6 minute read

Cover story

from MPN NA Issue 18

by MPN Magazine

ARJUN LUTHRA, COMMERCIAL DIRECTOR, BIOINTERACTIONS, DISCUSSES AN ENHANCED MULTI-ACTION BIOCOMPATIBLE COATING IS ENHANCING BIOCOMPATIBILITY AND ANTIMICROBIAL PROTECTION ON MEDICAL DEVICES FOR EXTENSIVE PERIODS OF TIME.

Killing germs inside you, on you & around you

The case for revolutionary technologies and solutions that greatly enhance the standards of our health services plays a significant role in our quality of living. This has never been more important than now.

Innovations which protect and enhance the standard routines used by healthcare services are in constant demand and are especially critical considering the global Covid-19 pandemic. As the pandemic has persisted, our healthcare services and innovative technologies battle to keep up with the viral evolutions as well as mitigate impact to core areas of healthcare services. This highlights the importance and the necessity for preventative technologies to be used at global scale to effectively prevent infections, reduce antibiotic resistance, and enhance healthcare infrastructure.

The prevention measures and standards must focus on efficacy against a broad spectrum of pathogens equal to medical device requirements, durable protection to minimise costs of implementation and safe variations which are biocompatible to allow for large scale application. Materials play a critical role in improving the performance of the technology and can improve the implementation and application into a range of environments and industries. The antimicrobial efficacy of materials involves critical interactions between the pathogen and surface interface. The successes of applications are dependent on a variety of biological events occurring at this interface and these events intensify the complications of procedures. This must be all addressed during innovation and development. The challenge of infection prevention will help us move toward long-term prevention mechanisms and enhanced medical devices as well as industrial & consumer products. The biological events which occur at the pathogensurface interface is critical to improving the prevention technology against pathogens. Biological responses are complex processes which are governed by a variety of factors. These factors range from surface properties to protein interactions which includes the chemistry, topography, wettability, as well as the composition of a surface and the biological entities present at the interface

Infection and pathogens on surfaces have been long studied as it is a significant challenge which has impeded improvement of long-term medical devices & a range of industrial applications. A variety of techniques including silver, copper, chlorhexidine, and other leaching chemistries used on medical devices have not proven to be significantly effective and highlight the need for an innovative solution. It has been seen in a randomized study of surface treatments to prevent infections that silver surface treatments have failed to reduce infection rates. It has also been seen that the use of silver-impregnated collagen cuffs can impede catheter fixation due to the killing of fibroblasts and cause the catheter to dislodge. Therefore, highlighting the limits and toxic impacts of similar leaching chemistries to silver technology on eukaryotic cells. Furthermore, it has been recommended that any catheter which has caused bacteremia should be immediately removed and only replaced once results of blood cultures normalised. This highlights the difficulty previous technologies experience when combating infections safely on a surface over long periods of time. These approaches have had limited success, whilst additionally requiring the consistent use of antibiotics, leading to resistance and further complications.

The biological events which occur on a surface are a complex result of interactions between the surface and the proteins and cells which are present at the pathogen-surface interface. These complex challenges require a multi-action material which considers all these varying factors in one straightforward technology. Multi-action materials provide a highperformance surface which are the most effective at preventing pathogen growth, as well as the longest durability, all whilst improving safety to the patient in one straight-forward solution.

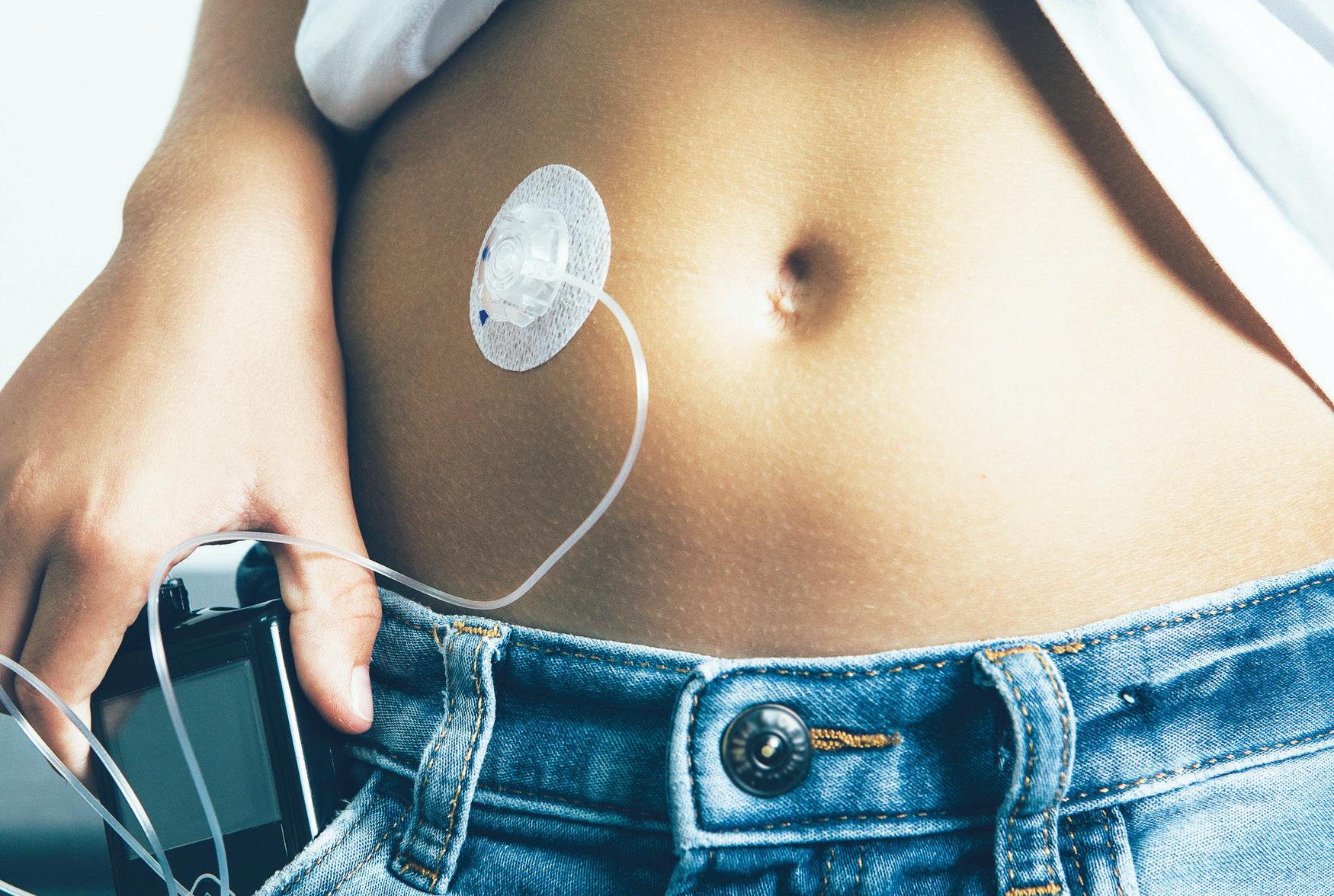

BioInteractions Ltd. have utilised their multi-action materials to develop TridAnt®, the most effective and advanced antimicrobial technology for medical devices. The technology enhances the protection against a broad spectrum of pathogens which includes gram-positive and gram-negative bacteria as well as yeast. TridAnt® is the only medical device coating which kills 99.999% (5 log reduction) of bacteria and yeast as for up to 100 days. We utilise advanced multi-action materials which are biocompatible and non-leaching to ensure a consistent level of efficacy on medical devices for extensive periods of time inside a patient.

TridAnt® biocompatible, antimicrobial technology is the only medical device coating to:

• Kills 99.999% of bacteria (gram positive and gram-negative) as well as yeast • Consistently protects medical devices which ensures devices maintain their protection for 100 days • Contact-Kill technology provides a highly effective mechanism to kills broad spectrum of pathogens as they interact with the device surface • Multi-Action material uses active and passive components to prevent deposition, protect against adhesion and kill pathogens on contact • Biocompatible and non-leaching coating assists in patient safety whilst targeting microbes

TridAnt® technology has been derived specifically to enhance the stateof-the-art in antimicrobial technology on medical devices. The technology utilises innovative features developed from over 30 years in the medical device industry to provide revolutionary benefits to the healthcare professional as well as the patient. The technology is the first of its kind to provide both market leading efficacy as well as the longest duration of an antimicrobial coating on a device. This is achieved by utilising multi-action materials to ensure the highest efficacy seen on a medical device to date. The non-leaching mechanisms ensure that antimicrobial efficacy stays on the surface and doesn’t flow through the blood. This also ensure that the amount of active component remains constant throughout the duration of the device to ensure a complete and consistent effect whilst implanted in a patient. The combination of highest efficacy, against a broad spectrum of pathogens for the longest duration seen on a medical device provides a platform for new procedures and products to be innovated. These benefits allow for devices to remain in the patient for longer, whilst also aiding in reducing the amount of antibiotics they are required to consume. TridAnt® has been further optimised to provide the World’s Most Advanced Infection Prevention Infrastructure. The prevention technology is the first line of defence and is a straightforward, long-term solution to protecting surfaces, preventing transmission, and controlling pathogens. The infrastructure provides enhanced protection against a broad spectrum of bacteria, viruses and fungi on surfaces ranging from stainless steel to skin. The infrastructure comprises of products which utilise TridAnt® technology to enhance protection and provide further long-term benefits to the healthcare and wider industrial environment. The use of TridAnt® as a daily tool provide a viable method to improve hygiene and healthcare standards whilst reducing maintenance costs as well as reliance on single-use items. The various products reduce the level of consumption of harsh chemicals as well as provides enhanced hygiene infrastructure which prevents future pathogens. The use of TridAnt® items actively disinfects surfaces on contact, therefore actively maintaining a healthy and hygienic environment. This helps us to move into a better normal where we maintain health and hygiene conveniently as well as reducing the costs of maintain the environment .

This complete infrastructure can be applied safely into schools, restaurants, hotels and hospitals to allow a swift recovery to our normal routines. TridAnt® technology uses hygiene of the future to bring back the good phoelings (“feelings) of the past.