3 minute read

SEAM Profile: Minh Nhat Dang

PhD Candidate, ARC SEAM, Swinburne University of Technology

recognised with a national consolation award for excellent undergraduate research and a Boston Fellowship to the hallowed hall of Harvard and MIT that reformed his mindset.

Returning to Vietnam, Minh took the roles of Laboratories Manager and Lead Researcher in national and private projects at leading institutions. There, his work on the scalable plasma-assisted production of graphene-based materials for sustainable construction and energy solutions gained him a patent, as well as the hope of improving local miners’ lives through high-end applications of graphite ore.

The quest for knowledge brought Minh to Swinburne, where he embarked on a PhD scholarship with ARC SEAM in partnership with Sutton Tools, an Australian leader in tool manufacturing with an over-100 year legacy of innovation. Minh's project aims to improve the edge preparation and surface finish of complex cutting tools with the integration of specialised hard wear-resistant thin-film coatings, by pushing the limits of mechanical polishing and developing agile electropolishing methods for tough tool materials like tungsten carbide and high-speed steel—resources once used in the trenches of world wars, now serving industries worldwide. Despite the century-long challenges in electrolytic polishing these stubborn materials, as well as commencing his PhD at the start of the longest Covid-19 lockdowns, he not only achieved an ultra-smooth mirror-like sub-100nm surface roughness but also honed cutting edges to micro-precision, positioning his work for potential patent applications—a significant step forward for the tool industry, furthering Sutton's commitment to delivering the world-finest tool life and performance.

Minh's academic achievements are noteworthy, with nearly 20 publications and as many conference presentations, earning him top poster awards, a compliment message from the ARC Director for his industrial accomplishment and a Swinburne School of Engineering Postgraduate of the Year (Commendation) for his PhD excellence.

Minh is a PhD Candidate with the Australian Research Council (ARC) Industrial Transformation Training Centre in Surface Engineering for Advanced Materials (SEAM) at Swinburne University of Technology.

Born within the walls of a small, century-old house that predated the wars that once ravaged his hometown, Minh had used a footstool, crafted from leftover door scraps, as a studying desk for 15 years of schoolwork. Outside the confines of those four walls, the young dreamer’s passion for science took flight, with water rockets refashioned from garbage Coca-Cola bottles launching toward the heights he was destined to reach in academia.

Minh's academic voyage began with a Bachelor in Nanotechnology from Vietnam-France University, where he graduated second in his class. He engaged himself in laboratory internships, studying a spectrum of materials from transition-metal dichalcogenide (TMDC) photocatalysts, gold quantum dots to nano-carbon structures. His dedication was

At Sutton Tools, Minh's insights have informed multimillion-dollar investments in new machinery, and his dual understanding of academic research and industrial processes have made him an invaluable bridge between the two worlds. This unique perspective has led to a direct offer from ANCA, a global leader in CNC and machine technology, even before his thesis submission. Now, Minh joins ANCA as a full-time EPX Application Engineer to cultivate the state-of-the-art stream finishing concepts, bringing not only a wealth of experience but also the consistent support of the SEAM family, who have been of huge support on his path.

For more information about SEAM, please visit www.arcseam.com.au/ or email seam@swinburne.edu.au

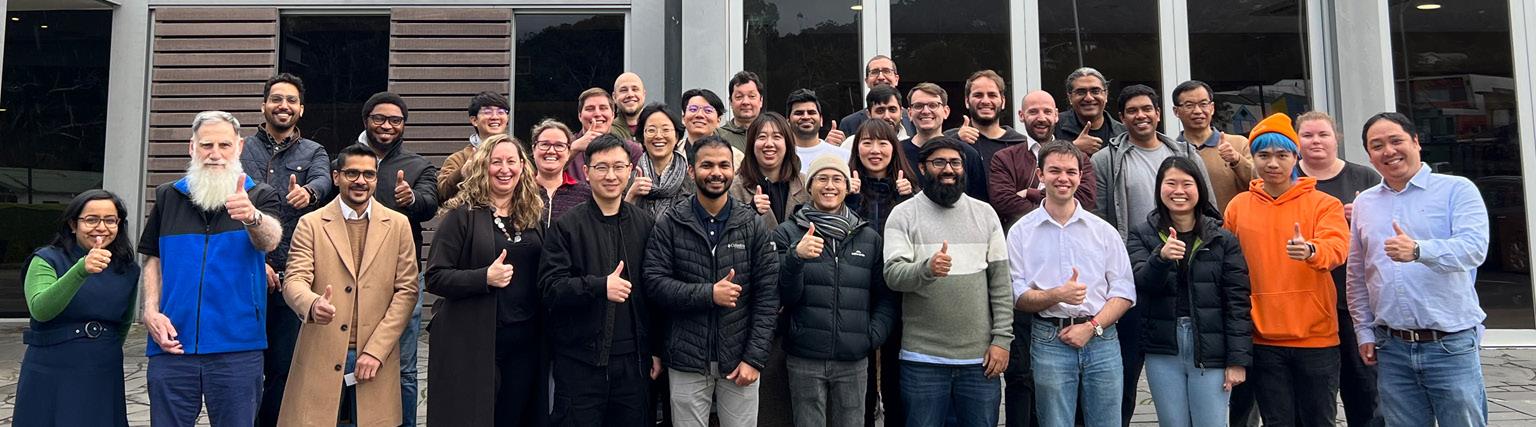

Founded in 2019 as a partnership between three universities, SEAM’s mission is to help solve critical surface engineering problems faced by industry, while training up talented industry- ready graduates for our future .

Titomic partnered with SEAM to elevate the TKF cold-spray process to the next level integrating advanced sensors to provide critical process insights in real- time, paired with a data analysis pipeline powered by machine learning , and all validated by testing and analytical capabilities at SEAM This collaboration has expedited development and fortified quality, unlocking high-value applications and access to global markets

MacTaggart Scott Australia delivers mission critical products and services to the Royal Australian Navy’s ships and submarines. The ongoing partnership with SEAM on the development of lightweight composite materials for marine applications, has yielded multiple significant improvements to existing and future product designs, through advances in the application of thermal spray technologies

This partnership between SEAM and Sutton Tools achieved significant enhancements in the surface quality of intricate cutting tools, thereby improving their performance. Leveraging innovative state-of- the- art electropolishing techniques, coupled alongside precise mechanical polishing and specialized wear-resistant surface coatings, Sutton continues to deliver leadingedge products that meet global standards of competitiveness