4 minute read

BCMPA

Record turnout of BCMPA members at Packaging Innovations confirms increasing importance of 3rd party outsourcing

This year’s Packaging Innovations event at the NEC hosted no fewer than 20 members of the BCMPA - The Association for Contract Manufacturing, Packing, Fulfilment & Logistics - in its Contract Pack & Fulfilment (CP&F) zone, with visitor numbers demonstrating significant demand from retailers, brands and new entrepreneurs for fully integrated and robust 3rd party supply chain partners.

From product manufacturing, filling, contract packing to end to end delivery, BCMPA members fielded an extensive range of enquiries from new prospects in a wide variety of sectors including Food, Nutraceuticals, Personal Care and Household Chemicals.

Almost 6,000 visitors visited the Packaging Innovations show, with the CP&F area proving popular on both days. In addition, the BCMPA sponsored panel exploring the challenges and current innovations in e-commerce and fulfilment, was a highlight, with strong engagement and interest shown by attendees.

Chaired by Emma Verkaik, Membership & Marketing Director of the BCMPA, attendees heard Neil Daniells from Prolog Fulfilment, Laura Palmer from PHL Group and Glenn Hayes from Worldwide Logistics, set out the benefits for brands and retailers, old and new, of using 3rd party co packers and fulfilment houses, from scale up to end-to-end distribution to customers.

In particular, the recent exponential growth in the number of businesses trading as resellers for online platforms has further increased demand for resilient and dependable third-party outsourcing suppliers – an area that BCMPA members have been able to embrace with speed and agility, by offering FBA and a full range of e-commerce fulfilment services.

Verkaik said, “We have exhibited at half a dozen shows this year, and at each one, the trend has been the same; whatever the sector, clients are becoming increasingly convinced of the importance of speaking with experts about the provision of an effective 3rd party supply chain, and the BCMPA has been able to introduce them to members active in their sector.”

“It was fantastic to be out again at our flagship show, and as we now represent over 200 members, we are already excited for 2023, when we fully expect the BCMPA Contract Pack & Fulfilment zone to grow still further.”

Emma Verkaik, Membership & Marketing Director of the BCMPA

Pepperl+Fuchs Presents New Portfolio of Vibration Sensors for Optimum Plant Availability

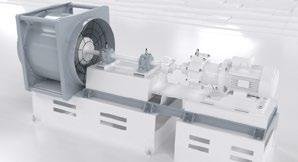

From milling machines to pumps and fans to wind turbines—wherever vibrations occur, condition monitoring and predictive maintenance play a crucial role in ensuring personnel and plant protection.

To perform reliable measurements of vibration velocity and acceleration in low or high-frequency ranges, Pepperl+Fuchs offers three new vibration sensor series. These devices for global applications come with approvals for hazardous areas up to Zone 1/21 and Div. 2 and certifications for functional safety SIL 1/ PL c and SIL 2/PL d—meeting the highest safety requirements.

THREE DESIGNS FOR VARIOUS REQUIREMENTS

Unlike comparable products, Pepperl+Fuchs vibration sensors boast a particularly wide measuring range, capable of measuring vibrations of up to 128 mm/second. These sensors stand out with encapsulated electronics in a rugged, compact housing due to their maintenance-free operation and exceptionally long service life. They are available in three designs with different functional ranges: The VIM3 sensors (coming soon) are the most miniature vibration sensors in the series, suited for less complex applications.

They are certified up to SIL 1/PL c for use in safety applications.

The sensors of the VIM6 series are designed for use in high-temperature areas, where they are deployed to measure temperature and vibration. An analogue output is available for each measured value. The VIM6 series is available with duplex steel housing and is approved for use in hazardous areas up to Zone 1/21. The VIM8 series with encapsulated electronics (coming soon) is designed for use in harsh environments and Zone 1/21 hazardous areas and offshore applications. The sensors come with SIL 2/PL d approval and a temperature range of -35 ... +125 °C. In addition, the vibration sensors are equipped with many sophisticated functions. For example, by means of the integrated crest function, the condition of machine bearings can be monitored, and machine downtime or failures can be prevented before damage occurs. Optionally, users can define two limit values via rotary switches. Once these values are exceeded, they are output via two relays for predictive maintenance purposes. This eliminates the need for extensive software development to evaluate the signal values in a PLC.

In turbines and other machines, the vibration sensors by Pepperl+Fuchs reliably measure vibration velocity and acceleration.

www.pepperl-fuchs.com

Building on experience. Driving technology. Maximizing performance.

Ultrasonic Sensor Series UC18GS with IO-Link

The new UC18GS series combines the advantages of ultrasonic technology with powerful features to create a sensor solution that meets virtually any application challenge.

For more information, visit pepperl-fuchs.com/pr-UC18GS