Welcome to my engineering portfolio, a testament to my passion for innovation, problem-solving, and creativity in the field of engineering. As you explore this collection of projects, designs, and accomplishments, you'll gain insight into my journey as an engineer and the diverse range of skills and experiences I bring to the table.

My journey in engineering and design began with a deep fascination for understanding how things work and a relentless drive to make them work better. From a young age, I found joy in dismantling gadgets to explore their inner workings, which ignited my curiosity for science and technology. This curiosity evolved into a lifelong commitment to pursuing excellence in engineering.

Throughout my academic and professional endeavors, I have continually sought out opportunities to challenge myself and expand my knowledge across various disciplines within engineering. Whether it's designing innovative solutions to complex problems, collaborating with multidisciplinary teams, or leveraging emerging technologies to drive advancements, I thrive on the dynamic nature of the engineering field.

In this portfolio, you'll find a curated selection of projects that highlight my expertise in areas such as mechanical engineering, industrial design and creative design. Each project represents not only a technical accomplishment but also a testament to my dedication, creativity, and problem-solving abilities.

As you delve into the pages of this portfolio, I invite you to explore the depth of my engineering skills, the breadth of my experiences, and the passion that drives me to push the boundaries of what's possible.

British Airways had the requirement to fit out a two-class cabin in the Boeing 777-200ER. The need was to maximise seating capacity whilst maintaining comfort to optimise profits.

This involved managing frequent feedback and design changes from client criteria resulting in multiple revisions.

Multiple renders of the internal layout were generated to better demonstrate the viability of the design.

The brief was simple. Reverse engineer Caterpillar and Komatsu wheel motor components to improve service life

I was in charge of the drafting, drawings, liaising with manufacturers, quality inspection, scanning, renders and animations of assemblies.

Hexagon

Polyworks Inspector

Inventor

Meshmixer

Through innovative laser scanning and probing from a Computer Measuring Machine (CMM), complex parts can be reversed engineered with the help of powerful metrology software.

Scanning tolerances are within 50μm which is also useful for quality assurance.

Then the scan can be accurately modelled in a Computer Aided Design (CAD) program like Autodesk Fusion 360.

Drawings were then drawn up to be sent to the manufacturer to understand without confusion.

Often these components had a service life five times higher due to increased tolerances over the OEM.

In collaboration with The Hemp Building Co. in creating the design for both the structure and internals of a modular home made of hempcrete.

The outcome was a success and was the first modular hempcrete house globally.

The structural design is currently in development intended for the prefabrication market.

*not a render

The brief was to craft a functional yet contemporary pair of glasses incorporating bone conduction audio in collaboration with the Bose Design Team.

Fusion 360 was used for both direct and parametric modelling to blend a fluid form into a parametric CAD format.

Knowledge of both of these modelling techniques was paramount in creating these glasses. The form would have been impossible otherwise.

Fusion ensured the marriage of both aesthetics and functionality, leading to a well-integrated holistic design.

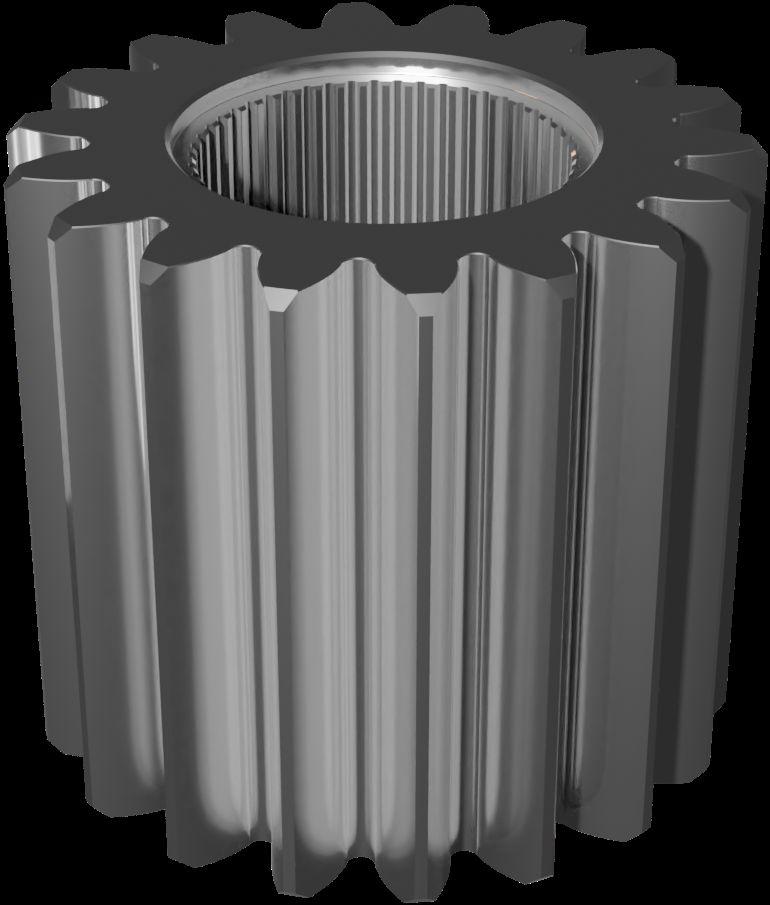

Fused Deposition Modelling (FDM) is the most efficient way to develop ideas into a tangible product using my skills in CAD.

This process has taught me to think about initial design and prototyping entirely differently, specifically the rapid prototyping workflow, testing new ideas, saving time and money on expensive tooling.

The part shown was a very complex direct-remote gear extruder with a 1:3 gearbox. This was to increase torque and lower weight on the print heads for faster and increased accuracy printing.

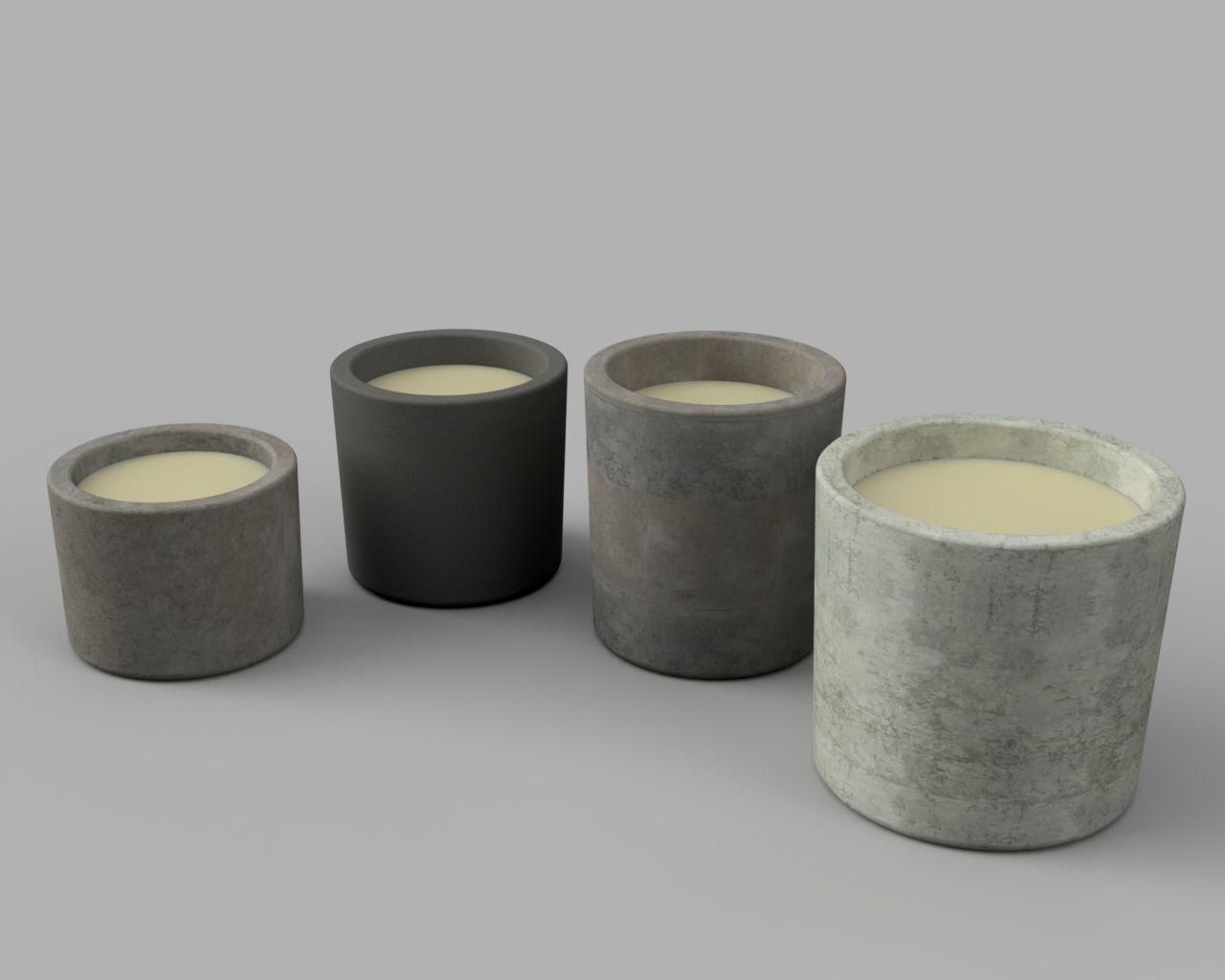

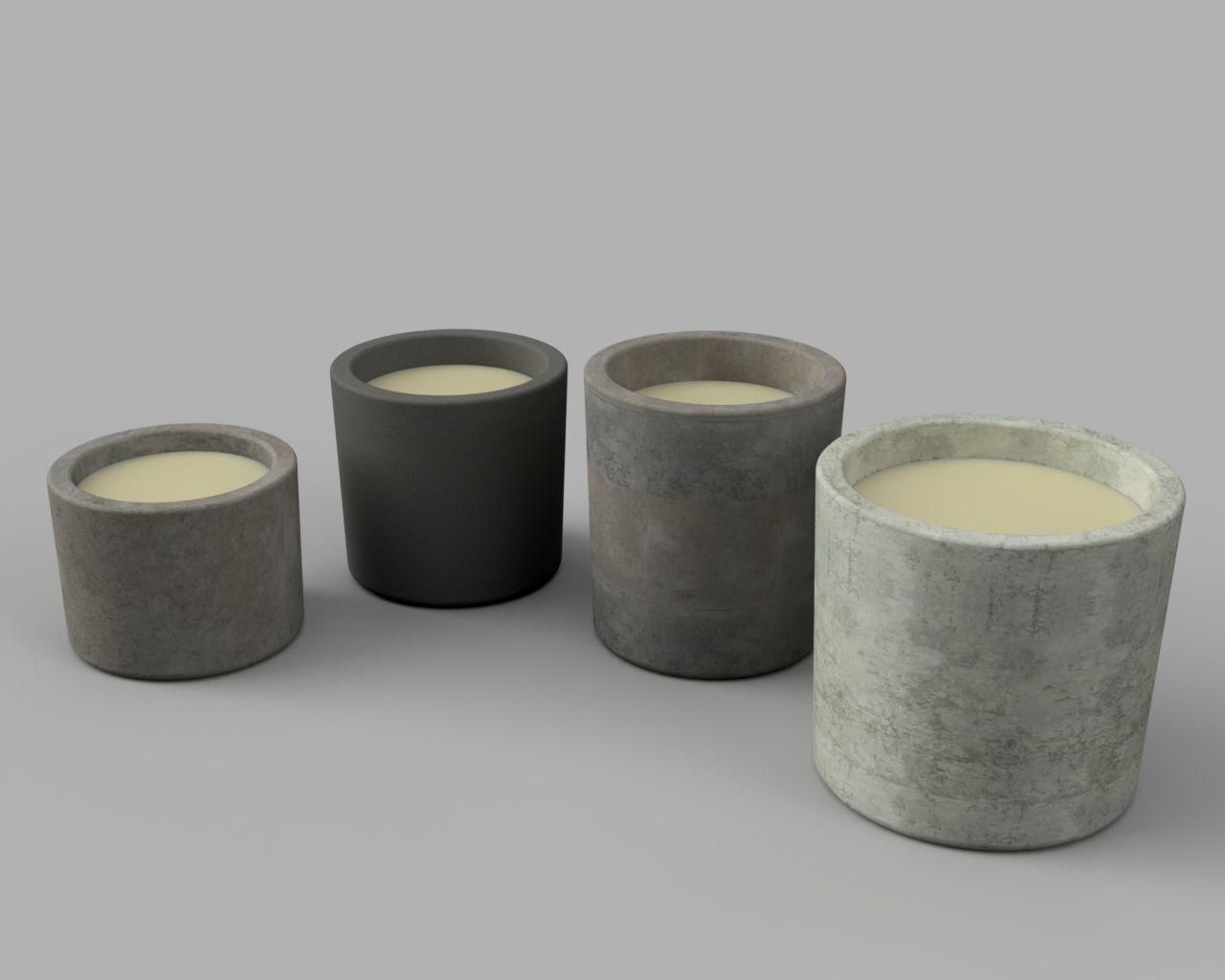

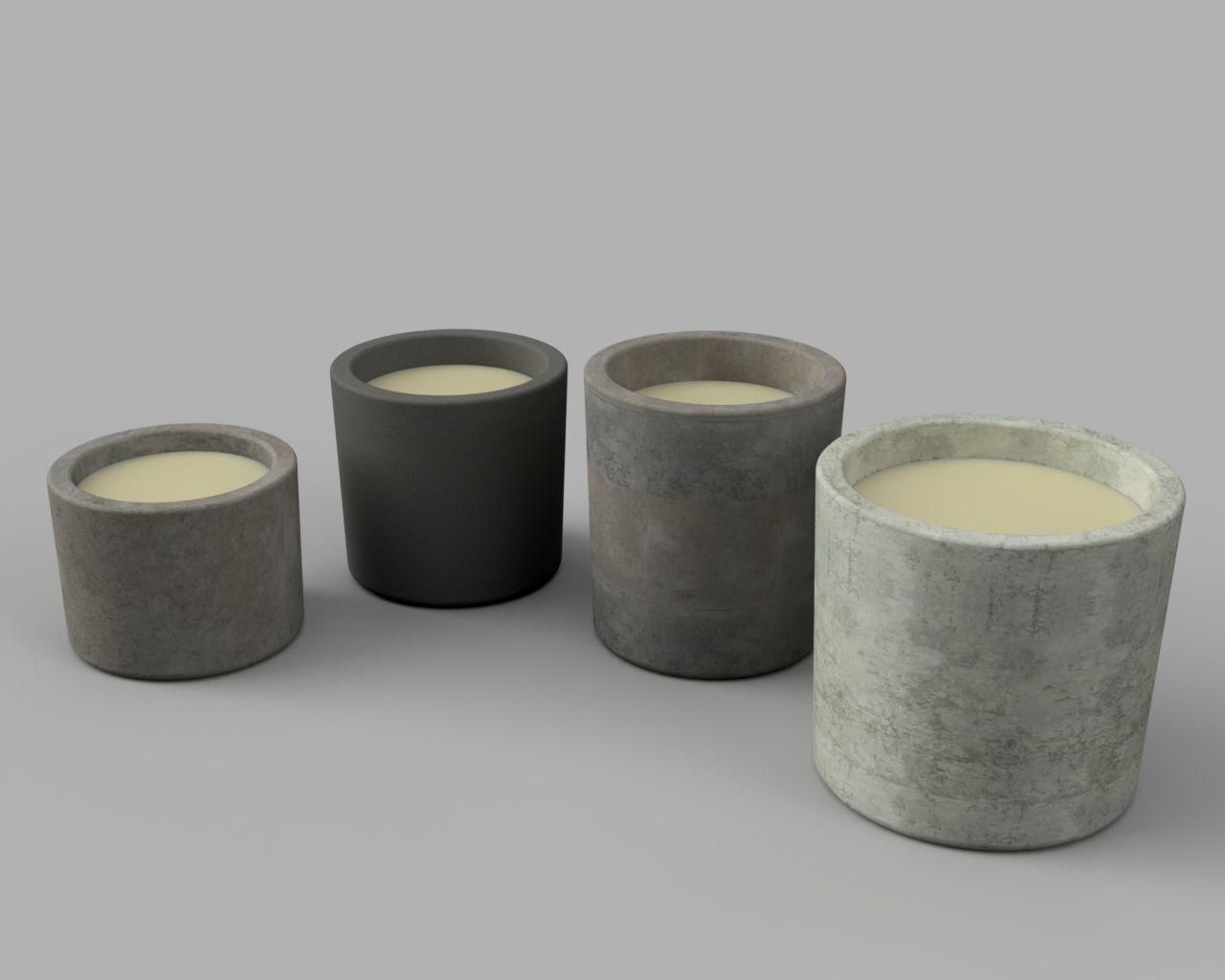

Candle vessel — Designed and produced a candle vessel made from sustainable composite material. I developed a material based on ‘hempcrete’ which is carbon negative.

These vessels were then sold to a local business and filled with eco-friendly soy wax.

This material has more significant implications than candles but is a solid foundation for an eco material replacement such as concrete.

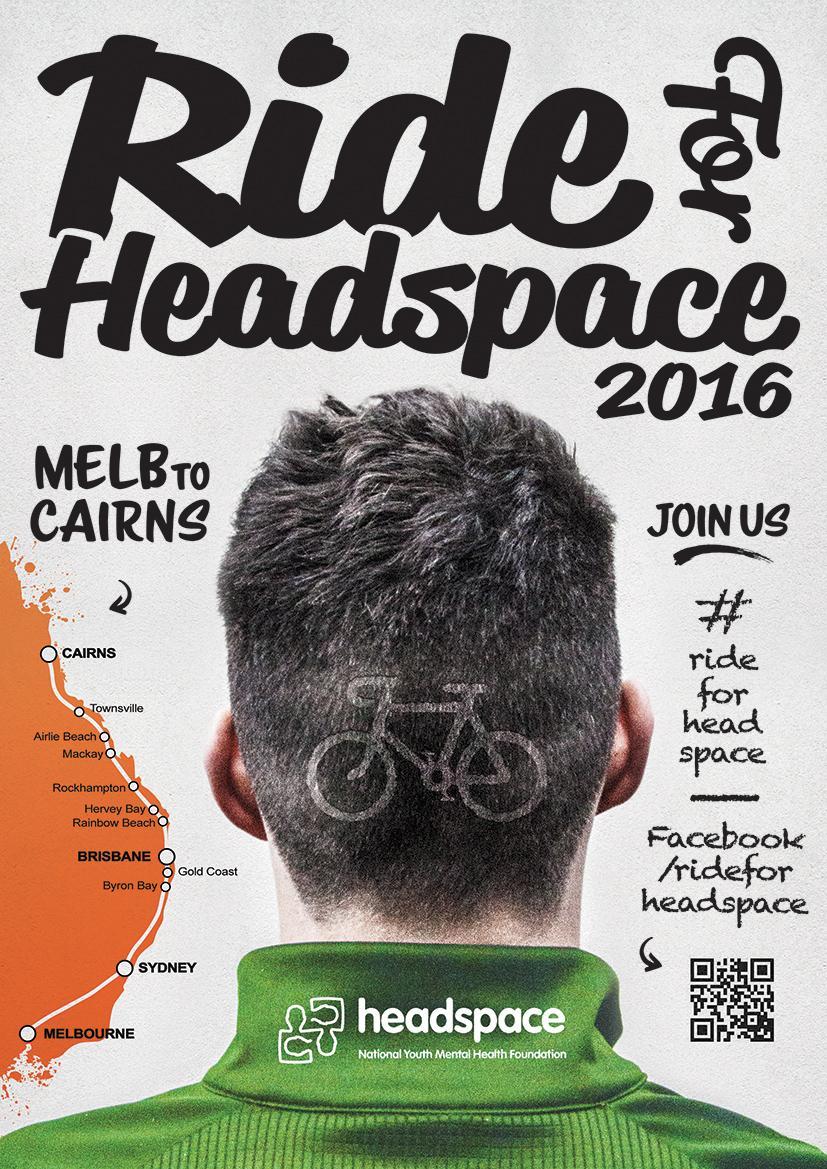

Solo fundraiser for a youth mental health foundation. Successfully raised awareness and $800. This foundation is important to me because it has affected my peers so is very relevant. It taught me that i can do anything i put my mind to and have the determination and drive to do the best in my work.