4 minute read

Materials: Determining polymer compatibility with harsh healthcare disinfectants — Part I

from MPN EU Issue 60

by MPN Magazine

Determining polymer compatibility with harsh healthcare disinfectants — Part I

WITH THE SPATE OF NEW, HARSH DISINFECTANTS BEING USED IN HEALTHCARE SETTINGS — PRIMARILY IN RESPONSE TO THE COVID-19 PANDEMIC — DEVICE MANUFACTURERS NEED TO CONSIDER NEWER MATERIAL SOLUTIONS WITH IMPROVED CHEMICAL RESISTANCE TO WITHSTAND THE CUMULATIVE EFFECTS OF CLEANING. NITHIN RAIKAR, SENIOR BUSINESS MANAGER, LNP COPOLYMERS FOCUSES ON THE TEST FOR COMPATIBILITY WITH HEALTHCARE DISINFECTANTS AMONG DIFFERENT MATERIALS, SUCH AS INDUSTRY STANDARD PC BLENDS AND ADVANCED PC COPOLYMERS.

According to the World Health Organization, healthcare-associated infections (HAIs) are the most frequent adverse event in care delivery worldwide. As the COVID-19 pandemic has prompted hospitals and clinics to implement enhanced cleaning protocols, there has been a clear shift in the way plastics are viewed to address infection control challenges.

The introduction of new disinfectants has pushed device manufacturers and material suppliers to seek better understanding of the compatibility of new chemical agents on plastic materials. Specifically, device manufacturers need to consider newer material solutions with improved chemical resistance to withstand the cumulative effects of cleaning — the combination of aggressive disinfectants and increased frequency in protocols. Disinfectants such as alcohols, peroxides and quaternary ammonium compounds can cause traditional polymers to become brittle and crack, shortening the lifespan of costly and critical devices.

Medical professionals face a dilemma: How can they trust their devices to keep patients safe and function optimally with increased cleaning? To address this challenge, SABIC has developed a new family of materials. The company’s LNP ELCRES CRX polycarbonate (PC) copolymers can provide superior resistance to some of the harsh disinfectants that are the norm in healthcare today.

MATERIAL SELECTION FOR SAFER, LONGER-LASTING MEDICAL EQUIPMENT

A primary side effect of repeated cleanings on plastics is polymer embrittlement. When plastics come into contact with chemicals under stress, a phenomenon, known as environmental stress cracking, occurs. In terms of polymer chemistry, exposure to chemicals may result in either physical degradation (stress cracking, crazing, swelling and discoloration) or chemical attack (reaction of chemical with polymer and loss of properties).

Amorphous polymers such as acrylonitrile-butadiene-styrene (ABS) and polycarbonate (PC) resins were traditionally used for medical device housings and enclosures. When

chemical resistance initially became an issue and components made with these materials started to fail from environmental stress cracking, manufacturers began replacing ABS and PC with blends of PC and ABS or semi crystalline polybutylene terephthalate (PBT). Even these incumbents, however, can fall short in chemical resistance, especially in view of additional measures to prevent COVID 19 transmission.

To help maintain the structural integrity of medical devices, SABIC’s Specialties business launched a new product portfolio, LNP ELCRES CRX resins, leveraging a unique new copolymer building block to help meet the needs of this developing market. CRX copolymers are designed to reduce susceptibility to chemical attack and to help minimize crack propagation. In addition to chemical resistance, polymers used in device enclosures and housings need high impact properties to withstand being dropped or resist an external applied force. Additional polymer features include flame retardancy for powered devices and custom colourability to enable styling and aesthetics in part. The retention of impact strength from repeated application of disinfectants is also a key factor for durability over time.

Advanced PC copolymers such as CRX may be a material solution that ticks all the boxes so that hospitals can continue to use aggressive and effective forms of disinfectants to keep patients safe while also keeping medical equipment serviceable for longer periods of time. Device manufacturers may also be less likely to face costly requests to replace devices under warranty.

ENVIRONMENTAL STRESS CRACKING (ESC) TESTING

The ultimate laboratory test for a plastic material for use in a finished part would be one that measures the performance over an entire range of temperatures, impact forces, loads, and chemical exposures in its actual end use. Unfortunately, such thorough testing has not yet been fully developed and would be extremely costly.

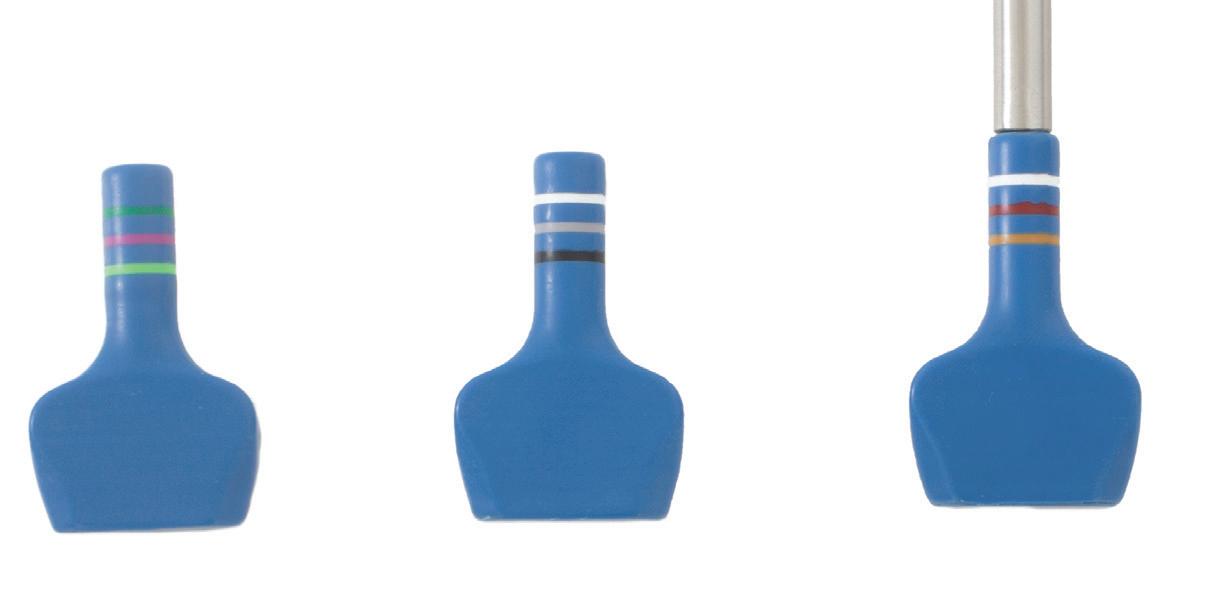

The ESC test has proven to be a useful indicator of expected performance and serves as a screening tool for polymer material candidates. SABIC follows an established ESC testing procedure (ASTM D543) to screen chemicals and environmental conditions that mimic the part application exposure. To test compatibility with various chemicals, SABIC has used a quantitative ESC test that evaluates retention of tensile properties from 3 to 7 days at 1% strain and at room temperature. These properties correlate to plastic failure modes and often provide insights on resistance to fracture. The test bars are kept saturated with the chemical agent (wrapped in disinfectant wipes) and are bent to a specific strain level (1% in this case) in a test fixture. Constant strain is maintained throughout the test period (Figure 1).

To demonstrate compatibility with a given chemical agent, a material must achieve >90% tensile stress at yield and 80–139% tensile elongation at break, per ASTM D638: Standard Test Method for Tensile Properties of Plastics.

With no widely adopted industry standard for chemical resistance testing, SABIC pushed the test conditions (the exposure duration and external stresses) to ensure that testing protocols serve as a highly accelerated version of real life exposure to disinfectant wipes in a healthcare setting. SABIC continues to collaborate with healthcare OEMs who are conducting their own testing to validate the materials in their applications and environment.

Note LNP and ELCRES are both Trademarks of SABIC or its subsidiaries or affiliates.