MATERIALS

Determining polymer compatibility with harsh healthcare disinfectants — Part I WITH THE SPATE OF NEW, HARSH DISINFECTANTS BEING USED IN HEALTHCARE SETTINGS — PRIMARILY IN RESPONSE TO THE COVID-19 PANDEMIC — DEVICE MANUFACTURERS NEED TO CONSIDER NEWER MATERIAL SOLUTIONS WITH IMPROVED CHEMICAL RESISTANCE TO WITHSTAND THE CUMULATIVE EFFECTS OF CLEANING. NITHIN RAIKAR, SENIOR BUSINESS MANAGER, LNP COPOLYMERS FOCUSES ON THE TEST FOR COMPATIBILITY WITH HEALTHCARE DISINFECTANTS AMONG DIFFERENT MATERIALS, SUCH AS INDUSTRY STANDARD PC BLENDS AND ADVANCED PC COPOLYMERS.

A

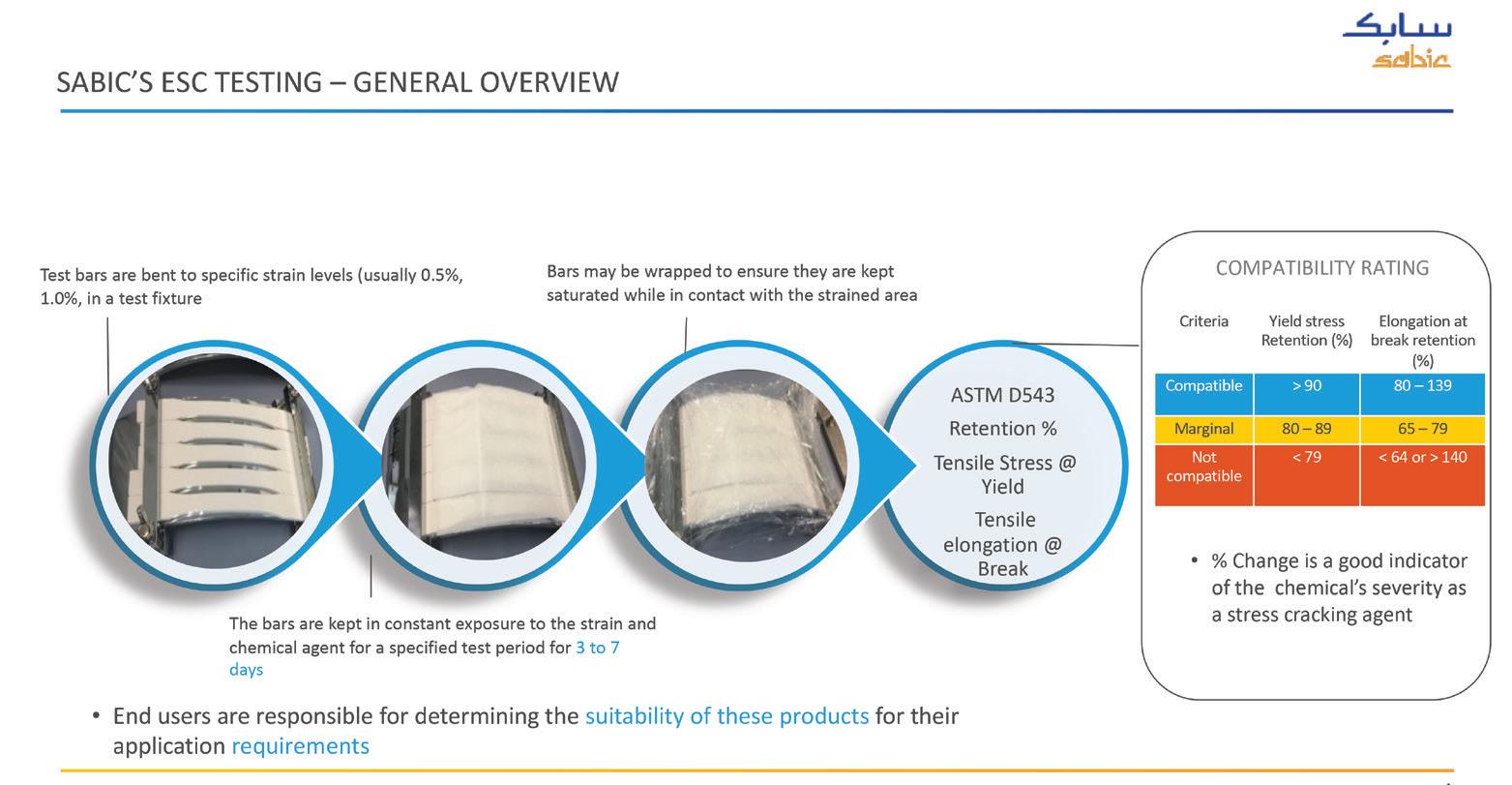

ccording to the World Health Organization, healthcare-associated infections (HAIs) are the most frequent adverse event in care delivery worldwide. As the COVID-19 pandemic has prompted hospitals and clinics to implement enhanced cleaning protocols, there has been a clear shift in the way plastics are viewed to address infection control challenges. The introduction of new disinfectants has pushed device manufacturers and material suppliers to seek better understanding of the compatibility of new chemical agents on plastic materials. Specifically, device manufacturers need to consider newer material solutions with improved chemical resistance to withstand the cumulative effects of cleaning — the combination of aggressive disinfectants and increased frequency in protocols. Disinfectants such as alcohols, peroxides and quaternary ammonium compounds can cause traditional polymers to become brittle and crack, shortening the lifespan of costly and critical devices. Medical professionals face a dilemma: How can they trust their devices to keep patients safe and function optimally with increased cleaning? To address this challenge, SABIC has developed a new family of materials. The company’s LNP ELCRES CRX polycarbonate (PC) copolymers can provide superior resistance to some of the harsh disinfectants that are the norm in healthcare today.

MATERIAL SELECTION FOR SAFER, LONGER-LASTING MEDICAL EQUIPMENT A primary side effect of repeated cleanings on plastics is polymer embrittlement. When plastics come into contact with chemicals under stress, a phenomenon, known as environmental stress cracking, occurs. In terms of polymer chemistry, exposure to chemicals may result in either physical degradation (stress cracking, crazing, swelling and discoloration) or chemical attack (reaction of chemical with polymer and loss of properties). Amorphous polymers such as acrylonitrile-butadiene-styrene (ABS) and polycarbonate (PC) resins were traditionally used for medical device housings and enclosures. When

W W W. M E D I C A L P L A S T I C S N E W S . C O M

19