38 minute read

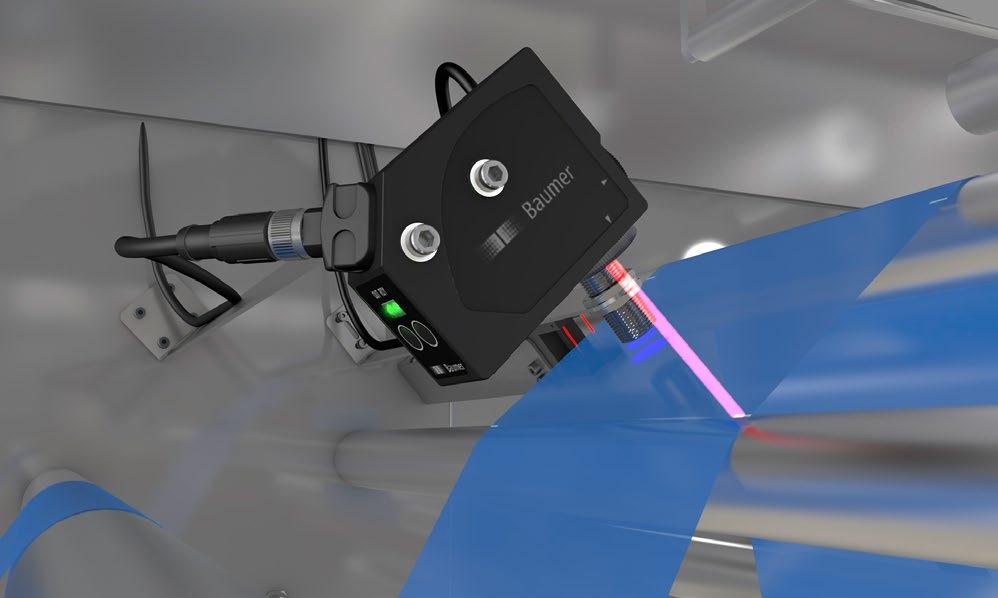

BAUMER

Contrast and luminescence Sensors are usually the ‘go to’ device for reliable detection of print marks and colour variances even at very low contrasts and are typically used for applications such as printing, labelling and packaging.

Sensing and instrumentation specialists BAUMER have developed one of the widest ranges of innovative sensing products and are now acknowledged as being one of the leading ‘one-stopshops’ for most process to packaging applications. A good example of this is their new range of OC50 / OC60 Contrast and Luminescence Sensors which provide reliable and precise detection of minute and invisible print marks even at very fast speeds thanks to low jitter>7µs. ‘Jitter’ is best described as any deviation in, or displacement of the signal pulses in a high-frequency digital signal and the amount of ‘allowable jitter’ is highly dependent on the sensing application. 6 FDPP - www.fdpp.co.uk

Developed on the intensity discrimination principle the OC50 is a basic contrast sensor with the ability to detect even the smallest differences between a mark and the background with a Jitter of >25 µs. It features RGB LED and single-lens optics, PMMA lenses all contained in a compact and robust plastic housing. It also has static teach-in with LED display and is available with optical lenses for distances up to 18mm.

The OC60 is offered for higher performance contrast sensing for lower Jitter measurements of >7 µs using the same RGB LED single lens optics as the OC50 although with glass lenses, static and dynamic teach-in within a metal housing. Optical lenses for this option are available for distance up to 40mm. The OC60 also has an adjustable cable outlet in 5 positions along with industry standard front and side mounting options. These features, along with a sensing beam that can leave the unit either vertically or horizontally ensures maximum positioning flexibility.

The OC60 luminescence sensing option features UV LED single lens optics, glass lenses and is designed for effective detection of fluorescent markings and can be adjusted for 5 sensitivity levels. It provides very quick response times of 0.34 ms and is available with optical lenses for distances up to 50mm.

The OC60D has a colour mode to detect not only the contrast but also the actual colour so is particularly suitable for colour detecting and sorting applications, such as those required for packaging in the food and drink processing industries.

More here: https://www.baumer.com/gb/ en/product-overview/object-detection/ photoelectric-sensors/contrast-andluminescence-sensors/c/42493

View Video: https://www.youtube.com/ watch?v=GTRa5mxbWGQ

Modi ed Atmosphere Systems Packaging Equipment

NEW!!

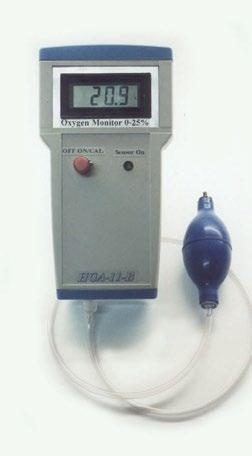

Model HGA-11-MAP is a fully portable residual oxygen monitor that can measure oxygen in very small volumes such as in Co ee Capsules (about 5-7cc). It is simple to operate and can make more than 100 measurements on one charge of battery. It is supplied with an additional rechargeable battery and battery charger.

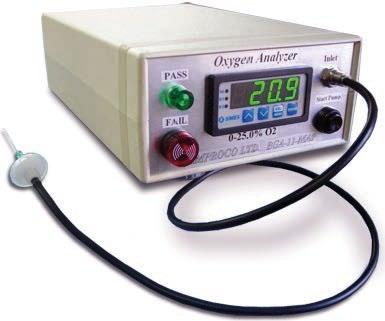

Model BGA-11-MAP is a small table-top, mains operated oxygen monitor suitable for measuring residual oxygen in small packages with sample volumes more than 10-15cc. It is simple to operate – a pushbutton initiates the internal electric sampling pump for programmable time, customer adjustable for di erent sample volumes.

NEW!!

Model 2BGA-SP-MAP is a small table-top, mains operated monitor which simultaneously measures residual oxygen and carbon dioxide CO2 in very small volumes, from 10-15cc or more. Operation is similar to the BGA-11-MAP instrument.

The ‘best’ of the cleaner, electrically heated high-pressure cleaners

Many companies in the food processing and production industry have been using electrically heated pressure washers for their cleaning needs where the advantages are clear:

• No exhaust fumes. • No CO2 emission • Cleaner, more reliable and cheaper to run than fossil fuel burning pressure washers.

But not all electrical heated hot water pressure washers work in the same way. Most require you to heat the water in a tank (much like a kettle does) prior to use which can take 10-15 minutes. While being operated, the heated water is topped up with incoming cold water this results in the output temperature dropping. Also when you finish cleaning remaining water in the tank will have been heated unnecessarily which is wasted energy. Kranzle e-therms are different.

Kranzle’s alternative and more efficient electrically heated e-therm pressure washers distinguish themselves from the rest by providing instant hot water, at a constant temperature using an innovative post-pump fully electrical heating system. No hot water tank and no pre-heating time required. Heating water after the pump has the added benefit of extending the life of the parts inside the pump, such as valves, seals and o-rings etc as well as using less electricity by leaving heated water in a tank. Greater reliability coupled with lower maintenance costs paired with lower running costs without polluting exhaust is achievable and favourable.

Kranzle, a privately owned and operated company, are renowned for their exceptional build quality and are well respected within the industry. Companies such as Walkers Snack Foods, British Sugar, Pepsi Cola to name a few have Kranzle e-therms, some for over 10 years with great results. The Kranzle family has grown its reputation by producing first-class cleaning equipment since 1974, not by offering the cheapest, but by providing the best. German built and designed; each machine is hand assembled then fully tested before leaving the factory in Bavaria.

The Kranzle range includes manual pushalong sweeping machines, a powerful vacuum cleaner in addition to their extensive range of pressure washers, available exclusively from specialist authorised distributors. A large range of specifically designed Kranzle accessories such as pipe cleaning hoses, domed floor cleaning tools, foam lances, non marking high pressure hoses & wheels and more are available.

If you have high demands regarding the reliability, quality, longevity, and function of the machinery you are buying, you deserve good advice, service and after-sales support from professional, experienced and trained companies. Authorised Kranzle distributors are nationwide.

Further information on the company and their products can be found online: www.kranzle.co.uk and they can be contacted on 01702 603462 or by emailing: sales@kranzle.co.uk

Modified and Controlled Modified and Controlled Atmosphere Systems Atmosphere Systems

Since 1993, Emproco Ltd, established Since 1993, Emproco Ltd, established on 1975, has been designing and on 1975, has been designing and manufacturing a wide range of Modified manufacturing a wide range of Modified and Controlled Atmosphere Systems for and Controlled Atmosphere Systems for application such as food packaging, storage application such as food packaging, storage of fruit, vegetables, grain and flowers and of fruit, vegetables, grain and flowers and CO2 enrichment for greenhouses. Products CO2 enrichment for greenhouses. Products were developed in conjunction with the were developed in conjunction with the Volcani Institute of Agricultural Research Volcani Institute of Agricultural Research Center in Israel. Center in Israel. Our range of instrumentation includes Our range of instrumentation includes on-line food packaging monitors for quality on-line food packaging monitors for quality control of modified atmosphere packaging control of modified atmosphere packaging of products such as coffee, cheese, of products such as coffee, cheese, processed meats, herbs, flour etc. Nitrogen processed meats, herbs, flour etc. Nitrogen and /or CO2 are used to extend the shelf and /or CO2 are used to extend the shelf life of these packaged products. We have life of these packaged products. We have developed instruments that measure very developed instruments that measure very small volumes of residual Oxygen and CO2 small volumes of residual Oxygen and CO2 to ensure the integrity of the packaging. to ensure the integrity of the packaging. For storage of fruit, vegetables, For storage of fruit, vegetables, grains, etc., we have designed multiple grains, etc., we have designed multiple programmable systems that control the programmable systems that control the storage atmosphere according to pre-set storage atmosphere according to pre-set parameters of Oxygen and CO2. These parameters of Oxygen and CO2. These systems use our propriety software to systems use our propriety software to optimize quantity of gases required to reach optimize quantity of gases required to reach the programmed concentrations in minimal the programmed concentrations in minimal time and to maintain these concentrations time and to maintain these concentrations within close tolerances. within close tolerances. CO2 enrichment of greenhouses for flowers CO2 enrichment of greenhouses for flowers and some types of fruit and vegetables and some types of fruit and vegetables provides improved the quality and quantity provides improved the quality and quantity of produce. Our systems use propriety of produce. Our systems use propriety software to optimize and maintain the CO2 software to optimize and maintain the CO2 levels over the complete growing levels over the complete growing cycle in multiple greenhouses. cycle in multiple greenhouses.

We can also design and We can also design and manufacture systems per manufacture systems per customer requirements customer requirements and parameters. All our and parameters. All our instrumentation are designed for instrumentation are designed for high reliability with minimum high reliability with minimum maintenance, which in most cases, maintenance, which in most cases, can be carried out by the end-user. can be carried out by the end-user.

Kecolhaveover25yearsof Kecolhaveover25yearsof experienceinhandlingalltypes experienceinhandlingalltypes ofviscousproductsinthefood, ofviscousproductsinthefood, pharmaceuticalandcosmetics pharmaceuticalandcosmetics markets,aswellasgeneral markets,aswellasgeneral industrialapplications. industrialapplications.

Asampleofproductswealreadypump… Asampleofproductswealreadypump…

Honey Honey PetroleumJelly PetroleumJelly Mascara Mascara Sauces Sauces Lanolin Lanolin LipGloss LipGloss Essences Essences EyeOintment EyeOintment MeatPaste MeatPaste ParaffinWax ParaffinWax FaceScrub FaceScrub TeethingGel TeethingGel TomatoPuree TomatoPuree MedicalAdhesives MedicalAdhesives VeterinaryCreams VeterinaryCreams FruitPaste FruitPaste Toothpaste Toothpaste Malt Malt Jam Jam Wax Wax

T:+44(0)1746764311 T:+44(0)1746764311 E:sales@kecol.co.uk E:sales@kecol.co.uk W:www.kecol.co.uk W:www.kecol.co.uk

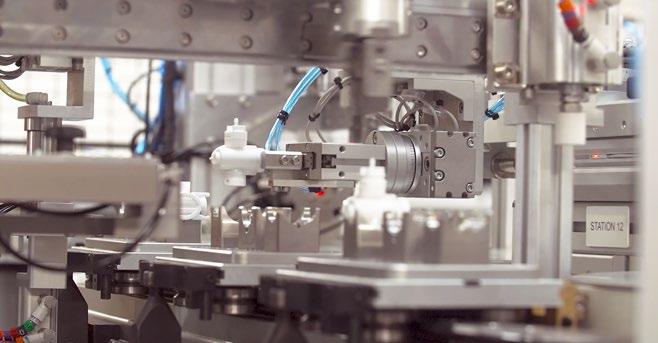

Game-Changing Recyclable Pump Technology Optimises Manufacturing Efficiency

Quantex, a PSG® brand, offers a unique and patented recyclable pump technology that is revolutionising liquid dispensing across industries. From consumer-facing dispensers in retail environments, hotels, offices, & vending machines, to industrial manufacturing lines in factories, Quantex is saving valuable time spent on cleaning, maintenance, and product replenishment, whilst providing an accurate and hygienic dispensing solution for food and beverage liquids.

These revolutionary, lightweight, plastic pumps form a part of the product’s primary packaging, similar to the way a wine tap is already fitted on a bag in box, except, rather than manually pressing the tap that allows the product to dribble out using gravity, the pump is clipped into a standard, low cost motor drive in the fixed equipment, and the product is dosed with precision, at a wide range of flowrates with high vacuum for effective bag evacuation.

When a product supply is finished you simply replace the bag and pump with a new bag and pump which means that no costly pump maintenance or calibration is required. No fluid travels through the fixed parts of the machine and therefore, products can be swapped in and out of the same channels in seconds, without cross-contamination, providing valuable uptime for manufacturing lines.

The pumps are primary container agnostic, so can be attached to a rigid cartridge, pouch, vat, bottle, syringe, or jerry can for example. The simple mechanics in this system mean that equipment footprint is more compact and low cost compared to other pump systems like peristaltic or gear pumps.

The range of pumps available can accurately dose micro-volumes of highly concentrated flavourings or additives from as little as 24µL, to faster flow ingredients up to 75mL/s (or 270L/h). The pumps can handle very high viscosity fluids from honey, jams (with seeds and fruit pieces smaller than 4mm in diameter), mayonnaise, ketchup and relish, highly concentrated apple or orange juice, all dairy products up to the viscosity of sour cream, as well as high acid and high alkaline concentrates.

A reverse cycle capability combined with a valve on the outlet means dispensing can be completely drip-free if required, and there is flexibility with the configuration because the pump can sit above as well as below the product it is pumping.

Quantex offers ‘Dilution’ versions of its pumps where a filtered waterline can be introduced directly into the pump to mix accurately with concentrates. This is particularly exciting for brands who are interested in saving cost and carbon emissions on shipping by taking water out of the distribution channel.

The positive displacement rotary action of the pumps means that fixed volumes are transferred, and by counting the number of revolutions, the motor drive can calculate the amount dispensed in real-time, providing valuable data to IoT platforms monitoring equipment. RFID or NFC chips can tell the machine how fast to run the pumps for each specific product and can transfer information to the cloud about the product’s ingredients and expiry date, for example. This makes product changeover times even faster since there is no need to programme data into systems.

Quantex is already producing its pumps in high volume for several forward-thinking global customers in lights out, white room automated assembly, with air pressure testing, and printed batch numbers for traceability. Quantex was a privately owned company until it was acquired in the summer of 2021 by PSG, an operating company of Dover Corporation, headquartered in Chicago, US. Having the support of a multi-billion-dollar global business behind it means that Quantex is perfectly positioned for rapid growth. The Quantex team now works collaboratively alongside 13 other PSG pump and flow measurement brands, including Mouvex® and Wilden®.

Quantex strives to help its customers meet their business needs, an example of this led to the development of an aseptic version of its pumps. Phil Medcalf, Quantex’s Product Manager, explains the benefits this brought to the customer: “Due to an aseptic version of the BiB19 pump, one of our customers is now able to ship fresh products at ambient temperatures rather than keeping them frozen in transit. This aseptic version of the pump uses a self-piercing foil seal, and the customer gamma irradiates the pump and bag. Shipping ambient product has enabled global distribution as well as reducing shipping cost and carbon emissions – it feels very rewarding to have provided such an impactful solution.”

An interesting application area for Quantex is the burgeoning refill market, where the consumer brings a reusable bottle to refill in a supermarket instead of using single-use plastic, pre-packaged bottles. Quantex’ Director – Marketing, Gillian Harding-Moore, recognised that Quantex provides the key to rolling liquid refill out at scale, and is driving this market segment. She explains: “Quantex is exciting many refill equipment manufacturers, global brands, and retailers, who are keen to meet sustainability goals and reduce single-use plastic packaging waste. Up until now, dispensing food & beverages hygienically and accurately has been challenging, and machines are usually too costly and time-consuming to maintain, but Quantex solves these common painpoints, providing a compact and low-cost, scalable platform. We are at the dawn of a historical movement, changing the way we distribute our goods and shop, and Quantex is at its centre, surrounded by innovators with a collaborative mindset. I am thrilled to be contributing to the sustainability of our planet.”

For more information about Quantex, visit www.quantex-arc.com or email quantex-info@psgdover.com. FDPP - www.fdpp.co.uk 13

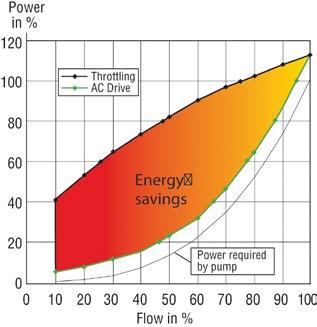

The Frightening Amount of Money You’re Losing and How Quantum’s ‘Try Before You Buy’ Energy-Saving Equipment Will Save You Thousands!

Systems powered by electric motors make up a whopping 40% of the world’s total electricity consumption and 65% in the UK.

However, many companies are unaware of the latest technologies that could significantly reduce energy prices and dramatically reduce global and UK electricity demand by 20% to 30%.

To improve the energy performance of your facility and save costs, Quantum Controls believes in a “try before you buy” approach.

This means business owners and engineers will find significant savings before spending a penny.

To optimize energy use, we look at your system, and test the following: • What is your installation designed to achieve?

• How well is it doing this? • What components are involved? • How do they work together? • On what grounds have they been selected?

• How well is the application still performing?

Installing high-efficiency motors and drives can result in great energy savings, providing that the installation works as intended in its current setup.

But frequently, users, eager to benefit from energy savings, fit drives in installations that are not properly set up. This may well lead to some energy savings, but the savings achievable by putting the process right would be much greater. 14 FDPP - www.fdpp.co.uk WE CAN HELP

Quantum Controls will come to your site and look at maximise the energy efficiency of your machinery before considering any energy solutions.

Our secret is to get the process right first and then investigate where potential losses occur.

For example, if a system – a conveyor belt, for instance – is frequently running empty, it may be useful to be able to start and stop it according to demand, using a variable-speed drive, without having to think of start-up. This will be a great boost to energy savings. And your bottom line.

If an application runs frequently with a low load, it can be a good idea to look at synchronous reluctance motors, which often halve losses in low-load conditions.

Optimising energy use is about identifying when energy is used for a purpose, and when it’s not.

The Quantum Controls Q360 Site Survey audit is a good first step toward ensuring that your plant is operating efficiently.

Quantum Controls has for many years offered a more in-depth solution by backing up these surveys with hire trials, whereby you get black and white results with regards to the energy savings available.

We will measure the energy consumption as it is today, then measure again whilst under the new method which is simulated using temporary hire equipment.

The Q360 Energy Survey looks at all aspects of the site surrounding the use of VSDs and power quality, considering all impacts the equipment can have on the site, and looking at all avenues of potential risk and rewards available, with or without the need to purchase new equipment.

For £650 we will do a full day’s audit split into 5 main sections, integrating all of the key areas.

HOW DOES IT WORK?

1. Power Quality We analyse the power factor and harmonics on-site as well as the transformer loading %, we also look at the bill and work out what you could save by improving the power quality, in this section will be general information on harmonics and PF, and what it means to the supply, plus site specific information based on what we found.

2. Asset Integrity We look at the existing assets, and their age, lifecycle position, maintenance history, failure history and general condition, in this section we group the assets into categories, active obsolete, soon to be obsolete etc, and give them a colour coded rating of what would be most damaging in the event of a failure, which items are the highest risk and would take the most work to repair / replace in the event of a breakdown. Recommendations will be made with regards to longevity of the asset life and risk exposure.

3. Asset Optimisation We have a look at the settings and setup of the VSDs to see how they are running, and we again make recommendation based on changing the control of the assets you already have to ensure they are getting the most out of them, both in terms or process control and energy efficiency, looking at things like parallel pumping, flux optimisation, duty standby control, PID control etc.

4. Energy saving upgrades This section of the survey would look at where upgrading and replacing assets would offer than an increase in energy efficiency, more in line with your typical energy report, however, we will use our three-phase logger to show what the load is right now, and predictions based on anticipated savings, the recommendations on this would be along the lines of hires to prove savings, or quotes for the upgrade where it’s beyond doubt.

5. Observations and Recommendations

This is an overview of the above sections with recommendations given financial savings, and also general engineers observations, such as filter media was dirty in all panels, or panels we excessively hot etc.

It will also bring all sections of the report together, in that we will consider the impact on Harmonics and power factor that the recommended VSDs will have, we will also offer guidance on where we feel the biggest benefits will be found and prioritise the actions recommended.

Take your first step into reducing the costs of your plant the planet and ensure you’re operating effectively by getting in touch today at service@quantum-controls.co.uk or +44 (0)1661 897332 and book your no-obligation free trial.

Handling the Appetite for Plant Based Meals

Global demand for meat and dairy free plant based products has seen tremendous growth, with sales reaching an all time high in 2021 of £800M.

As plant based meat and dairy free product demand soars, and with the market growing over 74% during the past 3 years (source:plantbasednews.org), food manufacturers may be wondering how should plant based Meats and dairy free food be handled, and if they should be dealt with differently?

PLANT BASED FOOD MANUFACTURE

Plant based foods can be crafted in a variety of ways once ingredients have been combined in mixer. One way is by extrusion cooking where thermal and mechanical forces are placed on food within a screw extruder to create shear, altering the protein structure and texture of food. This can create chunky meat like textures similar to those found in a thick fish fillet such as Salmon.

Other methods may involve a wet texturiser process which is used to add moisture in conjunction with starches or other fibres to alter a products texture. These methods can be combined with other processes such as dextrinisation (toasting) where heat is used to break down the sugar within starches, creating a toasted flavour as the food is browned.

PUMPING CONSIDERATIONS

As food manufacturers look to transfer new blends of food into extruders, machinery or process what considerations should be given to pumping equipment?

Some blends of plant based foods can be drier than meat based alternatives meaning they are more difficult to pump. If their viscosity is so high than the fluid does not flow, then pump selection can become extremely limited, in particular if a mechanical feed is required to ensure the pump inlet remains flooded, clogging does not occur and that controls are in place to ensure that the pump does not operate without fluid - damaging itself.

The solid handling capability of pumps will need to be carefully studied to ensure that any soft solids remain intact or if any large solids or textures are ok with being compressed are handled appropriately. Similarly if any process trialed at pilot plant level, that the solution is scalable to meet increased demand at higher output.

As plant based ingredients are yet to meet industrial scale quantities, availability and most importantly price point, ensuring high value ingredients are metered and dosed accurately into process ensures full cost control, especially during a time where plant based foods remain more expensive than their meat counterparts and cost is ever increasing. is another key consideration– where the recipe for plant based meals can change suddenly due to key ingredient shortages as we have seen with sunflower oil, seasonality or simply changes in recipes or new adoptions in consumer taste. Whilst Milk traditionally thickens when mixed or pumped at high speed (Shear Thickening & Newtonian in nature), non dairy milks such as Coconut or Hazelnut Milk can be shear thinning and non Newtonian in nature.

Having the ability to handle fluids according to their rheology, and across a wide viscosity range will ensure any changes in fluid thickness or texture can be easily accommodated, future proofing your process.

All in all, the correct pump technology will be the pump which achieves your outcome, without compromise to the fluid or process at the lowest lifetime cost.

If you are looking to handle plant based or dairy free products, visit www.northridgepumps.com or contact us on 01773 302 660 to see how we can help. Mechanically Fed Hygienic Pump

We’re pump specialists, so you don’t need to be

Sanitary Pumps Engineered for Your Process

Optimise performance with specialist support

Whether you’re dealing with clogging, separation, downtime, or other issue - it’s costly. Time wasted troubleshooting and lower production mean missed targets and less profit. A sanitary pump is the solution but choosing the right one feels like stepping into a minefield. You know what you need it to do but with so many options, it’s difficult to know which is best for your process and parameters.

+ Accelerated stator wear + Clogging + Changes to fluid consistency + Clean-in-place and sterilise-in-place hygiene issues + Crushing of sensitive products + Inconsistency in finished product + Inaccurate transfer of flavourings or ingredients + Liquid separation + Seal wear or failure We’ve been engineering sanitary pumps for sectors such as distilling, brewing, food manufacturing/processing, and more, for 20+ years. We understand industry-specific processes and know what it takes to optimise performance through better-suited pump design - giving you complete peace of mind.

EXPERT GUIDANCE:

Our expert engineers understand your process and guide you through the options, so you can confidently select the most suitable sanitary pump.

EXAMPLE PRODUCTS:

+ Abrasive mixtures + Creams, milk & ice cream + Edible oils & fats + Fish & meat + Fruits eg. cooked apples, plums, berries, grapes + Grains & seeds + Pastes & purees + Syrups, juices & alcohols + Vegetables & peelings + Waste eg. trimmings, packaging & offcuts + Sheer sensitive liquids + Solid laden or viscous mixtures

Optimise Your Liquid Batching System: 5 Flow Meter Considerations

Titan Enterprises, a leading provider of flow metering solutions, have been designing and manufacturing accurate and reliable flow meters for batch control systems for over 40 years. Titan reports on the considerations required when choosing a flow measuring device for batching control.

Titan has published a white paper on the use of ultrasonic flowmeters in high-speed batching but here we focus on the general batching system. We discuss five key considerations when choosing a flow meter that will ensure your batching process runs smoothly.

Probably the most recognised batch filling system is that of beverages, either directly into a glass or into bottles. But batching systems are also integral to the pharmaceutical and medical, and chemical and oil industries. Additive injection or chemical dosing are typical applications where flow meters are used to precisely control the amount of liquid dispensed, which is critical in such processes.

1.Repeatability is essential for a productive batching process

Multiple uncertainties can change the amount of liquid being dispensed, causing 18 FDPP - www.fdpp.co.uk

a negative effect on the repeatability of the system. Controlling as many process variables as possible will help to ensure the accuracy and repeatability of flow measurement. Flowmeters, such as Titans’ mini turbines, can boast repeatability of 0.1% or better when operating under the same conditions.

2.The physical properties of the batch-filled liquid will dictate equipment requirements The choice of flowmeter may be limited by the properties of the liquid – whether it is viscous, volatile, corrosive, flammable, or contaminated with particles, for example. An oval gear flowmeter would be ideal for batch-dosing high-viscosity liquids such as syrups, whereas a turbine flow device, such as Titan’s 800-series flowmeters, are more appropriate for water and beer dispensing.

3. Maintaining constant process conditions

Changes in flow rate, temperature and pressure may cause the flow meter to function in an unpredictable dynamic way. Although maintaining operating parameters at a stable point is optimal, this may not always be possible and fluctuating flow rates for example, can be compensated for by using a higher specification measuring device, such as Titans’ Atrato® ultrasonic flowmeter.

4. Constant liquid flow or pulsations?

Keeping the overall flow constant and avoiding any pulsations within the batching system will prevent aliasing and incorrect flow readings over the batch operating cycle. If pulsation is inherent, the choice of flowmeter is crucial in mitigating the effects of pulsating flow.

5. Limiting system inertia

Simple adjustments to the batch system design, such as control value specification and the positioning of the flow meter, can help to offset the effects of inertia.

Choosing the correct flow meter for a batch system can be complex and Titan Enterprises are happy to help you find the best flow meter solution for your process and plant.

For further information on Titan’s flowmeter and instrumentation range or to discuss any process and technical issues, please contact Titan Enterprises on +44 (0)1935 812790 or sales@flowmeters.co.uk. Visit our website at www.flowmeters.co.uk

Snap-on’s Level 5 tool management system guards against FOD

Engineers and technicians working in the food and drink processing and packaging industries are well aware of the possible consequences of tools going missing. Foreign object damage (FOD) is a threat in any manufacturing or line maintenance workplace, especially those where food or drinks are being produced.

Keeping track of every tool and item of equipment presents a major challenge, making professional tool storage and management more important than ever. Snap-on Industrial’s Level 5™ automated tool management system constantly tracks every tool, advising with voice announcements which tools have been removed or when they are returned, ensuring greater protection against FOD.

It also enables engineers and technicians to find every tool they need quickly, saving time and easing stress. Major benefits of the system include: • No individual tool scanning required; • No RFID tags to install or replace; • No limitations on tool size: from ¼” screwdriver bit upwards; • Intuitive interface, via touchscreen; • Audible voice confirmation of tool removal and replacement; • Automatic locking for maximum security; • Errors announced and displayed to indicate incorrect tool position or advise when a drawer is not closed.

Says Richard Packham, Director UK & Europe for Snap-on Industrial: “Snap-on’s automated system takes tool management to an entirely new level. The ability to monitor several boxes from one central computer offers managers a huge time saving advantage.”

For more information visit: www.snapon-industrial.co.uk; call (01536) 413904 or e-mail: industrialuk@snapon.com

Metering accurate steam use in dynamic industrial processes

In commercial brewing — as with other food, chemical, or industrial processes — control over steam heating can have significant influence on process costs and consistent quality in the final product. But its measurement and control can also be impacted by unique circumstances of those applications. Here is how changing just one aspect of steam measurement brought economy and consistency to multiple aspects of a brewer’s overall process.

DON’T COMPROMISE YOUR PROCESS

In general, having uninterrupted, accurate steam measurement can make noticeable differences in the viability of specific processes and other facets of business operations: prices rising significantly, having pinpoint control over steam measurement can minimize excessive consumption and its associated costs.

• Process Efficiency. Retrofitting existing temperature-critical applications with the addition of a compact drop-in meter unit can refine steam measurement and control to improve process efficiency and consistency without extensive capital investment — even in space-constrained applications.

• Product Quality. The volume, timing, and consistency of steam delivery can impact the quality and consistency of the final product. Problems can manifest themselves as noticeable differences in physical composition or taste related to inconsistent steam heating. Each industrial process can have its own unique demands that impact the rate and volume of steam required and the way in which it is measured. As with other gas or liquid process line measurements, steam piping’s size, shape, and constrictions/ restrictions can impact the accuracy of a meter’s output. Paying attention to such influences can lead to better, more accurate, and more cost-effective meter selection.

In food and beverage applications, however, deviations in precise steam measurement can do more than just impact production costs and profit margins. Resulting inconsistencies that influence the taste or texture of a product can actually damage consumer perceptions and brand reputations. In the brewing industry specifically, the acquisition of

smaller, older brewing operations with existing structural limitations can create challenges for global brewing companies trying to standardize on a common process or equipment layout at all their breweries.

ESCAPING THE VORTEX OF BREWING PROBLEMS

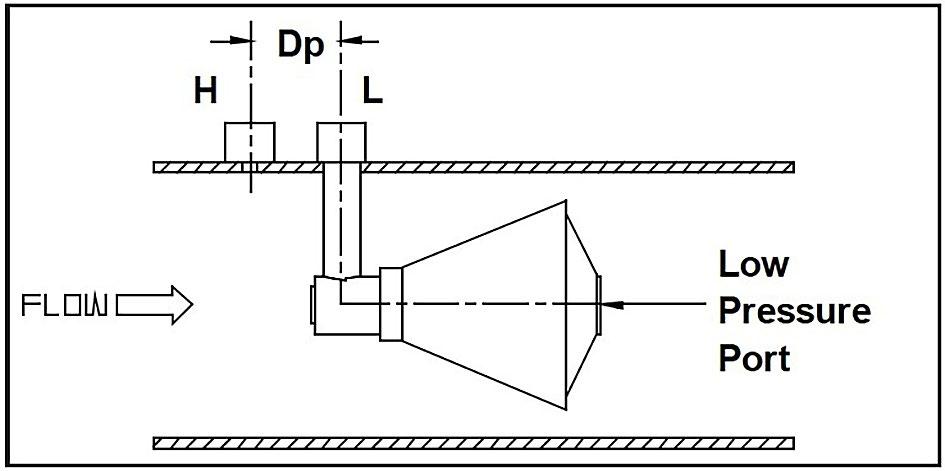

Brewing beer is a prime example of how steam measurement can impact production conditions. In the following example, a brewery switching from vortex meters to V-Cone differential pressure (DP) meters (Fig 1) benefitted from the opportunity to refine steam measurement and provide more finite control over its wort boiling process. This steam calculator demonstrates just how large the annual benefits can be, based on user-supplied variables for pressure, line size, and flow rate.

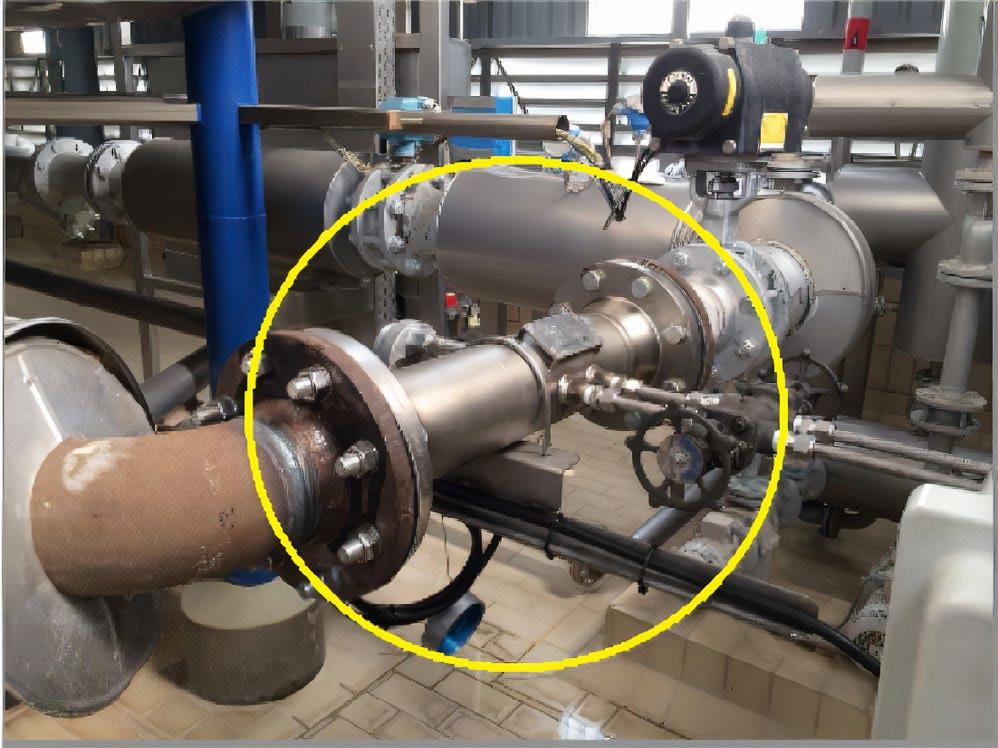

Fig 1. A V-Cone DP meter compares the differential between the high-pressure flow (H) before the cone and the low-pressure port opening (L) on the back of the cone. Because the cone forces turbulent flow out to the periphery of the pipe, the meter is unaffected by turbulence generated from turns or obstructions located immediately upstream of the meter.

Accurate temperature control is a critical to any wort boiling kettle, since it is a sensitive process and one of the most energyintensive aspects of beer production. In this case, the kettle is a large vat with tubing coiled around the exterior wall. The tubing carries a mix of steam and water to heat the wort in the kettle. Modulating the proportion of steam vs. water in the tubing enables the brewery to control the thermal transfer profile of the batch process.

The wort boiling process demands a high volume of steam in its initial phase, enough to bring the large batch up to temperature quickly but without burning the wort at points of direct heat transfer. Once the entire contents of the wort kettle reach a boil, a much lower rate of steam feed can then be used to maintain a desirable temperature for the remainder of the heating cycle.

Variability in steam demand across the 12-hour process — plus the fact that the accuracy of the previously installed vortex meter suffered when running at extremely high or extremely low flow rates — exacerbated the difficulties of steam measurement. Inaccuracy at the high flow rate needed to bring the wort boiling kettle up to temperature could cause overconsumption of steam and even result in some burning of the wort. Also, once the wort kettle achieved a full boil, inaccurate readings from the vortex meter often resulted in cyclical overshooting/ undershooting of the ideal steam flow rate as the system tried to maintain a consistent temperature. This was particularly troublesome at the lower flow rates (< 300 m3/hr) demanded for about half of the total heating cycle. Unfortunately, at those flow rates, eddies and irregularities in flow through the vortex meter caused the resulting calculation to become inaccurate. Even as some unknown volume of steam was still getting through, the meter often registered zero flow. When that happened, the brewery was forced to manage the process by instinct.

The same vortex meters had performed appropriately in larger brewery installations having sufficient lengths of straight-run piping but could not generate accurate readings at low flows in a more condensed environment crowded with fittings and tight turns. Turbulence created by the tight piping configuration contributed to occasional loss of readings. The dropout of those readings left the brewery with a blind spot in the control of their heating process.

Figure 1

Since steam is a gas, whose volume is affected by temperature and pressure, the raw flow readings from the vortex meter required separate compensation calculations to be interpreted accurately. In this case, separate inputs from the vortex meter, a resistance temperature detector (RTD), and a pressure transmitter all feed into an algorithm in the digital control system (DCS), where the compensating calculations are performed.

By contrast, the replacement V-Cone meter included differential pressure, temperature compensation, and pressure compensation in one unit, so it could calculate and transmit accurate readings even at low flow. The unit in turn provided a temperature-compensated and pressure-compensated 4-20 mA signal to the DCS system. It used two DP cells — one focused on the low range (0 to 50 percent) and one on the high range (51 to 100 percent) — to deliver + 0.5 percent accuracy from zero to full scale (10,000 m3/hr) with turndown ratios as high as 50:1.

FAVOURABLE PERFORMANCE = FAVOURABLE OUTCOMES

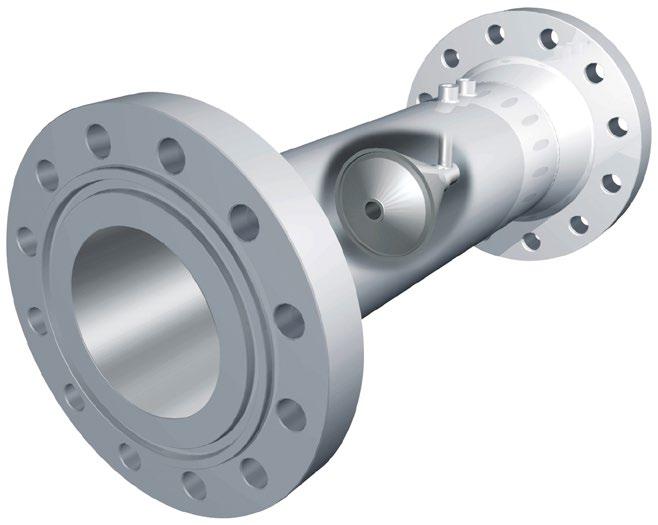

Once the V-Cone concept was proved at the first brewery, it was then rolled out to similar applications at several related breweries. The practical outcomes gained from switching to the V-Cone meter (Fig 2) provided the brewer with multiple benefits:

• The high turndown ratio on the V-Cone operation lets the brewer maintain precise readings at high temperatures to bring the wort to a boil and constantly refine the simmer to maintain a lower temperature toward the end of the cycle. • Knowing the correlation of steam volume to process temperature provided a timelier understanding of the heating process, without delays that can be introduced by direct temperature sensing methods.

• The breweries experienced an average 40 percent reduction in steam consumption derived from the fact that they: 22 FDPP - www.fdpp.co.uk

• were not running the boilers unfettered at maximum heat to start the process, • were not overrunning targeted boil temperatures in the middle of the process, and • were able to use proportional integral derivative (PID) control to sustain a lower but more consistent cooking temperature after the initial boil. • A totalizer on each V-Cone package collected analogue readings at userdirected intervals and wrote those readings to digital files for process monitoring and subsequent analysis.

Fig 2. The V-Cone meter circled in this photo eliminates the need for extended straight pipe length requirements upstream and downstream of the meter. The previously used vortex meter still visible in the background had suffered from turbulence caused by the lack of sufficient straight-run piping.

Beyond process efficiency, another valuable advantage to global brewing organizations is the ability to maintain a very steady and repeatable process from brewery to brewery, country to country, and continent to continent. Doing so helps them maintain consistent product quality and a clean, crisp flavour for their flagship brands. The V-Cone meter’s ability to fit easily into existing infrastructure can also contribute to both improved capital expense (CAPEX) and operating expense (OPEX) spending.

HOW A V-CONE METER REDUCES COMPROMISE

Whether an application involves steam, gas, or a non-viscous liquid in brewing or other industrial processes, the nature of a V-Cone DP meter eliminates many of the limitations of other meter designs. Because the shape of the cone within the pipeline conditions the flow around the periphery of the pipe (Fig 3), it eliminates any pre-existing turbulence in the upstream flow to protect reading accuracy. This makes the V-Cone design an attractive and affordable choice for + 0.5 percent accuracy even in congested piping configurations featuring elbows (single or double), valves, step downs, and other structures that can create havoc for other types of meters. This video demonstrates those V-Cone principles in practice.`

Figure 2

velocity profile of the steam as it approaches the meter (left), flattening it into the shape of a well-developed profile. The short vortices formed at the back end of the cone (right) create a consistent pressure profile to establish the differential pressure between the flow at the front of the cone and the open port at the back of the cone.

CONCLUSION - BETTER BREWS, BETTER BUSINESS RESULTS

Whether changing demands are due to organic growth or corporate acquisitions, being able to improve steam measurement and control with a meter that is more compatible to the process enables breweries and other process industries to optimize both product quality and production efficiency. The V-Cone meter’s ability to fit easily into existing infrastructure can also contribute to both improved capital expense (CAPEX) and operating expense (OPEX) spending.

Fitting a V-Cone meter spool piece as short as 18” into an existing piping layout can eliminate the need to expand, move, or replace existing piping infrastructure, with all its attendant CAPEX equipment acquisition and labour costs. In turn, improved steam measurement accuracy not only reduces the OPEX cost of wasted energy consumption, but it can also minimize costs for extra quality control testing or even the dumping of bad batches.

Equally important, providing the information needed to match control of the heating source more closely and more consistently to the dynamics of the process provides greater consistency. That helps to ensure more dependable outcomes that standardize product quality, maintain high customer satisfaction, and reinforce the brand reputation of the manufacturer.

Revolutionising printing

As we enter the second half of the year I have tried to reflect on the past 18 months of trading., All I can think is WOW! What just happened.

We have introduced a revolutionary polymer resin based HP 2.5 thermal inkjet cartridge in to the U.K. Market.

Also we have introduced new state of the art equipment into our range of products. Above all we have established our company and gained new and exciting customers and made great alliances with several U.K. Manufacturers

Business has been very steady and has helped the company grow at a comfortable rate. own inks, so you will be purchasing direct from source rather than a third party supplier.

Our aim is to research and develop high quality inks that require no intervention by operators. Increasing uptime, reducing cost’s and provide the best service to our customers, making any purchase a pleasurable experience.

DISTINCTLY DIFFERENT THERMAL INKJET

Unlike competitor TIJ inks that require constant maintenance & wiping,

POLYtij ® PERFECTA ® range of inks; Limitless Plus & Barcode inks offer significant operational and print performance advantages over all other TIJ inks available in the global market today. With unrivaled 24 month shelf life and the best thermal inkjet adhesion qualities on the market today

POLYtij ® PERFECTA ® BARCODE and POLYtij ® PERFECTA ® Limitless Plus inks offer superior printabiliwty and are first print perfect after 15min, 30min,1hour, 8hour, 24hour & 72hour shutdowns.

POLYtij ® PERFECTA ® Plus & Barcode HP thermal inkjet inks eliminate human intervention that causes factory operators to break cartridges due to The daily handling of them when removing them at the end of the workday so that they do not dry out and re-insert them the next day.

Digital Ink Technologies Pty Ltd is an official HP SPST TIJ2.5 filling licensee.

DISTINCTLY DIFFERENT

THERMAL INKJET

Polymer thermal inkjet technology is unique. It is the only TIJ 1.0 and TIJ 2.5 thermal inkjet ink containing polymer resins.

Like other printing technologies such as continuous inkjet (CIJ) and Thermal transfer overprinters (TTO) it is the polymer resins that offer the high adhesion on glass, metal and most plastics used in the fastmoving consumer goods market.

Hence POLYtij®in ks offer superior adhesion of more than 50+ rubs on most substrates whilst offering long production ready times. This means our inks offer the best ink delivery volume of any nonporous cartridge in the market today thus maximising your production uptime.