17 minute read

Breaking News

Sydney's ‘Factory of The Future’ Ready to Drive Statewide Innovation

The University of Sydney recently launched a $25 million facility to drive innovation and foster industrial output. The Sydney Manufacturing Hub is a research facility that will deliver cutting-edge research and development in additive manufacturing and materials processing. It will enable concept-to-production demonstration capabilities, including advanced pre- and post-processing of materials for faculty, students, small and medium-sized companies, and larger companies. The University of Sydney’s Vice-Chancellor, Professor Mark Scott AO, said the university has continued to demonstrate its capability as a leader in the region by working closely with the public and private sectors. “The Sydney Manufacturing Hub, situated in Darlington at the very heart of 'Tech Central' is a key demonstrator for what's ultimately possible when government, industry and higher education work together on high-impact technologies.” The hub provides for design, topological optimisation, the 3D printing of metals, ceramics and polymers. It also paves the way for new technology in industries like aerospace, autonomous vehicles, biomedical, defence, maritime, and robotics.

The NSW Minister for Trade and Industry, the Hon Stuart Ayres MP said the facility is a gamechanger. "The concept of modern and additive manufacturing, rather than deductive manufacturing, is completely changing the opportunities that are available to Australians.”

Together, additive manufacturing is a transformative approach to industrial production that enables the creation of lighter, stronger parts and systems. It is yet another technological advancement made possible by the transition from analogue to digital processes. The hub is based at the University of Sydney's engineering precinct at its Darlington campus.

University of Sydney Vice-Chancellor Professor Mark Scott AO and University of Sydney Chancellor Belinda Hutchinson AC with the Minister for Jobs, Investment, Tourism and Western Sydney and Minister for Trade and Industry the Hon. Stuart Ayres at the launch of the Sydney Manufacturing Hub. Image credit: Bill Green/ University of Sydney.

UQ Research Unlocks the Technology to Produce Unbreakable Screens

Luminating composite glasses. Image credit: University of Queensland (UQ).

Research conducted at the University of Queensland could make cracked phone screens a thing of the past. A global team of researchers, led by Dr Jingwei Hou, Professor Lianzhou Wang and Professor Vicki Chen, have unlocked technology to produce next-generation composite glass for lighting LEDs. This development could ultimately change smartphone, television and computer screen usage and protection. Dr Hou said the discovery was a huge step forward in perovskite nanocrystal technology. “The emitting materials are made from nanocrystals, called lead-halide perovskites.” “They can harvest sunlight and concert it into renewable electricity - playing a vital role in low-cost and highefficiency new generation solar cells and many promising applications like lighting,” Dr Hou explained. Researchers have previously only produced this technology in the bone-dry atmosphere of a laboratory setting. “Unfortunately, these nanocrystals are extremely sensitive to light, heat, air and water—even water vapour in our air would kill the current devices in a matter of minutes,” Dr Hou said. The findings will manufacture glass screens that are not only unbreakable but also deliver crystal clear image quality. “Our team of chemical engineers and material scientists has developed a process to wrap or bind the nanocrystals in porous glass. This process is key to stabilising the materials, enhancing its efficiency and inhibits the toxic lead ions from leaching out from the materials,” Dr Hou said. This research is a collaborative effort between the University of Queensland, the University of Leeds, Université Paris-Saclay and University of Cambridge.

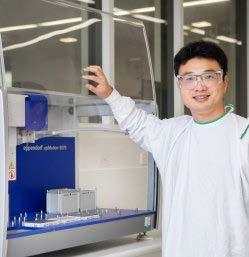

Dr Jingwei Hou, Professor Lianzhou Wang, and Professor Vicki Chen. Image credit: University of Queensland (UQ).

No More Moving Parts: Liquid Metal Enabled Chemical Reactors

Metals that are liquid at room temperature, such as gallium and its alloys, are attractive materials due to their unique electrical, thermal and fluidic properties. But in recent a study, a research team led by University of New South Wales (UNSW) Sydney has shown that liquid metals can offer their characteristics to the pharmaceutical and chemical industries.

This opens a range of new possibilities to eliminate moving parts in continuous flow reactors, and provide improved performance and reduced maintenance costs. Traditional mechanical pumps and moving parts could potentially be replaced by ‘soft’ components that have never failed in the life of the machine. Flow reactors are being increasingly adopted in pharmaceutical and chemical industries, with their operation and maintenance representing an important factor in these industries. Continuous flow reactors allow fast reactions, offer safe control, and enable easy scaling-up opportunities. These industries are inclined to implement flow reactors for increasing product quality and yield of chemical and biochemical reactions.

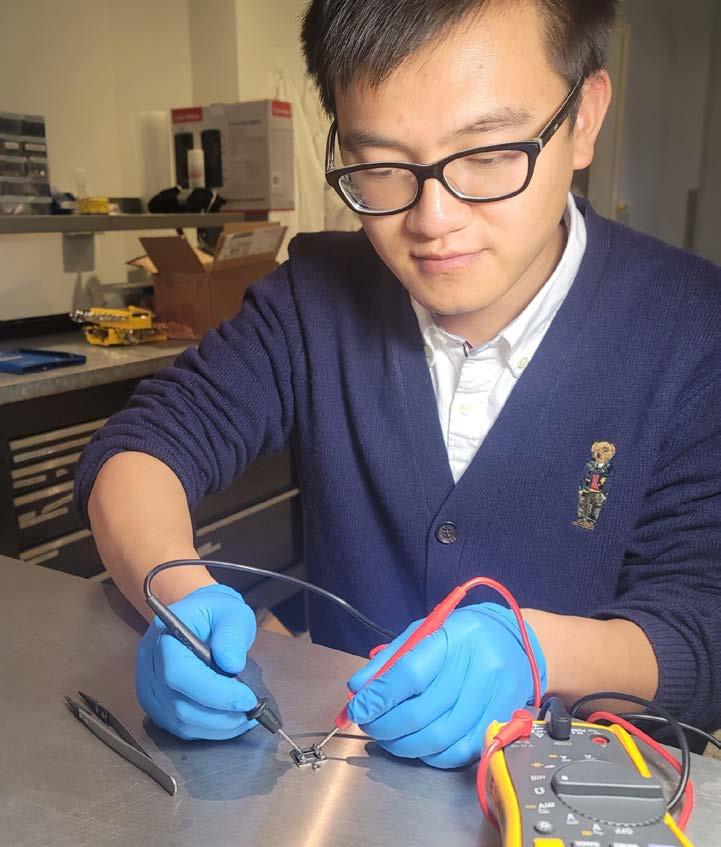

UNSW researchers, and their collaborators from Queensland University of Technology, and the University of California have demonstrated a continuous flow reactor enabled by liquid metal droplets in their cores. According to Jialuo Han, the first author of the study and a research assistant at UNSW, the breakthrough is a win for the sector.

“The liquid metal can be easily integrated into a fluidic channel for constructing the continuous flow reactor,” Han explained. “The liquid metal itself can spontaneously produce materials on the surface and the material is repelled away from its surface with the application of an external voltage.”

Traditional mechanical pumps can be replaced by liquid metal components whose changing shape is controlled by voltagecontrolled surface tension.

A liquid metal droplet as the core of a continuous flow reactor for both chemical reaction and mass transport.

Data Innovation Hub to Boost Skills in Data Analytics and AI

A new Data Innovation Hub at RMIT University will offer students fresh opportunities to work with leading organisations using data analytics. The program will prepare students for emerging jobs through practical bootcamps, industry mentoring, paid internships, on-the-job coaching and other integrated learning experiences. Professor Aleks Subic (Deputy Vice-Chancellor STEM College and Vice-President Digital Innovation at RMIT University) said the Data Innovation Hub will prepare graduates for a successful career.

“Through this unique partnership model involving the enterprise and academic parts of the university, students will work as data consultants both in our own University data analytics operations, and through placements with our industry partners, following an innovative Bootcamp based training program,” said Professor Subic. The program has been developed in partnership with several industry partners, including Deloitte, Commonwealth Bank, Amazon Web Services, EY, Latitude Financial Services and Macquarie Group. “As we lead the digital transformation at RMIT, we want to deliver authentic industry experiences for our students and provide a truly innovative education experience that will prepare them for work and life,” Professor Subic explained. According to Nonna Milmeister (Chief Data and Analytics Officer at RMIT), the initiative provides a suite of benefits for industry. “Demand for skilled data analysts and data scientists is strong and is projected to increase, so the Data Innovation Hub will facilitate Work Integrated Learning at scale in the field of Data Analytics,” said Milmeister. The Data Innovation Hub forms part of RMIT’s investments in new models of education and engagement to help accelerate the digital capabilities of students, staff, researchers and industry partners.

Breakthrough In Sizing Nanoparticles Using Fluid-Filled Tubes

Discovery has implications to vaccine development where particle size can inform on their effectiveness. Image credit: The University of Melbourne.

Scientists from the University of Melbourne and Massachusetts Institute of Technology have discovered a new process for simultaneously measuring the properties for the same nanoparticle. The functionality of nanoparticles in a host of applications, including drug delivery and nano-optics, is often dictated by their mass and size.

But researchers recently detailed how they made the discovery using existing instrumentation and new mathematics.

The team studied how nanoparticles move when placed in a mechanical fluid-filled tube that is vibrating. “While previous applications have focused on the up-anddown motion of nanoparticles relative to the surrounding fluid, we wondered about the effect of rotational motion,” said Dr Jesse Collis (University of Melbourne Research Fellow). Scientists previously thought that if a nanoparticle is floated in a tube and shaken, the response would be proportional to the mass of the particle. However, this recent study shows that there is a second response, which is proportional to the size of the particle. According to Georgios Katsikis, a co-lead on this study who made the key experimental observation, “Basically, the nanoparticle creates a hole in the liquid which alters the liquid flow.” “It is this phenomenon that allows us to develop new mathematics to link the tube vibration to the hole, and hence the particle size in addition to its mass,” Katsikis said. Viral vectors in vaccine development can be weighed to check if DNA is successfully packed inside a virus. Size can provide crucial information if the virus forms clumps of aggregates, which reduces efficacy of treatment.

Nanotechnology Offers Pain Relief for Tooth Sensitivity

In an Australian first, researchers from the University of Queensland have used nanotechnology to develop effective ways to manage tooth sensitivity. Dr Chun Xu, who works in the university’s School of Dentistry, said the approach may provide more effective long-term pain relief for people with sensitive teeth, compared to current treatment options. “Dentin tubules are located in the dentin, one of the layers below the enamel surface of your teeth,” Dr Xu said. “When tooth enamel has been worn down, and the dentin are exposed, eating or drinking something cold or hot can cause a sudden sharp flash of pain. The nanomaterials used in this preclinical study can rapidly block the exposed dentin tubules and prevent the unpleasant pain.” Tooth sensitivity affects up to 74 per cent of the population, and at times, severely impacts the quality of life and requires expensive treatment. “Our approach acts faster and lasts longer than current treatment options. The materials could be developed into a paste, so people who have sensitive teeth could simply apply this paste to the tooth and massage for one to three minutes,” Dr Xu said. This research will undertake clinical trials, which will pave the way for people to benefit from this new method that can be used at home.

“We hope this study encourages more research using nanotechnology to address dental problems,” Dr Xu said. The team also included researchers from the Australian Institute for Bioengineering and Nanotechnology.

Dr Chun Xu from the University of Queensland’s School of Dentistry. Image credit: University of Queensland (UQ).

Improving the Production of Piezoelectric Materials for Naval Sonar Systems

A key supplier to the Australian Defence Forces recently posed an industrial challenge to National Graduate Innovation Forum participants about the production of piezoelectric ceramic components. According to Peter Goodwin (who examines underwater systems at Thales Australia), these components are used in naval sonar arrays and systems. “It is the same basic technology, but obviously there are great opportunities in the development of new materials and in making improvements to manufacturing processes,” Goodwin explained. Piezoelectric ceramics have properties that make them useful in navigation, measuring distances, detecting objects or vessels on or under the surface of the water and communication.

The technology has been widely used since the Second World War and is one of several types of materials used in underwater sonar transducers. Thales manufactures a diverse range of piezoelectric ceramic components for clients.

“You need large arrays of ceramics to send a signal or ‘ping’ many kilometres through the water column and then listen for the reflected signal to try and find something such as a submarine,” Goodwin said. Thales’ Acoustics Centre of Excellence manufactures its ceramics with a ‘mixed oxide’ technique designed to produce optimal properties at a minimal cost. Overall, this process involves the blending of raw material oxides, pre-reacting them, grinding the oxides to a fine particle size, forming the powder into the desired shape and firing the body. “A lot of production processes controls, such milling speed, have been unchanged for a long time but that doesn’t mean they can’t be improved as we found recently,” Goodwin said.

Google Australia Announces $1 Billion Digital Future Initiative Investing in Australian Infrastructure, Research and Partnerships

The Australian Government recently paired up with Google Australia, and CSIRO to launch the Digital Future Initiative, which invests in the digital economy and infrastructure. Together, the partnership seeks to solve big challenges and accelerate Australia’s progress to becoming a leading digital economy. “The Digital Future Initiative is about bringing significant technology resources and capabilities to Australia, investing in the infrastructure that benefits people and businesses, and helping the best talent thrive here,” said Mel Silva, Managing Director of Google Australia. “A strong digital future creates opportunities, improves the everyday and enables the extraordinary—and we’d love to help Australia and Australians make the most of the opportunity and build for tomorrow,” Silva explained. Google’s Digital Future Initiative is expected to support 6,529 new direct jobs and 28,057 total jobs across Australia. It will also deliver $1.259 billion in direct investment and $6.716 billion in total economic impact. Dr Larry Marshall, Chief Executive of CSIRO, said the partnership opens a suite of new opportunities. “CSIRO’s science makes life better for every Australian, and when amplified by Google’s Technology it will catalyse collaborative projects across our entire national innovation system, driving opportunity for businesses of all sizes across every market.” ‘Google Research Australia’ will form a crucial part of the program. It is Google's first research hub in Australia. It links local researchers and engineers to explore ways that artificial intelligence can help tackle issues that are important in Australia, and around the world.“Our research provides valuable inspiration for the design of other metal-sulphur batteries, not just ones that use aluminium-sulphur technology,” Professor Qiao concluded.

Nanosensing To Solar Fuels: Sydney Nano Unveils New Grand Challenges

Four new visionary projects that are spanning sustainability, biosecurity, solar energy and health are drawing talent from across the University of Sydney’s major faculties. The university’s Nano Institute recently announced four new multidisciplinary Grand Challenge projects to focus on emerging issues facing society, the economy and everyday life. Sydney Nano Director, Professor Ben Eggleton, praised the high standard of entries from across the university. “The high-calibre of applications for our second round of Sydney Nano Grand Challenges is thanks to the success of the six inaugural Grand Challenge teams. It also exemplifies the unified interest across the University to work together to make a better society,” said Professor Eggleton. The visionary projects will capitalise on talents across faculties, seek engagement with industry and leverage expertise at the at one of the world’s best facilities for big ideas at the nanoscale. The four new Grand Challenges are: 1. Nanosensing airborne pathogens for public biosecurity 2. Eco-active building envelopes 3. Solar fuels 4. Organ-on-chip for blood clot assessment "The combined focus of the four new projects is telling of the challenges the global population faces today, spanning biosecurity, sustainability, and health. It was a difficult task to narrow down to four winning teams and I applaud the selection committee for their work,” Professor Eggleton said. Sydney Nano will provide up to $75,000 a year to each Grand Challenge team for two years to seed-fund their projects. The Grand Challenges bring researchers together into multidisciplinary teams supporting sustainable, long-term areas of research.

Sydney Nano brings expertise together from across the University. Image credit: The University of Sydney. The Mitchell Building at the University of Adelaide.

Quantum Materials Deliver a Better World

The University of Adelaide recently launched its Quantum Materials strategy. The fresh strategy realigns the university with a focus on cutting-edge fundamental research and delivering new quantum-enabled technologies for a safer, wealthier and healthier world. Quantum materials were the backbone of the transformative quantum technologies revolution of the late 20th Century, and led to solid-state transistors used in nearly everything. According to Professor Glenn Solomon, the Inaugural Hicks Chair of Quantum Materials at the University of Adelaide, the strategy will prepare Australia for the future. “We are now on the cusp of a second quantum technology revolution, with the hope and expectation that research in quantum materials will deliver revolutionary technologies for next generation communications, navigation, computing, cybersecurity and biomedicine.” Overall, the strategy seeks to: • Establish sovereign and world-class capability in fundamental and applied quantum materials research • Become a trusted partner of industry and the department of defence • Rank the university as one of the top five globally specialising in quantum materials • Create an educated workforce for future industry, defence and academic environments “We are building a coherent and collaborative research program in quantum materials across schools at the University of Adelaide that will translate into new and serendipitous discoveries and emerging technologies. These will contribute to emerging concepts in physics and help shape Australia’s future industries,” Professor Solomon said. Education and training will be a key component of the quantum materials ecosystem. “We will provide a state-of-the-art cross-disciplinary education which will produce the future leaders in the field,” Professor Solomon said.

Stretchable, Washable Batteries Designed for Wearables

Dr Ngoc Tan Nguyen has created a battery that is both flexible and washable. Photo credit: Kai Jacobson.

Researchers from The University of British Columbia have created a battery that is both flexible and washable. This means that it can work even when it is twisted or stretched to twice its normal length, or after being tossed in the laundry. According to Dr Ngoc Tan Nguyen, a postdoctoral fellow at the University of British Columbia, the breakthrough offers several engineering advantages. In normal batteries, the internal layers are hard materials encased in a rigid exterior. But the research team made the key compounds—zinc and manganese dioxide—stretchable by grinding them into small pieces and then embedding them in a rubbery plastic, or polymer. The battery comprises several ultrathin layers of these polymers wrapped inside the casing of the same polymer. This construction creates an airtight, waterproof seal that ensures the integrity of the battery through repeated use. “Wearable electronics are a big market and stretchable batteries are essential to their development,” Dr Nguyen said. “However, up until now, stretchable batteries have not been washable. This is a critical addition if they are to withstand the demands of everyday use.” Work is also underway to increase the battery’s power output and cycle life. The innovation has attracted commercial interest. The researchers believe that when the new battery is ready for consumers, it could cost the same as an ordinary rechargeable battery. In addition to watches and patches for measuring vital signs, the battery might also be integrated with clothing that can actively change colour or temperature.

Making A ‘Sandwich’ out of Magnets and Topological Insulators

A Monash University-led research team has discovered that a structure comprising an ultra-thin topological insulator sandwiched between two 2D ferromagnetic insulators becomes a large-bandgap quantum anomalous Hall insulator. Such a heterostructure provides an avenue towards viable ultra-low energy future electronics, or even topological photovoltaics. In the researchers’ new heterostructure, a ferromagnetic material forms the ‘bread’ of the sandwich, while a topological insulator (such as a material displaying nontrivial topology) takes the place of the ‘filling’. Combining magnetism and nontrivial band topology gives rise to quantum anomalous Hall (QAH) insulators, as well as exotic quantum phases such as the QAH effect where current flows without dissipation along quantized edge states. Inducing magnetic order in topological insulators via proximity to a magnetic material offers a promising pathway towards achieving QAH effect at higher temperatures (approaching or exceeding room temperature) for lossless transport applications. When two ferromagnets are placed on the top and bottom surfaces of a topological insulator, a gap is opened in the topological surface state, whilst the edge allows electrons to flow without resistance. One promising architecture involves a sandwich structure comprising two single layers of MnBi2Te4 (a 2D ferromagnetic insulator) either side of ultra-thin Bi2Te3 in the middle (a topological insulator). This structure has been predicted to yield a robust QAH insulator phase with a bandgap well above the thermal energy available at room temperature (25 meV). The new Monash-led study demonstrated the growth of a MnBi2Te4 / Bi2Te3 / MnBi2Te4 heterostructure via molecular beam epitaxy, and probed the structure’s electronic structure using angle resolved photoelectron spectroscopy.

Lead author FLEET PhD student Qile Li (FLEET/Monash).