+ IN-DEPTH FEATURE ON REYCLING MEDICAL PLASTICS TECHNOLOGY TO REDUCE THE COST OF LABELLING MATERIALS INSIGHT WITH POLYPLASTICS WWW.MEDICALPLASTICSNEWS.COM M edical P lastics EUROPEAN EDITION NEWS | INTERNATIONAL ISSUE 68 Jan/Feb/Mar 2023 The past, present and future of antimicrobial coatings THE HOME OF INFECTION PROTECTION

1 CONTENTS MPN Europe | Issue 68 | Jan/Feb/Mar 2023 Regulars 3 Comment Olivia Friett reflects on the innovation of 2022 4 Digital Spy Sharing some of the latest news in the medical plastics industry 10 Cover Story BioInteractions discusses everything there is to know about antimicrobial coatings 32 Q&A Polyplastics shares its expert insights on medical materials Features 6 Coatings TekCyte highlights the importance of coatings on implantable devices 12 Packaging Avient explores sustainable solutions to reduce the industry’s carbon footprint 20 Micromoulding Trelleborg explains how miniaturisation is possible 24 Making Drug Delivery Devices Covestro shares how to avoid drug delivery device challenges WWW. M EDICALPLASTICSNEWS .COM

All trademarks and registered trademarks are the property of their respective owners. Qosina is a leading global supplier of thousands of OEM single-use components to the medical and pharmaceutical industries. We offer free samples, low minimums, just-in-time delivery, modification of existing molds, and new product design and development. Log on to qosina.com today to see our full product offering. 2002-Q Orville Drive North, Ronkonkoma, NY 11779 USA +1 631 242-3000 info@qosina.com qosina.com Viale Giacomo Matteotti 26, 20095 Cusano Milanino (MI) Italy +39 02 66401337 info@qosinaeurope.com Qosina Europe: Qosina Corp.: 10226 Mini Point Tip Swab 80303 Hemostasis Valve Y Connector Rotating MLL FLL Sideport Locking Forceps 16606 99516 2-Way Stopcock FLL, Port, Barb Port 11044 Slide Clamp C3305 BD™ Syringe, MLL 32347 Tear-Away Introducer Sheath with Dilator 71619 MLL Connector 97360 3-Part Torquer 41524 Catheter Hub Connector 41423 Fixing Wing 32303 Introducer Needle Visit Qosina at MD&M West 2023 at Booth #3113 25152 Ratchet-Style Pinch Clamp 28251 Hydrophobic Filter FLL Inlet, MLS Outlet 65436 Straight Connector Barbed Reducer 91050 High-Flow Check Valve Barbed 61687 Y Connector Barbed 80330 FLO 30™ Tuohy Borst Adapter 61866 T Connector Barbed Reducer 80227 Needleless Injection Site Swabbable with Hermetic Seal FLL, Tubing Port

editor | olivia friett olivia.friett@rapidnews.com

group portfolio sales manager | caroline jackson caroline.jackson@rapidnews.com

advertising | victoria dunsmore victoria.dunsmore@rapidnews.com

advertising | helen hickey helen.hickey@rapidnews.com

vp, sales & sales talent | julie balmforth julie.balmforth@rapidnews.com

head of studio & production | sam hamlyn

Medical Plastics News NA

Print subscription - qualifying criteria

US/Canada – Free UK & Europe – £249 ROW – £249

Medical Plastics News Europe

Print subscription - qualifying criteria UK & Europe – Free US/Canada – £249 ROW – £249

FREE on iOS and Android devices

Subscription enquiries to subscriptions@rapidnews.com

Medical Plastics News is published by: Rapid Life Sciences Ltd, Carlton House, Sandpiper Way, Chester Business Park, Chester, CH4 9QE

T: +44(0)1244 680222 F: +44(0)1244 671074

© 2023 Rapid Life Sciences Ltd

While every attempt has been made to ensure that the information contained within this publication is accurate the publisher accepts no liability for information published in error, or for views expressed. All rights for Medical Plastics News are reserved. Reproduction in whole or in part without prior written permission from the publisher is strictly prohibited.

ISSN No: 2047 - 4741 (Print) 2047 - 475X (Digital)

Editor’s Comment

OLIVIA FRIETT

NEW YEAR, NEW INNOVATION

Only a few weeks into the new year and I have already given up on my new year’s resolution – I can’t be the only one, surely? Wanting to walk and ride my bike more than drive has been more of a challenge than imagined, but I’m going to blame the cold and wet weather. But enough of all this “new year, new me” malarky, I’m more excited to see the new innovation in the medical industry that 2023 is going to bring.

10 months ago, when I began my journey in this sector, I never thought I’d not only write about some incredible products, but actually get to see them in action too.

One example that springs to mind is Primasil and the University of Huddersfield improving on Paxman’s head cooling equipment design. The device was originally made in the 1990s, but last year, the duo made further developments on the device in order for it to bring relief to cancer patients undergoing chemotherapy by reducing the risk of hairloss. It’s a silicone rubber cap that sits on the head and has an instant cooling capability to help prevent chemotherapy-induced alopecia.

Medical innovation is not always about finding a cure or a solution, it can be helping the patient and easing them through their treatment, which is exactly what this is.

Studies have showed that the equipment was successful on 53% of women in a cooling group versus 0% of women in a non-cooling group, meaning over half of women are able to retain their self-confidence whilst going through this ordeal.

Another device is the Bluetree Medical transparent face masks; it makes so much sense and seems like such a simple idea

but thinking about it as someone not in the industry, during the pandemic, I never would have thought about the downside to masks. Of course, we all disliked the ‘inconvenience’ of having to wear them and as someone who wears glasses, they fogged up quite often, but we never stopped to think about the true downside to wearing masks, such as people who rely on lip reading.

It’s not only people with hearing difficulties who rely on lip reading, in fact about 46% of British people are believed to lip read as part of everyday communication. That’s nearly half the nation having their communication affected by wearing face masks. Bluetree has several different transparent face mask designs that are all Department for Health and Social Care (DHSC) approved.

GlucoRx have designed a needle free monitoring device for people with diabetes. The multi sensor continuous glucose monitor uses radio frequency technology to measure blood glucose levels every minute.

The device, called GlucoRx BioXensor, comes to market at the perfect time, as about 422 million people have diabetes, according to the World Health Organization. The GlucoRx BioXensor can prevent onset diabetes with its alarms, meaning patients no longer have to prick their finger several times a day to test their blood. This device is yet another example of the incredible innovation in this industry.

These devices don’t necessarily save a life, but make the lives of patients easier, safer and more comfortable and, of course, last year is going to be hard to top, but I’m looking forward to seeing what’s new to come to the industry in 2023.

3

BPA Worldwide Membership

2 23 WWW. M EDICALPLASTICSNEWS .COM

DIGITAL spy

INJECTION MOULDING UPDATE

https://sumitomo-shi-demag.co.uk/

SUMITOMO (SHI) DEMAG EXPANDS FAST-CYCLE PLATFORM

Engineered specifically for high volume packaging, medical and automotive applications requiring the highest processing precision in the fastest cycle time, Sumitomo (SHI) Demag is expanding its global expansion of the IntElect platform.

Filling a gap in the mass-manufacturing market, notably thin-wall packaging, the company is releasing new sizes within its IntElect S allelectric high-performance injection moulding machine range, including medium clamping force (mid-size) machines between 220 and 450 tons. Product manager of the IntElect series, Peter Gladigau, emphasises that with this latest release

moulders requiring cycle time speeds of between three to 12 seconds now no longer need to compromise on any aspect of productivity, energy efficiency and processing speed and stability.

Featuring optimised tool movement, nozzle position, injection and ejector movements and metering speed, the IntElect S model outperforms previous generations of IntElect machines.

DISTRIBUTION UPDATE

https://www.microcare.com/

MicroCare celebrates opening of distribution centre

MicroCare has announced the opening of a new warehouse and distribution centre in Leeds, West Yorkshire, England. The new location will improve service and support of MicroCare distributors and end-users throughout Great Britain, Europe and Africa.

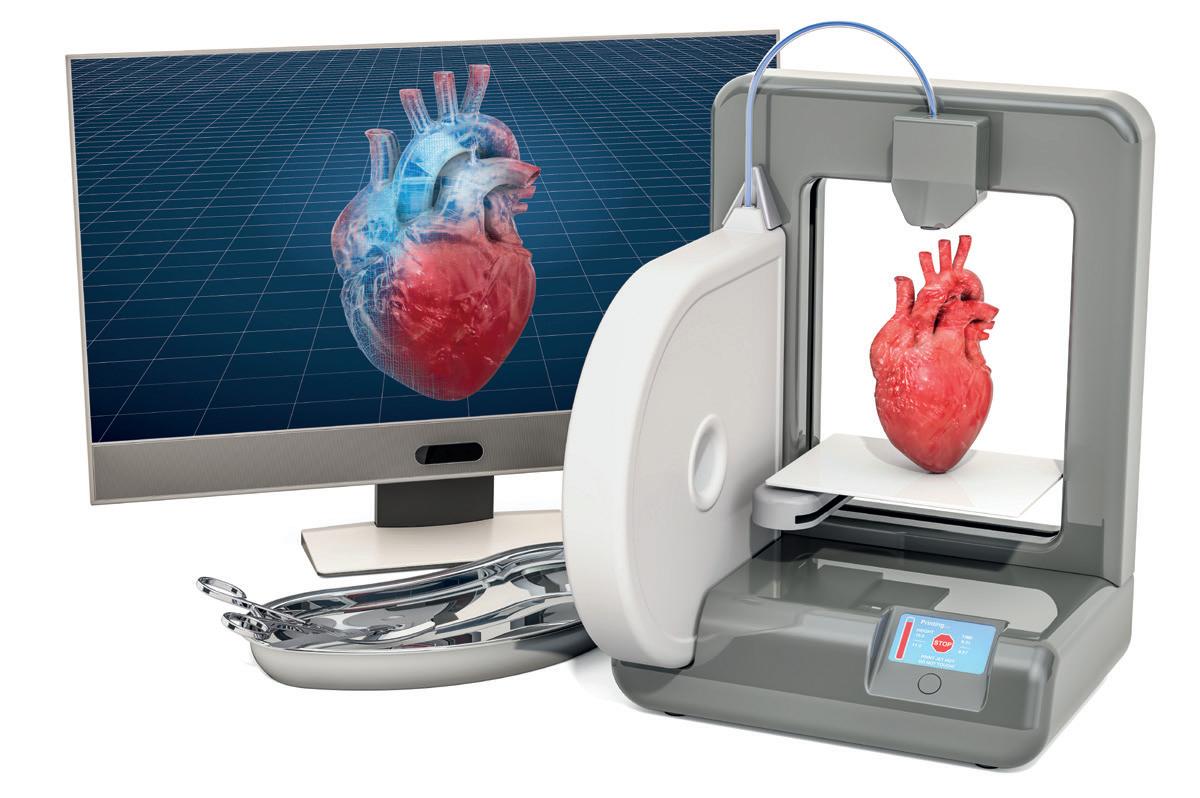

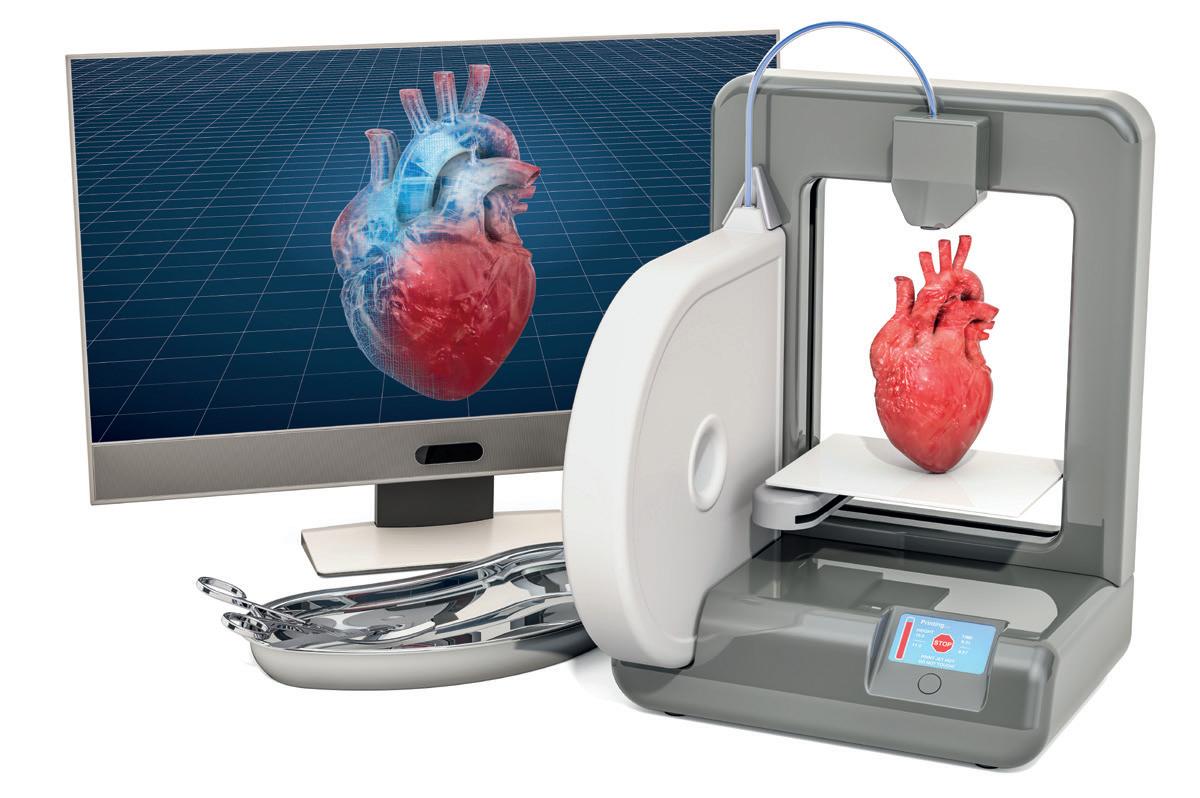

3D PRINTING UPDATE

The new centre spans 790 square metres and now serves as the primary shipping facility within the U.K. for MicroCare, MicroCare Medical and Sticklers cleaning fluids and tools. The new facility will provide access to thousands of SKUs, as well as product staging, kitting, and packing capabilities. It will also serve as the MicroCare U.K. office headquarters.

“The new distribution centre represents the

MicroCare,

MicroCare commitment to best support our customers throughout the region,” says Scott Wells, MicroCare European general manager. “It was a massive undertaking since the new facility required full renovation and modernisation to make it functional.”

https://www.nottingham.ac.uk/

Researchers in Nottingham have been awarded a £6 million grant from the EPSRC to develop a toolkit for 3D printing - Additive Manufacturing - in UK healthcare.

The toolkit will act as an instruction manual to improve the pathway from research all the way through to development and clinical adoption - giving healthcare professionals access to the latest cutting-edge science faster.

Medtech industries have up until now struggled to adopt this promising technology. The problem is that although there is a need for personalised, tailored,

and effective medtech devices, the materials have not been available, product development is arduous and the route to market is long.

The Centre for Additive Manufacturing, a multidisciplinary research group at The University of Nottingham, is addressing this problem by helping to unlock a bottleneck that prevents the bringing of new innovative engineering to the NHS.

The grant will help researchers create a toolkit platform by which industry can deliver, on demand, the materials and processes needed to 3D print medical technology and devices.

WWW. M EDICALPLASTICSNEWS .COM 4

Researchers awarded £6m grant for 3D printing toolkit

https://www.emerson.com/en-us

Emerson valves deliver flow control performance

Emerson has introduced the ASCOTM Series 209 proportional flow control valves, which offer the highest standards of precision, pressure ratings, flow characteristics and energy efficiency available in a purpose-built, compact architecture. With this combination of size and performance, Series 209 valves allow users to precisely regulate the flow of fluid in a wide range of devices that require exacting performance.

Series 209 valves have low hysteresis (less than or equal to 5%), “excellent” repeatability (less than or equal to 1%) and high sensitivity (less than or equal to 0.2%) that contribute to their precision.

An improved internal design

AQUISITION UPDATE

prevents metal-on-metal contact that causes clicking, which allows valves to operate at extremely low sound levels that are crucial for occupant comfort and well-being in medical environments.

https://www.dovercorporation.com/

DOVER ACQUIRES WITTE PUMPS & TECHNOLOGY

Dover has announced that it has completed the acquisition of Witte Pumps & Technology a manufacturer of precision gear pumps. Witte will become part of the Maag business unit within Dover’s Pumps & Process Solutions segment.

Witte is a recognised manufacturer of gear pumps and associated spare parts and services for the chemical, plastic & polymer processing, and pharmaceutical industries.

Speaking about the acquisition, Maag’s president, Ueli Thürig, said, “The acquisition of Witte complements and expands Maag’s product and technology offering, improves our geographic reach, and provides access to new customer segments. The integrated business will be better positioned to serve our global

customer bases from 22 worldwide locations, and better enable us to drive strong growth grounded in the technological leadership that Maag and Witte are known for globally. Additionally, we expect to drive significant cost efficiencies through our integrated and larger scale footprint.”

COATINGS UPDATE

https://www.magog.co.uk/

Magog offers coatings that enhance lifespan

Magog Industries offers its latest range in coatings and materials, designed to further enhance longer life and greater resistance in demanding processing where increased proportions of glass reinforced and recycled material is used.

Enhanced coatings specification includes Thin Dense Chrome (TDC) to enhance wear with low friction. Ceramic Seal coatings reduce porosity and increase plating/coating life up to 10 times longer in corrosive environments.

In addition, HVOF (High Velocity Oxygen Fuel) that is thermally spray applied provides a crackfree 98% density with hardness of 62 to 72 HRC.

COMPANY UPDATE

https://www.dovercorporation.com/

Web Industries appoints new vice president

Web Industries has named Amy Reardon Doherty as vice president, legal. Over her career, Doherty has advised executives and business partners on a wide range of legal, financial, IP and business issues.

“Amy brings a great blend of private practice and in-house counsel experience in corporate law to our team—particularly around contract manufacturing and the business-to-business arena,” says John Madej, CEO. “She has a long history and established network within the business sectors we serve and a real talent for negotiating and structuring agreements in these areas. We are very pleased that she’s joining us.”

Doherty earned her law degree from Northeastern University School of Law, her bachelor’s degree in political science from Tufts University, and has completed additional studies through Harvard Business Publishing Corporate Learning.

5 DIGITAL SPY DEVICES UPDATE

WWW. M EDICALPLASTICSNEWS .COM

TEKCYTE’S NEW COATING DEVICE CAN REDUCE THE RISK OF BIOFILM. SMALL AND MIGHTY ALONG WITH TONY SIMULA, CEO, TEKCYTE DISCUSS THE IMPORTANCE OF CREATING A SAFER OUTCOME FOR PATIENTS.

NOT S ING IS BELIEVING

TekCyte has developed a biocompatible medical device coating that can be chemically bonded to, for example, a stent or catheter surface. This provides a protective barrier against the body’s natural responses to foreign objects, making implantable devices less visible to the body’s immune system.

Stents and other vascular devices coated in this drug-free coating repel accumulation of platelets, proteins, and cells. This aims to reduce complications from stents such as clotting and restenosis and therefore, more reliable for surgeons and more durable for patients.

“We developed BIOINVISBLE to be easily applied to any existing metal stents. The coating process is scalable to meet future commercial demands, providing medical device manufacturers a reliable, safer and drug-free alternative stent.” says Dr Tony Simula, CEO at TekCyte.

More recently BIOINVISIBLE has also been shown to significantly reduce the risk of biofilm on coated surfaces, which could help infection or device failure caused by biofilm.

Helping guard against the development of biofilm reduces the likelihood of later medical complications. At the same time, the protective qualities of this technology also enhance the durability of the medical device that the coating is applied to.

WHAT ARE BIOFILMS?

Biofilms are estimated to be responsible for more than 65% of nosocomial infections, almost 80% of chronic infections, and approximately 60% of all human bacterial infections. Biofilm treatment is very challenging because treatment with antibiotics is often ineffective. Implants are very susceptible to the formation of biofilm, which can develop over days, or even over several months.

The safety of any new technology is paramount and according to tests conducted at NAMSA, all studies have successfully shown no evidence of systemic toxicity, irritation, cytotoxicity, haemolysis or sensitivity associated with exposure to BIOINVISIBLE.

“Our research shows that BIOINVISIBLE has the potential to address complications associated with biofilm buildup, without the release of drugs or other active agents,” says Dr Simula.

In fact, TekCyte’s research has shown that catheters and cannulae coated with BIOINVISIBLE could have markedly reduced rates of biofilm from organisms such as Candidaalbicans, Pseudomonas aeruginosa and Staphylococcus aureus.

BIOFILM SIDE EFFECTS

Urinary tract infections are one of the most common types of infection associated with catheters and is almost always the result of the development of biofilm. According to the Center for Disease Control in the United States, approximately 75% of UTI’s are associated with a urinary catheter.

Several studies have shown that opportunistic pathogenic yeast C. albicans can form polymicrobial biofilms, in vitro and in vivo, and that these biofilms can affect disease course and management. Polymicrobial biofilms such as this are often resistant to antimicrobial drugs.

Many researchers have tried to target microbial biofilms to reduce their impact on patient outcomes, however unfortunately current conventional antimicrobial strategies don’t work well to counter biofilm development.

By combating the formation of biofilm on medical devices, it helps to reduce the possibility of later complications for patients. This has long been a complex issue for health practitioners, however, we are now on the cusp of great advances due to the active role that BIOINVISIBLE can play in reducing complications from medical devices.

IS BIOINVISIBLE THE ANSWER?

Providing better outcomes for patients is at the heart of the ethos of BIOINVISIBLE, which may be especially beneficial for those with pre-existing medical conditions. Those that increase the risk of developing infection and other complications after intervention with a medical device.

“It is clear that BIOINVISIBLE has significant possibilities to address current biofilm challenges and we’re excited by the prospect of working with major device companies to bring to market the first truly biocompatible medical coating.” says Dr Simula.

COATINGS

The Home of Multi-Action Coatings | https://biointeractions.com WWW. M EDICALPLASTICSNEWS .COM 6

CYROLITE® has been working in hospitals and labs for more than 40 years. Thanks to their excellent properties, our high-performance acrylics are perfect for use in a wide range of medical devices. CYROLITE® is highly transparent and easily processed into intricate parts. It can be reliably sterilized using most common methods and is BPA- and DEHP-free. This has impressed both patients and healthcare professionals alike: CYROLITE® meets the requirements of USP Class VI, ISO 10993-1, and REACH. You can find more details at www.cyrolite.com.

Lipid-resistant, BPA-free, and highly transparent: CYROLITE® acrylics are the reliable invisible helpers in hospitals and labs. Visit us at MD&M West, Febuary7-9, Booth 1389

The Home of Multi-Action Coatings |

COATINGS

ENGINEER AT

CLEANLINESS

The ebb and flow of a hospital setting is ceaselessly dynamic, with patients, visitors and staff making up a high volume of foot traffic travelling through corridors daily. It is no surprise that there is widespread exposure to microorganisms in this environment, and it is a constant struggle for healthcare providers to maintain clean conditions to limit the proliferation of bacteria. Regular cleaning is crucial; however, standard disinfectants retain limited residual activity after application, leaving high touch surfaces vulnerable to contamination through direct contact or airborne droplets. This is where antimicrobial coatings can augment regular cleaning, as dry-film formulations impart long-lasting and autonomous microbial control to coated surfaces. The recent rise in coating technologies, along with a drive for improved durability, better regulatory status and increased sustainability, has led to developments in antimicrobial additives in line with these goals.

TRANSFORMING WATER-BASED COATINGS

Current trends in coating technologies are focused on advancing the durability of coatings and simplifying regulatory processes. In addition, sustainability initiatives in recent years have stressed the importance of features like biocompatibility, biostability and

non-toxicity, making water-based coatings that contain fewer volatile organic compounds increasingly appealing to manufacturers. Traditionally, in-can antimicrobial technologies have been employed in aqueous coatings to improve their shelf life during storage, but the benefits of these formulations are minimal once the solution has dried, leaving coatings vulnerable to attack by microbes. Therefore, long-lasting dry-film antimicrobial chemistries are integral to improving coating durability.

OVERCOMING THE TECHNICAL CHALLENGES OF ERADICATING SURFACE BACTERIA

Dry-film antimicrobial additives for water-based coatings must evolve in line with coating trends, while looking to overcome a range of technical challenges. Dispersing additives into existing formulations has historically triggered aggregation and sedimentation, negatively impacting the appearance of coated products. Similarly, UV instability has reduced clarity and resulted in discolouration and premature surface degradation of coatings in the past. These factors can make coatings unsuitable for transparent applications, reduce the lifespan of coated products, and greatly increase production costs. However, recent innovations in antimicrobial technologies have led to easier integration, avoiding sedimentation, irregularities, or clumping defects, as well as improved stability and durability of formulations.

ENHANCING HOSPITAL CLEANLINESS

Antimicrobial coatings, like LapisShield by Microban, work as built-in adjuncts to normal cleaning practices, providing long-lasting protection that does not wear away to surfaces such as hospital curtains, countertops, clipboards and equipment. The active ingredient in this example works by disrupting internal enzymes, blocking metabolic pathways, and creating an inhospitable environment to interrupt bacterial reproduction.

Sophisticated antibacterial additives like this can be integrated into numerous high-touch surfaces within a hospital environment, including wood, metal, polymers and glass, using standard coating processes, such as spraying, roll-to-roll or dip application methods. In fact, studies have shown that built-in antimicrobial treatments in healthcare equipment can inhibit gram-negative and gram-positive bacteria – including antibiotic-resistant MRSA, E.coli and VRE – by up to 99.9 %.

SERVING HEALTHCARE FAR INTO THE FUTURE

Incorporating antibacterial additives into hospital surfaces at the point of manufacture is an integral part of ongoing plans to enhance hospital cleanliness. The healthcare segment accounted for 26 % of the overall global revenue share of the antimicrobial additives market in 2021 and is expected to experience the fastest annual growth rate between 2022 and 2030.

Rising demand for autonomous product protection against microbes in a variety of medical products and surfaces – from flooring and wall cladding to trolleys and clinical apparatus – means that manufacturers worldwide are seeking to integrate these innovative chemistries into coatings. New antimicrobial technologies that are easy to incorporate, aesthetically pleasing, highly functional and free from heavy metals can transform coatings in healthcare environments, ensuring greater peace of mind for staff and patients alike.

JAMES RAPLEY, PRODUCT DEVELOPMENT

MICROBAN, SHOWS HOW ANTIMICROBIAL COATINGS MAKE IT EASIER TO MAINTAIN CLEANLINESS IN MEDICAL ENVIRONMENTS.

BEFORE AFTER https://biointeractions.com WWW. M EDICALPLASTICSNEWS .COM 8

MARK SCOTT, MARKETING MANAGER AT PEERLESS, EXPLAINS HOW HARD COATINGS CAN IMPROVE SUSTAINABILITY IN THE INDUSTRY.

As the plastic industry, along with all industries, focusses on improvements to sustainability it is worth noting the fact that a solution to improving the sustainability of plastic products has been available for many years yet remains underutilised.

Imagine a specially formulated treatment that provides abrasion resistances to protect the surface of plastic products from scuffs and scratches caused by general, everyday wear and tear. A treatment that provides chemical resistance to plastic surfaces that otherwise could be easily damaged by solvents and chemicals they are exposed to during use. A treatment that can offer additional surface properties such as UV resistance, anti-fog, anti-static, anti-glare, anti-microbial and anti-graffiti properties, to name a few. Such surface treatments significantly extend the lifespan of plastic products, ensuring they are fit for purpose, made to last and potentially eliminating the need for replacement during the products life span, helping to lower carbon footprints in the process.

All these specially formulated properties, which extend the useful life of products can be granted to the surface with the application of hard coatings.

Hard coatings are applied to plastic substrates in a liquid form and cured using heat or UV energy. The level of abrasion and chemical resistance can vary depending on the hard coating’s formulation. Some coatings offer a lower abrasion resistance but in doing so offer an extended life under external weathering conditions.

WHAT ARE HARD COATINGS USED FOR IN THE INDUSTRY?

Hard coatings are particularly useful in medical applications such as:

• Hard coated hygienic wall cladding and surface covers, incorporating specialist properties such as anti-microbial protection. The hard coating in these applications offers a robust surface to decorative wall coverings to meet the daily wear and tear of hospital corridors, operating theatres, kitchens, toilets/rest rooms, etc. Hard coatings can also be applied to protect the plastic parts used on patient beds and in areas that are subject to daily wear and tear saving on replacement costs.

• Hard coated and Anti-Fog PPE providing a tough long-lasting solution for medical visors and goggles, whilst guaranteeing clear vision without fogging up. This helps to ensure the wearer is comfortable and able to keep PPE on at all times keeping them and patients safe.

• Antimicrobial hard coatings applied to door furniture such as handles and push plates, offering hygienic surfaces for high traffic areas.

• Operating Theatre lighting, with an abrasion and chemical resistant hard coating to allow for regular cleaning of the lighting lens, to ensure optimal light transmission for the life of the product.

HOW CAN HARD COATINGS IMPROVE SUSTAINABILITY?

Advances in plastic production and ensuring materials are recycled in recent years, have, and will continue to make a difference, but less focus has been placed on ensuring materials last longer and therefore need to be replaced less often.

The use of hard coatings on plastic substrates in many other applications

would reduce the need for replacement/ recycling, ultimately reducing the carbon footprint and improving the sustainability of said product or project. Once a hard coated plastic product comes to the end of its useful life, it can still be recycled just the same as the uncoated product would have been, so it’s a win-win scenario.

As more industries start to utilise hard coatings on their plastic products, they begin to understand the many benefits offered. Not just superior surface performance and protection, but also improved sustainability and help to lower carbon footprints due to lasting significantly longer and ultimately reducing costs associated with replacements.

9

COATINGS The Home of Multi-Action Coatings | https://biointeractions.com WWW. M EDICALPLASTICSNEWS .COM

BIOINTERACTIONS, CREATOR OF THE REVOLUTIONARY COATING FOR MEDICAL DEVICESTRIDANT, SHARES ITS EXPERTISE ON COATINGS, THEIR USES AND THE PREDICTED FUTURE OF ANTIMICROBIALS.

In the past century, modern medicine has broken countless barriers towards a safer, more effective healthcare protocol. Arguably, one of the most important discoveries has been antibiotics. Unfortunately, over the last few decades the widespread use of antibiotics has seen the rise of drug resistant bacteria which has led to antibiotics becoming less effective over time.

According to the European Centre for Disease Prevention and Control, more than 4 million people acquire a HealthcareAssociated Infection (HCAI) each year, resulting in 37,000 deaths. Combatting HCAIs is a significant problem for the healthcare sector globally. HCAIs are the sixth leading cause of death in western countries. However, treating these infections with antibiotics is lowering the effectiveness of the treatments and the public’s trust in medicine. Researchers have been able to pinpoint the cause of most of these infections: bacteria-infested surfaces inside of hospitals. There is an identified need to protect surfaces from germs and microbes by using antimicrobial coatings.

An antimicrobial coating is an application of a chemical agent on a surface that can stop the growth of disease-causing microorganisms. Apart from increasing the surface’s durability, appearance and corrosion resistance for example, these coatings also protect from harmful disease-causing microbes. When medical equipment is coated with an antimicrobial solution, it can prevent up to 99.999% of pathogens, significantly reducing the risk of infection for the patients. Revolutionary antimicrobial coatings stick to the surface they are applied on and remain effective for a considerable period of time without reducing efficacy, defining them as one of the best options to fight bacteria in a medical environment.

CURRENT STATE-OF-THE-ART ANTIMICROBIAL COATINGS AND THEIR USES

Everything is susceptible to microbes—surfaces, healthcare devices, equipment, walls, textiles; the list is almost endless. From these surfaces, microbes find their way to humans. Unfortunately, strict hygiene regimes and existing disinfectants have limited efficacy and require a considerable level of maintenance to reduce the risk of infection for prolonged periods of time. New developments are bringing to light state-of-the-art antimicrobial coatings, such as TridAnt, which offer a new way to combat infections more effectively, efficiently and for longer periods of time. TridAnt is proven to provide monoclonal protection, which kills a broad spectrum of gram-positive and gram-negative bacteria as well as enveloped and non-enveloped viruses, including E.Coli,

THE HOME OF INFECTION PROTECTION

COVER STORY

10

PROTECTION

MRSA, Influenza, Vaccinae, Adenovirus, Norovirus and SARS-Cov-2. TridAnt is also suitable for skin protection as well as most other surfaces including woven and non-woven fabrics, as well as hard surfaces such as metals (nitinol and stainless steel) and polymers (polycarbonate and polyurethanes).

The new antimicrobial technology is non-leaching and therefore completely safe to use in all environments and even for implants inside the human body including class 3 medical devices. Its active components target microbes (prokaryotic cells) and are non-leaching which provide consistent protection on the device. For the first time, medical device technology is able to kill enveloped and non-enveloped viruses, gram-positive and gram-negative bacteria as well as preventing the formation of biofilms for long-periods of time of up to 365 days (as well as safe enough to protect skin for up to 48 hours) without any noticeable reduction in efficacy over time. As a result, antimicrobial-coated medical devices are protected with a highly effective and non-leaching shield for a consistent level of protection for the device.

WHAT’S NEEDED TO ADVANCE THE TECHNOLOGY TO MAKE THAT FUTURE A REALITY

One of the main factors stunting the widespread use of antimicrobial coatings are the current regulations in place. Under today’s European Union (EU) regulations for example, medical devices are a part of the new Medical Device Regulations and are therefore required to be submitted to regulatory bodies for approval. Regulators want to make sure that any positive effects an antimicrobial coating have are risk free, able to be replicated across the board, in different settings and for different patients.

In the USA, the use of antimicrobial coatings is more widespread than in the EU. The US Food and Drug Administration (FDA, which oversees drug and medical device developments) allows the use of chlorhexidine and other coatings, regardless of them leaching and reducing their effectivity overtime. In the EU, however, this is seen as a risk to the patient and regulated against. Thorough testing and aiming for perfection in all medical-adjacent products are especially important not only for patient care, but also to bring about a continued cycle of technology innovation. This current method of testing helps hospitals, patients and doctors to be certain that antimicrobial coatings are effective against HCAIs. However, this process can be very long, at times up to years, for technologies ultimately to earn accreditation, which slows down progress. Regulations need to be thorough and effective, but they also need to move forward to assist with innovation.

OTHER GROUNDBREAKING PRODUCTS AVAILABLE

BioInteractions is not only responsible for creating and developing the revolutionary coating for medical devices - TridAnt, but also the globally used Astute and Assist solutions.

Astute Antithrombogenic Coating is a legacy technology which has been utilised on a variety of class 3 medical devices for its safe and successful use to prevent blood clots on chronic medical devices. The active antithrombogenic components halts the blood clotting cascade mechanism. This is combined with passive non-thrombogenic elements to prevent deposition

and adhesion on the device surface. Assist Hydrophilic Coating has delivered a high-performance lubricious surface for high-stress applications without particulate formation or delamination of the coating on devices approved both in the USA and Europe. The coating enhances biocompatibility of the surfaces whilst enabling the surface to significantly decrease the frictional resistance even under stress. This radically reduces tissue damage and improves comfort when delivering or removing devices from the patient.

PROMISING AND POTENTIAL USES IN THE FUTURE

The prospect of a biocompatible technology which can enhance the function of medical devices through eliminating existing microbes and also preventing the formation of new colonies consistently over extensive periods of time represents a paradigm shift in prevention and treatment of surgical infections. The future will bring further developments in material sterilisation, bacterial reduction and viral prevention. Antimicrobial coatings will cement themselves as the golden standard of excellence in healthcare, used in all things that go inside the patient and around open wounds. Additionally, they will help prolong the active lifecycle of medical devices, which has a significant economic, health and social care impact.

As time goes on, the focus in the healthcare sector will switch from infection reaction to infection prevention. Once science understands how to prevent infections, we will also be able to prevent pandemics, lockdowns, and raise the public’s confidence in antibiotics and vaccines.

11

COVER STORY

VOLKER DICKFIELD, GLOBAL MARKETING MANAGER, HEALTHCARE AT AVIENT, EXPLORES

PACKING UP HEALTHCARE EMISSI NS

When we think about the industries that contribute the most to climate change, healthcare might not be the first to come to mind. However, a Health Care Without Harm and ARUP report found that 71% of the sector’s emissions are primarily derived from the healthcare supply chain through the production, transportation, and disposal of goods and services. This can make it difficult for manufacturers of medical devices and pharmaceutical packaging to know where and how to start reducing emissions.

The healthcare market’s challenge is finding solutions that do not compromise safety and comply with strict industry regulations while facing significant issues in securing the supply of materials. The good news is that there is an easy, fast, and controlled way to start reducing the carbon footprint of medical plastics: switching to Mevopur biobased polymer solutions.

WHAT ARE MEVOPUR BIO-BASED POLYMER SOLUTIONS?

Avient’s Mevopur bio-based polymer solutions are colourants and functional additives using biopolymers as carrier resin that are specifically for use in healthcare applications. The portfolio includes solutions formulated with and for bio-based polypropylene, polyethylene, polycarbonate, acrylonitrile butadiene styrene (ABS), and styrenic resins. Mevopur bio-based polymer solutions are available as concentrates (masterbatches) to dilute at a specific ratio into the virgin polymer during the plastic conversion process or ready-to-use formulations that already contain the right amount of colour. They are drop-in solutions that can be used the same way as fossil-fuel-based polymers in injection moulding,

blow moulding, and extrusion, which means there is no need for additional equipment or manufacturing process adjustment. As with all Mevopur solutions, these products come with well-characterised raw materials, fully secured change management beyond ISO 13485, and full support with regulatory documents.

This also means projects involving bio-based polymer solutions can be managed as any medical plastic colouration project with fossilbased polymer solutions. Possible applications include casings of drug delivery devices (e.g., autoinjectors, syringes), diagnostic devices (e.g., blood glucose monitors, pregnancy tests), or pharmaceutical containers and caps. The colour concentrates and pre-coloured formulations are developed in bio-based polymers by a team of experts in colour matching for healthcare applications. Functional additives can be combined with the colour to provide additional features such as laser marking, laser welding, improved protection during irradiation sterilisation, UV/VIS protection, friction reduction, antistatic properties, or protection from thermo oxidative degradation.

SUSTAINABILITY IMPACT

The bio-based polymers used in these Mevopur solutions are produced using non-fossil resources to build the monomers. All bio-based polymers have a specific reduction of greenhouse gas emissions (measured as CO2 equivalent) compared to fossil-based counterparts. Some bio-based polymers even have a consuming CO2 effect, meaning the raw materials consume more CO2 than emitted, resulting in a lower carbon footprint material. This is the case with bio-polypropylene and bio-polyethylene. Biopolypropylene (bio-PP) can achieve the highest bio-content, up to 100%, along with bio-polyethylene (bio-PE) at 95%. In comparison, other similar

12

SUSTAINABLE SOLUTIONS TO REDUCE THE IMPACT OF THE INDUSTRY’S GAS EMISSIONS.

PACKAGING WWW. M EDICALPLASTICSNEWS .COM

products typically contain between 70% and 95% of bio-content – calculated to ASTM D6866 standard. This means bio-PP and bio-PE are good options when switching to bio-based polymers.

Therefore, Avient started with these polymers to develop their first biobased polymer solutions, launched last year at Pharmapack. They are particularly interesting for pharmaceutical packaging due to higher production volumes, making the sustainability impact more significant. Eventually, any switch to bio-based polymer solutions, no matter the application or the resin, will be a step forward to a reduced carbon footprint and increased sustainability. In addition, the plastics made from bio-PP, bioPE, bio-PC (polycarbonate), bio-ABS, and other bio-styrenics are recyclable through the same recycling channels as conventional fossil-based polymers.

RISK MITIGATION AND REGULATORY COMPLIANCE DOCUMENTATION

The Mevopur bio-based polymer solutions follow the same concept of enhanced risk mitigation as all Mevopur products. The first cornerstone of the concept is the pre-testing of raw materials, including bio-based polymers, to relevant medical standard protocols. Those include ISO 10993-1, USP chapters <87> and <88> (including Class VI), European Pharmacopeia monographs 3.1.3 and 3.1.5. (polyolefin packaging materials), USP <661.1> (polyethylene) and ICH Q3D guidelines for elemental impurities. Documentation for this testing is provided to customers to help increase the certainty of regulatory compliance for their devices and packaging.

In addition, Drug Master File (type III) and/or Device Master File registrations by the Food and Drug Administration (FDA) and food contact according to U.S. FDA and EU norms are also generally available for all Mevopur products.

Another cornerstone of the risk mitigation concept is manufacturing Mevopur colourants and additives in four ISO 13485:2016 third-party certified sites in Asia, Europe, and North America. All four sites use a globally harmonised raw material range which facilitates the transfer of a project from one region to another and provides backup options to increase the security of supply. For increased risk mitigation, all sites also offer change control agreements beyond Chemical Abstracts Service (CAS) number.

THE FUTURE OF SUSTAINABILITY IN HEALTHCARE APPLICATIONS

Avient supports the healthcare industry with sustainable material solutions under the Mevopur brand name. This includes developing more solutions in existing sustainable resins and qualifying new resin classes when available. The sustainability aspect can be further enhanced by combining bio-based polymers with functional additives.

Medical diagnostic equipment & biotech applications

ALBIS offers the medical industry an unparalleled choice of high performance polymers from renowned producers. This offering is complemented by customized polymer compound solutions tailored to customer’s needs and made by ALBIS’ sister company MOCOM.

We support numerous projects in the medical and pharmaceutical sector as well as for diagnostic equipment and biotechnology applications. Addressing the latest trend towards an increasing use of sustainable solutions our portfolio includes newest and state of the art sustainable polymers which are specifically developed to fulfil the strict regulatory and service needs of the healthcare industry.

albisuk@albis.com

albis.com

PACKAGING

Welcome to the Recycling Medical Plastics feature of Medical Plastics News. 2023 is the year to reinforce recycling with laws changing throughout the globe.

This issue covers all aspects of recycling – discussing innovative devices and facilities, implementing the circular economy into the industry and even advice from sustainability experts.

A company gives its insight on how to recycle one of the most disposed of plastics in the medical sector and a global company shares the news of its technology which breaks down and rebuilds plastic, as well as their large facility made specially to process plastic waste.

It’s Global Recycling Day on 18th March, how will you be implementing this across your company? Have a read throughout the following features for inspiration.

CLEANROOMS

WWW. M EDICALPLASTICSNEWS .COM 14

WASTE NOT, WANT NOT

GERTRUD MASURE, EMEAF MARKET DEVELOPMENT MANAGER AND ABIGAIL AGENTIS, AMERICAS MARKET DEVELOPMENT MANAGER AT EXXONMOBIL, EXPLAIN THE IMPORTANCE OF PATIENT SAFETY WHEN IT COMES TO BEING SUSTAINABLE.

the meaning of sustainability

potentially play a role in the medical field.” Masure said.

“What the technology basically does is it takes mixed plastic waste, breaks it down to its molecular building blocks and rebuilds polymers using existing petrochemical facilities. This results in virgin equivalent, high performance polymers that can comply with the industry’s highest requirements on cleanliness, purity and product safety.”

THE FINISHING TOUCH

Sustainability is at the forefront of multiple industries, however when we think of sustainability, we think of recycling and the reusing of products, but in the medical industry it’s not always so simple.

For the most part, it’s safe to reuse or recycle a product, such as packaging, but what happens when it comes to syringes and face masks? This is where hygiene and patient safety become a huge factor. Exxonmobil believe that patient safety is a form of sustainability in itself.

PATIENT SAFETY

Exxonmobil aim to look at different solutions to try and find ways to keep patients safe whilst being as sustainable as possible.

Abigail Agentis, Americas market development manager, said: “We definitely recognise that sustainability is a key driver across all industries and not just medical. And so that’s definitely at the forefront of our minds when we’re looking at developing solutions for this industry. I would say that we have, within our expanded portfolio, a lot of great new alternatives to existing incumbent materials that could be leveraged towards companies’ sustainability goals.”

Gertrud Masure, EMEAF market development manager, added: “It’s about how can we change and look at different solutions that are important for a patient’s safety - and to me, that’s part of the sustainability story in the same sense as well. It’s like, how can we provide better healthcare in the longer term for patients, for the safety of everyone.”

HOW CAN THIS BE SOLVED?

So how can we recycle medical plastics without risking harm to patients?

Exxonmobil has developed a technology, called Exxtend, which breaks waste and rebuilds the material, allowing plastic waste to be converted into brand new products.

“The medical industry is also looking at recycling opportunities. Now, of course there is a whole patient safety related to it, so one of the things we are studying and looking into is how our Exxtend technology for advanced recycling of plastic waste to produce certified-circular polymers can

Exxonmobil has created a largescale facility in Baytown to process plastic waste.

As of June 2022, the company had processed more than 5,000 metric tonnes of waste. Upon completion, Exxonmobil states it’s now among North America’s largest advanced plastic waste recycling facilities, with a goal to recycle 30,000 metric tonnes of plastic waste each year.

Exxtend can be rapidly scaled to process a wide range of plastic waste. The company aims to have the advanced recycling capacity of up to 500,000 metric tonnes per year by the end of 2026, globally.

15 CLEANROOMS RECYCLING MEDICAL PLASTICS

WWW. M EDICALPLASTICSNEWS .COM

MARTIN GADSBY,

VP OF OPTIMAL INDUSTRIAL AUTOMATION, LOOKS AT HOW INDUSTRIAL AUTOMATION CAN SUPPORT THE CREATION OF A CIRCULAR ECONOMY FOR MEDICAL PLASTICS.

Got it down PAT

Plastic can be found everywhere in medical and healthcare settings – in fact, we probably cannot imagine sanitary practices in the sector without it. Given that the material is so ubiquitous, it is no surprise that hospitals and other health centres generate large volumes of plastic waste. However, using data-driven chemical recycling strategies, this can be turned into a valuable resource, supporting circularity while potentially reducing costs.

However, the sector uses massive volumes of disposable medical plastics. It has been estimated that these represent approximately 25%-30% of landfilled medical solid waste. When looking at the UK National Health Service (NHS), 133,000 tonnes of plastic are disposed of every year, with only about 5% of this currently being recovered.

As these products are rarely recyclable at their end of life, they contribute to plastic pollution. Moreover, as most components are made from oil-based virgin raw materials, they are advancing the depletion of non-renewable sources. How can healthcare professionals overcome this?

GOOD CHEMISTRY

Currently, mechanical recycling is the most widely used strategy. However, this comes with key limitations in terms of the types of polymers that can be processed and produced as well as end product quality. Materials produced in this way typically feature inferior physicochemical properties, due to the presence of impurities and other contaminants, the popularity of mixed polymer blends, the presence of multilayer materials and the heterogeneity of the initial waste.

Chemical recycling methods, which are typically based on pyrolysis, depolymerisation or solvent-based selective polymer recovery, offer a valid alternative to address these challenges. They can address feedstock variability, remove coatings, dyes and other substances from medical equipment as well as separate the components of mixed materials. As a result, advanced chemical solutions can deliver high-purity monomers and polymers with virgin-like properties.

An obvious strategy for recycling facilities is to adopt robotic and/or machine vision systems to perform rapid and accurate sorting of large volumes of waste. When looking at the chemical reaction, separation and purification stages, automated process control strategies should be applied to optimise the operating conditions.

ON THE PAT WATCH

A highly effective solution is setting up self-regulating processes driven by Process Analytical Technology (PAT). More precisely, this framework consists of univariate and multivariate analysers that monitor the physicochemical properties of the plastic feedstock and process conditions, preferably via real-time, on-line measurements. Among the most suitable analytical devices that can be used are Raman and mass spectrometers, and nuclear magnetic resonance (NMR) instruments.

The data generated by these analysers is then shared with a PAT knowledge management platform, such as synTQ from Optimal Industrial Technologies. This platform combines the information via data fusion strategies and feeds chemometric and other predictive models to provide in-depth insights. These include determining the expected physicochemical properties of end products, when processes are complete and can move on to the next stage, as well as how the process can be optimised to meet quality and efficiency targets.

ENABLING MEDICAL PLASTIC CIRCULARITY

Ultimately, smart chemical recycling plants can set up automatic feedback and feedforward closed-loop control. This can maximise yield, throughput, recovery rates and product purity while minimising cycle times, energy usage and solvent utilisation, if the recycling route requires it, as well as reduce waste and reworks. As a result, it is possible to limit the environmental impact of recycling activities and make them commercially viable, delivering monomers or polymers at a cost that can compete with virgin-based counterparts.

A skilled automation specialist with experience in implementing PAT-driven solutions, such as Optimal Industrial Automation, is a key ally in the creation of successful, future-oriented processing facilities for medical plastic waste. By partnering with an expert in the industry, companies can drive forward financially feasible circularity in the sector and benefit customers with economical, highquality, greener products.

RECYCLING MEDICAL PLASTICS

WWW. M EDICALPLASTICSNEWS .COM 16

TOBIAS JOHNSEN, CONSULTANT AT VINYLPLUS, DISCUSSES THE POSSIBILITY OF A CIRCULAR PLASTIC ECONOMY IN HEALTHCARE.

Is it p ssible?

The use of plastics in healthcare presents a paradox. As a direct product of the petrochemical industry’s breakthrough after World War II, plastics paved the way for a tremendous innovation within medical devices. Suddenly it was possible to manufacture sterilisable, single-use medical equipment at a price that traditional materials such as metals, ceramics and glass could not beat. With rising living standards in many countries in the following decades, the demand for quality healthcare grew dramatically, which plastics helped to fulfil.

The other side of the coin was seen during the Covid-19 pandemic. Though single-use plastic medical devices played an essential role in the prevention and control of infection in hospitals, Covid-19 highlighted the challenges of properly managing and discarding the same life-saving devices after use.

WHAT’S THE SOLUTION?

The enormous amounts of waste generated has obliged hospitals to reconsider their waste management systems towards more cost and environmentally efficient practices. In addition, the increased focus on plastics in society acts also as a driver to make the use of polymers used in health settings more circular.

Some call for a phase-out of plastic in healthcare as a solution to the waste crisis. Though reduction is on top of the waste pyramid, it will be very difficult for health professionals to not have access to safe, reliable plastic-based medical devices in critical situations. In addition, the ageing population in some countries and rising incomes in others mean the demand for quality, affordable healthcare will not subside in the future.

The same voices then call for reuse, and of course this idea is appealing, it remains to be seen whether washing and re-sterilisation is practically and economically feasible for the many different low-cost disposable medical devices that doctors, nurses and other health staff rely on for diagnosis, treatment, and care.

Recycling is a step down from reuse in the waste pyramid but preferable to incineration or landfill. Here, the PVC industry has taken a leading role. In early 2022, the VinylPlus Med recycling programme was launched to accelerate sustainability in European healthcare. Starting in Belgium, the aim is to help hospitals sort their PVC waste stream. Currently 10 hospitals have joined VinylPlus Med, with more than 35 on the waiting list.

BUT WHY PVC?

First, market studies show PVC is the single most used polymer for disposable medical devices such as oxygen masks, tubing and dialysis

bags. Importantly, PVC will remain the material of choice in the years to come. Successful recycling depends on volume, so it makes sense to start with the most used plastic.

Second, PVC is easily recyclable due to the polymer’s chemical composition. As PVC can be made rigid and soft, it is also possible to manufacture mono-polymer products – another key to successful recycling. Medical grade PVC is sought after by recyclers and plastic converters, as it can be turned into a wide variety of applications. An example is vinyl wall covering, which can incorporate regrind PVC obtained through an environmentally benign process. After many years, the wall covering can be recycled and used in new wall covering.

When mentioning PVC in the context of healthcare, the discussion always gravitates towards the additives that give PVC its unique functional properties such as softness and flexibility. It must be stressed that only REACH-compliant non-DEHP PVC waste is collected. To meet this objective, a cost efficient portable near-infrared (NIR) scanner has been developed. By use of artificial intelligence, the scanner can detect the presence of DEHP in the waste stream. This scanner can be used on PVC waste streams from other sectors, thus facilitating an easy sorting of flexible PVC.

17 RECYCLING MEDICAL PLASTICS

WWW. M EDICALPLASTICSNEWS .COM

NICOLLE PORTILLA, SOCIAL MEDIA MANAGER AT RTS, SHARES HOW TO IMPLEMENT CIRCULARITY IN THE MEDICAL PLASTICS FIELD.

Thecircle oflife

Plastic is one of the essential materials used in the global economy. It has wide-ranging applications across the biggest industries and is a cost-effective solution that is easy to produce and transport. The healthcare industry is one of the fields that makes extensive use of plastic, as it is an incredibly versatile material that is used in the manufacturing of medical equipment.

However, plastic production is one of the leading causes of pollution worldwide. With over 380 million tons of plastic produced every year, a huge portion of it is never reused but simply dumped in landfills and oceans. Healthcare facilities overall are known to generate tens of thousands of tons of plastic waste per day. The irony is that around 85% of hospital waste is free from any contamination and health hazards — making it ideal for recycling and reusing.

THE CHALLENGES OF ADOPTING CIRCULARITY IN MEDICAL PLASTICS

The circular economy is a production and consumption model that has reusing, recycling, and repairing existing materials at its core. There are, however, many challenges within adopting circularity in the medical plastics industry, such as:

Regulatory issues and market barriers

There is not enough budget and willingness to invest in new and better recycling infrastructure and practices.

On top of that, healthcare is a field that is under heavy regulation

by government bodies. Most manufacturers of medical devices follow strict rules and are hesitant to deviate from the established formula. Introducing new materials into the manufacturing process will most likely be problematic in terms of regulation and industry standards.

Inconsistent performance

Another thing to keep in mind regarding medical plastics is that they need to meet certain requirements in order to be effective. In addition to overall strength and flexibility, manufacturers also have to consider sterilisation compatibility, permeability, and microbial barrier characteristics. If a product does not meet the standards in those categories, it will not perform as needed.

Unfortunately, as of now, incorporating recycled content in medical plastics results in inconsistent performance. Research has shown that there are significant challenges in terms of maintaining product integrity and overall quality.

Problems with traceability

There are specific standards and regulations when it comes to the traceability of medical devices and products. In order to find the cause of issues quickly and effectively, manufacturers are required to keep a Device History Record (DHR). DHR essentially traces any material content used in a product back to its source. Therefore, using recycled plastic for medical materials is quite impractical and in direct contradiction to those regulations.

RECYCLING MEDICAL PLASTICS

WWW. M EDICALPLASTICSNEWS .COM 18

IMPLEMENTING CIRCULARITY IN MEDICAL PLASTICS

While fully adopting circularity in medical plastics is still not possible, there are many new developments that will make the process easier. Technological advancements and legislative incentives will make the transition smoother for medical plastic manufacturers across the globe.

Innovation in recycling tech

The technology involved in medical plastic recycling is constantly undergoing changes and improvements. The main issue is that recycled plastics often suffer from downgrades in quality, impacting their performance and durability. However, new developments will make it possible to recycle plastic more effectively, resulting in a product that performs as if it was manufactured with brand new materials.

Improved infrastructure and legislation

Combating pollution and climate change is more needed than ever, and the topic is on the agenda of many global alliances, associations, and governments. As a result, more and more investments are being made across the globe to improve recycling infrastructure and technology. What is more, local governments are further regulating the plastic industry while incentivising manufacturers to adopt circularity in their processes.

Such developments will help deal both with regulatory challenges and market limitations. We can expect medical device manufacturers to rapidly implement circularity, as the barriers and complications surrounding the transitions disappear in the near future.

Using recycled materials in non-sterile products

As we already mentioned, there are strict regulations regarding the plastic used in medical devices. While recycled materials currently have performance issues, tests show that they are quite usable for non-sterile products and packaging. Certain devices and packaging do not need to be sterile, since they are sanitised right before use by hospital personnel. Other medical devices, such as disposal bins, are not required to be sterile at all. Until recycling technology improves and proper infrastructure is created, manufacturers should focus on using recycled materials for such products as much as possible.

Simple Solutions for Secondary Packaging

Transportation of Category B biological samples requires a multi-layered packaging system to meet the legal requirements of the UN3373 regulation.

These include: ■ Leak proof secondary packaging ■ Inclusion of adequate absorbent material ■ Separation of multiple tubes

Choose from two secondary sample packaging solutions that provide these features, helping you achieve compliance with ease, speed and reliability. ®

Rigid, clam shell construction protects samples

Built in absorbent gel prevents leaks

Multi-vial options with tube separation

Leak-proof pouch for individual vials

Fixed absorbent material within

Easy to open

95kPa compliant options

Find out more about our range of UN3373 compliant packaging solutions at www.UN3373.co.uk

Making UN3373 Compliance Quick and Easy T: 023 8048 3000 W: www.alphalabs.co.uk

Available from

COMPAMED / MEDICA

ROB CONNELLY, PRINCIPAL ENGINEER, TRELLEBORG HEALTHCARE & MEDICAL, EXPLAINS HOW PRECISION TOOLING, VALIDATION, AND SKILLED ENGINEERS MAKE MINIATURISATION POSSIBLE.

The demand for miniaturisation of silicone and thermoplastic moulded products for medical devices has heightened the importance of process validation, precision tool design, and skilled tool operators and engineers. According to Plastics News Research, advancements and miniaturisation in the medical device industry have improved healthcare around the globe, making treatments and monitoring of conditions simpler, less invasive, and more portable.

TAP INTO TOOLING AND PRECISION

To miniaturise devices, components must become smaller. This significantly increases the complexity of the manufacturing process and requires equipment, tooling and processes that promote a high level of precision. Additionally, experts should Design for Manufacturability (DfM) to shorten time to market, improve future production yield and ensure delivery of product in high volume.

Typical moulding tools and processes are not usually capable of providing the quality and precision needed for miniature devices. Therefore, it’s important to partner with a supplier that understands the complexities of micromoulding.

A robust micromoulding process starts with high-quality injection moulding tooling which will determine the quality of the final

product. All micromoulding tools, whether producing a plastic or silicone component, require a high degree of precision in tolerances and shut-off surfaces to precisely control the flow of material into the mould cavity. To achieve this level of quality, high-precision machining equipment is needed for mould fabrication.

In micromoulding processes, it is also vital to use equipment capable of injecting small doses of material into the mould cavity. Material doses or shot sizes of less than 1.0 grams are typical for these micro-sized components. Shot size control is critical for low viscosity Liquid Silicone Rubber (LSR) and is, therefore, a major focus with micromoulding equipment.

Without tight control over shot size, 5 to 10% of micro part cavity volume can easily “leak” from the mould cavity. This produces excess material around the perimeter of the part, commonly referred to as flash. In a larger, more typical sized moulded component, the size of a hand for instance, a small amount of flash is acceptable and can be removed in a secondary process. However, when a part is smaller than a pin head, the flash could be as large as the part itself, and flashless production becomes obligatory. This requires precision tooling, smaller injection units, better control of heat zones, and greater precision of injection units.

When working with a highly capable manufacturer of micromoulded components, more advanced capabilities, such as multicomponent injection

WWW. M EDICALPLASTICSNEWS .COM 20

MICROMOULDING

moulding, also commonly referred to as 2K, 2shot, or 2C LSR, are ideal. Involving the simultaneous injection of LSR in combination with technical plastics, this highly advanced technique allows the combination of parts within an assembly into a single integrated component, eliminating potential assembly failures and dead space in which bacteria can breed. However, it requires sophisticated tool and process engineering.

PUTTING VALUE IN VALIDATION

In addition to high-precision moulds and equipment, robust process validation and measurement methods are also critical to ensure miniaturised components are manufactured within specification. Validation of micromoulded components is challenging due to process control complexity and difficulty in measuring, handling, and inspecting small features. For example, micromoulded parts are so small, static can literally cause the parts to fly away during handling. Therefore, special handling and static-mitigation devices are necessary throughout the manufacturing process.

Automated grippers are generally too large when demoulding extremely small silicone parts, while ejectors are not suitable for silicone parts regardless of size. This is because of silicone’s propensity to flow into the clearance of an ejector system. Another alternative is using brushes to remove parts from the mould, but the tiny micromoulded parts stick to the brush itself, rather than release from the mould and “fall” into a container below. The solution is specialised grippers designed specifically for microsized parts.

Packaging also needs to be considered in the production process, since standard polyethylene bags are not practical for extremely small parts. The parts will statically stick to the surface of the bag and be extremely difficult to remove. Therefore, parts may need to be packaged in small hard plastic containers or on double sided tape, for instance.

Gauge repeatability and reproducibility studies play an important role in ensuring the measurement processes for micromoulded components. These tests measure accuracy of the measurement process and help ensure measurements are repeatable by a single inspector and reproducible by multiple inspectors. As parts or part features and their associated tolerances become smaller, measurement equipment and methods increase in complexity. Methods and equipment must be engineered to achieve minimal measurement error and demonstrate statistical process capability and control.

Experienced micromoulding manufacturers balance the trade-offs between increasing the number of cavities in a mould and the challenges of validating those additional cavities. Higher cavitation in a tool enables increased throughput and potentially lower costs. However, the additional cavitation increases the challenge of tooling and process control, which increases the

complexity of validation. It’s also important to include in-process controls that enable components to be individually analysed by cavity.

EXPERIENCE IS CRITICAL FOR SUCCESS

The precise nature of micromoulding demands consistency and a deep working knowledge of tooling, equipment, process and material science, and engineering. Experts are needed to understand the challenges and variations that exist in micromoulding to anticipate and mitigate challenges before they occur. Finding a partner with longevity in the medical device industry and a significant depth of capabilities is invaluable for micromoulding.

CONCLUSION

Micromoulded parts are highly beneficial in the healthcare and medical industry because they facilitate development of medical devices to improve patients’ quality of life, shorten hospital stays, and reduce healthcare costs. The requirement for quality and invasive surgical methods, and a larger demographic of ageing people are driving demand for miniaturisation. Device manufacturers should consider the critical elements of micromoulding - tooling, equipment, process controls, knowledge of materials, measurement systems, process and product validation, and overall engineering expertise - and partner with experienced moulders to ensure devices deliver the desired quality, consistency and patient outcomes.

21 WWW. M EDICALPLASTICSNEWS .COM MICROMOULDING

According to the Healthcare Plastic Recycling Council design guidelines, medical packaging producers are obliged to follow specific rules when designing packaging solutions for healthcare products. The key mentioned demands include switching to monomaterials whenever possible, allowing easy separation during the recycling process and minimising the use of adhesives and inks.

The topic of packaging recyclability is just one aspect of the process, though. Another is the product safety, which must be safeguarded by the optimal choice of available sterilisation methods, and the overall packaging convenience for end-users.

SUSTAINABLE PACKAGING MATERIALS AT THE FOREFRONT

“At Coveris we take sustainability very seriously and focus on developing monomaterial solutions that offer up to 90% recyclability. The unquestionable benefit of mono structure is the fact that the material can be added to the recycling circle and reused, if necessary, to produce a new material”, explained Alexander Schmidt.

A good example are the packaging solutions recently introduced at Compamed trade show: the Formpeel T film, designed for bulk medical devices, and the Flexopeel T pouch film, both based on 100% PE material. Besides their sustainable benefits, they also allow easy processing on all conventional FFS lines, low re-shrinking and improved puncture resistance compared to standard PE. These solutions also perfectly fit with Ethylene Oxide (ETO) sterilisation, as well as X-ray and gamma irradiation. The advantage of monomaterials versus multi-layered structures was confirmed by Institute Cyclos-HTP, which proved in its research that monomaterial solutions can help save up to 48,000 tonnes of packaging waste.

OPTIMAL STERILISATION FOR EVERY MEDICAL PRODUCT

Once the sustainable packaging material is chosen, the healthcare companies need to select the optimal type of sterilisation to enhance their product protection.

Coveris offer packaging systems that provide microbial barrier, long-term stability, good performance during transport and work with three different types of sterilisation: high temperature (steam), ETO gas or irradiation (gamma or X-ray). However, due to different product needs, not every sterilisation type can be used.

For example, surgical instruments are usually sterilised using high temperatures (up to 134 degrees Celsius) from steam autoclave. This type of sterilisation is not only environmentally safe but also very cost-effective, reliable, and fast.

Still, it is not adequate for heat-sensitive materials, like syringes or tubes, which are sterilised using chemicals instead, like ethylene oxide gas. Although it safely eliminates bacteria in low temperatures (up to 60 degrees Celsius), it is a long and expensive process (can last up to 18 hours to complete) and may leave toxic residues than can contaminate the environment.

For single-use products like implants, gloves or IV systems, Coveris suggests gamma and X-ray radiation. “This method allows sterilisation even in lower temperatures from 30-40 degrees Celsius, comparable to using gas, takes usually less time to process (up to few hours) and is technically simpler and more cost-effective.”, summarised Michael Degener.

CONVENIENCE TAILORED TO INDIVIDUAL NEEDS

An equally important topic in designing the optimal medical packaging is usability, which can be enhanced by adding easy opening features, improving resistance to external factors or simplifying identification of the contents.

Additionally, the optimal packaging needs to eliminate potential contamination during its long-term storage. This can be achieved by hermetical sealing that ensures microbial impermeability.

Flexopeel film solution, for example, can offer up to 10 years of product shelf life, depending on individual product features.

Last, but not least, a truly convenient medical packaging should allow fast identification of the content. “This can be achieved by adding colour indicators, like in our Medipeel pouches and tubes, that reduce the timeconsuming application of labels. An alternative solution is a transparent pouch or bag that allows immediate identification”, added Degener.

WWW. M EDICALPLASTICSNEWS .COM 22 THERMOFORMING

ALEXANDER SCHMIDT AND MICHAEL DEGENER, PRODUCT DEVELOPMENT & TECHNICAL SUPPORT AT COVERIS, HIGHLIGHT THE THREE KEY ASPECTS WHEN DESIGNING SUSTAINABLE HEALTHCARE PACKAGING.

HIGH PERFORMANCE SOLUTIONS FOR LEADING MEDICAL APPLICATIONS.

Precision meets speed and cleanliness. The all-electric ELION is the ideal injection molding machine for the cost-effective mass production of consumables for in-vitro diagnostics, primary packaging and drug delivery systems, as well as healthcare and medical disposables.

• Clamping force range 800-2800 kN

• Cleanroom equipment adapted to your product requirements

Perfect precision and reproducibility

Excellent overall equipment effectiveness

Added productivity boost with NETSTAL Smart Operation (available as an option)

Leading price-performance ratio Worldwide customer service

More details on

SCAN ME

www.netstal.com NEW SERVICE Machine calibration according to ISO/IEC 17025:2017 on-site at customer’s premises

LAUREN ZETTS, GLOBAL HEAD OF MARKETING FOR HEALTHCARE AT COVESTRO, DELVES INTO THE DIFFERENT DEVICES THE COMPANY HAS DEVELOPED AND HOW THEY’RE CHANGING THE WAY WE DEAL WITH DRUG DELIVERY.

ome delivery

in this device utilise Makrolon 2458 for the biocompatibility and durability supporting an innovative device introduction to the market.

ADDRESSING TRENDS IN THE INDUSTRY

Device makers are addressing key mega trends and incorporating digital features into new devices. Connectivity in devices supports patient adherence to dosing and frequency all while allowing patients to administer in the convenience of their homes or on-the-go. Connectivity is also impacting this segment with smart pill dispensing. A concept developed in collaboration with Shenkar College of Engineer, Design and Art was created for enhanced safety and well-being of patients that depend on the regular use of medication. This smart pill dispenser concept intends to improve ease of use – offering reminders and notification when refills are needed for both the convenience of patients and caregivers.

Drug delivery is constantly changing – and the materials to support new applications must continue to evolve as well. Meeting current and future needs requires innovative materials to overcome age-old familiar hurdles and Covestro experts are leading the way.

Continuous innovation in the pharmaceutical industry requires novel drug delivery devices. These new devices can offer solutions to address ease-of-use, sustainability, and safety concerns for both patients and healthcare providers across a variety of treatments including flexibility to use at-home or on-the-go. As a result, devices such as inhalers, pens or autoinjectors have seen strong growth over a number of years. Advances in this space require innovative materials to ensure reliable administration of pharmaceuticals. Covestro’s medical portfolio of Makrolon polycarbonates (PC), Bayblend PC+ABS blend and Makroblend PC+ polyester grade plastics provide reliability and quality for use in drug delivery devices.

One device comes from Pirouette Medical with their single-use, portable auto-injector device for the safe dosing of epinephrine and other medications. With this disklike design, it considers the patient anxiety and unwanted attention that a traditional pen-like autoinjector can cause. A number of components

KEEPING IT SUSTAINABLE

Simply having a connected device is no longer enough. Consumers are increasingly demanding more sustainable solutions as well. Circular economy and sustainability are now considered by pharmaceutical and device companies in the design of new devices. In order to support this, Covestro has introduced a proof-of-concept drug delivery device. This device demonstrates by using polycarbonates in each piece, the possibility for simplified sorting and recycling after disposal of bio-contaminated pieces is available. Each material used can play a specific and significant role in creating a high-functioning and sustainable solution that can reduce medical waste and enhance patient comfort.

For further emphasis on sustainability, the expanding CQ portfolio of low carbon footprint materials now includes Makrolon RE polycarbonate, Bayblend RE PC+ABS and Apec RE high temperature PC for healthcare can also be used to support companies’ sustainability targets. These products offer a drop-in solution that utlise raw material from mass-balanced bio-waste and residues.

FURTHER DEVLOPMENTS IN DRUG DELIVERY DEVICES

Safety will always be a top priority in the healthcare industry. Needle-free injectors are one step to improve safety and prevent needle-stick injuries while ease-of-use and patient acceptance are also touted as benefits compared to traditional needle injections. Needle-free injectors find applications in vaccines and other treatments. One example of a needle-free injector is the PharmaJet’s Needle-free Injection System (NFIS) that provides a more effective way of administering drug and biologics and are preferred by patients, caregivers and healthcare workers.