❖❖ Oscillators

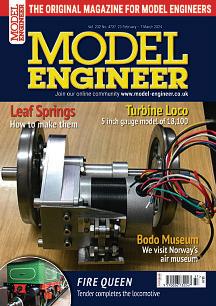

FlyingScotsman Reversingstand foran LNERA3 SteamEngine Trevithick patentshis steamengine Llanelli Popularspring rallyat Pembrey Park LL AN EL LI SP RI NG RA LLY TH EO RI GI NA LM AGAZ IN EF OR MO DE LE NG IN EE RS Vol. 232 No.474317 –30May 2024 Join ouronlinecommunity www.model-engineer.co.uk Shor twheelbase Foden steam lorry Shor twheelbase Foden steam lorry

Noveldesign approaches to oscillating engines

PublishedbyMortons MediaGroup Ltd,

MediaCentre, Morton Way, Horncastle,Lincs LN96JR

Tel: 01507 529589 Fax: 01507 371066

©2023 MortonsMedia ISSN 0026-7325 www.model-engineer.co.uk

EDITORIAL

Editor: Martin R. Evans

MEeditor@mortons.co.uk

Deputy editor: DianeCarney

Designer: DruckMedia Pvt. Ltd.

Club News: GeoffTheasby Illustrator: GrahameChambers

Publisher: SteveO’Hara

CUSTOMER SERVICES

GeneralQueries andBackIssues 01507 529529 Monday-Friday: 8.30am-5pm Answerphone24hr help@classicmagazines.co.uk www.classicmagazines.co.uk

ADVERTISING

GROUPHEADOFINVESTMENT– Lifestyle& TractorPublications |www.talk-media.uk MasonPonti mason@talk-media.uk

A: Talk Media, TheGranary,Downs Court, YaldingHill, Yalding, Kent ME18 6AL

Investment Manager: KarenDavies karen@talk-media.uk

PUBLISHING

Salesand distribution manager: Carl Smith

Marketingmanager: Charlotte Park

Commercialdirector: NigelHole

Publishing director: DanSavage

SUBSCRIPTION

Full subscription rates(butsee page 666for offer): (12months, 26 issues,inc post andpacking)–UK £128.70. Export ratesare also available, UK subscriptionsare zero-rated forthe purposes of ValueAddedTax Enquiries: subscriptions@mortons.co.uk

PRINTAND DISTRIBUTIONS

Printedby: WilliamGibbons &Son,26Planetary Road,Willenhall, West Midlands,WV133XB Distribution by: SeymourDistributionLimited, 2EastPoultry Avenue,LondonEC1A9PT

EDITORIALCONTRIBUTION

Accepted photographsand articles will be paid for upon publication. Itemswecannotuse will be returned if accompaniedbya stampedaddressed envelope andrecordeddeliverymustclearly statesoand enclosesufficient postage. In commonwithpractice on otherperiodicals,all material is sent or returned at thecontributor’s ownriskand neitherModel Engineer, theeditor, thestaff norMortons MediaLtd canbe held responsiblefor loss or damage,howsoever caused.The opinions expressedinModel Engineer arenot necessarily thoseofthe editor or staff. This periodical must not, withoutthe writtenconsent of the publishers first beinggiven,belent, sold,hired outor otherwisedisposedofina mutilatedcondition or in otherunauthorisedcover by wayoftrade or annexed to or as part of anypublicationoradvertising,literary or pictorialmannerwhatsoever.

http://www.facebook.com/modelengineersworkshop

http://twitter.com/ modelengineers

668 SMOKERINGS

News,views andcomment on theworld of modelengineering

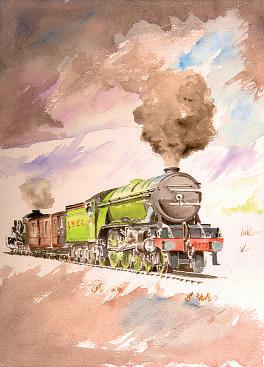

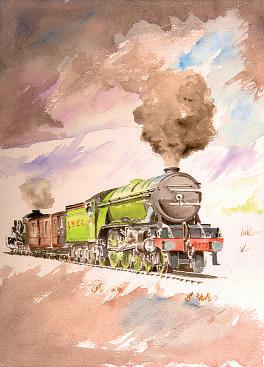

669 FLYING SCOTSMAN IN 5INCHGAUGE

PeterSeymour-Howellbuildsa highly detailed A3 locomotive basedonDon Young’sdrawings.

673 LLANELLI’S SPRING RALLY

John Arrowsmith visits PembreyParkto attend Llanelli’spopular spring rally

678 OSCILLATINGENGINEDESIGN

Martin Gearingtakes alook at some novel approaches to oscillatingengines

682 LNER B1 LOCOMOTIVE

Doug Hewson presents atruetoscale fiveinch gaugemodel of Thompson’s B1

686 BOOK REVIEW

RogerBackhouse readsSimon Martin’s book on thelifeand work of SirNigel Gresley.

687 POSTBAG

Readers’ letters

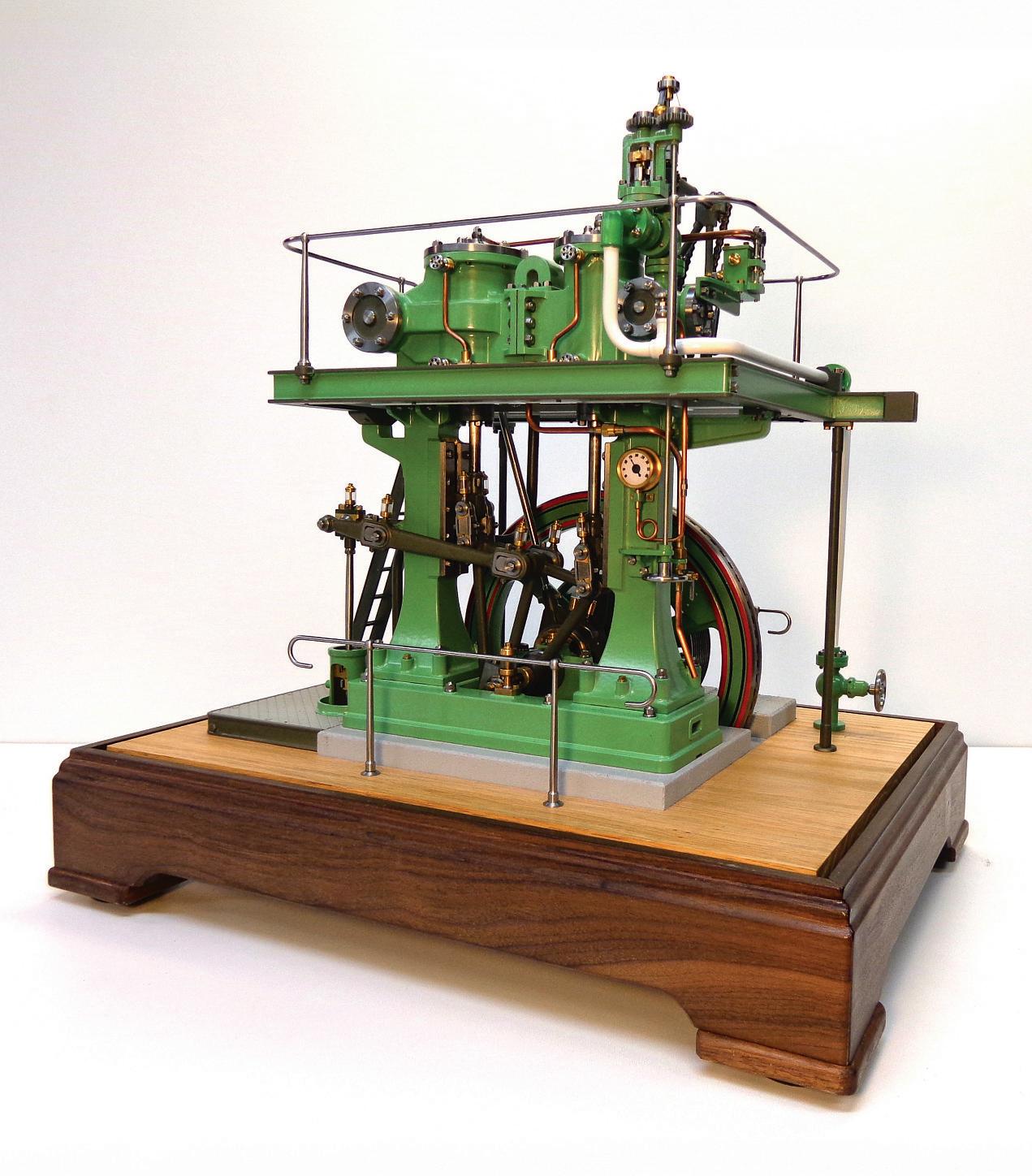

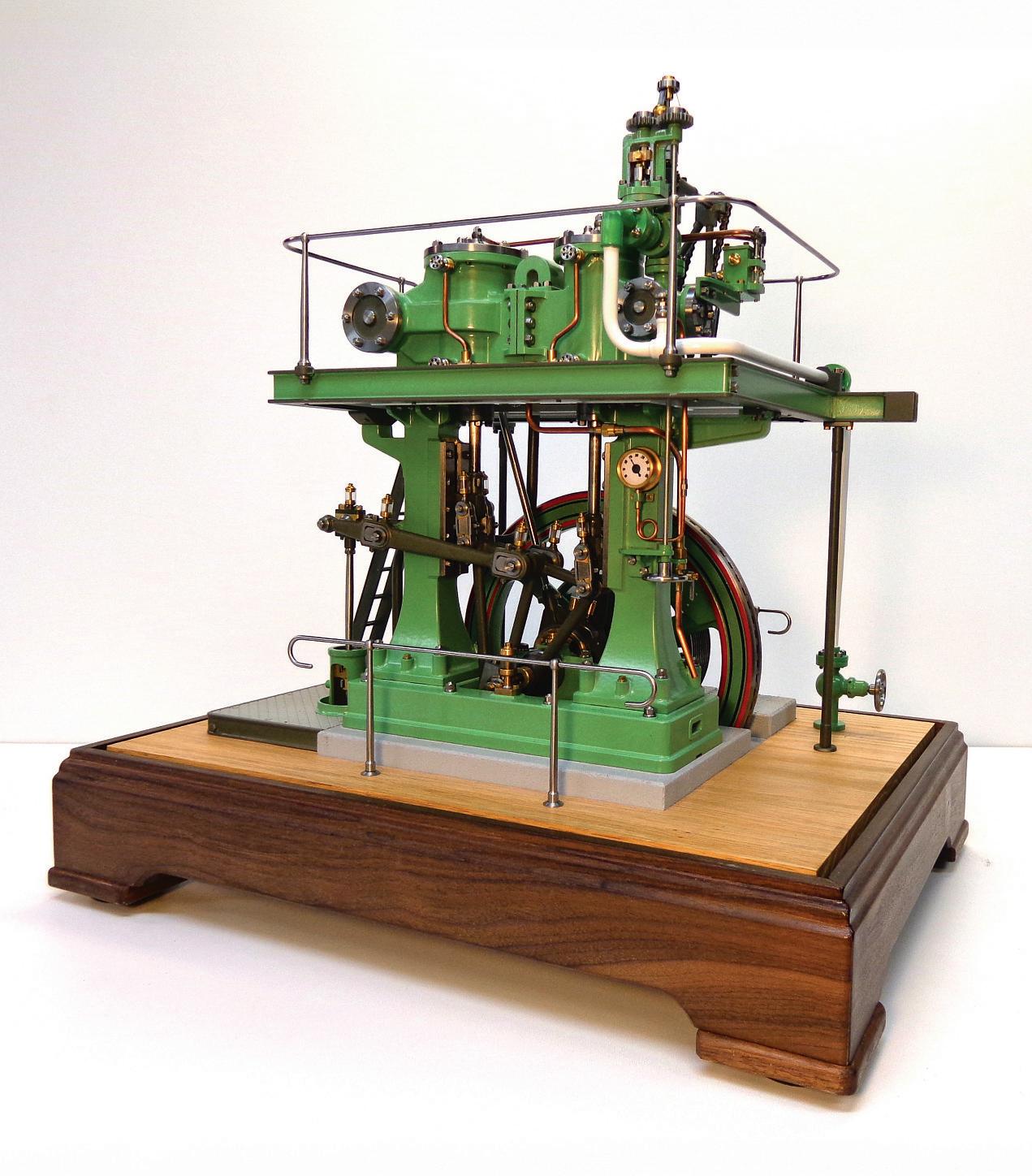

688 ATWINTANDEMCOMPOUND STEAMENGINE

Graeme Quayle presents an interesting design fora compound windingengine.

692 THESTATIONARY STEAMENGINE

RonFitzgerald tells thestory of the developmentofthe stationary steamengine.

696 BUTTERSIDE DOWN

SteveGoodbody returnswithfurther tales of thetrials andtribulationsofa model engineer’s life.

700 REDESIGNINGA GASBURNER

Graham AstburymodifiesT.E.Haynes’s original burner design fora hotair engine to runonpropane rather than town gas.

705 AN ADMIRALTYCASEFOR A REGULATOR

Adrian Garner showsthatmakinganelegant case fora regulator timepiecedoesnot requiresophisticated woodworkingskills

709

BUILDING 3020 CORNWALL IN 5INCHGAUGE

JimClarkbuildsa modelofFrancis Trevithick’s LNWR 2-2-2locomotive.

712

CLUB NEWS

GeoffTheasby compilesthe latestfrommodel engineeringclubs around theworld

715

CLUB DIARY

Future Events.

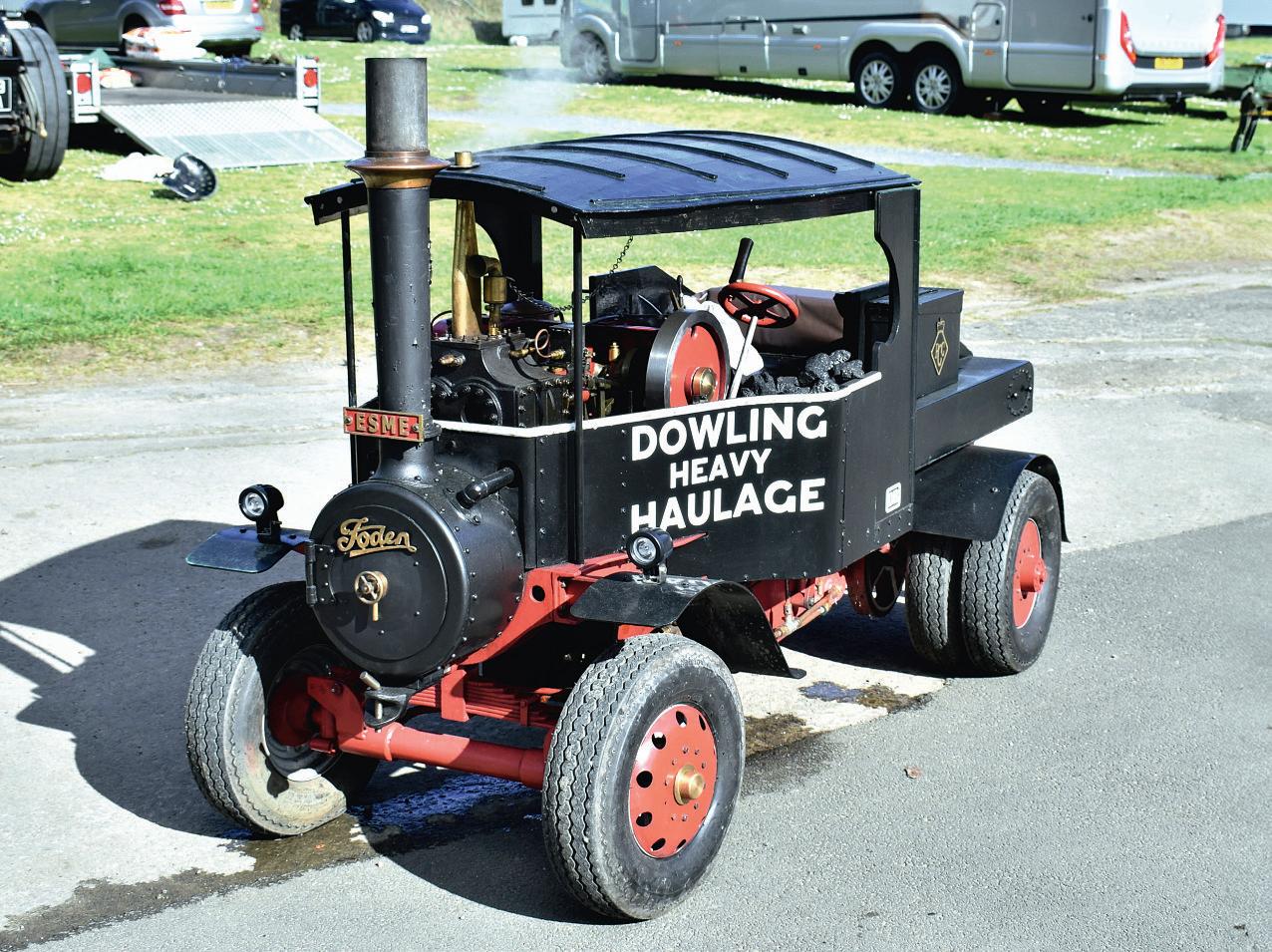

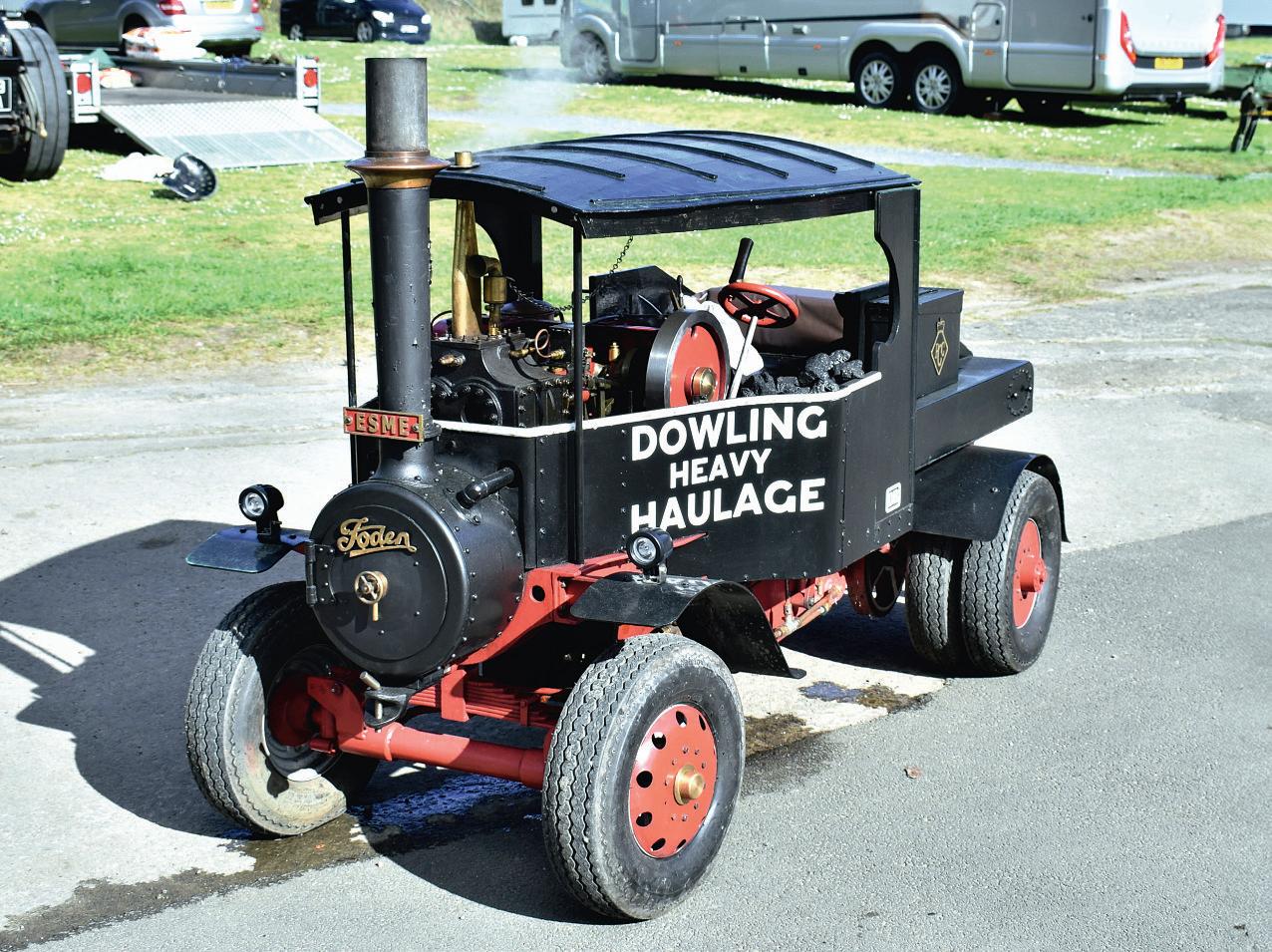

ON TH E CO VER

Ashort wheelbaseFoden steamlorry built from aSteam TractorWorld kitbyJames Dowling(photobyJohnArrowsmith)

www.model-engineer.co.uk 663

Vol. 232

2024

No.4743 17 –30May

...

This issuewas publishedonMay 17,2024. Thenextwill be on sale on May31, 2024. Oscillators Oscillat Novel design approaches to oscillating oscillat engines Flying Scotsman Reversing stand foran LNER A3 Steam Engine Trevithick Tr ithick patents his steam engine Llanelli Popular spring pular rally at Pembrey y Park LLANELLI SPRING RALLY THEORIGINALMAGAZINEFOR MODELENGINEERS ay ng Shor twheelbase Foden steam lorry twheelbase Foden steam lorry SUBSCRIBE&SAVEUP TO49%Seepage666for details www.model-engineer.co.uk 687 709

SUBSCRIBE ANDSAVE

Enjoy12monthsfor just £68

PRINT

ONLY

PR

Quar terly direc tdebit for £19

1year direc tdebit for £68

1year credit/debit card for £74

INT +D IGITAL

DIGITAL ONLY

Quar terly direc tdebit for £22*

1year direct debit for £85*

1year credit/debit card for £88*

1year direc tdebit for £50*

1year credit/debit card for £54*

*Any digital subscription package includes access to theonlinearchive.

>> Free UK deliver ytoyourdoor or instantdownload to your digital device

>> Save moneyonshop prices >> Nevermiss an issue

>> Receiveyourissue before it goesonsale in the shop

Greatreasons

to subscribe

classicmagazines.co.uk/ MEDPS 01507 529529 and quote MEDPS Lines areopen from 8.30am-5pm weekdays GMT Ofer ends De ce mb er 31,2024. Subscriptionswills tart with thenex tavailab le issue. Dire ct De bitp ay me nt sw illcontinueonthe agre ed plan unless youtellusother wise Tov iewthe privac yp olic yfor MMGLtd (pub lisher of Mo de lEnginee r),p leasev isit ww w. mortons.co.uk/privac y Pl ease vi si tw ww.c lass ic maga zi ne s.co.u k/ te rm sfor fu ll te rm s&con di tions . ( 8

MARTIN EVANS Editor

MARTIN EVANS Editor

Following theevent,there will be apublic running dayon Sunday the1st of September 2024 whichall attendees and familiesare invitedtotakepart.

FMES Rally

DIANE CARNEY Assistant Editor

This year theFederation of ModelEngineering SocietyRally is being held at theNottingham SocietyofModel and Experimental Engineers at theirRuddington headquarters on the31stof August.Set in theNottingham TransportHeritageCentre in Ruddington, therailway includes akilometreof7¼ inch gaugegroundlevel track with gradientsofupto1 in 85 andalmost½ mile of 3½ and5-inchgauge raised trackwhere gradientsupto amaximum of 1in115 and tunnels addinteresttothis attractive railway.The club will also welcomevisitorswith miniaturetractionengines and otherexamplesofthe hobby to show andenter theFederation Autumn Rally Competition. Therally is open to all membersofclubs affiliated with theFederation. Please visitthe club website(www. nsmee.org.uk)for more informationonthisevent.

areavailable. Thehighlight of each dayisthe steamroad rundownintothe village to theWhite Lion pub. Exhibitors arewelcome andifyou would liketobring alonga model, a bookingformisavailableat mmdmes.wixsite.com/home/ steamweekend2024

Bradford Cup

Do notforgettovotefor the Bradford Cup, awardedeach year to thewriterofthe best articleinModel Engineer in thepreviousyear. This year’s nominationsare:

TheStationarySteam Engine –RonFitzgerald Radial ValveGears Again–Duncan Webster Fire Queen –Luker

Please register your vote with me before theend of May–onevoteofcourseper reader

Mar tin Evans can be contacted on the mobile number or email belowand would be delighted to receive your contributions, in the form of items of correspondence, comment or ar ticles. 07710-192953 MEeditor@mortons.co.uk

On theday of therally,all visitors with eligible models areinvited to enterthe two competitions that will be held.These arethe regular AustralianAssociation of Live Steamers (AALS) trophy and theFederationAutumnRally Competition. Therules forboth competitions canbefound on theFMESwebsite (fmes.org. uk/project/fmes-autumn-rallyat-nottingham).For theclub to plan theresources properly forhosting visitors,please complete thebookingformon theclubrally page as soon as possible.

This year’s steamrally at Whissendine, Rutland, organisedbythe Melton Mowbrayand District Model EngineeringSociety,takes placeonthe weekendof June the1st and2nd,atthe WhissendineSportsClub ground.Entry is free and refreshments andsteam rides

Here is apicture of the trophy,tobeawarded to the luckywinner. Thepicture was takenatthe National Railway Museum,York, during the awardofthe cuptolastyear’s winner,Steve Goodbody,but whichlocomotiveisitsitting on?Noprizesfor correct guesses, I’mafraid…

Cock-upCorner

In theClubDiary last time,I wronglyclaimed theParklands week at Hemsby wouldtake placeduringthe first week of June.Thatisincorrect –itwill actually take placeduringthe last week of May, starting on May25th.

ModelEngineer 17 May2024

668

NSMEE

Whissendine

FMES Rally

Whissendine

Flying Scotsman an in 5Inch Gauge aug

IPeter SeymourHowell

buildsa fne, fully detailedmodel of Gresley’siconic locomotive to Don Young’sdrawings.

Continuedfromp.129, M.E.4734, January 12

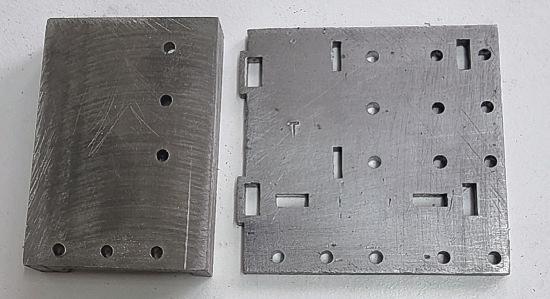

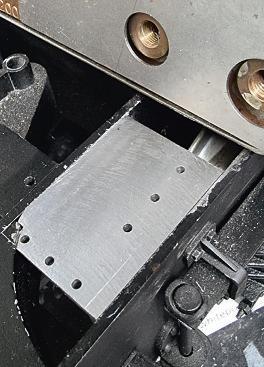

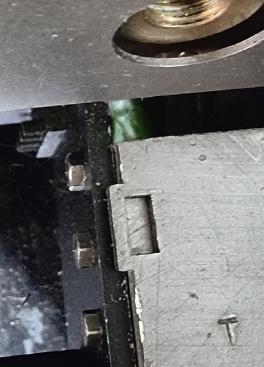

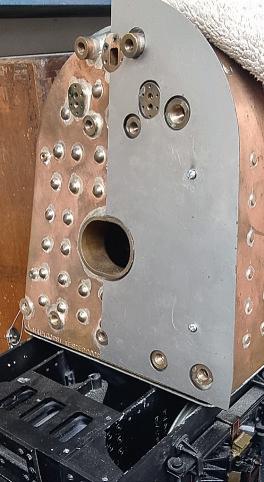

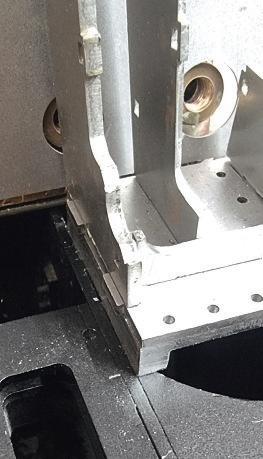

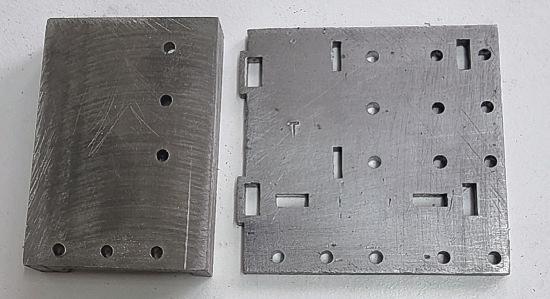

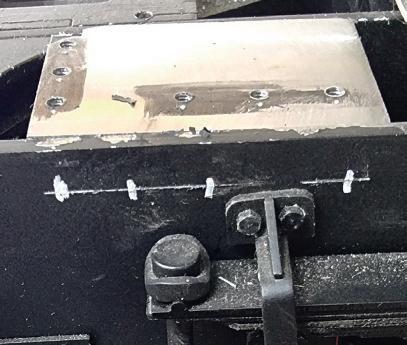

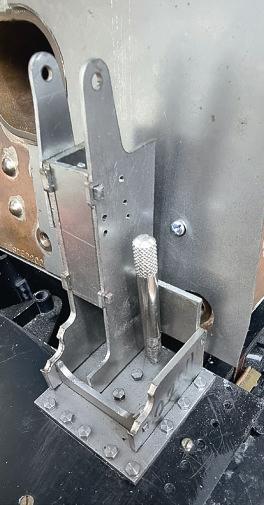

nthe last articlewehad the reverser readyfor brazingbut we’renot readyfor that stage et e first need to transfer the mounting holestothe reverser stool which, of course,hasn’t yetbeenmadeand then work outthe exactpositionofthe stool whichwill sitinbetween themainand trailingframes. Thestool itself is asimple rectangleof inches madetofit from alengthof 7/16 inch steel.Not having anything closetothatsizeI machined from theclosest size in stockwhich was75mm x50mmx 12mm -a weebit of machiningrequired. Iused agrinder to getclose to size andthenmachinedtosizeand thickness nota fi e minute job. With thestool machined/ squaredtosize, thenextstage wastomachine achannelinto theunderside creating aU channel. Donstatestomachine achannellea ing inchonthe side to thetrailingframe and alittlewider on theother side to give enough metaltotap into once this side hasbeen taperedtomatch themain frame(photo1

1

Firstmillingoperation on thereverser stool

2

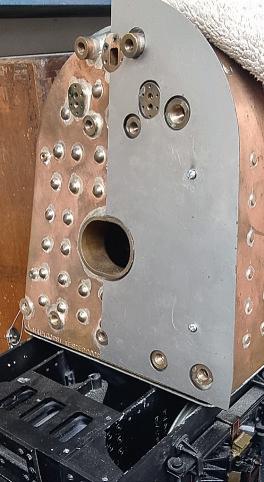

Onehalfofthe backhead ftted temporarily.

o work outthe taper first needed to take into account thereverser’srelativedistance back from thebackheadto allowfor heat expansion; Don advisestoallowfor 5/32 inch Before Ican do this Ineeded to placethe backheadroughly in position.The backhead sections were cutfromsteel b d odel ngineers aser some time agoand at thetime Ithought theplottedholes mightneed moving butnow that I’ve hadtimetolook at this more closelytheyjust needed alittlefettlingtofit Photograph 2 showsone-half of thebackheadtemporally held usingtwo 3mmscrews into themountingbushes kindl fittedb aul outhern oilers td onl need to fit thesideofthe re erser for now. Note that thetwo tapped

bushes at thebottomwill be fittedwithblankingplugs with thecornerbushbeing fitted with awashout plug forboiler cleaning.The outsideedgewill of course be formed to curve around theouter edge of the backhead. With thebackhead positioned,I couldthenplace thestool roughlyinplace andsit thereverserontop (photo3 had left drilling themountingholes into the stool untilthisstage just in case Ihad missedanything(I did details later cannow seethatI candrill said holes readyfor mounting thereverser oncebra ed again more on that later. In thephotograph Ihaverestedthe stool with itsfinished edge up against theinnertrailingframe edge allowing the inch mm gapbetween thereverserand boiler.

3

669 www.model-engineer.co.uk >>

PA RT 59 – REVERSER

( CO NTINUED )

STAND

Establishing thepositionofthe reverser stool

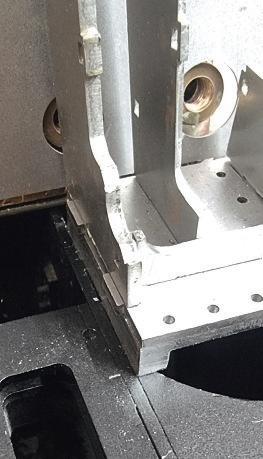

With thereverserinplace, Icould see/judgethe taper required on themainframe edge and, as canbeseen in photo4,it’snot alot.I also notedthatI need to either remove alittlefromthe frame stiffenerorthe stool.I’llopt for thestool

Ithenmarkedthe edge that requires tapering,the plan beingtofirstachie e thecorrect taperand then remove metaluntil thestool fitsbetween theframes s ou cansee in photo5 there’snot much to remove andsoI didso with ahandfile

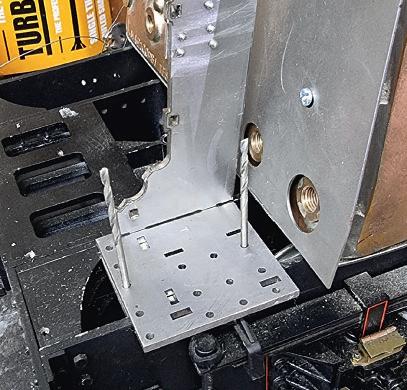

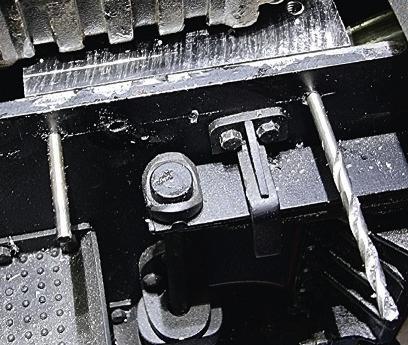

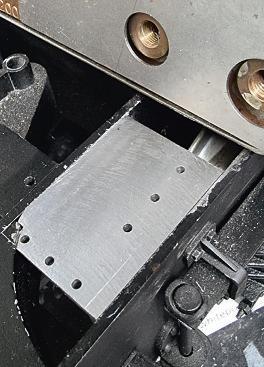

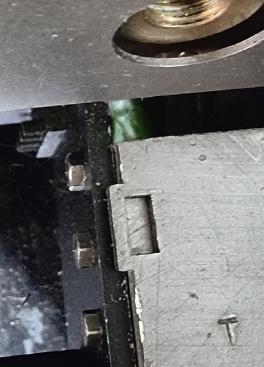

Ithenneeded to transfer the reverser mounting plateholes to thestool.TodothisI held thestool in themachine vice alongwiththe mounting plate sitting on top drilledthe first hole from this,plotted at zero, andthenthe rest usingthe DRO (photo6

In photo7 we cansee thesix holesnow transferred. Note that theseare at No.42tapping size for with themountingplate holesrequiring to be drilledout forclearance No.34. later. It wasnow time to decide on there erser sfinal position whilecheckingfor Don’ssuggested expansion allowancegap.I also needed to be mindfulthatthe backhead cleading will have some insulation sandwiched between it andthe boiler s photo8 shows, there’snot alot of

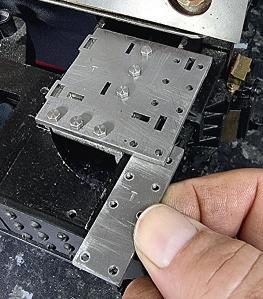

room so Ihaveleftthe cleading mounting bushes as supplied whichgives just enough room to clearthe copperstayheads andallowancefor some insulation material s mentioned filed the taperbyhandand checked forfit photo9 on s drawingshows that twoof themountingholes into the mainframes aresharedwith thedragbox stiffener. Iamnot goingtouse theseasfitting them wouldbemorethana littleproblematic.I have also shaped therearofthe stoolto clearsaidstiffener. With thestool in position,I placed thereverseronitusing acoupleofNo.42 drills to hold it in placewhile Ichecked the gap; thegap here is just under 5mmsoa littlelargerthanDon stated (photo10

To transfer theinnerbolt holes first marked theholes with afine pointpen not easy to reachthisarea, so transferring holesinthe normal wa isnot possible andthen setthe stool up to usethe DRO fordrillingthe holestomatch thoseinthe mainframes.With theholes drilledand tapped Imadelifea littleeasierby putting apoint on the bolts as shownin photo11. In photo12 we seethe three boltsfittedtightl andread formarking/drillingthe outside mounting bolts. o keep e er thing atfor theholes to be transferred/ drilledI bolted thereverser base to thestool readyfor markingout theholes.Itwas here that Idiscoveredanerror that had made when fitting the

670 ModelEngineer 17 May2024

Judgingthe taperrequiredonthe frame edge.Checkingthe spacebehindthe backhead forinsulation.

Checking thereverserstool forft.

Drillingthe reverser mounting plates in thestool.

Sixholes transferredfromthe mounting platetothe stool.

4

6

Filingthe taperonthe stool

5

7

8 9

Accidental misalignmentoffxing holes.

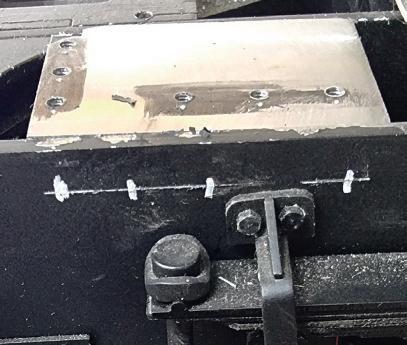

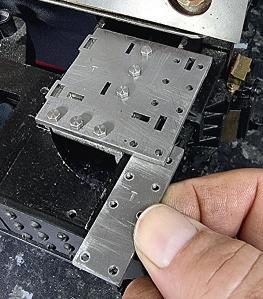

reverser base to thestool.I had placed thebasedirectlyonthe stool but, actually,it’soffset to theoutside.I only noticedthis when checking thefitwiththe base doublerboltedtoits base No bigdeal- Ijustneeded to redrill/tap theoffending holesbut an annoying delay nonetheless. Photograph 13, with thedoubler plateheld, showsthe problem- there needstobea gapmatchingthe thicknessofthe frames

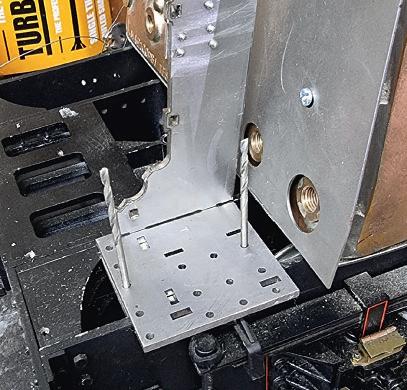

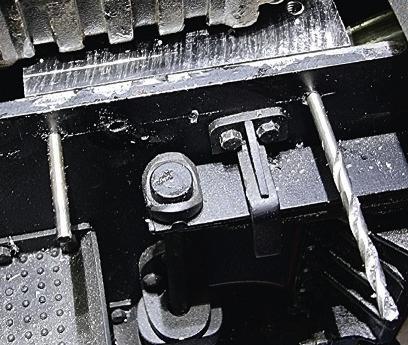

Before taking thebaseoff I first transferredwhere theholes should be andthenmarked theframesdownfromthe top edge 9/32 inch forwhere the outsideholes need to be drilled (photo14 chose to mark wherethe holeswould best be avoiding thespringguards whichDon left offhis drawings Ihatedrillingintopainted partsbut if needsbe, I’ll have some tidyinguptodolater fterdrillinga hole placed aspare drill to keep things in placewhile drillingbyhand (photo15

Markingthe positionsofthe outsidemountingholes

Drillingthe outsidemountingholes

Thereverserbasemounted on thestool

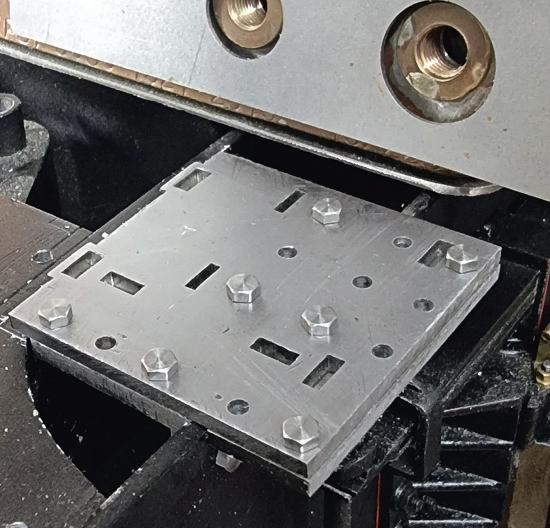

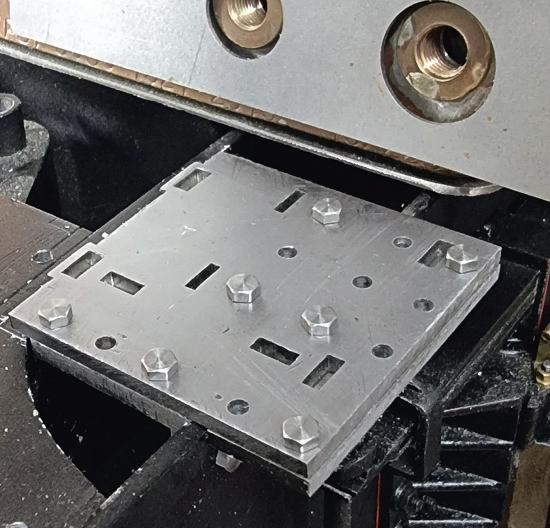

Photograph 16 showsthe reverser base on itsstool whichissecurelymounted andsandwichedbetween the mainframes andtrailingframes.

To quotethe greatDon Young: ‘The standwill test both ourresolve andpatience’.That maybesobut then youadd nutter’slikeme, andmanyof

youother buildersout there whoadd extradetailtothe equation,thatattimes can test thepatienceofa saint, I suspectthatthe reverser will be such an item n wa on with thecraziness.

Before getting to brazingthe reverser assembly together firstneeded to decide on howthe base wouldmeet thecab oor wo options carefull cutthe oor around thebaseormount throughit. Cutting around thereverser mightmakeremovingthe cab oor easier buttodothat ou dfirstha etoremo ea lotmoreparts anyway,and it wouldalsoleave thefront right-hand corner unsupported, so notanoption o do plot theholes with precisionor do Imakelifeeasier, andcut largeslots or even remove the middlesection entirely?Don states that thereverseron theprototype wasverystiff. FellowbuildersofGresley acificsha ealsowarnedme

671 www.model-engineer.co.uk >> FLYING SC OT SM AN

Firstthree boltsftted readyfor marking anddrillingthe otherside.

Trialftofthe reverser on thestool

Apoint on a6BA bolt to make locating thebolta littleeasier.

10 11

12 13 14

15

16

of this so Iwill notremovethe middlesection butcut slots so that thereverserbasehas more supportunderneath. Thereasonfor choosingslots over slightly larger holesfor clearanceispurelya ‘justin case’scenariowhere Imight, forsomereason, need to work on somethingonthe ou know,whenatthe trackwith limited resources.

Enough rambling -ontothe jobathand. Before cutting an thing lined up the oor and marked approximatelywhere to startmachining fter taking afew measurements Imarked

wherethe hole in thetop right centre of thebasewill be (not thedoubler and photo17 showswhere Iwill setthe DROtozerowhenheldinthe machinevice.

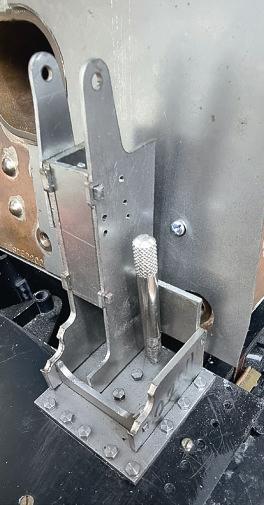

fterchain drillingrowsof holesI used an endmill cutter perhaps alittletoo large to create slotswhich gave me far more clearancethanI should ever need (photo18 reverser nowhas ageargate… Do yourecallmementioning acunning plan forfollowing the prototypemoreclosely butstill beingabletoget access to the mounting bolts? Well, Iplanto have theshelf,thatsitsabove

Thefull-sizedreversershowing the shelf(lowerleftofthe photograph).

thebolts,hingedsoI canget at them Photograph 19 shows this shelf, whichalsohas a frontshieldtoit. I’ll addthat lateralong with otherparts This photograph is also useful forsomething else although notjustyet -itjusthappens to show theindicator armstill attached giving agoodidea of itsangle andheight. This informationwillbecomehandy er soon modification (photo20 simpl in ol es filingthe shelffittingtabsround so that theshelf becomes hinged -simple.

thendid atestfitofthe assembly so far. Here theshelf is seen in itslowered position (photo21 lso clearhereis that thewashout plug will need there erserremo ed first for access to be able to cleanthis corner of theboiler- notreally aproblem as such an operation won’tbedonethatoften ndhere photo22 show theshelf raised with abox spanneronone of themore difficult boltstoreach itwould be toodifficulttoreach with the shelffi ed ote some s hadthe reverser on theleftand some on theright.The setof lasercut partscan of course be assembledwitheither handedness.

To be continued.

672 ModelEngineer 17 May2024

17

Markingout thefoorfor accommodating thereverserstool. Clearanceslots forthe reverser mounting bolts.

Shelf in itsclosedposition.

Shelfinits open position

18 19 20 21 22

Asimplemodifcation to achievea hinged shelf.

Llan elli’sS pr ing Rally

John Arrowsmith takesa trip to NorthWalesand a busy spring rally,blessed wit fneweat er.

Thiswell-established eventinthe model engineer’s calendar washeldatthe PembreyPark site of theLlanelliand District ModelEngineers. Theweather forecast forthe weekend wasnot encouragingbut,as oftenisthe case,after early morningrainonSaturdaythe remainderofthe weekend en o edsomefine sunshine anddry days.The wind was abit sharpattimes butas is theway with true model engineers, everyone just goton with enjoying themselves.Rob Rayner andhis fellowmembers hadorganised awidevariety of both locomotivesand traction enginestotakepart. Thegreat thingabout thelocationisthat thewhole area wasoncea MoDMunitions facilitysothere is plenty of hard standing and surfaced roads, whichmeans thetractionengines andsteam lorries were able to make full useofthese surfaces.The park itself is largeand is open to thegeneral public which ensuresthere arealways plenty of passengersfor the railway.Inaddition,ofcourse, it is adjacent to thelovely beachesofthispartofSouth Waleswhich is also another attraction.I didtakea stroll to thebeach whichlooked superb in thesunshineand thewalk really blew thecobwebs away Onto therally itself;itwas just getting into itsstridebythe time Igot there, with thebusy atmosphere of enginesbeing prepared forworkbothonthe trackand theroads.The multigauge7¼and 5inchgauge ground leveltrack extendsfor about2/3 mile throughtall pinesand theusual coastal foliage andisverywelllaidout with testinggradients to catch outthe inexperienceddriver. Thegroundlevel in thestation area is approximately2 metres lowerthanthe trackonthe far side of theroute,atBriaryHill

Halt,soyou cansee what I mean abouttesting gradients. This railway is supplemented with amulti-gauge raised track of 3½ and5 inch gauges of approx 1/3mile in length.This trackalsohas anicecurved tunnelwhich emergesjust belowthe summitwhich,again, catchessomedrivers outasit appearstobelevel in thetunnel butis, in fact,still on arising gradient.The trackdoesnot have thesteep gradient of the main linesoitiseasiertodrive smallerlocomotives without difficult

Themainstation is ashort distance from thesteaming bays so that spectators in the park cansee thepreparations withoutimpacting thequeue forrides.Theycan also seethe enginesbacking down from the‘shed’topickuptheir train in thestation,which is agood crowdpleaser.The ground leveltrack runs in aclockwise directionwiththe innerraised trackrunning anti-clockwise; this adds to thepassengers enjoyment, seeing passing trains during theirjourney.The club have acoupleofpowerful battery andpetrollocomotives forthese occasionsand with

sixheavy carriages to pull, plus passengers, they earn their keep.These trains were mixed with avariety of 7¼ inch gauge steamlocomotives that were also pullingfi e coachesat times.

On theroadwaysoutside theclub’sperimeter fence, the steamroadvehicleswerebusy as well andthatlovelyfamiliar atmosphere of steamand hot oilwas soon engulfing the spectators.I hada good feeling walkingaroundthe different enginesbeing prepared andI wasgreeted with a good humoured response to questionsrequesting informationabout thedrivers andtheir engines. Onein particular Ifound delightful; adrivertoldmethatsteam road vehicles always have a mate with them whohas to be registered with thevehicle when it arrives. In this case themate’snamewas Bob. I enquired what Bobwas doing andthe replywas …“askhim!” Iturnedtosee alovelyBeagle curled up on acomfy chair with twosoulful eyes watching my everymove(photo1)! The odensteam lorr wasa fine modeland wasowned by Phil

673 www.model-engineer.co.uk >>

Phil Weston’s lorry’s ‘mate’ -Bob theBeagle.

1

Weston (photo2). Phil had modifiedthe rear lorr oor b adding twoadditional water tanksoneitherside. This had changedthe appearance of the

modelbut also provided him with extracapacityand weight on thewheels(photo3). There were some interestingstories to be heardand seen.The

6inchscale traction engine ownedbyRay Wallace is a case in point, as this engine wasbuilt by ablacksmithinthe Shetland Islesovera sixmonth period -without anydrawings!

Rayhas ownedthe engine for 15 yearsand it is still goingwell (photo4). It wasalsogoodtosee theyoung engineersfrom theclubinvolvedwiththe

674 ModelEngineer 17 May2024

Phil Weston with hisFoden SteamLorry

Built in sixmonthsbya blacksmith withoutdrawingswas this 6inchfreelance traction engine ownedbyRay Wallace.

John Carrolwithhis 5inchgauge Manorpreparing hisenginefor theday

AnotherviewofPeter’s lorry with theadditional watertanks on thesideofthe fatbed

Thesteam up begins with theclubsecretary andchaplain, JimFlanaganand son Thomas steaming theirLNERtankengine.

2 3 4 5 6 7

Joel lookshappy with histrack time

day’soperations. Drivingon both theraisedtrack andthe ground levelsystem, allof them displayedcomposure andconfidence in dri ingthe availablelocomotives

hefirst oung man talked to wasThomasFlanagan whoisthe sonofthe club’s secretaryand chaplain,Jim Flanagan.Togetherthey were preparingtheir small5 inch gauge0-6-0 LNER tank engine foruse on theraised track. It wasanenginethey hadboughtbut whichneeded some work to become a reliablelocomotive(photo5). They soon haditinsteam and enjoyedtheir time on thetrack whereitperformed very well. Whilsttheyhad been working on thesteam locomotive, Thomas built a7¼inchgauge

Scampwhich wasrecognised by the7¼InchGauge Society whichawarded Thomas a ighl ommended certificate forhis efforts. This augurs well forhis future as agood model engineer with theclub. Anothergood looking locomotive wasalsobeing steamedatthe same time; a5 inch gaugeGWR Manor 7828 OdneyManor. This engine is nowowned by John Carrolwho wasinthe process of learning thebestway to driveit(photo ). He is also amemberofthe Cardiffclub. Twoother youngmembers of theclubwerealsoenjoying themselves on thetrack,both with individual enginesand then double heading. Jacob andJoel(photo7)werekeen to talk abouttheir involvement

with theclub. Jacobwas also drivinga large7¼inch gaugeLNERA2duringthe day, with allthe skill of a seasoned driver (photo8). With passenger trains in constant demand,itwas good to see theraisedtrack beingused by both electric andsteam locomotives. Joealsoenjoyed taking hisfamily fora drive andI thinkthe smilesontheir facessay it all(photo9). It wasalsogood to seehow the senior membersand visitors interacted with theyoungsters during theweekend, helping whenever they couldand,in onecase, Ifound Paul Pavier lyingacrossthe bedofhis steamlorry explaining in detail to avisitor howeverything worked.Watched by hismum, this youngman showed some real interest in what Paul was saying (photo10). Perhaps

thislittlechatwillinspire the youngfellowtoget involved andmaybe even pursue a long career in mechanical engineering!

During theweekendthere wassomespiritedrunning on theraisedtrack with arange of 3½ inch gaugelocomotives beingput throughtheir paces in some style. John Williams from theSouthport club was drivinganLBSCdesignversion of HeilanLassiebut,unlike theoriginal, this engine had Bakervalve gear anditwas absolutel ingaroundthe circuitatsomespeed,lap after lap(photo11). My camera has stoppedthe motion butI can assure youthatenginewas moving very quickly. Another smallenginethatwas making very light work of thetrack for anumberofhours during the daywas alittle3½inch0-6-0

675 LLANELLI www.model-engineer.co.uk >>

YoungmemberJacob starts thepowerfulA2awayfromthe stationwithhis family aspassengers.

John Williams concentrates on theroadahead as he powers HeilanLassie around the raised track.

JoeHockley takeshis family fora ride on theraisedtrack

8 9 10

PaulPaviershowing this youngvisitor theworkingsofhis steamlorry.

11

TomTaylortends the F sfre during astopatthe raised trackstation.

LMS4FdrivenbyTom Taylor (photo12). This locomotive’s motion wasjusta blur when it wasgoing.However,not to be outdonebythese littleengines a3½inchgauge Southern Q class0-6-0,drivenbyDanny Hayworth,was also making a name foritselfwitha similar

performance. Ihad aride behind Tomand the4Fand my extraweightdidn’tseem to reduce theperformance one iota.Itstill just buzzed around thetrack with consummate ease

As Imentioned abovethere wasa good selectionof7¼

inch gaugelocomotives,both home club enginesand visitors Alltook turnsatsometime during theweekendinhauling passenger trains,but thebulk of theworkwas done by a visiting LNER K2 locomotive ownedbyPeteLawson. This 2-6-0Mogul worked very well forlongperiods (photo13) and, alongwiththe club’s own electric engine workingvery hard,provideda continuous service(photo14). Chris

Wilson from theValeof Aylesburyclubhad brought hissuperbexample of aGWR Armstrong/Gooch4-4-0 to enjoysometrack time.This beautifull finishedlocomoti e went as well as it looked and climbing the1:45/50 incline really made thecrisp valve setting standout (photo15). notherfine lookingengine in steamand operatingfor long periodswas ararelyseen modelofanLNERA2. Built

676 ModelEngineer 17 May2024

Pete Lawsonwithhis K2 takesthe trainawayfromthe stationareaout into thecountry

Theclub’selectricenginewaits to leavethe stationwithvisitorsfromthe SwanleyBarnRailway as passengers.

12 13 14

Father andson,Garethand Andrew Williams have theSweet Williamgoing well as it departs thestation

some yearsago to work for theWalsall ModelRailway Society, they haditfor about 20 yearsbeforeitwentinto privatehands.Colin Palin from Nottinghamhas hadit forabout sixmonths. This is theenginethatyoung club member,Jacob washandling likea seasoned modelengineer (photo1 ). Afatherand son duo, Andrew andGareth Williams were drivinga very good lookingSweet William 0-4-2; both aremembers of the

PembrokeModel Engineers andwereenjoyingtheir time on thetrack (photo17).

Two15XXtanklocomotives ownedrespectivelybyBob Thompson andMikePearce, both membersofthe Salisbury club,werealsodoing sterling work during theweekend and combined to double-head theirtrain whichprovideda powerful combination. They hadnotrouble with thetrack gradients(photo18 nefinal trainwas that whichcontained

thedisabilitycar.Thisvehicle canaccommodate both a wheelchairand acoupleof passengerssothatalmostany disabilitycan be cateredfor.It wasuseda number of times during theweekendgivingrides to people whowithout it could nothaveenjoyed arideonthe train(photo19).

It wasa most enjoyable weekendwithplentyofgood naturedbanterand hospitality. Guests were well fedand wateredbytwo excellent vendorssuppliedbythe countrypark. Therewas a continuous supplyoftea and coffeeavailablefromthe club whichkeptthe driversand club visitors happy

Overall, theevent was ahappy time,enjoyed by everyone,withgood weather andsomeexcellent operating by thecluband theirvisitors -and also by thegeneral public whocontributed to theoverall atmosphere of theweekend. My thanks as usualtoRob Rayner andall themembers of theLlanelli club whoorganised theevent andtoall thepeopleI spoke to fortheir warmth andhelp with information. Theweekend wasa shiningexample of what canbeachievedinthese days of national doom andgloom Thankyou all.

677 LLANELLI www.model-engineer.co.uk

The7¼inchgauge A2 starts theclimbtothe summitwithplentyofsteam

Double motive powerasthe 1500 tanksworktogetheraroundthe circuit.

The club’s disabilitytrain in action during theweekend.

ChrisWilson with hislocomotivewaits departurefromthe station.

16 15 17 18 19

ME

Oscil lati ng lat in g Eng i n eD esig n in esign

Martin Gearing explores different approaches to thedesignofoscillators. PA RT 1

Iread DavidFulton’sarticle in ModelEngineer (ref1) on thebackgroundtothe design of hisveryneatlooking ‘Forerunner’ oscillating engine andwas struck that hismethod describedinthe ‘Moving Diagram’ sectionwould be able to overcome theerror in geometry of thedrawing shown in fig forthe setting outof theporting in an oscillating

engine attributed to Greenly and arris owe er the differencebetween thetwo methodsinactualgeometry of theportpositions wasn’t highlighted and ha ing seen thetwo items abeginnermight be confused makingfor a high chance they wouldmiss agoldenopportunitywhen buildinganengineofthisgenre from scratch. Although the

engine will doubtlessrun when finished sadl itwill notbeas good as it could/should be!

Theunderlyingdesign considerations of thegroup of engineswith‘oscillating’ (or‘wobbling’ -the term used on theother side of the ‘pond’)cylinders aregenerally overlooked or perhaps overshadowed by thefactthat it is most commonly seen in

678 ModelEngineer 17 May2024

,a 5-inch gaugelocomotivewithoscillating cylinders

Wapiti

1

useasthe powersourcefor thecheaper endmodelsbetter describedasto s wherethe were usually of thesimplest single acting form hat beingso therecan be very fewpeoplethatwould not actually be able to recognise oneand as isoften thecase with commonplacethings few people actually take agreat deal of interest in thedetail.

first encounterasa child waswitha littlevertical double acting Stuart Turner single that hadinitially seen lifeinsidea steampowered modelboatbeforepassing throughseveral owners’hands andthenarriving in mine.By that time thethreads securing thelower cylindercover had been strippedbut this hadbeen overcome by soft soldering thetwo partstogether. The glandnut thread hadwornso badlythatthe nutpresumably wouldn’t remain in placeso that hadbeen removedleaving theenginewithout apiston rodgland of anysort. These features didnothing to detract from thefactthatithad been giventomeand wastherefore m first engine

Varioussources andvarieties of invisiblegas were used to powerthe engine whichI won’t describe sufficeittosa that it neverexperienced steam untilman ears later when the need forthe missing glandto be replaced in some form was displayedbeyonddoubt!

Lookingatvarious oldtexts of commercialoscillating engines(in thesameway as hotair engines the seem to have hada briefperiodof popularity forinstallations requiringsomecheapsimple meansofrotation- untilboth were displacedbythe electric motoraselectricalsupply became available. Theone placetheyweresuitedtowas in e plosi eatmospheres usually running on airuntil replaced by themoreadvanced designsasindustryhungerfor powergrewmorevoracious

Therewereexceptions howe er such as powering seagoing shipsand as disco ered later also full si e industrial railway locomotives.

Oneexample of this came in theformofa 5-inch gauge (2½inchscale)locomotiveat AndoverModel Engineering ociet called Wapiti that had runverysuccessfully forin excess of 50 yearsbeforethe boilerrecentlyfaileddue to corrosion.

Wapiti hadbeen built by Gordon Howell (ref1 a dynamicfounder member of the club after he’d experienceddriving Reg Dimmer’soscillating cylinder locomotive at Durrington. Gordon askedReg to design somethingsimilar forhim rom what can disco er Wapiti wouldappear to be a fairl true cop of afullsi e inch gauge tonlocomoti e typically builtbyDewey rothers of enter treet oldsboro orth arolina America.

This companywas formed in b harles assisted by hisbrothersGeorgeW and rnest ewe taking over aformerbusiness. Due to thegrowthinthe area thecompany built between and se eral small industrial locomotivesaround tons mostl or configurationpowered b oscillating cylindersdirectly connected to thewheels describing them as a‘Four Wheel Connected Locomotive’. Theseusedthe conventional cylinderpivot placementin themid bore position with theports on a at side face Production of this type of locomotive stoppedabout the same time as thecompany introduced itsnew geared type nothercompan iler tower of ilwaukee made similarsi elocomoti es BUTwiththe wholecylinder containing thepistonand rod assembl ha ingan e e cast integral with it swinging about atrunnion fi ed across the framecontainingthe required porting. Both companies suppliedthe enginesmainlyto thelumberindustry.

Wapiti wasbuilt by Gordon in fifteen months ha ing two inch bore b inchstroke cylinders andsmall wheels whichwiththe 90 psiboiler

gave it areputationofbeing able to ‘pulla housedown’! n itsfirststeaming after ‘debugging’withReg Wilkins ilkie asheisalsoknown andstill aclubmember) as test dri er itdid laps non stop miles to pro eits worth fter ears thesteel fire tubeswerereplacedwith copper(photo1).

Gordon is probably remembered forhis eet of oscillating engine powered models including a inch bore by 2inchstrokeengine powering asix wheel Atkinson truck that ranonpneumatics

AfterthatGordonbuilt another this time a 2x 2inchcompoundoscillating engine using it to powera four wheel orkshiresteam tractor also on pneumatics t earsofage he then produced a oad ailer as acompromise feelinghe d ‘…notenoughtimelefttomake aproper7¼inchgauge loco’. by adapting theYorkshire road tractorasthe powerunitwithin a entinelt peshunter loosel basedonthe form of an 0–6–0 built forthe omba aroda entral ndia ailwa s removing thewheelsfromthe road tractoritcould be lowered onto thelocomotivechassis andthenrun on 7¼ inch tracks

This engine successfully ranatman locations e ents running forthe morninginthe oad ractor configurationand theafternoon in the‘Sentinel hunter configuration on the trackatGuildford.Another

1

Conventionally ported cylinder

time at aSouthampton track celebration it wasmentioned in areviewbyTed Joliffe in Model Engineer ( ).

Gordon latermadethe comment ‘Thismay notbe everybody’sideaofa 7¼ inch gaugeloco but ha e hada lotoffun andenjoyed many interestingconversations!’

Handsome lookingexamples of oscillating/wobbler engines arestill beingdesignedand built.One such exampleseen recently wasinanexcellent series of sixarticlesonthe buildingofa good-looking hori ontal twin doubleacting engine in Live Steam& Outdoor Railroad by PatJorgensen and KenKroeker (ref3).

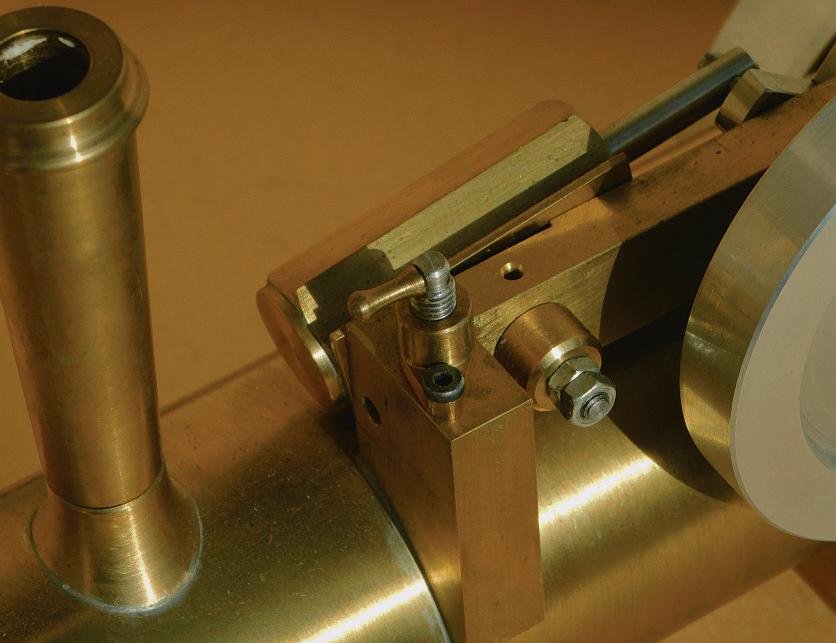

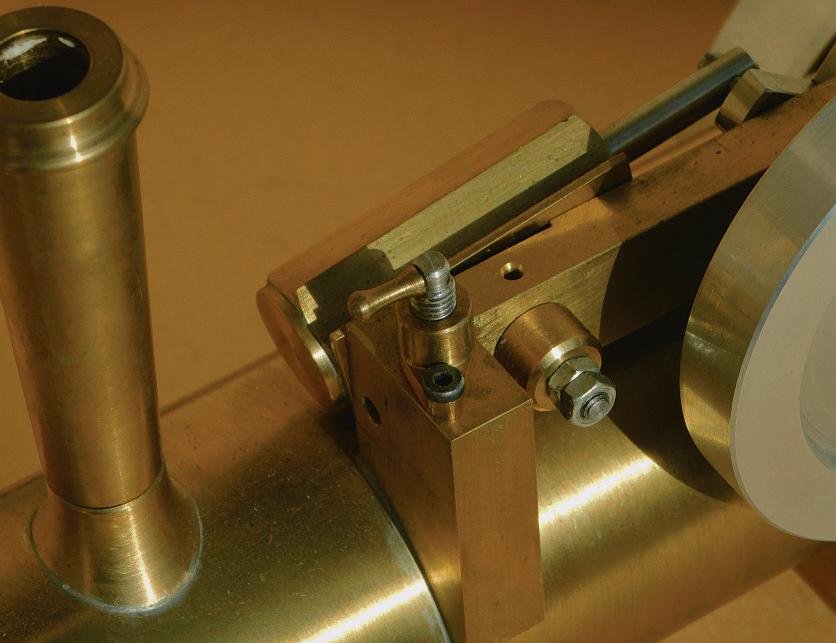

Iwas struck by thebrilliant method of achievingthe exhaustand inletports by radial millingofthe fi ed face portblock rather than by theconventionalmethod of pluggeddrilledholes as demanded by adoubleacting oscillating cylinder( 1). gain in the barstock interpretation of thesame basicdesignasthe Green Twin by JamesDonnelly ( 4) made tom e e a neater arrangementbyhavingthe twocircularportfaces facing inboard.

Thedownsidetothe radial port method wasthatit significantl adds to theforce needed to keep theportfaces in contact/sealed because of theincreased area under suppl pressure owe er ifa thin sandwich platewithonly

Bearingblock having radially milled inlet& exhaustcavitiesconnecting upper& lowerportlocations

Fig.1. Oscillating Engine PortingAsUsedOnGreen Twin

679 OSCILLAT ORS www.model-engineer.co.uk >>

Green Twin -radially milledports

Fig

2 therequiredportholedrillings is securedoverthe radial slots of thefi edface it gi esthe best of both worlds –easeof manufactureand retainingthe very neat circular appearance ( ).

Ported plate- when attached to the‘manifold’/bearing block, by reducing thesurface area exposedtopressure of theworking gas, reducesthe forcerequiredto seal theportfaces

Fig.2. Oscillating Engine PortingPlate

Oscillating engine -porting plate.

Useofa

solid thrust washer n thesamesub ect ha e foundthe conventional method of usinga spring to provide theforce (often unnecessarily excessive)thatisrequired

Traction engine with an oscillating cylinder.

to maintain asealofthe port faces as used in the ames onnelle bar stock ersion wouldbebetterreplacedbythe useofeithera Nylock or pair of lock nuts againsta thrust washer as used in theearlier original cast versionofGreen Twin by PatJorgensen and KenKroeker.Thiswill almost certainlyallowthe barstock engine to runwithlessfriction andhence agreater efficienc Just to provethatnothing is newI stumbled across this method describedina design of an oscillating feed pump by ETW(EdgarT Westbury)! (ref5)

Theproof of this design came aboutwhenI explored methodsofreducing unnecessary friction in what is best describedasoscillating enginesof‘LimitedPower’. The first wasinthe form of asmall modeltractionenginepowered b compressedair intended foroperation by youngchildren

680 ModelEngineer 17 May2024

2

3

Wooden oscillating engine

Fig

MARTIN EVANS Editor

MARTIN EVANS Editor