35 minute read

COMBUSTION SAFETY

UNDERSTANDING UNDERSTANDING

carbon monoxide dangers carbon monoxide dangers

“Something’s wrong with the new boiler,” bo oil ler, ” the anxious caller said, one December be er evening. Sensing his concern, I asked, “What happened?” “My CO alarm keeps ringing. It must be the boiler,” the man continued. The “new” boiler was actually installed five years earlier.

“Open your windows, turn off the boiler, and leave the house. I’m on the way.” Once there, I switched on my carbon monoxide meter outside the house to calibrate it before entering. The CO detector should be calibrated in a space without carbon monoxide exposure to avoid false readings when inside. When the digital display reached zero, I walked inside. In the home, the CO levels were safe, but not ideal, coming in between three and five parts per million. In the basement, I switched the boiler on and opened the hot water valve on the nearby sink to get a call for the water heater. Using the CO meter, I could see there was no carbon monoxide produced by either the water heater or the boiler. Walking upstairs, the nervous owner asked about the boiler. After assuring him both the water heater and boiler were working correctly, I asked what he was doing when the alarm sounded. “Baking Christmas cookies,” he said smiling.

How is it formed?

Carbon monoxide is formed during the combustion process, and is like the grumpy old neighbour who yells at the children about going in the yard. CO hates change. Any time you change the firing rate or fuel-to-air ratio of the flame, CO is produced. Even combustion air temperature can affect the production of CO, due to the density variations of air at different temperatures. A quarterturn of the gas pressure regulator can spike the carbon monoxide levels from zero PPM to several thousand PPM.

It only took a few minutes after switching the oven on before the numbers on my detector started rising rapidly. Turning the oven off, I explained the source of the alarm was the oven. A minute later, the CO alarm sounded, confirming my diagnosis. The customer thanked me and asked, “Are you going to charge me?” (I didn’t.) Each year, we hear stories of accidental carbon monoxide poisonings. I can recall a recent incident with a motel in Winnipeg where 46 people were sent to the hospital with CO poisoning, 15 in critical condition. The cause of the exposure was attributed to improper venting of the boiler. According to a 2017 study provided by the University of the Fraser Valley, between 2000 and 2013, there were 1,125 deaths in Canada with CO listed as the cause, so while the cause was not the heating system for my customer, the concern was valid. Carbon monoxide is not a gas to be taken lightly.

How to protect yourself

During one of my boiler seminars, an attendee boasted that he purchased a plug-in type of carbon monoxide alarm, similar to the one you may have in your home. He takes it with him on every service call and plugs it into the wall. While it seemed like a good idea, the plug-in types are not designed to be taken from job to job.

Kidde, a manufacturer of CO detectors, includes the following warning on its plug-in devices: “This CO alarm is designed to act as a monitor; it is not designed for use as a short-term testing device to perform a quick check for the presence of CO.” Obviously, this tech was not the only one to have this idea.

The drawback of using these alarms on a service call is the reaction time. Exposure to CO greater than 12,800 PPM can cause death within one to three minutes. The reaction time for these types of alarms to sense dangerous, life-threatening CO levels can be 15 minutes, and most need at least four minutes. As you can see, the math is against you.

I believe every service technician should have a carbon monoxide detector/meter with rapid reading capability and use it on every service call. Assume every customer has a dangerous level of carbon monoxide unless proven otherwise. Not only will it protect m the technician, but it will also protect the customer.

What is a part per million?

Carbon monoxide is measured in parts per million or PPM. To see just how small a PPM is, consider this: one PPM is equivalent to one goal in 16,666 hockey games or one day in 2,739 years. You may wonder how they measure something so small. In earlier times, miners used to take a canary in the coal mines with them. If the canary stopped singing because of elevated CO, the coal miners hastily exited the mine. Now, we have more humane ways of testing for carbon monoxide. These devices range from personal ones that attach to your belt, handheld versions, and permanently installed CO detectors.

Understanding your CO readings

When servicing a boiler, the limit is 400 PPM “air-free” CO in the flue gases. I work hard to get the reading well below that, and as close to zero as possible. Air-free CO is the carbon monoxide reading after you remove the excess air from the calculation. Think of it as a cup of coffee. You and a friend purchase a small coffee, and it tastes bitter. You add creamer to it to make it less bitter. Your coffee still has the same amount of bitterness as your friend’s, but you have added creamer to dilute it. That is what excess air does with CO. Stay safe out there!

Ray Wohlfarth is the author of Lessons Learned in a Boiler Room: A commonsense approach to servicing and installing commercial boilers, and president of Fire & Ice Heating and Cooling. He can be reached at ray@fireiceheat.com.

Why is CO dangerous?

Carbon monoxide displaces the oxygen in the body’s hemoglobin, essentially suffocating the organs. CO forms carboxyhemoglobin in the blood, and the weird part is your body prefers CO over two hundred times more than oxygen.

The troubling issue with CO is the five-hour half-life. Half-life is the amount of time it takes for your body’s blood to surrender the CO naturally and drop it to half the exposure level. If you were exposed to three hundred PPM of carbon monoxide, it would take five hours after being removed from the contaminated air for the CO level inside the blood to drop to half of that, or 150 PPM. After an additional five hours, the level would drop to 75 PPM.

In severe cases, the exposed person is placed inside a hyperbaric chamber, which can accelerate the process.

CO effects The human body has the following reactions to different levels of CO exposure

• 35 PPM - Headache and dizziness in 6 to 8 hours • 400 PPM - Frontal headaches in 1 to 2 hours, becoming life-threatening after 3 hours • 800 PPM - Nausea and convulsions present; death within 2 hours • 1,600 PPM - Nausea within 20 minutes; death within an hour • 12,800 PPM - Death in 1 to 3 minutes

PLUMBING Products

Thermostatic mixing valve g valve Bradley’s Navigator thermostatic mixing mixing valve (TMV) is designed for both commerommercial faucets and emergency safety eyewash eyewash fixtures in laboratory applications. Combining two valves in one reduces ces installation time and conserves underdersink space. During regular use the TMV delivers tempered water for uses such as handwashing. For emergencies, it delivers ANSI/ISEA-required A-required tepid water. www. bradleycorp.com

Cordless sectional machine

Milwaukee Tool’s M18 Fuel sectional l machine for 5/8 in. and 7/8 in. cable le is designed to clear heavy roots up to o 150 ft. out. Lightweight and compact, this ct, this cordless system can transition between outdoor use and indoor applications, and includes a carry strap for transporting onto rooftop jobs. Features include a brushless motor, intelligent communication to the lithium battery pack, and wireless tracking. www. milwaukeetool.ca

Follow Us on:

Mechanical cleanout plugs

Cherne’s mechanical cleanout plugs feature a two-stage locking mechanism that locks firmly in test and drain positions while still allowing for highpressure testing. No tools are required for installation or removal. The plugs are compatible with PVC, ABS and castiron cleanout tees. www. oatey.com

Heater stand and platform

HoldRite’s line of water heater quick stand and platform accessories is designed for both residential and commercial markets and meets all UPC code requirements. The stands and platforms can be used to secure and elevate water heaters above the floor and support up to 100 gallons. Accessories include sheds and straps. www. holdrite.com oldrite.com

Water heater Water heater installation accessories SharkBite offers flexible water heater connectors designed for joining pipes in tight spaces that do not line up. Its thermal expansion relief valves eliminate the need for an expansion tank, shut-off valve and fitting where high-pressure conditions are likely to occur. The valves are compatible with PEX, copper, CPVC, PE-RT and HDPE pipe. www. sharkbite.com

Bathroom collection

Belshire from DXV is an art deco-inspired suite of fittings, fixtures and furniture. It offers the choice of level, cross or cushion handles on low- or high-spout faucets. Available in satin brass, platinum nickel, brushed nickel or chrome finishes, the line includes faucets, shower and bath sets, as well as wall-hung toilets and a freestanding soaker tub. www. dxv.com

PLUMBING Products

Commercial gas water heaters

The eF 120 series of commercial gas water heaters from Bradford White Canada incorporate building management and modulation technologies for remote monitoring capability. Capacity is 119 gallons, with thermal efficiency ratings of 96.5% for the 400 3N, and 95% for the 500 3N models. www. bradfordwhite.com The M-Core valve system from Moen is designed to simplify installation of shower systems plumbed. Features include an integrated mounting bracket that secures the valve directly to a brace, a quicker temperature limit stop adjustment are available in several inlet and nd outlet options. www. moen.ca Fire sprinkler connections Anvil International’s SprinkFlex hose combined with the SprinkFlex Infinite Position Tall (IPT) bracket is designed to accommodate pendant, semi-recessed and concealed fire sprinkler heads. The fully braided hose is UL listed and has a 2 in. bend radius, 1 in. inner diameter and three-piece construction. The bracket ships with pre-installed mounting screws. Hoses are available in 28 in. to 71 in.

Electronic mixing valve

The Legiomix Station from Caleffi includes a 6000 Series electronic mixing valve for domestic hot water systems. It features a daily self-cleaning function, automatic scheduling of thermal disinfection, and is certified by ICC-ES for compliance with NSF/ANSI 372, ASSE 1017, CSA B125.3 and CSA Z317.1 standards, and IPC, IRC, NPC and UPC codes. www.

Valve system

by enabling adaptable functionnality once the system has been n process, and an integrated test t plug. Mixing and transfer valves es caleffi.com

Handheld drain cleaner

The Uni-Stand from General Pipe Cleaners supports hand-held drain cleaners when working in tight spaces. The adjustable clamp slides around the motor housing. It is designed to fit the Super-Vee, PowerVee and Handylectric hand-held drain cleaners. www.

drainbrain.com www. anvilintl.com

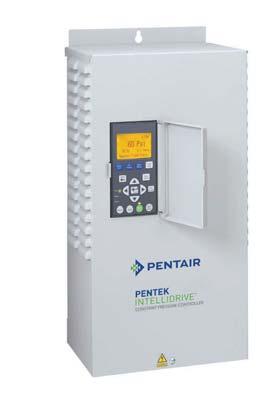

Intelligent variable frequency drive

sure control centre from Pentair is an intelligent VFD that responds to fluctuations in household demand by directing changes in submersible pump motor speed. It maintains constant water pressure, regardless of how many people or appliances are using water at the same time. Functions can be controlled through the Pentair Home app. www. pentair.com

Tower of Montréal, Downtown Montréal

(Photo courtesy of tomcondos.com)

SYSTEM XFR® DWV IS RIGHT AT HOME in a 40-storey condo building.

Certifi ed for use in noncombustible construction, high buildings and air return plenums.

System XFR® DWV from IPEX is an engineered PVC DWV system available in diameters from 1.5” to 18”.

It delivers greater corrosion resistance, fl ow rates and carrying capacity, and lower thermal conductivity than metal. It also has higher impact resistance, lasts longer, costs less to maintain AND weighs less than cast iron. System XFR® DWV… fast becoming the preferred choice across Canada.

Ask for System XFR® DWV by name.

Be sure to check out our entire line of DWV System pipe and fi tting products. For more information please contact 1-800-463-9572 or visit ipexna.com

Open your IOS or Android device and scan here for more information.

PLUMBING Products

Pressure balance rough-in valve

The GrohSafe 3.0 from Grohe is a pressure balance rough-in valve offering with coordinating trims. Design elements include a small valve body that fits into tight spaces, a flat back for sturdy installation, and a pre-installed flush plug that allows hot and cold water to be flushed simultaneously. The dezincification brass valves offer four connection options. www. grohe.ca

Filtered kitchen faucet

American Standard’s Saybrook filtered kitchen faucet delivers filtered water at the push of a button on the spray head. The design features two water channels to separate regular tap and drinking water, LED indicator for filter changes, and a pull-down, dual-function spray head. The faucet is available in polished chrome or stainless steel finishes. www. americanstandard.ca Dialectic union Nibco’s FIP x press dielectric union features a nylon insulator ring that interrupts the electric current caused by joining two pipes of dissimilar metals, helping to prevent galvanic corrosion. Features include dezincification resistant brass press ends. The product is certified lead-free, available in sizes ½ in.

Hands-free faucets

Delta commercial faucets with Proximity Sensing Technology are designed for facilities that require hands-free operation, vandal resistance, reliable operation and ease of maintenance. They allow users to turn on the water by simply placing a hand near the faucet spout. The entire faucet body acts as a sensor, responding when activated www. deltacommercialfaucets.ca

Portable hand washing stations s

Portable hand washing stations from Zurn can be deployed in a variety of daycares, doctors’ offices, break rooms and cafeterias to expand handwashing capabilities to meet healthcare guidelines. The units can also be used in outdoor settings where water is limited, such as sporting venues. www. zurn.ca

Follow Us on:

settings, including schools, to 1 in., and is compatible with several press tools. www. nibco.com

Electric hot water tank

Stainless steel electric tanks from Eco-King feature an integrated mixing valve and Nanopur insulation. They are available in single (S 200-300) or dual element (Saga SX 200300) options in 3 or 4.8 kW and 50- or 80-USG capacities. The systems are also 100% recyclable. www. kingheatingproducts.com

By George Micevski security blanket A for your customers’ security blanket

Battery-powered back-up systems ensure the sump pump runs, even when the power is out.

It is always a good idea to have a pump system in a basement to help protect your customer’s home and their belongings against the dangers of flooding. The only problem with a traditional pump system, however, is whether it will perform when it is most needed. The most likely time a basement will flood, of course, is during a severe rain storm. Incidentally, this is also the time of greatest risk of the power going out. No power in the home means no power to the pump, and if it fails, the risk of flooding increases significantly. A good solution is a battery-powered back up system that will keep the pump system running, no matter what is happening outside. A backup system may only be needed once out of every 100 storms, but your customer will always be thankful for the peace of mind it brings. It only takes a small amount of water to cause thousands of dollars in damage, not to mention the loss of potentially irreplaceable personal items. Homeowners and contractors alike need systems that not only have outstanding performance, but are also built to last. The nature of a backup system puts it in a demanding role of needing to work with vigour, even after years of neglect or lack of use.

Consider your customer’s needs (and your own)

There are a few key considerations contractors should take into account when presenting options to their clients:

• Compatibility: Customers may not be amenable to a system a system that requires them to purchase and install an entirely new sump ne smp pump. A battery back-up that can be installed alongside an existing system and keep it running when it needs to run is ideal. • Connectivity: We live in a connected world. Pumps are available with Wi-Fi- enabled control systems to monitor and notify homeowners and contractors with alerts.

• Built-in Redundancy: Floats that can get hung up on the walls of the basin and debris are a concern. A secondary float switch can provide redundancy, and a high-water alarm that can turn on the pump can also be beneficial. • Maintenance: Homeowners don’t want the burden of regular maintenance, and are likely to forget they have a pump system that needs regular monitoring and checking. A self-testing system can help, and it gives you more information about the system so you can better serve your customers.

Adding onto your sale

The best time to recommend the installation of a dependable battery backup system is when you are installing a new sump pump system. Making the homeowner aware of the technology and its benefits helps enhance your credibility, and shows that you are a contractor who cares about the longterm protection of their property.

Of course, this credibility will be negated if the system being sold is inferior, or does not do what it claims to. Be sure to research the product you are recommending. Ask your client if they are interested in some of the more recent advances in technical features, such as pumps with Wi-Fi sensor alarms.

Mechanical contracting shop takes early lead in NSF-61certification

Achieving CSA NSF/ANSI Standard 61 (NSF61) certification for drinking water system components is nothing out of the ordinary for a lot of organizations in the manufacturing sector. But it’s rare to see a mechanical contractor get the certification. That’s just what the stainless steel pipework fabrication team at Pitt Meadows Plumbing & Mechanical Systems Ltd. (PMP) managed to do.

As most in the trade know, NSF-61 is a set of national standards related to drinking water. It establishes stringent requirements for the control of parts, pieces and equipment that come into contact with potable water or products that support the production of potable water.

For months, the pre-fabrication team at PMP worked with the CSA Group to achieve the certification for domestic drinking water pipework spools. These are fabricated in their Maple Ridge, BC shop before shipping to job sites for installation across Metro Vancouver and beyond. The company achieved the certification in July 2020.

“We have worked closely with the CSA Group to ensure that our fabrication methods and welding standards meet the stringent requirements of the NSF/ANSI-61 certification,” said Sam Revel, senior pre-fabrication manager. “Over the last few years, we have developed some of the most advanced stainless-steel pipework production methods available to the market, leveraging 3D modelling, automated machinery, and orbital welding robots.”

Most Canadian businesses with this certification are suppliers of potable water tanks, piping and materials related to the delivery of drinking water, he explained. “It’s certainly unusual for a mechanical contractor to earn the certification. Typically, NSF-61 is required for suppliers and manufacturers producing pipe and fittings. I believe we’re the first in BC that is serving the high-rise residential and institutional sectors, whilst also completing the full scope of mechanical contract work.”

PRE-FAB MODEL WORKS WELL DURING PANDEMIC

The company’s pre-fabrication approach has delivered even more advantages since COVID restrictions came into play. Up to 75 per cent of each project’s installation is pre-built at the 55,000 sq. ft. Maple Ridge manufacturing facility, which has always been a highly controlled environment. “Since COVID hit our model benefits our clients and their customers more than ever, because it reduces the number of workers required on site,” Revel said. “And the layout of our facility makes it easy to distance workers and set up dividers, as well as control access and egress.”

Revel said its decision to apply for certification provided them with an opportunity to maximize the welding of stainless pipework and remove potential leak paths from every system installed to ensure consistent plumbing installations. The decision was also driven by the City of Vancouver’s recent move to require the NSF/ANSI61 certificate to weld stainless steel pipework for plumbing systems, Revel explained.

“While the B.C. Plumbing Code allowed welding of stainless steel pipes, it was not regulated in any way, which poses a risk if correct fabrication

processes are not followed. The City identified that issue and decided to rectify it by having manufacturers of domestic drinking water spools certified to NSF standards,” said Revel.

It was a relatively easy transition for his team, he added. “The shop was already meeting the standards as our fabrication processes were already very stringent. We were very happy to achieve certification without having to change anything.”

After the mandate came down, the team began working with the certification group at CSA, beginning with a full presentation in January of 2020 on the fabrication process and the different elements in the processes and materials used. The audit also included a factory visit and inspection.

Sample spool pieces of pipe were sent to CSA for testing and certification. The head plumbing inspector for the city also visited the site to inspect the shop operations and processes.

“The local mechanical contractors that have become NSF-61 pre-fabricated welding shops really need to be acknowledged as leaders in this Industry,” said Phil White, manager of trades inspections with the City of Vancouver. “The public in the City of Vancouver can have confidence that by meeting the NSF/ ANSI/CAN 61: Drinking Water System Components–Health Effects certification, these certified welded stainless steel systems address human health protection and infrastructure longevity concerns.”

While the certification has not yet been required on projects, Revel believes it will increasingly become a key selling point for developers.

The focus in recent months has been on projects in and around the City of Vancouver area. But the certification can be applied further afield. “We expect to see this requirement come out in the next B.C. Plumbing Code update,” Revel said. “It will be fantastic to say we already have the certification.”

Automation kudos

The certification is just one feather in the cap of PMP’s achievements in recent years. The company recently won a Digital Supply Chain & Fabrication award from CanBIM for its implementation of Stratus automation software for off-site fabrication, highlighting its position as one of the leaders in off-site fabrication and 3D modelling in North America.

® WATCO QUICKTRIM

Upgrade a plain drain in minutes. Rough-in with ■ Upgrade to one of 12 chrome… special finishes in minutes (including Matte Black and Champagne Bronze) ■ Installs OVER drain with O-ring ■ No need to remove tub drain and risk crossthreading ■ Includes stopper and high-flow Innovator® overflow faceplate …trim with special finish

Always a step ahead 816.796.3900 watcomfg.com

Condensate neutralizers The NC-1W from Axiom is a wall hung condensate neutralizer that features a provisionally patented integrated bypass with float and magnetic latch for visual identification of required service due to an overflow condition. Other features include a reversible wall mount lid allowing for left or right outlet connections, along with a translucent vertical flow, two-chamber capsule. www. axiomind.com

Air-to-water heat pumps

SpacePak’s solstice inverter pump utilizes inverter compressors ssors and DC driven fan motors for r optimal load matching, The SIM is IM is available in 3 and 5 ton models for els for heating and cooling in residential ntial and light commercial applications. ions. Suited for zoning, it can be used in sed in conjunction with SpacePak’s hydronic hd i air handlers and fan coils, and other emitter options. ter options. www. w. spacepak.com cepak.com Burners ProFire SBR-5 series burners from CleaverBrooks are compatible with firetube and watertube boilers. Designed for use with applications where strict emission levels must be met, the series offers a natural gas fuel option from 10.5 to 42 MMBTU/H, and is capable of firing ultra-low sulfur diesel as a backup fuel. www. cleaverbrooks.com

monoblock air-to-water heat

Gas vents Cheminee Lining gas vents are s vents are an installation-ready venting venting solution for condensing ng boilers. They are offered in ered in stainless steel in diameters meters ranging from 6 in. to 48 in. o 48 in. The company also offers a ffers a full range of accessories, ries, including elbows, fittings, guides and supports. The vents are laser welded and UL/ULc listed. www. chemineelining.com om

3-Way ball valves Pro-Pal 3-way ball valves from Webstone are designed to divert, select, or mix fluids based on application needs. Flow options include a 90° handle operation to divert or select; or a 180° handle operation to divert, select, or mix. Forged from lead-free DZR brass, they are available in 1/2 in. to 2 in. sizes. webstonevalves.com Condensing boilers

www. Weil-McLain Canada’s ECO Tec highhighefficiency condensing boiler for residential sidential applications, delivers up to 95% efficiency in 4 heating (80, 110, 150 and 199 MBH) and 3 combi (110, 150 and 199 MBH) sizes. It can provide space heating and up to 5.4 GPM of domestic hot water at a 70°F rise and up to 10:1 turn-down, and can power and control up to five circulators. www. weil-mclain.ca

By-pass feeders Hood Chemical’s VTF series of by-pass feeders available from Neptune feature wide-mouth easy close caps and hold string wound filters. Working pressure is up to 300 psi max at 200°F for a two-gallon, 11 gauge steel unit. Max pressure is 300 psi when paired with an LMO filter housing. www. hoodchemical.com

Heat pump water heaters Lochinvar air source heat pumps for commercial and industrial applications heat domestic water to temperatures as high as 160°F. Designed to meet decarbonisation requirements, air source heat pumps transfer atmospheric heat via a refrigeration cycle for domestic hot water use. Available in six sizes, they offer 50 to 500 gallons ns per hour recovery rates and 25,000 to 250,000 BTU/H outputs. www. lochinvar.com

High-efficiency boilers The Camus DynaForce series of boilers feature thermal efficiency ratings up to 99%. They are available in sizes ranging from 300,000 to 5,000,000 BTU/H with a 5:1 turndown ratio. The units are built with stainless steel vertical, cylindrical heat exchangers. The boilers can be used for hydronic heating or domestic hot water production. www. camus-hydronics.com Control system The Vitotronic 300 GW6C from Viessmann is a digital boiler and system control that features an outdoor reset function. The unit modulates input and rotates boilers to meet the heating system’s load. The standard control package can regulate supply water temperatures for one high temperature circuit, two mixing valve circuits and one domestic hot water circuit. www. viessmann.ca

Gas appliance venting

High efficiency venting from Selkirk is suited to special gas vent applications. The venting is available in 3 in. to 32 in. diameters (ID), stainless steel single wall and double wall models, and multiple grade options. www. selkirkcorp.ca

Variable speed circulators Taco’s 0034e and 0034ePlus high-efficiency, variable speed, wet-rotor circulators are designed for large residential and light commercial hydronic heating, chilled water cooling and domestic hot water systems. They feature ECM permanent magnet technology and a dial (0034e) or digital user interface (0034ePlus). Their variable speed performance curves are equivalent to other Taco models. www. tacocomfort.com

Ultrasonic thermal energy meter The Dynasonics UHC100 ultrasonic thermal energy meter from Badger Meter calculates energy quantity by measuring the amount of liquid flowing through the flow sensor at a given time, and the liquid temperature at the supply and return flow positions to obtain the temperature difference. It is approved by Measurement Canada for liquid heating and cooling applications. www. badgermeter.com

Water tube condensing boiler Torus water tube condensing boilers and water heaters from RBI are available in sizes ranging from 1,250,000 to 4,000,000 BTU/H. Boilers are up to o 97.5% and water heaters up to 98% efficient. Units feature a 5:1 turndown. Additional features include a 316L stainless steel heat exchanger, and a 4-pass design that works in concert with mutli-channel manifold and increased tube diameters. www. rbiwaterheaters.com Buffer tank Flexcon’s Argosy is a pressurized composite buffer tank designed for potable and nonpotable water. Features include threaded stainless steel water connections, a continuous strand fibreglass inner tank, high R-value closed cell foam insulation, and a non-corrosive plastic outer jacket. www. flexcon.com

Commercial and industrial boiler

Fulton’s Endura+ condensing boiler is designed for variable primary flow systems in commercial and industrial applications. Equipped with a duplex steel heat exchanger, it is available in sizes from 2.5 million to 6 million

BTU/H. Units have a turndown ratio of up to 15:1 and attain a thermal efficiency of up to 96.8%.

Ten boilers can be sequenced together in a single system.

Fire tube boiler

The Instinct stainless steel fire tube boiler from Triangle Tube is available in solo sizes ranging from 110,000 to 199,000 BTU/H, and combination sizes ranging from 155,000 to 199,000 BTU/H. They offer turndown ratios up to 8:1 and are built with a 3-in-1 universal vent adapter. The boilers have efficiencies up to 95% AFUE. www.

triangletube.com www. fulton.com

Inverter heat pumps GeoSmart NetZero variable capacity water-to-water inverter heat pumps offer COP ratings of over 5.0. The units can be used with a variety of renewable energy sources, including ground source, air source or in hybrid arrangements. Its products cover from 3 kW to 600 kW with the range of modulation starting as low as 25%. www. geosmartenergy.com

What is replacing THE REGULATORY SCENE R-410A At present, there are no specific federal regulations in Canada or the U.S. to restrict the supply or use of R-410A in the LCRAC sector. At the provincial level in Canada, the government of Quebec released a proposal in July of 2019 to eliminate the use of HFCs in certain types of refrigeration and air conditioning equipment by 2021. in the residential and In the U.S., the only jurisdiction proposing regulations that would affect R-410A in regulations that would affect R-410A in light commercial sector? the LCRAC sector is California. The state is proposing as of January 1, 2023, refrigerants in newly installed air conditioning systems must the LCRAC sector is California. The state is proposing as of January 1, 2023, refrigerants in newly installed air conditioning systems must The refrigeration and air conditioning (RAC) industry has moved ning (RAC) industry has moved run on a refrigerant with a GWP of less than 750 (R-410A has a GWP of 2088). run on a refrigerant with a GWP of less than 750 (R-410A has a GWP of 2088). through significant refrigerant changes since the early 1990s nges since the early 1990s because of environmental concerns over ozone depletion and global warming. To date, CFC ns over ozone date, CFC In May 2020, the U.S. Environmental Protection Agency (EPA) published Proposed Rule 23 In May 2020, the U.S. Environmental Protection Agency (EPA) published Proposed Rule 23 refrigerants have been phased out, virgin , virgin under its Significant New under its Significant New HCFCs are no longer available in Alternatives Policy (SNAP) Alternatives Policy (SNAP) Canada, and certain HFCs are being ng program, which lists low program, which lists low phased down because of their high h GWP alternative GWP alternative global warming potentials (GWP). . Be aware though, the changes to refrigerants used in the RAC industry are ustry ar re e nowhere near over.

In 2015, the Kigali Amendment to o the Montreal Protocol included a phase down schedule to reduce the he availability of high GWP HFCs over the ver the e next 15 years. This was adopted to spur o spur the international development of refrigerant refrigerant alternatives that have lower GWP. The P. The development of the next generation of on of alternative refrigerants has been underway nderway for a number of years; both refrigerant erant and equipment manufacturers have been ve been or will be commercializing these new refrigerants to the RAC marketplace in the near future.

In addition to the HFC phase down, Environment & Climate Change Canada (ECCC) put in place regulations in 2016 that established maximum GWP limits for refrigerant used in a wide range of refrigeration and air conditioning applications, including chillers, stand alone and centralized refrigeration systems, and condensing units. These new regulations have started to come into force for certain equipment types in 2020. Specifically left off the list of equipment under the new regulations was light commercial and residential air conditioning equipment (LCRAC). Both the Canadian and U.S. governments agreed to delay specific regulations concerning the LCRAC sector to allow refrigerant and equipment manufacturers more time to develop alternatives for R-410A, which is the predominant refrigerant used in this sector.

refrigerants that re efrig gerants that would be acceptable wo oul ld d be acceptable for use in the LCRAC for use in the LCRAC sector. Each of the sector. Each of the alternatives listed in a the proposal is classified the by ASHRAE as A2L, which are refrigerants with low toxicity and mild flammability. Rule 23 also restricts use of these refrigerants to new A2L certified equipment, and A2Ls cannot be used to retrofit field installed units. Equipment using A2Ls must have a specific warning that states the unit uses a mildly flammable refrigerant. Note, this rule is only in the proposal stage at this point. In Canada, a regulatory issue affecting the new low GWP refrigerants is the requirement to have them listed in the building code of each province where they are proposed for use. The code committees and authorities will have to consider issues such as the mildly flammable rating of A2L refrigerants, and whether the alternatives can be used for retrofit applications as part of the approval process. The time needed to have these refrigerants approved and listed in the building codes is a key factor in determining when these alternatives will be introduced to the Canadian market.

As a contractor, how do you prepare for the coming changes in refrigerants? MB recently spoke with some industry manufacturers about their plans to deal with the coming refrigerant changes in the LCRAC sector, and how these changes would impact Canadian contractors. All agree that contractors need to be aware of the changes and how they will potentially affect their businesses. Most importantly, before these alternatives start to appear in the market, contractors need to take the time to learn about the new products GETTING READY from their suppliers. Decisions about low GWP replacements for Three of the leading candidates to replace R-410A and other HFCs in the LCRAC sector R-410A and other HFCs in the LCRAC sector are R-32, R-454B and R-466A. R-32 and R-454B are A2L rated. R-466A is A1 rated. Table 1 have not yet been made for some equipment reviews some of the technical aspects of each refrigerant: types. However, some of the new low GWP TABLE 1 SPECIFICATIONS OF LOW GWP REFRIGERANTS FOR LCRAC SECTOR refrigerants have started Refrigerant Type Composition GWP to be promoted to Canadian contractors (or will be starting in the R-32 A2L (single component) HFC-32 (100%) near future). How do you manage this? HFC-32 (68.9%) Here are a few suggestions: Make sure your employees are aware HFC-125 (11.5%) CF-31 (39.5%) that the next generation of refrigerants are on the horizon and explain why (have them read Keep in mind, these are three of the more prominent low GWP alternatives introduced to this article). date. There could be more alternatives released in the future for use in the LCRAC sector. Although there is some uncertainty about low GWP refrigerants right now, this will be changing relatively quickly in the next couple of years. Find a way to keep this transition on your company’s radar. Talk to your equipment suppliers, and find out where they are going with low GWP refrigerants and when. Ask how they will keep your company informed and trained on this subject in the future. Training technicians on the safe handling of new refrigerants is paramount. Industry manufacturers contacted agreed that training on these new refrigerants (particularly A2Ls) is necessary to ensure safe handling throughout the supply chain, and safe management by technicians in the field. Whether training is offered through refrigerant manufacturers, equipment manufacturers, wholesalers or industry associations such as HRAI and MCAC, proper guidelines to address new challenges, such as the mildly flammable rating of A2L, will need to be established and included in codes and standards, as well as training programs.

Make sure you make informed choices by fully understanding the pros and cons of the new refrigerants and equipment. We all need to be prepared for the coming changes. Get engaged in the process. Assign someone in your company to take the lead on this matter. Remember, all new refrigerants have to go through extensive testing and evaluation before being commercially sold. When considering the various refrigerant options that are available, examine all aspects of each option (such as ease of use and maintenance) so you’ll make an informed choice when the time comes. Simply be a good consumer and do your homework. Your investment of time at this stage will be recouped by having an efficient and effective company transition to the next generation of refrigerants.

WHAT SHOULD CONTRACTORS DO?

The next generation of refrigerants will not have a “single solution refrigerant” for the LCRAC sector and each alternative will have differing characteristics and safety ratings. There are several things contractors can do to mitigate this: 1. Tap into reliable resources that provide information on the new generation of refrigerants as they appear to ensure informed decisions are made in the future. 2. Decide what type of equipment to stock based on what fits best with your business model.

3. Research safety concerns for each refrigerant option and ensure your technicians are properly trained to handle them. 4. In the longer term, decide how broadly based your equipment service will continue to be, and how widely your technicians will be trained: will you cover all types of equipment in the field, or narrow your focus by specializing in certain refrigerants and equipment?

Readers can reach Jonathon Harp at editorial@mechanicalbusiness.com.