16 minute read

News Extra

French chemical company charged over 2019 plant fire

The French subsidiary of US chemical company Lubrizol has been charged with pollution and failing to meet safety standards after an explosion and fire at its plant in Rouen, northern France. The blaze at the lubricant plant in September and October 2019 produced a thick black cloud for several days that spread across the region and caused nausea, headaches, and vomiting amongst locals.

Advertisement

Lubrizol France was charged on February 27 with the Paris prosecutor’s office releasing a statement saying the company had been ordered to pay a holding amount of ¤375,000 and an extra ¤4 million “to guarantee the rights of victims by allowing for the repair of human and environmental damage that may have been caused.”

Being charged under French law does not necessarily mean a company or individual will face trial in court. The Paris prosecutor’s statement said that investigators are still yet to determine the cause of the initial explosion.

Lubrizol produces lubricants and fuel additives and has its headquarters in Ohio, US. The company is owned by US billionaire Warren Buffet. More than 9,000 tonnes of chemicals were destroyed in the fire in September.

The Paris prosecutor’s statement added that the failure to meet safety standards resulted in serious health issues and degraded air quality in the area. The amounts that Lubrizol France was ordered to pay “correspond to the magnitude of the disaster,” the statement said.

The explosion occurred in the early hours of September 28. Firefighters managed to bring the fire under control after 24 hours, but toxic black smoke and soot remained in the following days and spread across the region as far as Belgium and the Netherlands.

US pipeline owner agrees to pay $60 million for 2015 spill

Refugio beach in May 2015 - Image: USFWS

Plains All American Pipeline has agreed to pay $60 million to settle civil charges in relation to an oil spill in May 2015 at Refugio State Beach near Santa Barbara, California. The US Department of Justice announced on March 13 that the Texas-based oil company would settle the charges after violating federal pipeline safety laws.

The $60 million includes $24 million in penalties and $22 million in compensation relating to environmental damage and clean-up costs. The government added that the settlement requires Plains All American to implement safeguards across its national pipeline system to address factors which contributed to the 2015 spill. Although a settlement was reached with the Department of Justice and the US Environmental Protection Agency, Plains did not admit any wrongdoing or liability.

The spill in May 2015 saw an estimated 142,800 gallons (541,000 litres) of oil spilt, killing hundreds of both marine mammals and birds. The company’s 2017 annual report estimated costs from the spill at $335 million, not including lost revenues. The spill from a corroded pipeline crippled the local oil business because the pipeline was used to transport crude to refineries from seven offshore rigs, including three owned by Exxon Mobil.

After the incident, federal inspectors found that Plains had made several preventable errors, failed to quickly detect the pipeline rupture and responded too slowly as oil flowed toward the ocean. Plains operators working from a Texas control room more than 1,000 miles away had turned off an alarm that would have signalled a leak and, unaware a spill had occurred, restarted the leaking line after it had shut down.

Explosion at Petronas-Aramco refinery in Malaysia kills five

An explosion and fire at the Pengerang refining complex in Malaysia killed five people on March 15. The blast occurred at the plant’s diesel hydrotreater unit, which uses hydrogen to remove sulphur waste from raw diesel.

The Pengerang Integrated Complex, located near Kota Tinggi in the southern state of Johor, processes around 300,000 barrels of crude oil per day and has a yearly capacity of around 3.3 million tonnes. The Johor state Fire and Rescue Department said that after responding to an emergency call, its team arrived at the site to find a significant fire. Five people were killed and one person was severely injured having suffered burns. One person was able to escape unharmed.

An investigation into the explosion is underway. The refinery’s owner, Pengerang Refining and Petrochemical (PRefChem), said in a statement that it was working closely with authorities to find the cause behind the blast.

PRefChem is a strategic alliance of Malaysia’s national oil company, Petroliam Nasional Berhad (Petronas), and Saudi Aramco, the national oil company of Saudi Arabia.

The blast is the second incident at the Pengerang Integrated Complex in less than a year. In April 2019, two staff members were injured in an explosion and fire at the plant’s atmospheric residue desulphurisation unit.

Gas processing plant explosion kills 17, injures 25 in Nigeria

Representative image: Shutterstock

Ablast at a gas processing plant in Nigeria’s commercial capital, Lagos, killed at least 15 people and injured 25 others on March 15. The Nigerian National Petroleum Corporation (NNPC) said the explosion

was caused by a truck hitting gas cylinders near the company’s pipeline.

The explosion destroyed around 50 buildings and extensive damage was caused to many more nearby houses as well as the NNPC’s pipeline. All pumping operations on the Atlas Cove-Mosimi pipeline were halted, the state-owned oil company said in a statement.

Local media said that several people were taken to hospital with injuries and burns. Witnesses reported seeing large plumes of black smoke and a fire in the surrounding areas as firefighters worked to contain the spread of the blaze.

Pipeline explosions and fires are not uncommon in Nigeria, Africa’s largest crude oil producer. Theft and vandalism are common causes behind pipeline explosions in the country, which lost around $42bn to crude oil theft between 2009-2019.

Two recent incidents include a blast in January 2020 which killed five people and an explosion in June 2019 which killed 12. Both were the result of attempted oil thefts.

Representative image: Shutterstock

Mine explosions kill seven in Pakistan, 11 in Colombia

Mine explosions in March and April killed and injured several people in both Pakistan and Colombia. Seven miners were killed and three were injured on March 20 after an explosion at a coal mine in western Pakistan, while an explosion on April 3 killed at least 11 miners and injured four others in Colombia.

Local media reported that the Pakistan explosion was caused by a build-up of methane gas. Rescue workers and locals were able to retrieve all the bodies from the mine shortly after the explosion. There were 12 workers inside the mine at the time of the blast. Poor working conditions and lax safety standards in both Pakistan and neighbouring countries, such as India, mean mine explosions are not uncommon. In July 2019, 10 miners were rescued from another mine near Quetta after a gas explosion trapped the workers inside. According to the Pakistan Central Mines Labour Federation, between 100 and 200 labourers die on average in coal mine accidents every year.

Elsewhere, in Colombia, a mine blast killed at least 11 people, injured four, and left two more workers trapped in the mine in Cucunuba, north of Bogota.

The local fire department told local media that the explosion occurred in a legally operated mine but did not say what caused the explosion. Colombia, the world’s fifth-largest coal exporter of coal, has experienced several accidents in the past, often involving illegal mines which are common in the area surrounding Cucunuba.

China restricts new mine tailings dams to improve safety, reduce environmental risk

Representative image: Shutterstock

China’s Ministry of Emergency Management has said that the country will limit the number of new tailings dams built from mining projects in order to reduce environmental and safety risks. The use of existing tailings dams would also be limited, the ministry said in a notice posted online on March 20.

New mining projects are being encouraged to use existing tailings dams and to adhere to both environmental and safety regulations while doing so. The Ministry of Emergency Management is looking to local governments to help regulate mines and place a limit on the number of tailings dams within their region.

Mine tailings dams are made from the mining industry’s liquid and solid waste, known as tailings. The waste is typically stored in embankments called tailings dams, which have periodically failed with devastating consequences for communities, wildlife and ecosystems.

While work starts on gradually reducing the current number of mine tailings dams in China, the ministry added that new dams would be allowed should a mine be considered a strategic or critical necessity for filling a supply shortage.

In its statement, the Chinese Ministry of Emergency Management said that abandoned tailings dams or dams that have not been in service for more than three years must be closed down within a year. Local governments have been instructed to log details about tailings dams on their websites at the start of every year. Suitable emergency responses should also be established in order to deal with a dam collapse should one happen.

China has around 8,000 tailings dams. New dams will now be prohibited from being over 200 metres high (656 feet), within 1km (0.6 miles) of residential areas or critical infrastructure, and within 3km (1.86 miles) of the Yangtze or Yellow rivers.

Image: Shutterstock

Forest fires near Chernobyl cause radiation levels to spike

Two forest fires within the Chernobyl Exclusion Zone caused radiation levels to spike to much higher levels than the norm. Ukrainian emergency services said that the fires started on April 3 and that one of the fires had spread across 50 acres.

The head of the state ecological inspection service, Yehor Firsov, said in a statement that one of the fires, which had grown to around 12 acres in size, was extinguished on April 6. Hundreds of firefighters with the support of airplanes and helicopters were eventually able to put the larger blaze out on April 14.

Police arrested a 27-year-old man after he told them he had set fire to grass and rubbish “for fun”. He then tried to put them out but failed after the wind caused them to spread.

In his statement, Firsov said that radiation levels at the site of the fires was around 16 times above the normal level. The heightened levels meant the country’s emergency ministry sent out an alert in Kyiv on April 6 about the possibility of poor air quality but attributed the alert to meteorological conditions and not to the forest fires. Kyiv is located around 60 miles south of the Chernobyl Exclusion Zone.

Government specialists were sent to monitor air quality in the capital city but said there were no notable changes to radiation levels. Firsov released a further statement as a result and said locals did not need to be afraid of opening their windows.

There were fears that the fires could have reached the abandoned Chernobyl nuclear plant itself after Greenpeace Russia said on April 13 that one blaze had come within 1km of the plant.

The Chernobyl Exclusion Zone, established in 1986 following the world’s worst nuclear disaster, spans across 1,000-squaremiles (2,600-square-kilometres) and was abandoned since the meltdown of the No.4 reactor at the Ukrainian nuclear power station in 1986.

NEW MULTILED BOARD PLATES

HIGH BRIGHTNESS UP TO 21.000lm

EXCELLENT HEAT DISSIPATION AVAILABLE IN TRANSPORTABLE VERSION

WIDE RANGE OF VOLTAGES AND POWERS

AMBIENT TEMPERATURE -40°C +60°C

DARKNESS IS JUST A MEMORY

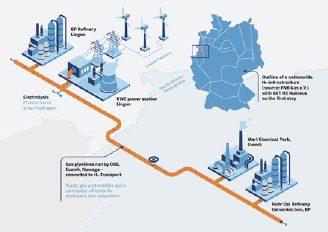

Image: OGE

80-mile hydrogen pipeline to be built in Germany

Open Grid Europe (OGE), a group of the 16 largest gas transmission grid operators in Germany, has announced plans for an 80-mile (130km) long hydrogen pipeline to be built in northwest Germany as part of the country’s move towards greener energy sources. The project is being developed by a consortium which includes OGE, BP, Evonik, Nowega, and RWE Generation.

The consortium will develop Germany’s first publicly accessible hydrogen network to supply green hydrogen to industrial companies in the country’s north western states of Lower Saxony and North RhineWestphalia.

The idea behind the project is to convert power from renewable energies into hydrogen and use it as a carbon-free source of energy in industry and other sectors. OGE announced the plans on March 17 and said green hydrogen would be produced from renewable energies in Lingen, Lower Saxony via a 100 MW electrolyser owned by RWE Generation. It will then be transported to industrial customers and refineries in Lingen, Marl and Gelsenkirchen – mainly via existing gas pipelines operated by transmission system operators Nowega and OGE and converted for the transportation of 100 percent hydrogen, but also via a partially new construction by Evonik.

The project is called GET H2 Nukleus which comes from the name for RWE’s planned hydrogen plant in Lingen, the ‘Get H2’ pilot plant.

The plans would see existing, but underused, natural gas pipelines be converted for transporting hydrogen. The pipeline would be open to use by third parties in a non-discriminatory way, including all generators, traders and consumers, as is already the case with power grids and gas networks.

Currently, Germany uses around 55 terawatt hours (TWh) of fossil-fuel derived hydrogen.

INEOS postpones shutdown of Forties Pipeline System until Spring 2021 due to coronavirus

On April 7, INEOS announced that it would delay the shutdown of the Forties Pipeline System until Spring 2021 due to the ongoing coronavirus pandemic.

The Summer shutdown for maintenance had been planned for June 16, however due to the ongoing government restrictions in relation to the coronavirus pandemic, INEOS said it would postpone its plans to enable its customers and the UK oil and gas industry to plan with greater certainty.

In a statement, the company said it would continue working with customers and relevant parties to prepare for the shutdown in 2021. INEOS said it had written to all its customers announcing its decision after “there was a desire to delay the shutdown to 2021 by the majority of its customers.” INEOS said it would communicate the exact start date of the shutdown as soon as it is able to.

The Forties Pipeline System is carries 30% of the UK’s oil – around 550,000 thousand barrels per day – from North Sea terminals to shore before the pipeline terminates at the INEOS-owned Kinneil processing facility in Grangemouth. INEOS bought the network from BP in 2017.

Judge Brian Morris – Image: US Gov

US court rules against permit for Keystone XL pipeline just two weeks after construction begins

TC Energy’s Keystone XL pipeline suffered a fresh setback on April 15 after a US court ruled against a permit that allows new energy pipelines to cross bodies of water. The ruling came just two weeks after TC Energy announced on March 31 that construction of the pipeline would go ahead following a $1.1 billion investment by the Alberta government.

Montana Chief District Judge Brian Morris ruled that when issuing a nationwide permit for Keystone XL in 2017, the US Army Corp of Engineers had failed to consider the risks posed to endangered species and habitats in rivers and bodies of water which the pipeline would be crossing. The ruling is another setback for the longdelayed project which was first proposed in 2008. If completed, the pipeline will be 1,210 miles (1,947 kilometres) in length and carry around 830,000 barrels of crude oil per day.

This latest ruling does not affect a span of the pipeline across the Canada-US border where work began in early April after the Government of Alberta’s $1.1 billion investment was announced. The investment would have covered the planned construction costs through the end of 2020, but TC Energy must now re-apply for the relevant permit.

The ruling came after several activist groups challenged the US Army Corp of Engineers’ re-issuance of the nationwide permit. Nationwide permits help streamline the approval of pipelines and utility lines but must be reissued every five years. Judge Morris declared that the Corps failed to consult on the risks posed to endangered species and habitats and must comply with the ruling before it can reissue the nationwide permit to any more projects.

A spokesman for TC Energy said that the Alberta-based company is reviewing the decision but remains committed to building the “important energy infrastructure project.” It remains to be seen whether the court ruling will force TC Energy to revaluate its expectations of the pipeline entering service in 2023.

You stand for safety. We stand behind you.

UK HSE issues notices against two companies for exposing workers to risk of explosions

The UK Health & Safety Executive (HSE) issued an improvement notice against an oil and gas operator in the North Sea on February 14 and a prohibition notice against an Aberdeenbased drilling equipment company on February 21.

Ithaca Energy was given an improvement notice after an HSE inspector visited Ithaca’s Alba floating storage unit (FSU) in the North Sea between January 14-16 and found that workers had been exposed to the risk of injury from fire or explosion.

The notice states that Ithaca had failed to demonstrate “appropriate measures to prevent formation of a flammable atmosphere within the cargo tanks or associated pipework thereby exposing the personnel onboard to the risk of serious personal injury or death from fire and explosion.” The HSE inspector said that the piping on the open hazardous drains system of the Alba FSU had integrity issues which created potential routes for oxygen ingress into the tanks through the drainpipe. Furthermore, no records were made available to confirm whether there was an oxygen deficient atmosphere within the cargo tanks.

Ithaca Energy has until August 14 to comply with the issues raised by the improvement notice. Ithaca Energy was founded in 2004 and is owned by Israel’s Delek Group. It took over the Alba FSU as part of the £1.6 billion ($2bn) purchase of Chevron’s North Sea assets in November 2019.

Elsewhere, Premium Drilling Tools was issued a prohibition notice on February 21 and told to immediately halt works in some areas of the business after the HSE found several failings, including damage to equipment which gave rise to the risk of electric shock and explosion due to exposed parts.

The HSE says that Premium Drilling Tools had also failed to maintain some machinery “so far as is reasonably practicable to prevent danger.” Amongst a list of failures, the drilling equipment manufacturer had also failed to take suitable and sufficient steps to prevent, as far as reasonably practicable, any person falling a distance liable to cause injury.

Prohibition notices are a step further than improvement notices as they mean that certain operations in a business must be stopped immediately. An improvement notice gives a company a certain amount of time to respond to the HSE’s comments and make the necessary changes to improve the safety of their operations without having to halt them.

Pneumatic Timers and Counters

• On or off delay timing function

• 0.2 seconds up to 100 hours timing

• Base, panel or DIN-rail mounting

• 6 or 8 digit totalising counters

• 3 or 5 digit adding / subtracting preset counters