Nov 23 No.333

ofJohnSmith’sseries helooksatways ofturningalarge convexradius. GetmoreoutofyourworkshopwithMEW Jointheconversationat: www.model-engineer.co.uk MACHINELIGHTING–ANO-DRILLSOLUTIONFORSHERLINEMILLINGMACHINES. AROBUST DIVIDINGHEAD–MOREDETAILEDPLANSANDINSTRUCTIONS. MAKINGANDUSINGYOUROWN CIRCULARCLIPS AFILESTORAGESYSTEM-ALANBRYANGETSHISFILESINORDER. YOU’VE BEENFRAMED–CARLOSDINIZONARCHIVALTECHNIQUES. ORGANISEYOURALLENKEYS! EMCOMAXIMAT–GRAHAMMEEK’SPRECISIONCARRIAGEHANDWHEELDIAL. AQUARTER ROUNDFIXTURE–ALHANSONSIMPLIFIESATRICKYTASK. PLUSALLYOURREGULARFAVOURITES! ROCKETMAN TheinsidestoryofGraham Sykes’worldrecord breakingsteambike. MikeJosephexplainshowtorestorea smoothactiontoanageinggauge. THEMAGAZINEFORHOBBYENGINEERS,MAKERSANDMODELLERSNOVEMBER2023ISSUE333WWW.MODEL-ENGINEER.CO.UK ANER16INDEXER AdesignforcompactmillingmachinesfromBernardTowers ArtfulDodges

INSIDETHISPACKEDISSUE: SERVICINGADTI Inthelastinstalment

EDITORIAL

Editor: NeilWyatt

Designer: DruckMediaPvt.Ltd.

Publisher: SteveO’Hara

Bypost: ModelEngineers’Workshop, MortonsMediaGroup,MediaCentre, MortonWay,Horncastle,LincsLN96JR

Tel: 01507529589 Fax: 01507371006

Email: meweditor@mortons.co.uk

©2022MortonsMediaISSN0033-8923

CUSTOMERSERVICES

GeneralQueries&BackIssues

01507529529

Monday-Friday:8.30-5pm

Answerphone24hr

ADVERTISING

Groupadvertisingmanager: SueKeily

Advertising: AngelaPrice aprice@mortons.co.ukTel:01507529411

ByPost: ModelEngineers’Workshopadvertising, MortonsMediaGroup,MediaCentre, MortonWay,Horncastle,LincsLN96JR

PUBLISHING

SalesandDistributionManager: CarlSmith

MarketingManager: CharlottePark

CommercialDirector: NigelHole

PublishingDirector: DanSavage

Publishedby: MortonsMediaGroup, MediaCentre,MortonWay,Horncastle, LincsLN96JR

SUBSCRIPTION

Fullsubscriptionrates(butseepage54foroffer): (12months12issues,incpostandpacking)–UK £56.40.Exportratesarealsoavailable–seepage 46formoredetails.UKsubscriptionsarezeroratedforthepurposeofValueAddedTax. Enquiries:subscriptions@mortons.co.uk

PRINTANDDISTRIBUTIONS

Printedby:AcornWebOffsetLtd.,W.Yorkshire

Distributionby:SeymourDistributionLimited, 2EastPoultryAvenue,London,EC1A9PT TelNo:02074294000

EDITORIALCONT2RIBUTION

Acceptedphotographsandarticleswillbepaidforuponpublication.Itemswecannot usewillbereturnedifaccompaniedbyastampedaddressedenvelope,andrecorded deliverymustclearlystatesoandenclosesuffcientpostage.Incommonwithpractice onotherperiodicals,allmaterialissentorreturnedat thecontributorsownriskandneither ModelEngineers’WorkshopMagazine theeditor,thestaffnorMortonsMediaLtdcanbeheldresponsibleforloss ordamage,howsoevercaused.TheopinionsexpressedinMEWarenot necessarilythoseoftheeditororstaff.Thisperiodicalmustnot,withoutthewritten consentofthepublishersfrstbeinggiven,belent,sold,hiredoutorotherwise disposedofinamutilatedconditionor,inanyunauthorisedcoverbywayoftradeor annexedtooraspartofanypublicationoradvertising, literaryorpictorialmatterwhatsoever.

Thisissuewaspublishedon10October2023. Thenextissuewillbeonsale15November2023.

Onthe Editor'sBench

NewForumSofware

Bythetimeyoureadthis,itishopedthatnewsofwarewillbeupandrunningforthe forumatwww.model-engineer.co.uk.Theold sitewillhavegoneofinetheday wegotopress(5October)andaholdingpageputup.

Allbeingwellthenewsitewillbeupandrunningby12October.Updateswillbe postedhere:

www.mortonsdigital.co.uk/blog/2023/10/02/model-engineer-model-boatsforum-migration-updates/

Whenthenewsitegoeslive,youwillneedtologinwithyouremailaddress andpassword.Ifthatdoesn’twork,youcandoapasswordreset.Wehavetested passwordrecovery,soaslongasyoucanaccesstheemailaddressassociated withyouraccountyoushouldnothaveanyproblemsrecoveringaccessifyou loseyourpassword.

Thisispartlyaresponsetocriticismsofwhatisnowaveryoldandclunkybespoke systemthatworkedverydiferentlyfrommostotherforumsofware.Ithadalso becomehardtomaintainandweneededtomakeiteasierforuserswithmobile phonesandtabletstouse.

Thechangestotheappearanceandnavigationoftheforummeanitwilltakea whiletogetusedtothenewlayoutandcontrols.

I’dliketothanAndyandDarrenfortheirworkonthenewforumandthe volunteers,especiallyJasonandDave,fortheirmassivecontributiontotesting theforum.Manypeople,especiallythevolunteermoderators,haveputahuge amountofefortintotestingandhaveprovidedmuchvaluablefeedbackwhich hasresultedinmanychangesandimprovements,althoughnodoubttherewillbe further‘tweaks’required.

Weknowtheremaystillbesomeissues,sowewillbesupportingusersany problems.Ifyoudohaveproblems,pleaseaskforhelp–therewillbededicated threadsforassistanceandacontactformforraisingissues.Thanksforyourpatience, andIamsurethatbyournextissue,everythingwillbeworkingsmoothly.

3 November2023

NeilWyatt

9 AMetalworkFileStorage System

AlanBryanbuildsastrongandstable storageunitanddetailstheprocessof designandplanninghetook.

15 ReconditioningDTIGauges

MikeJosephshareshisexperienceswith bringingstickydialtestindicatorsinto goodworkingorder.

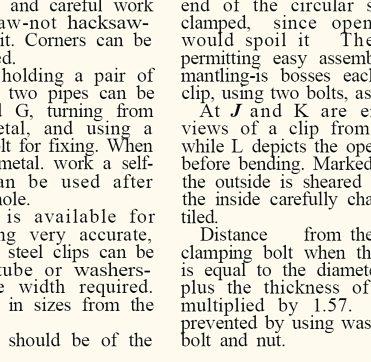

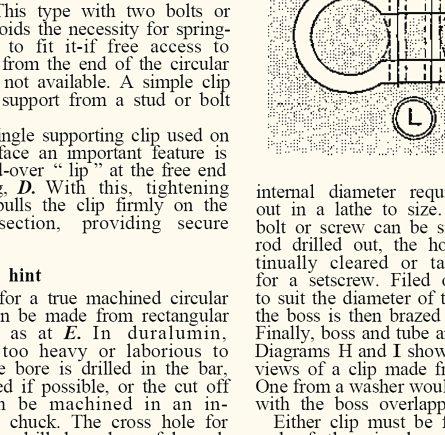

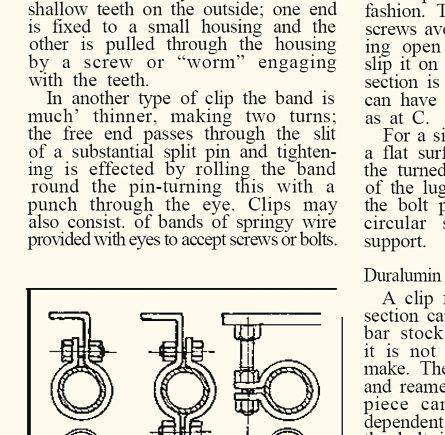

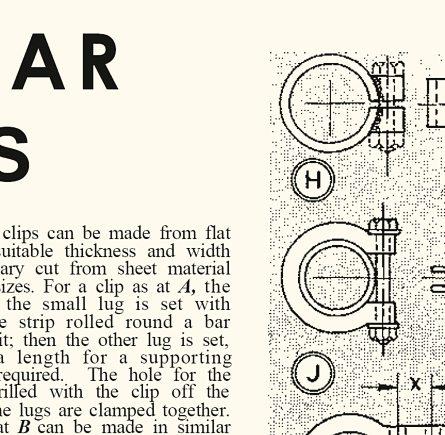

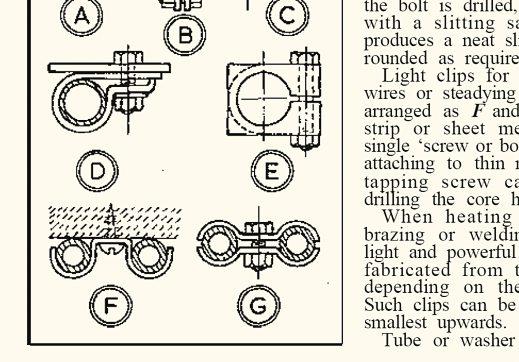

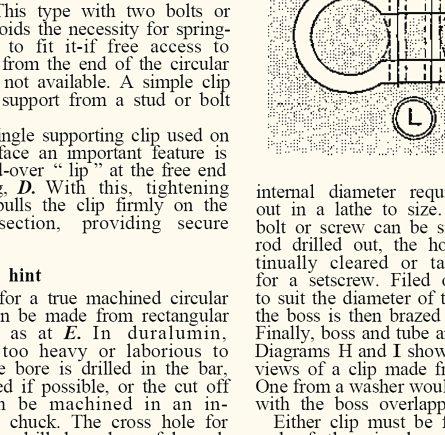

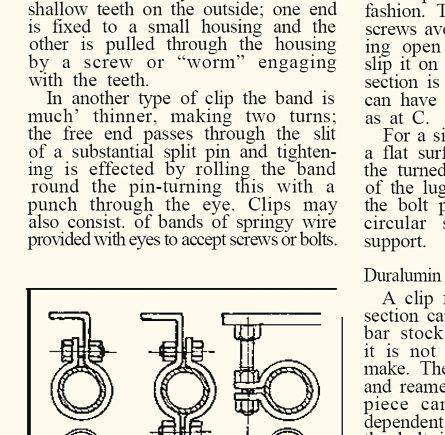

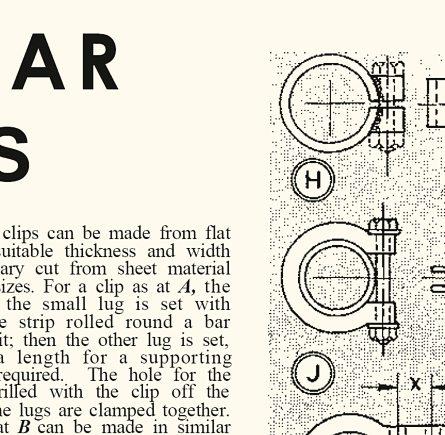

54 Beginner’sWorkshop. ThismonthGeometerlooksatmaking andusingcircularclips.

23 WorkshopTales.

AlecIssigonis,designeroftheMiniwas amodelengineer.

24 It’snotalltooling!

ContributorMurrayLanepresents twooftheproductsof fyyearsof workshopactivity.

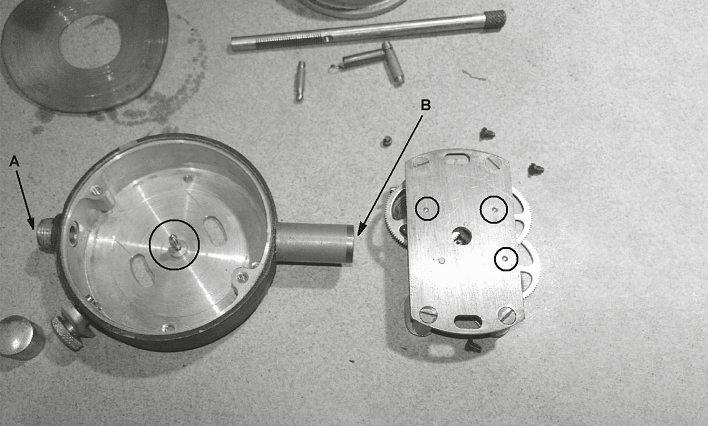

26 CompactDividingHead

ChrisHallawaydesignedandmadethis CompactDividingHead,presented withdetailedplansandinstructions.

33 TheThirdDimension

NeilWyattintroducesanoccasional serieslookingatdiferentapproaches toengineeringchallenges,starting withapro ectinvolvingmanydiferent technologies.

34 SteamMotorcycles

NotallreadersofModelEngineers’ Workshoparemodelengineers!Here’s newsofanambitiousbackyardproject

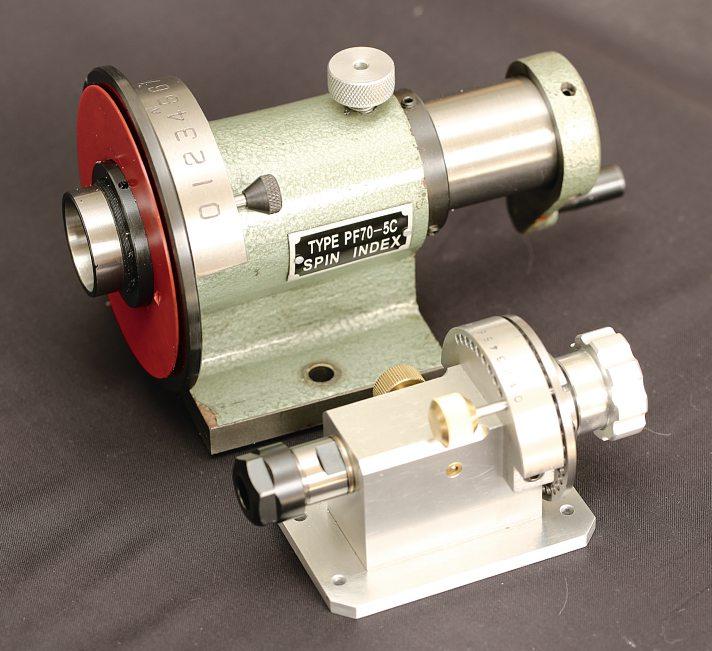

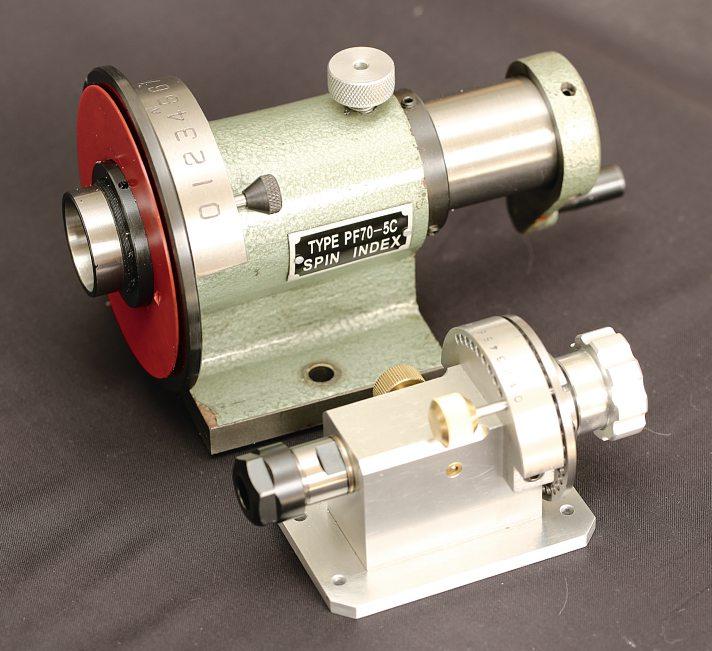

ANER16INDEXER AdesignforcompactmillingmachinesfromBernardTowers

THEMAGAZINEFORHOBBYENGINEERS,MAKERSANDMODELLERSNOVEMBER2023ISSUE333WWW.MODEL-ENGINEER.CO.UK

ArtfulDodges ArtfulDodges

andarecordbreaker.

36 Squaringthecircle. GrahamMeekcompleteshisaccurate dialsfortheEmcoMaximat’scarriage handle.

43 WhenYouFrameIt,DoIt Right.

CarlosDiniz,aprofessionalarchivist,

SUBSCRIBETODAY!

GETYOURFAVOURITE MAGAZINEFORLESS

DELIVEREDTOYOURDOOR!

Seepage54-55fordetails.

ofersdetailedadviceofframingvalued documentsintheworkshop.

47 FromtheArchives. Celebrating125yearsofModelEngineer withadesignforathreadchaserand tipsforaligninglathecentres.

55 ArtfulDodges.

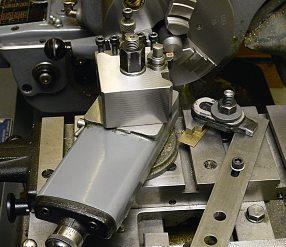

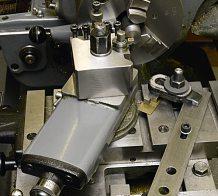

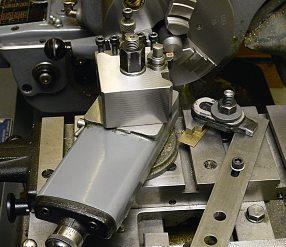

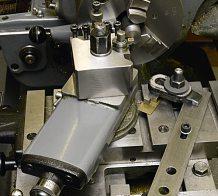

Inhisfinaldodge,JohnSmithlooksat waystoturnalargeconvexradius.

56 ER16Indexer

BernardTowersusesapre-madeER16 spindletomakeavernierindexer suitableforsmallermillingmachines.

60 AFixtureforSplicing QuarterRound

AlHansondescribesahandydeviceto simplifythejoiningofquadranttrims.

63 AMachineLight

AlanDonovanmadeamachinelightfor hisWarcomWM18withsomespecial clipstoprovideano-drillsolution.

Contents ModelEngineers’Workshop www.model-engineer.co.uk 6 56 £5.75 No.333 INSIDETHISPACKEDISSUE: SERVICINGADTI Inthelastinst ofJohnSmith’sseries helooksat ways ofturningalarge convexradius. GetmoreoutofyourworkshopwithMEW Jointheconversationat: www.model-engineer.co.uk MACHINELIGHTING–ANO-DRILLSOLUTIONFORSHERLINEMILLINGMACHINES. AROBUST DIVIDINGHEAD–MOREDETAILEDPLANSANDINSTRUCTIONS MAKINGANDUSINGYOUROWN CIRCULARCLIPS AFILESTORAGESYSTEM-ALANBRYANGETSHISFILESINORDER. YOU’VE BEENFRAMED–CARLOSDINIZONARCHIVALTECHNIQUES. ORGANISEYOURALLENKEYS! EMCOMAXIMAT–GRAHAMMEEK’SPRECISIONCARRIAGEHANDWHEELDIAL. AQUARTER ROUNDFIXTURE–ALHANSONSIMPLIFIESATRICKYTASK. PLUSALLYOURREGULARFAVOURITES! ROCKETMAN TheinsidestoryofGraham Sykes’worldrecord breakingsteambike. MikeJosephexplainshowtorestorea

smoothactiontoanageinggauge.

3 OntheEditor’sBench. Theeditorexplainsthechangestothewww.model-engineer. co.ukforum.

22 ScribeALine. Another neselectionoffeedbackandcommentfromreaders. Wearealwayskeentohearfromyou–justsendanemailto meweditor@mortons.co.uk.

24 Readers’Tips. OurwinnerthismonthwantstohelporganiseyourAllen keys!Sendyourtipstomeweditor@mortons.co.uk,youcould winaprize.

50 OntheWire. Ourmonthlyroundupofnewsfromtheworldofengineering.

66 Readers’Classifieds. Anothergreatselectionofreaders’saleandwantedads.

ONTHECOVER

OurcovershowsJohnSmith’ssetup forlargeradiusturningonhisMyford lathe,seepages54-55.

www.model-engineer.co.uk

TheForumischanging!

Logontothenewforumusingyourexistingdetails.Therewillbeplenty ofhelpandassistanceavailableifyouhaveanyquestionsorissues gettingtoknowyourwayaroundthenewforumsofware.Wehavealso setup‘practice’threadssoyoucantrypostingimagesanddocuments. www.model-engineer.co.uk

Otherhottopicsontheforuminclude:

*Oct2023:FORUMMIGRATIONTIMELINE* Latestnewsonthe forumchangesbyDarrenH.

WinterStorageOfLocomotives Howtokeepyourmodelingood conditionoutsidetherunningseasonby hufer

Bestwayofmovingmillingmachine What’sthebestwayof safelymovinganewmillingmachine?ByMichaelCallaghan

FurtherAdventureswiththeSiegKX3&KX1 Athreadfornew ownersofthesemachines,featuringsoincrediblework,byJasonB

ComeandhaveaChat!

Aswellasplentyofengineeringandhobbyrelateddiscussion,we arehappyforforummemberstouseittoshareadviceandsupport. Comeandjoinus–it’sfreetoallreaders!

November2023 7 WarrenWilliams celebrates50 yearsofGeorge H.Thomas’s UniversalPillar

Regulars No.333 INSIDETHISPACKEDISSUE: SERVICINGADTI Inthelastinstalment ofJohnSmith’sseries helooksatways ofturningalarge convexradius. GetmoreoutofyourworkshopwithMEW Jointheconversationat: www.model-engineer.co.uk MACHINELIGHTING–ANO-DRILLSOLUTIONFORSHERLINEMILLINGMACHINES. AROBUST DIVIDINGHEAD–MOREDETAILEDPLANSANDINSTRUCTIONS. MAKINGANDUSINGYOUROWN CIRCULARCLIPS AFILESTORAGESYSTEM-ALANBRYANGETSHISFILESINORDER. YOU’VE BEENFRAMED–CARLOSDINIZONARCHIVALTECHNIQUES. ORGANISEYOURALLENKEYS! EMCOMAXIMAT–GRAHAMMEEK’SPRECISIONCARRIAGEHANDWHEELDIAL. ROUNDFIXTURE–ALHANSONSIMPLIFIESATRICKYTASK. ROCKETMAN TheinsidestoryofGraham Sykes’worldrecord breakingsteambike. MikeJosephexplainshowtorestorea smoothactiontoanageinggauge. THEMAGAZINEFORHOBBYENGINEERS,MAKERSANDMODELLERSNOVEMBER2023ISSUE333WWW.MODEL-ENGINEER.CO.UK ANER16INDEXER AdesignforcompactmillingmachinesfromBernardTowers ArtfulDodges

Comingup… inournextissue

Tool.

Visitour Website WhynotfollowusonTwitter?twitter.com/ ModelEngineershashtag#MEW THISMONTH’SBONUSCONTENT

HOMEFEATURESWORKSHOPEVENTSFORUMSALBUMS

CLASSIFIEDSEXTRASUBSCRIBEARCHIVESUPPLIERS

AMetalworkFile StorageSystem,Part1

AlanBryanbreaksdowntheprocessofdesignandplanningbehindhisfle storagesystem.

Ihoardthingsasfarasmywifeis concerned.Idon’ttotallydisagreewith her,butIdon’tconsiderthatselecting materialswhichareofendiscardedas scrapandstoringitemsawayforfuture usewhichmightonedaybesuitablefor myhobby,ishoarding.Overtheyears I’verepeatedlyclaimedthattheywillbe usefulonedayandamoneysaver.

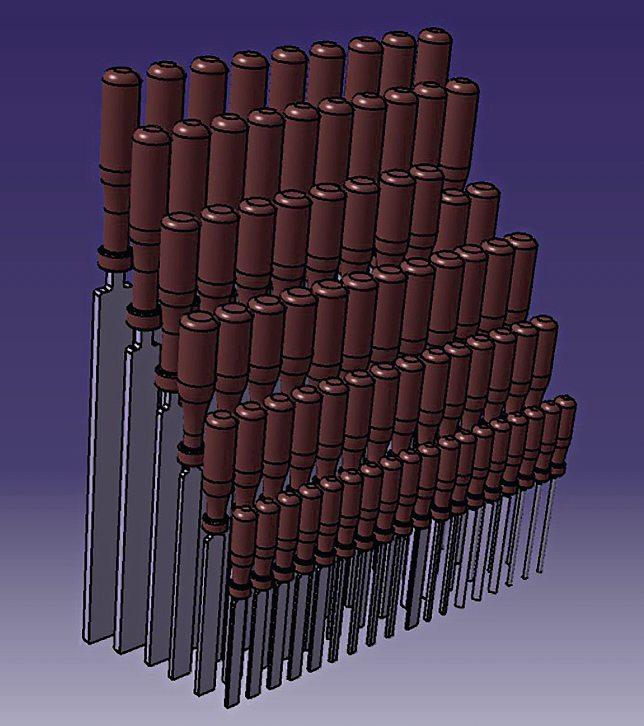

Howisthatrelevanttoengineer’s metalwork lestorageyouask Well, stickwithmeandallwillbecomeclear aswegetdeeperintothisbecauseI considerthatIdoprovemypoint.I maydeviatefromtheprimarysubject onceortwicebutpersevereplease, it’sallrelevant.Inthisarticle,Iwill touchonseveraldiferentaspectsof engineering,from3D-CAD,toworking withwood,allofitrelevanttothe productwhichisametalwork le storagesystem, photo1

AProblemBecomesApparent

IncommonwithmostofusI’ve accumulatedquiteacollectionof les ofvaryingsizesandsectionsoverthe fy-plusyearssinceIstartedmy apprenticeship.Sizealwaysreferstothe le’slength. achsi eincludesvarious sections,andcuts.Mycollectionalso includesneedle lesandafewri er les.Allwerepreviouslystoredtogether, withoutanymeansofseparationfrom eachother,inadrawerinoneofmy twoworkbenches.Thatsituationwas lessthanidealforseveralreasons. irstly, lesarecuttingtoolsandshould neverbeallowedtorubagainstother hardenedobjects.Filesareexpensive andmadeofhardenedsteel,sothey qualifyasbeingworthyofsegregation topreventanydamageorbluntingfrom occurring.Thedrawerinmyworkbench clearlywasn’ttheidealenvironment. Secondly,itwasn’talwayseasytoselect aparticular leforthe obinhandsince

theonethatIneededwasofenburied underneathothers.Animprovementin storagewascalledfor.

WhenIplannedandbuiltmy workshopeightyearsago,Imadeit largeenoughforwhatIthoughtmy needswouldbegoingforward.At rst itwas,andI’msureyouknowwhere

I’mcomingfromhere,becauseitwas biggerthananybuildingthatI’dhad previously.I’dtakenopportunities topopulatethosenicewideand clearopenspaceswithvariousother machinesastheybecameavailable, anditgradually lledup.Then, somethinghadtogiveandabouta

› 9 File Storage November2023

Theflestoragesystem.

1

yearago,IreluctantlyconcludedthatI hadseriouslymiscalculatedhowmuch storageIneeded,particularlyforthe materialswhichI’dcollected horded , andhowlittlespaceIhadlefto devotetohousingthem.Thatdecision boughtaboutareorganisation totrytoimprovematterswhich, apartfromconstructingsomewall cupboards,includedmodifyingoneof thebenchestoaccommodatemetal storage.Thatdecisionevictedthe lecollectionfromitsdrawerwhich meantthatitbecamenecessaryto provideabetterhomeforthem.The situationshownin photo1,clearly wasn’tsuitableforthelong-term.

TheSearchForSolutions Ihadbeenthinkingaboutvarious storagepossibilitiesforalongtime

beforetheevictionhappened,scouring Pinterestandmanyforaonthe internetlookingatavastnumberof ideas.Manycontributorswroteand postedaboutamultitudeofvaried ideas,butnonewereexactlywhatI waslookingforalthoughIdidshortlist asmallnumberofpotentialsolutions:-

1.Storageinaseriesoftrays,eachtray dividedintocompartmentsandeach compartmentsizedtoaccommodateone le.Thatdirectedmetosolutiontwo.

2.Atoolcabinet,likeatoolmaker’stool cabinet,housingthetraysasdrawers, sittingontheworkbench.

3.Drillaholeineachhandleandhang each leonahooka xedtoabatten screwedtothewalloverthebench.

4.Fixamagneticstriponthewallover thebenchandhangeach lefromitwith thehandleatthebottom.

5.Arotatinghorizontalplatelikea“Lazy Susan”arrangementwithaseriesof appropriatelyshapedholesforthe lestodropthroughthuspresenting thehandleofeach lereadilytobe withdrawn.

6.Fixedverticalstorageusinga perforatedplateasin .but ttedto thetopofaplasticbucketwhichhad containedliquidfertiliserinitsformerlife. Prosandconsofeachshort-listeditem wereasfollows:-

1. ro - very lewouldbeseparated fromitsneighbourandreadily availablewhenthetraywaspresented unobstructed.

Con:-Iwouldhavetostorethetrays somewherewhichmeantusinga sparedrawerwhichIdidn’thave. Also,Ireasonedthatsuchtrayswould probablybeaboutamaximumof

ModelEngineers’Workshop www.model-engineer.co.uk 10

2

Theflecollection.

30mmhighsotomaximisedrawer space,trayswouldbestackedwithin thedrawer.Meaningthat,ifIneeded a1 -inch le,thelargesttraywould probablybeatthebottomofthe stacksoIwouldhavetoremoveevery smaller letrayinthedrawerbeforeI couldgetmyhandsonit.

2. ro -The le-drawercabinetidea appealed.Itwouldbeeasytoproduce andwouldkeepthe lesfreeof workshopdustandair-borndirt. Con:-Itusedafarbitofbenchspaceand thecabinetitselfwouldhavehadalot ofdeadspacewithinitbecauseitwould needtobeapproximately20inches deeptoaccommodatea1 -inch le whereasthedrawertohousea4-inch lewouldhaveonlyneededtobe inchesorsodeep.

That rmlyestablishedmy rstand secondparameters.Firstly,that convenientaccessibilitytoallsizes, alwayswasverydesirable.Thesecond beingtouseaminimumofbenchspace.

3. ro - very lewouldbeaccessible andeasilyidenti able,anditwouldn’t takelongtomake.

on -Allmy leshavewooden handles;Idon’tyetpossessanyof themoremodernplastichandled variety.Sometimesahandlewillcome adriffromthe leandneedstobe re tted.Ihaven’t ttedmanyofmy leswithhandlesbyburningthe le intothewoodwhichisanomission thatIwanttocorrectinfuture.Icould alsovisualiseascenariowhereIcame intotheworkshoponemorningto ndadetached lebladeembedded insomethingwhichIhadmadethe daybeforeandfoolishlylefdirectly underneaththehanging les.Also, Ineededtheareaofthewallbehind thebenchforhangingotherthings onsotherewasnoconvenientspace available.Thatideawasquicklyrejected.

. ro -Thesteelthat lesaremade frommagnetisesveryeasilysothe les wouldbeheldsecurely.Also,hanging likein3.albeitupsidedown, leswould beeasilyidenti able. very lewould beaccessibleanditwouldn’ttakelong toinstallwithnothingtomakeandno holestodrillin lehandles.

on -Thesteelthat lesaremadefrom magnetisesveryeasily.Iknowbecause weusedamagnetisedrat-tailed le todiligently shoutswarffragments

fromthemassivesteelcastingsanddie bolsterswhenIwasanapprenticein oneofthedieshopsbelongingtothe BritishLeylandorganisation.Duringthe constructionoflargepress-tools,which wereandstillareusedtoproducecar bodypanels,theycamebackcameback fromthemillinganddrillstationsbrimfulloffragments.Idon’twantmy les tocollecttheswarfwhichtheyproduce. Also,Ihadalreadyruledoutwallhanging duetoaspacecrisis.Thatideawas quicklyrejectedtoo.

5.Pro:-Becauseofthelackofwallspace Ihaddecidedatthispointthatthe les wouldhavetooccupyaportionofthe availablebenchspace.Ihadseenand quitelikedseveral“LazySusan”concepts whichconcentratedeverythingintoa verycompactarea.Itmeantthatevery lewaspresentedandreadilyavailable withoutmovingothersoutoftheway. Con:-Iwouldneedtolookdown almostdirectlyontothetopofthat platewhenselectinga letoensure thatIwaswithdrawingthecorrect one.Storingthemallvertically,the heightatwhichtheplatewiththe slotsinitwouldbelocatedwouldbe establishedbythelongest le.Ihad calculatedthattheplateonthetopof the“LazySusan”wouldbe1275mm above oorlevel.Therefore,thetopof thehandleofa1 -inch lewouldbe atleast200mmabovethataswould every lestoredinthe a y usan . Itwouldbenecessarytokeepthe les neartothefrontofthebenchtobe abletoseethe epro leclearly. or convenience,ifIwastositeitnearto therearofthebenchtopthenthe les neededtobeangledtowardsthefront ofthebench.Also,whenreplacing a le,itwouldbedroppedthrough theplateanditspassagestoppedby contactbetweenthehandleferrule andtheplate.Therepetitiveimpact eventuallywouldeventuallydislodge the letangfromthehandle.Also, theferruleagainsttheplatewould obscuretheshapeoftheslotandthe tipofthe lebladesoIwouldn’tbe abletoseewhich leIwasselecting. Itneededaseriesofsurfacesbetween 3.75inchesand13.75inchesbelowthe topplateforthetipsofthe leblades torestagainstandIcouldn’twork outaneasilymanufacturedsolution tothat.Anglingitawayfromthe

verticalneededaratchetmechanism, orperhapsaseriesofsprungdetents inacircularpath,incorporatedinto thedesignofasimplerotating arrangement.Ireasonedthatthe heavierportionoftherackwould otherwisealwaysbefalltothe bottom.Suchamechanismwastoo complicatedforthetask.Plus,tomy mind,anglingthehandlestowardsthe frontmadetheinclusionofarotating bearingunnecessary.Ididn’ttotally dismissitthough.

6.Rotatingplatesystemswhichuse aplateperforatedappropriately tostorecolletsandwhichhavethe rotatingaxisangled,havetwoplates piercedwithconcentricholestoadmit entryforthestoreditems.Theyare spacedapproximately25mmto50mm aparttokeeptheaxisofthecolletor toolnormaltotheplatesurfaceand preventthecontentsoftherackfrom contactingeachother.Iwouldneedto dothatwiththe“LazySusan”concept too,especiallyifIwantedtoanglethe platetowardsme.So,forthebucket idea,becausetheendsofthehanging lescouldknockagainsteachother, IdecidedthatI’dneedtomaketwo plates,piercedidenticallyandspaced apartbutwithoneslightlysmalleron itsoutsidediameter.Thetopplate wouldsitintherecessatthelipof thebucketusingthatledgetostopit fromdroppingintothebucket.The diameterofthesmallerplatewould t closelyinsidethebucket50mmlower insideitthuslocatingtheplatesand lesperfectly.

Pro:-Itwoulduseanareaofthebenchof approximately350mmdiameter.Avery smallfootprintindeed very lewould bevisibleandeasytoselect. Con:-Theseweresix-fold.

a.Itwouldneedtobepositionednear tothefrontofthebenchtobeableto identifyeach leasin .

b.Itcouldn’tbeangledtowardsthe operatorbecausethebucketdidn’thave anangledbottom.

c.Producingtheperforatedplateswould beatime-consumingoperationforme oracostlyoneifIdecidedtogetthe plateslaserorwaterjetcut.

d.Ididn’tknowwhatthelifeexpectancy oftheplasticbucketwouldbeandI wantedthesolutionthatIarrivedatto bealongtermone.

› 11 File Storage November2023

e.Thesameproblemofpreventingthe lesdroppingthroughuntiltheferrule contactedtheplateapplied. f.Icouldn’taccommodatetheri erand needle lesintotheconcept. owever,now rmlyembeddedinmy thoughts,theappealofasmallfootprint wasn’tgoingtogoaway.

In-DepthInvestigations

Ithereforedecidedtothinkonthe prosandconsalittlelongerandspent sometimesketchingoutideas.Ialso measuredthesectionsofallmy les and lehandlesinpreparationfora comprehensive“packaging”study.I neededto ndout usthowsmalla spacemycollectioncouldbepackedinto andstillbeprotectedfromeachother butremainaccessiblewhenrequired withoutbeingblockedbyother les.

I’vealreadymentionedthatI measuredallmy lesand lehandles. Ialsotriedto ndwhattheactual sectionaldimensionsareofthe lesthat areproducedtodaybutIdrewablank onthat.AllthatIwasabletoascertain wasthat nglish lesareproducedin -inch, -inch, -inch,10-inch,12-inch

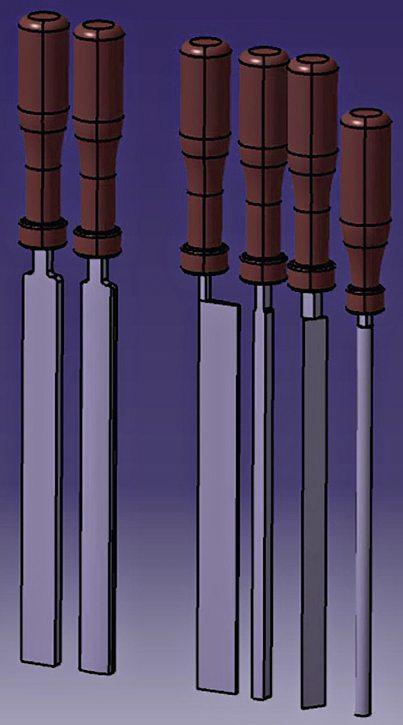

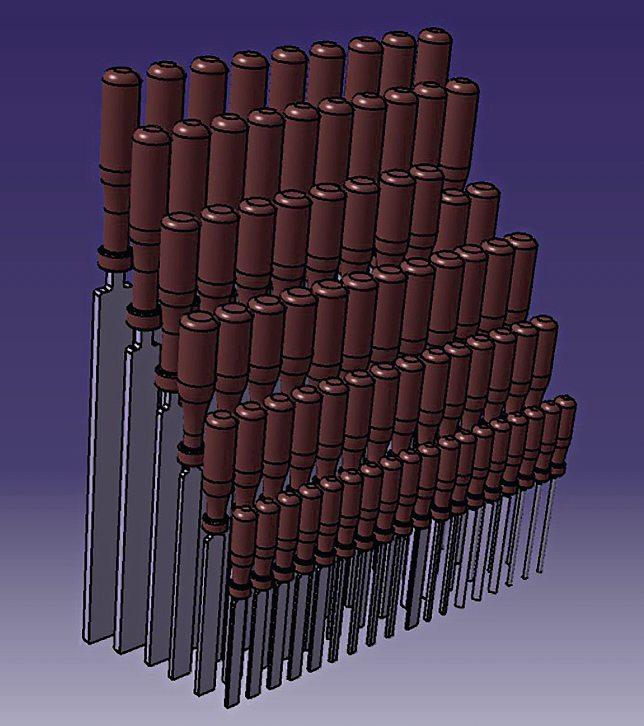

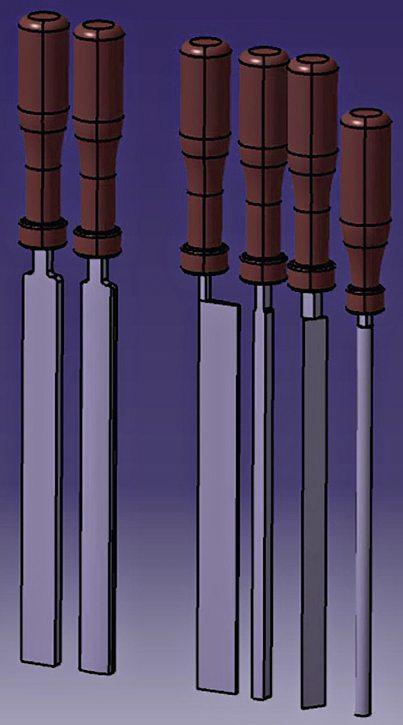

and14-inchlengths,withsomein15and 16-inchlengthsalso.Americanpattern lesaresimilarinrange https //www. apextoolgroup.com/content/nicholsonguide- les-and- ling . wisspattern lesarediferentthoughasareother uropean les.Thenofcoursethere areneedle lesandri er lesaswell. WithallthatinmindIdecidedtogo withwhatIhad,whichareall nglish pattern.Iwouldusethedimensionsof myown lestoproduceasetofvirtual lesandmakeasolidmodelofeach le thatIowned.AlthoughIsimpli edthe ledetailssomewhatthosesolidvirtual modelsweretoallintentsandpurposes almostidenticalinspeci cationto therealpart. very lepossessedthe materialpropertiesofwoodforthe handleandsteelforthebladeandthe systemcalculatedavirtualmassofeach toolwhichtoallintentsandpurposes wasidenticaltotheactual le.Igained afewbene tsfromthatlaterinthe project. Figure1 illustratestherangeof 1 -inch les.

Imodelledthe1 -inch les rstand thencopiedandmodi edthedata producedtomodelthesmallersizes

andhandles.Itonlytookafewhoursto produceallthe lemodels.Ididn’tmodel theri er lesandneedle lesthough, havingreasonedthatitwouldn’tbe necessaryaferstudyingthosewhichI hadinmycollection.

Iwasnowabletocheckhowtightly lescouldbepackedtogetheryetstillbe accessible.Ifoundthat -inch lesand smallerhaveahandlewhichislargerin diameterthanthebreadthof atand halfround les,but10-inchandlarger at lebladesarewiderthanthehandle diameter.Therefore,allsmaller les couldbepositionedatanequaldistance fromtheirneighbours.Withthelarger sizes,Icouldspacetheround,squareand triangular lesequallyapartaccording tothehandlediametersbutIcouldn’tdo thattosetthedistanceforthe atand halfround lesbecausethespacingwas controlledbythebladewidth.Inowhad allthatIneededtoarrangethe lesina varietyofpositionssoIcoulddecideon thebeststoragepattern.

TheCrystallisationOfAnIdea Ihadstudiedcommerciallymade chef’swoodenknifeblocksonand

ModelEngineers’Workshop www.model-engineer.co.uk 12

Ehftqd0- Ehftqd1-

offoralongtimewonderingifthe principalcouldbeadoptedasa le storagesolution.Ihadeventriedto sketchoutthebasisofsuchasystem previouslyinCADbuthadnotpursued itfurtherbecauseitdidn’tlookto beastraightforwardpropositionto manufactureone.Revisitingitnow,I realisedthatitoferedthepotential toutiliseasmallfootprintandreally deservedtobegivenanothergo.My previousattemptshadcentredaround thepossibilityofpackingthe lesinto ablockinacirculararrangement,but I’dnevergotanyfurtherwithit.Then itdawnedonmethatIcoulddesigna steppedarrangementfrom4inches to14incheshighwitheachsteptwo inchesabovethepreviousstep.Ialso realisedthatIcouldincludeafurther stepforstoringri er lesandneedle les.Thesteppedarrangementmeant thatthelengthofthe lewouldbea

visualclueofwhere lesbelong,each ledroppingintoaslotwiththeendof thebladebeingarrestedwhenithitthe baseboard.Thatremovedthedanger ofthe lehandlebeingdislodged byrepetitiveimpactbetweenthe handleferruleandaslottedplate. Also,becausethestepheightcouldbe lessthanthelengthofthe leblade, thehandleferrulewouldbespaced awayfromthestorageslotandthe typeof leisvisible,thusremoving theneedtoidentifywhichshapeof leisbeingstoredinaparticularslot. inally,sinceknifeblocksareofen angledtowardsthechefpresenting thehandle,readytobereadytobe graspedandwithdrawn,Idecidedto tryandincorporatethatfeaturetoo. Thus,meaningthattheblockcould bepositionedtowardstherearofthe benchratherthanoccupyingspaceat thefrontofit.

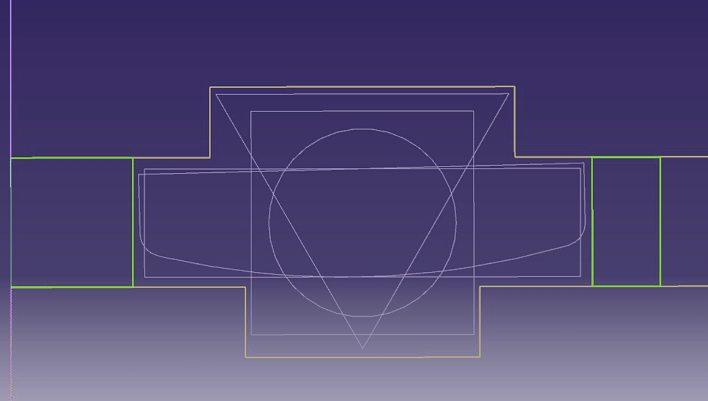

Ithereforerepackagedthe lesto followthatstorageprincipal.WhatI arrivedatisshownin g.

PlanningConstruction

Withthebasicsofmyschemethus establishedInowhadtodecidewhat tomakeitfrom.Firstandforemost,I decidedthattheprojecthadtobemade frommaterialswhichIalreadypossessed andhadtousemachineryandtooling whichIhadinmyworkshop.I’dalready ruledouta“LazySusan”bearingand pro lecuttingsoithadtobe madefrommaterialswhichIalready possessed,andwhichwouldn’tdamage the leteeth.Thatmeantwood.

Ihaveareasonablywell-equipped workshopwhichincludesColchester andMyfordlathes,aBridgeportmilling machine,ashaper,drillsetc.Ialso possessvariouswoodworkingmachines andpowertoolssuchasaMakita 260mmtablesaw,a12-inchdiscsander, a½inchrouterplussomeothersso thosecontrolledwhatoperationsIcould perform.It’salwaysimportanttodesign aroundwhatcanbeproducedfromone’s workshop,sowithallthatinmindIsetto workingoutaproposal.

Idecidedthateveryslotonevery stepwouldaccommodateall leshapes oferedinthatlength.Theexception tothatwastheknife lewhichhas thecentrelineofthehandlebiased towardsthewidestpartoftheblade. Alltheothersinmycollectionhavethe lebladecentrelinecoincidentwith thecentrelineofthehandle.Itherefore decidedtohaveoneslotineachstep solelytoaccommodateaknife le.

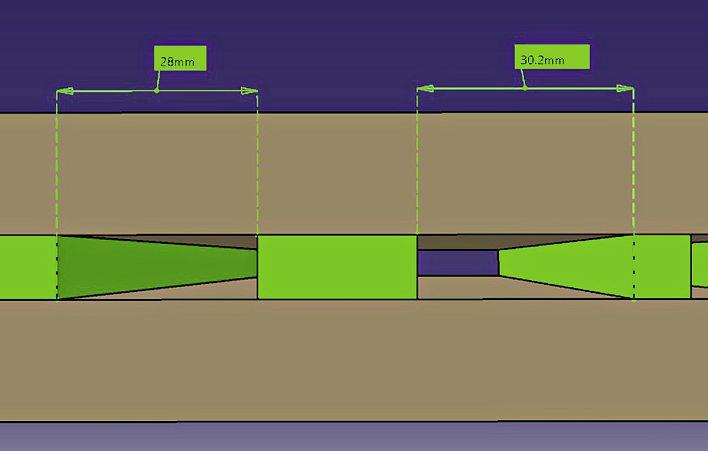

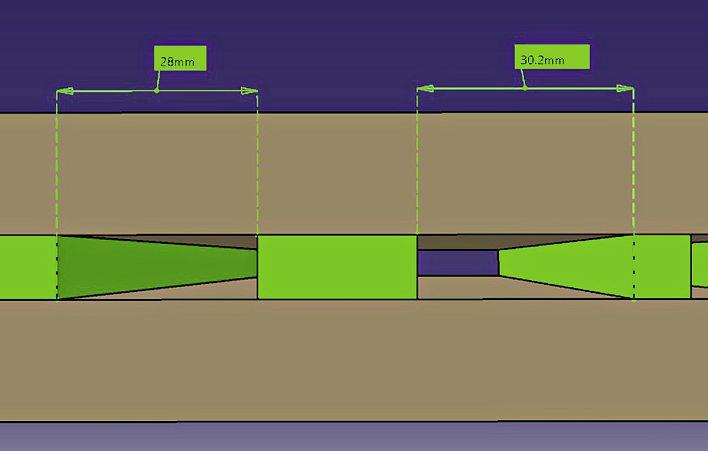

Figure3 illustratesthe10-inchstep, the2 mmslotwidthaccommodates at andhalfround les,whilstthe30.2mm isfortheknife le.Thatslotalsomust haveawiderspacingfromoneofits neighbourstoaccommodatetheofset locationofthehandle.

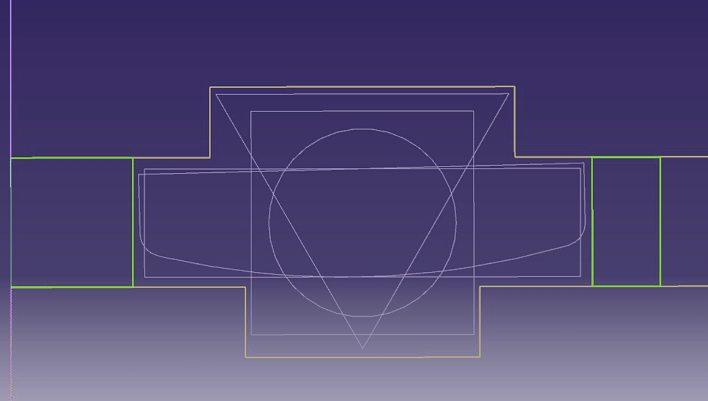

Ialsodecidedthateachslotwouldbe thecorrectsectiontosuita at leand ahalf-round le. lus,bymillinganother slotacrossthemiddleofthe rstslot, square,triangularandround leswould beaccommodatedinthesameslot withouttheslotbeingsowidethatthe at le oppedaroundinit.

Theversatilityofeachslotwhenthe secondaryslotisaddedisshownin g. Tobecontinued

13 File Storage November2023

Ehftqd2Ehftqd3-

Workshopsof thePast

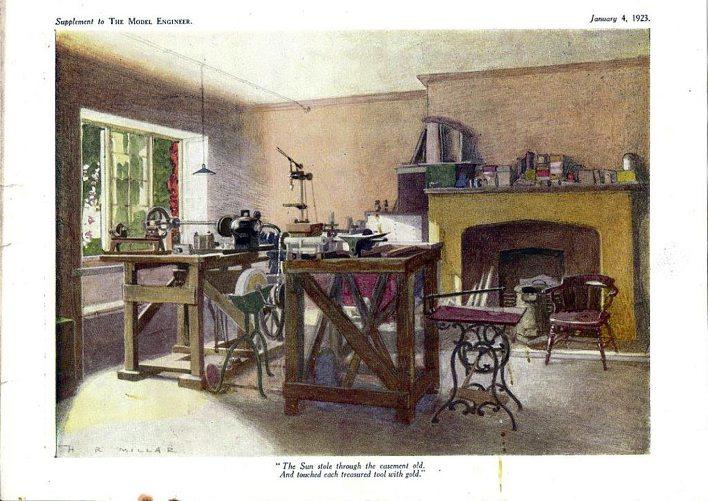

Modelengineeringemergedas ahobbyinthe19thcentury, Skilledfactoryworkerswanted tousetheirabilitiestomakethingsfor themselves,andofenthedesigners andsupervisorsinthefactorieswanted acreativeoutletaswell.Eveninthe early20thcentury,electricitywasthe exception,ratherthantherulesomost workshopswouldbepoweredby‘foot power’orthefortunatemighthavea steamorICenginedrivinganoverhead shaffromwhichseveraldiferent machinescouldbepowered.

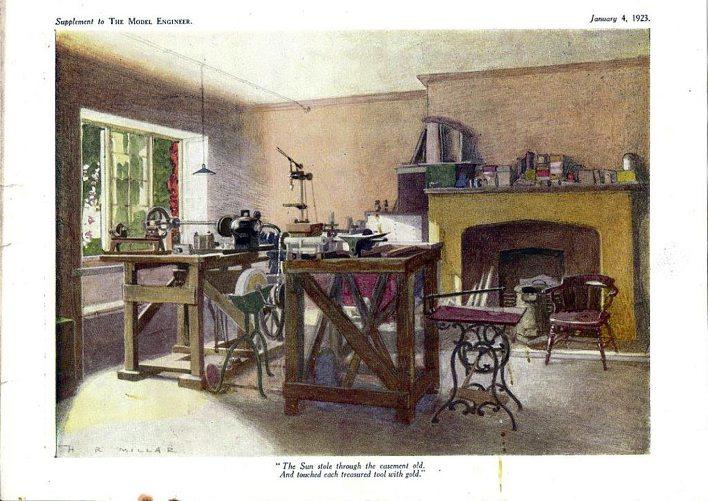

Ourpicture, photo1 showsa romanticisedearlymodeller’sworkshop paintedby . .Millar.Onthelefisa treadlepoweredlatheofquitelarge capacity,withamuchsmallerminiature latheinfrontofit.Nexttothelatheisa hand-crankedwhetstonegrindingwheel –imaginetryingtosharpenaccurately whilecrankingthehandle Itisdi cult tobesurewhatitemsareontheother bench,butattherightisatreadlefretsaw. Thiswouldhavebeenusedforthinmetal aswellaswoodensheet,fretworkwasa verypopularhobbyactivity.

Inthebackgroundisasensitivedrilling machine,itisn’tclearifitisfootpowered oritmayhaveasmallelectricmotor–theworkshopdoeshaveelectricityas thereisalight ttingontwobarelive wiressuspendedfromtheceiling!Such alampcouldbemovedbackandforth toconcentratethelightwhereitwas wanted.Storageislimited,amanydraweredtraditionaltoolcabinetbeside thedrillandallsortsofrandomitems piledonthemantelpiece.

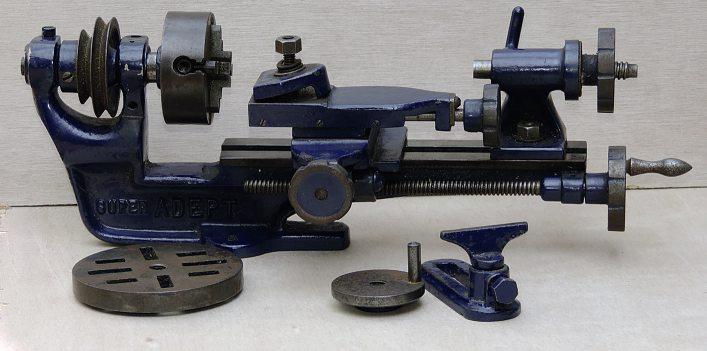

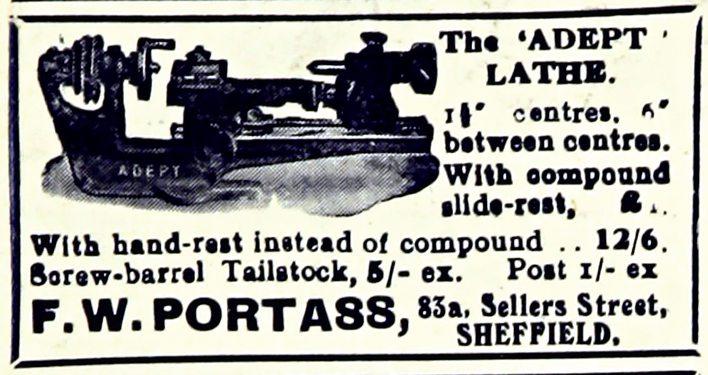

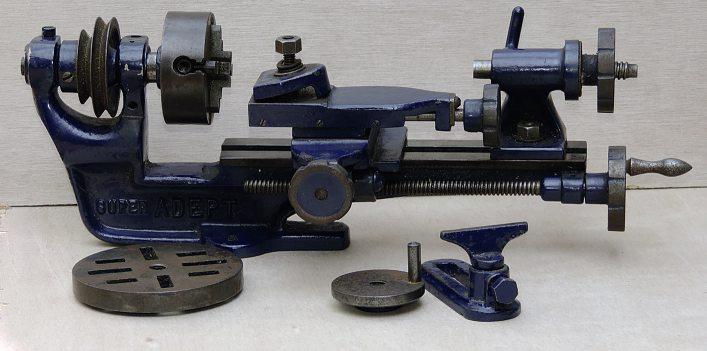

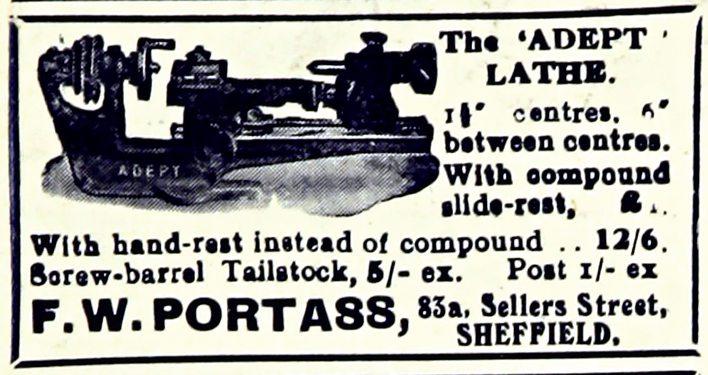

The‘SuperAdept’lathe, photos2 and 3, was rstproducedinthe1 30sby W Portasslimited.Evenforitstimeitwas aprimitivemachine,yetmachinessuch astheseprovidedaninexpensiveroute intomodelengineeringformanypeople. Itissoberingtoseesomeofthemodels madeinworkshopslikethisandsuch modestequipment.Thisistestimonyto theexceptionallevelsofcrafsmanship shownbyhobbyistsinthepast.

ModelEngineers’Workshop www.model-engineer.co.uk 14 Old Workshops 2 1 3

SuperAdeptlathe

A1932advertfortheSuperAdeptlathe.

Amodelengineer’s workshopfromthe early20thcentury.

Reconditioning DTIGauges

ike osepho ersso eg idanceonthetrickytaskofbringingstickydialtest indicatorsintogoodworkingorder

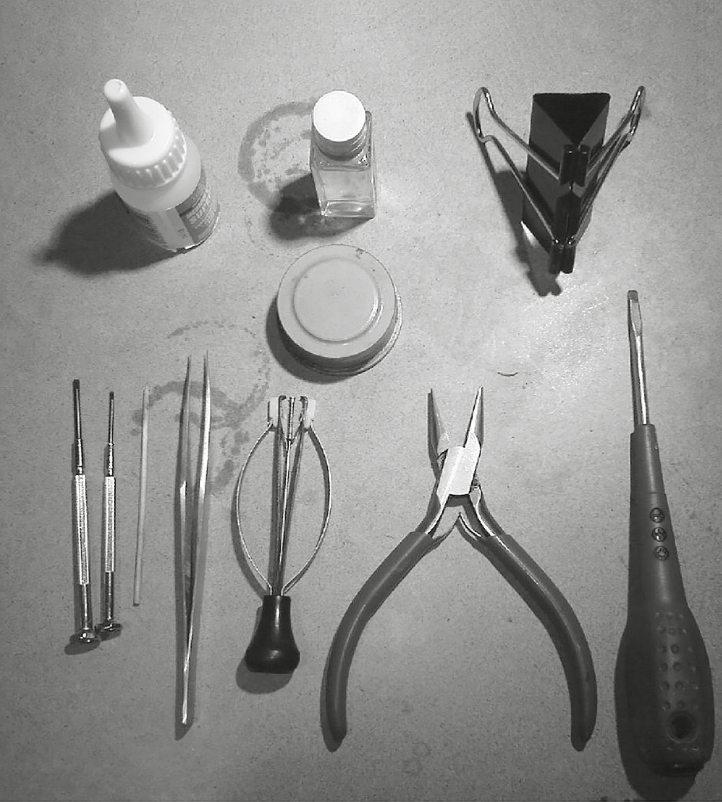

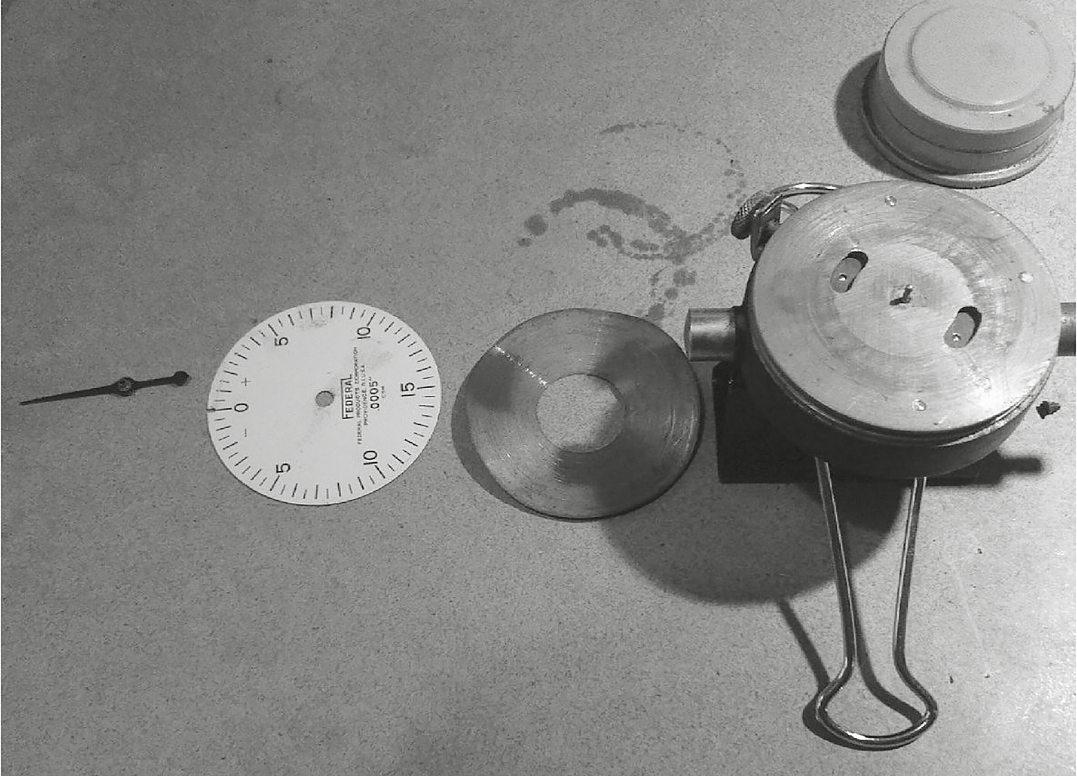

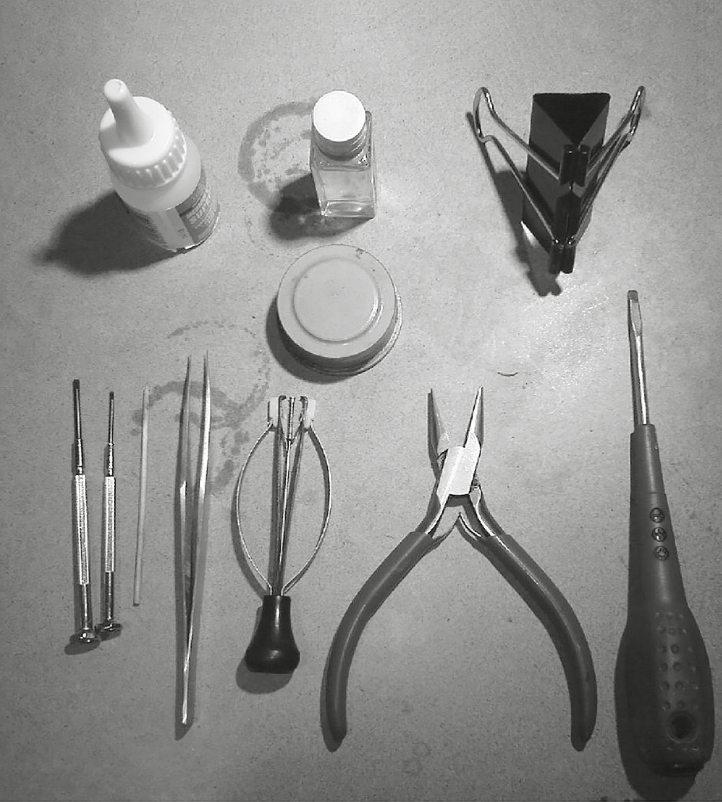

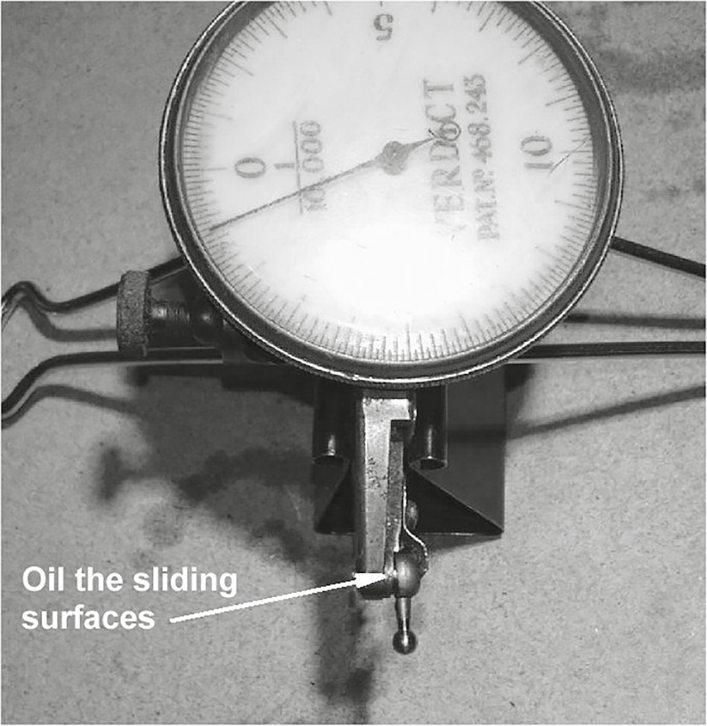

Dialtestindicators,DTIs,are availablesecondhandbutare ofensticky,i.e.notmoving cleanly mostofminewere .Thisis simpletorectifywithgentleoilingat thecorrectpoints.Ifeltthatacomplete dismantleandservicewasnotnecessary becauseDTIsareonlyoccasionallyused, unlikeclocksandtheywereallveryclean internally.Thetoolsareillustratedin photo1 andare:

uperglue,mediumviscosity

ocketwatchoil

Oilpot asmalllidwilldothe ob oldbackclip,smallviceorsimilarto holdtheDTI

Watchmakers’screwdrivers egwoodor netoothpick Watchhandremover

Pliers mallscrewdriver 1/ bladeorso . Theonlyitemsunlikelytobeinan engineer’stoolkitarethewatchhand remover,andthepocketwatchoil.

Theoilpotcontainsacoupleofdrops fromtheoil ar decantedtoprevent contamination andthepegwoodor toothpickisusedtoapplyavery ne dropofoil.

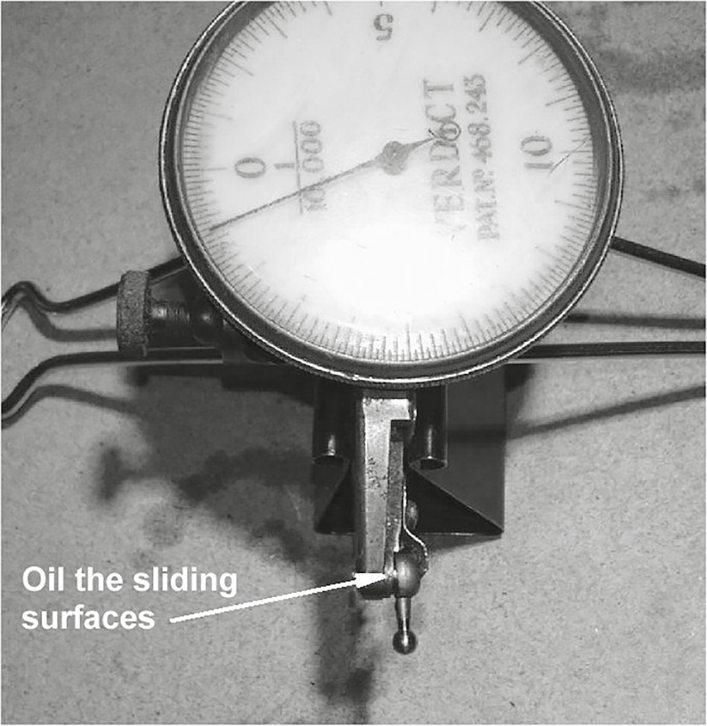

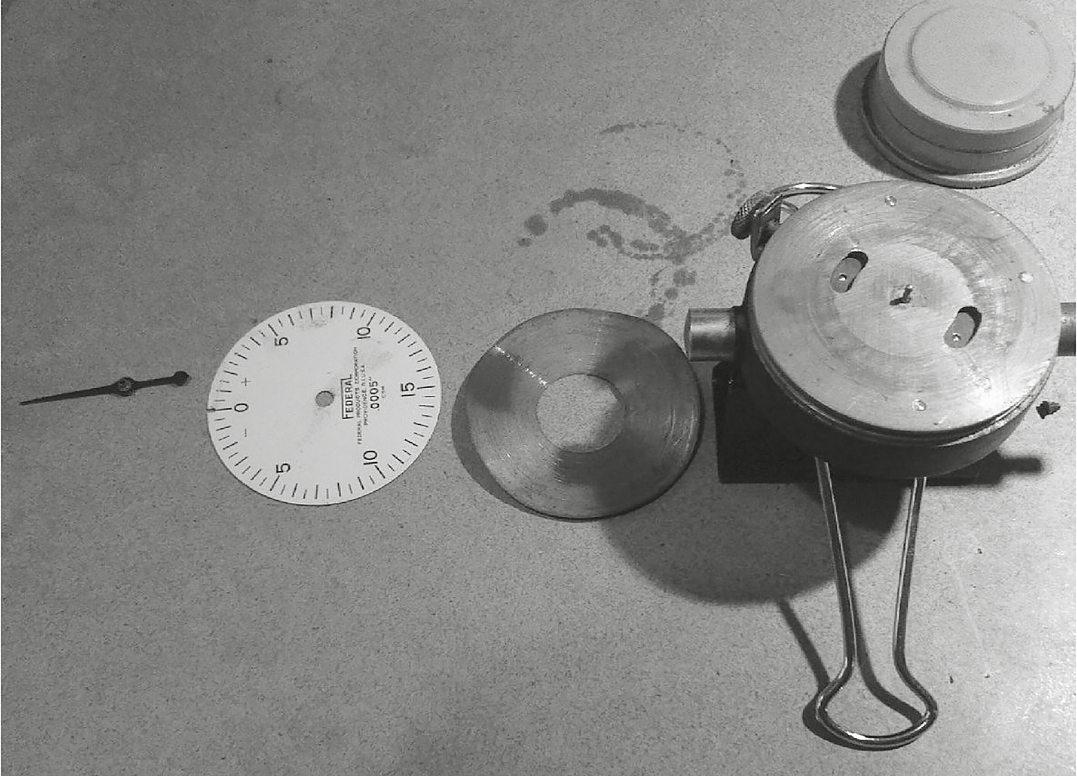

Twotypesofgaugearecovered, thelever dialtestindicator andthe plungeroperated dialgauge , photo 2.Thelevertypeistheeasiesttodeal with in photo3 oncethecoveris removed,thereisamovingarmand spiralgear.Donotlubricatethissince

› November2023 15 Servicing DTIs

T o i erentty

T.

Tools se . e erty e T. 1 3 2

eso

oilattractsdustandformsaverygood grindingpaste–clockgearsarenever oiled,onlythepivots–itwillonlyneed alighttouchofoilontheslidingfaces, photo4

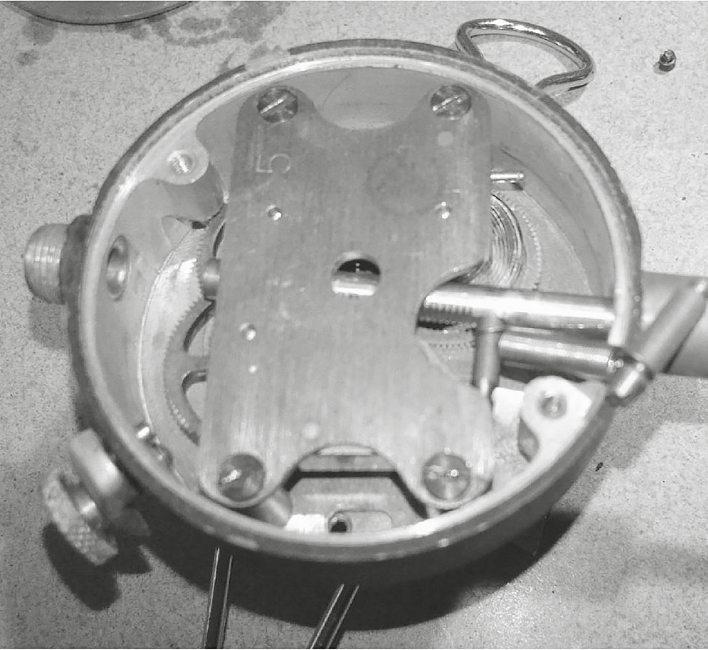

Theplungertypeneedstobe partiallydismantled.Afertakingof theslipringandglasscover usually heldonbyoneormorescrews ,use thewatchhandremovertopriseof thehand, photo5.Itmaybepossible touseasetof neprybars–with paperbetweenthemandthedialto preventscratching.Interestingly,in thisexample,thehandappearedto beupsidedownbutwasde nitely taperedthatwayandwouldnotgo onthe‘normal’way. Photograph6 showswhatisunderthedial,aspring topressthedialagainsttheunderside oftheslipring.

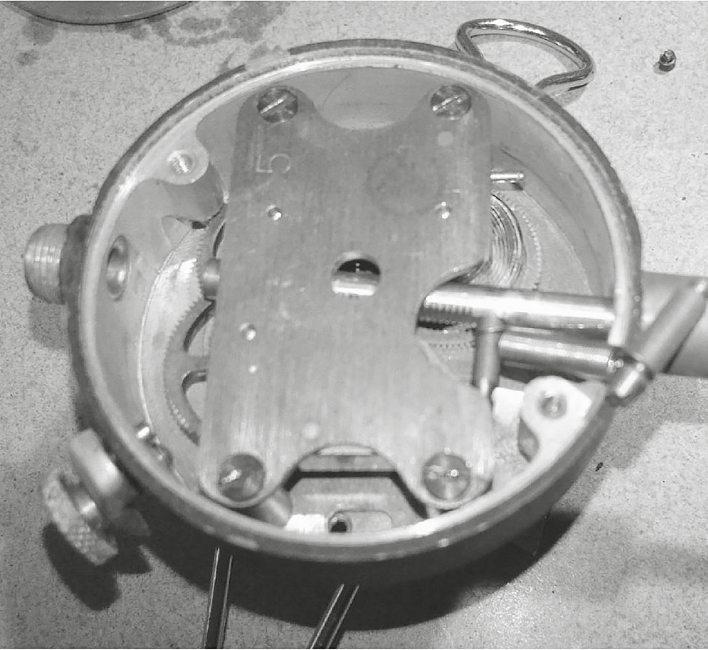

emovethedustcapshownonthe lefofthedial, photo7,andremove theretainingscrew, photo8.Thereare twoscrewstoberemovedthatad ust theengagementoftherackandhold theworksinplace, photo9. ext,the pinthatsecuresoneendofthereturn springhastobeunscrewedandthen displacedasshown, photo10,toallow

ModelEngineers’Workshop www.model-engineer.co.uk 16

tatiny tinyto cho oilonthele er i ot.

singthe atchhan remo altool.

5 4

emo etheretainingscre insi e.

› November2023 17 Servicing DTIs the n er ial arts. T istthemo ement. emo ethet oengagementscre s. emo ethe stca onthee treme le circle . 7 9 6 10

thearmtobemovedrightacrossso thattheotherpinandthespringcan beunscrewed, photo11 therackis alsoshowninthisview.

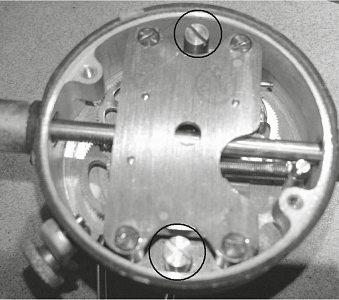

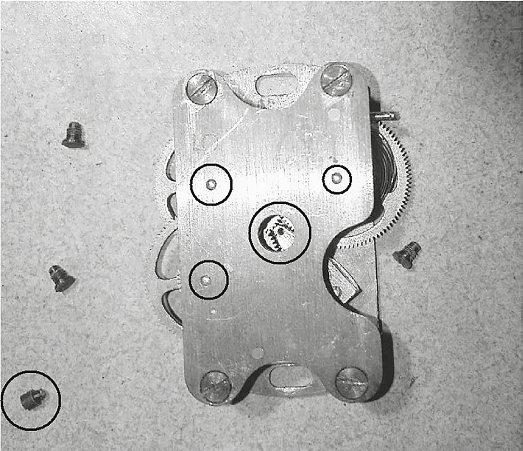

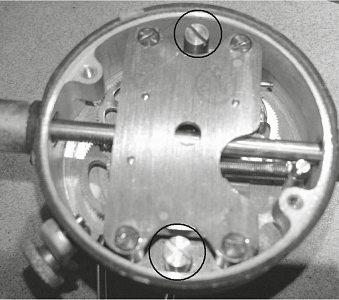

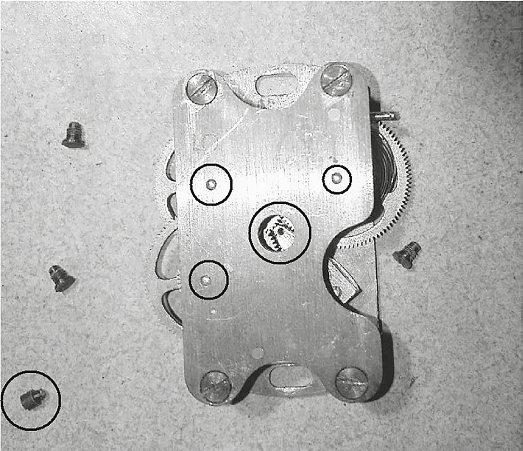

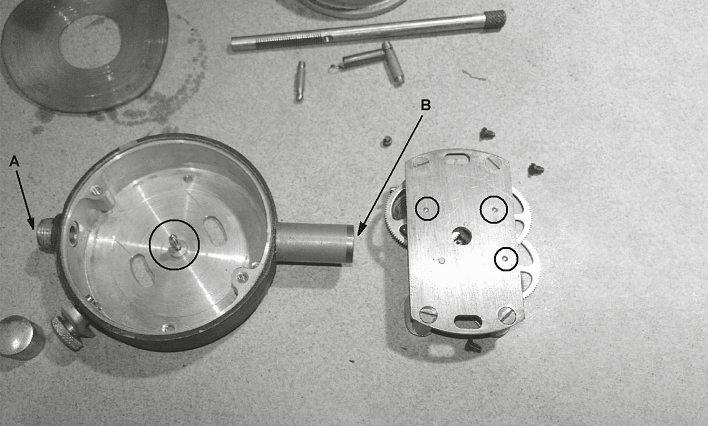

Photograph12 showstheworks andthepivotpointstobeoiled–notethatinthiscasethefinalarbor wasintegralwiththemaincaseand needsadropofoil.Alsoshown, pointsAandB,willneedasmall dropofoilonthearm’sbearings. Photo13 showstheotherside anditsoilingpoints,oneofwhich supportsthefinalarbor–thatone deepintheworks Thecircledscrew poppedoutofthecasewhenopened andisnotpartoftheDTIatall–it musthavedroppedinthereduring manufacture Theotherthreescrews retaintheslipring.

leantheglassanddialbefore replacingthehandandslipring.

e-assemblyisthereverseofthe dismantling,exceptthatin photo 14 Ishowmymethodforreplacing thehandusingtwee ers. inally,the supergluewasusedononeDTIto holdtheglassinplace,eitheritwas under-si edorperhapstheacetate hadshrunkovertheyears. inceithas lastedallthistimewithoutattention,I don’tthinkthatIwillbetoobothered ifIcannotremovetheglassinabout another 0or 0years

ModelEngineers’Workshop www.model-engineer.co.uk 18

e ersesi eo themo ementsho ingoiling oints. e assem ly.

13 11 14 12

emo ethe inan s ring.

an an thecircle i ots sho l elightlyoile .

BEGINNERSWORKSHOP

ThesearticlesbyGeometer(IanBradley)werewrittenabouthalfacenturyago.Whiletheycontainmuchgoodadvice,they alsocontainreferencestothingsthatmaybeoutofdateordescribepracticesormaterialsthatwewouldnotusetodayeither becausemuchbetterwaysareavailableofforsafetyreasons.Thesearticlesareoferedfortheirhistoricinterestandbecause theymayinspiremoremodernapproachesaswellasremindingushowourhobbywaspracticedinthepast.

November2023 19 Beginners’ Workshop

Scribealine

YOURCHANCETOTALKTOUS!

Readers!Wewanttohearfromyou!Dropusalinesharingyouradvice,questions oropinions.Whynotsendusapictureofyourlatestworkshopcreation,orthat strangetoolyoufoundinabootsale?Emailyourcontributionsto meweditor@mortons.co.uk.

LatheSpeedSensors

DearNeil,KeithFiskmakesthevalidpointregardingthe useof all fectsensorsforlathespeedmonitoring inthattheyareofruggeddesignandimmuneto contaminationfromdirtor uids.Thosethatweare likelytouseonlatheswillhavebeendesignedforusein theenginebayofmotorvehiclessocaneasilycopewith theheat,vibrationandoilswehaveinourworkshops.

However,Idonotthinkthatweshouldbeunduly worriedaboutthematerialfromwhichthegearsare madeasitwouldbeimpossibleforustousethem attheirmaximumfrequency,typically100kHz,and unlikelythattheywouldbeusedwithagearthat compromisestheirmagneticperformance.Most articlesdescribethetargetgearforthesensorashaving rectangularteeth0.1”widewith0.1”spacebetweenand manufacturedfromhighpermeabilitymaterial.Thisis equivalenttoagearwithaCPof5andaDPof15.7.For atargetgeardesignedpurelyforusewiththesensor theseparameterscanbemetbutthegearswearelikely tobeusinghavetocombinebeingthesensortarget withtheirnormalfunctionofbeingasimpleinvolute formgearwheel.Threefactorsallowustoworkoutside theidealparameters, rst,thepulseratesareverylow inelectronicterms,second,itisnottooimportantifthe oddpulseismissedandthirdwearenotinterestedin accuratemeasurementoftherotationangle,merelythe rotationalspeed.Myownspeedmonitorusesa16DP gearastarget,whichworksperfectlygivingastableand accuratereading.

SincewritingtheaboveIhavemovedmysensor fromitsworkingpositiontoatemporarymounting usinga20DPchangewheelastarget.Itgivesa reading,obviouslynotanaccuratespeedreading,but theinterestingpointisthatthereadingisnotstable suggestingthatpulsesarebeinglost.Soitseems thatthese all fectdevicesneedatargetgearwith amaximumDPofaround16asindicatedintheir speci cations.

ChrisGardiner,Chelmsford

Sourcing all ect Sensors

DearNeil,Iwasveryinterestedinthetiprelatingto revcountersensorintheaboveissue.Havingmade, averylooseterm,oneusingaplywooddisc,magnet andreedswitch,Ithoughtthatthetipgaveavery neatsolution.TheproblemisthatIhavenotfounda reasonablypricedsensor.InotethereaderlivesinNew ealandbutevenallowingforimportsIcouldnot nd one.Perhapsyouhaveanideaofasourceofsupply, eitherdirectlyorviayourcontacts.

LaurieLeonard,byemail

HiLaurie,formyownspeedsensors,madesome twentyyearsago,Iused‘ ogic evel all fect Sensors’.Aninternetsearchofthisphraseshouldturn upsomethingthatwillworkasasubstituteforthereed switchwithminimaladditionalcomponents–Neil.

WoodscrewSizes

DearNeil,Ihaveawoodworkingpocketbookwhich containsasectiononwoodscrews.To ndthegaugeof themostcommonsizesthefollowingisuseful.Measure acrossthediameteroftheheadin16ths.ofaninch. Doublethenumberofsixteenthsandthensubtract two.Thiswillgivethegaugenumber.Apparently,the rangeofgaugeswasfrom0000to50.Iwonderif anyonehasusedthoseattheextremes?Ofcoursewe havenowmovedtometricsizes.

IanVarty,byemail

ModelEngineers’Workshop www.model-engineer.co.uk 20