8 minute read

UPDATES

CROWLEY AND SHELL

Advertisement

TO BUILD AND CHARTER JONES ACT LNG BUNKER BARGE

CROWLEY MARITIME CORPORATION has signed a long-term time charter with Shell NA LNG LLC, providing for the building and operation of a new U.S.built, LNG bunker barge. With a capacity of 12,000 cubic meters, it will be the largest Jones Act-compliant vessel of its kind.

It will be built at Fincantieri Bay Shipbuilding in Sturgeon Bay, Wis., and will be the second LNG bunkering barge to be built at the shipyard, which is currently constructing a 5,400-cubic-meter unit for Polaris New Energy that is set for delivery later this year.

“This additional LNG barge will serve as another demonstration of our commitment to building and servicing sustainable maritime endeavors, both in the United States and globally,” said Dario Deste, president and CEO of Fincantieri Marine Group.

“The new bunker barge will extend Crowley’s commitment to deliver cleaner, innovative solutions to help the shipping industry continue on the path to decarbonization,” said Tucker Gilliam, vice president, Crowley Shipping. “Orders for ships fueled by liquefied natural gas continue to rise, and the vessel will provide Shell an innovative and reliable service to meet demands for more sustainable energy sources.”

The 416 foot long barge will feature advanced technologies in cargo handling capabilities and increased transfer rates, including a state-of-the-art solution from Shell and Crowley Engineering Services to flexibly deliver LNG to various types of LNG containment systems. The design will offer capacity for 12,000 m3 (3.17 million gallons) and product supply equipment to fully serve ocean carriers.

The vessel becomes the second Jones Act-compliant bunker barge Shell has under long-term charter in the U.S. It is expected to be deployed to serve LNG-fueled ships that call on ports on the U.S. East Coast starting in 2024.

“Shell is dedicated to growing our LNG bunkering network across key trade routes, and this barge supports our commitment to helping provide our customers with the energy solution they are looking for,” said Tahir Faruqui, general manager, Global DLNG for Shell. “The shipping sector is making progress toward decarbonization, and LNG offers immediate emissions reduction with the potential to become a net zero emission marine fuel given the possible roles of bio-LNG and synthetic LNG.”

Crowley says that, aligned with actions by its New Energy division in support of the company’s sustainability commitment, the expansion of LNG capacity will allow Crowley and its customers to realize more immediate emissions reductions and fasttrack the transition to new energy sources that reduce greenhouse gas emissions.

Maersk Makes Major Move on Methanol

A.P. MOLLER – Maersk says that in the first quarter of 2024 it will introduce the first in a series of up to 12 large oceangoing containerships capable of being operated on carbon neutral methanol. Hyundai Heavy Industries will build the 16,000 TEU vessels and the initial agreement with the shipbuilder for eight ships includes an option for an additional four vessels in 2025.

The vessels will have dual fuel engines and Maersk says the additional capital expenditure (CAPEX) for the dual fuel capability, which enables operation on methanol as well as conventional low sulfur fuel, will be in the range of 10-15% of the total price.

The ships’ methanol propulsion configuration has been developed in collaboration with MAN Energy Solutions, Hyundai (Himsen) and Alfa Laval and represents a significant scale-up of the technology from the previous size limit of around 2,000 TEU, so it is no surprise to learn that they will be powered by the largest, methanol fueled engines ever built.

Hyundai’s Shipbuilding Division, HHI-SBD, has ordered eight MAN B&W 8G95ME-LGIM (Liquid Gas Injection Methanol) engines for the initial eight ships. The “95” in the designation indicates the cylinder bore in centimeters, And at 95 centimeters it is a significant upgrade on the existing 50 centimeter bore ME-LGIM engines in the MAN Energy Solutions portfolio.

Hyundai Engine & Machinery Division, HHI-EMD, will build the engines. The order contains an option for a further four engines with the first of the confirmed vessels due to enter service in first quarter 2024.

The vessels will be classed by ABS and sail under Danish flags.

More than half of Maersk’s 200 largest customers have set—or are in the process of setting—ambitious science-based or zero carbon targets for their supply chains. As part of Maersk’s ongoing collaboration with customers, corporate sustainability leaders including Amazon, Disney, H&M Group, HP Inc., Levi Strauss & Co., Microsoft, Novo Nordisk, Procter and Gamble, Puma, Schneider Electric, Signify, Syngenta and Unilever have committed to actively use and scale zero-carbon solutions for their ocean transport, with many more expected to follow.

“The time to act is now, if we are to solve shipping’s climate challenge,” says A.P. Moller – Maersk CEO Søren Skou. “This order proves that carbon neutral solutions are available today across container vessel segments and that Maersk stands committed to the growing number of our customers who look to decarbonize their supply chains. Further, this is a firm signal to fuel producers that sizable market demand for the green fuels of the future is emerging at speed.”

Maersk says it will operate the vessels on carbon neutral e-methanol or sustainable bio-methanol “as soon as possible.” However, it adds that “sourcing an adequate amount of carbon-neutral methanol from day one in service will be challenging, as it requires a significant production ramp up of proper carbon neutral methanol production, for which Maersk continues to engage in partnerships and collaborations with relevant players.

Dry Docks Work Boats Barges

JMS-Designed

Modular Dry Dock 200’ expandable to 420’ 3,800 to 7,500t Lift Capacity Designed by JMS for Group Ocean New Brunswick

Let’s make plans.

Naval Architecture Marine Engineering www.JMSnet.com 860.536.0009

OHT Heavy Lift Ship Completes Tricky Balancing Act

NORWEGIAN SPECIALIST transportation and installation contractor OHT has released details of a challenging contract earlier this year that saw its semi-submersible heavy lift ship M/V Hawk doing a 40-day balancing act with a 180 meter long floating dry dock.

OHT was chartered by Promaritime International to transport the dry dock, ADBS-1, from Abu Dhabi, around the Cape of Good Hope, to Brest, France.

The project got underway at the end of April in Abu Dhabi, where the dry-dock measuring 180 meters long by 37 meters wide, was loaded and diagonally stowed on the Hawk’s deck. The overhang of the dock, measuring approximately 32 meters long on each side of the Hawk, in combination with the vessel’s beam of 55.5 meters resulted in an overall transport width of close to 120 meters.

OHT reports that thanks to the exceptional experience of its captain and crew, the Hawk was able to safely navigate around the Cape of Good Hope with only minimal delays due to adverse weather and without stopping in any safe haven, such as Port Elizabeth.

The Hawk arrived in Brest on June 8, 2021, where the floating dry dock was smoothly and seamlessly discharged the following day, with professional support from Promaritime in the coordination of the marine operations.

According to Promaritime, ADBS-1 was next towed to Damen Shiprepair Brest for two months of painting and repairs prior to be towed to the port of Rouen to get ready for operations.

AAM Launches America’s First Hydrogen Fuel Cell Ferry

ALL AMERICAN MARINE INC. (AAM), Bellingham, Wash., and vessel owner SWITCH Maritime report that the 70-foot, 75-passenger hydrogen fuel cell powered ferry Sea Change has been launched and has started operational trials. The vessel will operate in California’s Bay Area and has been developed and constructed to demonstrate a pathway to commercialization for zero-emission hydrogen fuel cell marine technologies. Its launch marks both a U.S. and a world first.

While still working on permitting of hydrogen fuel systems for maritime vessels with the U.S. Coast Guard, the completed ferry will exhibit the viability of this zero-carbon ship propulsion technology for the commercial and regulatory communities.

The project is funded by private capital from SWITCH, an impact investment platform that is building the first fleet of exclusively zero-carbon maritime vessels to accelerate the decarbonization and energy transition of the U.S. maritime sector.

SWITCH acquired the vessel, then named the Water–Go–Round, from project initiator Golden Gate Zero Emission Marine (GGZEM), now named Zero Emissions Industries, in June 2019.

The vessel is equipped with a hydrogen fuel cell power package provided by Zero Emissions Industries, comprised of 360 kW of Cummins fuel cells and Hexagon hydrogen storage tanks with a capacity of 246 kg. This system is integrated with 100 kWh of lithium-ion battery provided by XALT and a 2 x 300 kW electric propulsion system provided by BAE Systems.

The hydrogen fuel cell powertrain system delivers the same operational flexibility as diesel with zero emissions and less maintenance. The vessel design originates from Incat Crowther, and the construction supervision and management is led by Hornblower Group.

Prepare for Paperless Transit as NOAA sunsets paper charts by 2025

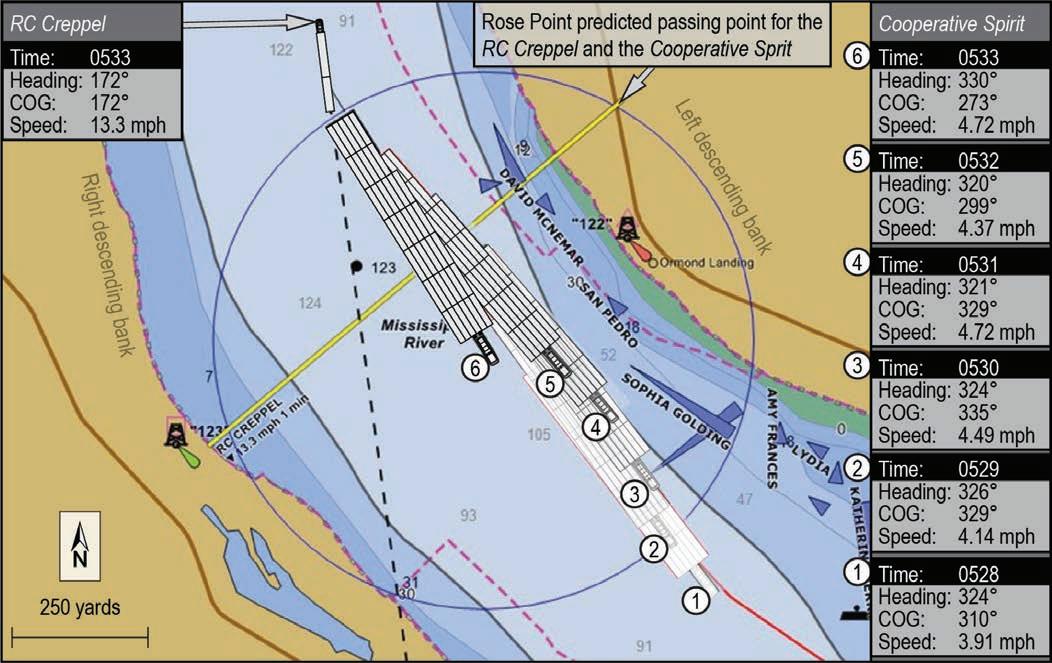

Rose Point ECS software combined with HATTTELAND® Series X Gen2 panel computers will meet the specification for paperless carriage requirements set forth in USCG NVIC 01-16.

Don’t get caught behind this momentous change!

Choose a complete system from Rose Point Navigation Systems that combines the best ECS on the market with a 19” or 24” all-in-one system from HATTTELAND® – the best solution for your fleet to maintain compliance!

For more information, please contact us at: