25 minute read

Session 6

Ports/Terminals: Transitioning to Clean Fuels – The key Steps

BRENT PERRY

CEO, Shift Clean Energy

BIOGRAPHY

Brent Perry is the CEO of Shift Clean Energy and a marine battery industry pioneer. Perry defined an industry when he oversaw development of the world’s first battery for marine propulsion. Energy storage systems are now a major – and increasingly important – player on the global marine energy scene. In the years since that first battery, he has become a world expert on lithium energy storage in marine applications. His 30-year history in commercial shipbuilding and deep knowledge of energy systems gives him a unique perspective on the hybrid and electric marine industry.

ABOUT

Shift Clean Energy unlocks the potential of clean energy through leading-edge energy storage systems.

The company’s pioneering innovation is making low and zeroemissions operations a reality for the maritime and heavy industry. Shift’s solutions provide its global customers a safe, reliable, affordable way to electrify and reduce GHG emissions.

PWRSwäp De-risks Decarbonization Actions for Marine Industry

SHIFT CLEAN ENERGY’S KEY FINDINGS // PROOF POINTS

5 70% of global marine emissions occur in coastal areas; 60-90% while ships are berthing in ports.

5 ~60,000 deaths are associated with ship exhaust worldwide[1].

5 Fully electrifying or hybridising vessels or on-land projects can save up to 80% in operating costs.

5 For a single electric ship, that’s equivalent to 1,560 tons of emissions saved each year.

5 Switching from diesel to electricity pays for moving to zero emission on day one.

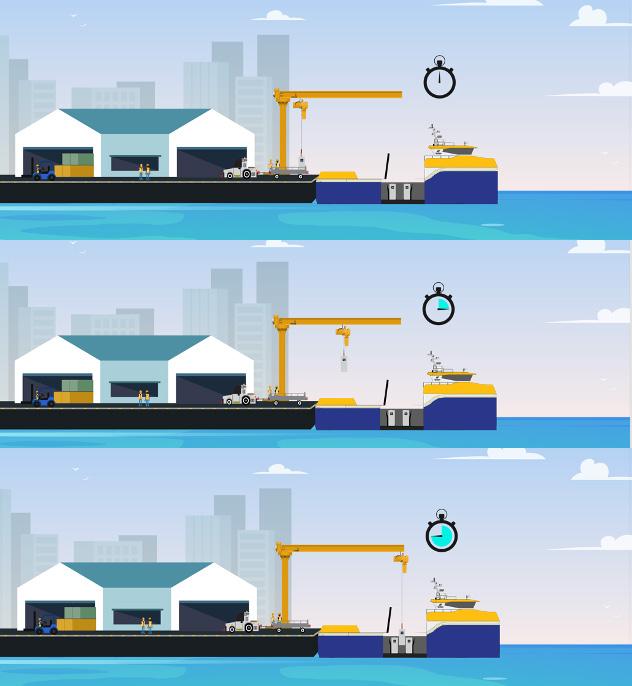

5 With PwrSwäp, battery e-Pods can be charged on-shore or off-shore, significantly reducing downtime and loss of productivity.

1. INTRODUCTION

Shift Clean Energy (Shift) has launched a climate action solution that empowers customers to move to a zero emissions model – with zero cost outlay.

Shift’s PwrSwäp service is a practical pay-as-you-go service?based on swappable battery e-Pods providing customers clean energy, with more reliability?and?less risk. The solution integrates energy storage system (ESS) and renewable energy for commercial maritime applications to electrify ports, terminals, inland waterways, industrial sites and even entire communities, through full electrification or hybridisation.

As an accompaniment to Brent Perry’s presentation, the below outlines the market-changing PwrSwäp solution, its decarbonising capabilities on a multi-system level, and the central benefits it provides to owners and operators, the industry, and the public.

2. BACKGROUND

Pressure is building for the maritime and marine energy industries to reduce their carbon footprint. With new EU targets and ongoing efforts by the IMO to see change in the shipping sector, one of the largest emitters on the planet.

What’s more, governments and investors are increasingly concerned over environmental, social and governance (ESG) commitments being met, resulting in ports and terminals moving aptly to decarbonise.

However, owners, operators, and other sector leaders are facing three core (and crucial) challenges in their need to reduce emissions:

1. the market is overwhelmed with potential solutions, all of which boast differing benefits and considerations;

2. the investment to implement many of these is significant, and can require mass infrastructure changes or retrofits; and

3. the ROI rates can be low, or require long-term operational success in order to see a substantial return.

Underpinning all of this is the concern shared by many that knowing which solution to implement, when and how seems nearly impossible, and securing the results needed is far from a certainty.

Yet failure can not only set back a company’s GHG emissions goals (as well as many other business objectives), but it could go as far as cripple an organisation.

Shift’s PWRSwäp aims to tackle each of these three core challenges, as well as additional needs and concerns when it comes to cleaner energy solutions.

3. PWRSWÄP – PAY-AS-YOU-GO ENERGY ECOSYSTEM

3.1 Overview

A full-spectrum, multi-system solution, PwrSwäp has a range of capabilities.

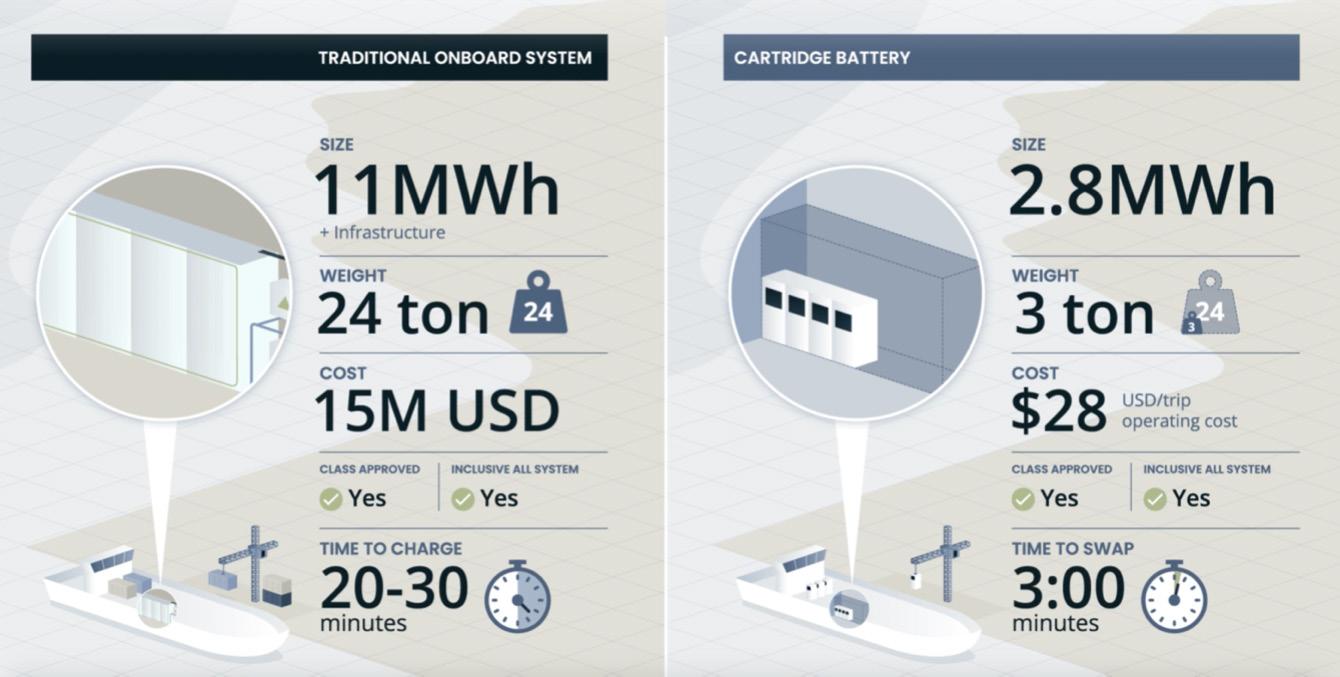

Unlike others available on the market, the ESS technology drastically reduces common blockers to adopting electric solutions and batteries, such as size, cost, weight and importantly, charging time.

Moreover, because of the adaptability of the model, Shift envisions a future where the technology is easily accessible not only to the maritime and marine sectors, but to other modes of transport, reducing emissions across the global supply chain.

3.2 Energy Sources & Charging

ESS and charging stations are at the core of PwrSwäp.

Where many ESS solutions fail in their capabilities due to charging time, or inaccessible charging links, Shift has supported this at its foundation. E-Pods can be charged either at an onshore station, or off-shore on the vessel itself. They can also be easily swapped within a matter of minutes – drastically reducing downtime. A huge benefit for vessels such as ferries which make frequent, shorter journeys.

When low or ‘out’, the depleted battery can be recharged slowly at the docking station, avoiding the degradation caused by rapid charging, meaning it can easily, safely and efficiently be re-used, and ultimately, supporting sustainable efforts to minimise material waste.

Moreover, Shift can set up shared technology such as charging stations that help lower costs even more. The company harnesses wind power by turning turbines into battery chargers, and the technology has the ability to integrate other renewable energy sources, with charging coming either from the grid or from a renewable energy sources built for the purpose, such as offshore wind, solar or others.

3.3 Cost

The model is hugely cost-effective – a central benefit when many other ‘green’ solutions require significant infrastructure, retrofits, investment or all of the above. As customers pay a baseline subscription service fee, and then simply the electricity on a payas-you-go basis, there’s no need to pay for more than the energy purchased – not the e-Pod battery or station – meaning no capex is needed.

See this side-by-side of a traditional onboard system, and a cartridge battery.

3.4 Safety

Shift’s market-leading safety credentials, testing and standards is what drives PwrSwäp.

The solution is based on the safest and most reliable technology available today, and has successfully passed the following ESS testing procedures:

5 A60 Testing. Through rigorous testing, it was determined that Shift’s batteries would not contribute its energy to the intensity of an existing fire of over 1,000 degrees Celsius for at least 1 hour, and would continue to function should a fire occur in one of the cells.

5 DNV GL Type Approval Certificate. Across nine separate, successful tests, Shift was an early adopter of the DNV GL revised certification, which substantially mitigates the risk of a fire spreading by eliminating the propagation of thermal runaway within a battery module.

5 Penetration Testing. This test abruptly inserts a nail in the batteries in order to determine the strength, longevity and sustainability of cells, demonstrating that the ESS technology could continue to run in the event of material damage.

The successful safety testing is largely due to Shift Clean Energy’s proprietary safety measures, installed in each and every piece of its technology. Including:

5 Integrated Cooling. CellCool© system enables all cells to consistently operate at optimal temperature. Reverses thermal runaway incident within a cell or block of cells and extends cell life for overall maximum value.

5 Cell Level Cooling. Each cell is encased in its own cooling channel. The result – Shift’s technology pulls heat out faster than the lithium chemistry can generate it.

5 Gas Extraction. Shift uses a uni-direction valve connected to the duct in the rack, without the possibility of a back blow, safely removing any potential for fire.

3.5 Software

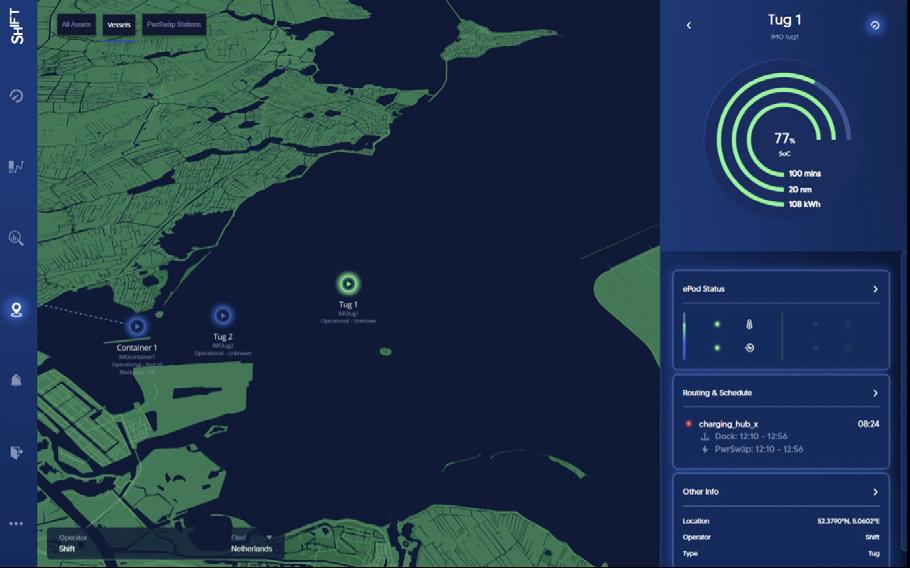

Shift has developed bespoke software that is designed for:

5 technology management; - monitoring and assessing the performance of any ESS solutions - managing the safe operations of the ESS

5 asset management; - measuring the real cost performance of operating vessels - uploading the environmental impact of the vessel in real time

5 operational management; - plan and forecast the arrival and departure of the vessel - offer GPS tracking and integrated vessel operations

4. PWRSWÄP IN USE: KOTUG INTERNATIONAL & CARGILL

To take just one example of the PwrSwäp solution in a real-life scenario, here is how Shift is partnering with KOTUG.

Leading maritime, family-owned company, KOTUG has partnered with Shift to develop new E-Pushers for the European market, getting trucks off the road by using electrified marine vessels along inland waterways.

KOTUG will deploy the KOTUG E-Pusher type M and four barges for zero-emission barging of cocoa beans from Cargill between the Port of Amsterdam, the largest cocoa import port in the world, and their cacao facilities in Zaandam.

The vessel is equipped with swappable battery energy containers from Shift Clean Energy (Shift), which is part of the revolutionary design of the vessel and will utilise Shift’s unique battery swapping and charging stations.

Cargill will be the first company with this fully electrified industrial setup for inland shipping. With the 100% electric E-Pusher, KOTUG supports companies that want to build more resilient and sustainable supply chains. The modular and scalable electric pusher tug is powered by swappable energy containers. With this zero-emission solution, KOTUG supports the worldwide energy transition and the modal shift from road transport to waterways.

Furthermore, due to the modular approach and lean assembly method, KOTUG reduced the construction time by more than half compared to traditional pusher boats. The E-Pusher type M can push barges with up to 4,000 tons of cargo.

The E-Pusher Series consists of three types: Small, Medium and Large, respectively for transportation in inner cities, over short distances and the larger inland waterways.

5. CONCLUSION

For too long the ability for businesses to address the climate emergency has relied on their ability to tackle emissions whilst simply surviving – let alone making a commercial profit. The maritime and marine industries’ abilities to efficiently tackle their emissions and corresponding carbon footprint will rely on viable electric solutions.

Northern Europe has around 6,000 inland waterway vessels alone. Around 300 kilos of Co2 is emitted by each vessel every hour alone, but by creating an holistic package designed not only to reduce emissions but increase efficiency and therefore profits, it’ll be much simpler to secure buy-in – and achieve meaningful results.

The PwrSwäp solution takes these central factors into consideration, providing a multi-system, cost-efficient, safe and scalable solution. Moreover, it’s a solution which not only serves its purpose now, but one which has the ability to evolve in the years and decades to come. Annually or in total?

Operational impact of electric cargo handling equipment

METTE KJEMS BAERENTZEN

Product Portfolio Manager, Kalmar

BIOGRAPHY

Mette Kjems Bærentzen is responsible for the development of Kalmar’s portfolio of Reachstackers and Empty Container Handlers.

Mette has worked at Kalmar for three years focusing on a broad scope of development initiatives of counterbalanced container handlers including digitalisation, electrification and automation. She has 20 years of experience in both technical and digital product development as well as business development. Mette has a Master of Engineering degree (M. Eng) from Technical University of Denmark (DTU) and a Bachelor of International Marketing from Copenhagen Business School.

ABSTRACT:

Sustainability and reducing CO2 emissions are some of the most burning issues our industry is currently facing. But how to get starting on a complex journey and operational transition and how will it impact operations to go electric? And what will a deep dive into current operations and equipment usage reveal about a possible transition to electrification? This presentation will give an overview of the different stages of the electrification journey and show an example of an operational analysis of a diesel reachstacker for the purpose of configuring an electric reachstacker with a battery and charger options that will not impact operational productivity compared to a diesel reachstacker.

MANFRED LEBMEIER

BIOGRAPHY

Manfred Lebmeier joined the Hamburg Port Authority (HPA) in 2013. He is an environmental engineer and works for the environmental and sustainability department as senior environmental advisor. Onshore power and the Green Deal with the Fit for 55 package is a main task of his work. He is an active member of several national and international committees and working groups like in ESPO or IAPH. Additionally, he worked for more than 2 years for the IAPH as ESI (Environmental Ship Index) administrator.

Innovation Competition ‘ZeroEmission@Berth’

The German seaports, represented by the respective port infrastructure companies, wanted to support the path of decarbonization of shipping with the innovation competition ‘ZeroEmission@ Berth’ to enable ship operation at the berth without emissions. Onshore Power Supply with 100 percent renewable power, on-grid land-based power supply facilities can be an effective measure to reduce emissions from seagoing and inland waterway vessels docked in port, but not for every port, not for every berth, and not for every ship. For this reason, nine German seaports wanted to get to know more innovative solutions, concepts and ideas in order to operate ships at berth with as few emissions as possible and initiated the international ZeroEmission@Berth innovation competition. The competition asked for innovative solutions in 3 categories, concept, prototypes and existing solutions. A seven-member panel of industry experts assessed the ideas and voted for the winners.

30 applications from 14 countries in the 3 categories were submitted and assessed. The winners of the competition were announced at the 29th September 2022 in Berlin.

ALEX RUIJS

Senior Consultant, Electrical Power & Energy, Royal Haskoning DHV

BIOGRAPHY

With 38 years of industry experience, Alex is one of Royal HaskoningDHV’s leading authorities in electrical power and energy projects.

As a Senior Consultant, he is responsible for overseeing the large-scale application of renewable power in ports and industrial sites across the globe – a position that requires a variety of skillsets, from conceptual design to testing and commissioning.

This work will ultimately lead to the replacement of oil, diesel, and natural gas as the primary energy carriers in these environments – helping society to achieve its goal of powering sites with renewable energy alone.

Working for a company with an engineering heritage that spans more than 140 years and with a dedicated Green Ports team, Alex takes a long view of the possibilities and limitations of the technologies available today. He’s always happy to discuss new and creative ways to overcome common obstacles, and the challenges involved in bringing the renewable energy vision to life.

An integral view on green energy for ports and marine applications

1. Introduction

Traditionally fuel oil, diesel and electricity from conventional sources (natural gas and coal) are the most relevant energy carriers for mobile port equipment, ships and many other port-based industries and services.

Transportation and logistics of these energy carriers is an important business for most ports.

Fig. 1: Coal fired power plant in the Port of Rotterdam

In the coming decade a rapid change in this pattern is expected. Increasing environmental awareness, legislation and cost saving are the main drivers for this development on the way to a full renewable energy operated port, with handling of renewable based energy carriers as an important new activity.

The energy transition process from conventional to renewable energy can be executed in many ways and there is not a one-fits-all best solution for general application in every port. Making a port green requires an integral view on energy use, energy storage and renewable power generation.

This abstract will show various options for port greening from the consulting engineers’ point of view and will include items such as: 5 Electrification: Land and seaside; 5 Integration of large-scale renewable generation: Within and outside the port; 5 Use of hydrogen and hydrogen-based to replace fossil fuels; 5 The economic aspects of the transition to renewable energy, especially related to the current situation in the energy market.

Fig. 2: Windfarm under construction in the Port of Rotterdam

Apart from making the port itself greener there is also the aspect of changing cargo flows through the port, related to the energy transition. The following items are relevant:

5 Role of hydrogen and hydrogen-based fuels in the energy transition; 5 Reduced cargo flows of conventional energy carriers such as coal and oil (-products); 5 New services and cargo types related to the energy transition.

2. Challenge of Energy Transition

The Energy Transition from conventional energy (in most cases fossil fuel based) to renewable energy is a process that is ongoing worldwide.

The most important drivers for the Energy Transition are: 5 Climate change; 5 Increasing social and environmental impact of the production and use of fossil fuels; 5 Availability of conventional energy sources related to the political situation; 5 Increasing costs of energy from fossil fuels.

Theoretically the Energy Transition is an easy process: The daily quantity of energy that the earth receives via solar radiation is more than a thousand times the worlds’ total energy consumption.

There are 3 main challenges that in practice slow down the transition process:

1. Investment costs: The initial investment in renewable energy generation systems is high but during the exploitation period the operational costs are significantly lower compared to conventional energy, mainly because there are no fuel costs; 2. Spatial impact: Renewable power systems require large surfaces and can cause inconvenience to people living close by; 3. Energy storage and transportation: Renewable energy is generated at the moment and at the spot where the energy source (wind, sun) is available and that does not always match with the demand. Therefore technologies for energy storage and/or long distance transportation are required.

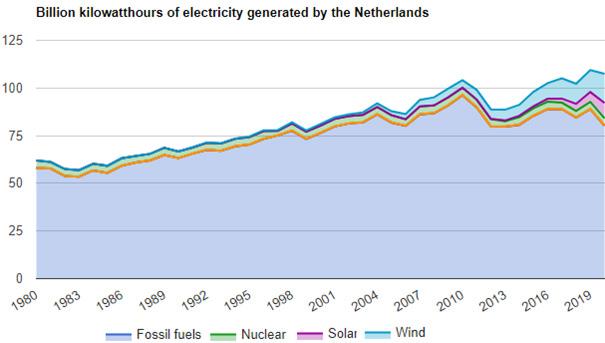

Despite these issues the worldwide development of renewable power generation systems is rapidly increasing. It is expected that in the near future better and more cost-effective energy storage systems will become available. This will not only stimulate the use of renewable energy locally, but it can also result in generation and use of renewable energy at different places. Once storage and transportation of renewable energy is economically feasible, generation can be facilitated at locations with high availability of sunshine and / or high average wind speed. The graph in Fig. 3 shows the development of renewable power generation in The Netherlands, where appr. 20% of the used electricity is generated from renewables.

Fig. 3: Development of renewable generation in The Netherlands (Source: Globalpetrolprices.com)

3. Energy transition and port operations

3.1 Mobile port equipment

Port operations require heavy equipment for the (un-)loading of goods from ships and for internal transportation within the port boundaries. Mobile port equipment is in most cases diesel powered because this used to be the only method to provide sufficient power to mobile equipment.

Due to technological developments and economies of scale, alternatives are becoming more and more available. Most feasible alternatives are: 5 Battery electrification 5 Hydrogen 5 Liquid renewable energy carriers such as methanol (from CO2 and green hydrogen)

Battery electrification systems are available as standard products more and more, which is a consequence of the electrification trend in transportation (cars and trucks). Use of hydrogen or hydrogen-based energy carriers is not yet common practice and this is mainly caused by the high costs and low total efficiency of these systems. Future technological developments might change this and can have a huge impact on the way renewable energy is used for mobile applications.

For battery electrification a choice needs to be made on how and where the batteries will be charged. There are 3 options:

1. Normal charging (From 20-80% in appr. 4-8 hours): Use longer idle periods of the equipment to recharge the batteries, for example overnight. This charging method is good for the battery-lifetime, and it requires relatively small chargers and grid power capacity. When the required charging time (1-2 hours minimum) is acceptable this is the most economical solution. 2. Fast charging (From 20-80% in less than ? hour): Fast charging requires more specific charging equipment (DC charging) and it reduces the lifetime of batteries. The main advantage is reduced idle time. Charging can with this method be done for example during a coffee break. 3. Exchangeable batteries: When batteries can be easily exchanged it is possible to charge them at a central position and at a suitable moment. This system allows to use cheap power (in case of flexible tariffs), the charging power can be limited (long charging time is acceptable) and charging can be done in optimal (temperature) conditions. Disadvantages are the requirement for additional batteries (1 charging, 1 operational for each piece of equipment) and the provisions required to exchange the heavy batteries in a short time period.

Fig. 4: Battery electric automatically guided vehicle (Source VDL)

3.2 Fixed and semi-mobile port equipment

For port equipment on a fixed position or with limited movement the use of electricity as energy carrier is common practice. The main challenge to run this type of equipment on renewable energy is the mismatch between actual generation and consumption of energy. This mismatch can only be covered by energy storage systems which are not yet common practice for this type of equipment.

Fig. 5: Electrification system for Rubber Tyred Gantry cranes In some cases, the local grid operator allows to deduct renewable generated energy from the consumed energy. This is very cost effective for the client but on a larger scale less attractive for the grid operator.

In those cases where the grid operator does not allow to deduct renewable generated energy, a battery storage system can be a solution to balance generation and demand. Battery storage systems are costly, voluminous and their lifetime is limited.

3.3 Energy transition – New business for the port

The expectation that the energy transition process is growing rapidly in the coming years will have its impact on port business. Examples of energy transition related business are:

5 Windfarm construction and maintenance services: For a significant increase in renewable energy production windfarms at sea are inevitable for many countries such as The Netherlands. Soon it is likely that there will be daily transports of 1 or more wind turbine(s) from the land towards the installation position at sea. Maintenance will be executed at tens of turbines every day. And finally: With a number of years also the first wind turbines will need replacement. All these activities at sea, combined with the extensive electrical installation works require a huge capacity of ports that can facilitate these works. It is not only the seaside: Also the land side of the port must be suitable for transportation and storage of the heavy wind turbine components.

Fig. 6: Cable reel for windfarm cabling installation prepared in the port

5 Transportation of renewable hydrogen: Hydrogen produced in places in the world where renewable energy is available in excess. Hydrogen transportation is complicated due to the extremely low temperature required in combination with the explosion risk. Therefore, it will be challenging for ports to facilitate the large-scale import of hydrogen. The development of the application of hydrogen-based energy carriers such as methanol or ammonia is still uncertain. If one or more of these will grow rapidly this will have a large effect on ports too, because it will require a completely new infrastructure of (un-)loading systems, pipelines and storage tanks.

4. Clean energy supply for ships

Besides port equipment, ships themselves will in the future also become consumers of renewable energy. Power supply to ships during their stay in the port can be used to meet the power demand, so that the on-board diesel generator(s) can be switched off. This is the principle of shore power installations that are currently being rolled out over ports worldwide. Once shore power is in place the power supply potential of such a system can also be used for other applications, for example for charging on-board battery packages that can be used for short sailing distances or for at least entering and leaving the port emission free.

For short distance sailing barges and ferries the trend towards electrification is clearly visible. This will have an impact on the utilisation and on the capacity requirements for shore power systems and should therefore be taken into account for new shore power developments.

In those cases where battery-electric propulsion is not an option, the use of clean fuels such as methanol could be an alternative for fossil fuels. This will also require an additional fuel logistic system to produce the fuel and distribute it to the ships that can use it.

5. Economic aspects

Recent developments on the worldwide energy marked have shown that the cost prices for conventional energy can be very volatile. One of the major advantages of renewable energy is that this type of power generation results in a long-term fixed energy price. The investment

is done in the construction phase of a project and the costs (Maintenance and depreciation) are quite exactly known. Cost prices of renewable energy from wind and solar depend on local circumstances (sun intensity, average wind speed), project scale, availability of free space and conditions such as temperature, air pollution. However, once the location of a renewable energy project is known the revenues and therewith the cost price per MWh can be calculated very accurate over the expected lifetime of the project (15-25 years).

In many cases the cost price of a MWh from a renewable source is less than 100 USD. This price level, especially when it is fixed for 20 years or more, makes renewable energy very competitive with conventional energy sources.

In the near future it can be expected that the total costs of energy from conventional sources will rather rise than fall. Charges for CO2 emission will increase the cost price of conventional energy and shortage on the world market for energy might even increase the price further.

6. The integral view

Developing a Green Port strategy is a process that does not stand on its own. The energy transition is an integral process in which ports play a crucial role. The port is an energy consumer, it is the place where energy intensive industries are based, and the port is the gateway for energy carriers to be distributed into the hinterland. Making a port greener requires therefore an integral view on all processes that take place in the port, related to energy. Only when all aspects are considered optimal solutions can be developed.

The following aspects should be considered as part of the development of a Green Port strategy: 5 Energy consumption of the port itself (Energy carriers and quantities) – Increase energy efficiency and move to cleaner energy carriers; 5 Energy delivered to ships (Propulsion and consumption while in the port) – Facilitate shore power use and replace conventional fuels by clean energy; 5 Transportation and logistics of conventional energy carriers (Coal, oil, LNG) – Volumes might decrease following the ongoing energy transition; 5 Potential for transportation and handling of new, renewables-based energy carriers; 5 Options for renewable energy production within the port; 5 New business for the port related to renewable energy production (Wind farms at sea); 5 New or upgraded renewable energy distribution networks within the port and to the hinterland.

Implementation of the Green Port strategy and optimising the economic performance of the port are actions that show more and more synergy, which is enhanced by the rising energy prices .

7. Examples of applications

7.1 Hydrogen production and distribution in the port

A port that is the home base of several chemical industries can produce hydrogen from excess power of windfarms (at sea or within the port boundaries). In future hydrogen will also be imported from locations with an excess of renewable energy. The hydrogen produced and imported can be used as raw material for the chemical industries, but it can also be applied as energy carrier for mobile applications. The port becomes a hydrogen hub and to make this work it is required that there is a distribution network in place and sufficient unloading and storage capacity.

Fig. 7: Impression of new hydrogen production plant in Port of Rotterdam using renewable energy from the North Sea (Source: De Ingenieur)

7.2 Renewable shore power

Providing shore power to ships is a proven technology to reduce ships’ emissions in the port. It is not always effective: If the power is generated from fossil fuels, especially if that is done in an inefficient way, causing much pollution, it seems to be contra-productive. Combining shore power with renewable power generation can be a very effective way to make shore power much more attractive. Power costs go down and the energy delivered to the ship is completely emission free. Of course this requires cooperation with the grid operator who must be willing to accept power feedback into his grid and supply at moments of renewable shortage.

Fig. 8: Port of Mombasa Cruise Terminal – Shore power and building climatisation powered (partly) by solar energy

7.3 Power plant and LNG terminal

LNG terminals require significant quantities of thermal energy for the regassification of LNG into gas. When thermal energy is not available locally it can be required to burn gas to produce heat for regassification. Waste heat of a conventional power plant which cannot be used any more is an ideal energy source for the regassification process. When the distance between the power plant and the terminal is not too far this can be a very energy and cost efficient combination.

Fig. 9: Port of Rotterdam: LNG Terminal uses waste heat from power plant at 3km distance (Source: Google Earth)