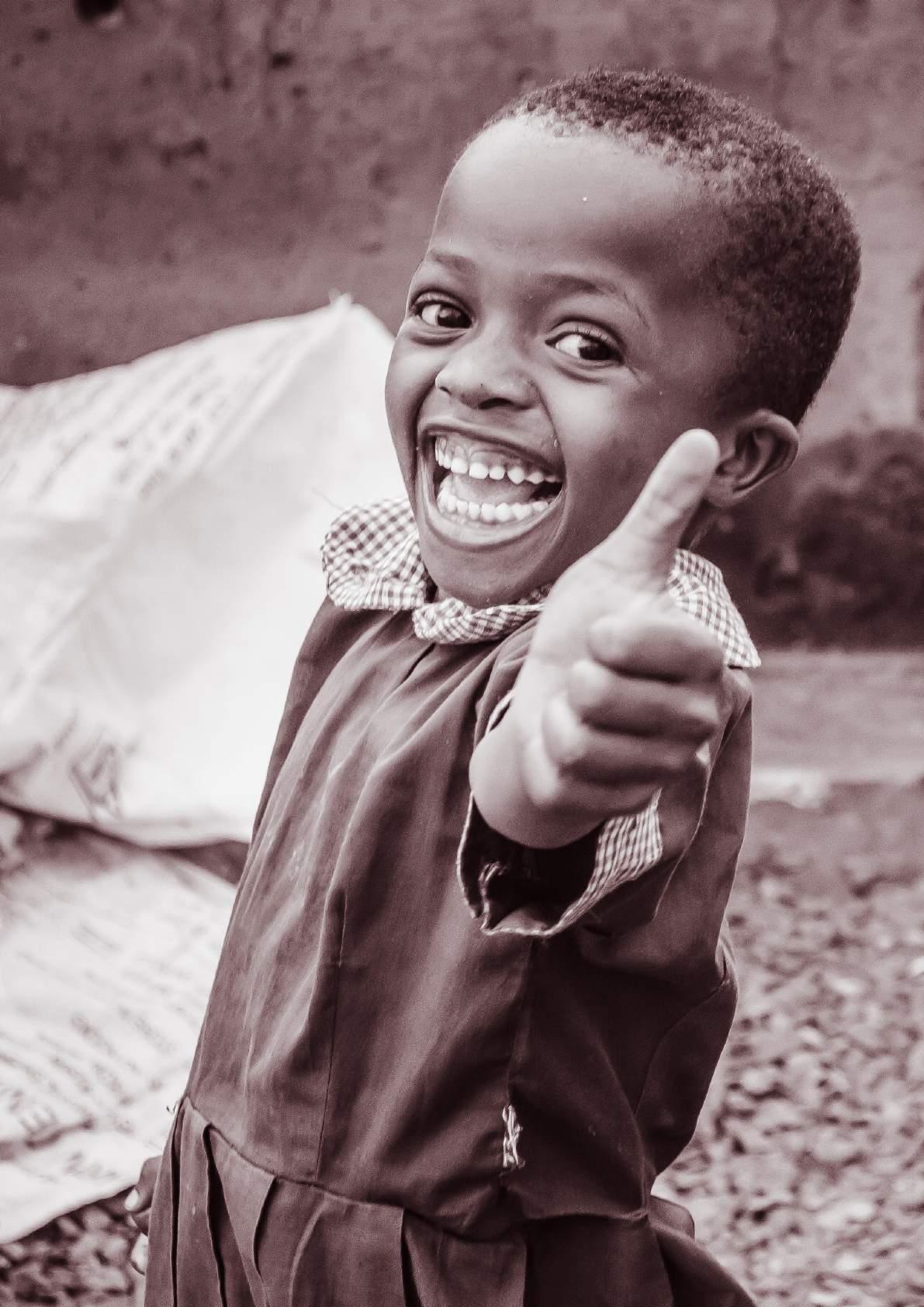

THE STORY OF ROONEY

To explain the “house is a roof” concept, we demonstrate it with a fictive scenario, which we made up. For our story we chose Rooney, a kid from the Emmaus Blessed School, which we met and really appreciated. Let’s follow his fictive life.

Hypothesis.

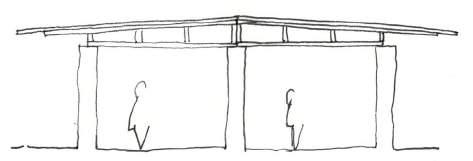

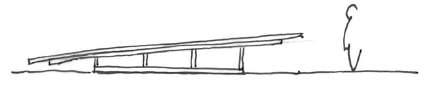

A HOUSE IS A ROOF

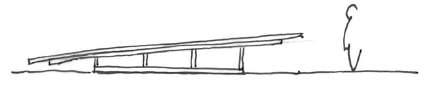

Use local soil, from the site, as a building material could mean that the house is resumed at one roof, possibly moveable. Many people living in Obunga aspire to leave the slum for the countryside but the economic opportunities are keeping them in the slum. Some inhabitants of Obunga already own a plot of land for their retirement. We heard that murram is commonly found (the type of soil necessary to build a rammed earth wall) on site in the countryside. As in the Luo tradition, where each mud house was built for a unique person which gets demolished after they passed away, we imagined a modular housing system. By only spending money on the roof and moving it or adding to it according to the needs, costs can be kept low. This proposition is an adaptation of our concept to new build houses.

SCENARIO 1

SCENARIO 2

SCENARIO 3

SCENARIO 4

37 Reality Studio June 2018

4 5 6 Continue The second room could be upgraded with the same principle. After doing the facade wall, two walls are already done for this second room. Redo The next rooms are following the same idea until the upgrading is completed. Or stop

any time the works could be stopped and the two entities, the new and the old one, could work independently. 38

At

Ram-up Obunga

39 Reality Studio June 2018

2018 - Rooney is buying a metal frame for his future house.

2018 - Rooney is building rammed earth walls to erect his house and put his frame on it.

2020 - Rooney saved money during two years and can now afford to add another room to his home. He bought new frames for this new room.

2022 - The family of Rooney grew bigger and he decided to build a new room on top of the previous one. He reused the old frame and puts it again on top of the second storey.

40 Ram-up Obunga Prototype.

2030 - The family of Rooney decided to move. They dismantled the house and took their frames to build another house somewhere else.

After having the idea of building a prototype we looked for the best place to erect it. We chose to link the prototype with the nursrery class situated close to the entrance in order to attract public attention by opening the construction site to every curious person. We conceived the walls size according to the time we had to erect it, but big enough to be recognized as a functional prototype. We decided to extend the wall arround the corner and design a L shape in order to maximize the stability of the wall.

The design of the wall was quick and left us some time to plan the construction site. Our partner Evance was our main reference concerning the materials, but also for the finding of workers for the foundations. We planed the arrivals of materials related to a timeline scheduled before hand. We started to shape a network around us involved in the project to ensure its viability.

PROTOTYPE.

FINANCING THE PROTOTYPE

To finance the prototype wall we started a collection on internet through a crowdfunding campaign. This collection was also a pretext to inform through the funding of our adventure. We were building at the same time so we kept in touch the donors, with news directly from Kisumu. This experience was full of learnings for us. We experimented the research and the management of a budget. At the beginning of the works we estimated the total cost of the prototype and we started our crowfunding campaign. We used the international website Ulule and spread the link to our entourage. The platform has the interest to propose several languages for the same project. It was mandatory for us to communicate broadly our message. The collection lasted 30 days and we recuperated our personal investment after finishing the works. Our donors were principally family, friends and entourage. We were really affected that the involvement of our entourage. It is also a way to share this adventure together. They are involved and a part of this project.

42 Ram-up Obunga Prototype.

PLANNING OF THE WALL

Design of the protoype. Entrance 420cm 118cm 43 cm thick Little window to show the inside and the thickness of the wall. Wooden poles going a cross the wall to hang up things. Inside they are supporting a shelf. Brick foundations 43 Reality Studio June 2018 Potential places for the prototype wall Time schedule for the building of the prototype Calculation rules for the thickness of the wall 44 Ram-up Obunga Prototype.

Screenshot of the Ulule webpage presenting the project.

Evance, material specialist, our main support in this adventure.

Evance is the manager of the craftsman association of Zingira situated in Kisumu, not far from Obunga. Evance is working with the Reality Studio since 2005 and he is really invested in his community. Evance was our resource guy in terms of materials or craftsman advice. He is the key member who make possible the construction of the prototype.

Kennedy, the headteacher of the Emmaus Blessed School.

Kennedy is the headteacher of the Emmaus Blessed School. He is really involved in the condition of orphans in Obunga and he is taking care of some of them. We were impressed by his comprehension of the project and he offered us the opportunity to achieve our project in his school without hesitation.

Steve, our partner in construction, now specialist in rammed earth construction.

Steve was a surprise in the adventure. He was open to our ideas and towards learning new things in a way we couldn’t imagine before hand. The circumstances lead us to meet him and he followed us with great trust into this venture. He joined us as a brick specialist, we left him as a rammed earth specialist.

Nothing would have been possible without the strong network of people involved, which supported us. We chose to build a prototype when we were sure that the community around us was supporting the project. The project enabled also new relation inside the informal settlement and linked the craftsman association Zingira to the Emmaus Blessed School for further interactions.

45 Reality Studio June 2018 46 Ram-up Obunga Prototype. OUR PARTNERS

ZINGIRA Evance

Charlie

Samson

Kennedy

The widows PROTOTYPE 47 Reality Studio June 2018

Steve Mason Steve Manager

Carpenter

EMMAUS

Dominic

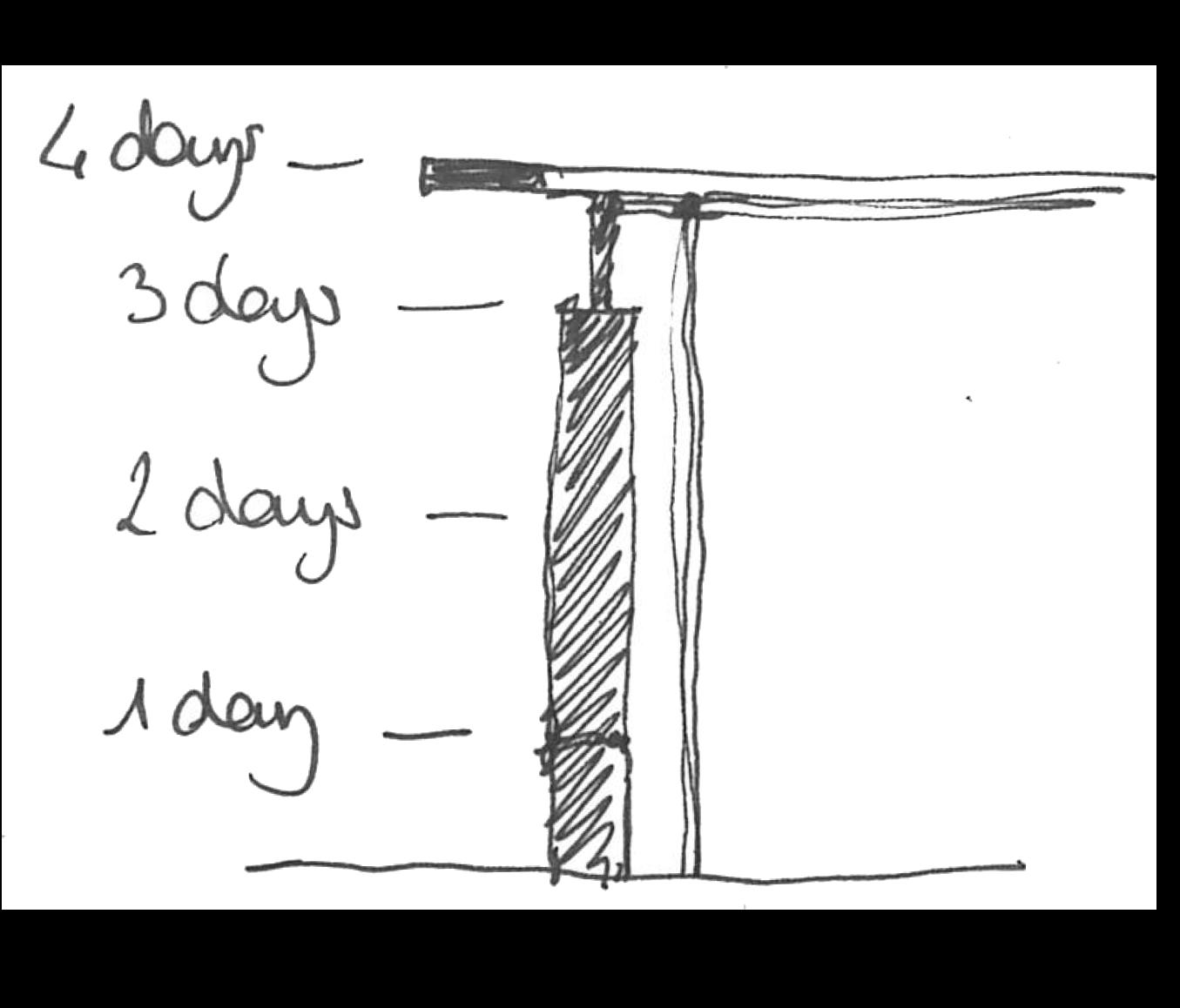

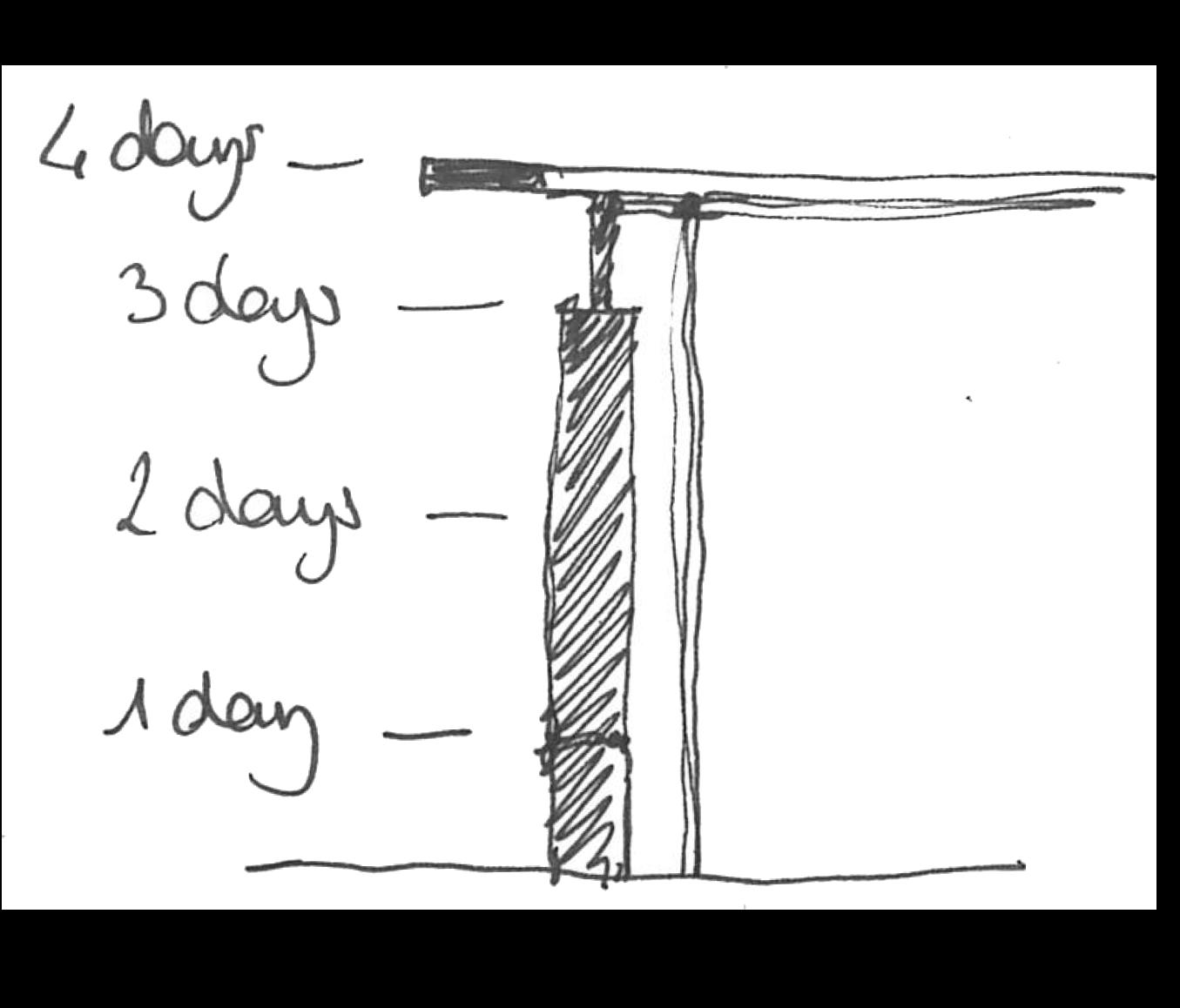

48 Ram-up Obunga Prototype. CONSTRUCTION TIMELINE Existing statement The existing classroom made from metal sheets. Digging for the foundations Digging of 1,5 feet (about 45 cm) deep ditch by hand with a pickaxe. Pouring the slab Pouring of a concrete slab as a stable base for the brick foundation. First earth brick We started with the little brick of the corner and tested the methode for the first time. Second earth brick For the 2nd earth brick, we tried the realization of a corner with bricks method thanks to the modularity of the formwork. Finishing of the 1st layer The same day we moved the formwork to finish the first layer which is about 50 cm high. Do the angle We realized afterwards the mini part of the second layer asking a big efforts to put in place the formwork. Last earth brick In the last brick we implemented a little window in order to show the inside of the wall and the posibility of windows. Wooden frame To connect the new wall to the previous structure we teared down the old wall and added a wooden frame on the new one. 23rd of March 24th of March 31st of March 2nd of April 2nd of April 4th of April 5th of April 6th of April 2 3 7 8 9 13 14 15 1

After finding the workers to follow us and the materials to build, we decided to start the works on Friday the 23rd of March. During the works, we had to plan with the schedule of the school. Children have sport outside the school on Fridays so it was an opportunity for us to start this part that needs a bit of space to be done. In total, we spend 4 days on the foundations, 3 days on the construction of the formwork and 6 days in the construction of the wall itself. Replanning

our

April with some “margin days” in case of delays. Finally we used all of these days because of the different problems we faced.

THE LOCAL PARTICIPATION

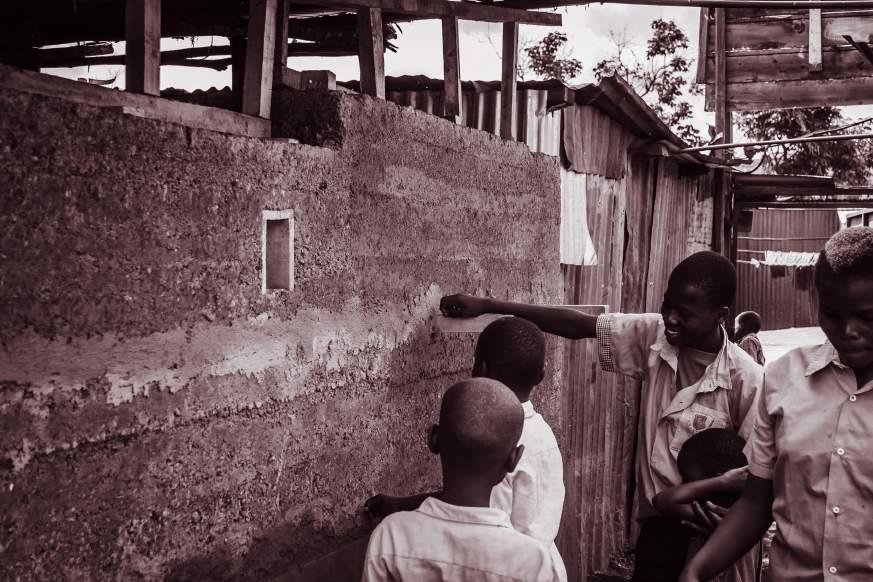

The main aim of the wall as a prototype, is to show the technique of the rammed earth construction and to provide questions. The time of the works was suitable to share knowledge with different audiences such as children, stakeholders, experts or curious bypassers. We based the planning of the construction site on the participation. Our idea is to showcase and put in place knowledge that can be taken up and continued. We had the opportunity to work in partnership with a craftsman, Steve, to implement the technique in a bigger scale. He is now owning the knowledge of the technique and can spread it. The headteacher of Emmaus Blessed School was really involved in the project and he also owns the knowledge to further extend the school by himself.

OBJECTIVES

Inhabitants

SCALE OF THE SLUM

Workers

Challenging practice with children. Participation without planning it.

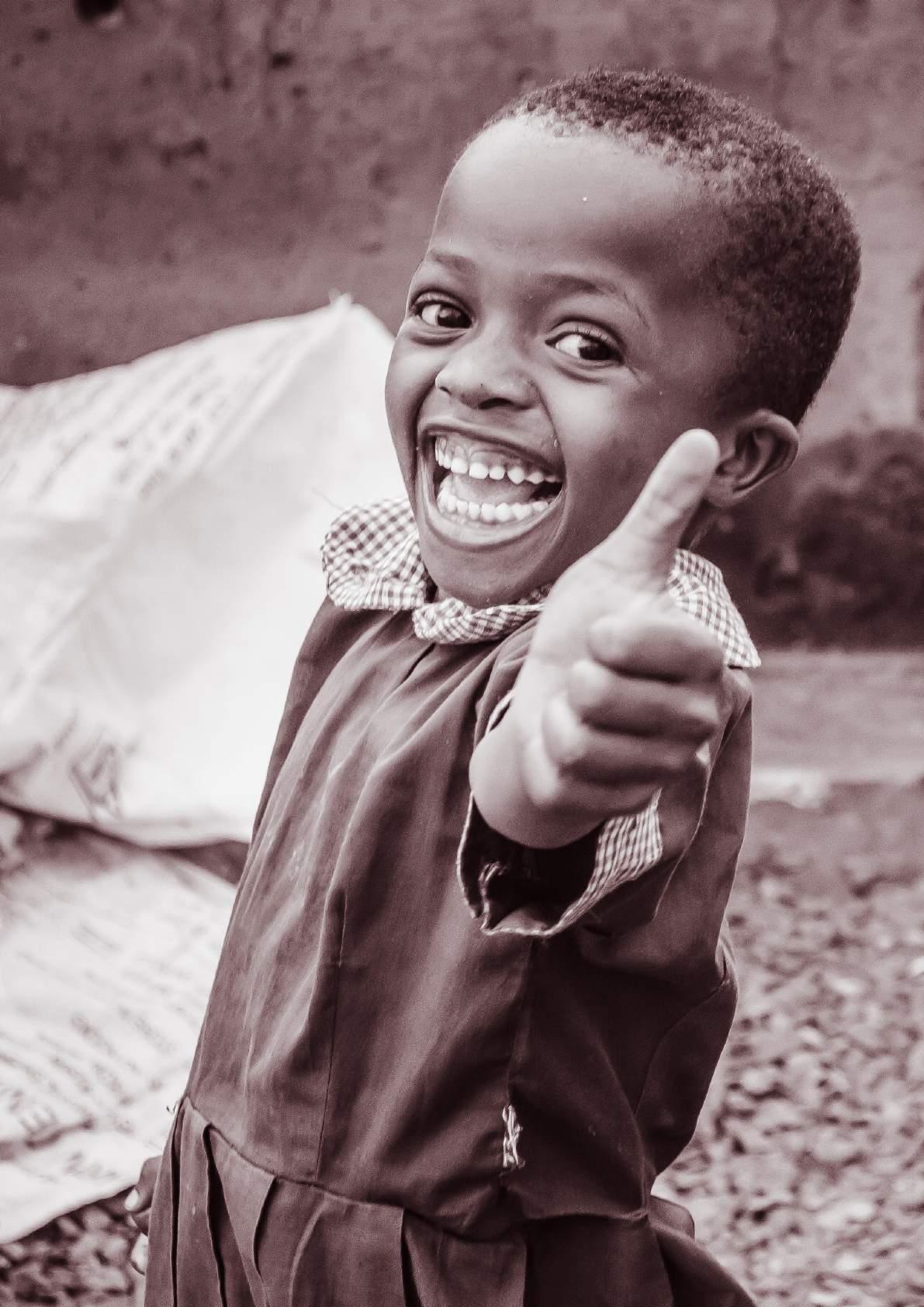

Our first audience to catch were the children. We did not know at first how to involve them but they found the solution, they involved themselves! They were copying us from the first moment and we chose that way to transmit knowledge together with a few explanations. We waited for the questions to come up and tried to answer them with an adequate language. We were surprised by their capacity to understand and also to work together accomplishing the tasks. It is one of the lesson we took from informality. It was obvious that preparing a formal involvement will be difficult and not work out. The experience teaches us that informal participation could also work well. By working with them, our objectives were multiple. Firstly we touched in that way the next generation of Obunga. The ones who will build the next Obunga. Secondly making them aware of sustainability is a key to change the next generations mentality. We also had the objective to empower them and give them pride in their work. It was also new for them to see the work of an architect and we hope that we inspired some of them.

One child: “Can I help you to mix the cement?”

Another child: “It is not cement, it is lime!”

With our experience we can confirm that rammed earth construction is children friendly. It is easy to propose to them simple activities, fun and safe. They can easily understand how it works and get proud of what they did.

The tools are not ours. The open door technique.

During the works, we were careful to let people participate and join us. As much as possible, we left the tools to someone else so that he/ her could try to do it. Especially ramming was a popular task. Almost all the teachers tried to do a part of the wall and used their break to give us a hand or to see how the wall was growing. It was also time planned in, in our schedule. We did not want to be taken by the time and miss this transmission, the most import part of the process to achieve our goal of spreading the technique. People where attracted by the “noise of the wall” and their curiosity about what was happening pushed them to enter the school and ask questions on their own, about that technique completely new to them. The prototype has the power to attract people and push to speak about what is going on. Our aim is to convince in order to spread the knowledge and the prototype is our tool to do so. Learning by doing with your hands is an effective and efficient way of knowledge transmission. Lifting up a rammer of 10 kg and pushing it against the soil is an experience which you keep in mind.

COMMUNITY

The technique was easily “sharable”. No prerequisites are necessary, the tools are approachable to everybody.

49 Reality Studio June 2018 Brick foundations Erection of the brick foundations. Concrete filling Filling up of the foundations with concrete to shape the imprint of the earth wall. Finishing bricks The two last layers of the foundations are made completely from bricks to stabilize the formwork. Starting of the 2nd layer To realize the second layer we moved the formwork up and laid it on the first layer. Second brick As for the first layer we connected the next brick directly to the previous brick of earth. Hanging woods In the previous formwork we put pieces of wood that we removed to put longer ones in place which are going trough the wallorder to hang up things on them. Roof extention To close the classroom we added new pieces of metal sheet as a roof and connected the wall to the metal one. 25th of March 26th of March 26th of March 3rd of April 3rd of April 4th of April 6th of April

construction. Before

4 5 6 10 11 12 16 50

during the

starting, we scheduled

construction between the 23rd of March and the 6th of

Ram-up Obunga Prototype.

SCALE OF THE SCHOOL Children Teachers

51 Reality Studio June 2018

CHILDREN

52

Ram-up Obunga

Prototype.

Speaking about female empowerment. Statistics of involvement.

Even if we did as much as we could to invite a maximum of people to join us during the construction, we did not see many women on the construction site. Our technique was not to push people to join us but to try to find a way in which they feel welcome on site. No women joined us to ask questions during the works except for the fruit seller, who join us in the morning for the fruit-break. She was called “the good girl in a bad city” by Steve.

It was easier with the girls of the schools to involve them, but on the contrary to the boys, we had to invite them specifically. In the school, the genders are quiet differentiated. First, by their uniform but also by the tasks given by the teachers. The girls are more often asked to help with the cooking and boys to do more physically demanding tasks. Through some stratagem we have put the tools in the hands of girls motivating them to work with us on the wall.

WOMEN

A gender-equal team. Who run the world?

As we were two students to lead this project, one man and one woman, we were representing the job of an architect without gender orientation. It was interesting to show a leading position from both sex, equally distributed between us. We took this opportunity to show, to the young girls that responsibilities are not a question of gender. We did face only few real differences of consideration between us from our partners. When we met this kind of situation, we used humour, to affirm our position about the question. The “female part” of our team has received many comments like “You are a really strong girl, to do that!”. Her comments on the construction had sometimes to be validated by the “male part” of the team according to the mind-set of certain stakeholders. Generally we answered kindly to these remarks (except when the “female part” was asked several times to provide water to the team. No way).

What we are most proud of: Leaving the knowledge behind and disappear.

After starting the earth part of the wall, we thought, that we will need help with it to finish in time. For the foundations, we asked for the help of Steve, “fundi” and expert mason. He was interested in what we wanted to put on top of our foundations. We took the opportunity of his curiosity to invite him, to follow us through the rest of the adventure. Having a craftsman with the knowledge about technique is one of the best ways to spread it with quality. It was our first practical experience with rammed earth and we shared it with Steve. He did the tests together with us and discovered the results at the same time as we did. We did not anticipate this key factor in the project, which brought a completely different extent to the project, another scale of spreading. We were impressed by his interest in rammed earth and he became entirely convinced by the technique. We left the knowledge to him and tried to “disappear” as much as possible during the process to let him be the holder, of the rammed earth knowledge in Obunga. Since he has built the prototype in the Emmaus Blessed School, he is recognized as the expert of rammed earth in Obunga.

Keeping in contact, news from Obunga.

Thanks to telecommunications and especially WhatsApp we kept in touch with our network on site and especially Steve who is calling us to inform, about his work in Obunga. We learned from him that he has made some contacts and he is planning to realized a rammed earth house in the countryside for a potential client.

THE MATERIALS FOR THE RECIPE

THE EARTH

way of spreading through a local person that people can more easily believe (even more when the explanation is in Swahili thanks to Steve). He also joined us during the exhibition in the city centre of Kisumu and we left the billboards to him. Our goal to transmit was reached, we chose to disappear...

The earth is the most crucial material of a rammed earth construction. Different types of soil can be used. All over the world, suitable soils can be found. As basic rule of thumb is; only subsoil free from organic matter should be used. At the same time, the soil should not be sourced to deeply either. Ideally the soil should be sieved to get rid of stones and gravel that are too big. Stones generally should not be bigger than 2cm. The soil composition should be around 70% sand and gravel, 15% silt and 15% clay. The clay content is crucial because it acts as binder holding together the other parts. Clay has the property to expand when in contact with water and to shrink when drying out. To little clay means that a wall would not hold together, too much clay would create cracks in the wall when drying out. Those proportions can be tested as explained in the earth testing chapter. If the clay content is to low the soil has to be mixed with a more clay rich soil to get the mix right. If there is too much, the soil should be mixed with sand or the addition of some lime can also help too, to a certain extent. The subsoil we used is called murram and is part of the laterite soil family, which is particularly well suited for earth constructions. Attention has just to be paid to the clay content, which can vary a lot. Lateritic soils are most common in tropical and subtropical climate zones, as it needs for its development high temperatures. The colour is most often somewhere between beige, ochre or red, this due to varying amounts of iron oxides in the soil. Those lateritic soils, as well as murram are usually well known by the local people and also very popular in road constructions arround the world.

Earth can be used without additives for rammed earth construction, when tested properly. As we were lacking practical experience we decided to play it safe and stabilized the earth with lime. The lime has a binding effect in order to “provide adequate compressive strength and durability. Unlike cement, which works with the coarse particles of a soil, nonhydraulic lime works with the clay minerals in a soil.”1

1 V. Maniatidis, P. Walker, A Review of Rammed Earth Construction, University of Bath, 2003.

53 Reality Studio June 2018

54

The construction site as a technique of spreading female empowerment.

Ram-up Obunga

Prototype.

CRAFTSMAN

55 Reality Studio June 2018

STEVE

Steve was our best ambassador of rammed earth. During the construction time, he quickly took the responsibility to answer to questions from visitors. It was a nice

56 Ram-up

Obunga Prototype.

LIME CEMENT CLASH

Most persons in Europe but especially in Kenya have never heard about lime as an alternative to cement. Cement as we know exists only since about 200 years, the modern cement we know is called Portland cement and is the worldwide most produced construction material. But its production and also during the hardening process emits a lot of CO2 making it ecologically very unsustainable. Concrete is in fact the main CO2 emitter within the construction industry. Lime or slaked lime is what the ancient civilisation and everybody else used before the discovery of Portland cement used. The Pantheon in Rome is built with a concrete from slaked lime volcanic pozzolana and a few other materials. Slaked lime is made from fired lime stone but uses only about half the temperature that Portland cement needs. Lime hardens slower than cement does but it takes up CO2 form the environment to do so and in that way, reduces its footprint overtime. Compared to cement it lets pass through a certain amount of humidity letting a wall breath and keeping the humidity from building up behind a plaster for example. Because of its chemical structure lime also bonds better to earth/mud and is in that way better suited as a plastering material than cement. We used for our prototype 25kg bags of hydraulic lime that we bought for around 500 Ksh at a local hardware store. Most people didn’t know about lime but it is widely available. It might be that because of the little quantity sold prices were a bit high.

EARTH TESTING

By being the main resource of the construction, the choice of the earth is the most important one. The structural part of the construction is assured by it and we are completely dependant on it. Earth is an inconsistent resource, what means that there is variations between the composition of different samples. The first step, done before starting the construction, was to test the earth available. Before buying a huge quantity of earth, we took a sample of murram to test the composition. For that we follow a series of tests we found during our literature study. It is quite difficult to compare static images and comments to real tests, which needs to be interpreted. We did not have the possibility to ask questions, we needed to interpret our results ourselfs.

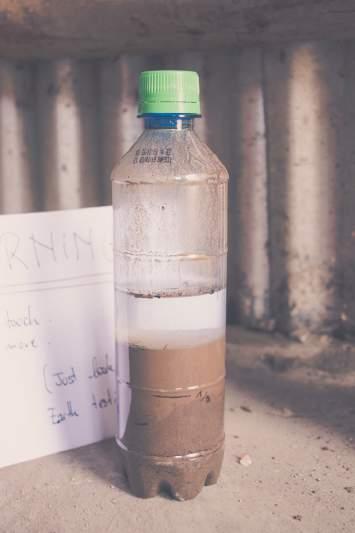

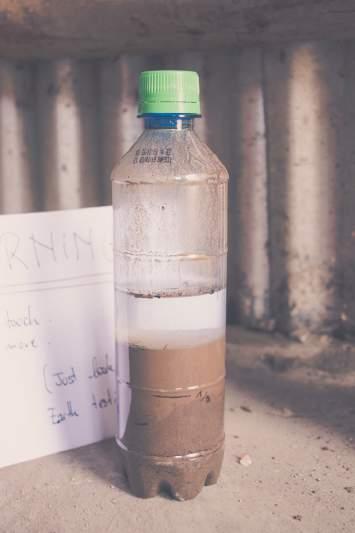

Sedimentation test.

The first test we made was a sedimentation test to know the composition of earth, especially the percentage of clay, sand and if there is organic materials. We put in a plastic bottle 1/3 of earth, 1/3 of water and the rest empty. We shook it strongly and let it rest. After 24h we examined the sedimentation which occured. The results were really hard to read and our own reading has shown that a tiny quantity of clay was present (picture shown on the right). Even if this test is used a lot, a study led by the University of Kassel has shown that the margin of error is around 1750% with this test.1 Afterwards we decided to make a test specifically to test the quantity of clay in the earth (see test 2).

1 G. Minke, Building with Earth: Design and Technology of a Sustainable Architecture, 2012.

Cohesion test. This second test has the aim to test the quantity of clay in the earth. The quantity of clay is important in earth construction because it is the “glue” of the material. In rammed earth construction, the quantity does not have to be as much as in other earth techniques but a certain amount is necessary. The cohesion test consists to make a ball of wet earth around 4 cm diameter and let it dry under the sun until it is completely dry. We did it with the result, that the ball of earth was still one piece without major cracks, when it was completely dry. This test has shown us that there is enough clay in the earth composition.

Baby brick.

To test the technique before starting the construction, we realized a baby brick of rammed earth. This little workshop amused the children and they kept the little prototype in their classroom for a time. We kept this sample until the exhibition in town to show the techniques materiality. This little object was a game for the children during a long time. They where playing with it, returning it and trying to destroy it. The last day before the exhibition, the brick broke into two.

2 3 4

Drop test. This test is used to find the ideal water content in the earth during the construction. Before putting each layer of earth in the formwork, we squeezed the damp soil into a ball of around 40 mm diameter and dropped it from 1,5 m hight onto a clean piece of wood placed on level ground. The ball should not stay in one piece (in this case it is too wet and it has to dry before use) but also not explode in too many pieces (in this case it is too dry and it needs more water). Our own optimal result is shown on the picture on the left. Because we stabilized the earth with lime, but also because the temperature dried the soil really quickly, we used a bit more of water than the tests have shown.

57 Reality Studio June 2018

Mixture of

58

earth, lime and water before mixing.

Ram-up Obunga

Prototype.

1 59 Reality Studio June 2018

60 Ram-up Obunga The works.

THE WORKS.

Conveniently the county government was digging a two meter deep trench in front of the schools door, when our bricks and cement arrived and had to be transported into the school. This is part of the challenge to work in such an environment you never know what surprises await you the next day.

We started the bricks foundations on Sunday the 25 of March which are supposed to support our several tons heavy rammed earth wall. To do this properly, we were working together with Steve, a local mason expert in brick buildings, our wonderful fundi (the Swahili word for worker). He showed a lot of interest in what we were doing and it should not be the last time we met. It was really helpful to discuss with him the foundations. He understood the challenges and we designed hands in hands, even though with some missunderstandings in the beginning.

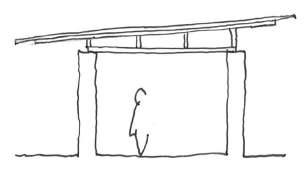

THE BRICK FOUNDATIONS

Keable writes in his “code of practice”, a rammed earth wall is only as good as its hat and shoes. The foundations being the shoes, they need to be as solid as possible and prevent a several tones heavy wall from collapsing. They should go down to a solid ground structure ideally bedrock and also protect the bottom of the wall from humidity coming up through capillarity as well as from rain splash back.

On Friday the 23rd of March, we started to actually build our prototype. We decided to focus our prototype on the rammed earth part of it and to build up on local traditions The choice was made to use a conventional foundation limiting the experimentations to the upper part of the wall. Do to local regulations we were limited when it came to the depth of the foundations to 2 feet (to stay within temporary structures). We hired two local workers to dig out the footprint of our prototype within about this depth of 2 feet. Apparently digging was too hard of a job for Mzungus and we were advised to ask for help.

The day after, on Saturday the 24th of March a slab of about 20 cm high of concrete was poured in the trench and we occupied our afternoon with the earth testing during the time of drying.

Starting day of the foundations. Our little construction site had to deal with huge sewage works in front of its doors, on its first day.

Technical section of the rammed earth wall put on its foundations. We followed the advises of locals to do the foundations. The design is quiet exotic.

Concrete fill in Gravels + concrete fill in

LOOKING FOR THE BRICKS.

To buy cheap bricks we did a little trip with a truck to the edge of Kisumu. There we discovered how they are making bricks traditionally. We took a long straight road from Kondele. After few kilometres, the landscape changed into a repetition of piles of bricks. Each seller is standing close to his pile. The bricks are cooked directly on site in an oven made by bricks itself. After drying, the bricks are sold on site and even the bricks of the oven are sold as bricks of construction.

62

The

Ram-up Obunga

works.

63 Reality Studio June 2018

64 Ram-up Obunga The works.

THE WOODEN FORMWORK

To design the formwork, we mainly based our drawings on the extensive literature we gathered before hand. We had a look at technical drawings but also at experiences of others. Without previous experiences, we based our ideas on the experiences of the others, to catch what failed or what was efficient. We used the common open source knowledge shared on the internet and this also made us realising the importance for us to share our experience afterwards. The design of the framework followed several steps. We drew something, which got changed by the reality of the materials available in this context, then changed again, by the reality of the materials we received and changed once again during the construction, when new unforeseen issues appeared.

The design tries to be efficient in term of cost, use, flexibility and durability. We chose the wood, which is easy to tool (but is more and more expensive in Kenya now) and permits a certain degree of flexibility. To link the two sides of the framework in the bottom, we designed metal rods, with the help of Evance and used traditional ropes to fasten the upper part. This combination mixes efficiency, cost and modern & old tradition, to do rammed earth construction.

65 Reality Studio June 2018 66 Ram-up Obunga The works. 67 Reality Studio June 2018 The

On

We

2

68 Ram-up Obunga The works.

finished brick foundations

the right, the entrance to the Emmaus Blessed School.

put the bricks directly on the concrete slab. It took

days to do the brick foundations.

Example showing the flexibility of the used formwork.

After finishing the foundations, we started the construction of the formwork on Tuesday the 27th of March. We were working in another School called Future Hope Academy located on the same road not far from our school. The space in Emmaus is really limited and other student groups were working at the Future Hope School. We took the opportunity to work there, share tools, knowledge and motivation.

We were thinking to spend 1 or 2 days on the construction of the formwork, it finally took us 3 days. We started to build with a lot of open questions. They got solved one by one directly on site during the construction. It was an interesting way of planning by experimentation, which was the best way of working in this context.

We transported the (quiet heavy) formwork back to Emmaus, with the help of some workers from Future Hope. The journey along the main street of Obunga took a lot of public attention. Things were turning out, as they should, even if a bit to slow.

METAL RODS, LEARNING FROM KENYA

The bottom fastening of the formwork is done by a metal rod. In our first drawings, we designed a simple long threaded rod fastened with two bolts, one on each side. When we met Evance to order the materials, he explained us that, it is almost impossible to find that and if, its super expensive. This confrontation with the reality of the context pushed our design further, into a cost efficient and beautiful tool. It is part of what we call: learning from Kenya.

Inches and feet, our fight.

Building in Kenya means also changing our reference of measure. To order our first delivery of wood we had to convert centimetres into feet and we had to deal with the sections available. Earlier plans became obsolete once more. To communicate and work easily we bought a measurement tape, which had both centimetres as well as inches, some of our best invested schillings. After a while, we started to be used to it (more or less) and we were drawing with theses unites for more comprehension between each other.

THE EARTH RAMMING

A rammed earth wall is composed by several layers of soil put inside a formwork and compressed thanks to a tool called rammer. We used a mixture of murram (sub-soil) and lime (ca. 3-5%). The wall is three of frameworks high, what means 150 cm (5 feet) laid on foundations 40 cm (16 inches) above the soil level. We realized eight bricks of rammed earth, made in five days with three workers. The time includes the dismantling of the former corrugated iron wall, the extension of the roof and the plastering. To know more about the technique, let’s follow the time-line on the next page!

rain)

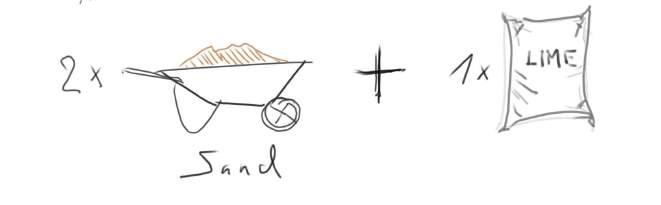

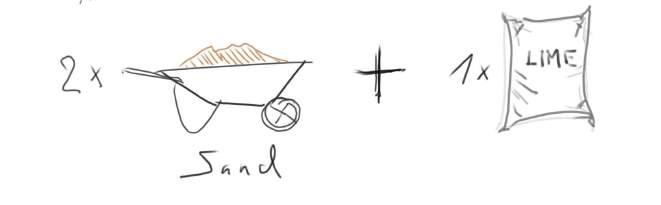

OUR RECIPE

Trough a mix of gut-feeling and literature study we came up with this formula, which comes down to about 3-5% lime.

THE RAMMER

We ordered two metal rammers from a welder in Kondele. One about 3/4 kilos and the other one heavier. Finally we used almost only the little one.

The little rammer, more used.

The big rammer, was to big.

69 Reality Studio June 2018

70 Ram-up Obunga The works.

First assembly of the formwork in the Future Hope Academy with the help of Evance.

16in 20in 23in 100in 85in 82.5in

71 Reality Studio June 2018 16in 3in 32in 1in 1in 2in 2in

Technical drawings of the formwork used during the construction. Theses drawings were done afterwards. During the construction of the formwork we did not work with precise plans.

Ram-up Obunga The works.

Teamwork at the Future Hope Academy School. From the left: Evance, Léon, Oskar, Marine. Behind the camera: Nikola. Working along with other groups was a wonderful mood. Future Hope was the site of the project of two new classrooms by Siddu but also the project for new furniture by Nikola & Oskar and the project Cool-centration of Bane & Sena. Sometimes we were also visited by other groups like Out of Tubes (Jule & Maxime). We were supporting each other and sharing resources (sweats, fruits, fun, laughs and also

72

THE

MANUAL

On this second day of the Easter holidays we started the rammed earth construction! We received the help of the children and organized an informal workshop with them. We spend all the afternoon to only do one “brick” of earth, but it was the time needed to test the technique and evaluate the tests. At the end of the day, we were excited to open the framework but we decided to leave it in place to protect the wall “against” the energy of the children.

Back to school we opened the formwork to discover the first brick. From this day on, Steve was following us through this adventure. We spend this first day together to test the earth and the technique by the production of the corner of the wall. Many people joined us to ram and discuss, the production of a public debate was starting better than we could have dreamed of.

We realized some correction onto the formwork directly on site when it was needed.

73 Reality Studio June 2018 Starting The formwork is put in place on top of the foundations made by bricks to do the first “earth brick”. Ramming After putting a layer of 10-15cm of soil into the formwork, a tool called “rammer” is used to ram down the earth inside. Finish the first brick When the upper edge of the formwork is reached, the brick is finish and the formwork can be moved. Formwork removal I The first step is to remove the endpieces, ropes and bolts of the formwork. The formwork sides are still hold in up by the metal rods. Formwork removal II The metal rods are pulled out of the wall and the formwork sides removed to set free the earth brick. Formwork preparation The formwork sides are put first on the existing earth brick, in preparation for the next one. Setting up the formwork Metal rods, bolts, end pieces and ropes are put in place again and the ramming can start again. Result A several bricks high rammed earth wall.

IKEA

74 Ram-up Obunga The works. Saturday the 31st of March

75 Reality Studio June 2018 Our first brick of earth achieved with the help and happiness of the children. 76 Ram-up Obunga The works. Monday the 2nd of April

Experiencing the formwork.

On Wednesday we received the visit of some of our friends from the Reality Studio. We started into the day with a hard hitting sun and finished it with heavy rain. We protected our wall with a big tarps of tailored together cement bags. We found them in the market called Kibuye. Rammed earth construction seems to be possible even during rainy season.

Still a lot of ramming and soil mixing. We started to take the habit of the technique when... the context changed once again! Tuesday was our first day of works with the children and we had to changed a bit our way of working and especially being careful with our tools to be not spread all over the school...

77 Reality Studio June 2018 78 Ram-up Obunga The works. Tuesday the 3rd of April

Bricks after bricks the wall is growing up.

79 Reality Studio June 2018

Visitors inspecting and discussing the wall

the 4th of April 80 Ram-up Obunga The works.

Wednesday

the 5th of April

On Thursday we finished the earthen part of the wall! The rain has slowed down a bit the works but we finally finished. We had to order a new truck of earth but there was almost no clay content in the soil compared to the previous one. We had to deal with this issue and reconsider our mixture. We decided then to mix the murram with a very clay rich soil.

81 Reality Studio June 2018 82 Ram-up Obunga The works. 83 Reality Studio June 2018

Thursday

Finishing of the earthen part of the wall before the opening of the classroom. 84

The

Ram-up Obunga

works.

On our last day we opened the classroom by demolishing the previous wall and connecting the existing roof to the new one. We realized a wooden frame to put on the rammed earth wall and extended the previous structure with recycled wooden branches.