3 minute read

Technology Update: Creating a safe path to digital with open standards

Ed Harrington, Ed Harrington, The Open Group

Open standards, a digital path

Advertisement

New open standards balance uptime requirements with digital technologies.

Competing in this data-driven economy means organizations need to have a clear open-strategy for technology adoption and a clear vision for future systems. Companies are trying to digitally transform because of the clear benefit it provides. Accenture said companies that have implemented emerging technologies into core processes see revenue grow two times faster than those who are not. Yet 97% of information technology (IT) decision-makers say legacy infrastructures are holding them back; many companies struggle to quickly deploy new technologies.

Within the context of process automation – industries that cannot turn off factories ever – organizations often can’t take advantage of advances in digital technologies due to the inability to insert these advances within a facility’s infrastructure. To keep pace with the digital age, the critical infrastructure and automation industries are looking beyond today’s control systems for new, common technologies that can deliver uptime and take advantage of digital technologies. Open standards can help.

Open standards, best in class

Process automation control systems are central to any industry required to maintain operations. These include, among others, oil and gas, petro- and specialty chemicals, utilities, mining and metal, pharmaceutical, food and beverage, and pulp and paper. For most, downtime is not an option. The power generation and distribution industries fuel our lives.

The same type of equipment and processes often are deployed across sectors, yet only a few suppliers provide relevant services. These suppliers have a complete “stack,” running from a device to providing information to a separate planning system. These systems are proprietary and cannot be easily replaced, creating vendor lock-in. Digital transformation can be limited if innovations aren’t provided by the current supplier. Organizations seek common technologies that can help balance requirements for uptime, security and safety with the need to take advantage of digital innovation. Digital transformation does not require a “rip and replace” approach. Organizations improve the functional capabilities of the facility and move to a new software environment that extends life of traditional legacy systems. Many commonalities exist in process

M

More

ANSWERS KEYWORDS: Open process

standards, interoperability

Finding common ground, best in class process automation Process automation cost savings and efficiency are goals. CONSIDER THIS If today’s industrial standards efforts lead to interoperability, will you help? ONLINE If reading from the digital edition, click on the headline for more resources. www.opengroup.org/forum/ open-process-automation-forum

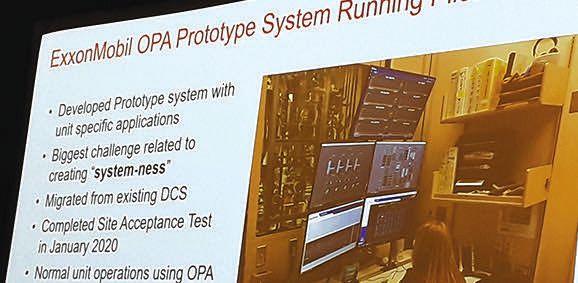

ExxonMobil, at ARC Forum 2020, discussed its open process control pilot, using multiple vendors. Courtesy: Control Engineering

automation industries for efficiency, interoperability and the ability to integrate best-in-class technologies. Recognizing the need for collaboration, three years ago a group of companies discussed the possibility of developing an open standard for process automation; more flexible solutions was the driver.

The Open Process Automation Forum (OPAF) was born under the guidance of The Open Group. The Forum been developing a standard for the security, interoperability and scalability of new control systems. A year ago, over 90 member organizations created OPAF’s O-PAS Standard, Version 1.0, now a full standard of The Open Group.

While industry standards for process automation are available and fit for purpose, the O-PAS Standard focuses on interoperability, using existing industry standards and adopting and adapting them to create a “standard of standards.”

Digital technologies are the future. This is why we’re already seeing end-user and supplier organizations work with peers to agree on technical standards that are open and based on common interfaces. This will make it easier and cheaper to replace and repair control systems and to reduce operational costs. It will be easier for digital transformation initiatives to be done at a low cost and with minimal disruption.

Work continues. More companies are expected to follow the first, who are already looking to open standards to help improve operational efficiency and ease digital complexity. A safe path to digital unlocks significant cost savings and efficiency for the process automation industry. ce

Ed Harrington is forum director, Open Process Automation Forum, The Open Group. Edited by Mark T. Hoske, content manager, Control Engineering, CFE Media and Technology, mhoske@cfemedia.com.