14 minute read

TSS International - First orders for LC300 Armour mobility products received!

FIRST ORDERS FOR LC300 ARMOUR MOBILITY PRODUCTS RECEIVED!

TSS is proud to announce that the first orders for serial production Armoured Toyota Land Cruiser 300s have been received. The carefully composed package of Armour Mobility products has been approved by several of our armouring customers.

The package consists of, among others:

• TSS Heavy Duty Wheels have been approved by TüV for a 2250kg payload! Combine our 8,5x18” rims with Rodgard BPX

Runflats and a heavy Duty Tyre of your choice, such as the

Maxxis JRZ Bravo 275/70R18, to carry the extra weight of your vehicle’s protection. • The first TSS ProtecTank® : The only true self-sealing fuel tank technology on the market. Tailor-made to fit the Land

Cruiser 300, to add protection and save weight in the armouring package. • MOV’IT Security: Heavy Duty Brakes, tailored to the increased weight and changed weight distribution. Consistent braking power with an OEM-compatible, integrated parking brake! The first complete vehicle system (front and rear axle) has been successfully tested!

• TSS/JRZ Heavy Duty Suspension: high quality suspension systems for all budgets and driving styles. A KDSS-compatible version is also available!

• SKYDEX shock mitigation products: for that last bit of protection to pass the new VPAM ERV VR7 or VR9 Standard with

Bio-Fidel dummy! • B&G Intercom Systems: Discretely installed two-way communication systems, with speaking power up to 250W!

Customisable sirens and red/blue/yellow LED-lights are also easily integrated.

Since the launch of the new Toyota Land Cruiser 300 in the summer of 2021, many vehicle converters around the world have been putting all their efforts into designing new armouring packages for this vehicle, to provide the best possible protection for Aid Workers, Police, Defence- & Security Forces and Government Officials all over the world.

The quality of the armouring plays a large role in the protection of the occupants against bullets and other ballistic threats. However, the mobility of the vehicle determines how long the occupants can make use of that protection. Keeping on the move is key to the survivability of the vehicle.

That is why TSS International specialises in the mobility of armoured vehicles. Over the past 10+ years the company has supplied hundreds of armoured versions of the highly successful Land Cruiser 200 with Heavy Duty Runflat Wheel Assemblies, Security Brake Systems, Self-Sealing Fuel Tanks, Vehicle Intercoms. A complete package of products carefully designed and selected for the highest level of safety and security: Armour Mobility! Through close collaboration with customers and suppliers, TSS International’s goal is to deliver a tailored package of mobility products, designed for strength, reliability and durability.

Other platforms that have protected their mobility with TSS products since its founding in 1976 include MB-G Class, MB-S Class, Nissan Patrol, Chevrolet Suburban, GMC Yukon, MB Sprinter, Boxer 8x8, BMW 7-series, Lexus LS & LX570 and many, many more. products and services. Where possible, we test our products at renowned institutions such as TüV, TNO, Beschussamt, and our quality management processes are ISO 9001:2015 certified by Lloyds.

For more information and more products, please - visit our NEW website www.TSSH.com - email us at sales@tssh.com or - phone us via +31 180 618 922.

TSS International BV will be participating in Eurosatory 2022, from 13-17 June in Paris Villepinte. Contact us now or click the button to schedule a meeting! Click here

THE PROGRESSION TO HIGH FIDELITY SURVIVAL TRAINING

If risk is involved accidents happen. In the event of a catastrophic incident, survival rate is frequently dependent on prior training.

Those who fly aircraft or operate boats or vehicles: over, on, or near the water are subject to the risks of ditching and frequently overturn.

They are faced with a survival situation potentially of sudden impact followed by being turned upside down and immersed in cold water. Reaction has to be intuitive, reflexive, and based on muscle memory skill sets learned in high-fidelity training environments. Training for these critical skill sets are among the most difficult subjects for individuals who form crews of military aircraft, vehicles or water-craft to achieve when upside down and/or under water and escape, or egress, become the priority and the necessity. Survival Systems Limited (SSL) of Nova Scotia, Canada, is an acknowledged expert in provision of safe, highfidelity simulator systems used in training for these eventualities. Commercial industry and militaries worldwide have trusted SSL as a partner relied on for 40-years due to it’s dedication to enhancing and preserving workers’ lives through safety education, training technologies, and applied research and development. SSL’s Founder, Albert Bohemier, a former Royal Canadian Air Force, Sea King Pilot, became acutely aware that the pilot and aircrew ditching survival rate was extremely low. Albert and others in the aviation industry set out to correct this. Naturally this focused on training helicopter aircrew based on the unreasonably high percentage of ditchings resulting in fatal accidents that involved drowning whilst trapped in the helicopter. why helicopters were crashing, what happened when they did crash into water (usually inversion based on the high centre of gravity associated with engine mass being on top), what happened during the crash, and what happened after the aircraft had stopped moving.

Early training to help aircrew survive a ditching was actually exacerbating the problem. Defence forces were primarily, and almost, the only operators of helicopters over water. Along with Defence having major concerns, helicopter manufacturers and survivors of incidents became determined to prevent their colleagues undergo similar fatal consequences. There was a need to understand the training required, the equipment to facilitate such training, and the mechanisms to deliver the training.

Research and development had shown that disorientation is a significant factor in ditching fatalities. To help in the development of training outcomes to counter disorientation, the psychology and physiological effects of disorientation had to be defined, understood, and be repeatedly replicated in a safe, controlled training environment. To ensure that the training environment replicated the operational environment and allowed the trainee the best opportunity to learn the required egress skill sets whilst experiencing the effects of disorientation, a high-fidelity training simulator was required. This simulator needed to replicate the aircraft in terms of airframe configuration, exit function, seat position and aircraft furniture in relation to exit, harness operation, etc. Trainees needed to be trained in the equipment in which they operate to afford them the highest degree of realistic training and probability of survival.

Thoughts in the aviation industry were initially to utilise an actual helicopter airframe cleaned up and stripped to produce a mock-up of the helicopter for which incumbents were being trained. These first so-called Helicopter

Underwater Egress Trainers-HUET were not suitable for repeated training evolutions they were neither robust enough to withstand chemically treated water nor could they be quickly adapted between roles e.g. from anti-submarine to search and rescue.

A major point of consideration has always been trainee safety. Using an actual airframe is not practical and does not have the requisite safety features required for safe high-fidelity training. To facilitate safe, high-fidelity training Survival Systems Limited developed and manufactured the Modular Egress Training Simulator METS® . Safety characteristics incorporated into the METS® include, but are not limited to, floor and roof grating to minimise water retention on raising the simulator out of the water, high-fidelity exit design, exits able to be operated from within and from outside the METS® , harness Emergency Release Systems, accurate representation of mission furniture. These are but a few of the design features that are standard in SSL’s METS® where the priority is trainee safety.

Cost effective, efficient, multi-role, safe training solutions are paramount when Defence Forces choose their training system. Defence Forces have multi airframes in different services (Air Force, Army, Coast Guard, Marines, Navy, and Special Forces etc.) and operational roles that will necessitate different training platform configurations to deliver effective training. SSL has led industry innovation in developing the Modular Egress Training Simulator (METS®) with variants suitable for various vehicles and vessels. The METS® was developed to provide a number of airframe configurations on one platform model through its modularity. One METS® (e.g.; METS® Model 40) is able to be configured in a multitude of airframe types, as well as specific operational roles (e.g.; Search & Rescue, Anti-Submarine Warfare, Utility etc.). The METS® is very quickly reconfigured from one aircraft configuration to another thus allowing the training provider to utilise the same METS® model to change from one aircraft type or role in the morning and another in the afternoon for example.

In the continuum of a ditching event once the aircrew egresses the airframe the situation has not ended. Survivors are then faced with surviving at sea. This is contingent on how the individual copes with the survival equipment available to them and the environmental conditions in which they are now immersed. Survival in open water environmental conditions could mean coping with the effects of: cold water, waves, wind, sea spray, rain, lightning, fog, night conditions etc. Survival Systems Limited has developed a complete training theatre that allows trainees to learn necessary sea survival skill sets in a high-fidelity environment that simulates all environmental conditions that could be experienced. SSL designs and equips each Survival Training Simulation Theater (STST™) with high fidelity simulators and training practices with safety at the forefront. The SSL’s STST™ is equipped with proprietary integrated systems including personnel-rated lift systems that are fully redundant, a unique SSL provision, (no single point of failure), CCTV systems to record events and used in after action training as well as emergency E-Stops that are located through the theatre and at the theatre operator station should the need to stop the simulation for safety reasons arise.

The initial emphasis on helicopter ditching was largely because that was where the initial need was identified. Over time the training requirement evolved. SSL has led users and the industry and has adapted and expanded the METS® model inventory to include specific platforms such as; fixed wing airframes including JET modules, attack helicopters, amphibious assault vehicles or indeed any vehicle operating close to water where an overturn is possible even 4x4 vehicles, small boats, light aircraft, etc.. The latest METS® variant is the METS® Model Rigid Hull Inflatable Boat (RHIB). Survival Systems Limited (SSL), incorporated in 1982, is located in Dartmouth, Nova Scotia, Canada. SSL is committed to the preservation of human life through the development of technologies that provide realistic survival and safety training while addressing risk at all levels of the process. The company is a leader renowned worldwide for its proven; record, experience, on-time and within budget delivery, advisory role and trust in industry, survivor testimonials, client references, research into human factors, and reputation.

SSL is the Original Equipment Manufacturer (OEM) of high-fidelity Modular Egress Training Simulator (METS®) devices; integrated Personnel-Rated Lift Systems; high-fidelity Environmental Training Aids; and Modular Fire & Rescue Simulators. The all-inclusive integrated services include design consulting, manufacturing, producing, commissioning, training, warranty, and servicing of the complete product line. SSL has delivered 117 METS®; 63 Personnel-Rated Lift Systems; 90+ Environmental Training Aids in more than 30 countries. We have previously provided Survival Training Simulation Theater (STST™) turnkey solutions to the United States Army, Air Force and Coast Guard, Shell, and other commercial and military clients. SSL’s extensive experience and trusted reputation is reflected by SSL’s global clients list and the facilitation of 17 further Theaters as follows.

• United States Coast Guard – North Carolina, USA • Toll Group / Helicorp – Bankstown, Australia • United States Army – Kentucky, USA • United States Air Force – Washington, USA • Special Air Services Regiment – Swanbourne, Australia • Spanish Navy – Rota, Spain • Indian Navy – Kochi, India • CESSAN (French Navy) – Brest, France • Republic of Korea Navy – P’ohang, South Korea • Survivex – Aberdeen, Scotland • LUKOIL – Astrakhan, Russia • Falck Safety Services – Nova Scotia, Canada • Tolmann Allied Services – Port Harcourt, Nigeria • Offshore Safety Survival Centre, Marine Institute – Newfoundland, Canada • Shell Robert – Louisiana, USA • Falck Safety Services – Newfoundland, Canada • Survival Systems USA Inc. – Connecticut, USA

Survival Systems Limited’s mission to enhance and preserve workers lives includes high risk areas associated with ship and offshore oil platform helidecks. SSL has also developed scalable high fidelity Fire Rescue Simulation Systems (FRSS) that enable training providers to prepare and support first responders to deal with emergencies in an effective and environmentally responsible manner. SSL continues to be at the forefront of developing safe, high fidelity, innovative training technologies and methodologies that simulate high risk operations in a realistic, controlled environment that prepares trainees to survive actual emergency situations.

www.survivalsystemsgroup.com

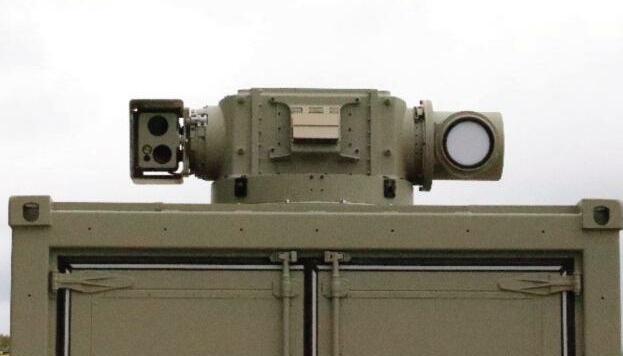

Suicide drone swarms are present an asymmetric threat Titanis 35kW Directed Energy Beam Director on containerised system

TITANIS DRONE DEFEAT

It is expected that unmanned aerial systems (UAS) will be used increasingly for malicious purposes as the cameras, weapons, toxic chemicals and explosives they are able to carry will be used for acts of terrorism, espionage and smuggling.

The Titanis Counter UAS (C-UAS) system has been developed by EOS to address the growing threat from malicious and threatening unmanned aircraft systems.

Based on the EOS R-Series remote weapon stations (RWS), Titanis is a fully integrated, scalable C-UAS suite combining speci c detection, command and control (C2), and layered hard and soft kill defeat capabilities necessary to acquire, track, and defeat swarming UAS threats.

The Titanis system allows the operators to match kill solutions to large numbers and varying combinations of small and large drones to ensure that the threat can be mitigated regardless of their direction, numbers and capabilities while managing the environmental, geographic, airspace and personnel safety considerations.

A typical all-up Titanis con guration incorporates direct re engagement systems, passive and active soft kill electronic warfare (EW) systems, an integrated sensor suiteincluding Pulse-Doppler, software-de ned radar, day/thermal camera, laser range nder and radio frequency (RF) detection systems - and an optional directed energy (DE) kill system. These systems sit together with, and are integrated through, a proprietary C2 and re control system developed by EOS. series minigun to larger calibre 30mm guns (e.g. the Northrop Grumman M230LF 30mm cannon with EOS R400S Mk2 RWS, or Mk44 II Bushmaster chain gun with the heavier weight EOS R800 RWS) ring airburst munitions (including 30mm x 113mm proximity fused airbursts and 30mm x 173mm airburst rounds) to deliver C-UAS effects out to 3000m.

One of the key differences between C-UAS and other missions is the high angular speed that can be achieved by the UAS at relatively short range. EOS RWS have been modi ed with a fourth-axis independently slewing sensor unit that can move independently in azimuth to track fast-moving targets. A 1-Hz laser provides laser ranging and tracking throughout the engagement.

Passive and active soft kill EW systems, designed to operate across all-threat frequency bands are, as with the radar solutions, integrated according to customer preference. Typical solutions include offerings from Blighter in the UK, Echodyne in the US and RADA in Israel.

Titanis ’ DE system has been deployed with a 35kW high energy laser (HEL), although the HEL in its current format is capable of scaling to around 55kW. The HEL system has been demonstrated as a small containerised system; however, while the DE beam director is slightly different to a weapons station it has 60% commonality with the R400S RWS and will therefore be employable from deployable platforms.

Developed and manufactured in-house by EOS, the DE system – which includes the beam director, and co-mounted optical target identi cation and tracking system – is designed to address Groups I, II, and III UAS swarm threats, with high rates of target engagement, out to ranges of 4000m. The ability to maintain and manage the quality of the beam, the software that ensures precision engagement and drives the process, and all the mechanical designs and architectures, are all EOS designs and intellectual property.

Arguably, the largest growth rate in lightweight lethality systems is in the unmanned systems space, for both integration on unmanned platforms with remote operation, and also for the engagement and defeat of unmanned systems. In a C-UAS application, Titanis with direct engagement/point defence, passive and active EW and directed energy capabilities constitutes a signi cant force multiplier.

Kinetic C-UAS using airburst munition

RWS tted with Dillon Aero M134-Series Minigun