On the Editor's Benc h

The only Constant is Change!

By its nature, model and hobby engineering is an experimental hobby It attracts creative thinkers with open minds We are always repurposing things, stretching the capabilities of our equipment and looking for ways to make things, better, simpler or more fexible When I became editor, it was my assumption that the hobby was fairly static; how wrong I was For example, around then inverter controlled motors were becoming more afordable and it seemed everyone was ftting them to their machine (including me!)

This issue sees a review of a stereolithography or ‘resin’ 3D printer It seems remarkable that this is the frst time this technology has appeared in MEW, yet it’s only about tens years since such machines became a practical option for a hobby workshop. Five years or so ago I wrote a book on 3D printing, and at the time resin printing was so unusual for hobbyists I’m not sure I even mentioned it; even the original RepRap fused flament printer was invented only seventeen years ago!

In 2023 we have already featured several articles featuring 3D printing, chiefy for making enclosures, but this month’s Readers Tip has a particularly useful application. It seems that a well-equipped hobby workshop now has a lathe, mill, pillar drill, grinder and a 3D printer! Embedded electronic are also commonplace – in this issue a project combines 3D printing and an Arduino to help make an automatic oiler for a 75-year old lathe design!

What’s next? Small plasma cutters are now getting so afordable they are sold in supermarkets! Laser cutters and engravers are becoming increasingly afordable, although something cutting more than wood still demands a hefy price tag There are also small laser-based precision welders that promise an easy alternative to silver soldering for small fabrications

I would be pleased to hear from readers who are trying out such machines I’m particularly interested in reviews that signpost other readers to machines worth having and how-to articles that help people understand their capabilities and applications That said, I also appreciate reviews and write ups of more traditional machines – whether modern lathes or antique ones!

3 May 2023

Neil Wyatt

9 An Auto-Oiler for a Myford Lathe

Myford’s drop oiling system is notoriously fckle. ulian almer has devised a system that means you don’t have to remember to put the oil fow on or of

17 Sharpening Cutting Tools acques Maurel completes his fexible accessories that extend the versatility of his sharpening attachment

26 Artful Dodges

ohn Smith explains how to use toolmakers’ buttons to set up obs on your lathe.

28 The Morphing of a Tool

Matt Shaw tells the story of a multi purpose spindle mounted too for his oxford lathe that is easily adapted to other machines.

31 Review: The Creality Halot One Plus

The latest generation of SL printers promise outstanding quality at a similar price to D machines. eil Wyatt fnds out how this machine from reality measures up.

40 The King is Dead! – Long Live the King!

Matt Shaw replaced his century old pillar drill with a new larke machine, switching over various modifcations and beefng it up for obs beyond its original capacity

46 From the Archives

This month we only nip back a couple of decades in our series celebrating 2 years of Model Engineer

51 Upgrading a Mill with a High-Speed Spindle

Simon Davies found his shop made spindle couldn’t take the extreme speeds he wanted to use in this issue he gets the spindle up and working and sees how it performs

59 Beginner’s Workshop

This month eometer looks at hardening and tempering. 31

Contents Model Engineers’ Workshop www.model-engineer co.uk 6 17 £ 75 2 No.327 INSIDE THIS PACKED ISSUE USING TOOLMAKERS’ BUTTONS We Review the C An essential aid to accuracy in setting up Get more out of your workshop with MEW in th sat ww d l-eng .u HARDENING AND TEMPERING STEEL A HOLDER FOR SHARPENING VARIOUS TOOLS A NEW WAY TO SET GRINDING ANGLES THE KING OF MY WORKSHOP LAMINATING WALLCHARTS FIND OUT MORE ABOUT YOUR HOBBY! A HIGH-SPEED THREAD STRIKING ATTACHMENT PLUS ALL YOUR REGULAR FAVOURITES BOXFORD SPINDLE ACCESSORY A multi-purpose tool for a classic lathe. S, MAKER AND MODELLERS M 2023 SS E 327 WWW.MODEL-ENG NEER O UK A LATHE AUTO OILER A System Suitable For Myford And Other Drip Oiled Lathes 3D Resin Printing in Your Workshop SUBSCRIBE TODAY! GET YOUR FAVOURITE MAGAZINE FOR LESS DELIVERED TO YOUR DOOR! See page 54-55 for details

about the forum, and a computer generated contribution

66 Readers’ Classifieds

This month’s selection of readers’ sale and wanted ads, carefully transcribed by eidi who can decrypt the most obscure handwriting!

www.model-engineer.co.uk

Why not follow us on Twitter? twitter.com/ ModelEngineers hashtag #MEW

THIS MONTH’S BONUS CONTENT Log On to The Website for Extra Content:

isit our website to see Matt Shaw’s oxford Spindle Tool in action, and see more of the alot ne. www.model-engineer.co.uk

Other hot topics on the forum include:

Why is the world of model engineering still imperial? sks aul McDonough.

Simple case hardening recipe What’s a modern solution by choochoo baloo

Oscillating Engine Simulator by ames Stanley Parting off using a powered cross feed y .

Come and have a Chat!

s well as plenty of engineering and hobby related discussion, we are happy for forum members to use it to share advice and support. ome and oin us – it’s free to all readers!

Coming up… in our next issue May 2023 7 ernard Towers makes a depth stop for collets Regulars No.327 INSIDE THIS PACKED ISSUE USING TOOLMAKERS’ BUTTONS We Review the Creality Halot One Plus An essential aid to accuracy in setting up Get more out of your workshop with MEW .model-engineer HARDENING AND TEMPERING STEEL A HOLDER FOR SHARPENING VARIOUS TOOLS A NEW FIND OUT MORE ABOUT YOUR HOBBY! A HIGH-SPEED THREAD STRIKING ATTACHMENT PLUS BOXFORD SPINDLE ACCESSORY A multi-purpose tool f a classic lathe.A LATHE AUTO OILER A Sy tem Suitable F Myf d And Other Drip Oiled Lathes. 3D Resin Printing in Your Workshop

cover shows a ferocious Frost Dragon hanging over the resin vat of the Creality Halot One Plus resinprinter

On the Editor ’s Bench The editor is surprised ust how much things have changed in our hobby

our

her

always

to hear

and

ON THE COVER Our

3

37 Scribe A Line More news from

readers

in the and from around the world We are

keen

from you – ust send an email to meweditor mortons co uk 50 Readers’ Tips ur winner this month has a neat

tidy update on a popular modifcation Send your tips to meweditor mortons co uk 60 On the Wire ews

Visit our Website

ME E T RES W R S E E TS R MS L MS L SSI IEDS E TR S S RI E R I E S LIERS

An Auto-Oiler for a Myford Lathe

Julian Palmer struggled to set the drip oilers on his ML7 lathe, and was fed up of fnding the machine standing in a puddle of lubricant. He decided to design an electronic auto oiler system and get rid of the problem once and for all. It’s potentially suitable for use with any drip-oiled lathe.

Having owned my Myford ML7 for some 30+ years I’ve never quite mastered the vagaries of the spindle drip lubrication system. I found it nigh on impossible to set a regular drip at a suitable frequency and was always forgetting to shut them of resulting in pools of wasted oil under the lathe. These issues combined with ftting an inverter and three phase motor capable of running at higher speeds set me wondering if such hit and miss lubrication was adequate fer much pondering, I came up with the idea of using a peristaltic pump driven by a stepper motor turning a number of steps to deliver a metered quantity of oil to each bearing, the stepper timing being controlled by an rduino, a small inexpensive

microcontroller fer several prototypes and many hours of testing, it worked to a degree, but I wasn’t happy with the repeatability nor my ability to write code for the Arduino

At this point I turned to a very good and long sufering friend who, to say the least, is a bit of a whi when it comes to programming Mark had previously helped me sort out problems I was having with my electronic lead screw by writing sofware that counted encoder pulses and highlighted when the system was picking up spurious signals, a fantastic bit of work without which I’d have never got the system working accurately.

Now with some brains on the project things could progress to add more features and allowing a change to DC motors (although we have retained

the code for stepper motors if people wish to use them) This is a relatively cheap, fully automated, oiling system which I believe solves most of the problems many people experience with mechanical oilers

The system operates as follows: An Arduino controls two motors which drive two separate peristaltic pumps The pumps draw oil from a small oil tank and pump oil to two sight glasses mounted on each spindle bearing which replace the original drip oilers A thin pipe at the top of the sight glass drips oil into the bearing and triggers a photo interrupter I sensor to confrm that the bearing has been oiled The system will give an alert if no drip has occurred Photograph 1 shows all the components which comprise the system.

› 9 Auto -Oiler May 2023

System components prior to installation

1

It should be possible to build this for around the cost of new manual oilers

The system can work in three modes

1) Elapsed time mode (Default)

Oiling occurs at a preset frequency irrespective of the lathe running

Whenever the Arduino is powered up oiling occurs at preset time intervals until power is switched of This is default mode and relies on the operator remembering to switch it on and of

2 owered time, or power on mode

Oiling occurs at a preset frequency whenever the lathe is running A signal to the Arduino whenever the lathe starts and stops initiates oiling This set up will require the lathe to have both an isolator switch and a start/stop switch Turning on the lathe isolator also powers the Arduino which does an initial oiling prior to the lathe running It then oils at preset time intervals whenever the lathe is running

3 Work done or machine work mode

Oiling frequency based on lathe rpm

An isolator and a start/stop switch are required for this mode which again allows for oiling prior to the lathe being started A tachometer or encoder is required or a photointerrupter (PI) sensor similar to the drip sensor can be used With this mode, drips are delivered based on a

preset number of spindle revolutions so the faster the spindle is turning the more frequent the oiling This is the system I built and, in my opinion, is to be preferred as the bearings are oiled more frequently at higher speeds The system has an alert function which triggers if a drip is not detected afer a preset number of seconds or revs, thus indicating if there is a blockage or oil has run out Number of drips per cycle can be preset. If required, the rduino sketch can control up to D motors I employed the use of a somewhat ageing 3D printer, but it would be quite possible to build a system using alternative components such as hobby boxes and to machine the pump to motor adapter

Prospective builders not familiar with microcontrollers or electronics should not be put of by their use The electronics are really quite simple if you follow the circuit diagram and Mark has written some very clever Windows sofware which creates the sketch for you to subsequently compile and load using the rduino sofware.

full download of rduino sketches, the sofware to write sketches, an in depth wiki explaining the rduino library that Mark put together, electrical schematics, STL fles for 3D printing and a bill of materials with prices current at the time of building are all available from

Marks it ub at github com naylom OilerLib

ll the code on Marks it ub is freely available without restrictions on use. The bill of materials (BOM) lists all the major components required for the project Parts may well be found cheaper with a little hunting around. I sourced most of my components from the

Model Engineers’ Workshop www.model-engineer co.uk 10

Sight glass showing PI sensor fitted to the slot in the acrylic tube, oil feed tube at the top and a drip forming on the drip pipe

Sightglasses ftted to the spindle bearings.

2 3

internet and I’ve assumed that, as typical hobby engineers, prospective builders will have all the usual bits of scrap, fxings and hoarded items available to complete most mechanical parts

Sight glasses

These are a relatively easy turning exercise I made mine from aluminium bar and 15mm OD acrylic tube The thread used between the Acrylic tube and aluminium housings was x 0 75mm A slot is milled in the acrylic to accept the PI sensor such that it’s a tight ft and held snugly, photo 2 and 3.

The small-bore tube which produces the drips is super glued into a hole in the top of the sight glass and, if long enough, can be used to strengthen the hose tail by running its full length The one critical dimension is between the end of the drip tube and the top of the PI sensor which should be no less than 3 5 - 4mm This allows a drip to leave the drip tube completely before triggering the PI sensor

Acrylic tube of the appropriate dimensions is readily available online as is the drip tube which was obtained by buying a couple of dropper bottles which come with a selection of interchangeable no les

I used the 2 mm D no le which, as best as I can measure, has an ID of

mm Stripping the plastic of the tube in preference to cutting the tube should give su cient length to reinforce the hose tail A bonus of buying the tubes this way is that you get a couple of handy dropper bottles for cutting fuid or other duties

The male thread at the bottom obviously needs to suit the bearing to which you are ftting it and in the case of the Myford is S Lock nut will be required to fx it in position with the I sensor located to the rear of the lathe

PI sensors and cables

I used S cables as these have the correct number of cores, are cheap and are readily available as are the sockets into which they plug. The PI sensors are ref number 2 also readily available online To pre-empt any questions – yes they seem to work ust fne doused in oil

Wires were soldered to the PI sensor and it was then potted with hot melt glue using a simple mould machined out of a suitable plastic block e careful not to use too much hot glue when potting as it’s possible to fll the sensor completely and obscure the LED and phototransistor If you buy fabric braided cable as I did, putting a drop of superglue on the braid before cutting keeps everything neat and tidy until you pot it, photo 4.

Motors, pumps and housing

The peristaltic pumps available online are supplied with a direct drive motor which is way too fast for this duty, photo 5. I replaced the motors with 12vDC geared motors type S30 available from the same sources An adapter between pump and gearbox was incorporated into the 3D printed housing design. Alternatively stepper motors type 28BYJ-48 can be used along with the driver board type ULN2003 A wiring

› 11 Auto -Oiler May 2023

PI sensor with cable attachedinplastic mouldpriorto potting with hot glue.

Ratherpoor-quality3D printed motor andpump housing complete with oil tank mounted on the Myford belt guard.

4 5

schematic for the stepper motor version is available as part of the download from Marks it ub

I 3D printed my housing, photos 6 and 7, but if you don’t have access to a 3D printer it would be an easy machining ob to make an adaptor and mount everything in a proprietary pro ect box.

A simple drive adapter needs to be made to connect the motors to the pumps, photo 8 The thin end directly drives the pump rollers and the slot engages with the motor gearbox shaf

In testing I noticed a slight erratic rotation which, although it worked ust fne, I believe is due to this coupling. It’s efectively half an ldham coupling, so as an improvement I’d suggest a full Oldham coupling could be better employed

The pump housing contains a small bread board’ and a couple of S sockets, photo 9 The bread board is a means of connecting the S sockets used for the I sensors, and the motors to a multicore cable running to the Arduino It’s also a convenient location to mount some of the electrical components. I utilised spare cores in the multicore cable to remotely locate a red alert LED in the pump housing

Oil tank

The oil tank in my design is made from 20mm acrylic tube glued to a printed manifold and the assembly glued on to the motor housing, photo 10 Making it separate to the housing made for easier printing ll parts were printed in S which glues extremely well with acetone or drain pipe solvent adhesive

Brass hose tails were turned with an M thread, heated up and screwed into M modelled threads in the manifold, photo 11 If you get the temperature right and don’t mess them around whilst cooling, this fxing method forms an exceptionally strong and oil tight oint simple press ft lid was printed to cover

the top of the tank, photo 12

I had considered other ways of making the oil tank Top of the list was a Tic Tac sweets container which is transparent and has a ready-made cap It seemed a little large at the time, so I made my own In retrospect and with the experience of use, a larger tank would be preferable,

Model Engineers’ Workshop www.model-engineer co.uk 12

3DprintedMotor and pumphousing.

Underside of Motorandpumphousingshowing tube arrangement and USB sockets for PI sensor connections to the rear

New, turned drive shaf. Thethinendpushesbetween the roller oftheperistaltic pump to give a direct drive and the slotted end mates with the motorgearbox output shaf.

7 8

and the idea may also be of use to those without a 3D printer

Arduino and screw shield

An Arduino Uno is used to control the system We’ve only tested it using a no and as Mark has employed some low level register instructions, it may not run on other micro controller boards The Uno and its various clones (Arduino products are open source and hence many clones are freely available) are cheap and readily available micro controllers which are more than capable of handling this relatively simple code

A screw terminal shield (a PCB that plugs into the Arduino and has screw terminals for wire connections) is well worth the investment as it allows mounting of various components and makes for easy connecting to the Arduino.

n my rduino shield, I ftted two green LEDs to indicate when each pump motor is running and a red LED for the alert indication.

simple 3D printed bracket was made to mount the rduino in an existing electrical cabinet containing other lathe control gear A cut out in the enclosure was made which allows the S socket on the Arduino to be accessed. The multicore cable connecting the pump housing to the rduino was ftted with a cheap multi pin plug and socket to access the enclosure.

I mounted the Arduino remotely from the lathe, but provided the wiring schematic is followed, it doesn’t really matter where the various electrical components are located

Electronics

ot my area of excellence, so apologies if anyone spots any errors The circuit does, however, appear work satisfactorily!

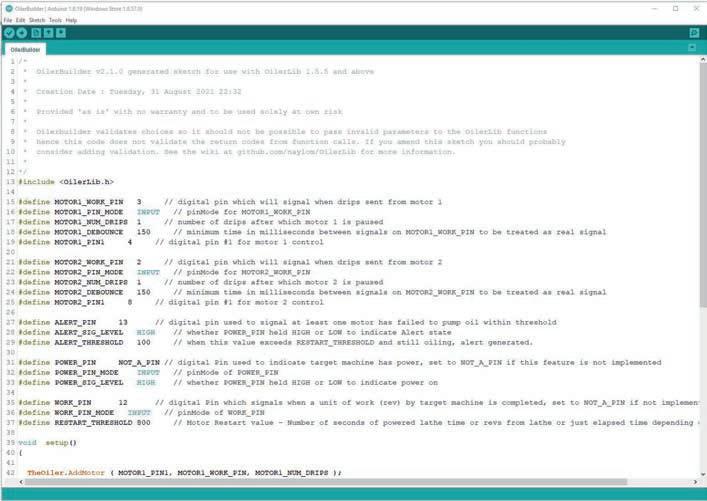

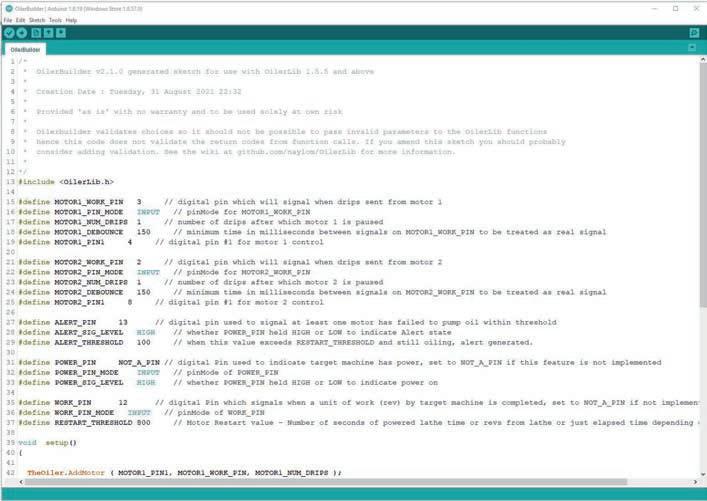

Two electrical schematics, one for the DC motor version and one for the stepper version are available on Marks it ub The D motor version shows two options in blue dashed boxes top lef ne is for Work done mode’ and the other for power on or powered time mode You need to use the version suited to the system you are building. Do not use both!

Component part numbers and values are shown on each schematic

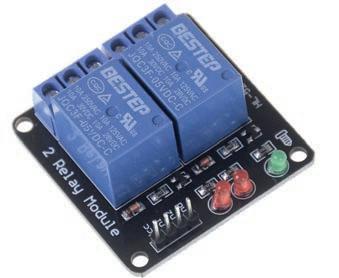

Since building the oiling system and frst writing this article, I have realised an error with my electronics The original design had the motor relays driven directly from the Arduino output pins.

lthough my build works ust fne and continues to do so afer a year or so, the relays draw more current than the Arduino output pins are rated for A quick fx for this is to use a relay module These are readily available and can be had for just three or four pounds A two relay module is shown, suitable for

› 13 Auto -Oiler May 2023

Pumpandmotor housingshowing the bread board which serves to connect the motors, USB sockets for the PI sensors and the multi core cable running to the Arduino It also ofers a useful location for some ofthe resistors. A Red LED was ftted to indicate alert condition.

M5 brass hose tail.

3Dprintedoil tank with brass hose tails fttedpriortoglueing to the motor and pumphousing.

12 11 10

Oil tank fxedinplace and ftted with a withasimplepush ft3Dprintedcap

relays The 5V supply from the Arduino board is more than capable of providing su cient current for this duty The electronic schematic shown in this article includes the relay module and the downloadable version on Marks it ub has been up dated

The schematic, g , shows specifc pins being used but any digital pin can be used for any duty provided it’s correctly detailed in the rduino sketch

Where you locate the various components will depend on your build but follow the schematic and everything should work sing shielded cable with

the shield connected to Arduino ground for all external cable runs will help guard against any disruption in digital signals

Pulsed signal for spindle revs

This is only required if using work done’ mode. On my system I used a spare phase from a spindle driven encoder ftted for my electronic lead screw owever for completeness and to assist others who may be interested in implementing the work done’ mode I made a quick lash up of an encoder using the same PI sensor as used to monitor the oil drips and tested it with Marks ilerLib sketch to in excess of 1200 rpm The cost of this arrangement is minimal and it seems to work ust fne

Lashupof an RPM sensor An aluminium angleisclamped to thespindle with a jubileeclipandaH92B4 PI sensor (as used to monitorthedrips)isclamped to the head stockcasting.

running two motors If you’re running more motors purchase a board with the correct number of relays, photo 13 These relay boards take the low current Arduino signal and use an additional 5V supply to switch the

Arduino ‘screw shield’ with Arduino Uno mounted behind,housing the motor relays and some ofthe electrical components. There is a green LED to show each motorisrunningandared LED to indicate an alert condition.

My test version of this pulsed signal really was a lash-up. I clamped a bit of bent aluminium to the collar on the lef of the spindle ‘V’ pulleys with a hose clamp, and I fxed the I sensor on the front edge of the head stock casting using a clamp, photo 14 I’m sure prospective builders could come up with a far more elegant solution

rduino s etc and so ware

s with electronics, this is not my area of excellence ll the sketches and sofware for this system were written by Mark without whose expertise this pro ect would not have been possible

Model Engineers’ Workshop www.model-engineer co.uk 14

Future add tion Nextion touch screen contro RX TX GND +5V DC+ GND VIN D 1 3 D 1 2 D 1 1 D 1 0 D 9 D 8 D 7 D 6 D 5 D 4 D 3 D 2 D 1 / T X D 0 / R X S C L / A 5 S D A A 4 A 3 D 1 7 A 2 D 1 6 A 1 D 1 5 A 0 D 1 4 A R E F OR E F R E S E T S C L / A 5 / D 1 9 S D A A 4 D 1 8 3V3 +5V GND GND DCL N 3 5” Next on disp ay PS1 Power supply 12V DC 3 2 4 5 A 5 2 1 1 2 3 4 4 3 5 2 1 2 M M 1 A C C E A C C E 2 1 2 1 4 3 5 4 3 C C E D1 Diode 1N4148 A1 Ardu no UNO R3 D4 Alert LED UX Optical sw tch H92B4 KX To suit supply R5 100R RX 100R RX 10K RX 10K K1 G5LE-1 330R R6 330R R7 ++D5 Motor 1 run LED D6 Motor 2 run LED Lathe Auto-Oiler Schematic With DC Motors And Relay Module M1 Geared DC Motor S30K R1 100R R2 100R GND +5V +12V +12V +5V GND R3 10K R3 10K U1 Opt cal switch H92B4 U2 Optical switch H92B4 M2 Geared DC Motor S30K 5V re ay switch board module Or Power On Mode (dr p frequency based on t me when athe is runn ng) Notes: 1 Schemat c shows specif c pins employed as inputs & outputs but us ng the O ler ib sketch & OilerBuilder software any d gita p n may be used for any funct on provided it s correct y def ned in the Arduiono sketch 2 Resistor values are what worked on my oiler system Values may need to be changed to su t alternative components & a ter LED br ghtness etc 3 The pulsed s gnal shown on pin 12 for spind e revs can be created using a photo interrupter H92B4 as used to mon tor oi dr ps The circuit shown has been tested up to 1200rpm A ternat vely exist ng tachometer or encoder signal cou d be used but this may requ re a d fferent c rcu t 4 The Next on touch screen shown top r ght is not yet implemented but may be a future development Without touch screen various parameters may be adjusted in the sketch & uploaded to the Arduino n the normal way 5 Motor direction can be changed to su t requ red pump rotation by swapping + &connections on either motor Powered from lathe run sw tch both FWD & reverse This mode requires a pulsed signal from an encoder tachometer or as shown below a photo nterrupter as used to monitor the oi dr ps The circu t below has been tested with the Oi er ib sketch & works f ne up to 1200rpm Other encoders or tachometers may require a different c rcuit Work Done Mode (d ip frequency based on athe revs) V C C I N 1 I N 2 G N D K2 G5LE-1

13 14

Figure

1

or those with no experience of things rduino, there are numerous tutorials and how-tos available on line which explain things far better than I’m able, but as an overview for this specifc pro ect, you’ll need to down load the free rduino sofware known as rduino IDE from www arduino cc en sofware

hoose an older release, rduino IDE

’ Select the version suitable for your operating system, download and install it The reason for downloading this older version of the rduino sofware is that it was current when Mark wrote the ilerLib sketches and sofware so we can’t guarantee that later releases will allow for the automatic placement of the library or completed sketches

ext download Marks sofware from github com/naylom/OilerLib

lick the green ode’ button, select ‘Download Zip’ Open the Arduino sofware and click Sketch Include Library dd ip Library’ Locate your download from Marks it ub called ‘OilerLib-master’ which will usually be in your Downloads’ folder and click pen’

In a blue bar towards the bottom of the window the rduino sofware should reward you with a confrmation that a library has been added to your libraries

ext you need to select the correct Arduino board and communication port o to Tools oard’ and select rduino no’ Then, with the rduino no board connected to your computer using a suitable S cable, go to Tools ort’ and select the correct port The Arduino sofware should have detected your board, and you’ll see something similar to M3 rduino no ’ click this and you’re all set to go

OilerBuilder app.

or the more experienced, you can build your own rduino oiling sketch using the examples included in the ilerLib release and Marks extensive it ub Wiki

ext step for the less experienced like myself is to run Marks iler uilder app which will write the rduino sketch for you.

In your fle manager go to Documents rduino ilerLib Examples’ and locate an application called ‘OilerBuilder’ lick on this and you’ll most likely get a warning because it’s by an unknown publisher’ Ignore this and afer a splash screen you’ll be presented with a window with various tabs where you can detail

the system you wish to build by entering a number of choices

For demonstration I’ll show OilerBuilder populated for the system I built, a two D motor system controlled by lathe rpm, but mention alternative variations as I run through This example uses the pin numbers shown on the electrical schematic

Motor 1 tab

This frst page, photo 15, defaults to a DC motor and relay setup but at the top is an option to set up a 4-pin stepper motor if preferred.

‘Inputs Pin#’ is the pin to which you’ve connected the output from the PI sensor pertaining to motor 1

‘Inputs PinMode’ selects INPUT or INPUT PULLUP The electrical schematic shows a pull down resistor so INPUT is appropriate, but if you are using an alternative circuit internal pull up resistors can be set here if required

‘Inputs # Drips to stop motor’ is pretty self explanatory, it’s the number of oil drips required from this motor each time it oils

‘Inputs Debounce time (ms)’ This setting determines the minimum number of milliseconds required between valid signals from the Photo Interrupter y setting a minimum value, it prevents duplicate or spurious signals implying a drip has occurred when it hasn’t If for any reason you fnd that one drip is being recorded as multiple drips this value can be increased

‘Outputs Pin 1#’ is the output pin which drives the relay to operate motor 1

If a stepper motor is chosen there will be four outputs pins to set along with the required direction of rotation.

Motor 2 tab

This is a repeat of motor , but obviously with the pin numbers to suit motor 2

Motor tabs 2 are not changed unless you are oiling more than two locations Alert tab

Shown in photo 16. ‘Alert pin#’ sets which pin gives the alert signal

‘Level held at during alert’ dictates how the alert pin behaves igh means it outputs 5v in alert condition and low means it sits at 5v all the time there is no alert, dropping to 0v in alert condition

‘Alert threshold’ sets the number of seconds or revs (dependant on later

OilerBuilder Alert tab showing setting for my system Ignore the red note regarding Multiples

OilerBuilder Oiled Machine tab showing setting for my system

confguration should pass between the start of an oiling operation and the alert being triggered Be aware that the pumps will take time to produce a drip so don’t set this number too low or the system will trigger the alert before the drip has occurred

Please ignore the red note about setting multiples. This was a feature we removed and omitted to delete the note … apologies!

Oiled Machine tab

ere, photo 17, you can set the mode

› 15 Auto -Oiler May 2023

OilerBuilder Motor 1 tab showing setting for my system.

15 17

OilerBuilder Final tab showing setting for my system

of operation Either ower on’ or Work done’ mode. You can enter details for both modes, but in the fnal tab you specify which mode you wish to use If neither is selected i e both input pins are set to -1 the system will run in default mode where the system oils every X number of seconds all the time the system has power irrespective of what the lathe is doing.

‘Power on’ mode uses a signal to say the lathe is running, typically an output from a relay operated by the lathe start/ stop switch. The pin to which this signal is connected is entered into the ‘Input in ’ box

‘PinMode’ selects INPUT or INPUT PULLUP. The electrical schematic shows a pull down resistor so INPUT is appropriate, but if you are using an alternative circuit internal pull up resistors can be set here if required.

Sig Level’ dictates how the pin should recognise the input signal. igh means that 5v will indicate the lathe is running and 0v indicates the lathe is stopped.

Low means the pin operates in the opposite fashion to above i e 0v means the lathe is running and 5v means the lathe is stopped.

Work done’ mode uses a pulsed signal for spindle speed The signal needs to be one pulse per revolution of the lathe spindle.

The pin to which this pulsed signal is connected is entered into the ‘Input Pin ’ box

‘Input PinMode’ selects INPUT or INPUT PULLUP The electrical schematic shows a pull down resistor so INPUT is appropriate, but if you are using an alternative circuit internal pull up resistors can be set here if required

Final tab

This tab, photo 18, is titled Set Motor Restart Mode’ ere you set the event that triggers motors to (re)start oiling Not all options will be visible depending on previous settings, but the three options are:

n elapsed time secs ’ Default mode, where the system restarts the motors afer a confgured number of seconds. Irrespective of what the lathe is doing

n powered time secs ’ System counts seconds that the lathe has been running and when this reaches the

confgured limit it restarts the motors

n machine work units ’ System restarts the motors afer a confgured number of revolutions of the lathe spindle

Select whichever mode you are using then and in the Threshold’ box, enter the number of seconds or revs between oiling operations inally Sketch pathname’ If you have the rduino sofware already installed, the iler uilder sofware will have created the sketch in a folder called ‘OilerBuilder’ in the standard Arduino sketch directory i e in the same place the rduino sofware normally stores sketches

If this cannot be found it will create the iler uilder sketch in the TEM ’ directory

You can change the path to another destination if you wish

If you are using the ‘Arduino Create’ web editor or the new ‘Arduino IDE 2 0 pc application’, iler uilder will not know where the sketches are normally kept and will, by default, put it in the TEM folder or your chosen location

That should be it, click reate Sketch’ You should get a small pop-up with an option to open the folder where the sketch is located, or you can open it via your fle manager

nce open, you should see a sketch similar to photo 19. You can change any of the defne parameters in the sketch Each has a description of its purpose lternatively you can make changes by running the iler uilder sofware again and create another sketch which will overwrite the frst pload it to your rduino by clicking the upload button (a right pointing arrow in a circle top lef of the rduino window The rduino sofware will compile the sketch and upload it to your board.

Power up the system and the pump motors should run before you start the lathe Each motor will run until its PI sensor has seen a drip. First priming the system could take some time as the pumps only produce a small fow and have to fll the interconnecting tubes prior to producing a drip. fer this, whichever mode of operation you choose should run automatically All you have to do is to remember to top up the oil tank.

Model Engineers’ Workshop www.model-engineer co.uk 16

Arduino sketch generated by Marks OilerBuilder app

18

Sharpening Cutting Tools - Part 2

Ha ing used his attachment to sharpen taps and dies ac ues aurel fnishes some further accessories (part numbers follow on from the previous articles) for sharpening other types of tools.

Notes on Drill Sharpening

Some adjustments are possible by turning the drill (using sideways movement of the cam) Ideally the result is good if the cutting edge of the drill is horizontal when just touching the wheel at the end of the sharpening

process This is function of the amount of material to remove, if the hand sharpening (always necessary before the machine one, see my article in MEW issue 245) has been well done, just a few tenth of mm are to be removed and don’t hesitate to grind of the heel as

the heel is of no use, takes time to grind and wears the sharpening wheel for nothing (the heel is the bête noir for drill sharpening) If ever the cutting edge is lower than horizontal, the clearance will be smaller, moving the cam to the right will solve the problem

If you use a cylindrical or conical grinding wheel, you’ll have to adjust the spindle axis height relative to the (horizontal) grinding wheel axis to get the right clearance angle, see g and photo 7 showing a conical CBN wheel the great advantage of which is the cold cutting action, it is also used for point splitting P otograp shows another possible position for drill sharpening with the CBN wheel (as the wheel angle is 30°) this relative angular position for the spindles is the same (but not the height) as the one necessary for drill point splitting (see later).

In these cases, h = (d/2)tan for a cylindrical wheel and d cos tan for the conical wheel (having 30° for half cone angle)

It is possible to sharpen drills having 0 point angle, 2 clearance is su cient if they are used for countersinking, to avoid chatter

› May 2023 17 Sharpening Cutting Tools

P d / 2 Ød h D/2 30 ° 30° Cone apex M

wheel

Tool

Conical

Cylindric wheel

7 8

Figure 8

It is also possible to

lodging the dividing stems, this allows 4-facet sharpening or the method described in my article (MEW issues 245

to 247), photo 9, to replace the dividing blocks

Drill point splitting

See p otos and The principle is the same as the one described in MEW issue 256. The advantages are:

The dividing (the attachment is only used for dividing in this case) And you don’t have to alter the “Z” setting when changing the drill diameter as was the case with dividing blocks

The “drill setting” is made directly on the spindle

The use of a CBN wheel gives an amazing “cold cut” even for a great amount of stock removal

The attachment must be made for the drill position adjustment, see g . The various numbered parts are shown in later fgures

ac ine and attac ent settings:

1 Set the spindles in the position shown on photo 11, the axis distance is adjusted for 35° angle between the drill axis and the splitting groove (see g )

2 Set the dividing cam fg and use two indexes in the dividing collar. Set the drill stop 29 at about 23mm from the collet, for the grinding wheel (working diameter 68mm) not to touch the collet closing nut (diameter 42mm)

4 Set the adjusting pin, about 30mm protruding out from the collet, and take a “0” along the Y axis, photo 12.

5 Free the adjusting pin, push it on the drill stop 29 and close the collet see p oto Turn then away the stop 29 in a downwards position.

Model Engineers’ Workshop www.model-engineer co.uk 18 6 2 1 0 4 3 2 44 20 r2 90° Thickness 2mm

use the attachment as a dividing spindle, using a special cam, g with a vee notch

11 9 10

9

Figure

While closing the collet nut, it’s necessary to push the adjusting pin from the back (any piece of rod between say 10 and 15 mm in diameter and about

100mm long will do the job) to maintain the contact with the stop as there is a slight backwards movement when collet closing This must also be done when

setting a drill for splitting

6 Tangent the adjusting pin along the X axis, photo 14, and set a machine stop for the table movement (X axis) Remove the

› May 2023 19 Sharpening Cutting Tools D D A A 30 25 24 23 22 27 Point Splitting Attachment 26 28 29 B B Stop Mirror ØD 35° h h = (D/2) x cos 35° = 0 41 x D

12 13 14

Figure 10 Figure 11

adjusting pin, you are now ready for drill point splitting whichever its diameter It is worth making a fne ad ustment of the stop on the frst drill to be split pointed

Routine for point splitting:

1 From the previous zero position, move the table axis to the lef for drill loading, and the Y axis backwards by about 5mm

2 Set a drill in the spindle, push it on the (previously reset) stop 29, photo 15, set the chisel edge vertical and turn the drill by about 20° in its cutting direction (to get a self-centring point) don’t close the collet now Turn part 24 for the mirror to be in front of the drill (ball lock, see photos 16 and 17) verify that the chisel edge is in the right position (adjust the angular position if necessary), reset the stop and close the collet (see previous note). Then turn the stop 29 into a downwards position

The chisel edge can be set vertical only for drills having a point end afer sharpening as is the case with the

Model Engineers’ Workshop www.model-engineer co.uk 20 100 7 5 4 M 6 Ø 8

A A B M6 B 10 10 90° Ø 8 3 Ø6 Ø28

22. Bracket Rod

23 Indexing Collar

15 16 17

Figure 12

Figure 13