7 minute read

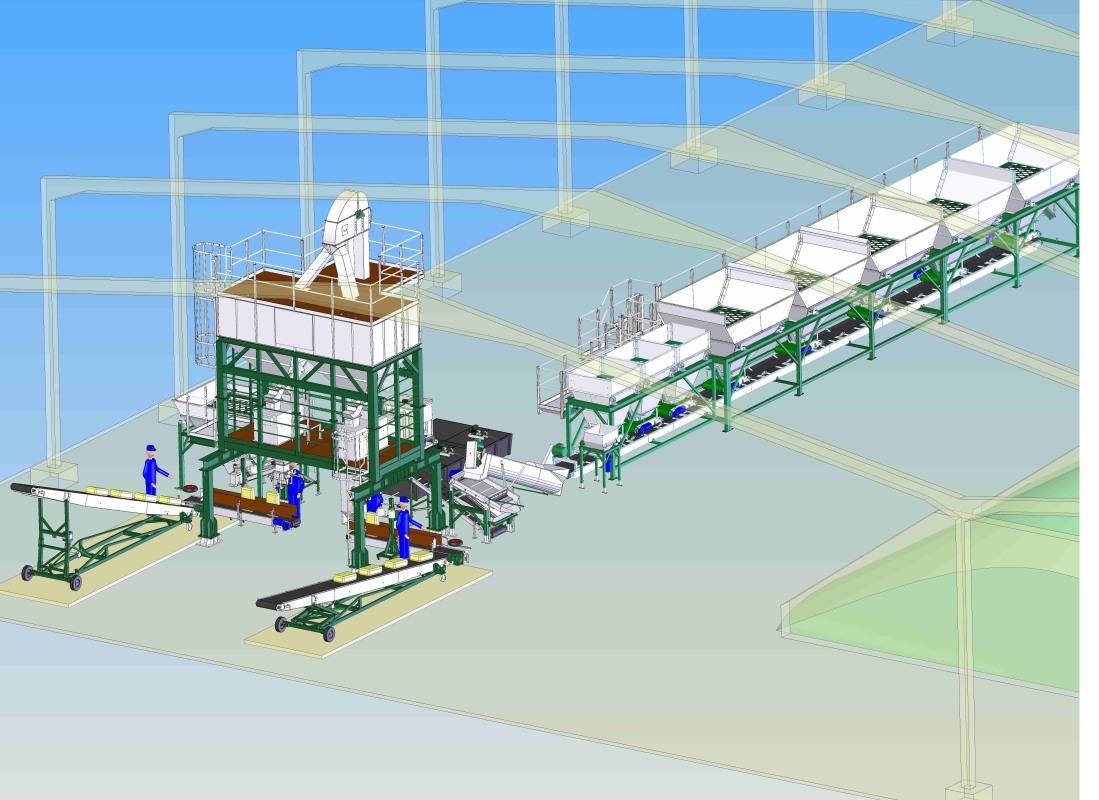

EMT –Fertiliser Blender and Bagging projects established in Africa

EMT, a manufacturer of Ferliser Blending and Bagging Equipment, has been heavily involved in the development of the African ferlizer industry. The company, based in the Netherlands, has a long list of references, in total we have installed more than 460 projects in more than 70 countries worldwide. The company has exported to more than 20 African countries in the previous years, as can also be found on the website. One of the most recent larger installaons on the connent has been a Weighcont Connuous Blender Line with small bag bagging lines. The company Glofert in Ghana has invested in a machine line with a capacity of 80 tons per hour. With its machine installaon Glofert can connuously produce blends and bag the ferlizer through 2 bagging lines of each 40 tons per hour. The company is a local Ghanaian company that is directly selling the ferliser to their local distributors. Ghana has a strong presence of Ferlizer blenders with EMT equipment including LDC – Chemico and Yara. Of which also Yara has recently expanded their facility with machines of EMT. Analysing the African market as a whole we can see Ethiopia as a big investor with EMT Blender and bagging lines on 4 different locaons. In the Sub Saharan countries South Africa has the highest presence of companies running with EMT equipment, but as Botswana, Angola, Cameroon, Ivory Coast, Malawi, Nigeria, Togo, South Africa and Zimbabwe. These local companies are running with blending and bagging equipment from the Dutch company. The African market is constantly in need of further development in its agricultural sector. Currently Rwanda, Burkina Faso, Mali and Nigeria have projects running together with EMT. New developments in the area but also outside of Africa is the upcoming from coang for Urea and/or Blended ferlizers. Almost all of EMT's blending equipment is suited for liquid adding so that the impregnaon of for example Urea, can be done in the same machine line. Also standalone coang units have been developed which are solely focussing on coang one type of ferlizer, usually urea, with an inhibitor. The years of experience in the ferlizer field have made EMT one of the largest well known machinery producers in the world. Its combinaon of blending lines and bagging lines which are supplied and

constructed by 1 Producer makes EMT a good partner for all types of customers. All machines are pre-assembled and tested in the EMT factory. The machines are all engineered to make them fit in to a container or truck/trailer. This is for easy transport to the customers. The installaon is done by the EMT Supervisor with help of the customer technicians. The whole machine set up is then a turn key set-up. With the different machines EMT is supplying all types of companies, from the local distributors to the mulnaonal producers, can always find the right machine line which fits into their budget and capacity request. For contact see the EMT website emt@emt.tech or contact the local distributor of EMT equipment

Advertisement

email: emt@emt.tech www.emt.tech

The Humane Slaughter Association – Providing Technical Advice And Support For Over A Century

The Humane Slaughter Associaon works to improve the welfare of food animals during transport, markeng, slaughter and killing for disease control and welfare reasons. It is a registered charity, based in the UK, but works all over the world through research, educaon, training and technical advances, to improve standards and bring praccal and lasng improvements to the welfare of food animals across the globe. The charity has gained an internaonal reputaon for being a knowledgeable and praccal organisaon, with a sound understanding of livestock and livestock handling. It provides educaon and training in the fields of transport, markeng and slaughter in the UK and around the world. Significant improvements connue to be achieved through working construcvely alongside agricultural, meat industry, veterinary and other welfare and professional organisaons.

Can we help you? The HSA provides:

Educaon and Training – courses and lectures, run by licensed personnel who have both theorecal and praccal knowledge of animal slaughter. These can be tailored to suit specific requirements and can be delivered at any suitable venue in the UK or abroad. As part of its educaon and training iniaves, the charity also produces up-todate technical and educaonal publicaons on all aspects of animal handling, transport, slaughter and killing in a range of formats and languages, many of which are available to download, free of charge, from our website. These guidance and technical notes have been taken up widely by the industry and have been found to be very helpful for training and promoon of humane operaon pracces. Funding for essenal research and other projects through grants and awards. Independent advice to governments, other welfare organisaons and the food industry. As an independent organisaon, the charity is beholden to neither polical nor trade nor emoonal pressures and is thus able to play an unbiased role in promong the humane treatment of livestock. Visits to markets and slaughterhouses to recommend and advise on improvements, where necessary. The HSA is oen approached for advice on animal welfare aspects of the operaon of equipment or systems for handling, transport or killing of livestock. We welcome opportunies to observe and assess the operaon of new or modified technologies or systems used in the handling, transport or killing of farmed food animals. Please see our website www.hsa.org.uk for more informaon on our work and to view and access the publicaons available. If you require advice on a parcular maer or would like to discuss something relevant to your facility, please email the HSA in the first instance at info@hsa.org.uk.

IEEE Expert Lightning Protection Consulting and Grounding Design

The world's best and most crical experse for the proper implementaon of IEEE Standard 1692; which is a trease for mul-purpose communicaons and highvoltage installaons. We have found from forty one (41) years of experience, and special experse, that it's far too easy to "get it wrong" in cookie-cuer applicaons of the tried-and-true requirements of Standard 1692, leaving expensive equipment vulnerable to costly damage and weeks off line for extensive repair. The most important aspect in the applicaon of IEEE Standard 1692 is that the final protecon package design has to be perfectly correct in every aspect to provide failure-proof protecon. One small error in proper applicaon can make a protecon design package totally useless. Ground Potenal Rise (GPR) isolaon and lightning protecon and grounding consulng and design for substaons, power plants and high-voltage corridors. Ground Potenal Rise (GPR) isolaon and lightning protecon and grounding consulng and design for 911 PSAP sites, PCS towers, radio and TV transmission towers. Ground Potenal Rise (GPR) isolaon and lightning protecon and grounding consulng and design for military communicaon sites, high-rise buildings, swimming pools, police and fire staons. Ground Potenal Rise (GPR) isolaon and lightning protecon and grounding consulng and design for railroad communicaon sites and railroad switching facilies as well as for every other kind of building, site and facility. We provide no products, only consulng, design, and recommendaons for the best lightning protecon and grounding installaons for substaons, electronic circuit boards, equipment components, power plants, high-voltage corridors, and broadband services for school systems.

GPR = A Ground Potenal Rise = A Ground Voltage Spike

A lightning strike to any grounded structure or a high-voltage flashover from a power line to a grounded structure will cause the ground in the vicinity to rise in voltage to dangerously high levels, which can electrocute personnel standing on the ground in the area and damage or destroy electronic equipment connected to ground. This site was created because Ground Potenal Rise (GPR), caused either by lightning strike or high-voltage electrical system power faulng to ground, causes unnecessary damage to manufacturing and storage facilies with crical stores - including explosive munions, flight operaons equipment, communicaons towers and antennas, communicaons equipment, and crical electronic equipment as well as pung crical communicaon links and operaons and maintenance personnel at risk. Praccing what you learn here will allow your company or organizaon to cut costs, remain operaonal even under severe lightning condions and may save your life or the life of a coworker.