4 minute read

Methane for transport and power generation

Areva H2Gen has developed a PEM electrolysis system which is being tested over a period of nine months in the Höchst industrial park.

Green methane for transport and power generation

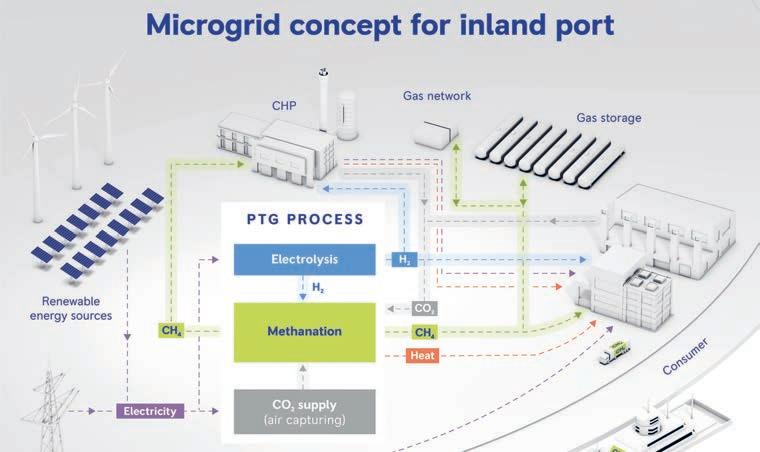

RESEARCHERS AND INDUSTRY PRESENT INTERIM RESULTS OF THE METHANQUEST PROJECT. THE PROJECT ENTAILS NEW TECHNOLOGIES FOR PRODUCING GAS FROM RENEWABLE SOURCES, FROM PEM TO DIRECT SEAWATER ELECTROLYSIS, TESTING OF HYDROGEN, METHANOL, AND METHANE FOR USE IN SHIPS, CARS, AND POWER GENERATION, AND A SECTOR COUPLING CONCEPT WITH LNG HUB AND MICROGRID IN THE RHINE PORT OF KARLSRUHE

ALL PHOTOS COURTESY OF ROLLS-ROYCE. The fagship project MethanQuest was launched in September 2018, and a total of 29 partners from the research, industry, and energy sector have come together to work on processes for producing hydrogen and methane from renewables and for using them to achieve climate-neutral mobility and power generaton. The project partcipants have now submited their interim results. These relate to electrolysis systems for producing hydrogen, both on land and in ofshore wind parks, equipment for producing methane, the use of gas engines in cars, ships, and CHP plants, and concepts for energy systems that efciently couple the transport, electrical power, gas, and heatng sectors. Common to all plants and processes is the integraton of renewables. >>

The microgrid is currently being tested in simulated scenarios using real data from the port facility and other components.

Several sub-projects are working on the numerous research projects of the MethanQuest project, which is led by DVGW and the Rolls-Royce business unit Power Systems. The MethanFuel group is researching new processes for manufacturing methane out of renewables. All the technologies involved – from water electrolysis to CO2 extracton and methanaton – have been examined and enhanced. Areva H2Gen, in collaboraton with its project partners Fraunhofer ISE and iGas energy, has developed an innovatve PEM electrolysis system which is being tested over a period of nine months in the Höchst industrial park. PEM electrolysis, in which hydrogen is produced using electrical power generated from renewables, is the frst step in the Power-to-Gas process. Flexibility is required in terms of the system’s power requirement – hence it is operable with up to 2.3MW as well as with a low partal load without running the risk of premature wear and tear or damage. That means that draw-of of electrical power for hydrogen producton can be selected according to the current demand and related prices.

10m3 of methane per hour

The steps involved in convertng hydrogen into methane have been successfully demonstrated by MethanQuest partner DVGW and the Engler-Bunte-

Insttut, Teilinsttut Chemische Energieträger – Brennstofechnologie (EBI ceb) of the Karlsruhe Insttute of Technology. Firstly, a long-term experiment in capturing CO2 from the air has been conducted. Furthermore, a new catalytc methanaton plant produces around 10m3 of pure methane per hour and displays excellent dynamic load behaviour. That is a signifcant advantage when it comes to dealing with the supply fuctuatons involved in using electricity produced from renewables.

Testing of hydrogen, methanol, and methane

In the three sub-projects MethanCar, MethanPower, and MethanMare, the partners are working on engines capable of combustng renewable gas highly efciently without producing harmful by-products. A car engine powered by methane built under the leadership of Ford is currently being put through its paces. The primary focus lies on achieving high efciency and on developing exhaust afertreatment strategies for the Oto engine. Coordinated by Rolls-Royce Power Systems, the MethanPower research group are currently investgatng a concept involving a large-sized innovatve Oto engine fuelled by hydrogen. Used in power generaton, the aim is for this engine to achieve the power density of a natural gas engine with minimum emissions. The researchers are delighted by the results so far, because hydrogen combuston produces few noxious emissions and achieves high power densites. The MethanMare sub-project is concerned with the energy revoluton in the maritme sector and shows how fuels manufactured from renewables can be used to support it. Research has found that with the use of catalysers and an extremely complex technique for high-pressure gas injecton, emissions from a methanepowered ship engine can be lowered by up to 80% compared with those of a conventonal gas engine.

LNG hub concept for Rhine port

The MethanGrid group has conceptualised an LNG hub for the Karlsruhe inland port that takes the form of a mult-functonal system of e-methane storage and distributon. Firstly, the hub secures the supply of LNG to ships navigatng the Rhine at regional level. Furthermore, the hub can also be used to supply trucks and larger distributon points with LNG and support the high-pressure gas network in BadenWürtemberg for peak load coverage.

Test bench with the single-cylinder engine at the Technical University of Munich.

The aim is for this engine to achieve the power density of a natural gas engine with minimum emissions.

Microgrid simulating sectorcoupling

In collaboraton with Rolls-Royce Power Systems and other partners, the DVGW Research Center has also developed a complete locally coupled energy supply system for the Karlsruhe inland port facility. Electricity, gas, heatng, industry, and transport – in other words, all the current sectors – are coupled by means of this microgrid so that the available energy, including renewables, can be optmally exploited. The microgrid is currently being tested in simulated scenarios using real data from the port facility and other components. This will enable the fnal development of a concept that is practcal to implement. The interim results provided by the MethanSys sub-project show how possible developments in e-methane throughout Germany’s energy system can be comprehensively modelled and evaluated along with the gas infrastructure.