Aug23 No.330 INSIDETHISPACKEDISSUE: CUTTINGGASKETS. Makesureyougetthemost accuratescrewedholes. GetmoreoutofyourworkshopwithMEW Jointheconversationat: www.model-engineer.co.uk ATELESCOPICCROSSFEEDSCREWFORMYFORDSUPER7LATHES. ASHOP-MADEPOWER HACKSAW. BRINGINGASWISSTOOLGRINDERBACKINTOUSE. MMEX2023–125BIRTHDAY TALKSPROGRAMME. LIFEWITHANADCOCKANDSHIPLEYMILLINGMACHINE. FITTINGAND JOININGPIPES. CALIPERSTORAGESOLUTION. PLUSALLYOURREGULARFAVOURITES! 3DPRINTER REVIEW: TheCrealityHalot MagePro. RonSharponmaking small,accurategasketsfor workingmodelengines. THEMAGAZINEFORHOBBYENGINEERS,MAKERSANDMODELLERSAUGUST2023ISSUE330WWW.MODEL-ENGINEER.CO.UK FROMTHEBEVELBOX ExperimentswithBevelGearsandDifferentialGearboxes. AccurateTapping

EDITORIAL

Editor: NeilWyatt

Designer: DruckMediaPvt.Ltd.

Publisher: SteveO’Hara

Bypost: ModelEngineers’Workshop, MortonsMediaGroup,MediaCentre, MortonWay,Horncastle,LincsLN96JR

Tel: 01507529589 Fax: 01507371006

Email: meweditor@mortons.co.uk ©2022MortonsMediaISSN0033-8923

CUSTOMERSERVICES

GeneralQueries&BackIssues

01507529529

Monday-Friday:8.30-5pm

Answerphone24hr

ADVERTISING

Groupadvertisingmanager: SueKeily

Advertising: AngelaPrice aprice@mortons.co.ukTel:01507529411

ByPost: ModelEngineers’Workshopadvertising, MortonsMediaGroup,MediaCentre, MortonWay,Horncastle,LincsLN96JR

PUBLISHING

SalesandDistributionManager: CarlSmith

MarketingManager: CharlottePark

CommercialDirector: NigelHole

PublishingDirector: DanSavage

Publishedby: MortonsMediaGroup, MediaCentre,MortonWay,Horncastle, LincsLN96JR

SUBSCRIPTION

Fullsubscriptionrates(butseepage54foroffer): (12months12issues,incpostandpacking)–UK £56.40.Exportratesarealsoavailable–seepage 46formoredetails.UKsubscriptionsarezeroratedforthepurposeofValueAddedTax. Enquiries:subscriptions@mortons.co.uk

PRINTANDDISTRIBUTIONS

Printedby:WilliamGibbons&SonWolverhampton

Distributionby:SeymourDistributionLimited, 2EastPoultryAvenue,London,EC1A9PT TelNo:02074294000

EDITORIALCONT2RIBUTION

Acceptedphotographsandarticleswillbepaidforuponpublication.Itemswecannot usewillbereturnedifaccompaniedbyastampedaddressedenvelope,andrecorded deliverymustclearlystatesoandenclosesuf cientpostage.Incommonwithpractice onotherperiodicals,allmaterialissentorreturnedat thecontributorsownriskandneither ModelEngineers’WorkshopMagazine theeditor,thestaffnorMortonsMediaLtdcanbeheldresponsibleforloss ordamage,howsoevercaused.TheopinionsexpressedinMEWarenot necessarilythoseoftheeditororstaff.Thisperiodicalmustnot,withoutthewritten consentofthepublishers rstbeinggiven,belent,sold,hiredoutorotherwise disposedofinamutilatedconditionor,inanyunauthorisedcoverbywayoftradeor annexedtooraspartofanypublicationoradvertising, literaryorpictorialmatterwhatsoever.

ThisissuewaspublishedonJune17,2022. ThenextwillbeonsaleonJuly22,2022.

Onthe Editor'sBench

TalksatMMEX2020

LaterinthisissueinnewsabouttheMidlandsModellingExhibitionisexciting newsaboutthereturnoflectures.Thisyearthetalkswillbegivenbywell-known contributorstoModelEngineers’WorkshopandModelEngineermagazines,andI’d liketoexpressmygratitudetoeveryonewhohaso eredtotakepart.

I’mhopingtoattendallthetalksandlookforwardtosomeinterestingdiscussions a ereachone.Ihopethatplentyofreaderswillbeabletocomealongforatleast oneofaninterestingandvariedprogrammeoflectures.

Iwillbegivingoneofthetalksmyself.It’sgrownoutofatalkIgavetotheSMEE in2018onmyexperienceswith‘fused lament’3Dprinting.Iwillbeupdatingitto re ectsomeofthelessonsIhavelearnedsince,andmymorerecentexperiences

ofSLAorresinprinting.Iwillalsoberunningdemonstrationsof3Dprintingonthe SMEEstand,whichwillbeanewchallengeforme!

Ifyouhaveanyquestionsabout3Dprinting,orissuesyou’dlikeexploredor evenhaveanitemyouareinterestedinhaving3Dprinted,dropmeanemailat meweditor@mortons.co.ukandIwillseeifit’ssomethingIcancoverattheshow. Thephotoshowsoneofmymorerecentmodels,printedontheHalotOnePro–the guresareTamiyaones..

3 August2023

NeilWyatt

9 OneManandHisMill–Adcock&Shipley2E. AndrewJohnstononlifewithauniversal horizontalmill,capableofmillinghelical gears,amongstotherthings.

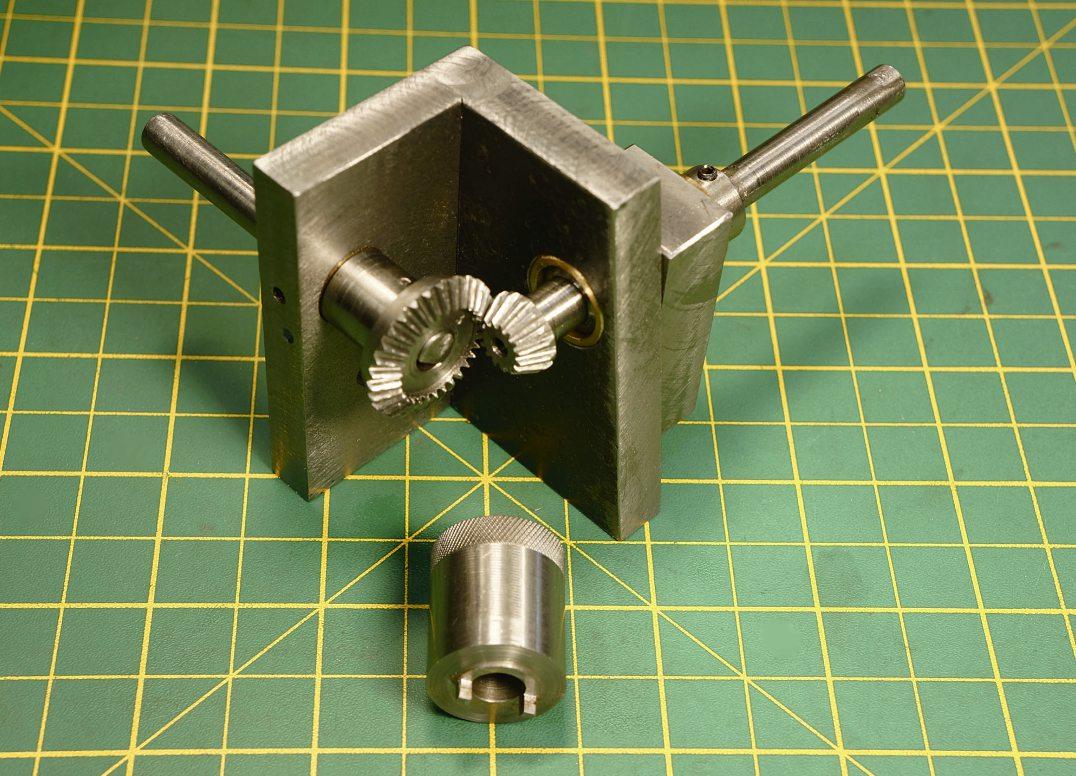

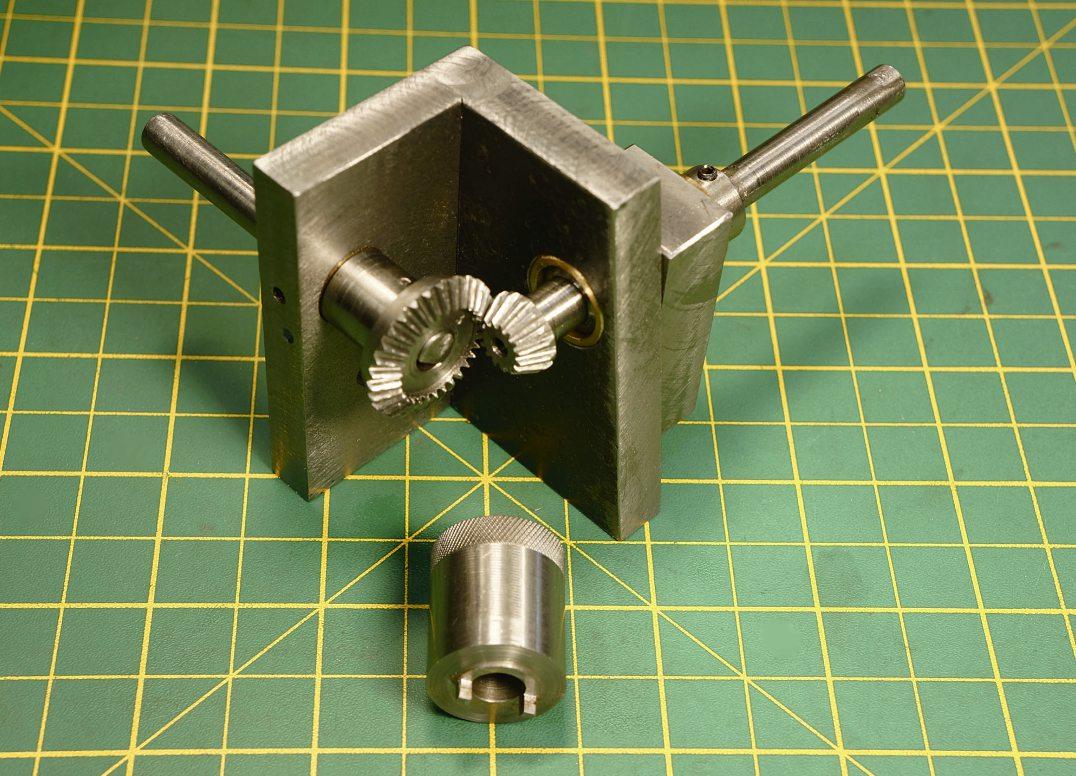

15 15Bob’sBetterBevels–Postscript.

A eralltheexperimentsinBobReeve’s serieshewasle withaboxof‘better bevels’,thisiswhathedidnext.

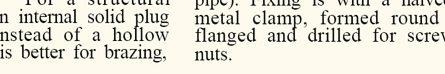

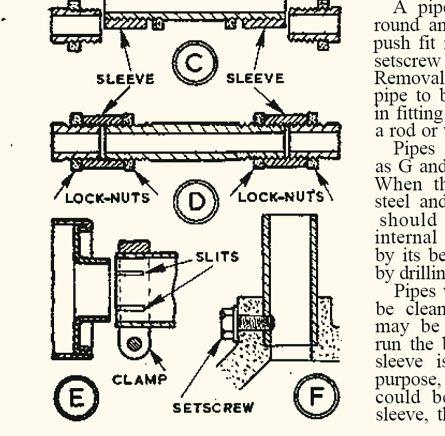

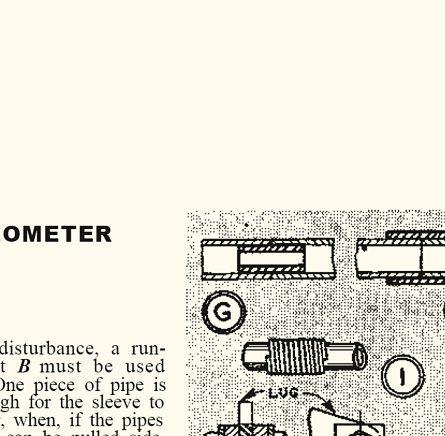

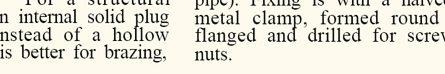

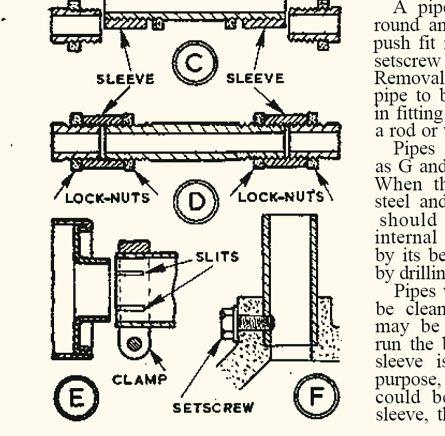

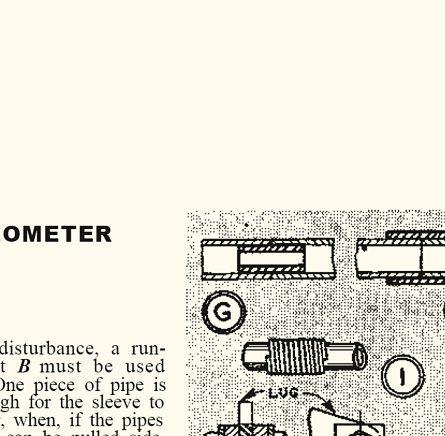

20 Beginner’sWorkshop. ThismonthGeometerlooksat methodsfor ttingandjoiningpipes, includingatipforsplitwaterpipesthat couldcomeinhandyoneday.

21 ASmallMachineSaw. OverfortyyearsagoAlanJacksontried tomakearotarymetalsaw;itwasn’t asuccessbutitevolvedintoapower hacksawthathasgiveoverthree decadesofgoodservice.

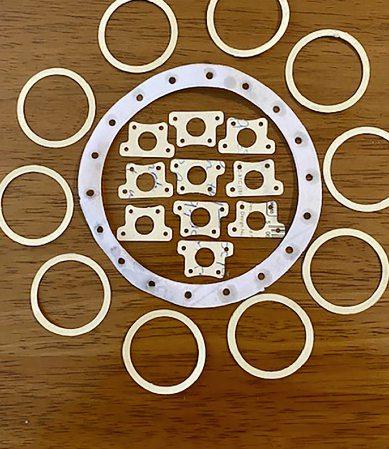

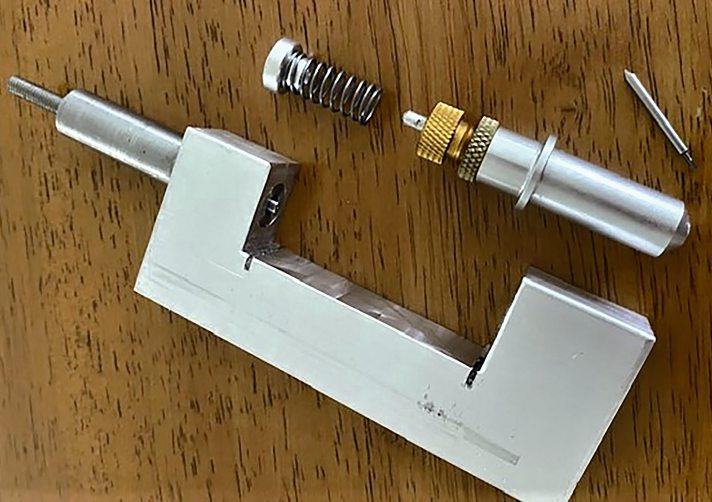

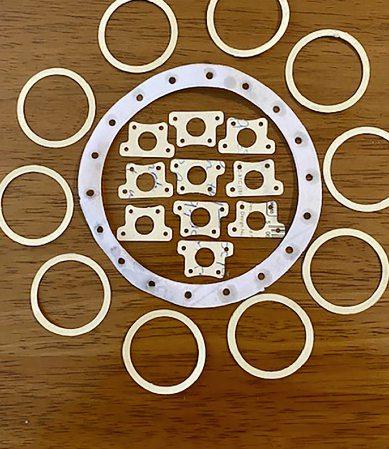

28 CuttingSmallGasketswith aCNCMill.

Ronsharpdescribeshisapproachto cuttingperfectgasketseverytimewith acomputercontrolledcutter.

34 GettinganOldToolGrinder UpToSpeed.

JohannesSchi boughtaSwissmade toolgrinder,butfoundsomeworkwas instorebeforehecoulduseit.

41 TheCrealityHalot-MagePro. Wereviewthenewtopoftherange3D resinprinterfromCreality.Itpromises

speed,capacityandahostofuseful features.

45 ATelescopicCross-Slide FeedscrewfortheMyford Super7.

GrahamMeekmodi esanideaby GeorgeH.Thomastoeasetheuse ofthepopularMyfordTaperTurning Attachment.

50 ArtfulDodges. JohnSmithexplainshowtoachieve accuratetappedholeseverytime.

56 FromtheArchives. Celebrating125yearsofModel Engineerwithawartimearticlefrom 1941onanautomaticlathestop.

58 TheMidlandsModel EngineeringExhibition Moreexcitingnewsaboutplansfor MMEXinOctober2023.

59 UniversalBeltGrinder. PaulLousickcompleteshisdesignfora compactbeltlinisherwhichcanbeused witheitheranabrasivebeltorgrinding wheels.

59

Contents ModelEngineers’Workshop www.model-engineer.co.uk 6 28 £5.75 Aug23 No.330 INSIDETHISPACKEDISSUE: CUTTINGGASKETS. Makesureyouget themost accuratescrewedholes. GetmoreoutofyourworkshopwithMEW Jointheconversationat www.model-engineer.co.uk ATELESCOPICCROSSFEEDSCREWFORMYFORD SUPER7LATHES. ASHOP-MADEPOWER HACKSAW BRINGINGA SWISSTOOLGRINDERBACK INTOUSE. MMEX2023–125BIRTHDAY TALKSPROGRAMME. LIFE WITH ANADCOCKANDSHIPLEYMILLINGMACHINE FITTINGAND JOININGPIPES. CALIPERSTORAGESOLUTION. PLUSALLYOURREGULARFAVOURITES! 3DPRINTER REVIEW: TheCrealityHalot MagePro. RonSharponmaking small, accurategasketsfor workingmodelengines. THEMAGAZINEFORHOBBYENGINEERS,MAKERSANDMODELLERSAUGUST2023ISSUE330WWW.MODEL-ENGINEER.CO.UK FROMTHEBEVELBOX Experiments withBevelGearsand DifferentialGearboxes. AccurateTapping AccurateTapping SUBSCRIBETODAY! GETYOURFAVOURITE MAGAZINEFORLESS DELIVEREDTOYOURDOOR! Seepage54-55fordetails.

ModelEngineeringExhibition.

50 ScribeALine. Newsfromtheworldofengineering.

54 OntheWire. Ourmonthlyroundupofnewsfromtheworldofengineering.

64 Readers’Tips

Ourwinnerthismonthhasatipforkeepingyourcalipersneatly stored.Sendyourtipstomeweditor@mortons.co.uk.

66 Readers’Classifieds

Anothergreatselectionofreaders’saleandwantedads.

WhynotfollowusonTwitter?twitter.com/

Checkoutthefreeplansavailablefordownloadat. www.model-engineer.co.uk/freeplan

Otherhottopicsontheforuminclude: WorkshopClock Itdoesn'tseemtoliketheworkshop;alighthearted complaintfromIainDowns

Rotarybroaching HowcanIsucceedatrotarybroachingbyDaniel Brannan

Oldtoolsrestoration Di erentapproachestorescuingoldtoolsby SonicEscape

WaveWasherinMyfordResettableDialArticle,MEW328 DiscussionrelatingtoPeteBarker’sarticle–seeScribeaLine–by Hopper

ComeandhaveaChat!

Aswellasplentyofengineeringandhobbyrelateddiscussion,we arehappyforforummemberstouseittoshareadviceandsupport. Comeandjoinus–it’sfreetoallreaders!

Comingup… inournextissue August2023 7 KeithKeenadoptsa boringheadforuseon thelathetailstock. Regulars £5.75 Aug23 No.330 INSIDETHISPACKEDISSUE: CUTTINGGASKETS. Makesureyougetthemost accuratescrewedholes. GetmoreoutofyourworkshopwithMEW Jointheconversationat: www.model-engineer.co.uk ATELESCOPICCROSSFEEDSCREWFORMYFORDSUPER7LATHES. ASHOP-MADEPOWER HACKSAW. BRINGINGASWISSTOOLGRINDERBACKINTOUSE. MMEX2023–125BIRTHDAY TALKSPROGRAMME. LIFEWITHANADCOCKANDSHIPLEYMILLINGMACHINE. FITTINGAND JOININGPIPES. 3DPRINTER REVIEW: TheCrealityHalot MagePro. RonSharponmaking small,accurategasketsfor workingmodelengines. FROMTHEBEVELBOX ExperimentswithBevelGearsandDifferentialGearboxes. AccurateTapping ONTHECOVER OurcovershowsJohnSmith demonstratinghowtoguideatapto createanaccuratescrewedhole.For moredetails,seepages50-51. 3 OntheEditor’sBench. Theeditorhasnewsaboutwhathe’llbedoingattheMidlands

Visitour Website

ModelEngineershashtag#MEW THISMONTH’SBONUSCONTENT LogOntoTheWebsiteforExtraContent:

HOMEFEATURESWORKSHOPEVENTSFORUMSALBUMS CLASSIFIEDSEXTRASUBSCRIBEARCHIVESUPPLIERS

www.model-engineer.co.uk

OneManandHisMill –Adcock&Shipley2E

AndrewJohnstonboughtthishe ymillonimpulse,buthasfounditavery usefulmachineinhisworkshop.

Ihadasmallworkshop,withapillar drillandlathe,whileIwasatschool. ThemachinesweresoldwhenIle schoolandstartedworkingawayfrom home.Fastforwardsomeyears;now thatIhaveapropertywithadouble garage,Ihavebeenabletobuildup aworkshopagain.My rstmachine toolswereaHarrisonM300latheand aBridgeportverticalmill.Bothofthese machineswerechosenasbeingsuitable fora4”scaletractionenginebuild.I amaprofessionalengineer,mainlyin electronicsandsignalprocessing,butmy onlyformalcra quali cationisO-level metalwork.

AcquiringtheMill

A ersettingupabasicworkshopI keptaneyeonadverts,bothonline andinmagazines,lookingforfurther purchasesofmachinesandtooling.In duecourseIsawatradeadvertforan Adcock&Shipley2Euniversalhorizontal mill, photo1,atanadvantageous price.Ihadbrie yusedaCincinnati horizontalmillingmachinebackinthe 1970s,whiletrainingattheRoyalAircra EstablishmentatFarnborough.Iam normallyquitecautiouswhenitcomes topurchases.Butinthiscasetheprice wassolowthatIthrewcautiontothe wind.Iphonedthetraderandchecked thatthemillwascompletewithoverarm andarborsupport.Iwasassured thatthiswasthecaseandIagreed topurchasethemill.Itwasalsotobe suppliedwith1”and1-1/4”arbors.The millweighswelloveroneandahalftons, whichIcan’tmovebymyself,soIasked thetradertoorganisedelivery.Cost ofthemillwas£175,anddeliverywas £200.Themillwasdulydeliveredusinga Hiablorry.Atmyinsistencethemillwas placedinsidethegarage,ontheconcrete oor,ratherthanonthegraveldrive

› 9 OneMan andHisMill August2023

1

A&E2EHorizontalMillingMachine

outside.A erdeliveryIdiscoveredthat thesuppliedarborswere1”and32mm.I queriedthiswiththetraderandwastold innouncertaintermsthat32mmwas

thesameas1-1/4”.Ireceivedaphone callfromthecompanyownershortly a erwards,whoapologisedandsaid thathehadtoldhiscolleague,equally

forcefully,that32mmwasnotthesame as1-1/4”whenitcametoarbors.We agreedthata1-1/4”arborwouldbe suppliedforthecostofthepostage.

TheMillandControls

TheAdcockandShipley2Eisauniversal horizontalmill.Thismeansthatthetable canbeswivelledallowinghelicesand spiralstobemachinedinconjunction withauniversaldividinghead.The2Eis afairlysmallhorizontalmillwithtravels of23”inX,8”inYandamaximumof 16”betweenspindlecentreandtable top.Myexamplehasmetricdials.The millhasanettweightof3,472lbs.Ithas beenmovedupanddownmyworkshop twice,usingrollersandacrowbar,before settlingintheplaceshown.Severalfeet wereknockedo theendofwall,visible onthele inphoto1,toaccommodate themill.

Electricallythemillhasthreemotors: adualspeedspindlemotor,a1hpmotor forthetableX-axispowerfeedanda fractionalhorsepowercoolantpump. Themainspindlemotoristwopolein highspeedrangeandfourpoleinlow speedrange.Aswellasswitchingpoles themotorcon gurationchangesfrom startodeltawhenmovingfromhighto lowrange.Inthehighrangethemotoris 5hp,butinlowrange,duetothechange todelta,is4hpratherthan2.5hp.Ihave a3-phasesupplyathome,soconnection wassimpleviaanisolatoranda5-pin 3-phaseplugalthoughtheneutralisnot connected.

Themainelectricalpanelisshownin photo2.Theleverswitchtoprightisthe mainisolator.Belowthataretwosets ofon/o pushbuttons,forthespindle motoronthele andthecoolantpump ontheright.Belowthepushbutton switchesaretworotaryswitches.The oneonthele controlsspindledirection andtheoneontherightisforhighand lowspeedrangesoftheX-axisfeedrate motor.

ThemainspindletaperisINT40.These areself-releasingtapers.Thedriveisvia twodogsratherthanrelyingonfriction withinthetaper.Thespindleisdrivenby xedmultiplebeltstoagearbox.Spindle speedischangedwithinthegearboxby aringandleverontherighthandside ofthecolumn, photo3.Theleverat thetopcanberotatedtobringsetsof threespeeds,markedontheouterring,

ModelEngineers’Workshop www.model-engineer.co.uk 10

MainElectricalPanel

2 3

SpeedChangeArrangement

tolineupwiththelabelonthele .The foursetsofthreespeedsaredelineated bythethickerradiallinesontheouter ring.Oneofthethreespeedsineach setisselectedbytheleverontheinner ringwhichcanbehorizontal(asshown), up,ordown.Belowtheringsisalever operatedelectricalswitchwhichchanges betweenthehighandlowspeedrange ofthespindlemotor.Inphoto3,with theelectricalswitchinhighrange,the spindlespeedissetto234rpm.Thereare 12speedsinhighrangefrom60rpmto 1200rpm,andanother12inlowrange from30rpmto600rpm.

Inusethespindlemotorruns continuously,andthespindleisengaged withaclutchlever.Theclutchlevers(one oneachsideofthecolumn)canbeseen inphoto1,towardsthetopofthecolumn andleaningforward,partiallyhiddenby thelowvoltagelight.

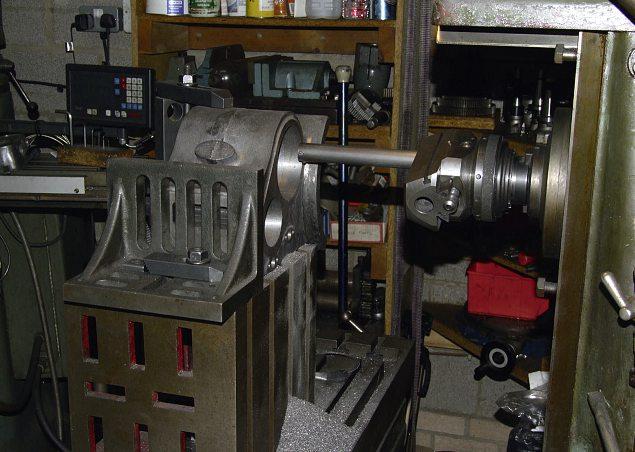

ThetableX-axisfeedisengagedby theverticalleverinthecentreofthe tableatthefront.Thetablemovesin thedirectionthattheleverismoved. Theleveractuatesanelectricalswitch whichenablesthefeedmotor.Arange ofninefeedrates,inbothhighandlow speedranges,areselectedusingtwo, threeposition,mechanicallevers, photo 4.Thetablefeedisallgeared,withthe naldrivetotheleadscrewbeingapair ofskewgears.

TheYandZaxeshaveadjustable mechanicalstopstolimitmovement. Ratherthanmechanicalstopsthe adjustablestopsontheX-axistripthe feedleverandthusdisengagethetable feed.

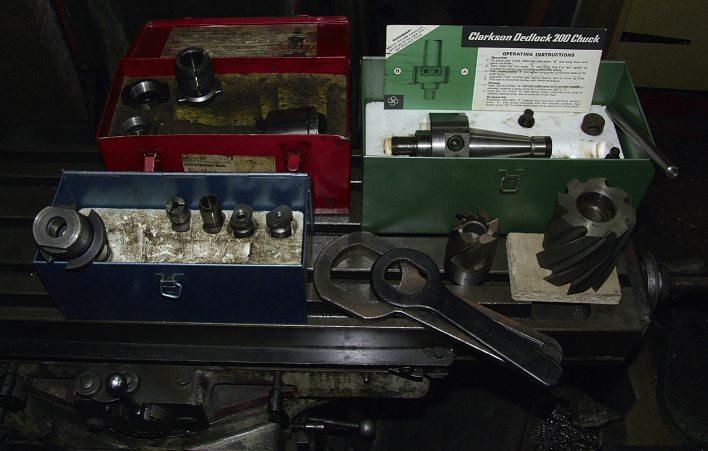

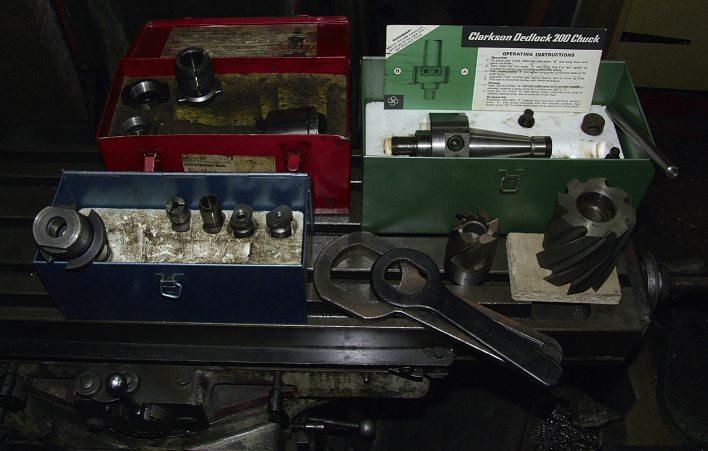

Accessories

Aspartofthegeneralworkshop equipmentIhavearangeofaccessories suchasmachinevices,angleplates,a rotarytableandadividinghead.Forthe A&Smillspeci cally,IhaveboughtInt40 adaptors,Clarksonstylecolletchucks, insmallerandlargersizes,withboth imperialandmetriccollets.Ialsobought aDedlock200chuck.Althoughthe Dedlocksystemisobsoletecommercially Ihavemanagedtoobtainenough cutterstomakeitworthwhilehaving thechuck, photo5.TheonlyAdcock andShipleyaccessoryIhaveforthe2E, isaverticalmillingattachment,bought onanauctionsite, photo6.Allofthe accessoriesaresecond-hand.

› 11 OneMan andHisMill August2023

VerticalMillingAttachment

MillingChucksandDedlockCutters

4 5 6

FeedRatePlateandLevers

Ihave63mmand80mminsertface millsonInt40taperswhichareuseful forcleaninguplargeareas.Thespindle speedscoverarangefastenoughforthe facemills;however,feedratesarethe limitingfactorandmeanthatthespindle speedsalsoneedtobelimited.Themill wouldhavebeendesignedforusewith HSScutters,sothefeedratelimitisnot asurprise.IhavealsobeenbuyingHSS cuttersforthehorizontalmilloverthe years,almostallsecond-handornewold stock, photo7. Themillcamewithadrawbarthreaded 5/8”BSW.Imadeanotherdrawbar, threadedM16,forthenewfacemillsand accessories.

UsingtheMill

Althoughboughtwithnoclearidea inmindoftheworktobedonethe horizontalmillhasprovedtobevery useful.Theworkingareaissmallerthan myBridgeportbutthehorizontalmillis considerablymorerigidandpowerful. Consequently,itcanshi metalwhen thereisaneed, photo8.Imostlyrun HSScuttersand oodcoolant.

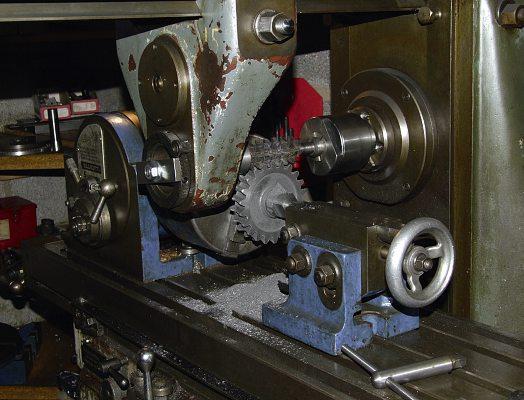

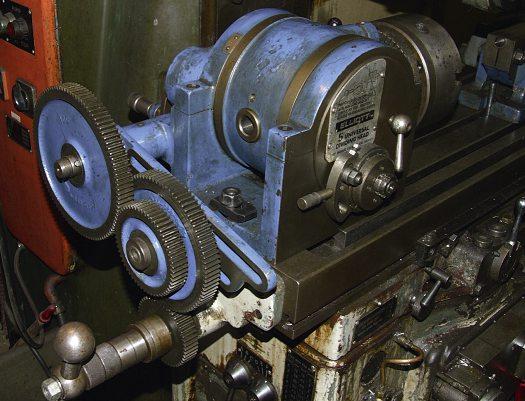

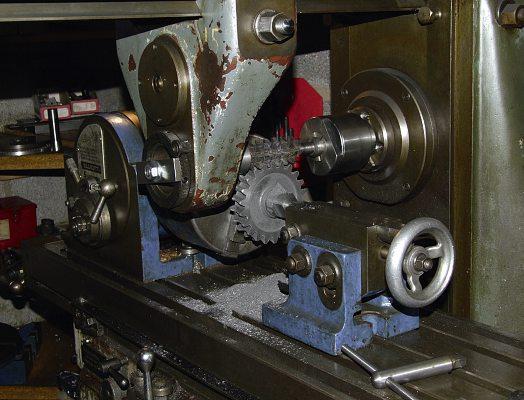

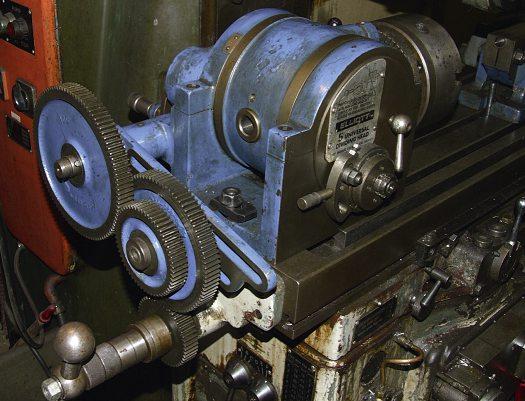

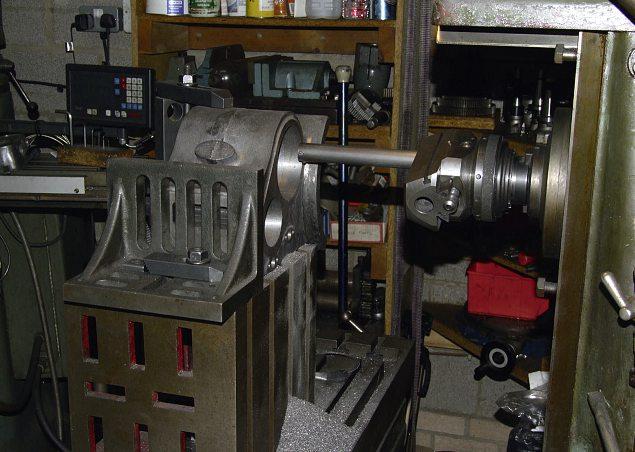

Aswellasnormalmillingoperations themillisusefulforgearcutting,both vertical, photo9,andhorizontalwhen thegearistoobigto tunderthe spindle, photo10.

Themillalsoprovedusefulforfree hobbingawormwheela ergashingon themillwithaninvolutecutterandthe tablesetoveratthehelixangle, photo 11.Thehobwashomemadefromsilver steelandwasdesignedwithascrewcut endto taClarksonstylechuck.

Onauniversalmillthetableswivels,

ModelEngineers’Workshop www.model-engineer.co.uk 12

HSSMillingCutters

SlabMillingHotRolledSteel

Vertical6DPGearCutting 7 8 9 10

Horizontal5DPGearCutting

CuttingaHelicalGear

allowingthemachiningofhelicesand spirals.Oneuseforthisistheproduction ofhelicalgears.Tomachineahelicalgear auniversaldividingheadisgearedto thetablefeedsothatasthegearblank

rotatesitalsomovesaxially.Thetableis swivelledtothehelixangleofthegearto becut.Thecombinedrotationandaxial movementmeanthattheworkmovesin ahelicalpathpastthecutter.Forcutting

ahelicalgearthegearingbetweenthe tableanddividingheadisshownin photo12.Thecuttingofahelicalgearis shownin photo13

Themillcanalsobeusedasa

› 13 OneMan andHisMill August2023

FreeHobbingaWormWheel

TabletoDividingHeadGearing

12 11 13

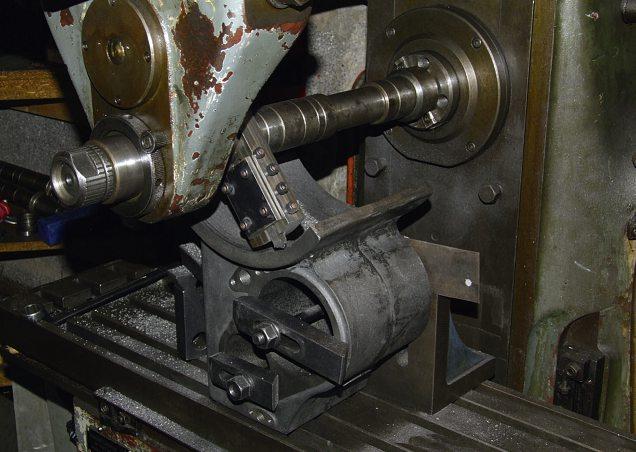

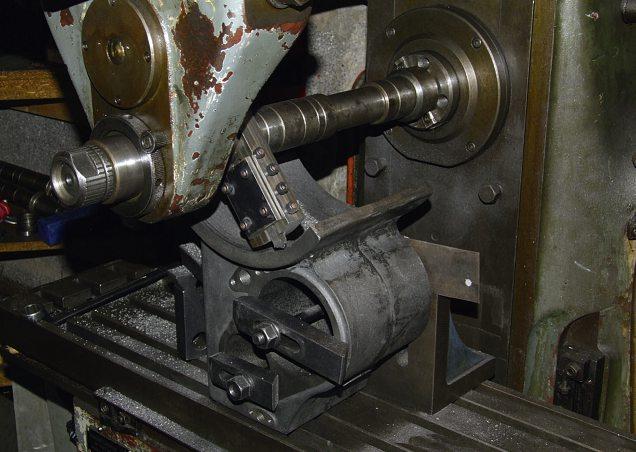

simplehorizontalborerwithaboring head, photo14.Thissetuphasbeen extensivelyusedforthecylindersand linersonmytractionengines.

Therigidityofthemillisalsohelpful when ycuttinglargediameters.In photo15 an8.6”diameterisbeing ycutona4”scaletractionengine cylinder,usinganHSStoolbitand ahomemade ycutter.Notethe

curvedendtothe ycutterbody.The ycutterbodyis8”diameterwhich helpstosimplifythetoolsetting.For diameterslargerthan8”thetable canbesetatthecorrectradiususing gaugeblocks,minus4”,againsta suitablereferencesurface.Thetool bitisthenadjustedtojusttouchthe referencesurface,withoutmovingthe table.Inphoto15thedepthofcutwas

Conclusion

AlthoughtheA&S2Emillwasanimpulse buyithasturnedouttobesurprisingly useful,inparticulartosupportthebuild ofmy4”scaletractionengines.Ifroomis available,Iwouldthoroughlyrecommend acquiringahorizontalmilltocomplement themorecommonlyfoundverticalmills. ❚

ModelEngineers’Workshop www.model-engineer.co.uk 14 DON'TMISSTHISGREATISSUE-SEEPAGE54-55FOROURLATESTSUBSCRIPTIONOFFER

KenLonie

rotarytablefroman automotive

R.Finch explainshowtogoabout millingcompoundangles.

makesalarge

ywheel.

NextIssue Inour Comingupinissue331, September2023 Onsale16August2023 Topre-orderyournextcopyofMEWvisit www.classicmagazines.co.ukorcall01507529529 Contentssubjecttochange

KeithKeen adoptsaboringheadfor useonthelathetailstock.

HorizontalBoring

1mmandthefeedwas0.2mmperrev.

FlyCuttingan8.6”DiameterSurface

15 14

Bob’sBetterBevels –Postscript,part1

BobReevedivesintothebigboxofbetterbevelsthatresultedfrom hisexperiments

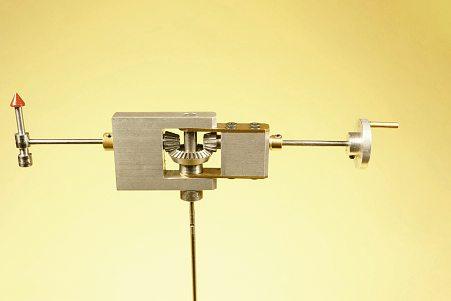

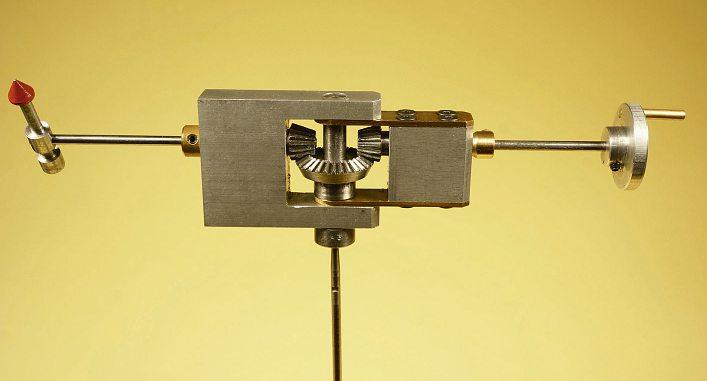

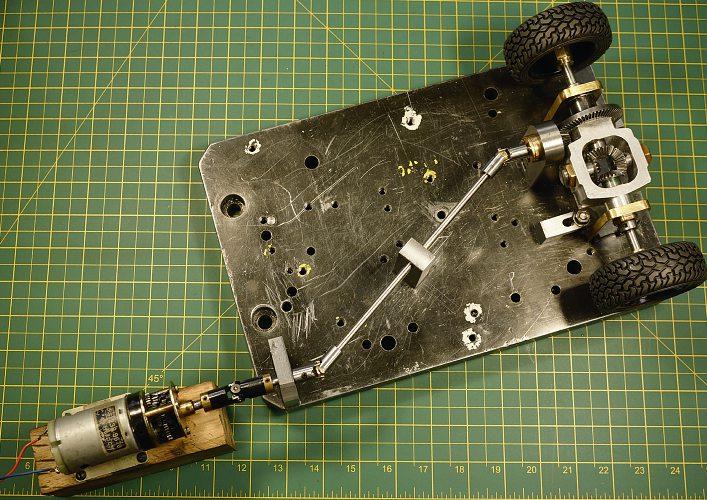

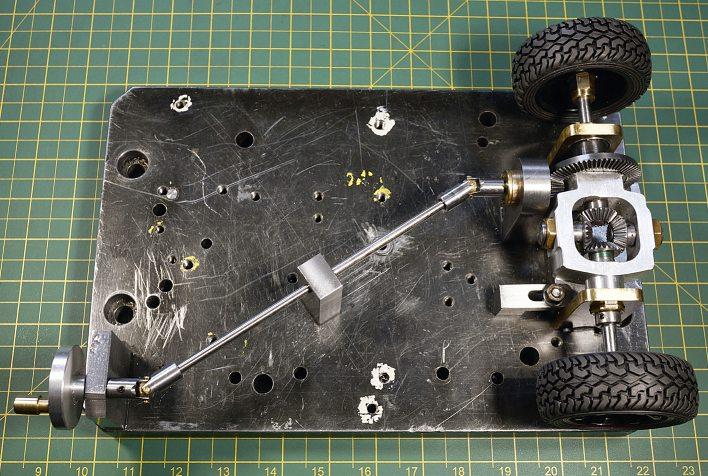

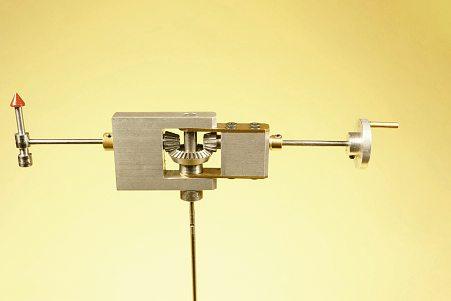

Part veofBob’sBetterBevels (MEW322),wasabouthigh ratiobevels.It nishedwiththe questionastowhattodowithallthe bevelsIhadproduced.Whatfollows providesacoupleofanswers.

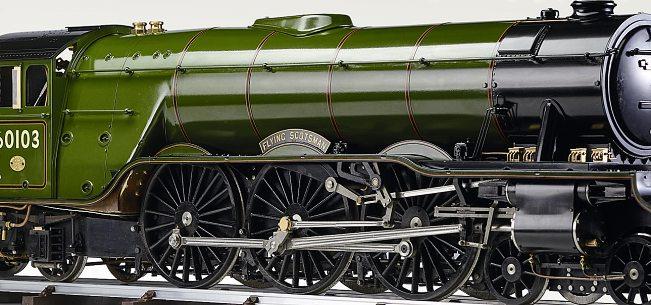

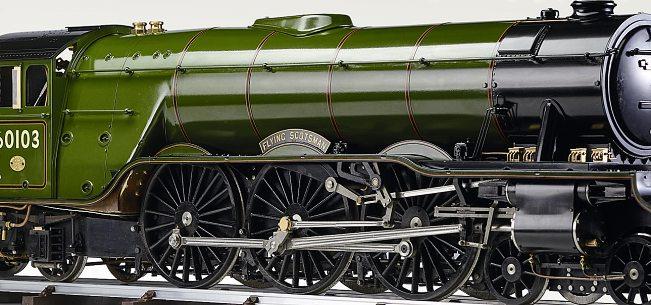

The rstexamplewasasuggestion foranalternativesolutionforavariable angledrive.Thiswasrequiredtoactuate thebrakeonthetenderofalocomotive beingbuiltbyfellowSMEEmember BrianNeale. Photograph1 showsthe originalsolutionwhichwase ectively apairofinsertedtoothbevelswhich mightalsohavebeendescribedasa pin-wheeldrive.

Spacewasverytight,andtheentire mechanismhadto tina1”cube.An alternativeusingmystandardbevel

gearsisshownin photo2.Thebevel wheelsalreadyexisted,sothedesign hasnotbeenoptimisedforthespace

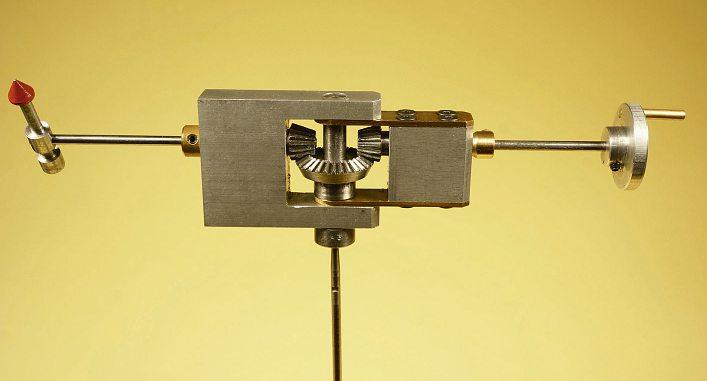

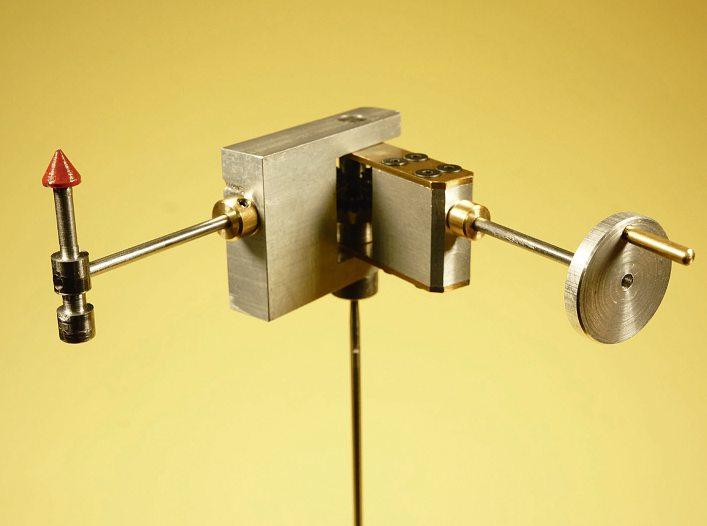

Alternativedriveusingbevels. available.The15&30toothMod.0.5 bevelscouldeasilyhavebeenmadewith fewerteethorsmallerteethifnecessary andtherectangularapertureinwhich thegearssitisonlyjustabovethe requiredsize.Theverticalrodisjusta supportfordisplaypurposes. Therewas,however,thequestion ofreversingthedirectionofrotation. At rstglancethepinwheeldrive reversesthedirectionasdoesthebevel geardrive;ordoesit? photo3 shows thebevelgeardriverotatedasmall anglefromphoto2.Whichcertainly looksliketheinputandoutputrotate inoppositedirections.

› 15 BetterBevels –Postscript August2023

1 3

2

Pinwheelbrakedrive, CourtesyBNeale.

A erapartialrotation oftheinput.

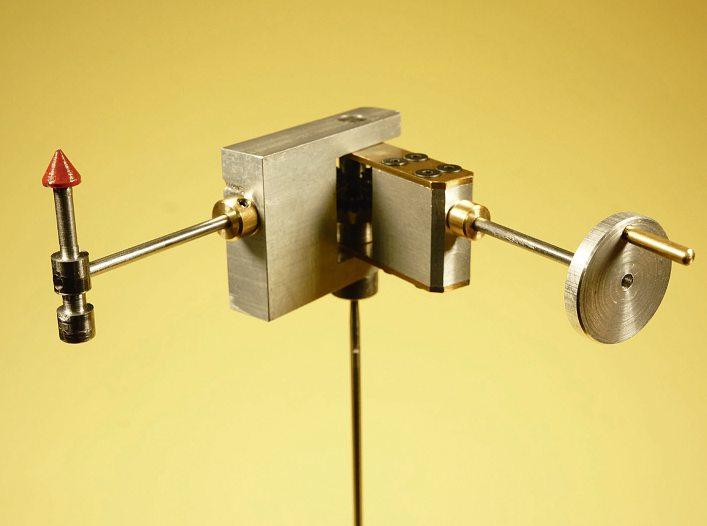

However photo4 showsthevariable angledrivefoldedup.Thehandleand pointerhavebeenalignedatthetop. Rotatingthehandlethroughasmall angleagainnowhasadi erentoutcome.

Thistime, photo5,theyappearto rotateinthesamedirection!Inwordsof theirownchoosing,readersmaywishto describehowtherotationscanbeboth thesameandopposite!

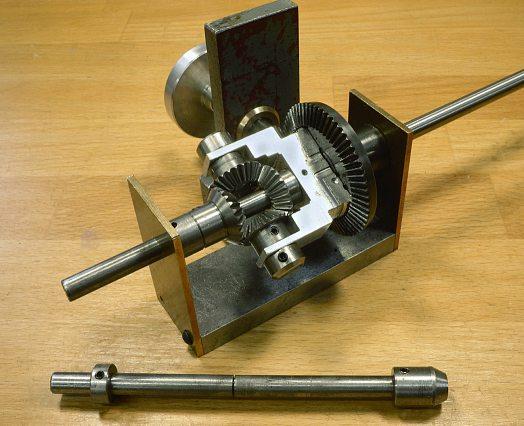

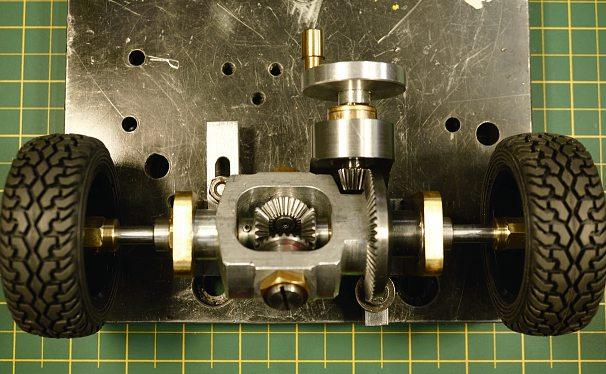

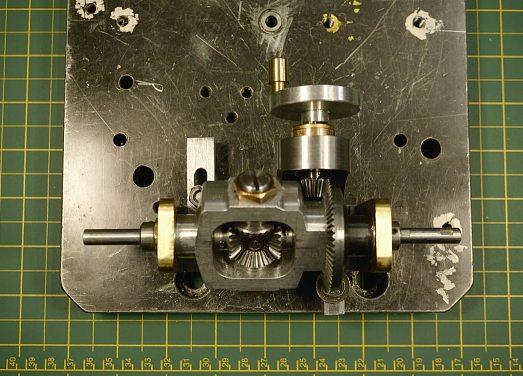

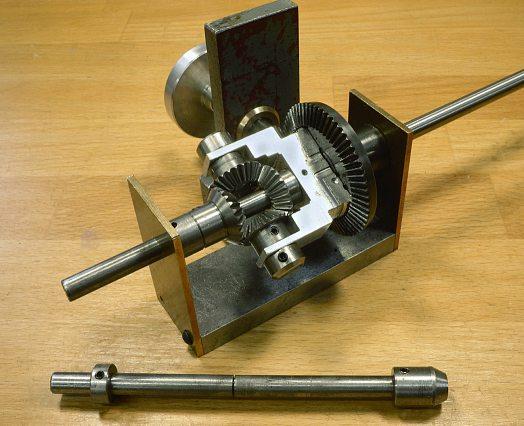

ForthenextexampleIwanted somethingthatwouldusemorethan3 bevels,preferablywithatleastoneof thehighratiobevels.Idecidedthata di erentialgeardrivemightprovidejust suchanexample.

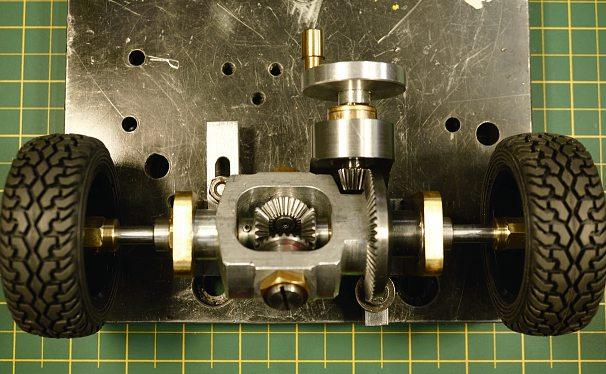

Photograph6 showsasimple di erentialasmightbefoundin aconventionalcarpoweredbyan internalcombustionengine.Thedriveis

providedbythesmallhandle,andfora car,thewheelswouldbeattachedtothe twosha sprotrudingatrightanglesto thedrive.

Thesha atthebottomisintwo parts,meetingatthecentreina runningjoint.Theideabeingtoprovide alignmentandrigidityforthesunand planetgears.Itisareplicaoftheaxial sha throughthemodel.

Itsortofworked–sometimes!Atother timesitwouldseizesolidandremainso untilIstartedtodismantleit,whenit wouldsuddenlyfreeupandworkagain. WhenIshowedfellowSMEEmembers, therewereusefulsuggestionslike“How aboutasquirtofoil”,butnosatisfactory explanationofwhatwasgoingon.

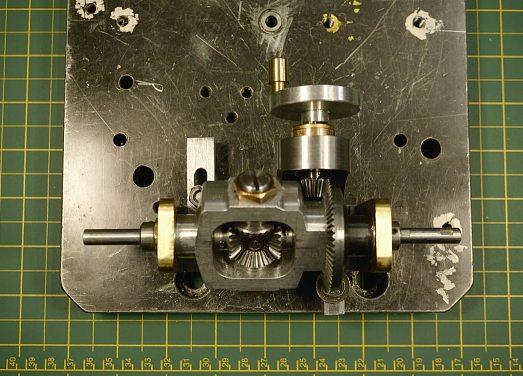

Therewasaconsensusthatthegear locationscouldprobablybeimproved sothatwasthestartingpointforaredesign. Figure1 showsthenewdesign. Whichprovidedamoreridgedyolkfor thesunandplanetwheels,eachwith individualcontroloverthemeshingwith itsneighbours.

Detailsofthisarrangementcanbe seenin photo7.Thiswasaslightly di erentapproachtotheusualmethod ofadjustingthemeshofbevelsby slidingthemalongthesha onwhich theyaremounted.Thetwoplanetbevels

ModelEngineers’Workshop www.model-engineer.co.uk 16

4 5

Drivefolded.

Rotationinthesame oradi erentsense?

arefreetorotateontheirmountings butconstrainedbyashoulderonthe threadedendofthesha anda xed washerattheotherend.The nethread andlocknutallowscarefuladjustment foroptimummesh.Theexample showsthesha smountedinascrapof aluminiumusedtoensureasnug tof thethreadsinthealuminiumyolk.

Thearrangementforthe(axial)sun wheelswassimilar,butthesha didnot haveawasherandrotatedwithinthe axialthreadedsleeve.Itwasretainedby acollarattheouterendandthebevel xedattheotherend.

Thisversionworkedmuchbetter thanthepreviousone.Itneededabit moreworktoaddballbearingsforthe yolkrotationandfortheadditionofan operatinghandle; photo8.

Initiallytherewasstillanoccasional tendencyforittoseizeupuntilon onesuchoccasionsInoticedadistinct clickasIdismantledit.Itsuddenly occurredtomethatthesamesort ofclicksometimesoccurredwhen dismantlingalockingtaper.Ibeganto suspectthatthemodi cationstothe toothgeometrymightwellresultina lockingtaperifforcedintomeshtoo far.Carefuladjustmentoftheend oat oneachofthefourbevels xedthe problembyprovidingtightercontrolon themaximummesh.However,theredid seemtobesomesortofservoaction whichencouragedover-meshing.Not whatmighthavebeneexpectedsince bevels,likehelicalspurgears,exert axialloadsontheirmountingsha s. Theseloadswouldtendtopushthe

› 17 BetterBevels –Postscript August2023

6 7 8

Simpledi erential.

Finishedexperimentaldi erential.

New ttingarrangement.

Figure1.Improveddifferentialdesign.

bevelsapart.Possiblyworthyoffurther investigationatalaterdate.

Therewasanimmediateneedfor xingthedi erentialtosomething substantialtokeepitinplacewhen turningthehandle.

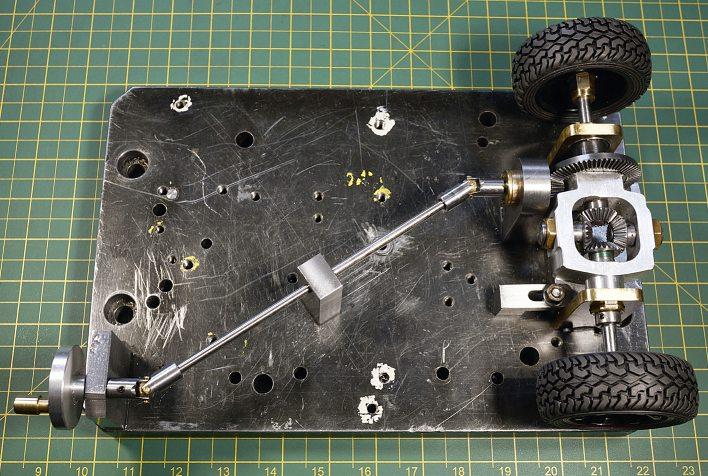

Photograph9 showsthedi erential clampedtoaratherscru y,but substantialsteelplate.Theplatecame fromaheapofmilitarysurplusandhas beenrepurposedmanytimes.

Inorderforthedi erentialto demonstratehowitworkedinpractice Ifeltitneededabitmoreelaboration tobeaconvincingdemonstrator, startingwithsomeroadwheelsfromthe internet, photo10.

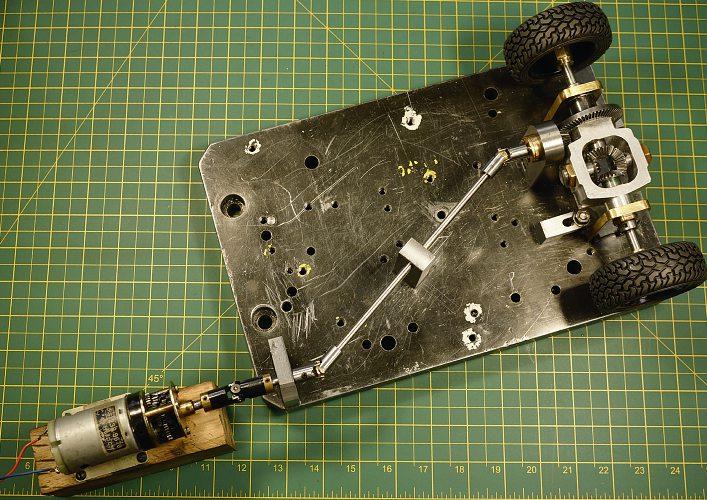

Buttheoperatinghandlewasnow inconvenientlyinthemiddleofthe plateandthemodelwouldhave bene tedfromdemonstratinghowthe drivewouldbeappliedinautomotive practice.Thehandlewasmovedtothe edgeoftheplate,whichmightwellbe consideredacorollaryofParkinson’s Law(Ref3)i.e.“Equipmentexpandsto occupythespaceavailable”; photo11. Theeagleeyedmightalsospotthat thetwouniversaljointshaveyettobe alignedcorrectly.

Thedemonstratorthenreplicated automotivepracticeforafrontengine, rearwheeldrivecar,theonlything missingwasanengine.Indeferenceto themovetoelectriccarsIdecidedtouse anelectricmotor.Ipleadpoeticlicense atthispoint,sincenoelectriccarthatI knowofhasthistypeofdrivetrain,but somedohavedi erentials.

Photograph12 showstheresult. Whichwasnotintendedtobethe nallayout,butmoreofatestbedto ndwhatpowerandspeedmightbe

ModelEngineers’Workshop www.model-engineer.co.uk 18

12 11 9 10

Di erentialattachedtobaseplate.

Newhandlearrangement.

Motorexperiment.

Roadwheels tted.

appropriateforthemotor.

Atthatpointavisitorarrivedand parkedafourwheeldriveversionof theFiatPandaonourdrive.Thathada transverseengine,whichdiddrivethe rearwheels(aswellasthoseatthefront).

Suchalayout,wouldbemorecompact, andmustsurelyhaveusedyetanother pairofbevels!

My rstattemptatasuitablebevel arrangementtopowerthedemonstrator wasunsuccessful.Ihadoptedfora

2:1increaseinspeed,butthetorque requirementstodothiswerebeyondthe simplesheetmetalmountingprovided withthemotor.Itwasseenvisibly bendingunderthestrain.

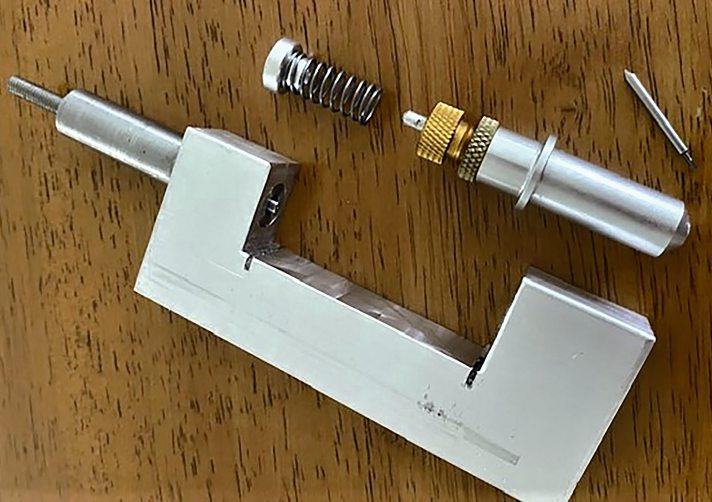

Mysecondattemptincorporateda morerobustmountingforthegears andaseparatemountingforthemotor. Thatdidn’tworkeither!Theoriginal problemwiththedi erentialwasthat itwouldlocksolidwithoutanyobvious provocationandthesamethingwas happeningagain. Photograph13 shows theconstruction,withbrassbushed bearingssimilartothoseusedearlier. Thetoolintheforegroundwastoadjust themeshofthebevels.

Puzzled,Iputthegearsbackonthe testrigwheretheybehavedimpeccably. Theproblemhadtobeinthebearing arrangement.Sincethegearsworked withtheballbearingsonthetestrig, Ichangedthedesigntoballbearings usingacassettetypearrangementas shownin photo14.

l Tobecontinued

19 BetterBevels –Postscript August2023

13 14

Troublesomearrangement…

Cassettebearingarrangement.

Beginners’ Workshop

BEGINNERSWORKSHOP

ThesearticlesbyGeometer(IanBradley)werewrittenabouthalfacenturyago.Whiletheycontainmuchgoodadvice,they alsocontainreferencestothingsthatmaybeoutofdateordescribepracticesormaterialsthatwewouldnotusetodayeither becausemuchbetterwaysareavailableofforsafetyreasons.Thesearticlesareofferedfortheirhistoricinterestandbecause theymayinspiremoremodernapproachesaswellasremindingushowourhobbywaspracticedinthepast.

ModelEngineers’Workshop 20 www.model-engineer.co.uk