Catalog

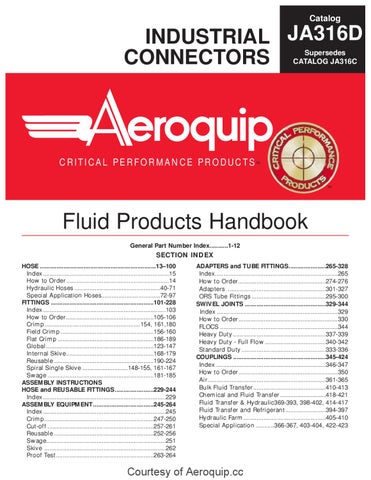

INDUSTRIAL JA316D CONNECTORS Supersedes CATALOG JA316C

CRITICAL PERFORMANCE PRODUCTS

TM

TM

Fluid Products Handbook General Part Number Index...........1-12

SECTION INDEX HOSE .....................................................................13–100 Index...........................................................................15 How to Order .............................................................14 Hydraulic Hoses ...................................................40-71 Special Application Hoses...................................72-97 FITTINGS .............................................................101-228 Index.........................................................................103 How to Order....................................................105-106 Crimp.........................................................154, 161,180 Field Crimp .......................................................156-160 Flat Crimp .........................................................186-189 Global................................................................123-147 Internal Skive....................................................168-179 Reusable ...........................................................190-224 Spiral Single Skive ...........................148-155, 161-167 Swage ...............................................................181-185 ASSEMBLY INSTRUCTIONS HOSE and REUSABLE FITTINGS.......................229-244 Index.........................................................................229 ASSEMBLY EQUIPMENT....................................245-264 Index.........................................................................245 Crimp.................................................................247-250 Cut-off ...............................................................257-261 Reusable ...........................................................252-256 Swage.......................................................................251 Skive ........................................................................262 Proof Test..........................................................263-264

ADAPTERS and TUBE FITTINGS......................265-328 Index.........................................................................265 How to Order....................................................274-276 Adapters ..........................................................301-327 ORS Tube Fittings ............................................295-300 SWIVEL JOINTS ................................................329-344 Index ........................................................................329 How to Order...........................................................330 FLOCS ......................................................................344 Heavy Duty .......................................................337-339 Heavy Duty - Full Flow ....................................340-342 Standard Duty ..................................................333-336 COUPLINGS .......................................................345-424 Index .................................................................346-347 How to Order...........................................................350 Air......................................................................361-365 Bulk Fluid Transfer ...........................................410-413 Chemical and Fluid Transfer ...........................418-421 Fluid Transfer & Hydraulic369-393, 398-402, 414-417 Fluid Transfer and Refrigerant........................394-397 Hydraulic Farm.................................................405-410 Special Application ...........366-367, 403-404, 422-423

Courtesy of Aeroquip.cc

Symbols

Hose Application Reference Industry symbols are provided for each hose indicating where it is typically used. But remember, a hose can be used in any industry, provided it meets the established application requirements. This list is provided as a guide. Final selection is further

dependent on pressure, fluid, fluid concentrations, temperature and intermittent or continuous exposures and government or industry specifications.

Air Conditioning

Air (High Pressure) Refer To Catalog JA466 for Further Information R-12 R-22 134A 1540 (p.86) FC202 (p.86) FC202 (p.86) FC363 (p.90) FC363 (p.90) FC363 (p.90) FC202 (p.86) FC505 (p.88) FC505 (p.88) FC505 (p.88) FC555 (p.88) FC555 (p.88) FC555 (p.88) FC655 (p.90) FC558 (p.86) FC655 (p.90) GH134 (p.88) FC765 (p.90)

Chemical Transfer

ALL FC202 FC363 FC505 FC555

(p.86) (p.90) (p.88) (p.88)

High Performance 2661 (p.40) FC318 (p.40) FC363 (p.90) FC364 (p.92) FC563 (p.92)

Low Temperature (–65°F)

Jack Hose See Performance Catalog JC86 FBA FBC FBG FBT FBU FBV

LPG

(10,000 PSI Max. for all Hoses) 2781-4 (p.60) FC136-06 (p.66) GH493-6 (p.66) GH781-4 (p.60)

Marine (Fuel & Oil)

2766 (p.62) FC474 (p.64)

Railroad Air Brake

1509 (p.44) 1529 (p. 60) FC300 (p.44)

FC321 (p.84)

FC234 p.78)

Sewer Cleaning 1531 (p.80) 1531A (p.80)

Shop Air FC700 (p. 74) FC701 (p. 76) FC702 (p. 76)

1525 (p.72) 2556 (p.72) 2565 (p.72) 2575 (p.74) FC332 (p.72)

Truck Heater FC252 (p. 82)

Utility

Coolant FC352 (p.84) (Straight Lengths Only)

Engine Fuel/Oil 1503 (p.44) FC235 (p.78) FC300 (p.44) FC350 (p.80) FC355 (p.80)

Air Brake 1503 (p.44) 2550 (p.82) 2570 (p. 82) FC300 (p.44) FC350 (p.80) FC355 (p.80)

Compressor 2807 (p.94) FC186 (p.94)

Power Steering 2555 (p. 78)

Waterblast FC372 (p.50) FC374 (p.52) FC376 (p.54)

(10,000 PSI Max. for all Hoses) FC254-08 (p.68)

© 1997 Aeroquip Corporation

Courtesy of Aeroquip.cc

Part Number Index Section Pages

Hose

13-100 101-228

Fittings

Part Number

Page

1A*BF* ..............................................139 1A*BFA*............................................140 1A*BFB*............................................140 1A*BP* ..............................................141 1A*BT* ..............................................141 1A*DK* ............................................143 1A*DL* ..............................................142 1A*DLA* ..........................................142 1A*DLB* ..........................................143 1A*DS* ............................................144 1A*DSA* ..........................................144 1A*DSB* ..........................................145 1A*EK* ..............................................145 1A*FL* ..............................................133 1A*FLA* ............................................134 1A*FLB* ............................................135 1A*FLD* ............................................135 1A*FLE* ............................................136 1A*FLG*............................................136 1A*JF* ..............................................146 1A*JM* ............................................139 1A*KF* ..............................................146 1A*KS*..............................................147 1A*KSA* ..........................................147 1A*KSB* ..........................................147 1A*SL* ..............................................132 1AA*FJ* ............................................124 1AA*FJA* ........................................125 1AA*FJB* ........................................126 1AA*FJC* ........................................127 1AA*FR* ..........................................129 1AA*FRA* ........................................130 1AA*FRB* ........................................131 1AA*FRC* ........................................131 1AA*FS* ..........................................128 1AA*MB* ..........................................128 1AA*MF* ..........................................132 1AA*MFA* ........................................132 1AA*MFB* ........................................133

Pages

Adapters, and Tube Fittings

265-328

Assembly Instructions

229-244

Swivel Joints

329-344

Assembly Equipment

245-264

Couplings

345-424

Section

Part Number

Page

1AA*MJ* ..........................................127 1AA*MP* ..........................................123 1AA*MR* ..........................................132 1AA*PS* ..........................................123 1AP*FL* ............................................133 1AP*FLA*..........................................134 1AP*FLB* ..........................................135 1AP*FLD*..........................................135 1AP*FLE* ..........................................136 1AP*JF* ............................................146 1AP*JM* ..........................................139 1AP*SL* ............................................132 1AR*FJ* ............................................124 1AR*FJA* ........................................125 1AR*FJB*..........................................126 1AR*FJC*..........................................127 1AR*FR*............................................129 1AR*FRA* ........................................130 1AR*FRB* ........................................131 1AR*FRC* ........................................131 1AR*MB* ..........................................128 1AR*MJ* ..........................................127 1AR*MP* ..........................................123 1AT*BF* ............................................139 1AT*BFA*..........................................140 1AT*BFB*..........................................140 1AT*BT* ............................................141 1AT*DK*............................................143 1AT*DL* ............................................142 1AT*DLA* ........................................142 1AT*DLB*..........................................143 1AT*FLA* ..........................................134 1AT*FLB* ..........................................135 1AT*FLD* ..........................................135 1AT*JF* ............................................146 1AT*JM* ..........................................139 1AT*SL* ............................................132 1AV*FJ* ............................................124 1AV*FJA*..........................................125

RETURN TO CONTENTS PAGE Courtesy of Aeroquip.cc

Part Number

Page

1AV*FJB* ..........................................126 1AV*FJC* ..........................................127 1AV*FR* ............................................129 1AV*FRA* ........................................130 1AV*FRB*..........................................131 1AV*FRC*..........................................131 1AV*MB* ..........................................128 1AV*MJ* ..........................................127 1AV*MP* ..........................................123 1B*BF* ..............................................139 1B*BFA* ............................................140 1B*BFB* ............................................140 1B*BT* ..............................................141 1B*DS*..............................................144 1B*DSA* ..........................................144 1B*DSB* ..........................................145 1B*EK* ..............................................145 1B*FH* ..............................................137 1B*FHA* ..........................................137 1B*FHB*............................................138 1B*FHD* ..........................................137 1B*FHE* ............................................138 1B*FHF* ............................................137 1B*FHG* ..........................................138 1B*FL* ..............................................133 1B*FLA* ............................................134 1B*FLB* ............................................135 1B*FLD* ............................................135 1B*FLE* ............................................136 1B*FLF* ............................................136 1B*FLG* ............................................136 1B*JF* ..............................................146 1B*KF* ..............................................146 1B*KS* ..............................................147 1B*KSA* ..........................................147 1B*KSB* ..........................................147 1B*SL* ..............................................132 1BA*FJ* ............................................124 1BA*FJA* ........................................125

1

Part Number Index

Section

Pages

Part Number Index

Part Number Index

Part Number

Page

1BA*FJB*..........................................126 1BA*FJC*..........................................127 1BA*FR*............................................129 1BA*FRA* ........................................130 1BA*FRB* ........................................131 1BA*FRC* ........................................131 1BA*FS*............................................128 1BA*MB* ..........................................128 1BA*MJ* ..........................................127 1BA*MP* ..........................................123 1BA*MR* ..........................................132 1G*BF* ..............................................139 1G*BFA*............................................140 1G*BFB* ..........................................140 1G*BP*..............................................141 1G*BT*..............................................141 1G*DK* ............................................143 1G*DL*..............................................142 1G*DLA* ..........................................142 1G*DLB* ..........................................143 1G*DS* ............................................144 1G*DSA* ..........................................144 1G*DSB* ..........................................145 1G*EK*..............................................145 1G*FL* ..............................................133 1G*FLA*............................................134 1G*FLB*............................................135 1G*FLG* ..........................................136 1G*JF* ..............................................146 1G*JM* ............................................139 1G*KF* ..............................................146 1G*KS* ............................................147 1G*KSA* ..........................................147 1G*KSB* ..........................................147 1G*SL* ..............................................132 1GA*FJ*............................................124 1GA*FJA* ........................................125 1GA*FJB* ........................................126 1GA*FJC* ........................................127 1GA*FR* ..........................................129 1GA*FRA* ........................................130 1GA*FRB* ........................................131 1GA*FRC* ........................................131 1GA*FS* ..........................................128 1GA*MB* ..........................................128 1GA*MF* ..........................................132 1GA*MFA* ........................................132

Part Number

Page

1GA*MFB* ........................................133 1GA*MJ* ..........................................127 1GA*MP* ..........................................123 1GA*MR* ..........................................132 1GA*PS* ..........................................123 1S*BF* ..............................................139 1S*BFA* ............................................140 1S*BFB*............................................140 1S*BP* ..............................................141 1S*BT* ..............................................141 1S*DK*..............................................143 1S*DL* ..............................................142 1S*DLA* ..........................................142 1S*DLB*............................................143 1S*DS*..............................................144 1S*DSA* ..........................................144 1S*EK* ..............................................145 1S*FL* ..............................................133 1S*FLA* ............................................134 1S*FLB* ............................................135 1S*FLD* ............................................135 1S*FLE* ............................................136 1S*FLG*............................................136 1S*JF* ..............................................146 1S*JM* ............................................139 1S*KF* ..............................................146 1S*KS* ..............................................147 1S*KSA* ..........................................147 1S*KSB* ..........................................147 1S*SL* ..............................................132 1SA*FJ* ............................................124 1SA*FJA* ........................................125 1SA*FJB*..........................................126 1SA*FJC*..........................................127 1SA*FR*............................................129 1SA*FRA* ........................................130 1SA*FRB* ........................................131 1SA*FRC* ........................................131 1SA*FS*............................................128 1SA*MB* ..........................................128 1SA*MF* ..........................................132 1SA*MFA* ........................................132 1SA*MFB* ........................................133 1SA*MJ* ..........................................127 1SA*MP* ..........................................123 1SA*MR* ..........................................132 1SA*PS* ..........................................123

Part Number

Page

2S72000 ............................................420 2S72001 ............................................421 2S72003 ............................................421 2S72004 ............................................421 2S72005 ............................................421 2S72006 ............................................421 2S72007 ............................................421 2S73000 ............................................419 2S73001 ............................................419 2S73002 ....................................419, 421 2S73005 ............................................419 2S73006 ............................................419 2S73007 ....................................419, 421 2S73008 ............................................419 2S73009 ............................................419 2S73010 ....................................419, 421 2S73011 ............................................419 2S75003 ............................................421 07.001 ................................................219 07.002 ........................................195-196 07.003 ................................................195 07.005 ................................................206 07.006 ................................................219 07.013 ................................................206 07.020 ................................................206 07.021 ................................................218 07.024 ................................................195 07.025 ................................................218 07.026 ................................................195 07.036 ................................................195 07.078 ................................................206 07.114 ................................................219 07.122 ................................................218 07.155 ................................................196 07.327 ................................................207 07.329 ................................................207 07.340 ................................................194 07.390 ................................................218 07.420 ................................................206 07.421 ................................................194 15.063 ................................................325 15.117 ................................................325 15.147 ................................................325 15.163 ................................................326 15.164 ................................................325 15.165 ................................................326 44-411................................................190

2

Courtesy of Aeroquip.cc

Part Number Index Part Number

Page

Page

2025 ..................................................308 2027 ..................................................314 2028 ..................................................309 2029 ..................................................310 2030 ..................................................309 2031 ..................................................310 2033 ..................................................316 2038 ..................................................220 2039 ..................................................315 2040 ..................................................301 2041 ..................................................314 2041-1................................................314 2042 ..................................................315 2042-1................................................315 2043 ..................................................315 2043-1................................................315 2044 ..................................................307 2045 ..................................................302 2046 ..................................................302 2047 ..................................................303 2048 ..................................................303 2049 ..................................................302 2050 ..................................................302 2060 ..................................................311 2061 ..................................................318 2061-1................................................318 2062 ..................................................318 2062-1................................................318 2063 ..................................................326 2066 ..................................................312 2067 ..................................................312 2067-1................................................312 2068 ..................................................312 2068-1................................................312 2070 ..................................................315 2071 ..................................................315 2080 ..................................................305 2081 ............................................38, 301 2082 ..................................................301 2083 ..................................................301 2084 ..................................................301 2085 ..................................................303 2087 ..................................................304 2088 ..................................................302 2089 ..................................................303 2090 ..................................................305 2091 ..................................................304

Part Number

Page

2092 ..................................................304 2093 ..................................................304 2096 ..................................................302 2215 ..................................................314 2216 ..................................................312 2216-1................................................312 2222 ..................................................301 2239 ..................................................306 2240 ..................................................306 2242 ..................................................306 2243 ..................................................307 2244 ..................................................308 2246 ..................................................312 2247 ..................................................302 2249 ..................................................308 2250 ..................................................308 2251 ..................................................303 2252 ..................................................303 2253 ..................................................304 2254 ..................................................304 2255 ..................................................304 2256 ..................................................304 2257 ..................................................304 2261 ..................................................313 2266 ..................................................318 2550 ............................................82, 239 2554 ............................................82, 239 2555 ............................................78, 239 2556 ............................................72, 237 2565 ............................................72, 237 2570 ............................................82, 239 2575 ............................................74, 237 2580 ....................................42, 236, 241 2583 ....................................................42 2651 ....................................46, 236, 241 2661 ............................................40, 241 2681 ....................................................48 2766 ............................................62, 236 2781 ............................................60, 236 2807 ............................................94, 240 2808 ............................................96, 240 4007 ..........................................108, 235 4010 ..........................................108, 235 4013 ..........................................108, 235 4401 ..................................................190 4402 ..................................................191 4411 ..................................................190

3

Courtesy of Aeroquip.cc

Part Number Index

44-412 ................................................190 150–22 ..............................................393 302A ....................................44, 236, 241 303 ......................................44, 236, 241 401 ....................................................190 403 ....................................................193 406 ....................................................190 411 ....................................................190 412 ....................................................190 458 ....................................................221 487 ....................................................396 583 ....................................................252 624 ..............................................37, 244 1206 ..........................................108, 235 1208 ..........................................108, 235 1210 ..........................................108, 235 1212 ..........................................108, 235 1214 ..........................................108, 235 1219 ..........................................108, 235 1290 ..................................................324 1503 ....................................44, 236, 241 1508 ............................................64, 238 1525 ............................................72, 237 1529 ............................................60, 236 1531 ............................................80, 239 1531A ..........................................80, 239 1540 ....................................86, 236, 241 1561 ..................................................252 1562 ..........................................253, 255 1563 ..................................................252 1582 ..................................................252 1597 ..................................................255 1598 ..................................................255 1599 ..................................................255 2000 ............................................38, 311 2001 ..................................................311 2002 ..................................................312 2003 ............................................38, 311 2004 ..................................................324 2007 ..................................................311 2015 ..................................................301 2018 ..................................................306 2020 ..................................................317 2021 ..................................................305 2022 ..................................................306 2023 ..................................................307 2024 ..................................................307

Part Number

Part Number Index

Part Number Index

Part Number

Page

4412 ..................................................190 4414 ..................................................191 4624 ..................................................322 4706 ..................................................210 4720 ..................................................204 4721 ..................................................203 259-4721............................................203 4722 ..................................................203 4725 ..................................................203 4729 ..................................................209 4730 ..................................................210 4738 ............................................38, 216 4739 ............................................38, 216 4740 ............................................38, 217 4741 ..................................................216 4742 ............................................38, 217 4743 ............................................38, 217 4744 ..................................................204 4745 ..................................................204 4750 ..................................................217 4753 ..................................................216 4767 ..................................................205 4772 ..................................................217 4775 ..................................................192 4776 ..................................................192 4777 ..................................................192 4779 ..................................................192 4790 ..................................................205 4797 ............................................38, 216 5100 ..........................................391, 393 5100–22 ............................................393 5100–S2 ............................................392 5100–S4 ............................................392 5100–S5 ............................................392 5100–S7 ............................................393 5100–S9 ............................................393 5101 ..................................................392 5110 ..................................................393 5110–S5 ............................................392 5111 ..................................................393 5144 ....................................................38 5400............................................394-397 5400–17 ............................................397 5400–53 ............................................397 5400–54 ............................................397 5400–S16 ..........................................397 5400–S19 ..........................................397

Part Number

Page

5400–S2 ............................................395 5400–S5 ............................................395 5400–S6 ............................................396 5400–S8 ............................................396 5400–S20 ..........................................397 5401 ..................................................396 5401–S14 ..........................................396 5401–S17 ..........................................395 5410 ..................................................395 5410–S14 ..........................................395 5410–S17 ..........................................395 5600 ............................................398-402 5601 ..................................................399 5602 ..................................................399 5603 ..................................402, 406, 408 5606 ..................................................401 5608 ..................................................401 5610 ..................................................401 5642 ..................................................399 5643 ..................................................399 5644 ..................................................399 5650 ..................................................400 5651 ..................................................400 5657 ..................................402, 406, 408 5659 ..................................402, 406, 408 5667 ..................................................402 5668 ..................................................402 5690 ..................................................402 5691 ..................................................401 22008 ................................................397 22012 ........................................228, 328 22033 ........................................228, 328 22046..................................227-228, 328 22068 ........................................228, 328 22546 ..................227-228, 328, 396-397 22617..........................227-228, 317, 328 23055 ..................................................37 62017 ................................................343 62018 ................................................343 62019 ................................................343 62020 ................................................343 62021 ................................................343 62022 ................................................343 62023 ................................................343 71416 ................................................322 71418 ................................................321 71422 ................................................322

Part Number

Page

71423 ................................................322 73014 ................................................322 73056 ................................................313 449-74446..................................226, 321 190000 ..............................................191 190111 ..............................................193 190231 ..............................................220 190235 ..............................................193 190260 ..............................................191 190261 ..............................................191 190263 ..............................................204 190264 ..............................................204 190265 ..............................................191 190276 ..............................................193 190277 ..............................................193 190287 ..............................................204 190295 ..............................................191 190296 ..............................................191 190297 ..............................................191 190299 ..............................................191 190301 ..............................................191 190302 ..............................................191 190326 ..............................................217 190327 ..............................................217 190328 ..............................................217 190350 ..............................................193 190371 ..............................................193 190414 ..............................................204 190463 ..............................................191 190464 ..............................................203 190468 ..............................................210 190469 ..............................................210 190470 ..............................................210 190516 ..............................................217 190528 ..............................................210 63-190535..........................................224 63-190600..........................................222 190604 ..............................................219 190605 ..............................................219 190606 ..............................................219 190607 ..............................................220 190608 ..............................................220 190609 ..............................................220 63-190626..........................................223 38-190627..........................................222 38-190628..........................................224 190672 ..............................................216

4

Courtesy of Aeroquip.cc

Part Number Index

Part Number

Page

Page

203101 ..............................................317 203102 ..............................................317 203103 ..............................................309 203104 ..............................................309 203301 ..............................................308 206209 ..............................................318 206209-1 ............................................318 206604 ..............................................312 206801 ..............................................313 206801-1 ............................................313 206804 ..............................................313 206804-1 ............................................313 208006 ..............................................305 208007 ..............................................305 210212 ..............................................310 210292 ..............................................310 210294 ..............................................323 221501 ..............................................315 222005 ........................................36, 244 222022 ........................................36, 244 222070 ..............................................230 226601 ..............................................318 472003 ..............................................210 474503 ..............................................211 476003 ..............................................211 476703 ..............................................211 479001 ..............................................211 479003 ..............................................211 479301 ..............................................219 479501 ..............................................219 479601 ..............................................219 500023 ..............................................319 500024 ..............................................320 500025 ..............................................319 500454 ..............................................316 504089 ..............................................321 504095 ..............................................316 560078 ..............................................401 565006 ..............................................400 565007 ..............................................400 565014 ..............................................402 565015 ..............................................402 900564 ........................................37, 243 900598 ..............................................318 900598-1 ............................................318 900599 ..............................................314 900605 ..............................................324

Part Number

Page

900705 ........................................36, 243 900729 ................................................36 900774 ..............................................220 900952 ........................................37, 243 AE13702–003 ....................................230 AE18900 ............................................413 BD5500 ..............................................333 BD55000 ............................................334 BD55001 ............................................334 BD55004 ............................................334 BD55005 ............................................334 BD55009 ............................................335 BD55011 ............................................335 BD55012 ............................................335 BD55014 ............................................335 BD55015 ............................................335 BD55021 ............................................336 BD55029 ............................................336 BD55031 ............................................336 BD55058 ............................................336 F2015 ................................................256 F2636 ................................................260 FA2877NPNO120 ..............................221 FA5644NPNO120 ..............................221 FB9218 ................................................74 FB9219 ................................................74 FB9220 ................................................74 FC136 ..........................................66, 238 FC186 ..........................................94, 240 FC194 ..................................................46 FC195 ..........................................58, 236 FC202 ..................................86, 236, 241 FC211 ..........................................48, 238 FC212 ..........................................62, 238 FC234 ..................................78, 236, 241 FC235 ..................................................78 FC250A ........................................66, 238 FC252 ..........................................82, 243 FC254 ..................................................68 FC273 ..................................................68 FC300 ..................................44, 236, 241 FC310 ..........................................56, 236 FC318 ..........................................40, 241 FC321 ..................................84, 236, 241 FC323 ..................................................64 FC324 ..................................................68 FC325 ..................................................70

5

Courtesy of Aeroquip.cc

Part Number Index

190718 ........................................39, 223 190742 ........................................39, 224 190772 ..............................................223 190773 ..............................................223 190800 ..............................................219 190846 ..............................................192 190933 ..............................................212 190934 ..............................................212 190935 ..............................................213 190936 ..............................................214 190937 ..............................................215 190944 ..............................................217 190950 ..............................................224 63-190990....................................39, 223 190992 ..............................................212 190997 ..............................................211 191000 ..............................................203 38-191074....................................39, 223 191321 ..............................................217 191395 ..............................................192 200001 ..............................................325 202003 ..............................................310 202006 ..............................................310 202113 ..............................................306 202114 ..............................................306 202124 ..............................................324 202208........................................396-397 202220 ..............................................396 202232 ..............................................322 202411 ..............................................307 202413 ..............................................307 202414 ..............................................308 202701 ..............................................317 202702 ..............................................317 202703 ..............................................318 202712 ..............................................314 202713 ..............................................318 202901 ..............................................309 203002 ..............................................316 203002-1............................................316 203003 ..............................................319 203003-1............................................319 203005 ..............................................319 203005-1............................................319 203006 ..............................................309 203007 ..............................................308 203008 ..............................................317

Part Number

Part Number Index

Part Number Index

Part Number

Page

FC332 ..........................................72, 237 FC350 ..................................80, 236, 241 FC352 ..........................................84, 243 FC355 ..................................80, 236, 241 FC363 ..........................................90, 242 FC364 ..........................................92, 242 FC372 ..........................................50, 239 FC373 ..........................................50, 239 FC374 ..................................................52 FC375 ..................................................54 FC376 ..................................................54 FC377 ..................................................54 FC390 ..................................................52 FC425 ..................................................37 FC465 ..........................................94, 240 FC466 ..................................................40 FC469 ..................................................96 FC474 ..................................................64 FC498 ..................................................42 FC505 ..................................................88 FC510 ..........................................58, 236 FC555 ..................................................88 FC558 ..................................86, 236, 241 FC563 ..........................................92, 242 FC606 ..................................................70 FC650 ..................................................76 FC665 ..................................................90 FC690 ..................................................52 FC700 ..................................................74 FC701 ..................................................76 FC702 ..................................................76 FC765 ..................................................90 FC1229 ..............................................296 FC1347 ..............................107, 188-189 FC1349 ......................................188-189 FC1373 ......................................188-189 FC1389 ..............................188-189, 222 FC1410 ......................................151-155 FC1411 ......................................148, 155 FC1531 ......................................188, 189 FC1586 ......................................108, 235 FC1601 ......................................107, 179 FC1851 ..............................................295 FC1857 ..............................................296 FC1941 ......................................108, 235 FC2119 ..............................226, 321-322 FC2325 ..............................................296

Part Number

Page

Part Number

Page

FC2326 ..............................................297 FC2383 ......................................108, 235 FC2540 ..............................107, 168-178 FC2542 ......................................108, 235 FC2642 ......................................108, 235 FC2652 ......................................108, 235 FC2697 ......................................168, 174 FC2710 ......................................168, 174 FC2713 ......................................226, 321 FC2717 ..............................107, 168-178 FC2875 ..............................................323 FC3023 ......................................107, 161 FC3425 ......................................226, 321 FC3443 ..............................107, 186, 187 FC3459 ......................................321-322 FC3471 ..............................107, 148-154 FC3596 ..............................107, 186-187 FC3680 ..............................................186 FC4014 ......................................168, 174 FC4049 ......................................169, 176 FC4050 ..............................................169 FC4051 ......................................170, 177 FC4052 ..............................................170 FC4053 ......................................172, 177 FC4054 ..............................................171 FC4098 ..............................................187 FC4373 ......................................171, 177 FC4374 ......................................170, 176 FC4387 ......................................170, 176 FC4507 ..............................................169 FC4513 ..............................................171 FC4562 ......................................168, 175 FC4564 ......................................169, 175 FC4571 ......................................168, 175 FC4582 ..............................................177 FC4612 ..............................................170 FC4957 ..............................................150 FC4960 ..............................................152 FC5014 ..............................................168 FC5026 ..............................................168 FC5049 ..............................................169 FC5050 ..............................................169 FC5051 ..............................................170 FC5052 ..............................................170 FC5053 ..............................................172 FC5054 ..............................................171 FC5060 ..............................................214

FC5075 FC5098 FC5130 FC5131 FC5133 FC5135 FC5136 FC5137 FC5138 FC5139 FC5140 FC5141 FC5142 FC5143 FC5144 FC5258 FC5275 FC5321 FC5322 FC5323 FC5325 FC5327 FC5329 FC5370 FC5371 FC5372 FC5373 FC5374 FC5379 FC5380 FC5387 FC5432 FC5503 FC5504 FC5507 FC5513 FC5560 FC5562 FC5564 FC5571 FC5582 FC5612 FC5805 FC5806 FC5807 FC5808 FC5809

..............................................199 ..............................................187 ..............................................200 ..............................................200 ..............................................200 ..............................................201 ..............................................201 ..............................................201 ..............................................201 ..............................................201 ..............................................201 ..............................................202 ..............................................201 ..............................................201 ..............................................200 ..............................................168 ..............................................180 ..............................................174 ..............................................174 ..............................................174 ..............................................176 ..............................................177 ..............................................177 ..............................................176 ..............................................177 ..............................................176 ..............................................171 ..............................................170 ..............................................200 ..............................................201 ..............................................170 ..............................................207 ..............................................175 ..............................................171 ..............................................169 ..............................................171 ..............................................175 ..............................................168 ..............................................169 ..............................................168 ..............................................171 ..............................................170 ..............................................181 ..............................................181 ..............................................181 ..............................................182 ..............................................182

6

Courtesy of Aeroquip.cc

Part Number Index

Page

Part Number

Page

FC5810 FC5811 FC5812 FC5813 FC5814 FC5847 FC5848 FC5849 FC5853 FC5936 FC5937 FC5954 FC5957 FC5960 FC5963 FC5965 FC5967 FC5969 FC5973 FC5974 FC5975 FC5976 FC5977 FC5978 FC5979 FC5980 FC5981 FC5982 FC5983 FC5984 FC5985 FC5986 FC5987 FC5988 FC5989 FC5990 FC5991 FC5992 FC5993 FC6216 FC6217 FC6220 FC6330 FC7031 FC7048 FC7049 FC7216

..............................................182 ..............................................183 ..............................................183 ..............................................183 ..............................................183 ..............................................217 ..............................................217 ..............................................217 ..............................................216 ..............................................183 ..............................................183 ..............................................196 ..............................................150 ..............................................152 ..............................................149 ..............................................149 ..............................................149 ..............................................149 ..............................................213 ..............................................213 ..............................................214 ..............................................214 ..............................................214 ..............................................212 ..............................................212 ..............................................213 ..............................................213 ..............................................213 ..............................................213 ..............................................213 ..............................................208 ..............................................208 ..............................................208 ..............................................208 ..............................................208 ..............................................208 ..............................................208 ..............................................208 ..............................................208 ..............................................187 ..............................................187 ..............................................187 ..............................................152 ..............................................193 ..............................................197 ..............................................197 ..............................................187

FC7217 FC7220 FC7275 FC7330 FC7370 FC7371 FC7372 FC7373 FC7374 FC7474 FC7573 FC7597 FC7603 FC7606 FC7639 FC7640 FC7646 FC7662 FC7703 FC7713 FC7714 FC7715 FC7740 FC7790 FC7811 FC7882 FC7883 FC7983 FC7984 FC7985 FC7986 FC7987 FC7988 FC7989 FC7990 FC7991 FC7992 FC8152 FC8153 FC8155 FC8625 FC8627 FC8724 FC8725 FC8726 FC8727 FC8779

..............................................187 ..............................................187 ..............................................219 ..............................................152 ..............................................213 ..............................................214 ..............................................214 ..............................................214 ..............................................215 ..............................................197 ..............................................197 ..............................................180 ..............................................180 ..............................................180 ..............................................212 ..............................................212 ..............................................197 ..............................................197 ..............................................215 ..............................................213 ..............................................213 ..............................................214 ..............................................212 ..............................................214 ..............................................214 ..............................................180 ..............................................180 ..............................................213 ..............................................214 ..............................................198 ..............................................198 ..............................................198 ..............................................198 ..............................................199 ..............................................199 ..............................................199 ..............................................199 ..............................................161 ..............................................161 ..............................................161 ..............................................149 ..............................................149 ..............................................151 ..............................................150 ..............................................152 ..............................................153 ..............................................186

Part Number

Page

FC8802 ..............................................152 FC8853 ..............................................150 FC8854 ..............................................151 FC8855 ..............................................151 FC8856 ..............................................153 FC8929 ..............................................150 FC9034 ..............................................214 FC9062 ..............................................224 FC9063 ..............................................224 FC9066 ..............................................214 FC9118 ..............................................214 FC9152 ..............................................161 FC9153 ..............................................161 FC9155 ..............................................161 FC9171 ..............................................223 FC9341 ..............................................223 FC9459 ..............................................214 FC9625 ..............................................149 FC9634 ..............................................213 FC9724 ..............................................151 FC9725 ..............................................150 FC9726 ..............................................152 FC9727 ..............................................153 FC9779 ..............................................186 FC9802 ..............................................152 FC9846 ..............................................186 FC9853 ..............................................150 FC9854 ..............................................151 FC9855 ..............................................151 FC9856 ..............................................153 FC9929 ..............................................150 FD15 ..................................................366 FD15–1000 ........................................367 FD15–1002 ........................................367 FD15–1025 ........................................367 FD15–1026 ........................................367 FD21 ..................................................368 FD21–1001 ........................................369 FD21–1002 ........................................369 FD35 ..................................................370 FD35–1000 ........................................371 FD35–1001 ........................................371 FD35–1002 ........................................371 FD35–1006 ........................................372 FD35–1007 ........................................371 FD35–1008 ........................................371 FD35–1042 ........................................372

7

Courtesy of Aeroquip.cc

Part Number Index

Part Number

Part Number Index

Part Number Index

Part Number

Page

FD35–1043 ........................................372 FD35–1044 ........................................372 FD40 ..................................................360 FD40–1000 ........................................361 FD40–1001 ........................................361 FD40–1013 ................................361, 365 FD40–1014 ................................361, 365 FD41 ..................................................362 FD41–1000 ........................................363 FD41–1013 ........................................363 FD41–1014 ........................................363 FD42 ..................................................373 FD42–1000 ........................................374 FD42–1001 ........................................374 FD42–1002 ........................................374 FD42–1006 ........................................374 FD42–1008 ........................................374 FD42–1010 ........................................374 FD43 ..................................................364 FD43–1001 ........................................365 FD43–1011 ........................................365 FD43–1031 ........................................365 FD45 Brass ........................................379 FD45 Stainless Steel ........................382 FD45 Steel ........................................376 FD45–1000 ........................................377 FD45–1001 ........................................383 FD45–1002 ........................................377 FD45–1003 ........................................377 FD45–1004 ........................................383 FD45–1005 ........................................383 FD45–1040 ........................378, 381, 384 FD45–1041 ........................378, 381, 384 FD45–1044 ........................................378 FD45–1045 ........................................378 FD45–1046 ........................................378 FD45–1047 ........................................377 FD45–1052 ........................................384 FD45–1053 ........................................383 FD45–1056 ........................................384 FD45–1059 ........................................384 FD45–1061 ........................................377 FD45–1062 ........................................383 FD45–1063 ........................................377 FD45–1064 ........................................377 FD45–1065 ........................................377 FD45–1070 ........................................377

Part Number

Page

FD45–1071 ........................................377 FD45–1072 ........................................377 FD45–1075 ........................................383 FD45–1076 ........................................383 FD45–1078 ........................................383 FD45–1086 ........................................380 FD45–1090 ........................................380 FD45–1091 ........................................380 FD45–1092 ........................................380 FD45–1100 ........................................380 FD45–1101 ........................................380 FD45–1120 ........................................383 FD45–1121 ........................................383 FD45–1122 ........................................383 FD45–1142 ........................................383 FD45–1143 ........................................384 FD45–1153 ........................................380 FD45–1156 ........................................380 FD45–1157 ........................................380 FD45–1172 ........................................377 FD45–1173 ........................................378 FD45–1174 ........................................381 FD45–1175 ........................................380 FD45–1176 ........................................380 FD45–1177 ........................................381 FD45–1178 ........................................380 FD45–1179 ........................................381 FD45–1180 ........................................380 FD45–1194 ........................................384 FD45–1195 ........................................383 FD45–1197 ........................................384 FD45–1199 ........................................381 FD45–1201 ........................................381 FD45–1203 ........................................381 FD45–1206 ........................................378 FD45–1207 ........................................377 FD45–1209 ........................................384 FD45–1211 ........................................381 FD45–1228 ........................................378 FD45–1229 ........................................378 FD45–1267 ........................................385 FD45–1270 ........................................385 FD45–1399 ........................................380 FD45–1400 ........................................380 FD48 ..................................................386 FD48–1000 ........................................387 FD48–1001 ........................................387

Part Number

Page

FD48–1002 ........................................387 FD48–1042 ................................375, 387 FD49 ..................................................388 FD49–1001 ........................................389 FD49–1002 ........................................389 FD49–1004 ........................................389 FD49–1005 ........................................389 FD49–1014 ........................................390 FD49–1042 ........................................390 FD49–1057 ........................................389 FD49–1088 ........................................390 FD49–1200 ........................................390 FD51–1264 ........................................392 FD51–1265 ........................................392 FD51–1266 ........................................392 FD51–1267 ........................................392 FD51–1268 ........................................392 FD51–1269 ........................................392 FD51–1270 ........................................392 FD51–1272 ........................................392 FD56–1009 ........................................401 FD56–1012 ........................................401 FD56–1037 ........................................399 FD56–1062 ........................................399 FD56–1064 ........................................399 FD56–1065 ........................................399 FD56–1070 ........................................400 FD56–1071 ........................................400 FD56–1072 ........................................401 FD56–1074 ........................................401 FD56–1075 ........................................401 FD56–1081 ........................................402 FD56–1082 ........................................402 FD56–1123 ........................................400 FD56–1125 ........................................400 FD56–1196 ........................................400 FD56–1201 ........................................400 FD56–1204 ........................................399 FD56–1205 ........................................400 FD56–1207 ........................................399 FD56–1208 ........................................400 FD56–1209 ........................................401 FD56–1210 ........................................402 FD56–1221 ........................................401 FD56–1225 ........................................399 FD56–1226 ........................................400 FD56–1233 ........................................401

8

Courtesy of Aeroquip.cc

Part Number Index

Part Number

Page

Page

FD86–1010 ........................................415 FD86–1016 ........................................417 FD86–1018 ........................................417 FD86–1035 ........................................417 FD86–1039 ........................................416 FD86–1040 ........................................416 FD86–1041 ........................................416 FD86–1042 ........................................415 FD86–1043 ........................................415 FD86–1044 ........................................415 FD86–1049 ........................................416 FD86–1050 ........................................416 FD86–1051 ........................................416 FD86–1052 ........................................415 FD86–1053 ........................................415 FD86–1054 ........................................415 FD86–1055 ........................................416 FD86–1056 ........................................416 FD86–1057 ........................................415 FD86–1058 ........................................415 FD86–1059 ........................................416 FD86–1060 ........................................416 FD86–1061 ........................................415 FD86–1062 ........................................415 FD90 ..................................................422 FD90–1004 ........................................423 FD90–1012 ........................................423 FD90–1021 ........................................423 FD90–1034 ........................................423 FD90–1035 ........................................423 FD90–1040 ........................................423 FD90–1041 ........................................423 FD90–1044 ........................................423 FD90–1045 ........................................423 FD90–1046 ........................................423 FD93–1047 ........................................423 FF013 ..........................................377-378 FF014 ..........................................377-378 FF015 ..........................................377-378 FF016 ..........................................380-381 FF017 ..........................................380-381 FF018 ..........................................380-381 FF028 ................................................343 FF054 ..........................................383-384 FF055 ..........................................383-384 FF056 ..........................................383-384 FF082 ..........................................399-402

Part Number

Page

FF092..........................................399-402 FF093..........................................399-402 FF095..........................................392-393 FF097..........................................392-393 FF098..........................................392-393 FF288 ..................................................39 FF593 ................................................226 FF595 ................................................226 FF824 ................................................226 FF974 ................................................343 FF975 ................................................343 FF1010 ..............................................318 FF1026 ..............................................313 FF1065 ..............................................317 FF1066 ..............................................315 FF1131 ..............................................323 FF1159 ..............................................313 FF1161 ..............................................319 FF1162 ..............................................303 FF1167 ..............................................319 FF1307 ..............................................323 FF1315 ..............................................323 FF1327 ..............................................324 FF1353 ..............................................324 FF1354 ..............................................324 FF1607 ..............................................375 FF1851T ............................................296 FF1852T ............................................297 FF1854T ............................................297 FF1856T ............................................296 FF1857T ............................................300 FF1858T ............................................296 FF1861T ............................................298 FF1865T ............................................298 FF1868T ............................................297 FF1898T ............................................299 FF1922T ............................................296 FF1980 ..............................................325 FF1981 ..............................................325 FF1994T ............................................300 FF2000T ............................................299 FF2001T ............................................298 FF2030T ............................................300 FF2031T ............................................298 FF2032T ............................................298 FF2035T ............................................299 FF2068T ............................................297

9

Courtesy of Aeroquip.cc

Part Number Index

FD56–1234 ........................................402 FD69 ..................................................403 FD69–1000 ........................................404 FD69–1001 ........................................404 FD69–1002 ........................................404 FD69–1010 ........................................404 FD69–1011 ........................................404 FD69–1012 ........................................404 FD69–1026 ........................................404 FD69–1027 ........................................404 FD69–1028 ........................................404 FD69–1029 ........................................404 FD70 ..................................................409 FD70–1010 ........................................409 FD71 ..................................................405 FD71–1001 ........................................406 FD72 ..................................................407 FD72–1001 ........................................408 FD76 ..................................................409 FD76–1002 ........................406, 408-409 FD76–1010 ........................................409 FD83 ..................................................410 FD83–1000 ........................................411 FD83–1001 ........................................411 FD83–1002 ........................................412 FD83–1003 ........................................411 FD83–1004 ........................................413 FD83–1005 ........................................411 FD83–1007 ........................................412 FD83–1008 ........................................412 FD83–1014 ........................................412 FD83–1024 ........................................413 FD83–1025 ........................................411 FD83–1026 ........................................412 FD83–1032 ........................................413 FD83–1033 ........................................413 FD83–1040 ........................................413 FD86 ..................................................414 FD86–1000 ........................................416 FD86–1001 ........................................416 FD86–1002 ........................................416 FD86–1003 ........................................416 FD86–1004 ........................................416 FD86–1005 ........................................415 FD86–1006 ........................................415 FD86–1007 ........................................415 FD86–1008 ........................................415

Part Number

Part Number Index

Part Number Index

Part Number

Page