Discover how to grow at scale from the top 1% of growers in the world.

• Unlock top level insights without paying for a consultant

• Step-by-step instructions for every phase of cultivation

• Advanced techniques for heavy yields that command top dollar

• Curated by growers consistently yielding 2.75-3.5 lbs per light

“With The Whipple Effect’s strategies, within t wo runs, we wer e hit ting 3 lbs a light!”

- Joe Gerlach, Korova Founder, Unrivaled Brands

Get Your Copy Today

There’s more to High

According to Nohtal Partansky, automation, the internet of things, and artificial intelligence make manufacturing

Alisha Holloway, PhD, reveals how rare cannabinoids could play a major role in the industry’s future.

According to management consultant Peter Drucker, “The best way to predict the future is to create it.” These technology leaders are helping the industry do exactly that.

Prodigy Processing Solutions founder and Chief Executive Officer Marc Beginin, Esq., defended targets of the war on drugs, owned an alcohol brand, and established two high-tech equipment manufacturers. He shares his perspective on Michigan’s rise, rescheduling’s potential, and safety in the extraction sector.

Dan

We

Randy

Allison Zervopoulos believes artificially intelligent forecasting is

Eliminating the much-reviled Section 280E could spark an investment feeding frenzy.

“The only limit to our realization of tomorrow will be our doubts of today.”

Franklin D. Roosevelt

One thing that never ceases to amaze me about this industry is the enormous amount of innovation occurring all the time. The pace of new-product development and systems reengineering has been particularly brisk lately, partially because there’s an enormous amount of competition for revenue. Add to that a dearth of investment capital, and companies quickly realize they’re faced with a choice: deliver something uniquely interesting or pack their bags.

Financially challenging times encourage companies to take creative risks they might not consider when the market is booming. Not all those risks pan out, but the potential consequences of failing to try often are more untenable than the consequences of maintaining the status quo. As Facebook founder and Chief Executive Officer Mark Zuckerberg said, “In a world that’s changing quickly, the only strategy that is guaranteed to fail is not taking risks.”

Our industry is no stranger to risk, but the environment may seem a little trickier than usual now. The White House and more than a few pivotal congressional seats are up for grabs in November, and a shift in the balance of power in Washington could have significant ramifications for the plant’s legal status. Whatever the Department of Justice and Drug Enforcement Administration decide about rescheduling definitely will have a sizable impact. Because accurately predicting political outcomes is notoriously difficult, planning for the future in a world where multiple crucial questions are unanswered can be daunting.

But that’s the thing about the future: Crystal balls are hardly ever crystal clear. What is clear is that no company that hopes to survive can stop forging a path forward even when the future is uncertain. Chaos in the present should encourage more innovation, not less.

In this issue, we share thought leaders’ insight about the future. What does their analysis tell them about manufacturing, cultivation, regulations, e-commerce, and industry consolidation? We also take a look at some software platforms with intriguing next-wave products and examine leading technology companies that are helping businesses prepare for growth no matter what tomorrow brings.

One clear theme emerges: Regardless what else the future holds, in this industry one can be sure tomorrow will teem with new products, processes, and ideas.

Kathee Brewer Editorial Director

ALISHA HOLLOWAY PhD, is the chief scientific officer at Phylos, where she leads the research-and-development and breeding groups that focus on discovery and implementation of genetic markers for high-value traits and develop new cannabis varieties via classical and marker-assisted breeding. She holds an assistant professorship appointment at the University of California San Francisco and was the founding director of the Gladstone Institutes Bioinformatics Core Facility. Phylos.bio

Serial entrepreneur NOHTAL PARTANSKY is founder and chief executive officer at Sorting Robotics. Previously, he was an engineer on the NASA Jet Propulsion Laboratory’s MOXIE team. There, he helped develop an instrument currently sitting on the surface of Mars and producing oxygen from the atmosphere. Sorting Robotics builds innovative AI-driven machines for cannabis manufacturers and vertically integrated brands. SortingRobotics.com

DAN SERARD is vice president of sales and marketing for Cannabis Creative Group, an award-winning marketing agency serving cannabis and hemp brands. A six-year veteran of the industry, he is a member of professional organizations including the Cannabis Marketing Association, Rolling Stone Culture Council, and the National Association of Cannabis Businesses. CannabisCreative.com

RANDY REED is vice president of scientific solutions at ACTIVE™, a vertically integrated manufacturer and distributor of vaporizer technology, and a founding member of VapeSAFER, a leading unified voice of the cannabis vaping sector. Reed is an awardwinning scientist with more than twenty years’ experience in botanical extraction, cannabinoid formulations, delivery systems, product development, manufacturing and engineering, and patient education. Active710.com

ALLISON ZERVOPOULOS

plant scientist at Neatleaf. She possesses more than sixteen years of experience in the cannabis industry, with a specialized focus on cultivation. Zervopoulos excels at optimizing practices to maximize yields and ensure high quality. As a successful startup leader and strategic consultant, she is driven by innovation, professionalism, and integrity and is dedicated to advancing the industry. Neatleaf.com

GOT A NEWS TIP OR STORY IDEA?

We’d love to hear about it! If you know of people, products,

Editorial Director KATHEE BREWER

editorial@inc-media.com

Creative Director ANGELA DERASMO

Digital Editor Jeff Hale

Contributing Writers Alain Vo, Alisha Holloway PhD, Allison Zervopoulos, Alyson Jaen Esq., Brendan McKee, Christopher Jones, Cy Scott, Danny Reed, Dan Serard, David Kooi, David Sandelman, Derek Ross, Gary Allen, Henry Baskerville Esq., Howard Sykes, Jay Virdi, Jess Phillips, Kim Prince, Kris Krane, Kyle Sherman, Lance C. Lambert, Laura Bianchi Esq., Marc Beginin Esq., Michael Mejer, Michael Wang, Nohtal Partansky, Paul Penney, Rachel Gillette Esq., Rachel Goldman, Randy Reed, Robert T. Hoban Esq., Ruth Rauls Esq., Scott Johnson Esq., Shane Johnson MD, Sue Dehnam, Taylor Engle

Artists/Photographers Christine Bishop, Steve Hedberg, Mike Rosati

Digital Strategist Dexter Nelson

Circulation Manager Faith Roberts

BRANDI MESTA

Senior Account Executive

Brandi@inc-media.com (424) 703-3198

BUSINESS OFFICES

Chief Executive Darren Roberts

Tech Architect Travis Abeyta

Accounting

Diane Sarmiento, Brittany Gambrell

Subscriptions subscribe.mgmagazine.com

Back Issues

store.mgmagazine.com

Mailing Address

mg Magazine 23055 Sherman Way, Box 5069 West Hills, CA 91308 (310) 421-1860 hello@inc-media.com

MEG CASHEL

Account Manager

Meg@inc-media.com (424) 246-8912

mg Magazine: For The Cannabis Professional Vol.10, No.8 (ISSN 2379-1659) is published monthly by Incunabulum LLC, located at 23055 Sherman Way, No. 5069, West Hills CA 91308. Periodicals Postage Paid at Las Vegas Post Office and additional mailing locations. POSTMASTER: Send all UAA to CFS. NON-POSTAL AND MILITARY FACILITIES: Send address corrections to mg Magazine, 23055 Sherman Way, No. 5069, West Hills CA 91308.

mg is printed in the USA and all rights are reserved. © 2024 by Incunabulum LLC. mg considers its sources reliable and verifies as much data as possible, although reporting inaccuracies can occur; consequently, readers using this information do so at their own risk. Each business opportunity and/or investment inherently contains criteria understanding that the publisher is not rendering legal or financial advice. Neither Incunabulum LLC nor its employees accept any responsibility whatsoever for contributors’ activities or content provided. All letters sent to mg Magazine will be treated as unconditionally assigned for publication, copyright purposes, and use in any publication or brochure and are subject to mg’s unrestricted right to edit and comment.

WASHINGTON – A reporting deadline is drawing closer for many of the industry’s most enduring companies, and this one has nothing to do with products, financial markets, or taxes.

All privately held businesses, domestic and foreign, that were registered to conduct business in the United States prior to January 1, 2024, must file an initial beneficial owner information (BOI) report with the Financial Crimes Enforcement Network (FinCEN) by January 1, 2025. Failure to file could result in a fine of up to $10,000 and two years in prison.

The BOI report is mandated by the Corporate Transparency Act (CTA), a landmark piece of legislation enacted by Congress in 2021 as part of the National Defense Authorization Act. Designed to combat illicit financial activity including money laundering, terrorism financing, corruption, and tax fraud, the act’s mandate applies to corporations, limited liability companies, and any other entities created by documents filed with a secretary of state or other similar office in the U.S.

The CTA requires businesses to disclose information about who owns or controls the business. Reporting companies must identify all individuals with at least a 25-percent ownership interest. They also must identify anyone who has “substantial control” over the business. This second and likely larger bucket includes chief executive officers, general counsels, important decision-makers, and anyone else with

the authority to remove certain officers or directors. Information required includes the individual’s legal name, address, date of birth, and social security number.

With the exception of twenty-three types of entities including publicly traded companies meeting specified requirements, many nonprofits, and certain large operating entities, most cannabis businesses likely will find themselves in the need-to-file camp.

Key reporting deadlines:

• Companies created or registered before 2024 have until January 1, 2025, to file their initial report.

• Companies created or registered in 2024 have ninety days from the time the company received actual notice that its creation or registration was accepted.

• Companies created or registered in 2025 will have thirty days from actual or public notice that the company’s creation or registration was accepted.

Additional reports are required within thirty days of each ownership or upper-level personnel change.

Businesses may report their company’s beneficial ownership information to FinCEN through a secure electronic filing system at BOIefiling.fincen.gov. There is no charge to file.

GAITHERSBURG, Md. – A federal standards-setting agency is reselling commercially purchased ground hemp at eye-popping prices in what the agency characterizes as an effort to increase precision and consistency across the legal cannabis industry. The reference material is designed to provide testing laboratories with a benchmark to ensure their test results are accurate.

The National Institute of Standards and Technology (NIST) calls the high-priced hemp, officially known as 8210 Hemp Plant, “some of the most carefully quantified cannabis ever sold.” The material sells for $783 per set of three 1.5-gram samples sealed inside aluminized pouches containing a desiccant pack. The price sorts to $174 per gram.

On June 28, the Cannabis Benchmarks wholesale spot price index registered an average of $978 per pound—or $2.16 per gram—for flower. Meanwhile, Headset’s June data showed ground cannabis flower selling for an average of $23.21 per gram in California retail establishments and $60.82 per gram in New York.

Why is NIST’s ground reference material, produced from commercially purchased hemp, so much more expensive than ground cannabis flower?

According to NIST, the 8210 Hemp Plant reference material is produced with a “very high degree of accuracy and precision” by sieving ground hemp to achieve a consistent particle size. The resulting material then is blended with low-THC flower to ensure

the final product reaches a total THC concentration just below the legal threshold of 0.3 percent for hemp.

The federal agency provides more than 1,200 standardized reference materials covering a wide range of consumer products, most with prices consumers probably would consider outrageous. For example, while the price for reconstituted hemp may sound exorbitant, it’s less expensive than a small jar of peanut butter, baking chocolate, soy milk, or baby food composite, each available from NIST for $1,143 per sample.

NIST hopes the precision-engineered materials will help labs help brands avoid product seizures that could devastate their business. In addition, the certified reference materials will help testing labs produce more accurate certificates of analysis, an agency spokesperson said.

Cannabis lab testing has been plagued by inconsistencies. A 2022 study conducted by Infinite Chemical Analysis Labs, a compliant laboratory in California, tested more than 150 randomly selected flower samples from retail shelves and found 87 percent failed to meet the total cannabinoid levels claimed on their labels. NIST’s introduction of new reference material could help address similar issues in all states by offering a standardized substance laboratories may use to calibrate their equipment and validate their methods.

Hoodie Analytics Closes

$5 Million Series A

Data firm

Hoodie Analytics secured $5 million in a Series A raise led by Measure 8 Partners with participation from Entourage Effect Capital and Satori Investors. The company plans to use the money primarily to fund market expansion of its newly launched market insights and product data management platform.

Lucid Green Secures $1.4 Million

Following a $10-million Series B round in 2022, “smart product identifier” platform

Lucid Green secured an additional $1.4 million in funding from an undisclosed source. The company said it will use the new funds to expand into new markets and enhance the capabilities of the InventoryAI component within the LucidID ecosystem.

Grown Rogue Loans ABCO $3 Million

Oregon’s Grown Rogue International Inc. extended a secured drawdown promissory note for up to $3 million to ABCO Garden State, a New Jersey cultivator of which Grown Rogue owns 44 percent. The initial draw of $500,000, plus any additional draws and interest of 10.5 percent per annum, are due June 25, 2025.

SNDL tendered a stalking horse bid for struggling Canadian operator Indiva, which entered creditor protection in June. According to the court-appointed monitor, SNDL, an existing creditor and significant stakeholder, will pay an estimated CAD$25–28 million for Indiva’s business and assets. The sale is expected to close by September 30.

LINCOLN, Neb. – Cannabis consumers are getting ripped off. So says a report from a nonprofit nongovernmental organization that has set weights and measures standards for the United States since 1905.

“In the retail cannabis trade, insufficient attention and guidance is given to moisture migration in or out of some cannabis packaging and as a result, the contents of some cannabis flower packaging have been found to be underweight, resulting in the patient/consumer paying for weight they are not receiving,” the National Conference of Weights and Measures (NCWM) stated in a recent report. “If you were shopping at any one of three stores of a popular brand, you’d have a 71-percent chance of buying a supposedly 1.75g package that is 21.6 percent underweight, meaning you have a 71-percent chance of being ripped off by $5 (assuming a $10-pergram price).”

In an effort to promote fair competition, foster confidence in marketplace transactions, and ultimately ensure consumers get what they pay for, the NCWM proposed new moisture standards for the National Institute of Standards and Technology (NIST), a division of the U.S. Department of Commerce, to adopt in the next edition of its official handbook.

help restore consumer confidence, the NCWM proposes a moisture variation allowance of 3 percent for packaged flower. This threshold is consistent with other items in the NIST handbook and aligns with California regulations that allow the same tolerance. Other consumer products with the same moisture allowance include flour, dry pet food, pasta, and fresh poultry.

There’s more to High Seas than meets the eye.

By Taylor Engle

Historically, the country has looked to California for clues about cannabis. After all, the Golden State was the first to legalize medicinal use and among the first to go recreational. California also gave us advocacy legends Brownie Mary and Denis Peron and cultivation mecca the Emerald Triangle. But despite all the plant progressiveness, one region in the southern part of the state remains mired, to a great extent, in prohibition: Orange County.

High Seas in Costa Mesa changed the status quo in Orange County, but not without a fight. After waiting months to obtain a license and enduring a lawsuit, police raids, and a legal settlement that wasn’t entirely satisfactory, High Seas became the first dispensary to open in the county outside Santa Ana—previously the only OC city where residents had voted to allow dispensaries to operate. Life behind the “orange curtain” is notoriously conservative compared to the majority of the state. As a result, most of the county’s 792.9 square miles constitute a cannabis desert. But with High Seas’ opening in April, it looks like reform is slowly but surely catching on.

Customers step into the ocean-themed dispensary and embark on a journey of the senses. Guiding guests through the space with clean scents, creative brand displays surrounded by flowers, and the sounds of nature whispering from motion-sensor speakers, the shop is less like a classic Santa Ana in-and-out dispensary and more akin to the luxury traditional retailers on swanky, nearby Bristol Street.

“It’s a higher-end experience,” said co-founder Michael Moussalli. “Customers come into the lobby from one of two

entrances, where they’re greeted and ID-checked. But rather than being rushed onto the sales floor from there, customers are encouraged to peruse the lobby, where several of our brand partners rented cubbies to display their marketing materials and products.”

The featured displays, which were developed by co-founder Rachel Xin, share the lobby with a muted merch shelf offering beach-town fashion, a 400-gallon fish tank, and a virtual 3D hologram greeter who educates visitors about the space and its offerings while they await their turn to browse.

Kombucha and cold brew are on tap in the lobby, and customers are encouraged to enjoy the opportunity to relax until their assigned “specialist” comes to collect them. From there, it’s straight to the sales floor, where consumers receive a one-on-one tour through the unique environment, equipped with two more fish tanks, soothing mood lighting, and products displayed in a manner accessible even to those new to the plant.

“Everything [except the kiosks in the lobby] is laid out by product type—not brand,” Moussalli said. “It’s easier for people to understand that way. We made sure to lay out the space in a way that doesn’t look overwhelming or cluttered; that’s why we don’t have a lot of packaging on display. We want people to buy based on their conversations with our specialists and what they feel is best for their needs.”

Convenience is the name of High Seas’ game—a tactic the founders said they picked up from luxury retail. All specialists carry iPads so they can place orders easily as customers browse, ensuring their bag of goodies is ready for them when they reach the checkout counter.

“From our virtual greeter to our directional speakers where people can hear waves crashing or birds chirping, we’ve aimed to create a soft, welcoming ambiance for folks,” Moussalli said. “Our store has an older demographic, and most of our customers just don’t want to feel like they’re shopping at a dispensary. They want to feel like they’re at South Coast Plaza [a nearby high-end mall], so that’s the experience we aim to deliver.”

The team worked closely with Remedy Design Group Principal Designer Cindy Lam to ensure the store’s design allows for that sort of journey: seamless, worry-free, and elevated.

Lam was brought onto the development project in 2021 at a time when the High Seas team knew only that they wanted to create an “engaging, experiential retail space.” They were more specific about what they didn’t want, but they needed Lam’s help to transform their business goals into a tangible, functional product.

“I came from retail and hospitality, so I’ve dealt with a lot of product displays in my day,” Lam said. “My team’s whole process was to jump straight in, the same way we’d lay out any other retail store. Product merchandising was the driver for design. Aside from aesthetics, we worked closely with the [dispensary’s] team to figure out what sort of products they planned to carry and whether it would be more grab-n-go, sit-n-stay, or some mix of the two.”

Starting at the sales counter, Lam and her team worked backwards, using the High Seas team’s desired end to the journey to understand how the space should look. The store’s founders answered an extensive questionnaire, which helped Lam and her crew figure out which merchandise categories would be offered, what percentage of products would be showcased at a time, and how the products would appear to consumers as they entered the expansive sales floor.

One of the key features in creating positive customer response is Remedy Design Group’s signature Scenting Jars, which are designed so consumers can stop and smell the flowers.

“I’ve been designing cannabis stores since early 2017,” Lam said. “Through that process, our team ended up developing our own line of jars specifically for cannabis so people can smell the product outside of its packaging. High Seas’ opening happened to be in parallel to our jar launch, so they adopted a wall of Scenting Jars for consumers to explore.”

Because the jars encourage consumers to explore at their own pace, they fit perfectly with High Seas’ goal of helping customers to relax and enjoy their journey.

“This concept is about letting people discover for themselves,” Lam said. “We wanted to give people an intimate opportunity to discover products while they learn more about the plant. Novice shoppers might not have felt comfortable going into a traditional dispensary. With that in mind, we wanted this store to say, ‘We’re not limiting ourselves to everyday seasoned smokers. We welcome the new and the old, all while catering to people with higher expectations for their shopping experience.’”

Lam and her team took cues from fashion, food and, perhaps most notably, coffee.

“When you walk into a Starbucks, what do you immediately smell?” Lam asked. “Beans. It entices you. Then you look through the glass case and see hot croissants on display. Before you know it, you want to buy. We wanted the cannabis experience to be similar.

“The industry is evolving every day,” she continued. “There are constantly new products rolling out, and it can be quite overwhelming for consumers. Our idea was to simplify things by designing a space that is clean, simple, and beautifully showcased.”

The High Seas team was completely on board with Lam’s suggestions from the beginning, she said, since one of the founders’ chief aims was to offer consumers a bespoke experience with an expertly curated product selection.

“There was a lot of trust between our teams, which is so important in this process,” Lam said. “With cannabis, you have so many people coming from different backgrounds. Some are new to the industry but seasoned in marketing or real estate; others are the opposite. But with everyone bringing something different to the table, it’s rare for someone to place their full trust in you.”

The dispensary and design teams worked closely with an architect, taking their time to determine precisely how the space would come to life.

“We cater to those who want education—not just products,” Moussalli said. “We’re not a store that targets folks who are looking

for the best deal in town. We’re targeting folks who are like, ‘Hey, we want to know more about that product. Can you talk to us about it?’ Our store is less quick pitstop and more of an attraction.

“I’d much rather see 200–300 people per day and have them thoroughly enjoy the store without feeling rushed than see 600 people just to get deals out the door,” he added.

While the OC remains somewhat stuffy and resistant when it comes to convenient cannabis access, High Seas is a first step toward reform in a way that is palatable for the local demographic.

“We often have customers come in and say, ‘If I knew there was a store like this, I’d have started shopping for cannabis a long time ago,” Xin said. “And the true testament to that? We’ve been open for less than thirty days, and have already seen 20 percent of those customers return at least a second time.”

The Costa Mesa store is the first in what Moussalli and Xin hope will become a chain. But they intend to be picky about future locations.

“We’re always looking at new cities that might introduce cannabis legislation, but at the same time, our store is very specific and we’re not willing to compromise that for a location,” said Moussalli. “I’d love to see High Seas in [OC cities] Newport [Beach], Dana Point, or Laguna Beach. However, legislation is still far behind for retail cannabis, so for now, we’re just keeping an eye on the landscape.”

Working in manufacturing is all fun and games until the kief particles are filling the air and coating not only the pre-rolls but also the operators, right? It’s no secret that without the proper technology, manufacturing centers can be hazardous places. Luckily, technologies like automation, the internet of things (IoT), and artificial intelligence (AI) are adding a new layer of workplace safety. How? Let’s get into it.

First, automation. Already, automation offers significant safety benefits across a variety of processes. For example, instead of workers manually dispensing heated liquid to fill vape carts, the process can be automated within a contained system. This reduces the risk of repetitive strain injuries like carpal tunnel syndrome and eliminates the potential for contamination from human contact. More importantly, automation creates a safer workplace because it enables operators to control the environment. Take the kief-coating example from earlier: After human operators roll joints in kief on open tables, they must brush the excess off the tabletops and sweep it up from the floor. That can cause the fine dust to become airborne, which creates a breathing hazard for humans. Instead, automated systems can enclose the process, capturing and containing any airborne materials while a machine coats the joints.

In the near future, I expect to see an increase in the adoption of automated machinery that contains the coating process within a volume, applies a vacuum, and filters the air, thus leaving

humans breathing room that is free from any unwanted particles. The automation in this scenario protects workers from inhaling harmful substances and ensures products like pre-rolls and concentrates remain free from bodily fluids or other contaminants that could be transferred by hand.

Remediation is another key area in which automation can create safer workplaces. Ozone- or UV-based remediation treatments are extremely dangerous to perform manually, but automation enables remediation that otherwise would be impossible due to the high human risk involved.

Next, IoT. Essentially, the internet of things is a network of interconnected devices that exchange data with each other via the cloud. In manufacturing, IoT benefits operators by providing deep insights into production flow rates and identifying production failures. When all manufacturing machinery is connected and something goes wrong, real-time surveillance allows safe, remote troubleshooting to get production back on track.

IoT also enables robust data analytics, providing operators with a reliable source of truth stored in the cloud rather than on a clipboard. I’ve seen many instances where companies replace manual processes—like having employees sign off on results— with automated online dashboards. This transition not only smooths out operations but also significantly enhances efficiency.

“But,” you ask, “how can IoT provide a safer work environment?” Here are a few ways:

• Certain IoT sensors can detect harmful levels of particles or contaminants in the air and alert the proper authorities that action must be taken to protect workers.

• IoT-enabled machines offer real-time data about their operating status, allowing for predictive maintenance and reducing the risk of accidents caused by equipment failure.

• IoT’s ability to execute track-and-trace functions at the machine level greatly reduces the number of errors that must be reported under Marijuana Enforcement Tracking Reporting Compliance (METRC).

In the future, I expect IoT systems will connect directly to compliance software. If this becomes a requirement for our industry, manual data entry could be eliminated, reducing the risk of human error and ensuring adherence to safety and reporting standards. Consider this example: When you write production data on a clipboard, there’s a risk of human error. Say someone writes a numeral one that looks like a seven. Not only will this cause significant discrepancies in reporting, but the error also could lead to operational mistakes.

Machines don’t have messy handwriting or make calculation errors. IoT devices capture and store data accurately, abstracting it to a database rather than leaving the process to chance on the shop floor.

Lastly, let’s look at AI. Today, AI serves as a significant qualitycontrol check in the manufacturing process, which can enhance

safety measures. Technology like computer vision can pattern-match to discern between passing and non-passing material.

For instance, a human inspector might miss a structural issue like a cracked glass tip. However, computer-vision systems don’t become distracted or suffer momentary vision lapses, so they identify defective items every time, thus protecting workers from cuts and end users from finding broken glass in the products they purchase.

In some cultivation facilities, machine-learning algorithms, a form of AI, are used to balance carbon dioxide (CO2) and sulfur levels. Overfilling a room with CO2 can be hazardous, and manually managing levels is risky. Combining AI algorithms with IoT devices programmed to control CO2 and sulfur levels significantly reduces the risk of failure.

As our industry grows, there will be a greater demand from the government and other regulatory entities calling on manufacturers to ensure workplace safety. Therefore, cannabis manufacturing is in a unique position to lead a novel approach to workplace safety with the integration of automation, IoT devices, and AI. Unlike older industries like food manufacturing, which would face costly retrofits, cannabis facilities are being built with IoT and automation capabilities from the start. While the industry is still operating on a small scale due to federal legality issues, as it scales up, facilities with large build-outs likely already will be fully integrated with automation, IoT, and AI.

The question is, how will you prepare for the new frontier in manufacturing and workplace safety?

Cannabis, a plant with a rich and complex history intertwined with human civilization, offers a vast array of chemical compounds. Beyond the well-known tetrahydrocannabinol (THC), the psychoactive component responsible for the “high,” lies a hidden world of rare cannabinoids with the potential to revolutionize recreational, health, and wellness markets. As we look to the future of cannabis, it’s important to understand the historical context of the plant’s use, the impact of selective breeding on cannabinoid diversity, and the exciting possibilities we’re only starting to discover about the potential of rare cannabinoids.

Throughout history, cannabis has played a multifaceted role in human cultures. Archaeological evidence suggests the plant was domesticated around 12,000 years ago. Traditional medicine systems across the globe have incorporated cannabis for pain relief, inflammation, and a variety of other ailments. Ceremonial and recreational use, driven by the plant’s psychoactive and mood-altering effects, also has been documented for centuries. This historical diversity of use reflects the complex chemical profile of the plant, with a multitude of cannabinoids, terpenes, and flavonoids contributing to its effects.

In the twentieth century, a significant shift took place. Cannabis prohibition in the 1930s, followed by the United States classifying the plant as a Schedule I drug in 1970, severely restricted research and cultivation. After states began legalizing the plant despite federal law, breeding programs shifted their focus toward maximizing THC content, prioritizing high-potency flower with appealing aesthetics. Intrepid breeders, limited by space and resources, inadvertently reduced the overall diversity of cannabinoids, particularly the rare and minor ones. However, with rescheduling potentially imminent in the U.S., we will have more freedom to explore.

To understand the potential hidden within the plant, we can look to landraces, as we have with other long-domesticated crops. Landraces are indigenous plant populations that thrive in their specific environment due to natural selection over generations. These varieties haven’t been bred with a focus on THC, unlike many of the varieties commercially available in the U.S.; therefore, they likely hold the key to unlocking the full spectrum of cannabinoids, because the plants may retain the genetic diversity to reveal diverse cannabinoid profiles. Researchers have identified more than 160 cannabinoids in Cannabis sativa L., highlighting the astounding heterogeneity of these compounds.

The true promise of rare cannabinoids lies in their potential effects both individually and in combination with other cannabinoids, terpenes,

and other secondary metabolites. Until recently, most research focused on isolated cannabinoids, primarily THC and cannabidiol (CBD), but others also have been the subject of compelling research. A 2010 study of cannabichromene (CBC) by Abit T. El-Alfy, PhD, and his colleagues at the University of Mississippi indicated significant antidepressant effects in mice. This type of work is crucial to unlocking the potential of the plant; however, a growing body of evidence suggests the “entourage effect” plays a crucial role in how cannabis is experienced. This concept, conceived by Raphael Mechoulam, PhD, and championed by Ethan Russo, MD, proposes the various components of the plant work synergistically to produce a more balanced and potentially more therapeutic outcome than isolated cannabinoids.

The entourage effect has been demonstrated in several studies. A 2023 study by Ryan Vandrey, PhD, and his colleagues at the Behavioral Pharmacology Research Unit at Johns Hopkins explored the interaction between the terpene limonene and THC. Vandrey’s results suggested limonene reduces anxiety caused by THC. This and other work highlights the value of moving beyond single-molecule isolates.

In fact, the rare cannabinoid THCV, when combined with THC, offers fascinating possibilities. A study Phylos recently conducted suggests THCV, when consumed with THC, may counteract some of THC’s unwanted effects, such as fatigue and increased appetite, while promoting motivation and energy. Studies like these open doors for products tailored to specific needs and desired experiences.

The exploration of rare cannabinoids holds immense promise for the future of the industry. Imagine a wider range of products catering to specific mood states, health needs, and desired effects. Consumers and patients could choose between products for relaxation and stress relief, focus and creativity, or pain management and improved sleep. This level of personalization has the potential to significantly improve consumer and pharmaceutical products.

The cannabis plant offers a treasure trove of potential benefits waiting to be unlocked. By delving into the world of rare cannabinoids and studying their individual and synergistic effects, the industry can create a future rich in diversity, offering consumers a more informed and targeted approach to incorporating the plant into their lives. This shift toward a deeper understanding of the whole plant, rather than just its isolated components, paves the way for a more responsible and potentially more beneficial relationship between humans and this fascinating botanical treasure.

Technology companies are bringing the future nearer, offering next-generation, scalable products and services that help businesses boost efficiency, product quality, and market competitiveness.

By Sue Dehnam

As it does in most other modern industries, technology plays a crucial role in cannabis, driving innovation, efficiency, and regulatory compliance. From seed to sale and even in consumers’ hands, software and hardware—alone and in combination with artificial intelligence (AI), automation, computer vision, and machine learning (ML)—are transforming the value chain, enhancing productivity, optimizing processes, and increasing the “wow” factor of products and services.

In the cultivation sector, DNA sequencing and analytical genomics can present growers with blueprints of any plant’s chemical composition. Researchers predict that, in the not-too-distant future, growers and manufacturers will use that knowledge to precisely target treatment outcomes or recreational desires while offering patients designed-for-them flavors, aromas, and potencies.

Chatbots powered by AI already improve customer service; by combining AI with blockchain, developers are redefining supply-chain management, inventory control, and compliance tracking. Automation streamlines operations from cultivation to manufacturing and packaging, reducing costs and errors. Computer vision enhances quality control by monitoring plant health and assembly lines, detecting anomalies before they become hazards. ML drives innovation in product development, and robotics help manufacturers improve cost-effectiveness and provide safer working environments.

And the pace of new developments has become so rapid that “the future” is harder and harder to define.

According to management consultant Peter Drucker, “The best way to predict the future is to create it.” The following technology leaders are helping industry businesses across all sectors do exactly that.

On the heels of rebranding to ACTIVE™, the company formerly known as AVD launched a new all-in-one device with a unique shape. The Leaf All-In-One stands out on shelves and will appeal to customers looking for something different. Despite its slim profile, the Leaf contains a one-milliliter or two-milliliter tank, offering brands the flexibility to choose a solution that suits their market. Plus, the device offers an extra-wide canvas for branding. The Leaf All-In-One is engineered for distillates and novels but is compatible with liquid live resin. It is USB-C rechargeable as well as mass-fill-ready and cap-ready using ACTIVE’s EZ Click low-torque fill-and-cap technology, which is compatible with leading automation platforms. (Active710.com)

Beaker & Wrench’s twelve-inch wiped-film evaporator offers a scalable solution for manufacturers who need a continuously high throughput of 90- to 95-percentpure oil. Equipped with Beaker & Wrench’s proprietary SinterTekTM mesh pleated wiper baffles, the machine can deliver fifteen to thirty liters of distillate per hour, and the hydraulic-tilt still body makes wiper maintenance easy. A dual-feed tank option allows multi-pass operation with a single-stage system. Compact, heated cycloidal gear pumps; a large, wide-bore vacuum manifold; preset vacuum states with automatic valves; and a dual-stage cold trap with high/low impedance baffles round out the impressive technology. Other signature features include an intuitive touch-screen interface, remote connectivity, and downloadable operating data. (BeakerAndWrench.com)

Mariner Business Solutions’ CannaPoint enterprise solution, powered by NCR’s inventory engine, is used in more than 17,000 retail operations. CannaPoint uses radio frequency identification (RFID) for precise, compliant inventory tracking, employing Mariner-provided scanners and software customizations that can count more than 54,000 tags a minute at a distance of more than twenty feet. The platform’s AI-enabled, mobile- and desktop-friendly analytics dashboard is color-coded for at-a-glance insight and allows business owners to track operations and project sales from anywhere. Other advanced features include digital menus, a kiosk check-in and ordering system, customer purchase tracking, and integrated payment processing, making CannPoint a comprehensive assistant for streamlining operations and reducing overhead (MarinerBusinessSolutions.com)

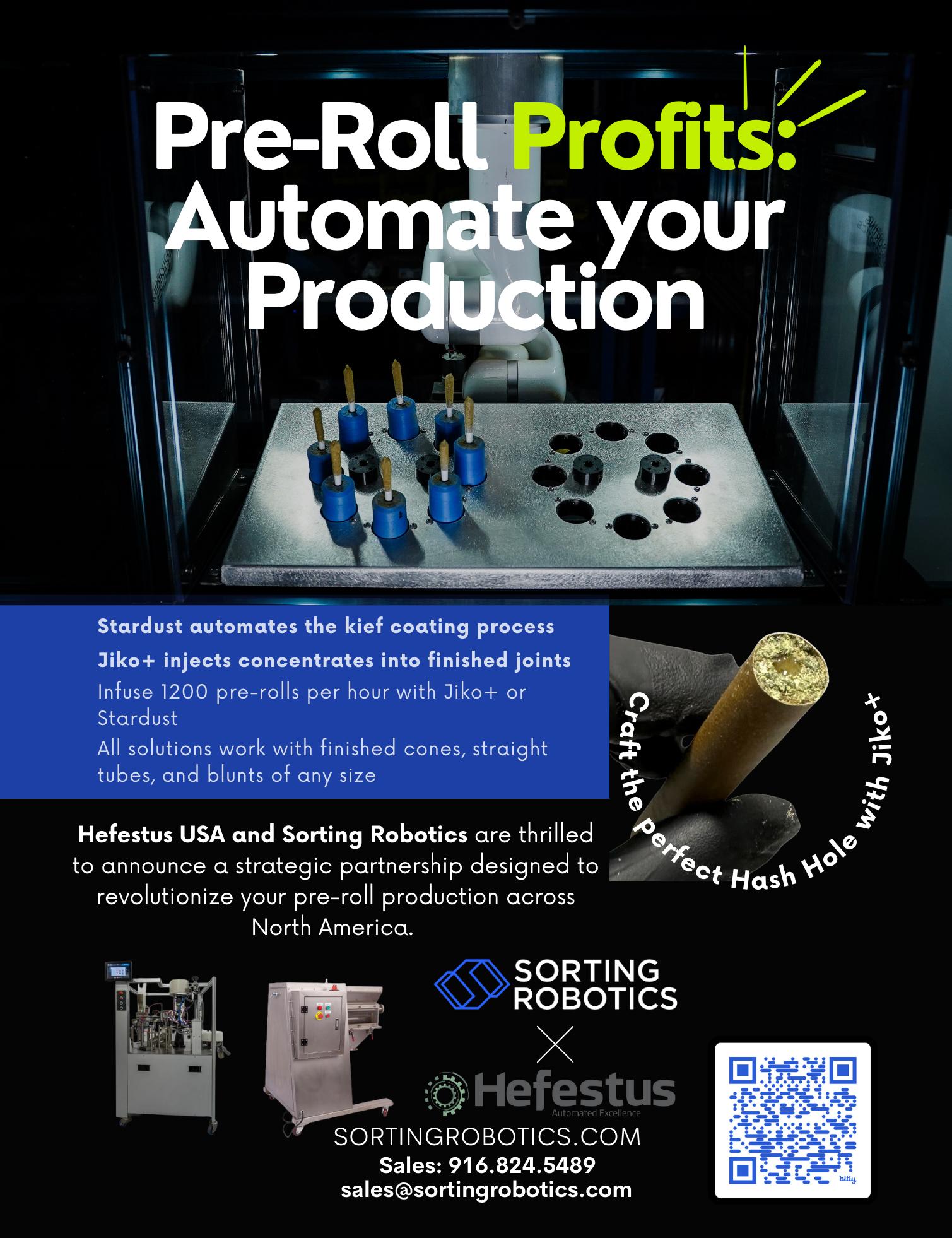

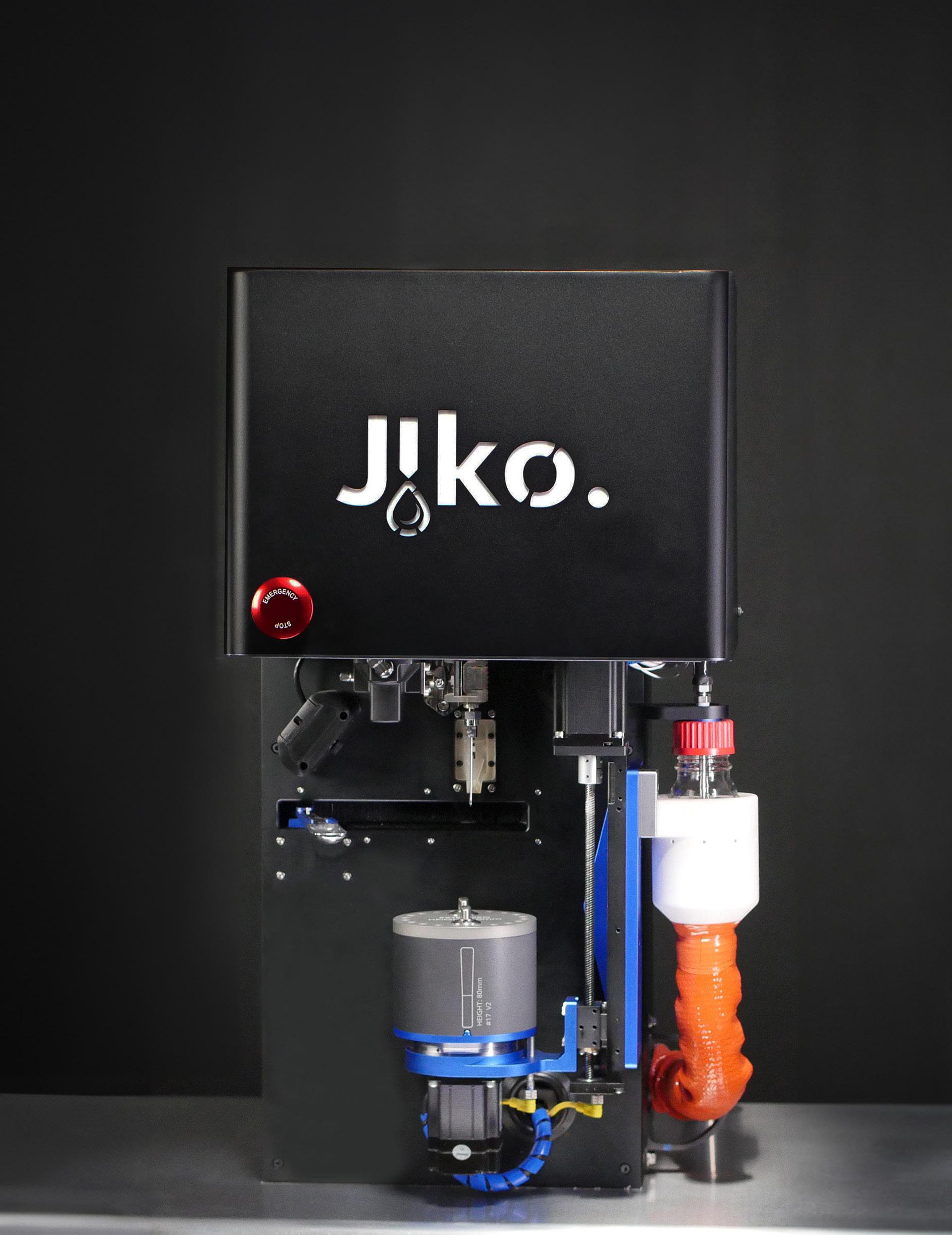

One of the most intriguing tech companies operating in the cannabis space today, Sorting Robotics is best known for its Stardust kief-coating robot. Just as Stardust brings automation, consistency, and increased operator safety to “fuzzy” joints, the company’s Jiko and Jiko+ robots perform similar functions for infused pre-roll production. The Jiko units use both pressure and temperature to control the infusion process based on settings the operator selects on a sophisticated touch-screen interface. Both machines accommodate a variety of pre-roll sizes and types. In addition, Jiko+ allows operators to automate production of uniform donut or “hash hole” joints at scale. (SortingRobotics.com)

Long an industry stalwart in retail data and analysis, New Frontier Data’s latest undertaking aims to help retailers transform their approach to customer acquisition. Called NXTeck, the platform leverages real-time data from more than 980,000 unique retail locations, 430 million devices, and 60 million consumers to help retailers attract foot traffic from what New Frontier estimates is an untapped market of hundreds of millions of potential brick-andmortar customers. Marketing- and advertising-focused NXTeck’s insights facilitate precise targeting of local consumers followed by strategic outreach to those most likely to purchase at the moment they’re ready to buy. Real-time campaign tracking helps retailers optimize operations, understand market trends, and drive growth. (NewFrontierData.com)

Building on expertise gained over decades in the food industry, Hefestus Technologies has spent the past ten years perfecting pre-roll automation. The company’s innovative AuraX system adapts to various strains, cone sizes, and infusions while producing up to thirty-six uniform pre-rolls per minute. The unit’s compact design and low power consumption make it energy- and space-efficient, and simplified, user-friendly operation requires minimal manpower. According to Cannabis Division Leader Shahar Yamay, “Our philosophy of ‘simplistic sophistication’ means we avoid overengineering. Our machines are easy for operators to work with and yet versatile enough to handle almost any type of joint while maintaining quality and consistency.” The Hefestus team provides onsite training and 24/7 tech support. (Hefestus-slb.com)

Phylos Bioscience, a provider of genetics and rare cannabinoids, stands out for its advanced DNA-markerassisted breeding technology. Home to what the company says are the industry’s first phenotypically stable, dayneutral, short-season, fully feminized F1 hybrid seed lines, Phylos leverages proprietary, patent-pending technology to provide rare cannabinoid genetics for both cannabis and hemp. In addition, the company’s Natural Natural brand powers a supply chain with naturally derived THCV. Phylos’s most recent research-backed release is Elite Seeds, a line of varieties that can compete with indoor clonal cultivars for top-shelf quality and potency. The company promotes sustainable cultivation by developing seeds that reduce resource use and pathogen risk. (Phylos.bio)

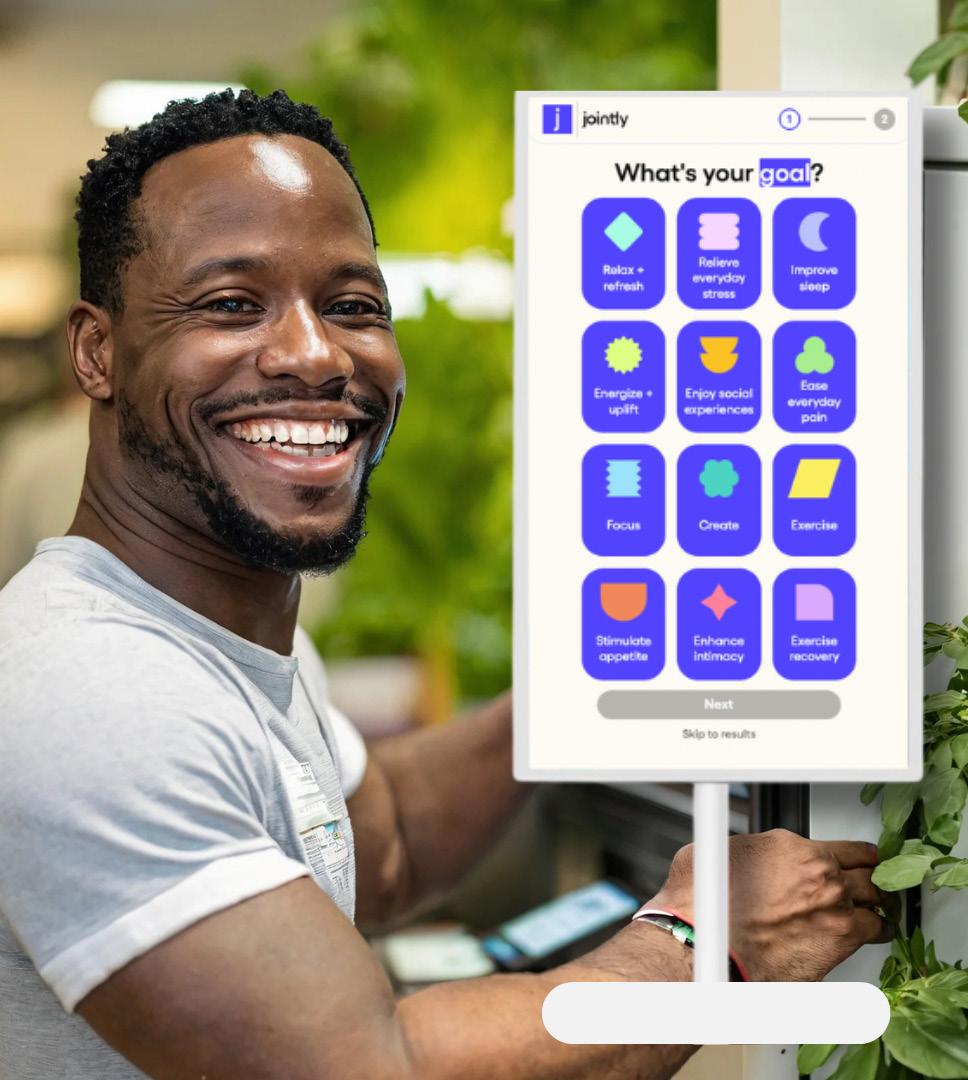

Jointly’s newest product, Spark Pro, provides budtenders with the insight and intel they need to fulfill their pivotal role in the ecosystem and improve customer experiences. Introduced in July, Spark Pro puts the power of first-party data in budtenders’ palms, leveraging AI to make sense of millions of data points from the organic reflections of consumers who use Jointly’s mobile app. With Spark Pro, budtenders can provide the kind of personalized recommendations and accurate answers experienced consumers would give their friends and family members. “This is the power of combining advanced AI with realworld data to transform the retail experience,” said Jointly co-founder and Chief Executive Officer David Kooi. (JointlyBetter.com)

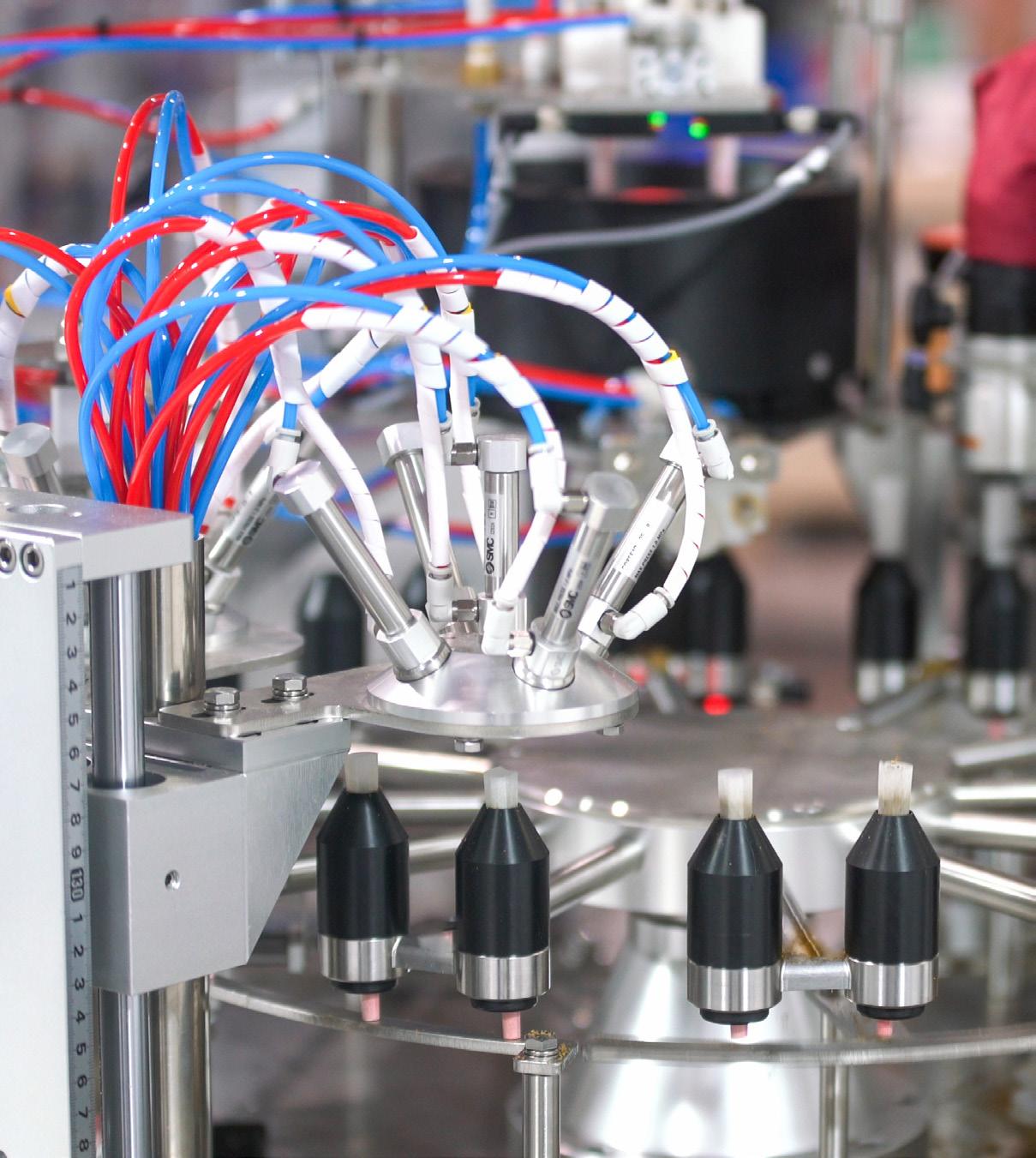

Xylem Robotics grew from a company that developed highly precise water baths and immersion circulators for laboratory environments. Using precision pharmaceutical-grade technology, the company’s robotic solutions allow manufacturers to scale quickly and efficiently. The Xylem X4, an automated cartridge filler, offers inline filling and capping at a rate of as many as 1,650 units per hour. Precision ceramic pumps, combined with inert gas overlay, result in finished carts with leak-resistant vacuum locks and visually higher fill lines. The Xylem Y1 low-temperature infusion system allows operators to infuse pre-rolls of any type at a rate of up to 600 units per hour. (XylemTech.com)

Prodigy Processing Solutions founder Marc Beginin shares his perspective on Michigan’s rise, rescheduling’s potential, and safety in the extraction sector.

By Christopher Jones

In the early days of adult use, companies made big bets on how and why consumers would engage with cannabis and planned their products and manufacturing accordingly.

Designing and prototyping new technologies was a big part of the process, and a handful of pioneers and visionaries became particularly notable for innovations that impacted the industry in ways they may never have imagined. Marc Beginin, at the time a criminal defense attorney in Michigan who represented cannabis offenders, was one such pioneer in the extraction sector, where he continues to shape the industry.

Today, the extracts and edibles segments account for nearly 50 percent of cannabis sales in the United States, but that hasn’t always been the case. Extracts were a tiny part of the total until the first vaporizer pens appeared in 2010, shortly before Colorado became the first state to legalize adult use. Vapes made puffing more socially acceptable and opened a massive new product category. But the technology for making the extracts to fill the devices remained crude and somewhat dangerous for about five years. “Open blasting,” one of the primary extraction methods, involved shooting butane through plant material in a narrow container to extract the precious oils.

In 2014, Beginin teamed up with Nick Tennant, who for several years had been tinkering with new designs for more sophisticated and safer extraction machines. Together, they founded Precision Extraction Solutions with an initial investment of $45,000. Precision helped launch a new market segment when it began offering off-the-shelf, turnkey “closed loop” extraction systems capable of safely isolating the plant’s chemical components and refining them into new, high-end— and, by then, highly sought—products.

Precision was in the right place at the right time, as the U.S. cannabis industry was entering a major growth stage with dozens of states gearing up for adult-use sales. By 2019, the company’s annual revenue skyrocketed to more than $40 million; in June 2021, Beginin orchestrated a merger with Cascade Sciences, creating a formidable equipment and solutions provider for extraction, post-processing, and testing. Then, a scant three months later, Massachusetts-based Agrify Corporation acquired the combined entity for $50 million in cash and stock. Beginin initially opposed the transaction but capitulated after negotiating what should have been “a poison pill” into the contract: He wouldn’t be constrained by a noncompete clause.

“It really should have killed the deal,” he said. “It’s crazy. Let the founder and largest shareholder and [chief executive officer] walk away with a ton of money and no noncompete [agreement]? Not a good idea.”

In 2022, Beginin founded Prodigy Processing Solutions, a designer and manufacturer of premium next-level, high-volume extraction equipment. Based in Miami with manufacturing operations in Hartville, Ohio, the company’s equipment meets or exceeds Food and Drug Administration (FDA), current Good Manufacturing Processes (cGMP), and European Union GMP (EU GMP) standards for food and pharmaceutical applications. All equipment is made in the U.S.

Over the course of his career, Beginin has served in several C-suite capacities in the industry. With his new company, he seems more motivated than ever to continue pushing the envelope on extraction technology. Partially, that’s because he envisions a near future when every company in the U.S. will have to adopt much more stringent manufacturing processes to ensure products meet standards set by the FDA and other regulatory bodies.

And partially, it’s because he just can’t give up on his longstanding role as an advocate. Ever since his days defending targets of the war on drugs, he’s wanted to change the landscape.

Why was Precision so successful?

We launched in December 2014 and really shot out of a cannon. We offered the first commercial closed-loop hydrocarbon extraction system. At the time, butane was being used to extract oil from the plant, but there were a lot of people just open blasting … and as they got larger and larger scale, that’s when you blow up an apartment or garage or whatever. So safety quickly became a big issue.

So we came out with really the first commercial system and, sight unseen, we collected a lot of deposits and produced a lot of equipment. And we did it right; we really ran the business like a business—certainly not like a hobby. And then we just continued to innovate and grow over time.

How did Prodigy build on your previous extractionsector experience?

Prodigy has the benefit of nine years of lessons learned [at Precision]. And that means everything from the technology to the people to the suppliers to the innovation. At Precision, we did final assembly testing for our own proprietary goods; we had third-party manufacturers build the components and then we would put them together. At Prodigy, our manufacturer is our business partner: Mitchell Fabricators in Hartville, Ohio. This was also a manufacturer for Precision toward the end of my tenure there, when we were moving to U.S. manufacturing because we learned the Chinese [components manufacturers] were woefully inadequate—and not just in terms of the quality of the builds but also the materials used. When they would say, “it’s 304 stainless steel,” it was something else.

If our customers become FDA-compliant and DEA-registered labs, they can do work for pharma, and then they will be able to operate in all fifty states.

At Prodigy, because the manufacturer is literally an equity partner, now we can produce 316L stainless steel that is made in the USA and manufactured at top-notch quality, because we don’t have that gap where we have to buy from a manufacturer, they mark it up, and then we mark it up. And that’s why we can afford to make quality products in the USA at reasonable prices.

Who are Prodigy’s target customers? What types of products are you developing for them?

Our target customers are sophisticated processors and extractors in the cannabis and hemp industries—the ones who value providing quality to their customers. They’re the [multistate operators], the publicly traded companies, and the sophisticated operators. If they’re not already GMP-compliant, they’re leaning into good manufacturing practices, which substantially has not been a thing in the cannabis industry due to [the plant’s] federal illegality.

This is why we’re making pharmaceutical-grade equipment. And there are no hydrocarbon systems out there that are GMP-compliant except for Prodigy’s. The whole industry was started with open blasting, so it’s been focused on operator safety, but now it’s shifted to consumer safety and testing for pesticides, heavy metals, mold, mildew, things like that. But [contemporary industry standards are] woefully inadequate as compared to FDA and GMP standards, whether food or pharmaceutical. So now, because of rescheduling, recalibrating for FDA and GMP compliance will be imminent.

Also, if our customers become FDA-compliant and DEAregistered labs, they can do work for pharma, and then they will be able to operate in all fifty states and cross state lines legally. It’s the ones that want to lean into pharma and the ones that are intense and meeting the standards that are going to come to us sooner or later on the recreational side. Your average lab that is just Frankensteining equipment together and pumping out some products, they don’t care and they are not our customer. But the ones that truly value operating in a highly sophisticated business manner—meaning really focusing not just on operator safety but also on consumer safety—they are going to be around for the long term, because they know the changes are coming. Why would you invest a half-million dollars into a piece of equipment that you know the FDA will not deem compliant when the time comes?

The industry expects cannabis’s status under the Controlled Substances Act to change sometime this year. How challenging will it be for extraction labs to meet new standards if the FDA and other agencies step in afterward?

Well, it’s going to be very easy if they use Prodigy equipment. We were built on the inevitability of cannabis becoming federally legal, and it turns out that is happening first by the switch to Schedule III. [The Department of Justice and Drug Enforcement Administration are considering moving the plant to a much-lessrestrictive classification that it currently holds. —Ed.] So here comes [the pharmaceutical industry], and this is an opportunity—a massive opportunity—for these labs. They have decades of experience that pharma doesn’t have. To meet those standards, it’s a learning curve, upgrading the equipment and the [standard operating procedures]. But with the proper guidance, it’s not that complicated, and it’s an investment in the future, that’s for sure.

What do you think are the most meaningful ways in which rescheduling will impact the industry?

Well, the change will usher in an [Internal Revenue Code Section] 280E exemption, but that’s more for the larger companies that don’t have a workaround already. I’m confident most companies have that anyway and are able to deduct business expenses. They often have [human resources] handled by a different company for their employees, as well as marketing and [other non-tax-deductible] things like that. That is significant, because without 280E you can easily just deduct your expenses. That’s a big one. I don’t believe that affects most operators out there, but it is significant because now it is also a signal to say, “Okay, we don’t have to play games with our accounting,” and people can just easily do more straightforward accounting.

I believe [dispensing with 280E] should open up banking as well. That’s maybe going to take a few more hoops to jump through, but the tax deduction is a big one. It’s just a formal

setting in motion of the road toward full legality in some fashion. Specifically, it is the opportunity presented to these processors to clean up in terms of their business.

For example, if they are developing precursor extracts for pharma, [those products go] to some other lab for final separation and inclusion in a pharmaceutical product or compounding prescription that’s legal under Schedule III. That is huge. So they’re going to be able to do fifteen to twenty times the sale price of what they’re already doing.

Or they can do the chemical separation and provide those components or take it all the way to a finished product. I think the word isn’t out yet on how these labs can capitalize on this massive opportunity.

Consistency and adhering to certain protocols in order to call them “standard operating procedures” and really sticking to them are geniune issues. In terms of operator safety, let’s just check that box as if we’re good, because normally the authority having jurisdiction is the municipal or county fire chief. They regularly have fire marshals do inspections, but operator safety during production is where problems happen.

Who’s doing consumer safety inspections? For cannabis, that’s the local health department, which is ill-equipped in terms of even a knowledge base to deal with a consumer food product. They’re too busy checking in on the local family restaurants and Taco Bells to make sure they’re adhering to their [standard operating procedures], which they understand very well. When you’re dealing with a [traditional] consumer product, the FDA does the inspections.

Companies are motivated to get a product out the door, and many of these labs may require someone to sign a piece of paper [certifying the product] that’s not actually part of their process. So again, when it comes to cleanliness and not leaving things lying around, moving things, it’s all about contamination. That’s the name of the game here. And that contamination doesn’t necessarily need to be a pesticide or a heavy metal; it can be bacteria. This is what you’re guarding against: contamination of all sorts. But if you use the proper equipment and engage with the proper procedures, you minimize that risk to some level.

Butane is a popular solvent. Could using butane in the extraction process lead to any health hazards?

Butane is a hydrocarbon and, generally speaking, it results in the fullest profile [of the plant] you’re going to get at the commercial level. The solvent at certain temperatures and pressures flows over the biomass and pulls out the material components and chemical compounds you desire. So it pulls what you want, like the terpenes, flavonoids, CBD, THC, all the cannabinoids, and

it leaves behind what you don’t want, like chlorophyll. That’s it. That’s the magic of it.

Now you have a mixture of solvent, cannabinoids, and other chemical compounds that goes to what we would call the collection vessel, where it’s heated. The solvent turns into a gas that boils off, and what you have left is the oil. And then you would further purge it [to remove any residual contaminants].

Another thing to consider is you probably can’t go a day without eating some sort of soy extract in something. Soybean oil is extracted using hexane, which also is a hydrocarbon. It’s sort of on the nastier end of hydrocarbons. This stuff has been going on forever, and it’s so common. The hydrocarbons boil off and you get down to non-detectable amounts, or they’re totally purged when you’re [finished with the process]. So it’s not really a health issue.

Competition is intense in this industry. What is the key to thriving in this market?

The liquor industry is similar to ours—or it’s going to be very similar, I believe, once cannabis is federally legal on the adult-use side. Back in the late 1990s, I started a vodka company—actually a brand called Zodiac—and eventually we got into twenty-two states. I was bought out of that company in 2005, but in the meantime I gained a lot of experience in dealing with a highly regulated industry. I don’t think cannabis is unique. Whether you’re running Apple Inc., General Motors Corporation, or a lemonade stand or restaurant, I’d say the fundamentals are all the same. Everything is consumer-focused, and this is what matters: providing value to the consumer.

Now, how do you do that? By creating a high-quality product that’s desired and then communicating to the consumer why they should want it. Building a great company culture and all the things that go along with that in terms of maintaining proper operations, costs, and the like support that mission. As federal legalization approaches, even beyond Schedule III, [the market will become] more competitive, not less, because now you have all these businesses getting involved that wouldn’t before, which means you’re going to have more sophisticated competition. If operators haven’t upped their game yet, they’re going to have to up their game soon.

You’re from Michigan, which recently leapfrogged California to become the state producing the most revenue. What makes Michigan so successful?

Yeah, we’re crushing it, and the market in California has four times as many people. California consumes way more cannabis than Michigan, but [California’s sales are] not all legal. In addition, California’s regulations, laws, and taxation are abusive, so they’re suppressing the legal market. In Michigan, on the other hand, medicinal and recreational use were legalized by public referendum. The referendums weren’t written by legislatures or

I don’t think cannabis is unique. Whether you’re running Apple Inc., General Motors Corporation, or a lemonade stand, I’d say the fundamentals are all the same.

people that had a ton of competing interests. They were written by pro-cannabis lobbyists—or just activists, actually. So now we have a market where laws and regulations are conducive to business. That’s why Michigan is thriving.

There’s an incredible entrepreneurial spirit and grit in [Michigan] as well. So you have healthy competition between a lot of people, and there’s no vagueness to compliance with laws and regulations. And there’s no overtaxation, either. That’s why it’s so successful.

Do you see any new categories of extraction products coming along in the near future?

I think the sky’s the limit for products, because everything that’s not flower is using extract, whether it’s a vape pen or a gummy, chocolate, a topical, sublingual, or cosmetic products—you name it. Every product you see out there that has cosmetic, nutraceutical, medicinal, or food value, you can use cannabis extract for. So I think it’s really up to the creativity of the brands and manufacturers.

B-REAL BERNER SWAMICHAITANYA MICHAEL‘BIGMIKE’STRAUMIETIS

STRAUMIETIS GARY ALLEN JILL AMEN LUKE ANDERSON

JIM BELUSHI ADAM BIERMAN JESSICA BILLINGSLEY

ERIC BRANDSTAD CHAD BRONSTEIN JAKE BULLOCK

BESS BYERS FRENCHY CANNOLI DINO CARTER ARIEL

CLARK JESSICACUEB DEREKCUMINGS STEVEDEANGELO

ISAAC DIETRICH CHRIS DRIESSEN OUTER ELEMENTS

DAVID ELIAS BOB ESCHINO JOSH FINK HYLER FORTIER

STEWART FORTIER MARA GORDON VIRGIL GRANT

BIANCA GREEN ADAM GROSSMAN JEREMY HEIDL

JULIE HERZOG JEREMY JACOBS AARON JUSTIS

TRIPPKEBER CHELSEAKITAHARA KRISTALKITAHARA

TYLERKNIGHT BENKOVLER KRISKRANE KYLEKUSHMAN

JACOB LAWRENCE BRUCE LINTON CONRAD LISCO

AARON LOCASCIO FIONA MA BRUCE MARGOLIN DARRNI

DANIMATHERS ROSIEMATTIO CHRISMCELVANY RALPH

MORGAN KENNYMORRISON KEVINMURPHY MELISSA

EMILYPAXHIA NATHANIELPENNINGTON DENNISPERON

ASHLEYPICILLO KARYRADESTOCK AMYRAZI FAITHROBE

KIMRIVERS EDROSENTHAL JOSHRYAN SOPHIERYAN

CODIESANCHEZ CHRISSAYEGH RICKSCARPELLO MIK

ADRIANSEDLIN LYNETTESHAW ERICSHEVIN AARONSMITH

SOFIOS NICK TENNANT PEBBLES TRIPPET

JONATHANVALDMAN ROGERVOLODARSKY WILWALKER

A collection of photography that showcases the people behind the business.

mgmagazine.com/moments

KYMBER WARD JIM ROBERT WEAKLEY JASON WHITE

The cannabis industry is hardly “new” anymore. The waves of adult-use legalization are more than ten years old now, and the days of cold, pharmaceutical-style in-person shopping are over. As consumers turn toward more sophisticated, interesting brands, the future of retail is evolving—and the online experience is more important than ever.

Third-party marketplaces such as Weedmaps and Leafly have cemented themselves as crucial components of the e-commerce ecosystem. These platforms attract significant traffic because they have earned domain authority and consistently rank well in search engines—often higher than the brands and dispensaries they feature. This makes them a convenient solution for both consumers and retailers, but convenience isn’t always the most cost-effective, profitable, or enjoyable way to approach a task.

Traditionally, self-hosted e-commerce solutions were beyond the financial and technological reach of most dispensaries, but the emergence of native e-commerce menus is changing how retailers present and sell products. Less disruptive for shoppers, better for discoverability in search engines, and relatively easy for dispensaries to implement, the technology offers numerous benefits over popular third-party solutions.

The most common third-party dispensary menus are implemented via an iframe plugin. Think of this kind of menu as reaching through a window on one website and interacting with a completely different site. The menu is hosted on the marketplace’s servers, which can present a number of challenges, including limited access to data generated by transactions.

The technology dates to the 1990s and was adopted as a way to get dispensary menus up and running quickly in a rapidly growing industry. While iframes allow for quick integration, the third-party marketplace ultimately controls everything from data to search engine optimization (SEO) and aesthetics.

With native e-commerce menus, the entire online shopping experience happens within a single website, which the e-commerce merchant controls. Nothing is handed off to a third-party marketplace. Major clothing retailers like Nike, Zara, and H&M use this structure. Among the nifty features native menus allow is sending direct links to product pages. That’s not possible with iframe menus.

Native e-commerce menus are coded directly into the dispensary’s website, providing the store with unfiltered access to SEO, style, user interface, and in-depth analytics. From

the moment a customer arrives on the site until they click the “purchase” button, the site’s owner has total access to all data, which can be leveraged to support marketing strategies.

A host of search engine optimization benefits also accrue. Native menus allow dispensaries to rank in search results for the products they carry in their online stores, enhancing visibility and driving organic traffic. Among other things, this means operators can access location-based data, attract more foot traffic, and cater to local consumers more effectively.

For instance, when a customer searches for competitive keywords like “cannabis near me” or “cannabis edibles,” rather than a thirdparty marketplace popping up in the coveted first few search engine results, an SEO-optimized native menu can help individual dispensaries rank there instead.

Beyond the SEO benefits, native menus allow for an enhanced and inclusive user experience. Seamless integration with a dispensary’s website creates trust and familiarity, allowing the website to mirror the in-store experience, potentially leading to higher conversion rates.

More importantly, clear site navigation lets every customer, regardless of abilities, easily use the site and shop the products. For example, clearly labeled links and URLs make it easier for those who use screen readers to understand the website’s structure.

More dispensaries are moving to native e-commerce in today’s competitive landscape. The early adopters are benefiting most, but it is likely the majority of dispensaries will move to a native solution soon.

Hennep, a recreational dispensary in Provincetown, Massachusetts, was an early adopter. A month after launching a native e-commerce menu, the online store’s organic traffic soared by 69.68 percent, its conversion rate improved by 104 percent, transactions were up 145 percent, and revenue increased by 74.3 percent. In other words, switching from a third-party menu provider to an SEO-optimized native menu helped Hennep increase its online visibility and brand awareness while driving customers to shop at its online store.

So, is it time for you to leave third-party marketplaces behind? New dispensaries with limited budgets may be better off sticking with an iframe solution for the short term. They’re easy to implement, the third-party marketplace handles most of the maintenance, and costs are reasonable. On the other hand, established retailers looking for long-term success may benefit from investing in an SEO-optimized native e-commerce menu.

The industry will continue to evolve. Whether they’re adapting to consumer behavior, new technology, or changing legislation and policies, operators constantly must ask “What is the future of cannabis?”—and meet their customers there.

In today’s digital world, software platforms are business essentials. These five are evolving to help retailers stay ahead of the market.

Operating a cannabis retail business without digital tools is akin to navigating a complex maze blindfolded. In an industry characterized by stringent regulatory requirements, software platforms provide a firm foundation for profitability and scaling.

Software enhances operational efficiency. Inventory management systems prevent overstocking or shortages, while point-of-sale systems streamline transactions and provide real-time sales data, allowing businesses to make informed decisions, optimize stock levels, and enhance customer satisfaction.

Additionally, software facilitates effective financial management. Integrated accounting tools track

expenses, revenue, and taxes, simplifying financial reporting and ensuring accuracy. This is crucial in an industry saddled with unique tax challenges due to federal prohibition.

Marketing and customer relationship management tools also play a pivotal role, helping businesses engage with consumers, personalize marketing efforts, and foster loyalty. In a competitive market, maintaining strong customer relationships is key to sustained growth.

To be effective and remain relevant, digital platforms must evolve more rapidly than the industry they serve. These five agile innovators are helping set the pace.

BLAZE has re-engineered its point-of-sale (POS) system to enhance the user experience, reduce costs, and improve operational transparency. BLAZE Retail, a hardwareagnostic, web-based system, is now 20 percent faster and supports both Windows and iOS. With features like integrated price-checking, seamless discount application, and intuitive customer notes, BLAZE Retail provides a one-stop solution offering efficiency and ease of use for both employees and customers. (Blaze.me)

Flētly (pronounced “fleetly”) offers a suite of tools to help dispensaries and delivery services manage and dispatch customer orders. From aggregating orders across multiple platforms to driver assignment, ID verification, order adjustments, compliance tracking, progress messaging, and manifest generation, the company’s automated system adds efficiency meant to help companies scale. An integrated analytics platform provides insight into operations, customers, and marketing. (Fletly.com)

Surfside’s Commerce Media platform offers retailers and brands new revenue opportunities by transforming e-commerce websites into advertising networks. Retailers can monetize their sites through ad placements, while brands gain increased product visibility and precise consumer targeting on a network that includes mainstream destinations. The platform-agnostic solution leverages first-party data for personalized ads, potentially increasing engagement and returns for dispensaries and product brands alike. (Surfside.io)

PROTEUS420 is revolutionizing cannabis consumption lounges with a groundbreaking update to its seed-to-sale platform. The software simplifies lounge operations by streamlining order fulfillment, payment methods, and THC consumption tracking. Customers receive wristbands to track their orders and limits, ensuring compliance with state laws. This innovation offers lounge operators flexibility, improved data capture, and enhanced marketing opportunities, making management more efficient and customer-friendly. (Proteus420.com)

Cova’s POS system stands out for its reliability, which is especially crucial for cannabis retailers. With built-in failsafes, Cova ensures business continuity during internet outages by locally storing sales data. This dedication to uptime prevents costly disruptions, maintaining compliance and customer satisfaction, especially during high-traffic periods like 4/20. Clients applaud Cova for its robust, always-on promise and commitment to customer-focused growth. (CovaSoftware.com)

OUR INDUSTRY CAN AVOID THE PITFALLS THAT PLAGUED E-CIGARETTES.

The federal government most likely will reschedule cannabis sometime this year. This reform makes it more pressing than ever for the vaporizer sector to proactively develop and promote scientific testing and research to establish the proper foundation for industry standardization and potential federal regulations.

If we, as an industry, do not allocate the necessary resources for comprehensive research and advocacy, cannabis vapes may very well be regulated the same way as nicotine vapes. This would present significant safety concerns for users and stunt the industry’s growth. That is exactly what we witnessed happen to the e-cigarette sector.

Cannabis must be regulated differently from e-cigs. Electronic nicotine delivery systems (ENDS), more commonly known as e-cigarettes, are required to submit a Premarket Tobacco Application (PMTA) to the U.S. Food and Drug Administration (FDA) and receive approval before selling any ENDS product. Among other requirements, the application sets a high standard for safety. The FDA requires testing for extractables

and leachables, aerosol chemistry, and ninety-three harmful and potentially harmful constituents (HPHCs). On the list of constituents are recognizably toxic compounds like formaldehyde, uranium, arsenic, and benzene.

Cannabis vapes currently fall under state regulatory frameworks, which have fewer requirements than the PMTA. This is especially true regarding aerosol chemistry, device materials and construction, extractables, leachables, and shelf stability.

Given the complexity of cannabis vape formulations, we should expect testing for a broader array of HPHCs than those for which ENDS are tested. Therefore, it is increasingly important to get ahead of such regulations to ensure they protect both the safety and viability of the cannabis vape market.

The FDA has authorized the marketing of only twenty-three ENDS products to date. Imagine a market as massive as the United States with only twenty-three legal cannabis vaporizer products. Talk about stagnant! Perhaps worse, the paucity of FDA-approved ENDS has created an enormous illicit market of e-cigarettes that are subject to absolutely no oversight, creating

immense risk for consumers who typically won’t know which products are safe for their intended use.

This should serve as a wake-up call for the cannabis vape sector: PMTA-style FDA regulations would be detrimental to the legal industry. Instead, we should advocate for a system that piggybacks off state regulations’ progress and supplements those regulations as needed to ensure safety without creating an insurmountable regulatory burden that leads to an illicit market of unsafe products.

How should the vape sector address testing and standardization to prepare for federal legalization? The obvious solution is demonstrating the ability to self-regulate before it’s too late. That means it’s time to prioritize safety.

First, we must ensure devices are intended for cannabis oil. Differentiating between e-cigarette devices and cannabis vaporizer devices is an important way to support more sensible regulation. It is well-established that nicotine vape cartridges do not work well with cannabis oil. If hardware is not intended for the appropriate oil, safety can be compromised.

Highlighting the differences using objective measures can strengthen the case for regulations independent of the e-cigarette industry. These objective measures should include puff topography, oil rheology, device thermography, particle character, and emissions chemistry.

Hardware certifications should have a clear rationale for specific applications to cannabis vape devices. Ideally, the industry should achieve a consensus around third-party and fit-for-purpose certifications before federal regulations arrive.

Many standards are in place, and aligning them to ensure safety and a robust market will be necessary. The organizations and testing standards industry hardware manufacturers currently use to ensure consumer safety include Underwriters Laboratories; Canadian Standards Association; Edison Testing Laboratories; Restriction of Hazardous Substances in Electrical and Electronic Equipment (more commonly known as RoHS); Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH); and Code of Federal Regulations Title 21.

Next, we must standardize ingredient and vapor safety testing for additives. Many formulators use additives to optimize viscosity, flavor, and effects. But are these additives safe for inhalation?