ENDORSED BY SAPMA, SAPSDA, SAVAMA AND VAMCOSA

SEP/OCT 2020

Golf Day 2020 TBA report back

CONTENT COVER STORY Get ready for the rain, Integrated Pump Rental is ready for you Make sure all pumps add to efficiency, urges expert

4 6

PIPES Plasti-Tech overcomes lockdown challenges to meet supply timelines 8 for a flagship project Connecting the world’s greenest data centre

10

Vesconite Hilube plate proves itself in rotary vacuum filter

12

Megapipes Solutions brings sustainable sanitation to Kenya

14

PUMPS BMG Steimel gear pumps for harsh mining applications

16

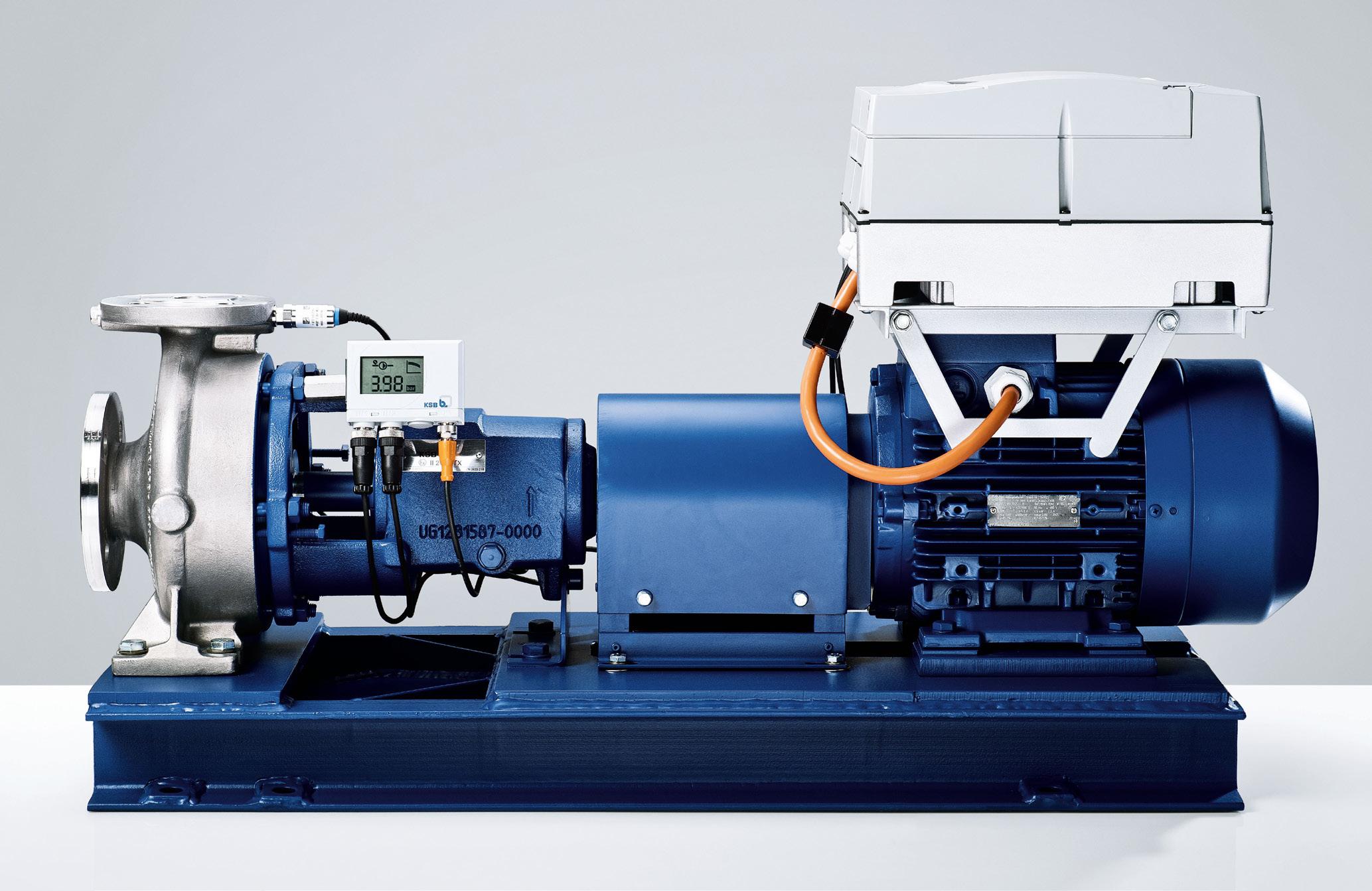

The chemical pump has set the standard worldwide

18

Intelligent water boosting systems for energy savings

19

Make pumps smart and flexible with Lowara Hydrovar variable pump controllers, a Xylem brand

20

The value of investing in future-proofed equipment

22

Upgraded rotor dynamics for pump shafts – reduce Shaft Deflection & Vibration

24

Solid momentum continues for the global pump industry

26

A new pump for filter systems

28

VALVES Never stop learning

30

Emerson’s new full-bore ball control valve combats vibration, cavitation and noise

32

INDUSTRY NEWS African Construction Expo IFAT Africa addresses challenges across the food-water-waste value chain BMG launches a new user friendly B2B online shopping platform

33 34 35

On the cover Integrated Pump Rental, +27 (0) 11 894-2906, admin@pumprental.co.za, www.pumprental.co.za

Pumps & Valves Africa

Managing Editor: Surita Marx Tel: +27 (0) 87 153-1217 Cell: +27 (0) 83 281-5761 Email: info@pumpsandvalves.co.za Web: www.pumpsandvalves.co.za Sales: Lusana Mrkusic Email: lusana@pumpsandvalves.co.za Production Manager: Xane Roestroff Email: adverts@pumpsandvalves.co.za

PRODUCTS & SERVICES Lincoln Lubrication South Africa secures Senegalese order for two complete lubrication systems Tips for restarting your VFD after lockdown Exceptional repair & refurbishment offering helps customers reduce hydraulic equipment downtime

36

Golf Day 2020

42

BUYERS GUIDE

43

Disclaimer

38 40

Opinions in this Publication are those of the authors and do not necessarily reflect those of this publication, its editorial board, its editor or its Publishers SAPMA. or VAMCOSA The mention of specific products in articles and advertisements does not imply that they are endorsed or recommended by this Publication or its publishers in preference to others of a similar nature, which are not mentioned or advertised. Reliance on any information contained in this journal is at your own risk. While every effort is made to ensure the accuracy of editorial board makes no representations or warranties, express or implied, as to the correctness or suitability contained and/or the products advertised in this publication. The Publisher shall not be liable for any damages or loss, howsoever arising, incurred by readers of this publication or any other person/s. The Publisher disclaims all responsibility and liability for any damages, includes pure economic loss and any consequential damages, resulting from the use of services or products advertised in this publication. Readers of this publication indemnify and hold harmless the publisher, its officers, employees, and servants for any demand action, application or other proceedings made by any third party and arising out or in connection with the use of any services and/or products or the reliance on any information contained in this publication.

Advertisers bauma Conexpo Africa IBC Bilfinger 13 Bray 15 Industrial Valves Summit 29 Integrated Pump Rental OFC Integrated Pump Technology IBC KSB 9 KV Controls 31 LVSA Group 21 Macsteel IFC Stewarts & Lloyds 37 Ultra Control Valves 27 Valve Hospital 39 Valve World Expo 17 Verder 23

Pipes, Pumps and Valves Africa - Sep/Oct 2020

3

COVER STORY

Get ready for the rain, Integrated Pump Rental is ready for you Pump users are increasingly taking the rental route for equipment as it offers definite market advantages while reducing capital costs. Henru Strydom, Operations Manager for Integrated Pump Rental, says the upward trend in the rental is expected to continue as the benefits are increasingly being realised. Efficient, reliable and cost-effective aptly describes pump rental. Furthermore, there is no initial capital outlay to purchasing the equipment and maintenance and repair costs are immediately reduced not to mention that the entire process is convenient, says Strydom. Ever since the economic downturn, the rental industry has seen a steady uptake. Industries, like mining, were hard hit by the Covid-19 pandemic and considering the above benefits renting makes financial sense in these tough economic times. “Industry is also increasingly more comfortable with the idea of renting versus buying,” says Strydom. “The delivery of a solution meeting their exact needs without any cost of ownership makes sense while it also includes flexibility and reduces risk.” Traditionally, South African companies have always opted to rather a purchase than rent, but the concept of rental is fast-evolving as the realization of the various market

4

Pipes, Pumps and Valves Africa - Sep/Oct 2020

advantages hit home. Rental considerations Pumps, for the most part, ar manufactured for a specific application. There is no one size fits all solution, explains Strydom. “One of the challenges for pump users is first, finding a fit-for-purpose solution and then the availability of those pump sets.” He says by renting users can far easier get what they need. “We have a variety of pumps available and fleet that can meet and fill the needs of every application out there.” Whether it is an efficient dewatering solution in a remote area, diesel-driven pump sets or submersibles – rental companies can deliver whatever the requirement. At the same time, the rental industry itself is constantly improving and evolving. According to Strydom, expanding its fleet is always on the agenda at Integrated Pump Rental.

client, the weather forecast is considered and a solution delivered that speaks directly to each situation.” Strydom says the company furthermore make sure they keep track of challenges and concerns ahead of bad weather allowing to mitigate against flooding of the mine as much as possible.

It is also far more advisable to rent than purchasing a cheap import that more often than not has no after-sales service included. “Be prepared for any situation by making sure you have a solution that is going to be efficient and cost-effective. Renting a pump delivers that.”

“We are continuously adding to our range to ensure we have versatility in our fleet to meet our customers’ needs. It is, however, not about quantity, but rather ensuring a range of equipment is available to fulfil the variety of requests in the market. Our goal is to cover all types of applications with all types of pumps.”

Renting also addresses the impact that breakages can have on operations. “Unforeseen breakages can have a massive impact on operations bringing them to a complete standstill. By renting this problem is eliminated. Rentals come with back-up solutions, maintenance, services and repairs all included in the monthly cost. It delivers flexibility and reliability to operations that can be the competitive advantage the company needs.”

COVER COVERSTORY STORY

Top tips With a constant need for specialised pump equipment renting, says Strydom, makes sense. “We can offer better pumps that meet specific application needs without the massive capital outlay.”

Meaning whether someone wants to empty a small swimming pool or rapidly dewater an open-pit mine, Integrated Pump Solutions can assist. “We have a variety of electrical submersible pumps in our rental fleet ranging from 1-90 kW dewatering, sludge and slurry to name a few. It also includes stainless steel submersible pumps. These pumps can deliver flows of up to 150 litres per second and heads of up to 200 meters,” says Strydom. The company has also opted to start manufacturing diesel units. “This is fulfilling a real need that we identified in the market. Especially in the mining sector where there is an ever-expanding need for efficient dewatering solutions.” These diesel units can deliver regardless of whether there is electricity – a real issue for operators in Africa – and can easily be installed in remote areas. “Also in the range is the diesel-driven pumps that we also offer in stainless steel options, ranging from 35-360 kW packages. These pumps can deliver flows of up to 180 litres per second and heads of up to 200 meters.” Being prepared According to Strydom, rentals are becoming very popular in the mining sector – especially opencast mines that need dewatering pumps or dredging or that need pumping solutions to process water. Also in underground mines where water needs to be drained to ensure operations can take place the need for pumps is growing. “Often mines are equipped to handle their needs but are caught off guard when it starts raining and flooding happens. More often than not the pumps are not able to perform sufficiently. This is where renting pumps play a role as it ensures users are never in such situations.” He says Integrated Pump Rental not only deliver bespoke solutions but they also ensure that the pumps are maintained and operational at all times. “We make sure we know the pit area of our

Integrated Pump Rental, +27 (0) 11 894-2906, admin@pumprental.co.za, www.pumprental.co.za Pipes, Pumps and Valves Africa - Sep/Oct 2020

5

COVER STORY

Make sure all pumps add to efficiency, urges expert With difficult economic conditions only getting worse during the Covid-19 pandemic, pump users need to make the most of their operational inventory, even pumps that may be considered redundant. Pump expert Lee Vine, managing director of specialist companies Integrated Pump Technology and Integrated Pump Rental, says all industries can benefit from improved pump efficiencies. “In our daily contact with pump users, we ensure not only that the pumps we sell, and rent are looked after,” Vine says. “We also repair and refurbish other brands that customers have on their work sites.” Their depth of technical capability is based on combined experience within the companies of some six decades in the pump business. While Integrated Pump Technology specialises in Grindex and Faggiolati slurry pumps and Leyboldt vacuum pumps, the Integrated Pump Rental business focuses on its locally produced SlurrySucker dredging system, Sykes diesel drove pump sets and the Grindex submersible range. “To support our product ranges – and keep our own rental fleet in optimal condition – we invest continuously in our quality-accredited workshop facilities,” Vine says. “This includes extensive testing capability, with a test tank that can accommodate motors up to 150 kW in power.” Workshop manager Fred Slabbert, a master electrician and millwright, highlights the value of optimising assets to costeffectively promote operational efficiency. “With our experience of various pump brands, we make sure that all work is done to original equipment manufacturer (OEM) standards,” he says. “This gives customers peace of mind, and allows us to give a six-month warranty on repairs and refurbishment.” Slabbert says pump reliability is now more important than ever, as mining and industrial operations must optimise uptime to remain profitable in these challenging economic times. “We conduct professional assessments on any pumping equipment – even redundant units – for customers,” he says. “On the basis of a detailed condition report from us, along with a competitive quotation, companies can assess the refurbishment option – which usually makes good business sense all round.” Integrated Pump Technology, 27 (0) 11 824 4810, info@pumptechnology.co.za, www.pumptechnology.co.za 6

Pipes, Pumps and Valves Africa - Sep/Oct 2020

COVER COVERSTORY STORY Pipes, Pumps and Valves Africa - Sep/Oct 2020

7

Plasti-Tech overcomes lockdown challenges to meet supply timelines for a flagship project

PIPES

Leading importer and supplier of HDPE piping systems in southern Africa, Plasti-Tech Piping Systems, was recently contracted to supply HDPE pipes, fittings and welding equipment for a Mozambican overland piping, supply and installation project. Despite the COVID-19 lockdown challenges, the company leveraged its expertise to deliver the order on time, allowing the contractor, Binvic, to meet its deadline on site. As an international project and full-service management company, Binvic recognises the importance of communication, leadership and meeting deadlines. “Our reputation depends on the successful management of relationships between companies as well as cross-border communication with project teams on the ground,” says Dennis Keenan, MD of Binvic. With that in mind, the company contracted Plasti-Tech to deliver a crucial HDPE piping, fittings and welding equipment order for one of its flagship projects in Mozambique where the delivery timeline was stringent, despite the need to execute the contract right in the middle of the lockdown. Binvic contracted Plasti-Tech to manufacture and supply HDPE piping (450 mm & 200 mm diameter) of 18 300 metres, which included welding of stub ends for the Kenmare WCP-B (Pilivili) project, package CM020 – an overland piping, supply and installation project. PlastiTech was also tasked with supplying Hurner CNC welding equipment, four 500 mm welding machines, a Suda buttfusion machine, as well as various fittings and flanges for the project. Brad Chamont, the Managing Member at Plasti-Tech, explains that the contract was awarded in March, some two weeks just before the hard lockdown in South Africa. “We received our essential service provider approvals and certificates, which allowed us to continue working during the lockdown, under stringent safety parameters,” he says, adding that the order was completed within five weeks. Chamont concedes that the lockdown put a lot of stress on the team to get the order done. “However, with our expertise and understanding of the significance of this project, we managed to deliver the order on time, despite the challenges,” he says. Keenan agrees, saying that execution of this portion of the project was during the COVID-19 lockdown between Alert Level 5 and Level 3, which posed a lot of challenges. “This put a lot of strain on the deadlines and the ability to deliver the product on time across the border in Mozambique,” he says. Plasti-Tech’s good business practices, administrative and communication management skills contributed greatly to 8

Pipes, Pumps and Valves Africa - Sep/Oct 2020

the success and timeous execution of this portion of the project, says Keenan. “It was a pleasure working with the Plasti-Tech team, and Binvic is proud to be associated with this company. We can easily recommend them for similar projects,” he says. Chamont is equally pleased to have been part of such a flagship project. He notes that Kenmare WCP-B is one of the largest dredge moving projects in the world. “It was a proud moment for us as a company to be part of such a large project. We are grateful to Binvic for entrusting us with such a crucial responsibility,” he says. Chamont adds that despite the challenges of having to work during the lockdown, the R27-million project came just at the right time for Plasti-Tech. “With lockdown shutting many businesses in South Africa, our business was very limited during the time and a project of this size is what we needed to help us get through these tough times,” concludes Chamont. Plasti-Tech Piping Systems, +27 (0) 11 609 5511, +27 (0) 82 471 5757, brad@plasti.co.za, www.plastitech.co.za

We offer valves for precision processes - and demandingapplications Our valves fulfill the highest of standards and are designed for many years of safe and reliable operation. Our service specialists regularly check, monitor and maintain all relevant system components - depending on what has been agreed. Our modular framework agreements offer you individual service and spare parts concepts. And we even go one step further. We additionally check systems for efficiency in order to reduce operating costs and increase productivity. For example, with the SES System Efficiency Service.

ZTS GATE VALVE

GATE VALVE AKG-A/AKGS-A

STAALWEDGE GATE VALVE AKDS/AKD

NORI 500

Contact our dedicated Valves Sales Engineers for all your Valve requirements 011-876-5600 or email us info-za@ksb.com KSB Pumps and Valves (Pty) Ltd • www.ksb.com/ksb-za Your B-BBEE Level 1 Partner

BOA - H

Connecting the world’s greenest data centre Built into the mountains of Stavanger, Norway, in what was formerly a NATO ammunition storage facility, is now one of the world’s most secure and energy-efficient data centres.

PIPES

For site owners, Green Mountain, the transition from the ammunition storage facility to the data centre was not without challenges. They were faced with confined spaces, existing structures and the need to install a reliable piping system to cool the server racks. The site, however, was also not without benefits – not least the cold Norwegian climate to keep data cool at lower costs and the vast supply of hydroelectric power. It has therefore proved to be a sensible investment for Green Mountain CEO, Kristian Gyland. Together with Victaulic, a world leader in mechanical pipe joining systems, and pipe installation contractor, Sig Halvorsen, Gyland overcame the many challenges that the site presented, constructing a truly unique data centre. From storing weapons to storing data The facility was constructed by NATO in 1964, during the height of the Cold War. The site initially spanned across three halls, and, in 1994, was extended to double its storage capacity to house mines and torpedoes. Following the de-escalation of geopolitical tensions, NATO no longer required the facility and decided to sell in 2009. And what NATO no longer needed, became a golden opportunity for Green Mountain’s first data centre.

10

Pipes, Pumps and Valves Africa - Sep/Oct 2020

“We opened this facility in 2013, with our first three customers. Since then we have continued to expand the site as we’ve grown. Today, we are covering 22.000 km² under the mountain and expect to reach full site capacity in 2023,” said Gyland. Secure and sustainable in Stavanger When they learned of the location, it was obvious to Green Mountain that the site offered several opportunities that were too good to pass up. Although the construction design would be challenging, the business potential was there. In the data centre industry, storing data in a secure environment is of utmost importance. Green Mountain had a vision that if a mountain could keep NATO’s weapons secure, then it could also keep data secure; and they were right. According to Gyland, the Stavanger site is one of the most secure data centres in the world. A feature which can be largely attributed to the centre’s location within the mountain. As well as being secure, the Stavanger site is located within proximity to the fjord, home to one of Europe’s lowestpriced sources of hydroelectric power. The data centre could therefore operate at lower costs, as well as with a sustainable power source.

“When we were presented with the mechanical pipe joining solution, it was only natural for us to use this technology for our piping systems. Using a system that is not welded provided us with the flexibility we needed and was a huge cost saver since it allowed us to build in phases. We didn’t have to make assumptions on where future data racks were going to be placed, and where the cooling system should run; we were simply able to build as we grew and add customers,” commented Gyland. “The only concern we had when we installed a grooved system in our facility was whether the joints would last over time,” continued Gyland.

Together with a vast supply of hydroelectric power, the site benefits from a cold Norwegian climate, providing a costeffective means to cool data.

Beyond the flexibility and reliability of the Victaulic solutions, Gyland was also pleased to partner with a company that aligned with their values on sustainability.

“We are located close to a fjord and the water we are collecting for our cooling system has a constant temperature of 8 degrees, meaning that we can use the outside to cool the data centre on the inside. So, in addition to the site being the most secure data centre in the world, it is also the most energy-efficient data centre in the world,” stated Gyland.

“As one of the most energy-efficient data centres in the world, it is also evident that one of the key areas of prioritization for Green Mountain is sustainability. As the grooved system avoids toxic fumes and gases and is produced in a production facility which uses 90% recycled material, the solution fitted our company’s sustainability ethos perfectly” noted Gyland.

Looking for versatility and durability Designing and installing a piping system in an existing structure is never without its challenges and turning an existing structure into a data centre adds a level of complexity.

Overcoming installation challenges Sig Halvorsen was the contractor tasked with installing the cooling system in the Green Mountain facility. Their employees are familiar with Victaulic solutions, particularly within data centres.

Faced with confined underfloor space, existing structures, and the need to have a system that is reliable and easily maintainable, Green Mountain needed an efficient pipe joining system, in addition to an installer that could do the job. Because Norway is heavily involved in the oil and gas business, welding is a common method of joining pipe in the region.

Frode Horpestad, Operations Manager at Sig Halvorsen, who worked on the Green Mountain installation, stated that Victaulic’s products allowed his team to overcome some of the site’s installation challenges and even cited Victaulic solutions as an aid in winning additional projects.

However, the site needed more flexibility than welding could offer. It was important to Green Mountain that they could easily expand the facility as their business grew. Victaulic offered the ideal solution, but with one concern for Green Mountain; would it last?

PIPES

“But having operated for close to 6 years now, we’re confident that this is a solution we will continue to work with, and we are happy with the way it’s working here at Green Mountain Data Centre.”

“It is a simple system to learn and has simple check methods to ensure proper installation. Our employees also received close follow-up from Victaulic’s representatives on the construction site if required – so it has worked very well. Using a flexible and robust technology has many advantages, for example installing Victaulic products allows us to use the same crew on every construction site, and we do not require certified welders for joining the pipes. Offering Victaulic solutions even helped us to win some major projects.” Considering the internet wasn’t invented until several years after the Stavanger NATO facility was built, it is safe to assume the engineers of the time never foresaw a day where the location would become a world-renown data centre. But as it turned out, the safety and security of a mountain, with a nearly unlimited hydro-power supply and cool climate, made for the perfect location. Victaulic, Marcel.Ley@victaulic.com, www.victaulic.com Pipes, Pumps and Valves Africa - Sep/Oct 2020

11

Vesconite Hilube plate proves itself in rotary vacuum filter A large food-processing company in South Africa is replacing several of the polyethylene plates on its rotary vacuum filters with plates made of the low-friction, high-compressive strength polymer known as Vesconite Hilube.

PIPES

This follows the successful use of the Vesconite Hilube plates on one of its rotary vacuum filters. Rotary vacuum filters are used for dewatering, washing and clarification, and rely on a vacuum to suck the water content out of a slurry mixture in which a vacuum drum rotates. After dewatering is completed, a dry cake remains on a cloth-covered drum, while the clarified liquid in the drum is transported out of the drum through a series of pipes. Vesconite Hilube wear plates have been successfully used at the interface between the vacuum drum and the exiting pipes at the South African company. The processor’s mechanical department maintenance coordinator informs that the 800-millimetre-diameter 25-millimetre-thick Vesconite Hilube plates need to ensure that there is an adequate seal that prevents the liquid from leaking. They also need to have sufficient compressive strength to be secured by a trunnion plate, he says, noting that the equipment agent’s wear plates were of a much softer material and that this resulted in wear and eventual leaking. In addition, they need to have the correct pipe exiting alignment, with 16 holes in place for some of the rotary vacuum drum designs and 14 for other of the designs.

12

Pipes, Pumps and Valves Africa - Sep/Oct 2020

Testing continues to verify the comparative wear life of the polyethylene wear plates and their replacement Vesconite Hilube wear plates. The processing company’s maintenance coordinator reports that the Vesconite Hilube plates have outlasted the polyethylene plates, but the exact wear life of both the polyethylene and Vesconite Hilube plates is unknown. Several variables can change the life expectancy of a plate including the installation personnel, alignment between the drum and the plate, and any drum vibration. The intention of the Vesconite Hilube plate installation is to keep the drum vacuum constant and reduce machine downtime that is caused by having to replace plates. The food-processing company has nine rotary vacuum filters on site. The company processes 800 tons per year of maize and produces dry milled starch and various grades of glucose for the food, beverage and pharmaceutical industries, as well as byproducts for the animal feed industry, among various other industries. Vesconite Bearings, +27 (0) 11 616 1111, vesconite@vesconite.com, www.vesconite.com

e

WE MAKE VALVE SUPPLY Bilfinger Intervalve Africa (Pty) Ltd. is one of the enterprises in Bilfinger Power Africa (Pty) Ltd., the South African subsidiary of German based Bilfinger SE. For years, we have been adding value to the power, mining, paper pulping and broader industry through comprehensive valve supply, valve maintenance and heat treatment solutions. www.intervalve.bilfinger.com

WORK

Megapipes Solutions brings sustainable sanitation to Kenya Proper sanitation and storm water management remain as two of the major challenges for devolved governments in Kenya as they grapple to improve on service delivery to citizens.

PIPES

Bringing innovative solutions and providing and maintaining safe off-site and decentralized sanitation systems, cannot happen without new investment and human technical capacity – particularly considering the growing population density in urban centers. Megapipes Solutions, a new company in Kenya, is offering large diameter plastic pipes to meet the challenge of poor sanitation through the use of Weholite which has been tried and tested right across Europe, North America and in several African countries including Tanzania and South Africa. Weholite is a lightweight, engineered structured wall pipe made from high density polyethylene (HDPE), and is used extensively around the world in low pressure or gravity applications for drinking water storage, storm water, sewage and various other liquids. Polyethylene pipes, first installed in the 1950s, are known to be a reliable, long-term solution for water, stormwater and sanitary systems. Science has since proven that HDPE pipes, such as Weholite will last over 100 years. “Weholite offers distinct chemical and physical advantages over other more traditional materials. Superior hydraulics and abrasion resistance mean that it will not corrode or deteriorate over time, making it a long-lasting solution for projects in Kenya,” says Jürg Flühmann, Managing Director at Megapipes Solutions.

According to Mr. Flühmann new production techniques have been combined with the latest raw materials technology to produce a durable pipe system with superior load-bearing properties. This makes Weholite the preferred solution for many municipal and industrial applications in both the public and private sector – including stormwater management, sewage treatment systems, culverts, marine pipelines and irrigation water distribution. Kenya failed to achieve its Millennium Development Goal for increasing access to water and sanitation. Only 30% of Kenyans have access to improved sanitation, or the use of sanitation facilities that hygienically separate excreta from human contact. This means that approximately 30 million Kenyans are still using unsafe sanitation methods like rudimentary types of latrines, and almost six million are defecating in the open. Access to improved sanitation is a major challenge both in urban and rural areas. It costs the country an estimated US $ 324 million annually for the gaps in its sanitation and hygiene services according to a World Health Organisation and UNICEF Joint Monitoring Programme. In urban areas, the challenge is even more daunting as urban growth outstrips the provision of basic services, sanitation included. Moreover, urban planning hardly precedes settlement, making it much harder for utilities to provide water and sanitation services. At the same time, having a toilet, either connected or not connected to a piped wastewater system is only one part of fecal waste management. Sanitation in the urban areas is further compounded by the inter-linkages with other services including storm water drainage, solid waste and water supply. Weholite pipes will be readily available in Kenya with the construction of a factory for manufacturing of the large diameter plastic pipes for drainage and sanitation Projects in Kenya and neighboring countries, already under way. Megapipes will be manufacturing innovative, state-ofthe-art products for the growing requirements of water storage, sanitation and drainage projects in Kenya, contributing to the local economy and industrialization process and avoiding importation of such products. Megapipes Solutions, +25 474 529 0318, sales@megapipes.com, www.megapipes.com

14

Pipes, Pumps and Valves Africa - Sep/Oct 2020

BMG Steimel gear pumps for harsh mining applications

BMG’s range of Steimel lubricant and feed gear pumps – the SF series – are used mainly on oil lube systems in mines, steel works, power stations and general industry.

PUMPS

“SF heavy duty pumps, which offer pulsation-free pumping delivery, are designed to pump any grade of lube oil, including high viscosity oils.” “These pumps are particularly suitable for transporting media with minimal lubricity, that is chemically compatible and does not contain solids,” says Joe Pinheiro, BMG’s National Product Manager, Pumps. “SF gear pumps are used as circulation pumps in oil lube systems, kidney systems and for transferring (off-loading or dispensing) of oils.” “This range - which has gained popularity throughout Africa - is available in Zambia from BMG’s Kitwe and Lusaka branches.” The BMG team works closely with clients to provide a technical advisory and support service for the oil lube systems on mills operating in Zambia, that were designed, built and supplied by BMG (originally by OMSA, which was acquired by BMG about seven years ago). “These compact pumps are easy to disassemble and assemble. The standard design is supplied with a clockwise rotation, which is easily altered to anti-clockwise, by rotating the end cover plate by 180˚.” The direction of delivery flow will change at the same time. An optional feature is an adjustable pressure relief valve built into the housing, for short term protection against pressure spikes. Optimum integration, with minimal tolerances of the pinions and gear wheels results in quiet, smooth running.

16

Pipes, Pumps and Valves Africa - Sep/Oct 2020

The use of gear wheels with 12 teeth reduces delivery flow pulsation and minimises noise during operation. Shaft journals are mounted in composite bearing bushes which ensures continuous duty and extended service life. All pumps sizes can be equipped with an anti-friction bearing at the driving end, to accommodate radial and axial forces.Standard pumps have a maximum rotational speed of 1 800 rpm for a maximum viscosity up to 380 cst and a differential pressure up to 25 bar. The maximum permissible rotational speed depends on the viscosity or lubricity of the medium. The higher the oil viscosity, the lower the speed. These pumps can handle media with a viscosity range from 5 to 50 000 cst and can withstand a temperature range between -40 ˚C and +250 ˚C. Also in the Steimel range are SF ATEX gear pumps, which provide a high degree of safety in potentially explosive environments. Type SF M feed pumps, with a magnetic coupling, are hermetically sealed and can operate safely in applications at elevated temperatures and withstand media that this difficult to seal. BMG also supplies the Steimel feed pump T series on request. These rotary gear pumps, which are designed to transport almost all media, can be used to maximum rotational speeds of 1 500 rpm, at pressures up to 16 bar.

01– 03 December

2020 Düsseldorf, Germany

WHERE DOES EVERYTHING REVOLVE AROUND INDUSTRIAL VALVES? Only at VALVE WORLD EXPO. Visit the world’s leading trade fair and get to know the latest products, processes and technologies. More than 700 exhibitors across more than 19,000 square metres, from 1 to 3 December 2020. Have discussions with other experts at the VALVE WORLD EXPO FORUM. Learn about ecoMetals’ new sustainable ways of adding value.

Steimel Model B lubricant and feed pumps are designed to efficiently handle highly fluid media, like waste oils, greases, hardening and hydraulic oils, resins, lubricating greases and oils, as well as turbine and thermal oils. These pumps have a permissible excess pressure up to 50 bar, a viscosity range up to 5000 cP and a displacement from 2 to 75 cm³/rotation.

Find out more now at: valveworldexpo.com

BMG offers a technical advisory service to ensure selection of the most suitable pump size for every specific application. The company supports this range with a spares facility and 24 hour maintenance service through more than 100 BMG branches and a wide distribution network in South Africa and across borders into Zambia, DRC, Swaziland, Botswana, Mozambique, Namibia and Tanzania.

BMG World, +27 (0) 82 852 9894, josep@bmgworld.net , www.bmgworld.net

Entrance tickets available from the summer through online ticket sales

valveworldexpo.com/2130

Sponsored by:

Southern African – German Chamber of Commerce and Industry NPC 47 Oxford Road _ Forest Town, Johannesburg P.O. Box 87078 _ Houghton 2041 Tel. +27 (0)11 486 2775 _ Fax +27 (0)86 675 21 75 tradefairs@germanchamber.co.za

www.germanchamber.co.za

vwe2002_BesucherAllg_90x267_ZA.indd 1

Pipes, Pumps and Valves Africa - Sep/Oct05.08.20 2020 11:21 17

KSB’s chemical pump has set the standard worldwide

PUMPS

Since its introduction more than two decades ago, KSB’s MegaCPK pump has changed the way chemical companies throughout the world pump dangerous and volatile materials.

18

The proven standardised chemical pump to DIN EN ISO 2858 / ISO 5199 and Directive 94/9/EC (ATEX) is especially used for handling aggressive liquids in the chemical and petrochemical industries where it provides a safe and reliable means of fluids transfer. The pump’s energy efficiency is also noteworthy and the series punches well above its weight in terms of output efficiency which means that identical operating data and conditions are achieved with smaller pump sizes. According to Dylan Mitchell, this is as a result of impeller trimming for energy savings which result in up to a 10 % improvement in efficiency. With a wide range of sizes and variants, users are most likely to find a pump that exactly meets their requirements.

available for standardised flow rates or high-performance variants depending on the customer’s specification Dylan says. He adds that KSBs MegaCPK has been designed for maximum operating reliability and ease-of-maintenance with back pull-out design for quick and easy access which is a milestone in standardised chemical pumps. These and other features and benefits of the pump series are the reason why the MegaCPK has become the basis for numerous standards.

He says the range has a modular design system with a variety of pump sizes, materials and components. Gland packing with single and double standardised mechanical seal or cartridge seal also available.

“The wide range of sizes, materials and features for almost any application including temperature extremes, the volatility of materials being pumped and widely differing chemical compositions make the Gold Standard in the industry. Combined with KSB Pumps and Valve’s service and support, as well as a long track record of service in the industry, makes it the obvious choice for standardised chemical pumps in South Africa and across the globe.

“We even have a choice of “medium-duty” bearing bracket designs with a cylindrical roller bearing as a radial bearing and a double angular contact ball bearing as a fixed bearing or users can specify our “economy” bearings which are arranged as floating ball bearings. Hydraulic systems are

KSB Pumps and Valves, +27 (0) 11 876 5600, Annett.Kriel@ksb.com, www.ksbpumps.co.za

Pipes, Pumps and Valves Africa - Sep/Oct 2020

Intelligent water boosting systems for energy savings Ensuring the right pressure and volume of water in a building today calls not just for a reliable system but one that is energy efficient, according to Grundfos external sales representative Nick Pluck. “Electricity costs are an increasing concern for owners and managers of buildings, and this is from residential and business blocks to hotels and industrial facilities,” says Pluck.

Known for their high performance and reliability, the Grundfos Hydro MPC booster systems also offer an advanced, intelligent cascade controller to further improve energy efficiency and ease of operation. “Over time, the CU 352 smart controller develops its patterns based on its understanding of a building’s daily requirements,” he explains. “It will register and remember how the water demand changes for a day and ensure the pumps meet that demand without running unnecessarily when demand is low.” Equipped with this controller, the Grundfos Control MPC can monitor up to six connected identical pumps, each driven by motors with variable speed drives (VSDs). “We incorporate the VSD so that the controller and MPC

“A four-pump system, therefore, could have three pumps running at full capacity while the fourth runs at just 60% saving energy while still meeting demand.” As the system’s algorithms calculate patterns, it can trim off waste energy consumption when less pumping is required. The controller can also alternate the starting sequence of the pumps, resulting in more even running time and less wear and tear across the pumps. This allows for more accurate and economical service planning and scheduling.

PUMPS

“This is where the Grundfos MPC booster systems offer enhanced value.”

can change the speed of each motor based on the demand requirement,” he says.

High-efficiency IE3 motors further enhance the Grundfos Hydro MPC’s energy efficiency while maintaining a constant pressure during changing flow demands. With a user-friendly interface, the systems offer ease of installation and commissioning, along with long-term value for money. Grundfos, +27 (0) 10 248 6000, www.grundfos.com

Pipes, Pumps and Valves Africa - Sep/Oct 2020

19

Make pumps smart and flexible with Lowara Hydrovar variable pump controllers, a Xylem brand

PUMPS

Xylem Africa continues our mission to provide our customers with greater control, efficiency, and performance over their pumping system - through the fifth generation of Lowara Hydrovar Variable Speed Pump Controllers.

Whether you have old yet reliable AC-motor pumps or newer equipment, Hydrovar enhances nearly any pump with smart technology to run better, react to conditions, and avoid damage.

Easy to install and retrofit Hydrovar system consists of a variable speed drive (VSD), a control card, sensors, EMC filters and motor/system protection. There’s no need for an external control panel when using Hydrovar, and each unit can support up to eight pumps. Hydrovar can be installed on top of the pump or be wall-mounted in tighter spaces.

The Hydrovar family of smart variable speed pump controllers have evolved to provide intelligent features to AC-motor pumps, combined with easy installation and commissioning, as well as many other features.

The system works with most pumps and can be connected to any AC motor. It supports the RS485 interface, BACnet, Modbus, analogue and digital I/O, direct motor control function, and offers an optional Wi-Fi card.

Hydrovar can reduce pump energy usage by as much as 70%. No wonder it’s being used in the world’s tallest building, the Burj Khalifa, by the Thames Water Authority, and in the Gotthard road tunnel - at 16.9 kilometres, the fourth-longest in the world.

Such compatibility ensures that Hydrovar can be retrofitted to older pumps. It is one of the fastest and easiest pump controllers to install and commission. Quick startup guides and logic menu systems make the Hydrovar straightforward to set up and operate. It’s also flexible: advanced programming features can optimise Hydrovar for almost any duty condition.

Traditional pumps either run full-throttle or not at all. But this creates staggering inefficiencies, adds significantly to costs, and contributes to environmental damage.

“Hydrovar was developed over the decades with two specific goals - to give you more control and insight over your pumps and to make them more intelligent,” said Chetan Mistry, Strategy and Marketing Manager for Xylem Africa. “At Xylem, we have refined and improved this ground-breaking controller family yet again with Hydrovar’s 5th generation.” These units are compatible with nearly every AC-motor pump and come with a slew of features that makes clear financial sense to our customers. Hydrovar isn’t a new kid on the block, and every advance it makes ends up being a significant improvement over what the market can offer.”

20

Pipes, Pumps and Valves Africa - Sep/Oct 2020

Enable active maintenance and damage prevention Maintenance and longevity is another reason why a Hydrovar investment makes sense. The system can safely and quickly stop pumps at zero demand. Hydrovar offers thermal protection of the motor via its software, dry run protection, and specific motor protections such as overtemperature, overcurrent and under-voltage monitoring. It generates timestamped error logs and can extend the lifetime of your pumps. One unit can manage up to 8 pumps - since every Hydrovar acts as a master unit, the system offers extensive

redundancy. The Hydrovar family was born in 1992 and has evolved over the decades to become the leading smart variable speed pump controller in the market. Designed both for modern and older equipment, it adds brains to your pumps that will help you save money, gain more performance, pre-empt maintenance, and avoid breakdowns. The smart controller that gives your pumps brains A motor running at 80% of its maximum speed uses 48% less energy. With energy savings of up to 70% on partial loads alone, the typical investment payback period is less than two years depending on energy costs and pump operating times.

VSA

GROUP (PTY) LTD

YOUR PVF PARTNER

If yozr pumps aren’t smart, make them Hydrovar smart. And if your pumps have some brains, check if they can offer everything Hydrovar does: ● Mountable in any standard AC motor ● Easy to program ● Error-proof energy-saving setup ● Each unit is a master - maximum redundancy ● Controls up to 8 pumps ● No external control panels needed ● Fast reaction on sudden demands ● Safe and fast stop of the pump at zero demand ● Smooth control of pressure ● Stable behaviour independent of external conditions ● Handles both quick ramps and gradual operation ● Reduce heating of the motor ● Extend the lifetime of the motor ● Thermal protection of the motor via software ● Dry run protection ● Specific motor protections such as overtemperature, overcurrent and under-voltage ● Log errors with the date and time stamps Hydrovar by Lowara, a Xylem brand, tackles many of the shortcomings of ‘dumb’ pumps, giving them the digital smarts to run better, faster and longer. Using software configuration to meet different demands, Hydrovar units are found across different industries, including municipal, industrial and domestic water supplies, HVAC systems, mining applications, agriculture, the food & beverage industry, geothermal applications, firefighting, and water displays.

.

Telephone : +27 (0) 11 680 2005 Email : sales@lvsa.co.za

Should your pumps run at 100% capacity all the time? Unless you have a good reason to do so, such thresholds will only cost you money and wear your pumps down faster. Hydrovar can change all of that, providing efficiencies that pay for your investment in no time and ensuring you get much more out of your pump systems.

Xylem, +27 (0) 11 966 9311, Chestan.mistry@Xylemic.com, www.xylem.com Pipes, Pumps and Valves Africa - Sep/Oct 2020

21

The value of investing in futureproofed equipment

PUMPS

The paper, pulp and board manufacturing industries are key economic contributors to the South African economy. Direct contributions are measured in the gross domestic product (GDP) and trade earnings, where according to the Paper Manufacturers Association of South Africa (PAMASA), the country’s paper, pulp and board manufacturing industries are valued at around R28 billion. And this value is potentially significantly more when we also consider the indirect and knock-on impact of socioeconomic benefits in job creation and local economic activities that can be traced back to the industrial activity linked to farming, milling and manufacturing, for example. Tacking industry trends In recent years, however, these industries have faced significant societal pressures – particularly surrounding concerns over the impact on the natural environment –

and as a result have undergone significant restructuring in terms of, but not limited to, three major trends: • 1 Focusing on operations and cost management – including adopting more sustainable business processes to lessen impacts on the natural environment and pressure on natural resources, such as water, • 2 Industrial diversification - leading on from the abovementioned trend, some market players have started to diversify their business (operations and product output) from what used to be their core business, and • 3 A greater push on recycling – this trend is also in line with changes to the National Environmental Management: Waste Act to reduce the amount and type of waste that is sent to landfills – and in particular, the introduction of the separation at source strategy that promotes waste minimisation, reuse, recycling and recovery. In fact, due to extensive market-wide drive to recycle paper, board and liquid packaging waste, for example, saw the country achieve it’s 2020 paper recycling target of 70% in 2017 – 3-years ahead of schedule. Additionally, as end-users become more conscious to environment issues, demand for recycled paper and tissue paper is healthy (and growing) – and this trend will continue to influence the business of paper, pulp and board manufacturers as they look to adopt a more circular economy thinking and approach to the products they produce. It should be stated though that there are indications that the various restructuring strategies are paying off, and there are signs that these industries – which were once under extreme pressure – are emerging with renewed focus and improved global competitiveness. And while these businesses are undergoing restructuring, they should also consider advances in equipment critical to the manufacturing process that can bring immense value in improving the operational efficiency potential. Investing in future-proofed equipment It is well understood that manufacturing paper is a resource-intensive process, even if it is 100% recycled material. Shredding wood, paper, and textiles to the right size, creating the pulp, and then pressing it into paper is a process that requires the right equipment, including pumps to move the slurry. Also, paper and wood pulp can be extremely abrasive to pumps, and the chemicals used in the bleaching process can be very corrosive as well. In the context of this; a poorly designed pump system may lead to lags in production due to premature wear

22

Pipes, Pumps and Valves Africa - Sep/Oct 2020

PUMPS

or failure of components in the processing production line – as this is not isolated to the pump itself – and can impact instrumentation, piping, valves and ancillary equipment too. With this, there is also the risk of workstoppage or excessive breakdowns, over-and-above routine planned maintenance. Any of these possible scenarios are guaranteed to hamper operational efficiencies and production outputs – not to mention potentially increase labour costs and inventory of spare parts - leading to operational expenses being driven up. On the other hand, the right advanced and integrated pumping solution support operational efficiency objectives. As these solutions are fit-for-purpose, not only are they suitable for pumping sensitive, abrasive or high viscous fluids, but while doing so also bode added benefits in water and energy efficiency and savings - thereby supporting the business’ operational efficiency objectives too.Navigating the technical obstacles of selecting the right pumping

solutions for specific applications can be complex. Yet, the effectiveness of a manufacturing plant partially depends on the longevity of the equipment – where lower life cycle costs of the equipment translate into higher efficiency and greater productiveness and cost savings for the customer in the long run. Paper and pulp manufacturers, therefore, need to look to a trusted and reputable brand that can offer not only a wide range of pumping solutions but solutions that are longlasting, cost-effective and energy-efficient – because they are 100% fit-for-purpose for the application – and for every step of the manufacturing process. Verder Pumps (Pty) Ltd, +27 (0) 11 704 7500, info@verder.co.za, www.verder.co.za

Verder is manufacturer of: Verderflex and Verderair pumps VERDER PUMPS SOUTH AFRICA (PTY) LTD

Tel.: +27 (0)11 704 7500

info@verder.co.za

www.verder.co.za

Pipes, Pumps and Valves Africa - Sep/Oct 2020

23

Upgraded rotor dynamics for pump shafts – reduce shaft deflection & vibration

PUMPS

Pump Vibration and Shaft Deflection of any Rotating Element is directly proportional to the diameter and length of the shaft, (L/D) the position of the impeller on the shaft (overhung or centred), mechanical and hydraulic balance of the impeller, and where the pump is operating on the pump curve. If the pump is not operating at the Best Efficiency Point (BEP) it is subject to recirculation cavitation and high radial loading, which will cause loss of performance, efficiency and very high vibrations and shaft deflections. Whether the pump is Horizontal, or Vertical, the weight, and inherent mechanical & hydraulic imbalance, of cast impellers (especially cast metallic impellers) even when they are brand new sets up a condition for premature bearing, ring, mechanical seal and motor failure. Like the Pendulum on a clock, the impeller acts as a weight at the end of the shaft and starts to wobble or deflect. Any Corrosion, Erosion, or Cavitation increases the Pendulum Effect Problem and substantially increases shaft deflection, and pump vibration! The motor bearings cannot hold the stresses that are set up by the Pendulum Effect and the Mechanical Seals, Sleeves, Bushings, Motor Bearings, and Motor fail prematurely. In extreme cases, the shafts break. Bearing and mechanical seal failures are directly proportional to the rotor weight, speed, the amplitude of the mechanical imbalance, as well as the radial loading on the shaft as a result of hydraulic imbalance. Often Customers complain about Mechanical Seal Failures, or Bearing Failures, and even Motor Failures. What most Customers do not realize is that they DO NOT have a Mechanical Seal Problem, or a Bearing Problem or a Motor Problem; rather, they have a “Hydraulics Problem” caused by Mechanical or Hydraulic Imbalance, Radial Thrust, or the Improper Design, Repair, or Manufacture of the Impeller! All of these problems can be eliminated by upgrading to SIMSITE® Structural Composite Carbon Fiber Impellers & Casing Rings!

The combination of our new patented SIMSITE® Carbon Fiber split stabilizing Bushing with our SIMSITE® Structural Carbon Fiber Impellers & Casing Rings completely changes the rotor dynamics FOR ANY ROTATING ELEMENT. The result is that shaft deflection and vibration are minimized. THE REASONS FOR THIS ARE AS FOLLOWS: 1 Less Weight SIMSITE® Patented Structural Composite Carbon Fiber Impellers, Rings, and Bushings are 85% Less Weight when compared to Bronze, or Stainless Steel, and even lighter when compared to duplex stainless steel! This reduces startup load and shaft deflection. 2 Perfect Balance both Mechanically and Hydraulically Imbalance and the "pendulum effect" are eliminated because SIMSITE® Impellers are machined on 5 to 8 axis machining centres from one centre position -- they are NOT cast or moulded like metallic impellers. 3 SIMSITE® Stabilizing Bushings The patented SIMSITE® Split Stabilizing Bushings offers superior shaft support and mechanical seal protection. They also protect the mechanical Seals from movement and debris! 4 No Corrosion SIMSITE® Patented Structural Composite Carbon Fiber Products do not corrode in Seawater, Sewage, Waste Water, River Water, or Chlorinated Water so performance, balance, and shaft deflection will not be affected! 5 Cavitation is Eliminated or Minimized Because SIMSITE® Impellers are machined and not cast or moulded, they are designed and engineered specifically for the best efficiency point eliminating hydraulic imbalance, radial loading, vibration, and shaft deflection! Cast or Molded impellers are not designed or engineered for the "Specific Operating Conditions" of the pump in service. Therefore, most pumps are not operating at the Best Efficiency Point (BEP) where radial loads, shaft deflection and vibration are negligible. Rather, they are operating "Out" on the performance curve, or "Back" on the performance curve away from the Best Efficiency Point. The farther away from the Best Efficiency Point (BEP) they operate, the higher the radial loads causing excessive vibration, shaft deflection, and premature bearing, seal, ring, motor and even shaft failures! This Pump Curve above shows a pump that was designed

24

Pipes, Pumps and Valves Africa - Sep/Oct 2020

Operating Point the Best Efficiency Point. It is not good enough to manufacture an impeller that will reach this point – the design point has to be the best efficiency point to maximize performance and efficiency and to eliminate vibration and shaft deflection. The SIMSITE® Structural Composite Carbon Fiber Impeller & Casing Ring Set will be lightweight, and 100% machined from solid blocks of the patented SIMSITE® composite which does not corrode, cavitate, or go into an imbalance. These machined SIMSITE® structural composite Impellers are 85% less weight than bronze, or stainless steel impellers and rings and they do not go into an imbalance because the vane passageways and exit ports are all equally spaced as a result of being machined.

Solution The solution is to use a SIMSITE® Impeller that will be designed specifically for the Operating Point making the

PUMPS

to operate at 5400 Gallons Per Minute (GPM) at 275 Feet of Head (FT) at 1750 RPM. This point is called the Best Efficiency Point (BEP) – the point at which the pump and impeller are designed to operate most efficiently. Instead, the pump was operating back on the pump curve – 26% away from the best efficiency point at 4000 GPM at 360 FT of Head at 1750 RPM. Operating at 74% of BEP put this pump into the Danger Zone for Recirculation Cavitation, which caused tremendous Vibration, Shaft Deflection, a loss of Efficiency, an increase in the Brake Horse Power (BHP) and total pump failure.

SIMSITE® Structural Composite Impellers are engineered and designed to operate at the Customer’s Operating Point (OP), making the Operating Point the Best Efficiency Point (BEP) Installing impellers that operate at the Best Efficiency Point is extremely important, because not only does it make the pump much more efficient, but it substantially reduces radial loads, shaft deflection, and eliminates hydraulic and mechanical imbalance! This allows the pump to operate substantially longer without premature failure of the bearings, rings, bushings, sleeves, mechanical seals, and motors. SIMSITE® Structural Composite Carbon Fiber Pumps, Impellers & Casing Rings, Sleeve Bearings, and Split Stabilizing Bushings pay for themselves over and over again because they substantially reduce repair, maintenance and energy expenses! Simsite, simsite@simsite.com, www.simsite.com

Pipes, Pumps and Valves Africa - Sep/Oct 2020

25

Solid momentum continues for the global pump industry The current business environment has been characterised by high uncertainty, driven primarily by Covid-19 and its economic fallout.

PUMPS

Demand for pumps has remained relatively high and the industry expects to see an uptake as markets start to recover. Pipes, Pumps & Valves Africa finds out more. Having initiated ambitious cost measures to mitigate the impacts of the pandemic, global leader in fluid engineering Sulzer has remained relatively optimistic amidst high levels of uncertainty. Thanks to a high order backlog the company managed to perform well in the first half of the year with an increase of 1.7% in its order intake compared with the same period last year. Order intake in Rotating Equipment Services grew by 10.2%, while orders in the Pumps Equipment division were up 6.0%. The Municipal and Wastewater activities showed continued momentum and grew by 2.5% organically. Energy-related orders were boosted by the Middle East, China and Brazil, which more than offset a steep decline in the US. Orders for Industry were down 6.3% on a COVID-19-related softening of the market. The Chemtech orders were 3.2% lower than in the first half of 2019, on customer postponements of larger projects, while Applicator Systems saw an abrupt drop in order intake of 27.3% as beauty outlets and dental practices were forced to temporarily close around the world. Dealing with lockdowns There is no denying that 2020 has been a year unlike any other with market disruptions and restricted access to customer sites due to lockdown and quarantine policies experienced everywhere in the world. Lockdowns impacted negatively on sales, according to Greg Poux-Guillaume, Sulzer CEO. Speaking recently about the company performance he said Sulzer saw an overall decrease of 3.9% in its sales. “Customer confinement measures such as limited site access and temporary closures of factories and front-end outlets impacted sales. While our sales in Rotating Equipment Services grew by 1.3%, Pumps Equipment’s sales declined by 4.4%. Higher sales in the Water segment could not offset the decrease in Energy and Industry, for example. In Chemtech, sales remained stable, despite a significant Covid-19 impact including the six-week lockdown of our Indian factory from the end of March until the beginning of May. In Applicator Systems, sales declined by 21.0%, caused by the abrupt closure of retail stores and dental clinics globally.” Stable outlook His outlook, however, remains positive and expectations are that operational profitability will be around 8.5–9.0% for the full year 2020 and that it will return to around prepandemic levels for the full year 2021. Heat pump manufacturer Nibe also reported stable growth having fended the effects of Covid-19 relatively well. 26

Pipes, Pumps and Valves Africa - Sep/Oct 2020

Managing Director Gerteric Lindquist said sales rose by 6% by the third quarter of the year. “The outbreak of Covid-19 is another uncertainty that has caused widespread change for most of the world’s communities and companies, including our own. While we were affected by the outbreak to a relatively modest degree in quarter 1, we were affected to a greater extent in the second quarter, but the situation remained manageable nevertheless. We also assume that most countries will try to return to a slightly more normal situation in the second half of the year. This, and the fact that our products are largely both necessary and sustainable, permits us to be cautiously positive about our performance in the second half of the year, despite all the uncertainties.” Both Poux-Guillaume and Lindquist say demand has varied between different market segments. Locally pump companies have felt a relatively hard-knock following the outbreak of Covid-19 considering the impact of the pandemic on the mining industry, one of the largest markets for pumps. The closure of mines and the overall slowdown in operations impacted negatively on especially pumping maintenance and refurbishment work. Furthermore, the sector has also had to deal with an increasing number of projects being put on hold.

A new pump for filter systems The NMP family of close-coupled self-priming centrifugal pumps with built-in prefilter has been updated with a new product: NMP 65/12, which replaces the previous NMP 65/16 model.

PUMPS

It is a completely renewed product, designed to answer market demands thanks to a wider range of flows. Its characteristics and performance make it perfect for circulating water in the filter systems of fountains or large swimming pools. In terms of reliability and performance, the new pump reaches levels only given by systems that

have a centrifugal pump with separate prefilter upstream. Product strong points Using 3D modelling systems and fluid dynamics simulations, our R&D team completely redesigned the pump from a hydraulic and a mechanical point of view. The team focused on both the rotor and the pump body, leading to the creation of innovative patented design. The pump, which is light and easy to handle, has an excellent suction capacity (NPSH). It has the same power as the previous NMP 65/16 model, yet it can easily reach a flow rate of 120 m3/h. Its large capacity stainless steel filter is easy to remove for cleaning and inspection. In addition to the cast iron version, there is also a bronze one, for use with aggressive liquids such as seawater.

Calpeda S.p.A info@calpeda.it www.calpeda.com

The Water Show Africa

The Water Show Africa team has been hard at work confirming expert speakers every day and building on our premium content. Your free pass gives you access to all of this and so much more! Here are 5 keynote speakers you can't miss: • Dr Peter Prevos, Manager of Data Science, Coliban Water • Dorcas Onyango, Director - Partnership Management, Coca-Cola Africa • Rose Alabaster, Director - Programme Development, WEHDI • Katrin Bruebach, Director: Urban Water and Sanitation Solutions, Global Resilient Cities Network • Gigi Karmous-Edward, President: Water Sector, KarmousEdwards Digital Consulting Conference channels you can’t miss: • Finance & Investment - Investing in water supply and sanitation projects by utilising risk mitigation instruments to bridge the financing gap • Desalination & Water Treatment - Shifting to digital transformation and non-conventional water resources to eliminate scarcity and deliver clean water supply • Water In Mining - Highlighting the challenges and milestones of water consumption and management in mining • Water In Agriculture - Water use in agriculture is at the 28

Pipes, Pumps and Valves Africa - Sep/Oct 2020

core of any discussion of water and food security. These sessions will help address the challenges and opportunities in water in agriculture • Infrastructure Development - Discarding of ageing infrastructure and investing in ICT systems to ensure water supply and sanitation, flood protection, drought and water quality management There are also tech showcases you can’t miss! We will be streaming short, sharp presentations and interesting case studies designed to help you learn more about the latest water solutions being implemented. This unparalleled content also includes "how-to" sessions packed with practical knowledge for you to utilise immediately. Can’t attend live? Register anyway! All sessions will be available on-demand immediately following their live broadcast. With so much content to cover and connections to be made, why not invite your team?We look forward to receiving your registration. www.terrapinn.com/exhibition/water-africa/index.stm

4

TH

International exhibition and conference on valve and flow control technologies

LEADING THE GLOBAL MARKET MAY 26 27 2021 FLOW TH

TH

BERGAMO - ITALY

www.industrialvalvesummit.com Attending IVS - Industrial Valve Summit gives you the opportunity to share knowledge, experience and ideas with other leading industry professionals and organisations.

IVS - Industrial Valve Summit is the: Forum for the industrial valves industry Innovations’ platform and technology summit Trend-setting meeting point Take-off for investment decisions International network of experts and specialists Organising Secretariat | Ph. +39 035 3230904 | Fax +39 035 3230966 | e-mail: info@industrialvalvesummit.com

ORGANIZERS

Never stop learning Valves perform extraordinarily varied and vital roles in the control and containment of fluids in modern industry and society. Anyone connected to or working in the valve industry should always be focussed on enhancing their knowledge.

VALVES

In the growing online digital environment training is now more accessible than ever before. Pipes, Pumps and Valves Africa finds out more. One of the most keenly felt needs in today’s industrial world is in all probability the lack of skilled employees. Skills are vital to any industry. Whilst lowered cost is often considered the number one driver of competitiveness, just an important element is talent. The impact of investing in human talent should not be underestimated when it comes to gaining an edge on one's competition. With this in mind, the British Valve and Actuator Association (BVAA) have ardently been advocating the valve industry at large to not let training and skills development go to the wayside during these times. The coronavirus pandemic has left many organisations under pressure, not to mention causing large scale economic turmoil. Rob Bartlett, director and CEO of the British Valve and Actuator Association (BVAA) says it was with this in mind that the organisation opted to take its training on-line. During a recent introductory webinar to its Introduction to Valves- course Bartlett said the move to online, virtual training allowed far more people to access training than ever before. The BVAA, for example, previously hosted all of their training in the United Kingdom making it an expensive endeavour for anyone out of the country to

30

Pipes, Pumps and Valves Africa - Sep/Oct 2020

attend. Now, courses can be accessed by the click of a button. Speaking at a seminar on the topic of online training, he said, courses were adapted to reach the online audience as efficiently and effectively as possible. "Our Introduction to Valves course, for example, is aimed at all individuals who have limited knowledge of valves or who wish to gain a broader perspective of their use. It is also suitable for engineers and technicians who wish to reintroduce themselves to the subject." The course itself, he said, was designed to give as much insight to attendees as possible. “It allows delegates to gain a thorough grasp of the basic principles and important aspects of valves and their associated use.� Offered over four sessions of an hour-and-a-half this type of training does not require someone to be away from their desk for hours on end. "You can continue with your workday and easily enough incorporate some training into the day." Costs considered Online training, says Bartlett, is also a more affordable option for companies, especially in the current tough economical environment. "Training online is far more costefficient and it is far less to do an online course than what it would be to come to our office and be trained in person." That does not mean that in-person training is a thing of the past. "We offer a choice to companies," said Bartlett.

VALVES

"They can either opt for online training or still come in and do our physical training at our offices." Offering a range of courses on valves, actuators, control and safety valves, prepared and delivered by the industry’s leading experts, Bartlett says the importance of ongoing training is critical. "Our courses range from introductory courses on valves or actuators to in-depth courses on specific valve types or industry directives. All are technically led by industry experts and are completely independent, with no sales pitch." Train for tomorrow Covid-19 has brought much change to the world. While many end-user markets that depend heavily on valves, such as oil and gas, have been down in recent months, the need for skills will only increase going forward. As technology gets more complicated, the greater the need

will be for knowledgeable employees. Learning about valves, actuators and controls in a non-product-specific manner only add to an organisation's competitiveness. Add product knowledge to the mix and one has a winning formula. Bartlett says reasonably priced valve training – thanks to the availability of online learning platforms – only sweetens the deal more. He maintains that training should never just be focussed on new-comers but that much needed technical information should be readily shared across a company with experienced professionals alike. British Valve & Actuator Association; +44 (0) 1295 22127; www.bvaa.org.uk

K N I F E G AT E VA LV E

Pipes, Pumps and Valves Africa - Sep/Oct 2020

31

Emerson’s new full-bore ball control valve combats vibration, cavitation and noise

VALVES

Fisher™ V280 ball valve with attenuator, 1061 piston actuator and FIELDVUE™ DVC6200. Fisher™ V280’s simplified construction allows the addition of noiseattenuating or anti-cavitation trims on the valve inlet or outlet. Today Emerson introduced the Fisher™ V280 full-bore trunnion-mounted ball control valve for severe and speciality pressure, flow and process control applications. The valve provides excellent dynamic process control by utilizing a robust drive train unique to the market that is designed to guide the shaft and properly absorb energy. Available attenuators for liquid and gas process fluids offer an effective solution for combatting the negative consequences of cavitation, such as vibration, erosion and noise. The body connections of the V280 valve have been reengineered to significantly simplify the design and reduce the number of parts while utilizing the same construction for the inlet and outlet. This allows an easy retrofit of single or dual ball seals with standard or customized noise attenuating aerodomes or anticavitation hydrodomes on the inlet, outlet or both. Typical applications include midstream oil and gas, particularly compressor anti-surge service. The V280 is a fully rated ANSI class 900 valve, available in 15 cm (6”), 20 cm (8”), 25 cm (10”), 30 cm (12”) and 40 cm (16”) sizes. A variety of high-performance packing materials

32

Pipes, Pumps and Valves Africa - Sep/Oct 2020

are available, including ENVIRO-SEAL™ live-loaded packing. Optional special materials and constructions are available to accommodate speciality applications. The valve comes standard as a single-seal construction but is available with optional dual-seal construction, allowing bi-directional flow and double block-and-bleed operation. The standard offering V280 complies with the NACE MR0175/ISO 15156 Sour Service/Sour Crude oil standard, carries the full ASME B16.5 Class 900 flange rating, and can handle fluid temperature ranges from -20 to 180 degrees F. Alternate seal options can handle temperatures from -50 to 400 degrees F. The valve can be fitted with a number of different positioners or auxiliary devices to suit hazardous or challenging environments. Together with the Fisher™ V260 and V270 valves, the V280 provides users with a complete portfolio of full bore ball control valves. Emerson, +27 (0) 11 451 3700, devesh.roopnarain@emerson.com, www.emerson.com

African Construction Expo The African Construction Expo is the only event in Africa that brings together 8,500 stakeholders involved in construction and infrastructure projects in Africa.

The expo provides workshops, training, demonstrations and other interactive features that facilitate commercial networking opportunities and drive private and public sector collaboration. African Construction Expo will be co-located with Totally Concrete Expo, African Smart Cities Summit and Woodex for Africa. The four events will be held from 29 June – 1 July 2021, at the Gallagher Convention Centre, Johannesburg, South Africa. African Construction Expo also hosts a series of webinars, podcasts interviews and thought leadership articles. The purpose of the digital offering is to provide accurate and relevant content about the industry, latest trends and innovative solutions as well as insight into how the industry is evolving. Totally Concrete Expo www.totallyconcrete.co.za The 7th annual Totally Concrete Expo offers contractors, engineers, quantity surveyors, architects, designers and property owners a one-stop-shop to identify viable project tenders and the materials that will help them to complete their projects on budget and on time.

Manufacturers, transporters, and processors of concrete will be provided with access to South Africa and Africa’s most influential project owners to build relationships, evaluate new technologies, overcome industry challenges and identify new and future commercial partners. To excel in a changing industry, you need the latest trends, the most sound best-practices and a crystal-clear picture of where the industry is headed. Readymix and pre-cast concrete producers, specifiers, contractors, engineers, architects – if you manufacture, sell, specify or work with concrete in any capacity then this is your show! Totally Concrete Expo will be co-located with African Construction Expo, African Smart Cities Summit and Woodex for Africa.

INDUSTRY NEWS

With over 200 exhibitors featured across the indoor and outdoor exhibition, African Construction Expo offers access to the most innovative building materials and technologies in Africa.

The four events will be held from 29 June – 1 July 2021, at the Gallagher Convention Centre, Johannesburg, South Africa. Pumps, Valves and Pipes Africa www.pumpsvalvesandpipesafrica.com Pumps, Valves and Pipes Africa is the largest African tradeshow dedicated to the industries involved in the conveyance of liquids, gases and slurries. Technical workshops on the expo floor will provide an opportunity for capacity building and networking for all professionals working in the sector. In 2020, the expo will form part of the African Construction Expo and Totally Concrete Expo, presenting even more growth opportunities within a broader spectrum of industries. Pumps, Valves and Pipes Africa will be held from 29 June – 1 July 2021, at the Gallagher Convention Centre, Johannesburg, South Africa. African Smart Cities Summit www.smart-summit.com The 4th annual African Smart Cities Summit will EXPLORE major trends, CELEBRATE Africa’s progress, DEBATE challenges and opportunities and DISCOVER the innovations set to advance African cities. The summit anticipates positive growth during its weeklong activities. The inclusion of the Smart Cities Pavilion on the exhibition floor showcases how technology and innovative solutions can transform African cities. Taking place at the Gallagher Convention Centre from 29 June – 2 July 2021, this exclusive gathering of buyers, sellers and contractors proves to be truly African as it co-locates with the African Construction Expo and Totally Concrete Expo, and Woodex for Africa. www.africanconstructionexpo.com Pipes, Pumps and Valves Africa - Sep/Oct 2020

33

INDUSTRY NEWS

IFAT Africa addresses challenges across the food-water-waste value chain Key environmental challenges facing the country

Food waste, pollution, water and waste management and energy - among the key environmental challenges facing the country – will all come under the spotlight at a crosssector trade show to be staged by Messe Muenchen South Africa next year. Suzette Scheepers, CEO of Messe Muenchen South Africa, says: "Energy reliability is a challenge across sectors, with growing awareness among enterprises that they need to look to cleaner, renewable sources of power for manufacturing. At the same time, our environment faces waste, refuse, water and wastewater challenges, and significant food security and waste problem.These challenges are interlinked to a large degree: water scarcity and poor water quality impact food manufacturing; manufacturing waste impact water and air quality; food packaging and production methods impact environmental quality and food security." Recognising that addressing these issues demands an integrated approach, Messe Muenchen will bring stakeholders together across the food-water-waste value chain at three co-located trade events in Johannesburg next year. IFAT Africa, food & drink technology Africa and analytica Lab Africa, to be co-located at the Gallagher Convention Centre from July 13 – 15, 2021, will convene thousands of stakeholders across overlapping sectors including food

34

Pipes, Pumps and Valves Africa - Sep/Oct 2020