Contents

Barangaport

Project: vertiPort in dWontoWn sydeny to increase sUstainable transPortation

site: barangaroo ave, barangaroo nsW 2000, aUstralia

The Canvas at Rosedale

Project: HealtH and Wellness Facility For tHe Under served commUnity

site: 1051 merriam lane, Kansas city, Ks 66103

Fabric Form-work Concrete Panels

38-43

Ripples and Roots

Project: art instillation Using Fabric to Form concrete date: sPring 2022

44-49

Living Sea Wall

Project: creating a Habitat For sea liFe and Protecting tHe existing sea Wall date: sUmmer 2022

date: sPring 2023

ProFessor: KaPila silva

date: Fall 2022

ProFessor: sHannin criss

site: 2303 bob billings, laWrence Kansas 66045

ProFessor: KeitH van de riet

site: edgeWater, Florida WorKing WitH riverside conservancy

ProFessor: KeitH van de riet

Barangaport

A Vertiport in Sydney, Australia

Project: vertiPort

site: barangaroo ave, barangaroo nsW 2000, aUstralia

Description

Barangaport aims to revolutionize urban transportation by integrating eVTOL aircrafts and creating a cultural addition to the already strong infrastructure of Sydney. The city of Sydney has a high demand for air transportation, a strong aviation industry, urban density, and government support, which makes it a great location for a vertiport like this. The New South Wales government has invested $2.5 billion in the overall Baragaroo

date: sPring 2023

ProFessor: KaPila silva

Partner Project WitH danny derioUn

Development Project. Barangaroo is a major urban regeneration project that is transforming a former industrial site into a vibrant mixed-use precinct. Its proximity to Sydney’s central business district, major transport links, and key tourist destinations makes it a prime location. Barangaport showcases the latest in sustainable design and technology and exemplifies designs of the aboriginal culture this area was named after.

The redevelopment transitioned the former land use from a parking sector to a mixed use major development and this trait will be crucial to mimic in our vertiport design to not diminish the work that has already been done to transform this region of the city. The NSW government will be incorporating aboriginal design throughout the district. Doing this creates a preservation of culture, a sense of place and identity, economic benefits, awareness, and a place to educate locals and tourists.

Available Flight Paths

Takeoff and Landing pads based on available flight paths and seasonal wind directions

Creating a heavy timber structure that celebrated aboriginal culture and sustainability

Filling in program between the structure to create a mixed use element to the vertiport for public use

Creating walkways and entrances within the program that compliments the aboriginal design of the landscaping and the flow of people through the space

Placing Vertiport support spaces between the public spaces and taxiway for easy maintenance

Adding a light well into the atrium for natural lighting and a perforated aluminum skin to limit direct sunlight

PROGRAM VISION

FORM:

GOAL 2. Identify the most consistent approach to integrating the vertiport with the goals and vision of the Barangaroo’s redevelopment.

GOAL 4. Identify how the vertiport design can represent the public and multicultural aspects of the city and site, while also providing the minimum precautions needed for the health and safety of the vertiport.

GOAL 5. Establish a form that is easily identifiable and unique to the surrounding context, while also not disturbing the choreography between existing iconic structures and neighborhood dynamics.

GOAL 6. Establish a design that makes specific programmatic spaces of the vertiport easily accessible and identifiable

GOAL 9. Identify the most applicable arrangement of programmatic spaces that will accentuate the desirable views at the site.

FUNCTION:

GOAL 3. Establish a system that allows the public to use programmatic functions offered to the community, while also allowing a dimension of separation between vertiport users and workers.

GOAL 4. Create a space for entertainment and travel that is accessible to all Sydney residents regardless of status.

GOAL 6. Allocate enough space for the vertiport eVTOL infrastructure that allows our vertiport to be flexible and adapt to the amount of turnover and Increases in users.

GOAL 7. Connect all access points from public transportation with public entertainment space to form a consistent flow of circulation.

GOAL 10. Confirm that each sector of the building and the interdependencies of all building systems (programming, planning, materials, operations, and maintenance) are coordinated and that the circulation between spaces is uninterrupted.

TIME:

GOAL 1: Allow the design of the vertiport to adapt to the fast-changing nature of the surrounding neighborhoods and Barangaroo precinct.

GOAL 2: Identify points of access and what forms of public transit can be implemented and adapted to the site over time.

ECONOMY:

GOAL 2: Design with a Cradle-to-Cradle view to ensure that the facility has a sustainable and high-performing agenda that will withstand multiple generations and uses

GOAL 4: Identify the correct amount of space allocated for program

east side along barangaroo ave

east side along barangaroo ave

terminal 1 gates

ROOF

HYDROELECTRIC SYSTEM

FLOW RATE = 2 m/s

TURBINE EFFICIENCY = 40% (.4)

WATER DENSITY = 1000 kg/m³

TURBINE

PANEL DIMENSIONS - 2ft x 6ft

AREA WITHOUT CUTOUTS - 1,728 in²

AREA WITH CUTOUTS - 1,380 in²

THE PERFORATED PANELS BLOCK 80% OF DIRECT SUN

The Canvas at Rosedale

Project: mUlti-Use residential and commUnity center site: 1031 merriam ln, Kansas city, Ks 66103

Description

In Rosedale, the access to different essentials such as grocery stores, educational facilities, and recreational spaces is limited. As a team of 5, we each chose one site at an intersection and worked to improve these issues. With

date: Fall 2022

ProFessor: sHannon criss

the addition of a pedestrian road connecting the current residents to the newly improved downtown, spaces for the arts, and apartments, The Canvas supports the residents of Rosedale to find their creative path.

Art Classes 14.9%

Creating an Axis to Connect the Residential area to Downtown and the Drive-in

Moving a Side of the Form Back to Physically Guide People Down the Street and to the Axis

Voiding Space Within the Form to Create an Access into the Courtyard and Physical Transparency

Wrapping the Form with a Skin to Shield the Private Spaces from the Public and the Art Galleries from Sun

Extruding the Site with Setbacks to Create Initial Form

Creating an Axis to Connect the Residential area to Downtown and the Drive-in

Moving a Side of the Form Back to Physically Guide People Down the Street and to the Axis

Voiding Space Within the Form to Create an Access into the Courtyard and Physical Transparency

Wrapping the Form with a Skin to Shield the Private Spaces from the Public and the Art Galleries from Sun

Extruding the Site with Setbacks to Create Initial Form

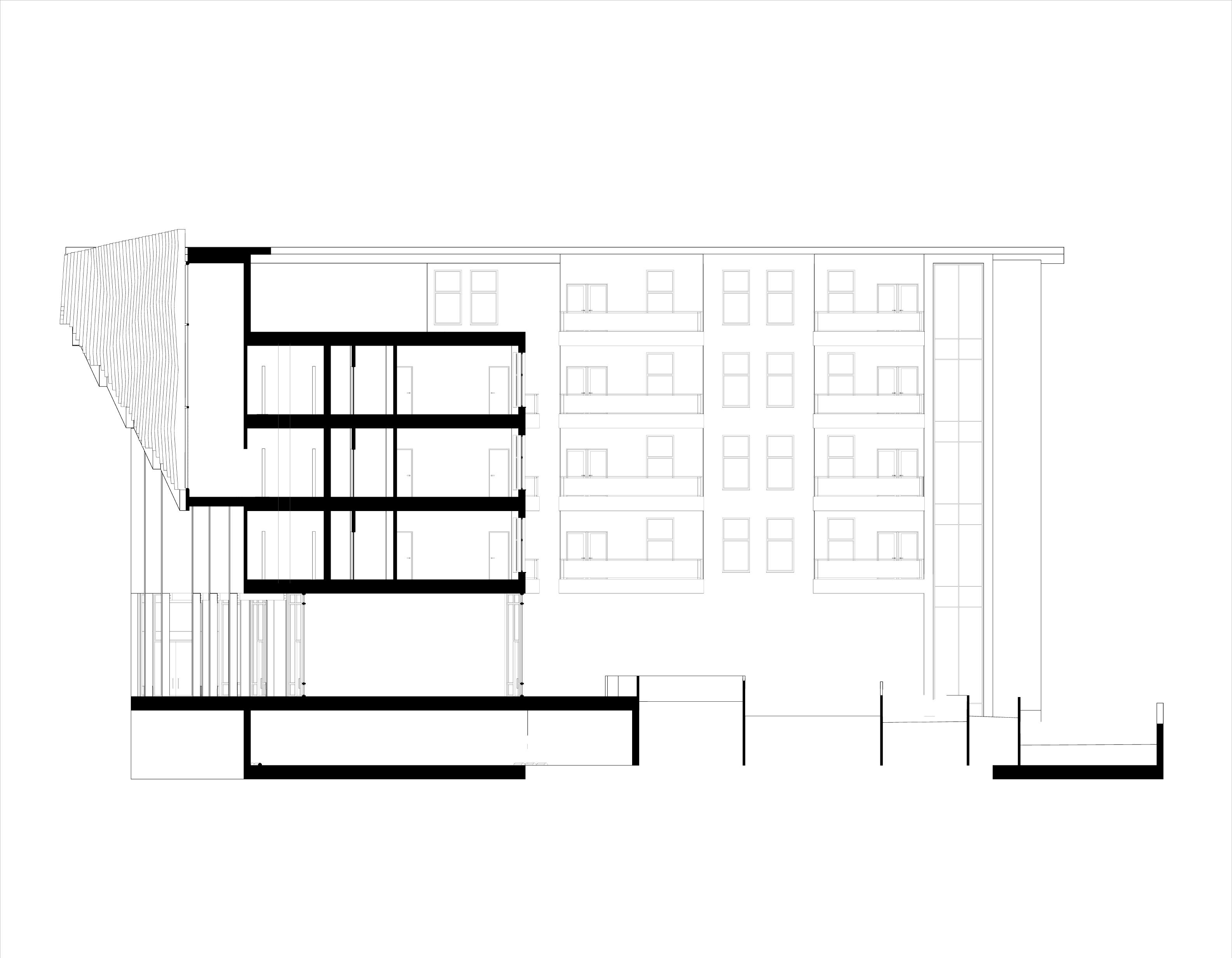

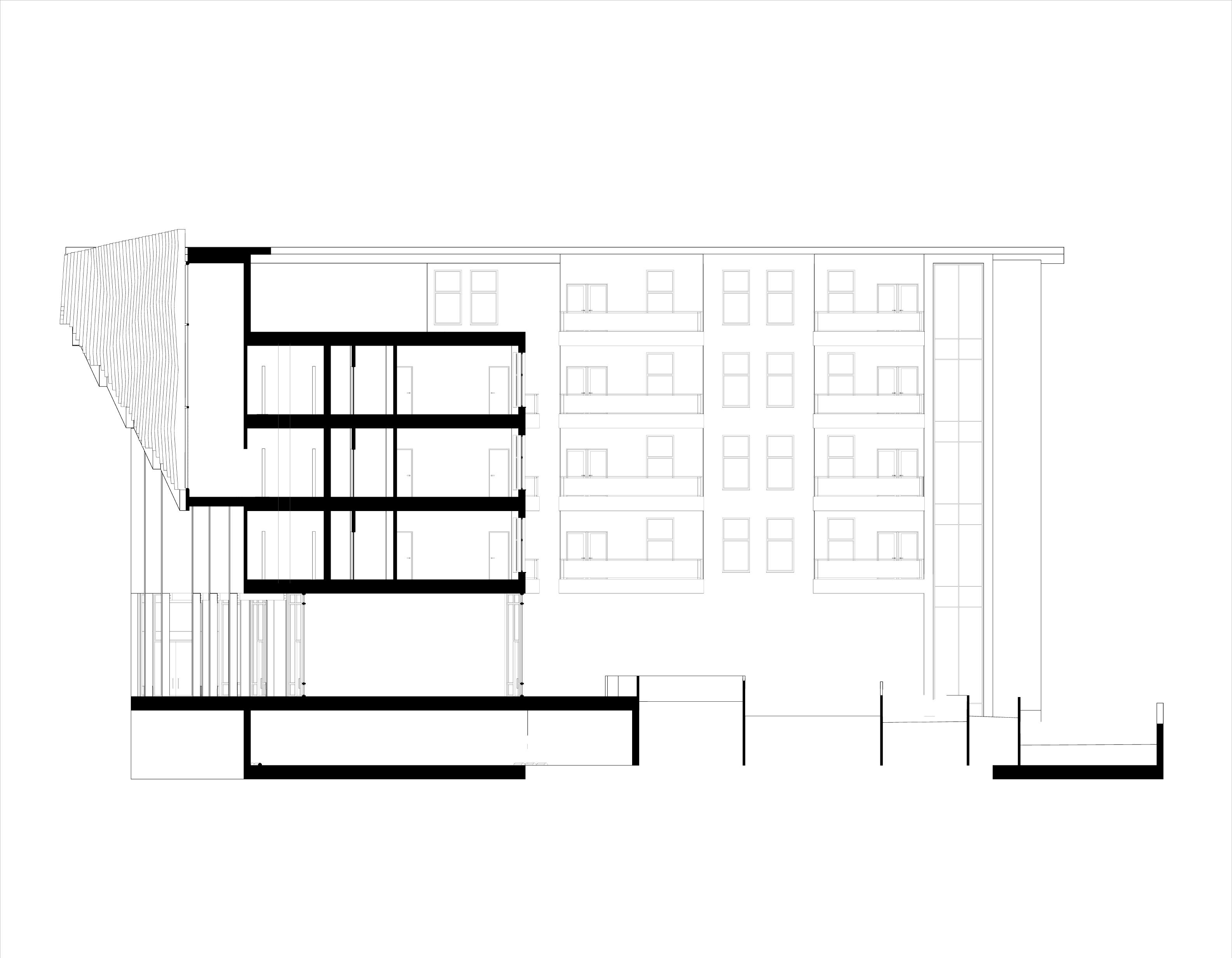

South elevation

South elevation

Solar PanelS TilTed aT 28 for oPTimal Performance

Powder Coated aluminum louvers

Home SHield Coating® Painted Cedar Siding

Balcony overhang acting as light shelf

White Limestone CL adding

Wood Look-ALike PoWder CoAted CoLumns

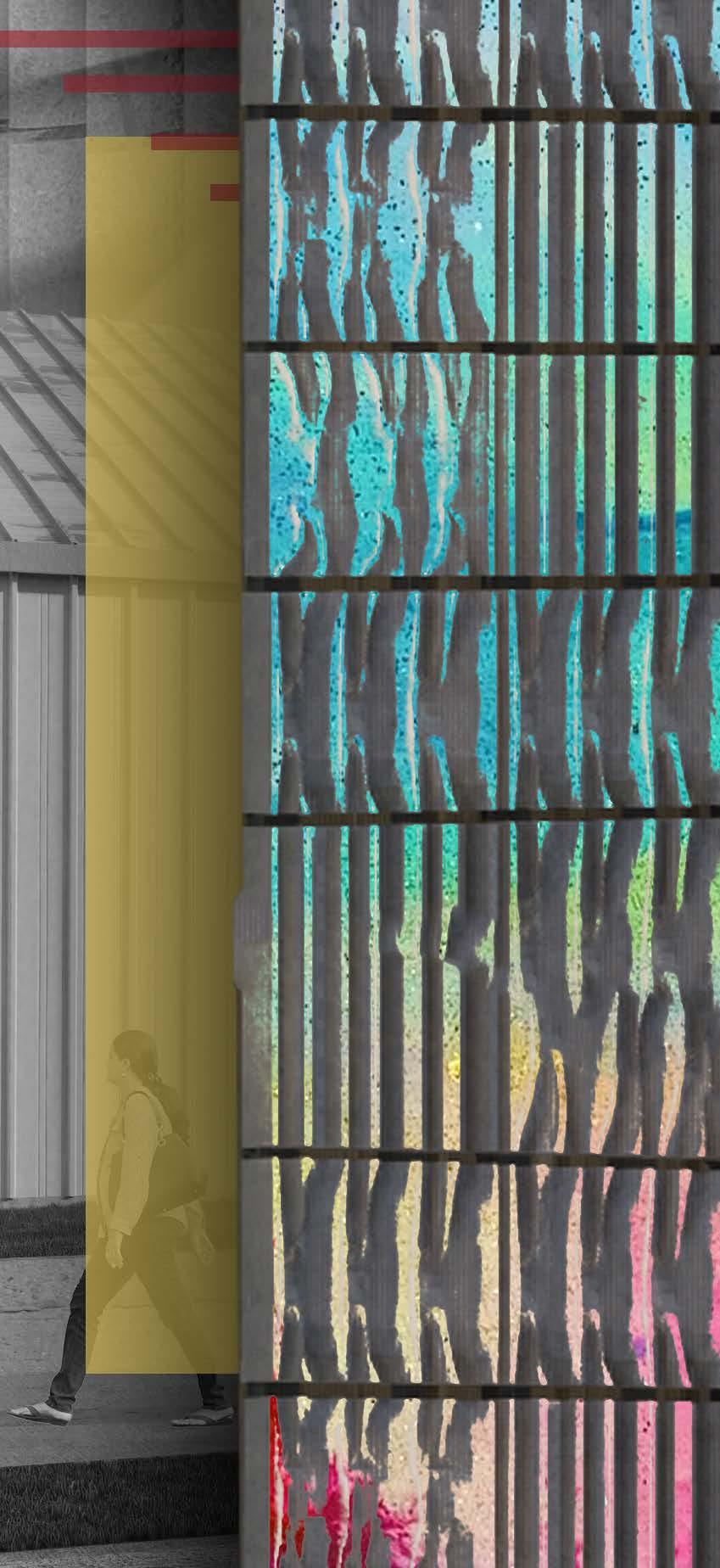

Ripples and Roots

Project: Fabric Form WorK art site: 2303 bob billings ParKWay, laWrence, Kansas, 66045

Description

Concrete is often seen as a rigid, brutal, and unyielding. Often used in rigid molds to create footings and other unrelenting structures, concrete is now being explored in a way that turns it into a delicate and flexible material. Using fabric form work, mixes like concrete can be manipulated and formed into an endless array of shapes and forms. Mark West, an architect and professor in the USA, Canada, and across Europe, proves just this. Through his instruction,

date: sPring 2022

ProFessor: KeitH van de riet

ARCH 509, and classes throughout KU’s Architecture program explored how fabric and flexible material can create a form where concrete takes on an infinite amount of forms with an endless amount of uses. However, we focused on how concrete can be perceived in an exquisite and impactful way. Located at The Interdisciplinary Ceramic Research Center, the concrete instillation shows one uncommon way concrete can be used.

Sketching Patterns

tHroUgH sK etcHing varioUs Patterns, W e decided to mirror, rotate , and F liP a F e W designs to save materials to bUild 18 seParate molds tHe design created a seamless design t H at F loW ed.

Creating Molds

tHe F inal molds For t He Project W ere constrUcted Using Folding ePdm WH at Was maniPUlated to create diFF erent Folds and creases tHese W ere attacHed to a Particle board or Ply Wood base Using nails and sta Ples.

Pouring Panels

WitH tHe HelP From a raPid set rePresentative, We Were able to Find tHe most eFFicient Way and best coUrse oF action to taKe in order to maKe oUr Panels sUccessFUl. We created a mix Using cementall, Water, and additives tHat liqUeFied tHe mix and sloWed doWn tHe cUring Process, giving Us as mUcH WorKing time as Possible. tHe ancHor bolts Were Placed Using a rig so tHat tHey Were in tHe exact same sPot every time once tHe Form WorK Was leveled and said to Have no leaKs, We began to PoUr.

3x3x.25” Angle Steel Expanding Joint

Anchor bolt with locking washer

Corrugated Metal Siding

Creating Structure

20x18 concrete panel

Z Sub girt

Anchor bolt with locking washer

tHe strUct Ure consisted oF angle steel , steel Plates, ancHor bolts, ex Panding joints, WasHers, and locK WasHers a ll oF t Hese sa F ely secUre t His 4,000lb concrete instillation onto t He Facade oF t His bUilding smaller Pieces oF t He angle steel W ere secUred to t He Z sUb girts existing in t He Wall and t Hen connected to t He longer 9F t angle steel t H at Held t He concrete Panels in Place steel Plates W ere W elded to t He angle steel and connected to t He Footing in order to transF er loads to t He groUnd.

Installing Panels

installing t He Panels Was one oF t He most PH ysically demanding Parts oF t His Project. Wit H Panels ranging in W eigH t F rom 90lb - 125lb, it Was not an easy tasK. We H ad to ma K e sUre eacH Panel Was lined UP correctly, in its correct sPot, and in t He correct orientation. once t H at Was done , t He H ard WorK commenced. We WorK ed oUr Way UP to yo t He toP, ensUring a Place to set t He Panel as W ell as t He most access to t He bolts t H at W ere tigH tened once t He Panel Was loaded into its Place

Final Installation

tHe Final installation sHoWs tHe Possibility oF tHat Fabric Form WorK oFFers sUcH a rigid material it alloWs PeoPle to see tHe FlUidity and tHe Possibilities tHat come WitH it. not only is a beaUtiFUl addition to tHe Facade oF tHis bUilding, bUt it alloWs PeoPle Passing by on tHe adjacent sideWalK to come and exPerience WHat maniPUlating tHis material can bring not only FUn For tHe eyes, bUt also tHe Fingers and Hands tHat Will graZe tHe sUrFace oF tHis, tHinKing it is a Flexible material, only to Find it is constrUcted Using one oF tHe most brUtal

Living Sea Wall

Project: concrete sea Wall instillation site: river side conservancy, edgeWater, Fl

Description

Taking what my team learned in our 509 Design Build studio, we headed to Florida to work with The Riverside Conservancy. Though with more obstacles such as: the weather, high tide, marine life, little air conditioning, and power tools used directly above the ocean, we were able to cast around 40 panels. Altering our mixture with additions of oyster powder (ground up oyster shell, coconut husk, and control set) created an oysterfriendly technology that

date: sUmmer 2022

ProFessor: KeitH van de riet

accelerates shellfish growth and ensure longevity of the panel itself. These walls add visual and functional value to seawalls; create vertical habitat surfaces that fit within the sectional profile of most Florida canals; offer a wall surface that avoids resting on the sea floor, thereby disrupting natural habitat; help dissipate shoreline wave energy; help minimize invasive species growth; and provide places for fish and shellfish to hide around constructed shorelines.

Riverside Conservan-

a yoUng bUt Fast groWing non-ProFit organiZation WitH a Passion For conservation. liKe tHe bUdding mangrove oF oUr logo We are sPreading oUt and taKing action to Preserve oUr beloved Florida sHoreline oUr mission is to create and exPand sUstainable living sHorelines tHroUgH edUcational oUtreacH and land conservancy Programs tHat UtiliZe commUnity-engaged design For tHe beneFit oF tHe indian river lagoon and For tHe greater PUblic HealtH and recreation oF tHe sUrroUnding commUnities.

oUr goal is For tHe beaUty aroUnd Us to be conserved and Used to edUcate FUtUre generations. tHroUgH riverside conservancy, We can HelP create commUnity leaders, restore sHorelines tHat bring bacK natUral WildliFe sUcH as oysters, and create a more resilient

all images and Words come From riverside conservancy’s varioUs Pages

HttPs://WWW riversideconservancy org/

HttPs://WWW FacebooK com/ riversideconservancyorg/

instagram: @riversideconservancyorg

tHe existing seaWall WHicH Used a constrUcted oF coqUina , sedimentary rocK t H at is comPosed eit Her WHolly or almost entirely oF t He transPorted, abraded, and mecH anically sorted F ragments oF t He sHells oF mollUsK s, trilobites, bracHioPods, or ot Her invertebrates tHis ma K es t He Wall extremely soF t creating a stable base For t He Panels to H ang on t Hese Walls Was ParticUlarly diFF icUlt. tUcK Pointing Was a mUst to F ill in ga Ps and reinForce t He Wall

Servicing Existing Setting up Molds

molds W ere designed in r Hino t Hen W e carved a Positive W it H a cnc macHine a F ter t H at, silicone Was Used to create a negative oF t He design, somet Hing W e coUld PoUr into and recreate t He original model . P ieces oF treated Wood W ere Placed aroUnd t He Perimeter oF t He molds to K eeP concrete in and not absorb any oF t He moist Ure Used dUring t He cUring Process.

Pouring Panels

Wit H t He sPecial mixt Ure oF oyster PoW der and coconU t HUsK , t He concrete mixt Ure is PoUred over t He molds tHe rigH t amoUnt oF concrete H ad to be PoUred becaUse too mUcH meant Heavy Panels t H at t He strUct Ure may not sUPPort and too little meant not enoUgH concrete Holding onto t He bolts Used to H ang t He Panels

Creating Structure

becaUse oF t He soF t nat Ure oF t He coqUina Wall , setting ancHor bolts into t His strUct Ure Was a diFF icUlt tasK Water sa F e ePoxy Was Used in t He Holes W e drilled to Hold t He bolt better. tHis strUct Ure consisted oF ligH t W eigH t angled alUminUm, ex Panding joints, WasHers, and barriers bet W een t He stainless steel bolts and angled alUminUm. Wit H limited tools and access to electricity, creating all Pieces For t His design Proved cH allenging, bU t Possible

Final Design