6 minute read

Protect your crop Part 2: Use the correct nozzles

from ProAgri BNZ 14

by ProAgri

Protect your crop Part 2

Advertisement

Use the correct nozzles

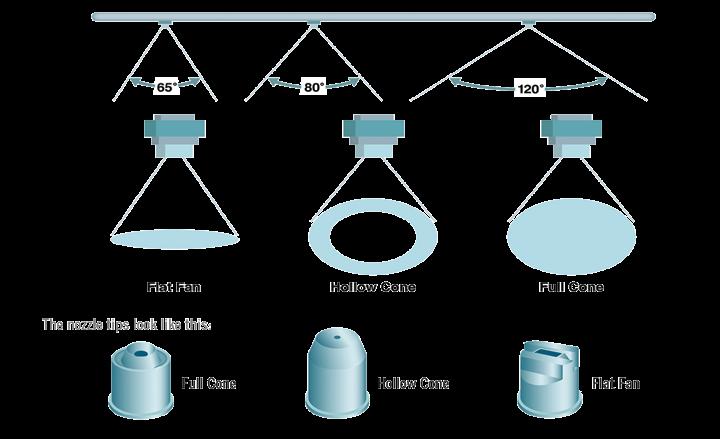

Good crop protection starts with indicate the delivery of the nozzle which Cone type nozzles a good sprayer. Last month we in this case will be: 4 US gallon per Of the cone type nozzles, the following discussed the parts of sprayers and minute at a pressure of 40 pounds per two are of great importance: what a farmer should consider when he square inch. buys a sprayer. In this issue we discuss Flat-fan nozzles with different spray Hollow cone nozzles different nozzles, and next month we angles and delivery volumes are avail- As the name indicates, the spray pattern compare costs of draw, hitch and self- able from suppliers. of this nozzle is in the form of a hollow propelled sprayers. cone. It is important to note the manner Strip spraying with flat-fan nozzles in which the nozzles should be assemNozzle types (Evenly) bled. Various overseas companies manufac- Code numbers on these nozzles are Hollow cone nozzles are suitable ture a wide range of nozzles, each with followed by an "E". This means that un- for the application of fungicides and its own purpose and application like the ordinary flat-fan nozzles, equal insecticides, and also for foliar feeding of quantities of the mixture are delivered plants. Flat-fan nozzles across the entire spray width of the The fact that it sprays in the form of a Flat fan nozzles are used on most farms spray pattern of a nozzle and therefore hollow cone, results in different droplets for the broad cast or strip application of do not allow for overlapping with other reaching the target at different angles herbicide on well-prepared soil. nozzles. The whole spray width is uni- of incidence. In this way, better intruformly covered by the one nozzle. sion and covering are obtained in dense Broad cast application with flat-fan The "E" type nozzles should not be leaves. For example, hidden insects and spraying used for broad cast applications. fungi can also be targeted easier. Flat-fan nozzles are mounted evenly on the spray bar. The spacing of the nozzles depends on the specific spray angle of the nozzle and the height of the spray bar from the ground. The spray bar must be placed at a specific height above the ground so that a 30% overlap is obtained on the sides of the spray patterns between nozzles.

A code number on the nozzle indicates the spray angle and delivery volume of flat-fan nozzles.

For example, the number 80 in the code number 8004 on the nozzle, indicates that the specific nozzle sprays out the mixture at an angle of 80°. The last two digits in the code, namely 04,

Compiled by JP le Roux

Plant equipment / Truck Sales / Transport

• Diesel fix Decontaminate • Mining equipment MB Crushing Buckets and attachments • Plant Trucks

2008 Bell 315 SJ:

Transmission refurbished

Hyundai 36 ton: 2011 Bell HD1430R:

8 800 hours / Working near PMB

Catterpiller 966 F:

Tyres 70% / Good condition

Bell B20B:

Working on site in Durban

2007 Komatsu PC200-7:

10 300 hours

Swift tri axle:

2007 Catterpiller 226 B turbo:

Skid steer / engine completely overhauled and new turbo (includes warranty) / trenching attachment piped for auger or hammer Includes a tandem axle transport trailer with ramps

Komatsu D85EX-21:

± 16 000 hours / Fully refurbished / new final dives, engine, blade side plates, undercarriage

2016 Fuso 4 ton Dropside:

140 000 km

We also offer: Repairs and maintenance, Diesel /petrol / hydraulic solutions

Karl Steyn

karlsteyn9@gmail.com / 072 017 7927 dorotheasteyn7@gmail.com / 064 517 2632 Admin: 076 418 7558 Location: Darnall / Nkwazi (KZN)

https://www.youtube.com/watch?v=pF85E41P1YE https://m.youtube.com/watch?v=CHNT5YRhGwg https://karlsplantfinder.wixsite.com/earthmoving

Hollow cone nozzles are particularly suitable for the application of contact as well as systemic plant protection agents. The application of one, two or three nozzles per row and their placement will depend on the size of the plants as well as the density of the leaves.

Characteristics of hollow cone nozzles:

• Droplets reach the target from different angles, which improves leaf wetting (especially in dense leaves). • Fine droplets are usually formed, which improves invasion and wetting, but also increases the danger of drifting. • Works at pressures of 300 to 500 kPa.

Full cone nozzles

By changing the core or swing plates of the nozzle, the spray pattern of a nozzle can be changed from hollow to full.

A full cone nozzle is suitable for the post-emergence control of weeds and insects in crops by broad casting or strip spraying.

This nozzle works at pressure levels of between 300 and 500 kPa.

The follow-up spraying of weeds in standing maize is a good example of the use of full cone nozzles.

Full cone nozzles can also be placed right above the maize rows to wet a specific target on the plants, such as the cups of maize plants infected with maize stalk borers.

If the caterpillars have not moved too deep into the cups, they can be effectively controlled by correct placement of hollow nozzles over the rows and the application of enough spray to effect droplet formation inside the cups.

Flat fan

Hollow Cone

The nozzle tips look like this:

Full Cone Hollow Cone Full Cone

Flat fan

Note

The application of the right nozzles, the right placement, pressure, and delivery are aspects that farmers still largely neglect, and which will eventually lead to poor control and a waste of expensive chemicals. When in doubt, ask an expert. A good harvest will compensate for any

Floodjet nozzles

This type of nozzle can be used efficiently for herbicides that have to work in the soil and, to a lesser extent, for pre-emergence weed control. In other countries, the nozzles are used to apply liquid fertiliser, but they are mostly used in orchards in South Africa, especially for applications under the leaves of trees. trouble or cost to get the right advice. Next month we shall discuss air assisted boom sprayers and compare the costs of hitch, draw and self-propelled sprayers. We thank Koos le Roux, compiler of the Mechanisation Guide for the article.

Properties of flood beam nozzles:

• Work at low pressure of 100 to 200 kPa • Deliver large droplets with little drift • Relatively large nozzle openings that do not clog easily • Deliver a broad spray width