16 minute read

Veg Revolution

from Culinary Playbook

MENUS

Veg Revolution

Key Principles:

• We are moving vegetables back to the center of the plate by creating delicious plant-based options, providing choices for our guests to eat the way they want.

• Plant-Forward can be defined as a style of cooking and eating that emphasizes but is not limited to, plant-based foods and reflects evidencebased principles of health and sustainability.

• VegRev is a chef’s personal approach to their cooking style as well as a larger, collective expression of better for you and more sustainable food choices. It is about expanding choices and fostering innovation.

*NOTE: For tools on MyCompass, make sure you are logged in with your Compass user ID & password for full access.

Use Veg Revolution on MyCompass under the Envision Group.

Why it’s important!

Morrison Community Living has recognized the importance of plant-forward menuing and are increasing training, partnerships and tracking to meet consumer demand.

MENUS

Sustainability

Use Sustainability Solutions on MyCompass under the Envision Group Why it’s important!

We care about people and the world we live in. Our strong commitment to sustainability forces us to pay attention to the products we use and how we use them.

Guidelines:

• Participate in Waste Not, limiting waste of food and other product.

• When using disposables, choose products that are environmentally friendly.

• Buy products that are locally made or grown whenever possible.

• Use products that are made or grown using environmentally-safe practices.

• Buy products that come from renewable resources such as sustainable seafood.

MENUS

Waste Not

Use Waste Not on MyCompass under the Envision Group. Why it’s important!

The U.S. wastes over 40% of the food we produce. We can minimize the cost and environmental impact of food waste at all Morrison Living accounts.

How It Works:

• Waste Not tracks and reports leftover food on OMS by station in 3 categories: overproduction, production and out of date inventory.

• Stations are listed sector specific and can be tracked through

SAP hierarchy (unit complex, region and sector levels).

• Participate in Stop Food Waste Day, Food Recovery programs,

Waste Not Wag a Lot and Imperfectly Delicious Produce to reduce waste at the source, raise awareness and promote solutions the positively impact the areas where we operate.

• Find your unit’s Waste Not score via MyResults reporting.

Don’t have access to MyResults? Gain access by sending an email to Shared.MyResults@compass-usa.com.

MENUS

Menu Management

Why it’s important!:

Having a defined menu helps: • Control the food cost. • Manage the food production tasks. • Plan the service for seasonal, regional and customer preferences. • Document the food you are serving.

• Cost out menus ahead of using them. Make changes to reduce cost if menu cost is higher than budget.

• Use foods listed in Foodbuy Managed Order Guide (MOG). Take advantage of recommended foods such as seasonal recommendations or Opportunity Buys.

• Plan food items that use approved recipes.

• Enter menus regardless of source into Webtrition Menu

Publishing for both cost and nutritional analysis.

FOOD PRODUCTION STANDARDS

FOOD PRODUCTION

General Production Standards

Why this is important:

Production standards help you to: • Control the food cost. • Meet company quality standards.

What to do:

Ownership • Executive Chefs own Food Cost and Food Quality and are the onsite leader for kitchen and culinary operations.

Food Tasting Requirement • In addition to following recipes, culinarians should taste food throughout production for quality control in accordance with proper QA standards. • Management and servers should taste menu items on both resident serving line and retail operations approximately 10 minutes prior to serving time.

Food Storage, Labeling & Dating • Use food product (orange) labels for commercial products after opened and for products prepared inhouse that will be held more than 24 hours. Labels available at Food Service Resources 1-800-367-4421. • Train staff on usage of orange labels.

Measuring Tools & Small Wares • Have an ample supply of scales, measuring cups/ spoons, rubber spatulas, knives, spoons etc. available.

Production System • Enter menus into Webtrition system Menu Publishing.

Station Set Up • Prepare plan-o-grams for proper production and station set up.

Right Product Right Application • Use product specified for each dish. All products have an application, but not all products work for every application.

Thawing of Meat • Thaw whole muscle meats under refrigeration. Only use forced thawing under cold running water as a last resort.

Meats should be roasted or braised according to recipe • Use proper cooking methods as per Webtrition recipes.

Steaming • Don’t steam products in pan deeper than 2” (perforated).

Entrées • All entrees are made in house and we don’t use convenience frozen entrées (lasagna,

Mac & Cheese, pot roast, etc.).

Vegetables • All vegetables are roasted, sautéed or steamed, batch cooked where possible and aren’t held in water.

Grilled Meats • Don’t hold grilled meats hot in Au Jus or water.

Batch Cooking is Required • Don’t hold hot food items (casseroles, roasted meats, starch side items, soups) more than 1 hours prior to meal service. • Cook vegetables less than 20 minutes before meal service and batch cook as needed. • Cook sautéed veggies within 15 minutes of service. • Prepare fried foods less than 30 minutes before meal service and batch cook as needed.

Grilled Chicken • Grill chicken to internal temperature of 165°F.

Pizza • Top pizza as close to baking time as possible. Our specified crusts can go from freezer to oven in as little as 10 minutes.

Scrambled Eggs • Don’t steam scrambled eggs. Batch cook scrambled eggs no more than 24 portions at a time.

Gelatin and Pudding • Make all gelatin and pudding in house. Only use portion packs for floor stock.

Pancakes & French Toast • Batch cook pancakes and French Toast. Don’t use frozen.

Mashed Potato • Make mashed potatoes from scratch.

Deli Meats • Shave deli meats paper-thin.

Garnish • Garnishes should be 100% edible and should enhance the product flavor. Don’t use kale.

Baked Goods • Bake rolls, biscuits, muffins and cookies in-house daily.

Casseroles • Prepare and serve in individual casserole dishes whenever possible. Don’t use anything larger than a 2” half sized hotel pan when not using individual dishes.

Hot Cobblers • For self-service cobblers use a 2” half-sized hotel pan.

Full crust pans are acceptable for cobbler that is served.

PUREé Program • Implement and use components of the PUREé program, as applicable to hospitals or communities with CEC approval for exceptions.

FOOD PRODUCTION

Daily Production Sheets

Why this is important:

Daily production worksheets and daily production summaries are important to manage the product we produce.

Production worksheets and summaries allow us to:

• Control cost by keeping the amount of product we use to exactly what we need.

• Control quality and avoid leftovers while ensuring that we have enough for our needs.

• Save labor through cross-functional preparation and cutting wasted time.

• Help with inventory control.

What to do:

1. Two days ahead of production: a. Create daily production worksheets or summaries for each production area (resident/guest, retail, catering etc.). Generate summaries using Webtrition production-forecasting tool. Some areas are: breakfast, entrées, vegetables, breads, salads and desserts. b. Make sure recipe name and number are on daily production worksheet or summary.

c. Make copies of daily production worksheets or summaries. Give one to the storeroom and one to each production area. d. List serving utensils as well as pan and garnish information on Taste/Temperature Record.

2. Before weekly ordering cycle: a. Prepare daily list of food items that need to thaw, cook ahead, or are partly prepared to meet recipe needs.

3. One day before service: a. Prepare foods for cold service to allow enough chilling time. This could include salad bar items prepared and placed in proper serving container where it is difficult to maintain temperatures during service periods. b. If products cannot or should not be prepared a day in advance, pre-chill servicing containers prior to placing product in them.

4. On the day of actual production: a. Check progress frequently in production areas. b. Determine use(s) for leftovers. Note them on daily production worksheet(s) or summaries and review with production staff. c. Look for additional changes (and reasons) made on daily production worksheets or summaries. d. Check storeroom’s copy of daily production worksheets or summaries to identify changes and reasons for those changes..

5. End of production day: a. Make notations regarding “numbers of servings” short or “number of servings” unused, or any ingredient in short or excessive amount for recipe preparation. Use this information in preparation of sheets for future repeated days in menu cycle. b. Only designated management can make decisions concerning discarding and utilization of unused portions. c. Accounts using computerized food production software should enter actual quantities (prepared, unused) into database on daily basis.

6. Retain production worksheets or summaries for minimum of six (6) weeks.

FOOD PRODUCTION

Daily Production Meetings

Why this is important:

Daily production meetings prevent miscommunication, errors, wasted effort, and corrective work. You will spend less time fixing issues and have less confusion in your kitchen if you have production meetings.

What to do:

Meet daily with production staff to cover: • Production sheets, recipes, food quality, presentation, food handling and HACCP issues • Leftover usage • Substitutions (menu or ingredient) • Menu items that contain common allergens: peanuts, tree nuts, soy, dairy, wheat, fish, shellfish, or eggs • Advance preparation • Special functions • Discuss potential problems and make a plan for managing them • Discuss past problems (previous day) and how to prevent them

Use the production meeting template as a place to capture your notes, creating a blueprint for a successful meeting to connect, communicate and educate your team each and every day!

Do you know what’s on the menu for today? Do you know what those items taste like? The best way to answer these questions is through food tasting.

Use recommended meeting guides for location.

Have team gather around serving area 15 minutes prior to meal time. It’s a good idea to bring other team members in as well.

This is a great time to share stories, train new associates and taste food. Encourage team to taste food as well. The more they know about it, the more they can speak positively about it.

To taste, place food in soup bowl or a vegetable dish. Use a new teaspoon or fork for each food item tasted. When tasting the food, look for the following:

• Was food prepared using correct recipe? • Is the food presentable? • Is food overcooked or undercooked? • Is food at proper serving temperature?

Any food not up to our quality standard should be removed and corrected. Make sure proper serving utensils are available at each serving station and associates know how to serve item. Make sure staff knows of foods that might contain the eight major allergens:

If customers have questions about allergens, associates should refer the questions to a manager, supervisor or chef.

*Source: (https://www.foodprotection.org/)

Why this is important:

Mealtimes are our “Showtime”. To make sure that staff is ready to interact with our customers and residents, they need to know exactly what to expect during meal service. They should also be prepared to answer questions from customers. This is a great time to answer their questions and rally the team to put their best foot forward.

FOOD PRODUCTION

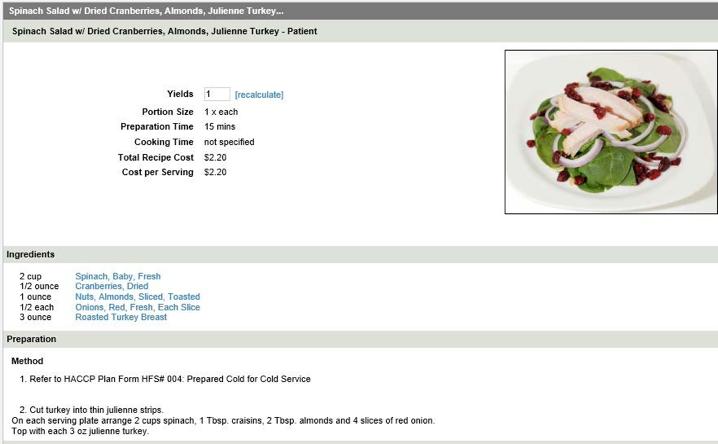

Standardized Recipes

Components of standardized recipe as generated by Webtrition are below:

• Use approved standardized recipes from Webtrition or included in quarterly marketing materials as provided by Marketing team for food production.

• Follow policies at your location regarding management and communication of allergens in recipes.

• Notify Chef, or person in charge, if ingredients must be substituted to avoid food allergy reactions.

• Post list of resident food allergies in an area visible to production associates (only allergies, not resident names/room numbers).

• Double check recipes prepared for texture-modified diets to ensure they have been prepared according to texture definition in recipe and diet manual.

• Read labels of new/replacement ingredients to determine whether there are food allergens in new/replacement product that were not in original product. If there are, note in. Menu Allergen-Intolerance Report.

• Have regional and local recipes approved by your

Corporate Executive Chef prior to use. Refer to Webtrition Recipe Approval Checklist.

FOOD PRODUCTION

Menu Substitutions

Why this is important:

While we should always have the goal of serving exactly what is on our menu, sometimes menu substitutions are necessary. When they are, it is our job to make sure that the substitution is coordinated with the rest of the menu and meets both our cost and quality commitments.

Confirm that the substitution is really necessary.

Pick substitute food that: • Has a similar nutritional value. • Is not on menu elsewhere within 24 hours before or after. • Is an item approved for service.

Make sure your dietitian approves of substitutions when appropriate.

Discuss substitution in production meetings to make sure whatever the cause, it is an exception not a regular thing. If it is an ongoing problem, fix it so substitutions don’t keep happening.

Make sure you have recorded every substitution on the production sheets. • Make sure that all staff knows of the substitution so that they can make the changes they need to make and in case a resident has an allergy to the food.

Check Taste/Temperature Record for recording of substitutions.

FOOD PRODUCTION

Unused Portions

Why this is important:

While you don’t want to run out of food, good production planning will help you to keep them to a minimum. Leftovers are never a good idea because you still have the cost of the food that was used but the quality is never as good as that of freshly prepared food. Leftovers also require careful handling to avoid contamination and spoilage.

Make sure you have fewest possible leftovers and waste by: • Recording them on daily production sheet for future reference.

• Checking production sheet and refrigerators after each meal.

• When preparing a new item on retail menu, plan for less until you know how well product is liked by your customers.

• Paying close attention to your resident or resident meal request numbers, especially for a new item

• Discussing leftover usage at daily production meeting.

• Keeping a record of leftovers and their usage.

Allow flexibility in retail menu to allow for usage of leftovers from resident or resident menu. • Make sure leftovers are used within two days. The first day of production is day one. The best plan is to use them in the next meal. Follow Food Handling Guidelines for how to chill, store and handle.

• Use leftovers once. Any leftovers you did not use in 2 days become food waste to be discarded. If you are using a

Trim Trax Waste Log write them in there.

• Never re-use leftover pureed foods. Treat them like waste after each meal.

FOOD PRODUCTION

Meal Service Support

Why this is important:

Residents are at the center of our business and serving them the best food possible is part of our brand promise. The only way to do this is for the culinary team to pay as much attention to the quality of product that you serve to residents as you do for any other service.

Guidelines:

• The culinary team owns quality of resident food as well as adheres to diet foods as needed.

• Make sure your team is carefully planning resident food service and discussing it as thoroughly as they do for retail service.

• Make sure to follow recipes, using correct product specs and following our culinary philosophy.

• Use Taste and Temperature Report available in Webtrition.

• Make sure you have recorded the substitution on production sheets.

• Check the P&P manual Taste/Temperature Record for recording of substitutions.

Hot Production Area

• Make sure you are batch cooking foods or cooking to order depending on system. Don’t cook and hold food more than two hours before meal.

• Make sure you lay out food diagrams to help with planning of pan sizes and placement. Do this ahead of time for the whole menu. There is a sample diagram but feel free to make your own.

• Use Webtrition “Production Station Worksheet Report” to manage this area.

Monday Dinner Workstation One

Traditional Beef Lasagna Squash Medley

Sauteed Zucchini, Yellow Squash & Red Peppers

Cooler One CA Cooler Additional

Vegetable Soup with Meatballs Chopped Lasagna Greek Salad with Chicken - Patient Fresh Strawberry Shortcake Peach Shortcake,

Beef Fettuccine Alfredo with Cheese * 6 oz Cream of Mushroom Soup, Sauce/Puree

Tomato Sauce Beef Broth Whipped Potatoes with Olive Oil

Strained Corn Bisque Peach Shortcake, slurried Chicken Salad Sand Orange Gelatin Chicken Salad Sand - Ground Greek Dressing

Merry Berry Smoothie Margarine PCs Crackers Italian Ice Apple Juice

Workstation Two

Traditional Beef Lasagna Squash Medley

Sauteed Zucchini, Yellow Squash & Red Peppers

Cooler Two CA Cooler Additional

Vegetable Soup with Meatballs Chopped Lasagna Greek Salad with Chicken - Patient Fresh Strawberry Shortcake Peach Shortcake,

Beef Fettuccine Alfredo with Cheese * 6 oz Cream of Mushroom Soup, Sauce/Puree

Tomato Sauce Beef Broth Whipped Potatoes with Olive Oil

Strained Corn Bisque Peach Shortcake, slurried Chicken Salad Sand Orange Gelatin Chicken Salad Sand - Ground Greek Dressing Merry Berry Smoothie Margarine PCs Crackers Italian Ice Apple Juice

Check and Record Temperatures of Foods:

• Before delivery to line or workstation, including backup pans: heat up pans that are not at correct temperatures.

• Record temperatures of food twice during service – at the beginning and again at either the mid-point or end of service.

Keep Pans Covered:

• Don’t put hot food on line or workstation more than 15 minutes ahead of lineup meeting.

• Restock food during meal and make sure it’s hot.

• At end of meal you should work with line supervisor to make sure there is food for NOW trays.

The rest become leftovers.

Cold Production Area

• Cold food should look delicious.

• Don’t leave food out at room temperature and make sure cooling systems for serving are working.

• Taste food before serving and fix any problems.

• Check and record temperature the same way you do hot food. If temperature is too high, put it in cooler or freezer to get it back down.