PART

THREE STEPS TO HEAVEN - STEP ONE - SUPER 5 MAJOR CHANGES

A NEW INTERCEPTOR

THREE STEPS TO HEAVEN - STEP TWO - THE CONTINENTAL GLAD ALL OVER INTO SOMETHING GOOD

THREE STEPS TO HEAVEN - STEP THREE - THE CONTINENTAL GT

THE LAST TIME KEEP ON RUNNING GOOD VIBRATIONS

ALL OR NOTHING

OUT OF TIME

I’M A BELIEVER

CHAPTER NINE - MADE IN CAVES 86 THE TROGGS

THOSE WERE THE DAYS GET BACK

SOMETHING IN THE AIR IN THE SUMMERTIME

PART TWO - INDIA

CHAPTER ONE - EARLY YEARS 94 BEGINNINGS

BECOMING ESTABLISHED

CHAPTER TWO - UPS AND DOWNS 100 CH CH CH CHANGES

DEFINITELY MY CUP OF DARJEELING INTO THE EIGHTIES BULLETS TO BLIGHTY

A LONG-TERM PLAN KEEPING IT LEAN COTSWOLDS CLASSICS

CHAPTER THREE - REINVENTION AND RENEWAL 108

A NEW CHAPTER INHERITANCE

MOVING FORWARDS NEW DEVELOPMENTS

THE INDIAN BULLET CLASSIC RESPONSE

RAPID EXPANSION

ROCKER RETRO

CHAPTER FOUR - ACQUISITION AND EXPANSION 118

PLATFORM FOR SUCCESS

AT DECADE’S END

CHAPTER SEVEN - SIXTIES OVERVIEW 68

THE TIMES THEY ARE A-CHANGIN’ END GAME

CHAPTER EIGHT - THE BEND-SWINGING SIXTIES 70

WHAT DO YOU WANT?

STARRY EYED

THE HIMALAYAN CONSOLIDATION

CHAPTER FIVE - A PARADIGM SHIFT 124

THE SAME BUT DIFFERENT

A FINE MACHINE

OWNING AND RIDING A ROYAL ENFIELD INTERCEPTOR MOTORCYCLING VERSATILITY

OWNING AND RIDING A ROYAL ENFIELD HIMALAYAN

A FAMOUS DEVOTEE

Author: Richard Skelton

Design: Burda Druck India Pvt. Ltd.

Publisher: Steve O’Hara

Published by: Mortons Media Group Ltd, Media Centre, Morton Way, Horncastle, Lincolnshire LN9 6JR Tel. 01507 529529

Printed by: William Gibbons and Sons, Wolverhampton

ISBN: 978-1-911639-38-1

© 2021 Mortons Media Group Ltd. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying, recording, or any information storage retrieval system without prior permission in writing from the publisher.

CONTENTS BUSINESS STRATEGY DEVELOPMENTS CHAPTER SIX - NOW AND FOREVER 134 OWNING AND RIDING A ROYAL ENFIELD 500 CLASSIC CLASSIC STATUS METEOR ON THE ROAD DAY TRIPPER DOWN TO EARTH CUSTOMISATION HIMALAYAN UPDATES CHAPTER SEVEN - ONWARDS AND UPWARDS 142 FACTORY VISIT A DIFFICULT YEAR A NEW CLASSIC LOOKING AHEAD ANNIVERSARIES AUTHENTICITY ENFIELD FOLK 149 SUCCESS AT LAST CLUB STALWART HITCHCOCKS MOTORCYCLES AFTERWORD AND ACKNOWLEDGEMENTS 154 INTRODUCTION 4

ONE

GREAT BRITAIN CHAPTER ONE - EARLY DAYS 8 BEGINNINGS CHANGE AND REORGANISATION THE AGE OF THE PIONEER A WAR TO END ALL WARS CHAPTER TWO - THE ROARING TWENTIES 18 A NEW ERA SPORTING TALES BRIGHT YOUNG THINGS CHAPTER THREE - SURVIVING THE DEPRESSION 24 A CAUTIOUS PHILOSOPHY A WORKING DAY ROYAL ENFIELDS IN THE THIRTIES CHAPTER FOUR - FOR KING AND COUNTRY 32 MOTORCYCLING THROUGH THE WAR THE FLYING FLEA WARTIME FACTORIES FACTORY NUMBER ONE FACTORY NUMBER TWO FURTHER FACTORIES CHAPTER FIVE - A NEW DAWN 38 OLD AND NEW A FAMILY ATMOSPHERE THE POST-WAR YEARS 1940s NEW LOOK ISDT ROAD RACING CHAMPION MID-WAY POINT

SIX - NEVER HAD IT SO GOOD 50 REWARDING MOTORCYCLES ENFIELD FOLK BY MILES THE BEST BADGE ENGINEERING CLIPPERS AND SUPER METEORS NEW BULLETS

AND BULLETS CRUSADER

CONSOLIDATION

QUALITY GOING WITH THE FLOW COST CLIPPING

-

CHAPTER

MUCK

DREAMLINER

STAR

INTRODUCTION

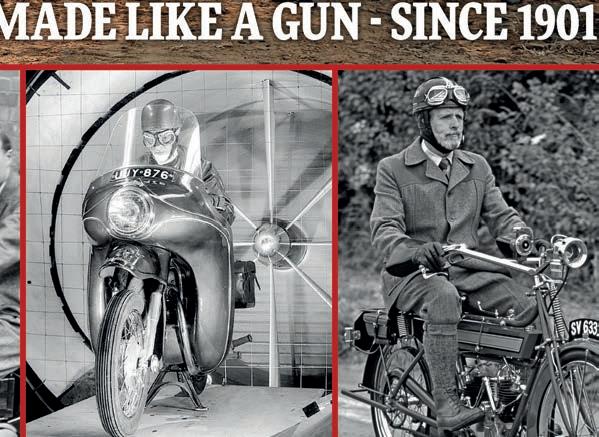

Royal Enfield is at once an historic motorcycle company with a truly unique heritage and a dynamic, modern concern with an exciting and profitable future ahead. Furthermore, while its bikes are creating millions of happy motorcyclists around the world, its business philosophy is blazing a trail for other manufacturers to follow, and in the process showing the way forward for motorcycling itself. That Royal Enfields have been in continuous production longer than any other motorcycle, and that the single-cylinder Bullet has been built and sold for more years in succession than any other bike in history, are statements of fact, albeit ones that require a degree of clarification. The firm, which had its beginnings in light industrial manufacturing in the English Midlands in the mid nineteenth century, began making motorcycles in 1901, a year before Triumph (which in any case dropped off the scene for much of the 1980s), and two before Messrs Harley and Davidson began production in Milwaukee, SA. In continental Europe BMW and Moto-Guzzi both began building bikes in 1921.

hat makes Royal Enfield unique is its dual heritage. The story is quite well known. hile the English firm closed

its Redditch factory’s doors in 1967, and went out of business completely in 1970, an independent Indian offshoot, which began selling Enfields in the 1940s and manufacturing them in the 1950s, continues as Royal Enfield to this day. And whether in the English Midlands or faraway Madras (or Chennai as it is now known), the Bullet has been built continuously since 1948, making it without doubt the longest-produced motorcycle in history. In fact, there were pre-war Redditch Bullets, but these were not part of the same lineage.

The Indian firm has become a global behemoth, massive in scale and scope compared with its British progenitor. But like its forebear it has, throughout its history, remained a paternal, family-

run company, owned and staffed by enthusiasts who love and ride the product. This holds true to an extent, even today. Around 15,000 Bullets were made in Redditch and several million Bullets and Bullet-derived Classics and cruisers have been built in Chennai. This alone is enough to ensure they will be a feature on roads all around the world for many years to come, but now an all-new Classic 350 has been launched and is set to keep the bike in the sales charts for the foreseeable future. Like its recent ancestors, today’s new Bullet is, in spirit, still a 1950s machine, but one that has been much improved, refined and made immeasurably more reliable, especially in its most recent incarnation. Over nearly 70 years the Enfield single has become part of culture and everyday life on the Indian sub-continent, providing practical transportation, positively affecting the lives of millions, and winning countless hearts and minds. And while it has continued to sell as an everyday motorcycle in its home market in formidable quantities, it has been exported around the world in steadily increasing numbers as a charming and delightful anachronism - a classic motorcycle that can be bought brand new with a warranty. Classical transportation of a time-travelling kind. But it is the exciting, new forward-looking models the firm has been exporting since 2018 that are starting to change the nature of modern motorcycling, and now the new Classic 350, launched globally in 2022, represents a convergence of these two trends.

In the later 20th century, while continuing to produce mostly homemarket Bullets by the thousands, Enfield India experienced various financial ups and downs until a takeover by the Eicher commercial vehicle group, with Bulletriding enthusiast Vikram Lal at its head, brought greater stability. Then his son Siddhartha Lal took the helm, instigating a new strategy and broader ambition. estern educated and a polymath, Lal is a charismatic and sophisticated man, but above all he is a proud Indian, and a

(Howard Allen)

4| Royal Enfield - A Global Motorcycling Success Story

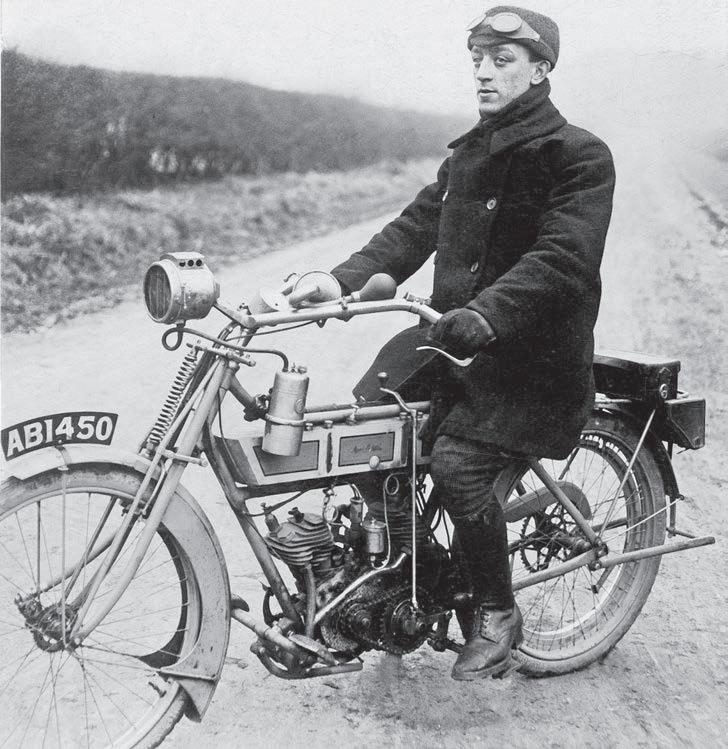

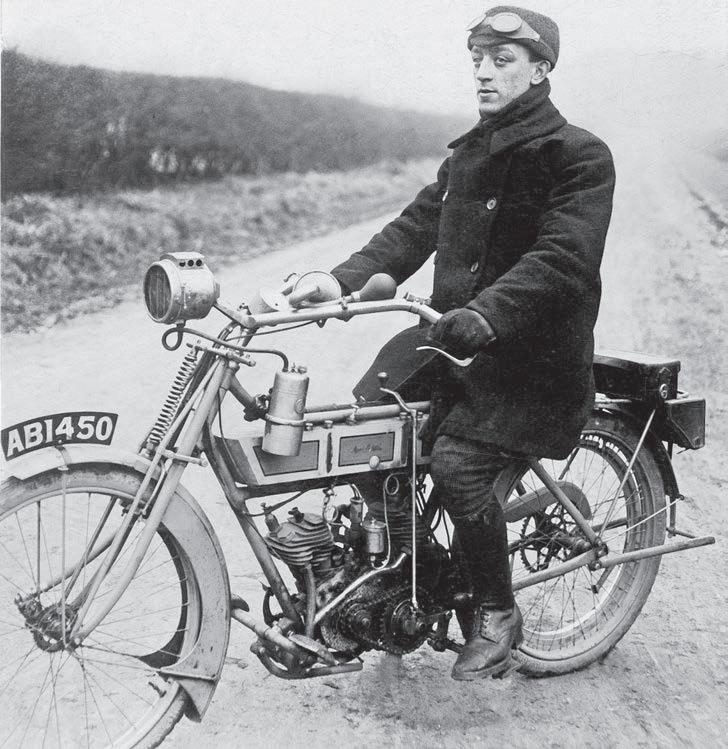

Motorcycling in the rain. An Enfield factory tester splashes through the puddles in 1916 (Mortons Archive)

dedicated motorcyclist who as a teenager would sneak out for rides on his father’s Bullet. Siddhartha Lal brought change. A new philosophy. His plan, to design and produce completely new models, and to improve engineering and build-quality standards at his factories to Japanese levels. For it was the Japanese motorcycle manufacturers - the still extant Yamaha, Suzuki, Kawasaki, and most of all Honda - who in the 1960s produced new motorcycles of such exquisite quality and of such reliability, and to many and various exciting, innovative designs, that over little more than a decade they killed the entire British motorcycle industry in its tracks; and of course the casualties included Royal Enfield of Redditch.

Japanese bikes in the sixties were also excellent value for money. Supplying the vast South East Asian market and a not inconsiderable need at home made for huge economies of scale. Additionally, machine tools and factory methods were fully up-to-date and geared to mass production, and clever design also helped keep costs down, whereas British bikes were still a product of machine shop

engineering practices. Lal learned these lessons well and sought to reapply them. He also noted that at the beginning of the twenty-first century motorcycling was in global decline. Times had changed. Many of the world’s roads were becoming crowded. Bikes had got too big, too powerful, and too expensive, and onerous rider legislation was choking off the supply of new recruits. He sought to bring about a reset, aiming to produce affordable, well-made, highly-usable medium-capacity motorcycles; and by doing so broaden motorcycling’s appeal and grow the market as Honda had done in America in the sixties with their highly successful ‘You Meet the Nicest People on a Honda’ advertising campaign. To Lal this was more than a business strategy. It was also and fundamentally about being pro motorcycling. Of course, Royal Enfield was in business to make profits and reward its investors, but first and foremost his vision entailed making top-quality motorbikes, products to be proud of and which bring joy to their owners. Then with these machines he aimed to set about reviving and expanding

motorcycling around the world. In the last few years Lal’s ambitious plan has started to bear fruit. In the mature and influential K and European market Royal Enfield has experienced tremendous sales growth, sales are also building strongly in the USA, and performance in the company’s huge and diverse home market remains robust despite fierce and targeted competition.

The first all-new Royal Enfield machine to roll off the production line as part of the Lal vision was the 411cc Himalayan. A highly practical, go-anywhere adventure bike first introduced in India in 2016, it was exported worldwide from 2018 onwards. That same year the Indian company green-lit the construction of a 2.5 million technology centre in Leicestershire, England. The new facility, which came on stream in 2017, became the company’s global headquarters for product strategy and development, featuring comprehensive design, engineering and testing facilities and an extensive private test track. Then, in late 2018, wholly new 650cc Interceptor and Continental GT parallel twins started

INTRODUCTION

Royal Enfield - A Global Motorcycling Success Story|5

nterceptor (Howard Allen)

rolling off the company’s production lines. These bikes were named after models from Enfield’s English past, and by deliberate design they were not overendowed with electronic technology, but they were, nonetheless, thoroughly modern motorcycles, engineered to exacting contemporary standards and backed by a Honda-beating three-year standard warranty. pon their release it was telling Royal Enfield did not state a specific target demographic (nor had they with the Himalayan). Instead Lal made it clear Royal Enfield’s intention was not just to find buyers for these motorcycles around the globe, but to revive and increase interest in motorcycling itself. These most attractive, supremely capable and not least, highly affordable bikes were, and still are, above all about making middleweight motorcycling accessible and fun again.

Launched in India in late 2020 and globally the following year, the 350 Meteor was a fourth new model from Lal’s company. Built on a third completely new engine-chassis platform, and given another

storied name from the firm’s history, it was a cruiser-style bike made available in three cosmetically differentiated variants, all sharing the same 350cc four-stroke, single-cylinder overhead camshaft engine. An abundance of torque gave the new engine great character as well as plenty of usable power, and its distinctive exhaust note, while differing in tone from that of the existing Bullet, had definitely got the Enfield ‘beat’ - the heartbeat of India. Laid-back, comfortable cruisers are a part of Royal Enfield culture in India, especially among younger riders, and small to medium-sized bikes are becoming increasingly popular in other countries. Biker demographics are changing worldwide and Enfield had once again spotted an underestimated market sector and moved to serve it. Furthermore, as industry pundits were quick to realise, the Meteor platform would soon form the basis of a new generation of Bulletstyle machine. The Classic 350 would be launched in India in September 2021, with worldwide roll-out scheduled for the first half of 2022. The Meteor bristled with

bright ideas and lovely design touches, not least Royal Enfield’s own Tripper satellite navigation system. These capable yet userfriendly middleweights are great beginner bikes and perfect too for older bikers, perhaps becoming less able to manage a big machine and looking for a stressfree way to extend their motorcycling adventures. They are also ideal city bikes and perfect alike for Sunday afternoon rides or long-distance cruising. In short, the Himalayan and the 650cc twins and the Meteors were great all-round motorbikes designed primarily to help people discover the practicality of motorcycling while capturing, or recapturing, its magic. And they were sold at value-for-money prices. Meanwhile, the Royal Enfield Bullet had remained a miracle machine, living on out of its time. Through long service and ubiquity it had cemented its place in the life and culture of a huge and great country, and it rode on around the world, provoking smiles and winning friends wherever it appeared, emblematic of the proud and historic company that made it. Now the new 350cc Classic represents

Time stands still

6|

Story

(Royal Enfield)

Royal Enfield - A Global Motorcycling Success

a new generation of Bullet, carrying the story on into the future where further chapters are yet to be written.

MODERN AND CLASSIC SCENE

A significant number of Redditch Royal Enfields are still on the road today, some in oily rag condition, many others having been faithfully and painstakingly restored. No account of the present-day

Royal Enfield classic and retro-classic scene would be complete without acknowledging the ongoing contribution of Hitchcocks Motorcycles. This specialist family-run concern based in Solihull in the English Midlands, exports Royal Enfield spares and accessories around the globe as well as serving a busy home market. Over 38 years the company has built up a phenomenal range of stock and developed an overall level expertise that is second to none worldwide. All Redditch machines from 1939 onwards are well provided for, together with all exported Indian Bullets, many now recognised as classics in their own right. Modern-day Chennai models are also covered, the firm having developed highquality performance parts and accessories in its spotless engineering workshop as well as buying-in selectively from India and elsewhere. The whole Hitchcock family has been involved in the business at various times, and founder Allan, his son Daniel and many of their staff are true Royal Enfield enthusiasts. ithout doubt Hitchcocks Motorcycles is very much a part of the Royal Enfield story. Also central to modern-day Enfield ownership is the Royal Enfield Owners’ Club (REOC) which was founded in the mid-late seventies after an earlier incarnation folded in the mid sixties (that club’s demise exactly mirroring that of the original Redditch factory). The aim of the REOC is to promote the riding, maintenance, restoration and history of all Royal Enfield motorcycles regardless of age or origin. It produces an excellent

bi-monthly maga ine, and offers technical assistance and an excellent dating service as well as regional, national and international friendship and fellowship.

LOOKING FORWARD

Royal Enfield of India now has three engine and chassis platforms on which to develop new models. A new generation of Bullet is being brought to market, rumours persist regarding a largecapacity street scrambler, and a parallel twin cruiser now seems to be on the way. More exotically, a V-twin concept bike exists, setting enthusiasts salivating at the prospect of a flagship model inspired by the luxurious large-capacity K and KX machines built in Redditch in the 1930s. hatever the future holds, Royal Enfield is a company taking the initiative.

hile carrying the Royal Enfield name forward to a new generation of riders, it is rethinking what motorcycling is all about, and through this it finds itself at the forefront of a larger movement to save the sport. It is a factory making the right bikes for the times and doing the biking world a good turn.

This publication is in part a celebration of that effort, and of the motorbikes the company makes today, but a greater part of it is an account of the unique history of a marque which in 2021 spanned 120 years and counting. It is a story of human effort and endeavour on two continents, manifesting itself in a combined total of 138 years of motorcycle production in India and England - 69 years in each country! ■

Royal Enfield - A Global Motorcycling Success Story|7

2021 Classic 350. Carrying the Enfield story into the future (Royal Enfield)

PART 1 I GREAT BRITAIN

EARLY DAYS

Time travel. 1911 Royal Enfield V-twin (Mortons Archive)

8 | Royal Enfield - A Global Motorcycling Success Story

CHAPTER ONE

BEGINNINGS

During the steam and machineage upheavals of the industrial revolution, participating British towns and cities came to specialise in mechanised production of varying kinds. Redditch, a small Worcestershire settlement near Birmingham, became known in early Victorian times for light engineering, and in particular the manufacture of sewing needles and fish hooks. George Townsend & Co, needle manufacturers in the town’s Hunt End district, were particularly inventive manufacturing engineers with many patents in their name. Their Givry Works was built in 1851 comprising a red brick, three-storey factory with owner’s accommodation attached. That year the business employed 16 men and two boys. By 1871, 170 workers were on the Townsend payroll, kept busy stamping out needles for hand and machine use. Additionally, the firm made shuttles, reels, and springs for sewing machines. Founder George Townsend, who was also an innkeeper and brewer, died in 1879, whereupon his half-brother, Fisher Townsend, and his son, George, took over the business. By then George junior lived in the works villa.

While continuing to make sewing needles and sewing machine parts, the Townsends sought to diversify, and, noting a nascent bicycling boom, moved into cycle component manufacture. Soon, having patented a one-piece sprung saddle frame, the company began to develop complete machines of its own. Safety bicycles, machines with wheels of equal size, started to appear in the early 1880s, and by the end of that decade the Townsend concern was self sufficient in the manufacture of cycles made wholly at the Givry factory. Velocipedes exhibited at Crystal Palace by Townsends included the Scorcher, the Business Rider and the Ecossais. Townsend bicycles were recognised for having strong frames and were proved in competition, not least by intrepid employee Fred Shelton.

CHANGE AND REORGANISATION

In the early 1890s, following the invention of the pneumatic tyre by John Boyd Dunlop in 1887, cycling was clearly set for further expansion, but the firm got into financial difficulties and struggled to take

advantage. Anxious not to miss out on potential profits, its investors brought in two-wheel troubleshooters Albert Eadie and Robert (Bob) Walker Smith, charged with turning the ailing business around. Although junior in years, Birminghamborn Eadie was the senior figure of the two. Tall and flamboyant, and given to wearing a Stetson hat and colourful waistcoats, he was garrulous and articulate - good attributes for a successful cycle salesman. Affectionately nicknamed ‘The Emperor’ (a soubriquet he enjoyed and encouraged), Eadie had a generous character and was well liked by his workers and business associates alike. Smith, for his part, came with a track record as an innovative works manager at D Rudge and Co of Coventry, later to become Rudge Whitworth, makers of high quality motorcycles and bicycles. Before this he had been an apprentice engineer at the Great Western Railway workshops and a pupil at Wolverhampton School of Art. The Rudge concern had been originally founded in that West Midlands town by bicycle manufacturing pioneer Daniel Rudge, who died in 1880. A keen cycling enthusiast, Smith designed Rudge’s first tandem bicycle and a tricycle, four and five-man tandems used as pacing machines on racing tracks, and many cycling accessories. He was also keenly involved with the production and development of a cycle boat.

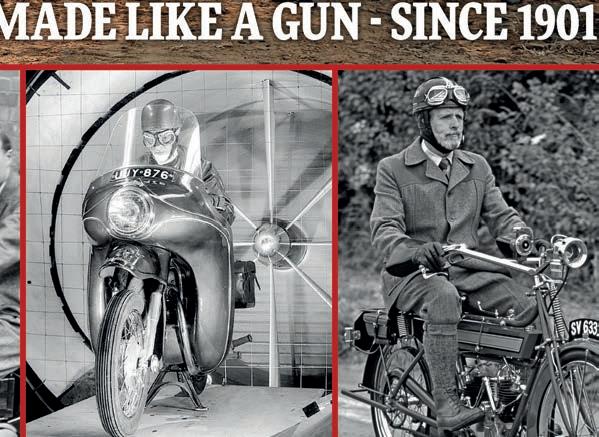

Eadie and Smith took over running the firm in November 1891 when they were 28 and 35 respectively, and in 1892 the company was renamed the Eadie Manufacturing Co Ltd and the needle-making side of the business was sold off. Despite this, the new concern was not solely cycle-centric. In 1892 a significant contract was secured by Eadie to manufacture rifle parts for the government-owned Royal Small Arms Company which was based in Enfield in Middlesex. This inspired two ideas: the Enfield name was given to a range of bicycles, and a new logo was devised featuring a military rifle together with the slogan ‘Made Like a Gun’. Furthermore, a new entity was created to build these new bikes called The Enfield Manufacturing Company. Then, in 1893, this firm’s bicycles were first given the name, Royal Enfield.

The company subsequently went through several reorganisations. By 1896 more manufacturing space was required and to alleviate the problem the Eadie operation was moved out to a separate factory in Redditch from which it supplied cycle components to other manufacturers worldwide, thus leaving the New Enfield Cycle Company to focus on the manufacture of complete bicycles. The new factory is now the site of Redditch’s B&Q DIY store. Only its iron gates survive.

Surviving Redditch needle mill with attached house, similar in design to the Givry Works at Hunt End (J Thomas)

Surviving Redditch needle mill with attached house, similar in design to the Givry Works at Hunt End (J Thomas)

CHAPTER 1 | EARLY DAYS Royal Enfield - A Global Motorcycling Success Story|9

Back in 1897 the new Eadie factory’s output included the Eadie Cycling Hubthe first drum brake ever fitted to a bicycle. This back-pedalling brake hub was a strong and well-made piece of engineering which took two tons riding strain in tests at Lloyds’ Proving House and was in production until 1927. Enfield’s bicycles were up-to-date machines featuring diamond frames and Enfield’s own twospeed gear hub, and in 1897 the companies combined employed 600 workers with up to 400 bicycles per week leaving the works.

At this point in history the motor bicycle had barely been invented, and when the Motor Car Act of 1896 famously dispensed with the obligation for a man to walk in front of all mechanically propelled road vehicles carrying a red flag, and simultaneously tripled the British speed limit from 4mph to a heady 12mph, there

was no home motorcycle industry to take advantage of the fantastic new freedoms this afforded.

In the late Victorian era the invention of rear freewheels such as the Eadie Coaster and the universal adoption of pneumatic tyres had led to a cycling boom, but tricycles were seen as the type of lightweight motorised vehicle most likely to take off (quite literally in some instances!). Usually of short wheelbase, the most favoured layout of these new-fangled contraptions featured a rudimentary engine mounted somewhat unwisely behind a pair of spindly rear wheels and a single front steering wheel controlled by a tiller. Inherently unstable even on smooth surfaces, these unfortunate and ill-conceived devices bobbed and bucked abominably on Britain’s dusty and rutted roads.

Despite this the Enfield concern was keen to get in on the act, and in the last two years of the 19th century a motorised tricycle and a quadricycle were produced featuring French De Dion 2.75hp engines mounted on their rear axles. These were the first ever motorised Enfields.

THE AGE OF THE PIONEER

In the spring of 1900 a demanding 1,000 mile national reliability trial was organised by the Automobile Club in an attempt to boost the infant motor trade. An Enfield motor quadricycle was entered by future newspaper baron, 23-year-old Edward Iliffe of Coventry, with Enfield factory employee Walter Ferdinando Grew on board as passenger. Iliffe’s eponymous firm (started by his father) founded the Autocar magazine in 1895, and in 1903 it would launch The Motor Cycle with Grew as its first ever editor. The trial attracted 83 entrants, of which 65 brave starters set off from Grosvenor Place in London intent on making their hilly way down to Bristol, and from there up to Birmingham and on to Derby, then over to Manchester and further north to Kendal in the Lake District. From there the intrepid pioneers surmounted the notorious Shap Fell destined for Carlisle, before bobbling on

PART 1 I GREAT BRITAIN

10 | Royal Enfield - A Global Motorcycling Success Story

The company’s rifle graphic was not entirely dissimilar to the BSA piled arms logo (REOC)

over the border to Edinburgh, at which point a remarkable 51 teams remained in the running. The return route went via Newcastle, York, Leeds, Sheffield, Lincoln, Nottingham, Leicester and Northampton, from which town 35 new-fangled motorised contraptions chugged and putt-putted back to the capital. The Enfield finished without serious mishap, one of only 15 non-factory entered machines to complete the course.

The first Royal Enfield motorised bicycle appeared in mid 1901. It featured a single-cylinder 1.75hp Minerva engine of Belgian design clipped in position ahead of the frame’s front downtube. The Autocar, (dedicated to: ‘…the interests of the mechanically-propelled road carriage’) included a detailed report on the company’s new powered twowheeler in its 21 September edition that year. Describing Royal Enfield as ‘…one of the latest houses of high reputation in the motor and cycle trades to take up the manufacture of motor bicycles’, the Autocar’s correspondent went on to declare the new machine had impressed him ‘most favourably’. It had a sturdy frame with strong back and chain stays, and flexible front forks designed to ‘… eliminate vibration from the rider’s

hands and arms’. Ingeniously, each fork leg comprised two broad blades which gave ‘...great lateral stability’ while being ‘…flexible in a vertical direction with the lower of the two springs [on each side] being permitted a certain action on the under face of the longer blade…’. Furthermore, being made of ‘stout material’ the forks were able ‘…to stand the extra load and shock of motor propulsion’.

Despite this encouraging review, Royal Enfield’s next effort featured conventional

bicycle forks and a totally different engine position, The company’s 1902 motor bicycle, designed by ex-pat Frenchman Jules Gobiet, used a 1.5hp Redditch-made unit sited above its front wheel. Power was transferred to the machine’s rear wheel via a long leather belt which crossed over near the headstock and ran behind a guard which shielded the inside of the rider’s leg. This strange arrangement was clearly far from perfect, but actually not unique at the time. Indeed, various other unsuitable and incongruous ideas were

CHAPTER 1 | EARLY DAYS

The Enfield cycle shop in the early 20th century (REOC)

A Royal Enfield quadricycle. This example was manufactured in 1901 (bonhams.com/bikes)

Royal Enfield - A Global Motorcycling Success Story | 11

1902 Minerva Royal Enfield with company personnel. L-R: Walter Grew, (motor cycle manager), Ernest Godbolt (general manager), David Doyle (works foreman) and Jules Gobiet (the machine’s designer) (Royal Enfield)

But the top and front-heavy Enfield had particular disadvantages and a machine of this type was described by early motorcycle journalist Basil Davies as ‘... the champion skidder of all time’. Davies once watched a be-goggled pioneer come through his home town on a wet day. ‘He skidded and fell heavily,’ reported Davies, ‘as well he might, for the machine was very tall and carried all its mechanism on a small platform above the front wheel, while his tyres were virtually bald. As soon as the machine lay flat, it caught fire and burnt furiously.’ This type of design would soon be abandoned, but sideslip remained motorcyclists’ great problem of the age. Altogether 214 motor bicycles were exhibited at the Stanley Cycle Show in November 1902, a sign that motorcycling was becoming popular in Britain. Just two years earlier there had been just one motorised machine on display. Earlier in 1902 Royal Enfield advertised their high engine, cross-belt model (‘The Royal Enfield motor bicycle - Made like a Gun’ - £50 : 0 : 0 net.), but by the time of the show it had been dropped and three new

designs were displayed ahead of the 1903 season, two of which featured engines situated centrally at the bottom of ‘looptype’ single cradle frames. A 2hp, 239cc belt-driven motor bicycle was priced at £45 guineas, while an ambitious watercooled model with a 277cc engine was set to be sold for £75 guineas. Altogether advanced in its day, this machine was manufactured in a new factory in Hunt End and featured a patented chain drive arrangement which doubled as a starting system. The engine, cooled by water routed through a radiator, featured an integral oil tank behind its crankcases which was a world first.

By 1904 there were racing successes. On the sands at New Brighton, L Hadley, campaigning a new 2hp Royal Enfield single, won a five-mile race in front of 4,000 cheering spectators, clearing off to win by half a lap, ahead of numerous other and more powerful machines. The Royal Enfield field gun trademark device reportedly first appeared in 1893. Various revised versions followed including a new form registered in July 1904 after which increased usage followed.

Business boomed and additional premises were obtained by the firm at Albert Street, in Redditch, and another new factory was built close to the railway on Hewell Road in the town. Its frontage featured offices and a board room, and behind this manufacturing took place in two wings. It was modern in its day, laid out to enable machine assembly in a logical sequence, and it was built with expansion in mind. It would eventually grow to cover 24 acres. But while early Royal Enfield motorcycles were well received, and the firm’s overall profitability was underpinned by its burgeoning bicycle manufacturing activities, attempts since 1901 at car and commercial vehicle manufacture had been less than successful in a crowded market. Development costs had been high and the company’s financial security began to be undermined. In 1906 car and motorcycle production were separated but the Enfield Autocar Company would exist for just two years, and in 1907 the original Givry Works was abandoned and the Eadie concern was taken over by BSA, with Albert Eadie resigning to join that company’s board. He would rise to become its managing director.

PART 1 I GREAT BRITAIN

Outgunning the opposition! (Hitchcocks)

Enfield’s owners Robert Walker Smith and Albert Eadie in a prototype Royal Enfield car, circa 1904. Smith crashed a De Dion Bouton car in 1900 while testing a gear mechanism of his own design and was severely injured (REOC)

12| Royal Enfield - A Global Motorcycling Success Story

being explored by fledgling motorcycle manufacturers, the ideal motorcycle engine and transmission layout having yet to be universally decided.

Co-founder Bob Walker Smith continued at the helm and in 1909 his son Frank joined the firm. Educated at Birmingham University, the younger man was a former BSA apprentice. heels within wheels! For his part Smith senior was a good engineer and inveterate problem-solver. The firm earned muchneeded cash by winning a contract to produce frames for the inventive AngloScot Alfred Angas Scott, who that year began making his distinctive Scott motorcycles in Bradford.

and often downright dangerous. The roads were also covered in animal dung, and as motorised traffic increased, gritty dust from stones and decaying faecal matter became a terrible problem in dry weather. Great plumes of it rooster-tailed into the air behind each passing vehicle and, subsequently, a smoggy brown cloud of muck would hang in the air for up to an hour.

product of the coal industry, and therefore readily and cheaply available, the process quickly gained favour in Britain. In 1906 an impressively forward-looking Royal Commission report on road building recommended further experimentation and research with a special emphasis on achieving ‘dustlessness’, and within three years there were more than a thousand miles of tarred roads in Great Britain.

And at the Stanley Cycle Show in November 1909, Royal Enfield exhibited a new model designed by Bob Walker Smith and French-speaking Swiss engineer Werner Guillon, a former employee of the Enfield Autocar Company. Powered by a smooth and flexible Motosacoche side-valve engine and featuring sprung front forks. It was a fine lightweight machine that would continue in production in one form or another for several years. Motosacoche of Geneva was founded in 1899 and started off selling an engine in a subframe for installation in bicycles, hence ‘engine in a bag’. The company’s small capacity 60 degree V-twin engines were advanced and intricate and delivered smooth power. Their purchase by Smith senior, no doubt at Guillon’s behest, was a wise choice. He realised vees need not be as bulky as thumping singles, nor as lumpy and explosive in nature, and V-twins of various capacities would bring praise and fame to the firm in years to come.

In these first years of the twentieth century, Britain’s roads remained truly terrible. Often no more than meandering tracks and footpaths widened for the horse and cart, they were narrow, dusty, bumpy, pot-holed and frequently overhung by trees. Livestock was driven along them and horse drawn travel was largely a leisurely affair. Bicyclists were generally the fastest users. The roads were heavily rutted by cart and wagon wheels, corners were especially chewed up and repairs were carried out only when absolutely necessary. Progress on unsprung, boneshaking, top heavy, clutchless motorcycles with smooth or barely treaded tyres was uncomfortable

Britain was a horse-riding nation and its roads were the trading and fighting routes of its ancestors. The country’s magistrates and MPs were horsemen and traditionalists; motor vehicles were not popular in the corridors of power and this put the pace of British motorisation a little behind that of many countries in Europe. But by the end of the Edwardian era progress was being made. In around 1905 a significant idea was imported from France. There, heated tar was being used as a binder for road construction instead of soil and water, and as tar was a by-

As traffic levels increased in towns and cities, the need for a free-engine clutch was becoming apparent to motorcycle manufacturers. Certainly, gears were becoming indispensable equipment and Bob Walker Smith had been applying himself to the problem. An advertisement in The Motor Cycle, in March 1911 described Royal Enfield’s two-speed model as ‘The most perfect lightweight ever produced,’ adding that: ‘Above the gentle purr of the engine can be heard the zipp of the tyres on the road, the only sounds made by the 2 hp. chainhorse and cart, they were narrow, along them and horse drawn travel repairs were carried out only boneshaking, top heavy, clutch-

CHAPTER 1 | EARLY DAYS

Factory rider Harry Greaves testing a Royal Enfield Motosacoche on a chilly Worcestershire day in 1912. The dusty, unmade road surface is typical of the time (Mortons Archive)

Royal Enfield - A Global Motorcycling Success Story | 13

Surviving Redditch needle mill with attached house, similar in design to the Givry Works at Hunt End (J Thomas)

Surviving Redditch needle mill with attached house, similar in design to the Givry Works at Hunt End (J Thomas)