2 minute read

Alpha Load Test & Services

ALPHA A4 advert

Offering the full service – What are the implications?

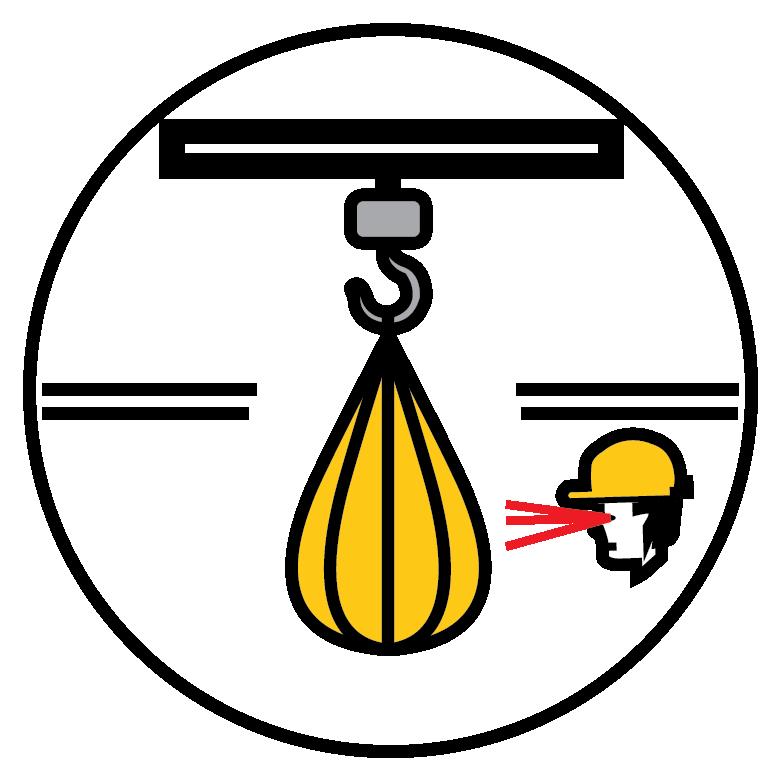

The principle of LME’s offering the “full service”- Repairs, Maintenance, Inspections & Load Testing – has become more prominent over the last several years. Isn’t that a conflict of interest?

The answer to that question is quite simply in many peoples’ opinions – YES! If an organization is offering “the full service” that includes repairs, maintenance, inspection and load testing, it is a direct conflict of interest. Essentially the organization is offering to certify their own work. Basically, the judge and the jury in this situation.

So why is it wrong? This goes back to why load testing companies were originally established – not only in South Africa but all around the world – a third party independent inspectorate. The reasons for this is simple

1) It promotes transparency between all service providers – companies that do not have a vested interest in repairs will not

8 Lifting Africa - Jan/Feb 2020 replace parts unnecessarily – not to say this occurs with all service providers but there are many cases everyone will know of. 2) It promotes quality assurance from all service providers. 3) It gives the owner/user peace of mind as they can be assured their equipment is safe to use – once again reiterating quality assurance. 4) Insurance companies will see the relationship as a conflict – confirmed by a major insurance assessor 5) The DEL (Department of Employment and Labour) see it as a conflict – confirmed by a senior member of the DEL. Should an incident occur on site, the user/ owner will be held legally liable – therefore it is not in the user/owner interests at all. Now there is more to this story – lately we have seen many inspection & load test reports that seem to have minimal information on them. To break it down in laymen’s terms you will be lucky to find the full date (the date consist of a full date including day – remember this is a legally binding document), serial number, SWL or WWL, deflection, the standard that was used to perform the test (by that we mean, not some generic standard used by the LME/LMI on every report that is not even relevant to the equipment being tested), LMI number, LME number and to top it all some nonsense about DMR 18 (5) & (6). I am aware that it is important to have the latter on the certificate, but it just shows that the LMI/LME’s do not know what “DMR (5) & (6)” refers to.

DMR 18 (5) refers to a “THOROUGH EXAMINATION OF ALL WORKING PARTS – Thorough not being superficial or partial and complete in every regard. Similarly, DMR 18 (6) refers to a THOROUGH EXAMINATION. So why are these individuals referencing DMR 18 (5) and (6) with regards to a thorough examination when they are only submitting 1-2 page reports for a