Eco S of t , developed by the innovati v e t eam a t Ca rpe t s Inter, ser v es a s a sustainabl e alt e rn a tive to trad itional PVC backings. O ur goal w as to craft a c a rpet tile b a ckin g th a t is en vironm e nt a ll y friendl y, pro motes user well-being , and ensu res long-te rm pe r formance . L aunched in 2005 , it quickly g a ined popula r it y as the p refe rred choic e fo r modula r carpeting , with widesp read adoption in ins t alla t ions wo rld wide

Be y ond its initial purpose as a carpet tile backing , EcoSoft now forms t he basis for Royal Thai Ac o ustic Panels and supports l arge-fo rmat mo dul a r p roduc t s like Ro y al Thai ' s MegaPlank Axminste r. This ve rsa tili t y a nd adap t abilit y refl ect our commitmen t t o cons t an t inn o va t ion a nd prog re ss

The en vironm ent al impact of PVC-based ca r pe t tile b a cking has been a g rowing concern wi t hin our in du s tr y. W ith tr a ditional backings, harmful chemic a ls can be release d in to the en vironment du r in g bo t h the production and disposal st a ges These chemicals can cont r ibute t o air pollution , wa te r contamination , a nd even h a rm hum a n he alth.

Eco S of t 's inno vativ e a pp ro ach eliminates t he use of PVC in its cons tru ction , opting instead fo r a recycled fib re backing. This not only add resses the health concerns a ssocia t ed wi t h t radi t ion a l PV C hard backin g s but also int roduces advanc e d envi ronment a l a nd perf o rmance benefi t s. These includ e a high re cycled content , cushioned backing , V OC-free ins t alla t ion, a nd superior acoustic p ro perties , making it a g roundb re aking s o lu t ion in t he field

EcoSoft uses roughly 50x550 ml. recycled PET bottles for every square meter of product. Our commitment to recycle 1 billion discarded plastic bottles by 2025

Primary Backing

Expl ore the s u stain a ble featu res aimed a t reducing envi ronm e ntal impac t and fos ter ing an ec o -friendly living en vironmen t.

fo r a h ea lthier environmen t

Eco So f t b a cking i s a z er o P V C b ac king and is DE CLAR E R ed Li s t F re e, Guarantees the absence of hazardous substances in our manufacturing process.

No harmful plasticizers or stabilizers that can leach toxins into the environment. Eliminates the potential for VOCs from chemical reactions with wet slab floors.

Certified to not contain any chemicals listed on the Living Building Challenge's Red List, ensuring that it is safe and sustainable for use in buildings aiming for LEED certification

For a fre sh and healthy environmen t

R edu c e p lastic wa st e

Re cycl ed PE T , sourced from bottles collected from land and sea, plays a vital role in fighting plastic pollution and promoting sustainability. To date, EcoSoft has facilitated the recycling of 1 bi l lion PE T b ot tl e s recycled .

Ec oS o ft 's bre athable c onstructio n allows moisture from the subfloor or from accidental spills to rise and evaporate through the carpet face eliminating the build-up of mold and unpleasant odors

L ig ht

h t

tru ction

to m ove , E as y to ins tal l

Reducing the weight of the product not only makes it easier to handle during installation and transportation but also contributes to lower fuel consumption during shipping, thereby reducing transpo r t c osts an d ca r

Enhanced Wel l being improveD Hea lth , E levat eD Pe rform an ce

Experience the luxury of our plush 4.0-4.5 mm. cushion backing that provides substantial underfoot comfort, helping to reduce fatigue and enhance your overall well-being. Treat your feet to

The breathable construction promotes a

healthier indoor environment by allowing

air circulation that helps prevent the development of unpleasant odors and mold ensuring a fresh and clean atmosphere for your space.

With over 20 years of proven success globally, EcoSoft demonstrates exceptional durability. Supported by a robust 15-year warranty, you can rely on its longevity and dependability. Engineered for top-tier performance, it consistently maintains its integrity, resisting shrinkage, expansion, cupping, doming, and delamination in any environmental condition.

Outperforms traditional hardback tiles by 150%-175% in sound absorption efficiency. EcoSoft effectively reduces ambient noise, absorbs impact sounds, minimizes sound reflection, and significantly lowers noise levels in any space. Perfect for creating a quieter and more comfortable environment.

Designed to perform at the highest levels, ensuring it maintains its shape without shrinking, expanding, cupping, doming, or delaminating when subjected to heat, cold, or moisture. This feature emphasizes the product's durability and reliability in all environmental conditions.

Upholding standards of low emissions of VOCs.

A building product that is renewable, environmentally responsible and where the impact is considered over the entire lifetime of the product.

SGBC sets high standards and benchmarks for green building solutions both locally and regionally to help build more sustainable cities for better living.

The standard enables organizations throughout the carpet supply chain to achieve sustainable attributes and demonstrate compliance.

EPD (Environmental Product Declaration) is an independently verified and registered document that communicates transparent and comparable information about the life-cycle environmental impact of products.

Free from chemicals listed on the Red List, which comprises harmful substances.

Recognized for contributing to healthy buildings under the WELL Building Certification.

Choosing EcoSoft demonstrates a commitment to environmental preservation and creating a better environment for their employees and customers, all while ensuring top-notch performance and long-lasting durability for their projects. EcoSoft isn't just a choice It’s a choice for a future built on sustainability.

Carpet tile backings are the backbone of any modular carpet. They provide strength and durability from layered construction, functionality with easy removal and replacement, comfort from softness and acoustic properties and recyclability from modular design.

EcoSoft is based on the same felted material construction used for high quality acoustic panels.

8 Million metric tons of plastic enters the ocean from the land every year. If this trend continues by 2050 there will be more plastic in the Ocean than fish.

A discarded PET bottle will take 450 years to decompose unless it is recycled.

It takes about three times as much water to produce a 1-liter bottle, than the 1 liter of water it holds.

More information on the benefits of EcoSoft are available on our website

Pl a sti c Po lluti on

( Upd a te/ replace Recycled/ Recycled ma t erial Oc t 2020 )

Acoustic Performance

( Upda t e P o si t ion pape r May 2020 )

Lightweig ht B en efits

( Upd a te position paper 2020 )

Wet o n Gre en C on crete Slabs

(Update/Replace Position paper July 2020)

Ene rgy cons er va tion is a dual commitmen t fo r our comp any, blending fi scal responsibili ty wi th en vironmen t al s tewa rdship. By p r ioritizing efficienc y a nd sus t ain a bilit y, we h a ve e ffecti v ely lessen e d o ur reliance on conventional ene rgy sou rces The incorpora t ion of sola r powe r into our ma n ufacturing p ro cesses sets t he st a ge for a g reene r, mo re eco-conscious futu re. In t he last t w ent y y e ars, dedicated work in t echnology and ene rgy man a gemen t has led to a significant 40% d ecre ase in electrical ene rgy use. Building on this p rog ress, the implement a ti on of solar arrays is now rev olu tio nizing ou r ene rgy envi ronment

From su nl igh t to su cce ss : Our c om mi tm en to S ol ar-Powered prod

In 2021, t he implementation of our first so la r a rr a y marked a pivotal step in ha rnes s in g renewable ene rgy specific to manufactu r ing. The facility in Thailand recei v es a b undant sunlight thanks to its ge ogra p hical location, making it an optimal choice for this implementation

R ed uct io n in fos si l fu el u sage

fr om ener gy red uct ion ini tiat iv e s an d So lar p o we r p r og ram

Th e initial 1 MWp solar system installation d emonst rat ed immedia te bene fi ts a nd set t he stage for th e su bsequen t rollout of a second installa t ion of 1 MWp in 2024. Plans for a ddition a l ph a ses in 2026 an d 2028 will expand our solar power gener a tion ca pacity to 4 MWp, t he equiv a lent of nearly 70% of o u r cur ren t daytime electrical usage

Th is t ran si tion is i ntegra l to our b roader go al o f at taini ng ne t -ze ro gree nh ous e gas e mi s sio n s b y

a commitment s et forth in 2023 that aligns wi t h our global vision fo r sustainable ope r ations

The a doption of solar power b r ings f o rth seve r al subst a nti a l benefi ts.

R educe d Greenh o use G a s Emis s ion s

S olar p ow e r substantially cuts down on th e e missions associated with convention al e lectrici t y p rod u ction, contributing to a healthier plane t.

Reliance on sola r p o wer demonstrates a long-term sustainable app roa ch to ene rgy usa g e, one that is rene w able and less harmful to the ecosystem

S mal ler

Ca r bon Fo o tprin t

The use of sol ar panels t r ansla t es d irect ly t o reduced ca r bon emissions , reinfo rci ng ou r dedic a tion to en vironment a ll y conside rat e p ra ct ices

Lo ng term COS T Saving s (2023) 20%

The use of s olar powe r s yst ems can reduce elec t ricit y cos t s leading to long term fin a ncial bene fi ts and reduced p roduct cost.

The inclusion of solar powe r in o ur ene rgy por t folio is a cruci al step towa rds red ucing our en vironm e ntal impac t . By h a rn e ssing the sun ' s renewable ene rgy, w e showcase our d edicatio n to sust a in a bility a nd a g re ener futu re

T hi s t ransi t ion n ot on ly benefi t s the envir onm ent but a lso hig hl ig hts o ur co mm i tm en t to inn ovat ion in c lean ener gy solutions.

1 MWh of sol ar power gener a ted today equivalent to running 330 homes for 1 hour ( sou rce C le a n en ergy authority )

O ur C ur rent 2 M Wp Solar a rr ay uses 3650 panels and c overs a n area of 18000 m 2

O ur cur re nt 2 M Wp Solar a rray offsets over 40 % of da ytime ene rg y a nd will inc rease to ne a rly 70% in 202 8

1 MWh of solar ene rgy is enough to offset the e quivalent of 1,250 to n s of CO 2 per ye ar

The sol a r pow e r gener a ted by our 2 a rra ys from 202 4 is c a pable of running our 74 % of our Carpet tile production (Estimate based on 2023 power data).

Solar ene rgy is the most a bundant ene rgy resou rce on e a rth -- 173 , 000 terawatts of sol ar ene rgy strikes the Earth c ontinuousl y. That ' s mo re th a n 10,000 times the world's tot al ene rgy use .

Appl e's headq u arters in Cupertino, Ca lifo r ni a , USA, is noted as the la rgest sola r- powe red building with a n imp ressive 260 , 000 m 2 of solar panels on its roof , gener a ting a 17 meg awa tts of ene rgy.

At Royal Thai, we take pride in crafting high-quality carpets that are not only visually stunning but also exceptionally durable, standing the test of time. However, when it's time to revamp your space with a new product and design, it's also crucial to consider the environmental impact. Ensure your old product doesn't end up in a landfill by taking advantage of the Royal Thai Carpet Take Back Program.

Our zero waste-to-landfill commitment in manufacturing has been in action since 2005, and we're proud to extend that commitment to the carpets that currently grace your floors. When it's time for an upgrade, we will ensure your old carpet doesn't just end up as waste; it transitions into a useful second-life product or is disposed of in the most environmentally friendly way possible

Recovering and recycling the waste we generate conserves our precious natural resources, reduces environmental impact, and supports the development of a more

We strive to provide closed-loop recycling solutions whereby waste materials are separated and recovered as secondary

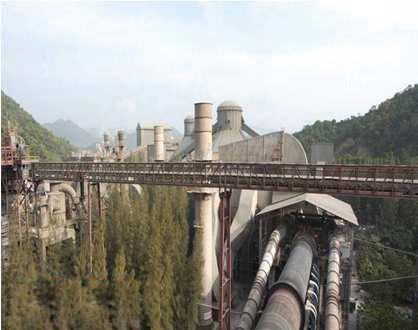

In Thailand, we're currently working in partnership with local facilities to convert old Carpet tile, Broadloom, and Axminster into refuse-derived fuel (RDF) pellets. These pellets are then utilized by industries such as cement manufacturing or power generation plants to produce clean energy. An impressive record speaks for itself, with over 1.3 million Kg of used carpet taken back and processed between 2020 and 2023 resources or used in the manufacture of new products. Where this is not possible, they are used as fuel in the production of clean energy.

Uplifting of old carpet 1

Our team will carefully remove your existing carpet during the new installation.

When you opt for a new Royal Thai carpet or Carpets Inter Carpet Tiles, our expert Installation team will handle it all. It's as Simple as That!

The used carpet will be sorted based on its condition, and ready for either recycling or reuse. Sorting and packing 2

4 3 4

Ensuring responsible disposal, we'll transport your old carpet to specialized local partner facilities. Removal and recycling

At the end of the process, you'll receive a certificate confirming the ethical disposal of your old carpet. Receiving waste disposal certificate

No matter the brand of your old carpet, our Installation team is equipped to take it away for recycling while installing your beautiful new carpet.

1

All customers, contractors and recyclers are encouraged to dispose of waste carpets that cannot be reused in the most environmentally way to avoid sending waste to landfill.

All waste to be converted to RDF (Refuse Derived Fuel) is analysed to ensure the physical and chemical properties will have no harmful emissions.

The high production capacity of cement kilns are capable of utilising large volumes of non-harmful industrial RDF (Refuse Derived Fuel) to power the cement kilns.

2

3 5

The Fly Ash from the incineration process is used in the production of cement ensuring that no waste goes to landfill.

A key success factor from RDF in cement manufacture is that waste generated by one industry is a resource for another. We support Cement for Green Buildings and Sustainable Infrastructure projects across Thailand.

4

Participating in the Carpet Take Back Program isn't just about convenience; it's a step towards a greener world

Your old carpet will have a second life instead of contributing to landfill growth.

Say goodbye to harmful disposal methods.

Waste converted into RDF pellets supports clean energy generation.

We offer this service at a low cost, so it's good for the planet and your budget.

Together we can help pave the way toward a cleaner, sustainable future

Note: Although this service is currently exclusive to Thailand, clients in other countries can speak to their local account managers about alternative local carpet recycling options.

Conventional Nylon is not biodegradable and will stay in landfill for decades.

It is estimated 89% of used carpet is sent to landfill every year.

Water has played a vital role in carpet manufacturing for years, particularly in processes like fiber dyeing and backing. However, this heavy reliance on water has a downside - the release of harmful effluents as a significant side effect. During fiber dyeing processes, the discharge of harmful substances into water bodies introduces a mix of chemicals, including dyes, heavy metals, and other toxins, which can pose substantial environmental risks. These pollutants disrupt aquatic ecosystems, endanger wildlife, and compromise water quality, making it unsuitable for consumption, irrigation, and other essential purposes. Amid increasing global environmental consciousness, the industry is gradually transitioning towards a circular water reuse approach, driven by the integration of new technologies and sustainable manufacturing practices. However, this transformation has been notably gradual.

Royal Thai identified the issue 25 years ago and decided to implement a more sustainable manufacturing process. This choice went beyond mere business strategy; it symbolized a dedication to the local environment, especially noteworthy given the factory's setting in a rice-growing region. The emphasis on maintaining high water quality reflects not only corporate principles but also a deep-seated commitment to serving the community.

The journey towards a more sustainable manufacturing process was intricate, marked by the integration of cutting-edge technologies like spray drying, advanced computerized water management systems, and highly efficient recycling systems.

These innovative steps not only reduced water usage by 70% but also propelled the company to a significant accomplishment. By 2015, Royal Thai achieved a major milestone with complete process water recycling, and Zero effluent output underscoring their dedication to environmental stewardship and resource efficiency.

Royal Thai saw an opportunity to go beyond water recycling. The industrial water recycling process mirrors consumer wastewater treatment, involving aeration, sedimentation, and filtration to eliminate solid waste. Typically, the outcome is solid waste sludge destined for landfills. However, Royal Thai viewed this not as an issue, but as a chance for innovation.

Working with a local fertilizer manufacturer, Royal Thai began discussions on how to use the biological sludge from the wastewater processing in fertilizer production. Together, the two partners modified the water processing system, which now takes the water through chemical, physical, and biological processes to output a waste sludge that meets stringent Department of Works standards for agricultural use

The result is a beautiful circle of life - the sludge is delivered to the fertilizer company, blended with growing nutrients like Dolomite, Marl, Nitrogen, Phosphate, and Potassium, and then converted into fertilizer pellets These pellets support the growth of local crops such as Pineapple, Cassava, Sweetcorn, and Rubber Trees.

Since the initiative began in 2015, Royal Thai has donated nearly 2000 tons of sludge, which has been turned into more than 400,000 bags of fertilizer. This achievement is a testament to how business can coexist harmoniously with the environment, creating an ecosystem where waste is not wasted, but put into service for new life.

Reverse osmosis (RO) is a membrane-based filtration process that separates contaminants from water by applying pressure to push it through a semipermeable membrane. This method is highly effective at removing a wide range of contaminants, including salts, microorganisms, and organic compounds making it ready for re-use.

A storage basin designed to collect wastewater and stabilize flow rates before further treatment. The pond helps manage fluctuations in inflow, allowing for more consistent treatment processes downstream.

Aeration is the process of adding air into wastewater to allow aerobic bio-degradation of the pollutant components. It is an integral part of most biological wastewater treatment systems.

Waste water recycled and recycles back to aquifer

A polishing pond is a shallow lagoon that provides additional treatment for wastewater after primary and secondary processes. It allows for natural processes such as further sedimentation, microbial activity, and nutrient uptake by plants, improving water quality before discharge.

Sludge dewatering is the process of removing excess water from sludge generated during wastewater treatment. It is achieved by pressing the water out of the solids reducing the volume and weight of the sludge and making it easier to handle and transport to be made into fertilizer.

Sedimentation is a physical process where particles suspended in wastewater settle out of the liquid. This is accomplished in a sedimentation basin where gravity causes solids to settle at the bottom, allowing clearer water to be drawn off from the top.

The addition of microorganisms metabolize organic matter in the wastewater breaking down the organic solids, leading to the formation of flocs (clumps or clusters of tiny particles, including microorganisms, organic matter, and other solids, that stick together in water) that can be easily separated from the water through sedimentation.

Textile production is estimated to be responsible for about 20% of global clean water pollution from dyeing and finishing products

https://www.europarl.europa.eu/topics/en/article/20201208STO93327/ the-impact-of-textile-production-and-waste-on-the-environment-infographics

The water we recycle is clean enough for fish to live

Our waste sludge has been used to manufacture over 200,000 tons of fertilizer

Organic farming naturally sequesters CO2 from the atmosphere. 1% of extra organic materials = 10 tons carbon draw down per year.

New Reverse Osmosis is a magic like process for water treatment, it which doesn’t just filter out contaminants, it removes dissolved salts, harmful chemicals and even difficult microbes often left by other treatments.

The biological treatment used for separating our waste water is a natural process (think bacteria eating up pollutants) It’s like having millions of cleaners working day and night without a break.

Fertilized crops can increase yield by 2 – 3 times more than untreated soil (Ionique)

Diverting waste from landfill

In our quest for environmental excellence, we take pride in our dedication to waste management. Maintaining Zero manufacturing waste to landfill since 2009 stands as a testament to our commitment and our battle against waste. Across our diverse range of carpet and acoustic products in our 160,000 m2 Thai facility, we have made significant progress in reducing our environmental impact.

20% over time. These reductions have not only enhanced our operational efficiency but also positively impacted the environment.

Improving manufacturing processes

20% reduction

over 15,000 m2 donated to Education institutions and local community projects in last 2 years

Material Recycling initiatives are in operation throughout the manufacturing process ensuring that we keep as much waste material as we can within the manufacturing loop. Our work in reclaiming and recycling wool recently achieved the prestigious BCG award for circular economy

After all the efforts to recycle within the manufacturing process are exhausted, any residual waste that cannot find a new purpose is donated to a local power plant to keep it out of landfill. This non-recyclable waste is converted into Refuse-Derived Fuel (RDF) pellets, used for clean electricity generation.

Carpet edge waste from manufacturing

Carpet installation waste (offcuts)

Waste from latex backing production

Used and damaged carpet material

O u r rel en tl es s p u r s uit of was t e elimination is a

y T h ro u gh initiati v es like our Bio-Ci rcula r-G reen ( B C G ) and N et - Ze ro G reenhouse G a s ( G HG ) p rogr a ms, ou r g oa l e xt ends be y on d me rely re ducing w as t e. W e st r ive to inno v ate and refine our p rocesses t o p revent waste c reat i on f ro m the start. We a re de dic ate d to o

i n t o all our p roduction activities.

The tables below illustrate our achievements in waste management over the years by displaying the manufacturing waste (Kg '000) alongside the equivalent energy (KWh) generated from that waste.

RDF serves as an alternative to non-renewable resources, thereby conserving valuable natural reserves. 2005 – 2009

Disposable waste diverted from landfill to incineration

From 2009 Carpet waste used for Cement manufacture

From 2014 Solid water waste (Sludge) used to make fertilizer

The Journey Beyond Zero Add a section to show what actions led to Zero to waste to landfill and what actions we took beyond Zero

From 2017 Manufacturing waste used for Electricity Generation

K e y b e n ef its RDF in E n e r g y Gener atio n

Utilizing RDF presents many advantages that align with our sustainability mission

R ed u ction o f F os si l Fuel Us e

De cr e a s e in L and f il l Wa s t e B y c o nve r ting w a s te t o ene r g y,

we minimize the volume of solid waste that would otherwise occupy landfill space.

Through RDF, we endorse the generation of cleaner energy, which reduces greenhouse gas emissions compared to conventional fossil fuels.