2 minute read

PACKAGING SOLUTIONS

DEEP EXPERIENCE + ADVANCED TECHNOLOGY + APPLICATION EMPATHY = THE PERFECT COFFEE INDUSTRY PACKAGING SOLUTION

You don’t get to be the world’s leading coffee industry secondary packaging machine company without significant experience and a class-leading range of solutions. Cama adds these to its customer-centric approach to deliver just what a fast-moving market needs.

Advertisement

The global coffee industry is incredibly competitive, while also facing stiff competition from other beverage sectors. Therefore, to stay competitive, suppliers, roasters and grinders must seek out maximum efficiency across all stages of the value chain.

Companies must innovate, not only to improve existing lines, but also to introduce new lines, flavours and delivery, serving & packaging concepts.

There are so many possibilities in terms of arrays, mixes, formats and materials that OEMs have to deliver astounding levels of flexibility and the agility for users to modify parameters as quickly and simply as possible.

As a global market leader in the secondary packaging of coffee products, Cama is at the forefront of new technology and innovations and, as a result, is helping to define the direction the industry is taking in terms of packaging concepts and technology.

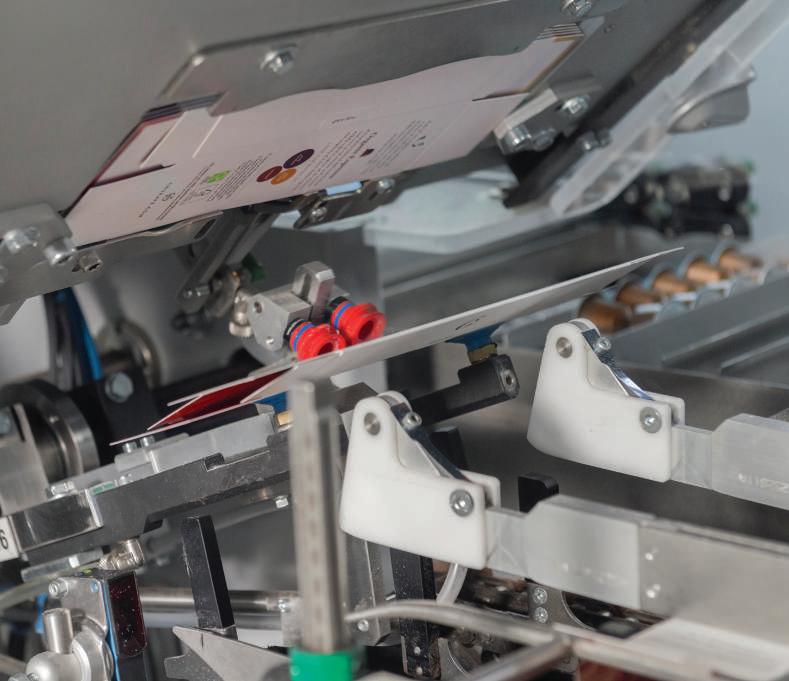

Cama has developed a core range of machine styles and packaging technologies that address the vast majority of secondary packaging needs. The coffee industry is one example where one size certainly does not fit all. Different products and different performance requirements can be better addressed by different technologies, including top loading and side loading.

Machine efficiency underpins another core metric of any successful machine

implementation; and it is not just in operational terms. The onus is on Cama to make changeovers as quick and painless as possible, and with the advent of Industry 4.0 technology and integrated communication solutions, we have taken this to a whole new level. Augmented Reality, Virtual Reality, QR coding and RF tagging are helping us to help our customers and to make not only changeover, but also maintenance and operation as simple and as straightforward as possible.

Today Cama has cut changeover in half – from 30 minutes to just 15. In coffee production, where production speed and output are so high, saving even 15 minutes per changeover is vital.

Our packaging design team and our dedicated training academy are available to help customers with design and training and our virtual consultancy delivers remote service support, using smart glasses and AR technology which can deliver scaled replicas of the customer’s machine onto a boardroom table.

Why do people come to Cama?

“Other companies wanted to talk technology, engineering and price, but our principal need was for someone to understand the flexibility we needed in production. Cama listened properly and came back with a solution… not just a quote”. Andy Fawkes, Managing Director Masteroast UK.

“Coming from another supplier, it was plain to see the differences in the way the two companies work. Cama understands what we need and more importantly why we need it!” Marco Padelli, CEO Gimoka Group IT.

For more information, visit www.camagroup.com