WEST COAST NUT

JULY 2023 ISSUE

SPOTLIGHT: ASSESSING PISTACHIO HULL INTEGRITY AND WHAT TO DO ABOUT IT

SEE PAGE 4

IN THIS ISSUE:

PROGRESS ON EARLY WARNING SYSTEM FOR LEAFFOOTED BUG SEE PAGE 34

UNDERSTAND YOUR ORCHARD TO PREVENT ANT DAMAGE SEE PAGE 52

DEALING WITH SUMMER FOLIAR DISEASES SEE PAGE 60

BY REAL CALIFORNIANS

PUBLICATION

Photo courtesy B. Blanco-Ulate

PRODUCED IN THE HEART OF

Monitoring is Key to Hull Split Spray Timing

Hull split spray timing is critical in preventing navel orangeworm damage in almonds. To get the timing right, the rst step is monitoring the crop to detect the beginning of hull split.

Phosphorus Trial Showed Improved Tree Growth in Young Almond Orchards

The macronutrient phosphorus is not often at the table when fertilization plans for new almond orchards are discussed. De ciencies of this nutrient are rarely seen in mature orchards, but research done by UCCE Farm Advisor Phoebe Gordon and USDA researcher Greg Browne found positive impacts from phosphorus applications in replant almond orchard eld trials.

Calculating When to Start Irrigation Can Save Money

Following a much wetter winter than normal, soil moisture in many tree nut growing regions of the state is adequate for seasonal tree growth. If you are thinking it is time to initiate irrigation, Tom Devol, Almond Board of California’s senior manager of eld outreach and education, said to rst check your soil moisture.

TOP ARTICLES FROM PREVIOUS ISSUES IN CASE YOU MISSED IT To subscribe scan the QR code or visit myaglife.com/subscribe Don’t miss a single article Subscribe Today receive them directly to your inbox Exclusive Articles Twice a Month

Publisher: Jason Scott

Email: jason@jcsmarketinginc.com

Editor: Marni Katz

Email: marni@jcsmarketinginc.com

Associate Editor: Cecilia Parsons

Email: cecilia@jcsmarketinginc.com

Production: design@jcsmarketinginc.com

Tel: 559.352.4456

Fax: 559.472.3113

Web: www.wcngg.com

Vicky Boyd

Contributing Writer

Kathy Coatney

Contributing Writer

Lori Fairchild

Contributing Writer

Brittney Goodrich Assistant Professor of Cooperative Extension, Department of Agricultural and Resource Economics, UC Davis

Brian Huff President, Diamond Foods

Roger A. Isom President/CEO, Western Agricultural Processors Association

Julie R. Johnson

Contributing Writer

Rich Kreps CCA, SSp., Contributing Writer

Mitch Lies

Contributing Writer

Chris McGlothlin Director of Technical Services, Western Agricultural Processors Association

Franz Niederholzer UCCE Farm Advisor, Colusa and Sutter/Yuba Counties

Steve Pastis

Contributing Writer

Kristin Platts

Contributing Writer

Scott Somerville Ph.D. Candidate, Department of Agricultural and Resource Economics, UC Davis

Award Winning Editorial By the Industry, For the Industry

Research and Extension Center

Kevin Day County Director/UCCE

Pomology Farm Advisor, Tulare/Kings Counties

Elizabeth Fichtner

UCCE Farm Advisor, Tulare County

Katherine Jarvis-Shean

UCCE Area Orchard Systems Advisor, Yolo and Solano

Steven Koike Tri-Cal Diagnostics

Jhalendra Rijal UCCE Integrated Pest Management Advisor, Stanislaus County

Mohammad Yaghmour UCCE Area Orchard Systems Advisor, Kern County

The articles, research, industry updates, company profiles, and advertisements in this publication are the professional opinions of writers and advertisers. West Coast Nut does not assume any responsibility for the opinions given in the publication.

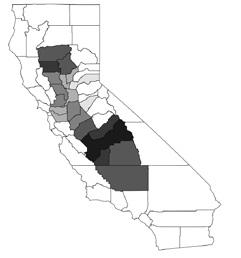

Research aims to improve understanding of the environmental conditions that lead to hull degradation in pistachios and how growers can predict and act on hull integrity.

4 Assessing Pistachio Hull Integrity and What to Do About It 8 Atwater Family Farm Hopes Branded Products Yield a Sweet Return 12 Economic Considerations for Navel Orangeworm Management in Almond Orchards 18 CARB Board Approves Expansive Truck Electrification Rule 22 Almond Acreage Decline Prompts Industry Introspection 26 Land IQ Brings Accuracy to the Nut Industry With Crop Mapping and Ground Truthing 30 Diamond Foods Bets on Snacking and Product Innovation to Help Increase Walnut and Pecan Consumption 34 Progress Being Made on Early Warning System for Leaffooted Bug 36 From the Orchard: From Peach Trees to Walnuts, Davin Norene Puts the Family Farm First 40 New Telone Restrictions Could Spell Trouble for Nematode Control 44 Almond Replant Disease, Phytophthora are Issues in Young Orchards 48 Chelated or Complexed Micronutrients: Choosing the Right Chemistry for Nutrient Uptake 50 Dial In Spray Coverage for Cost-Effective Spraying 52 Preventing Ant Damage Depends on Timing, Knowing Your Orchard 54 LandFlex Incentives Give Growers Options in Troubled Groundwater Basins 56 Getting the Best Out of Irrigation using Soil Moisture Monitoring and Weekly ET Report 60 Dealing with Summer Foliar Diseases 64 Cal/OSHA Standards Board Considers Regulation for Indoor Heat Illness Contributing Writers & Industry Support UC Cooperative Extension Advisory Board Surendra K. Dara Director, North Willamette

IN THIS ISSUE

View our ePublication on the web at www.wcngg.com See page 4

SPOTLIGHT:AssessingPistachioHullIntegrityandWhattoDoAboutIt

July 2023 www.wcngg.com 3

ASSESSING PISTACHIO HULL INTEGRITY AND WHAT TO DO ABOUT IT

By CECILIA PARSONS | Associate Editor

Pistachio hull integrity during the growing season is critical to preserving kernel quality. Hulls naturally degrade when nuts ripen, signaling harvest time. How long the hull remains intact, even though the nut is ripening, is hull integrity.

The hull of the pistachio is called the epicarp (exocarp and mesocarp). It

is about 1/16-inch thick and adheres tightly to the hard inner shell until the nut is ripe. It undergoes specific physical and chemical changes at nut maturity.

Those changes were outlined in a Pistachio Day presentation by Barbara Blanco-Ulate, UC Davis faculty in Plant Sciences. Blanco-Ulate and UC Davis

Plant Sciences faculty Giulia Marino note that little is known about how environmental differences in growing conditions affect pistachio ripening and NOW susceptibility. Since 2019, they have been conducting research funded by the California Pistachio Research Board (CPRB) to better understand how temperature drives the annual timing and extent of hull degradation in pistachio. Their research is also aimed at characterizing specific nut characteristics that can predict the extent of hull degradation in pistachios. These studies may allow better understanding of how navel orangeworm (NOW) respond to hull integrity.

Blanco-Ulate said her CPRB-funded project led her to rethink nut growth stages. She noted shell hardening and kernel growth happen at the same time. Hull ripening and kernel maturation start once the kernel reached the maximum size. There is also a peak in volatiles that happens just prior to hull ripening. Shell split occurs in parallel with hull softening. Hull softening and hull coloration to red are reliable biomarkers of hull breakdown. Blanco-Ulate explained that biomarkers are molecular or physical signatures that can be measured in the field to anticipate large physiological changes like hull ripening and breakdown. Pistachio hull breakdown occurs after nut ripening and leads to higher nut susceptibility to insect infestation and fungal decay.

Ripening Process

Pistachio nuts can display early or ‘pea split’ or normal ripening. The early splits are more likely to become infested by NOW several weeks prior to normal maturation, USDA-ARS Entomologist Joel Siegel said. NOW egg laying on normally maturing nuts does not increase until the hulls begin tearing and breaking down.

“Something is happening physiologically with early splits. Hulls can stick to the shell and expanding nuts tear the hull. When the hull breaks down, it

ContinuedonPage6

4 West Coast Nut July 2023

Hull softening and hull coloration to red are reliable biomarkers of hull breakdown (all photos courtesy B. Blanco-Ulate.)

ContinuedfromPage4

releases a chemical that attracts NOW,” Siegel said.

Hull breakdown is part of the ripening process, but tree stress or metabolic factors can cause early tears which will cause loss of crop quality. This “damage by other means” on grade sheets includes necrosis or shell defects which cause otherwise good kernels to be diverted to shelling stock.

Pistachio nuts that are ripening normally have shells that split under the hull. At this stage, hulls that begin to have a puffy or soft appearance and slip from the shell, signaling nuts are ready for harvest, generally around the end of August depending on orchard location. The trouble with recognizing crop maturity, Siegel noted, is that in a cluster of nuts, not all will reach maturity at the same time.

At the processor, hulls on the mature nuts slip off, but the hulls on less-than-mature nuts adhere to the shell.

Components of Hull Integrity

There are physiological and environmental components to hull integrity. Recognizing the physiological signs of hull breakdown at nut maturity can help growers develop management plans to ensure nut quality and time harvest to minimize NOW damage and increase nut quality.

Pistachio variety can also determine hull integrity. Blanco-Ulate’s research showed a faster hull breakdown in the Golden Hills variety compared to Kerman. Also, Golden Hills had the highest level of VOCs earlier in the season, while Kerman VOCs peaked two weeks later at a much lower

Pistachio nuts can display early or ‘pea split’ or normal ripening.

Pistachio nuts can display early or ‘pea split’ or normal ripening.

6 West Coast Nut July 2023

In a cluster of nuts, not all will reach maturity at the same time.

level. This faster rate of hull degradation could make nuts more susceptible to insect damage and fungal growth and is the reason growers of this variety are urged to harvest early.

Bloom time and spring temperatures during early nut growth also impact blanking and nut quality at harvest. Late-bloom nuts have higher incidence of blanks and filled nuts without splits. Blanco-Ulate’s research showed with normal bloom, 18% blank. Late bloom had 37% blanks. Normal bloom produced 94% shell split while late bloom in some locations only reached 55% shell split. Late-bloom nuts have significantly harder hulls and softer shells. She noted it is not always the case that kernel expansion forces shell splitting. It appears to be more than physical force, she noted.

Water and Nutrition

In the field, Setton Pistachio plant manager Jeff Gibbons said experience shows water and nutrition management set the stage for hull integrity during the growing season.

“I’ve been preaching this to growers for several years now, healthy trees play a part in hull integrity and that keeps navel orangeworm out,” Gibbons said.

Although the winter of 2022-23 provided plenty of water for pistachio orchards, that is not the case every year. Gibbons said keeping trees watered during dry winters and not deficit irrigating at bloom will result in better hull development from mid-April to June 1. Over application of nitrogen and insufficient calcium and potassium in the root zone can

also play a part in fruit development.

Weather during hull development is also a major factor in hull integrity, Gibbons said. In his experience, hot, dry weather during that time can compromise pistachio hulls. Cool, moist conditions can result in stronger hulls. This year, he said the weather cooperated and he expects better hull integrity throughout the growing season.

Zack Raven, farm manager at Keenan Farms, said as harvest nears, hull integrity has their attention. Keeping up with crop ET, particularly during heat spells, can help keep hulls intact. In addition to NOW damage, he said adhering hulls cause staining on shells. Stains on shells can mean loss of quality bonuses for growers.

Hull degradation and shell split are likely driven by interactions between tree physiology and environmental conditions, Houston Wilson, UCCE specialist and entomologist at UC Riverside, wrote in his research for CPRB. Better understanding of these interactions could allow for development of management strategies to influence these processes, opening the way for growers to better predict and even manage hull integrity and shell split.

Comments about this article? We want to hear from you. Feel free to email us at article@jcsmarketinginc.com

July 2023 www.wcngg.com 7

Toward Diversification

Atwater Family Farm Hopes Branded Products Yield a Sweet Return

By VICKY BOYD | Contributing Writer

By VICKY BOYD | Contributing Writer

What started out as a joke and a distraction during the COVID pandemic shutdown has morphed into the direct-to-consumer brand Sweet AF (Sweet Arnold Farms) for the Atwater-based family farming operation.

“It was a fun little side project and gave us something to look forward to,” said Craig Arnold, who grows almonds, cling and freestone peaches, and organic sweet potatoes with his father, Bill.

The brand also was born out of what the younger Arnold saw as changing consumer shopping patterns.

“I was watching, and consumers switched their shopping to pick-up and buying every-

thing on Amazon and having everything shipped direct,” he said. “I kept looking at it and wondered, ‘Why can‘t we do a little of that?’ Almond prices are going down to the grower, but the price in the stores and everyplace else is holding. So that just told me all the money was being made in the middle.”

Beginning with the 2022 season, Arnold Farms offered fresh peaches in season, sweet potatoes and flavored and roasted almonds to consumers for in-person pickup at their farm office or for local shipment.

Although Arnold said he doesn’t expect the Sweet AF brand to ever provide the bulk of their income, he said he’d like to grow it to where they could support local groups and organizations more than they do now.

Arnold Farms donated this bucket full of goodies to the recent Atwater FFA Ag Booster Dinner (photo courtesy Arnold Farms.)

In addition to almonds, sweet potatoes and peaches sold under the Sweet AF (Sweet Arnold Farms) brand, the Atwater operation also sells logo cups, cap and t-shirts (photo by V. Boyd.)

8 West Coast Nut July 2023 attorneycathycowin.com (559) 545-2020 * ATTORNEY ADVERTISING * REPRESENTING FARMERS SINCE 1991 LAW OFFICES OF CATHY COWIN

Ask about Representation of:

Arnold Farms works with a Ballico company, which adds flavoring to their almonds (photo by V. Boyd.)

We’re familiar with the challenges of agri-business. You’re not just growing crops, you’re running a sophisticated business requiring legal, accounting, insurance, and scientific skills as well as business acumen. We can help.

CATION-EX5 PLUS™

Capturing Maximum Genetic Potential

“Part of the motivation is when it’s making a little bit, I’d like to take that money and put a lot of that into the community if I can,” he said.

Birth of a Consumer Brand

Craig Arnold’s wife, Amanda, and office manager Jessica Egli developed the Sweet AF logo. In addition to their ag products, they also sell logo merchandise, including t-shirts, caps and insulated commuter mugs.

From the start, Arnold said they decided to sell online and designed a secure website, sweetarnoldfarms.com. Sweet AF also has a presence on social media that includes Facebook and Instagram. Egli handles sales and social media posts.

Selling What They Grow

The Sweet AF product line started with almonds. The Northern Merced Hulling Association in Ballico hulls them, while Monte Vista Farming Co. in Denair processes the kernels and packs 1,000 pounds at a time in 50-pound boxes. He said they use sheller-select 27/30 Nonpareils, considered a premium grade.

A Ballico company adds the flavors that include roasted-salted, Cheez-o, Snickerdoodle and Sweet Srircha. Snickerdoodle-flavored almond butter, sold in 8-ounce jars, also is made locally.

Last summer, Sweet AF added fresh peaches sold in buckets equivalent to 10 pounds and 25 pounds. Much like a refillable beer growler, customers can exchange the buckets when they return for more peaches.

Sweet potatoes from Arnold Farms’ climate-controlled storage facility are available much of the year in 3- and 5-pound boxes, which are more convenient for customers than industry-standard 20- and 40-pound cartons. So far, Arnold said customer feedback has been very encouraging.

“With fresh peaches, people come back with a lot of memories of getting fresh peaches years ago, especially here,” he said. “A lot of people remember going to J.R. Wood Fruit Co. when they were downtown. They could pull peaches right off the line.”

Push Toward Streamlining

Developing the brand also comes at a time when the family farming operation is striving to improve efficiency,

decrease costs where it makes sense, and adopt more mechanization.

Last winter, the Arnolds pulled an old almond orchard and plan to lease the ground to a local sweet potato grower for the next two years. Not only will that help break the pest cycle, but it is expected to give them time to research what crop holds the best potential.

Increasing production costs, particularly labor, also prompted them to reduce peach acreage from 180 acres in years’ past to this year’s 80 acres.

Last year, the California Canning Peach Association, which negotiates prices with processors on behalf of grower-members, was able to obtain a small price increase. And Arnold said he hoped that occurred again this season.

“The price increase last year was pretty much eaten up with labor and fertilizer costs,” he said. “This year, I’m hoping for another modest price increase, and hopefully labor will be available. It’s getting really tough to find anybody who’s willing to work a full day picking peaches.”

Labor costs also caused Arnold Farms to cut their sweet potato acreage this season to about 80 acres, less than half what it was last year. They are focusing entirely on organic production because of added premiums.

“I love growing peaches and I love growing sweet potatoes; I just really enjoy it,” Arnold said. “But with the added troubles of labor, especially because both of them are increasingly labor intensive, I understand why almonds are so appealing.”

This year, Arnold Farms also plans to plant 35 acres of French colombard winegrapes. Although Arnold admitted the white variety probably won’t net as much as one of the more popular varietals, such as sauvignon blanc, he’s banking on continued demand for its use in blending.

In addition, the operation plans to fully mechanize the vineyard from pruning to harvest, he said.

As part of diversification, Arnold Farms rents wooden field bins, each marked with its signature blue paint. The side business started with 5,000 bins as a partnership with a local fruit processing company. It has grown to the current 50,000 bins that also are rented to local sweet potato growers.

Active in the Ag Industry

Craig Arnold pointed to his great grandfather for starting the family’s Merced County farming legacy in 1909. As the family story goes, the elder Arnold either owned a grocery store or worked for one in San Francisco and left the city after the Great 1906 Earthquake and subsequent fire.

In the early 1900s, the Arnold’s farm was planted to grain crops and peanuts. Once the Merced Irrigation District brought surface water to the area, the crop mix evolved to include fruits, nuts and vegetables.

Craig Arnold, who received a bachelor’s degree in agricultural business from California State University, Chico, in 2003, said there was never any question about returning to the family farm. He, his father and his uncle, Glenn, farmed together until Glenn passed away in 2019.

Over the years, Arnold Farms has cooperated in University of California Cooperative Extension field trials, including at least two that involved almond rootstocks. A previous

ContinuedfromPage8

10 West Coast Nut July 2023

The cost of labor to pick peaches as well as just finding workers has been a challenge for Arnold Farms (photo by V. Boyd.)

one yielded the Bright’s hybrid rootstock. The current trial, established 8 to 10 years ago by then-UCCE farm advisor David Doll, comprises 10 acres near Winton.

“All of these things take 20 years to prove out,” Craig Arnold said. “If no one is willing to do the trials and willing to help with the research, how are we going to move the industry forward? We have these great resources out there with UC Cooperative Extension, UC and the state campuses. If they want to do the work on a project, I’m going to help them the best I can.”

The Arnolds embraced that same philosophy as a cooperator in a UC groundwater recharge trial from 2015-17 in a Delhi-area almond orchard.

Doll, who has been managing director of Rota Unica almonds in Portugal since leaving UCCE in November 2018, said the Arnolds’ involvement in the trials were “priceless” in helping develop local best practices.

“They contributed by providing teams to prepare fields, help plant and harvest the trial,” Doll wrote in an email from Portugal. “This has led to significant contributions to the almond industry, which included the identification of sodium and chloride tolerance of peach-almond hybrid rootstocks, rates of copper for management of bacterial spot, use of almonds for groundwater recharge and many more. Within peaches, they tested multiple varieties and rootstocks, which help extend the life of the industry. And with sweet potatoes, they have worked to identify new varieties while determining ways to reduce chemical usage.”

On a more personal level, Doll said he didn’t know where he would have been without them. “The Arnolds provided me with guidance from my first day, something in which I will be forever grateful. It was a privilege to work with them.”

Despite their busy schedules, both Bill and Craig Arnold are active in several agricultural groups. Bill is on the Merced County Farm Bureau board, while Craig sits on the California Canning Peach Association board, the California Sweetpotato Council executive board and several Merced Irrigation District advisory committees.

The younger Arnold said they volunteer their time because agriculture needs to be represented, especially with the ever-increasing flow of restrictions from Sacramento.

“I know we have all of these different regulations coming and I know we have these people on elected boards that are going to push all of these rules and regulations,” Craig Arnold said. “I want to be on the front side of them. Most of these are coming whether we want them or not. I want to have a say in them. I could sit back and complain, or I could at least try to be in the mix and knowledgeable and forecast where to position the company.”

As a fourth-generation farmer, Craig Arnold said he wonders whether the operation will still be around for the fifth generation, his 10-year-old daughter and 8-year-old son, when they’re old enough to farm.

“One of my constant questions is, ‘Do I keep fighting through and leave them a life like I grew up with? It’s a good life. You can make a decent living and come out with a lot of values and work ethics, or do I set them up with different options?’ I could easily sell everything.

“Right now, they want to come back, my daughter especially. I don’t know what’s going to happen in 10 more years. A lot can change, and a lot has changed.”

Comments about this article? We want to hear from you. Feel free to email us at article@jcsmarketinginc.com

July 2023 www.wcngg.com 11

Arnold said Arnold Farms plans to grow only organic sweet potatoes this year because of the premium they bring (photo by V. Boyd.)

ECONOMIC CONSIDERATIONS FOR NAVEL ORANGEWORM MANAGEMENT IN ALMOND ORCHARDS

Navel orangeworm (NOW) is one of the top pests affecting almond production in California. NOW damage decreases almond yield, quality of meats and the price a grower receives. Furthermore, NOW damage is linked to aflatoxin, a known human carcinogen. Aflatoxin contamination is highly regulated in key markets, such as the European Union, and can lead to rejected almond shipments. Ultimately, increased rejection rates could decrease global demand for U.S. almonds, making it imperative for growers to reduce NOW damage in their orchards.

The primary tools available to growers to combat NOW include monitoring NOW populations, winter sanitation (removing and destroying mummy nuts left from the previous year’s harvest), chemical pesticide sprays and timely harvest. The University of California Integrated Pest Management (IPM) Guidelines Publication 3431 provides a practical guide to the available tools. When used in combination, an IPM protocol can reduce the incidence of NOW damage and the share of harvested meats rejected by the processor, leading to increased yields and potentially price premiums for quality. In this article, we outline some economic considerations for growers as they make NOW management decisions for their almond orchards.

NOW Management Costs as a Percentage of Annual Operating Expenses

To illustrate the costs associated with an NOW pest management program, we referred to the 2019 UC Davis Cost Studies for conventional almond production in California. The representative farms in each of these studies use an NOW pest management program consisting of winter sanitation in January and two chemical pesticide

By BRITTNEY GOODRICH | Assistant Professor of Cooperative Extension, Department of Agricultural and Resource Economics, UC Davis

SCOTT SOMERVILLE | Ph.D. Candidate, Department of Agricultural and Resource Economics, UC Davis

By BRITTNEY GOODRICH | Assistant Professor of Cooperative Extension, Department of Agricultural and Resource Economics, UC Davis

SCOTT SOMERVILLE | Ph.D. Candidate, Department of Agricultural and Resource Economics, UC Davis

$/Planted acre Source: Authors calculations using CDPR PUR data for almond orchards, 2019-21. Application costs and winter sanitation costs are based on example IPM costs outlined in Table 1. Pesticide product prices are from 2022. (c) Average Pesticide Application and Winter Sanitation Costs per Acre (Assuming 82% of orchards receive sanitation) Figure 1: 2019-21 County Average Pesticide Applications and Costs of NOW Control (a) Average Number of NOW Pesticide Applications per Acre (b) Average NOW Pesticide Application Costs per Acre (Application plus materials cost) $/Planted acre Figure 1: 2019-21

12 West Coast Nut July 2023

County Average Pesticide Applications and Costs of NOW Control

Production Region

Table 1: NOW IPM practice costs as percentage of annual operating costs, 2019 Almond Cost and Returns Studies

Source: Author calculations based on 2019 Almond Cost and Returns Studies.

applications after hull split. Pesticides, equipment and labor costs have changed substantially since 2019, so rather than reporting dollar values of costs, we focus on NOW management costs as a percentage share of annual operating costs and present the estimates in Table 1. Across all three regions, NOW management costs are a substantial share of annual operating costs, ranging from 9.3% in the southern San Joaquin Valley to 14.1% in the northern San Joaquin Valley. Differing percentages across regions are due to differing NOW management practices as well as regional variation in other orchard operating costs.

NOW Management Costs by California County

Pesticide sprays targeting NOW are a meaningful share

REDUCE NUT DAMAGE FROM NOW

of orchard operating costs. To obtain a more accurate picture of spraying costs in recent years, we used data from the California Department of Pesticide Regulation (CDPR) Pesticide Use Reporting (PUR) database from 2019-21. Our analysis focuses on pesticide products specifically targeting NOW in almond orchards. Figure 1 (see page 12) shows results of this analysis. On average, almond growers use 1.4 pesticide applications per acre targeting NOW (Figure 1a). Using updated 2022 pesticide product, labor and fuel prices, we estimate on average, growers spend $93 per acre applying pesticides targeting NOW (Figure 1b). In both Figures 1a and 1b, it is clear there is regional variation in NOW pesti-

FIGHT NOW WITH BIOUNITE™

May Spray

Venerate XC Bioinsecticide

1 qt./A + Methoxyfenozide 16 fl. oz. OR Chlorantraniliprole 3 oz.

NOW Early Hullsplit

Venerate XC Bioinsecticide

1 qt./A + Methoxyfenozide 16 fl. oz. OR Chlorantraniliprole 3 oz.

NOW 2nd Hullsplit (14 days)

Venerate XC Bioinsecticide

1 qt./A + Methoxyfenozide16 fl. oz. OR Chlorantraniliprole 3 oz.

Control Mites

Rate: Apply foliar ground application in 75-150 gal./A with 2-4 qts./A of Venerate XC. Re-apply on a 7-day interval.

ContinuedonPage14

NOW IPM Practice Sacramento Valley San Joaquin Valley North San Joaquin Valley South Insecticide products 2.4% 3.9% 2.4% Pesticide application (Equipment, fuel and labor) 1.0% 1.0% 0.7% Winter sanitation 10.0% 9.3% 6.2% Total NOW IPM Costs as Percentage of Annual Operating Costs 13.4% 14.1% 9.3%

Almond

July 2023 www.wcngg.com 13

Assumptions: Yield distribution across varieties is 50% Nonpareil, 25% Monterey and 25% Carmel. Baseline Nonpareil price without premiums is $2/lb. Prices of Monterey and Carmel meats are assumed to be 86% and 89% of Nonpareil prices, respectively. Diesel price is $4.45/gal, and equipment operator and hand labor are $26.46 and $22.48, respectively.

Premium/discount schedule is from the Blue Diamond 2022 Crop Delivery Information. In orchard yield losses are assumed to be equal to the reject percentage at the handler.

DISCOVER THE STRENGTH OF SPEAR

Novel Peptide-Based Insecticide

cide applications and corresponding costs. Growers in Fresno and Madera counties spray for NOW more frequently and spend the most on spraying for NOW. Figure 1c shows costs per acre including winter sanitation. We assume 82% of almond orchards receive winter sanitation and that winter sanitation costs are $306/acre as outlined in Table 2 . The statewide average cost of pesticides plus winter sanitation is $344 per acre (Figure 1c). Using 1.37 million bearing acres of almonds, this means California growers on average spent over $471 million dollars on NOW management costs using 2022 prices, not including trap monitoring or mating disruption costs. This amounts to roughly 9% of the 2021/22 total almond value of $5 billion. These costs are substantial, especially in years with relatively low almond prices. However, when compared to losses associated with NOW damage, the economic benefits of the NOW IPM program outweigh the costs in most situations.

Comparing Economic Benefits of NOW IPM Programs

Spear® LEP targets lepidopteran pests on tree nuts and other high-value field and orchard crops. Field trials with Spear LEP show performance equivalent in efficacy and residual to conventional insecticides. With no known resistance or cross-resistance, Spear LEP works as a standalone, or in rotation with conventional insecticides as an excellent IPM.

Table 2 outlines the costs and associated returns comparing two NOW IPM programs on a per acre basis (monitoring NOW populations is assumed to occur in both IPM programs, but we do not incorporate these costs into the analysis.) In both IPM programs, the grower uses winter sanitation and applies two pesticides. In IPM 2, the grower also uses season-long mating disruption for NOW with in-orchard dispensers, which has been increasing in popularity over the last few years (see UC IPM Guidelines Publication 3431 for a list of mating disruption products.) In terms of the cost per pound of almond meats produced, IPM 1 and IPM 2 cost $0.20/lb and $0.25/ lb, respectively. For both IPM programs, the net returns per pound of almond meats produced are $1.69. Thinking of this another way, the grower could spend up to $1.69/lb on all other inputs (fertilizer, fungicides, etc.) and still break even with respect to annual operating costs. Thus, NOW IPM is costly but is likely essential for making almonds profitable due to the potential impacts on yield, quality and price.

Contact

Assessing the differences between the net economic benefits between IPM 1 and IPM 2 illustrates a framework growers can follow if they are considering adopting mating disruption or changing

NOW IPM Practices Winter sanitation 306 $ 306 $ Tree Shaker 130 $ 130 $ Nut Sweeper/Blower 86 $ 86 $ Flail Mow 45 $ 45 $ Hand Pole 45 $ 45 $ Pesticide Application (2x) 128 $ 128 $ Application Costs x 2 34 $ 34 $ Insecticide Product 1 52 $ 52 $ Insecticide Product 2 42 $ 42 $ Mating disruption - $ 120 $ Total IPM Cost ($/Acre) 434 $ 554 $ Total IPM Cost ($/lb) 0.20 $ 0.25 $ Expected Rejection Rate at Handler 2.1% 1.9% 1.89 $ 1.94 $ Almond Yield (lbs/acre) 2,204 2,213 Total revenues ($/Acre) 4,155 $ 4,283 $ Net Revenues ($/Acre) 3,722 $ 3,729 $ Net Revenues ($/lb) 1.69 $ 1.69 $ IPM 1 IPM 2 Weighted Average Almond Price Across Nonpareil, Monterey and Carmel ($/lb meats with reject and quality premiums)

Table 2: Example economic comparison of two NOW IPM programs for almond production

ContinuedfromPage13 ContinuedonPage16 14 West Coast Nut July 2023

MRL EXEMPT 4-HOUR REI 0-DAY PHI NEW IRAC GROUP 32

your Vestaron representative or local dealer to learn more or to place your order today.

NEW IRAC GROUP 32 PEPTIDE em POWER ed INSECTICIDE™ VES - West Coast NOW Ad L1-0.indd 1 6/28/23 2:21 PM

vwww.vestaron.com/contact

another part of their IPM program. IPM 2 is more costly per acre and per pound of meats produced due to the added cost of mating disruption (about $120/acre). However, in this example, adding mating disruption decreases the grower’s expected share of meats rejected at the handler from 2.1% to 1.9%. The lower rejection rate at the handler for IPM 2 also means price premiums and a higher yield of undamaged nuts. When comparing the net revenues per acre, IPM 2 exceeds that of IPM 1 by $7/acre. Thus, a grower choosing between these two programs would find it most profitable to choose to incorporate mating disruption into their NOW management program.

It is important to note that mating disruption may not decrease damage rates in all orchards. For example, mating disruption is generally less effective in small orchards (<40 acres) and long, narrow orchards due to populations of NOW in neighboring orchards (Wilson et al. 2020). However, a field study by Haviland et al. (2021) showed the use of mating disruption decreased kernel damage by 35% to 53%, so in some cases it can have a large impact on grower revenues.

Tables 3 and 4 (see page 17) show breakeven rates for comparing IPM programs 1 and 2 at various almond prices, costs of mating disruption and IPM 2 rejection rates. These tables show the net benefit of switching from IPM 1 (no mating disruption) to IPM 2 (mating disruption). Any shaded squares indicate that for the corresponding rejection rate at the handler, almond price and mating disruption cost scenario, switching to IPM 2 results in economic benefits.

Table 3 shows at a mating disruption cost of $120/acre, even modest decreases in expected rejection rates mean mating disruption is economically beneficial in some situations. For example, moving from 2.1% rejection rate with IPM 1 to a 1.9% rejection rate with IPM 2 results in small economic benefits when almond prices are low and modest benefits when prices are high. However, with the use of mating disruption, rejection rates as low as 1% are feasible (Haviland et al. 2021), and the benefits are substantial, ranging from $131 to $201 per acre, depending on the almond price level.

Similarly, Table 4 shows that for a cost of mating disruption of $100/acre, moving from rejection rates of 2.1% to 2.0% leads to a net economic benefit when the Nonpareil price is $2/lb. For the most expensive mating disruption scenario ($130/acre), it is only necessary for mating disruption to decrease the expected rejection rate at the handler to 1.8% for mating disruption to make economic sense.

Other Economic Considerations for NOW IPM

As growers make their IPM decisions, it is important to address the many uncertainties inherent in almond production. A grower who spends over $300/acre on winter sanitation only to have a frost occur during bloom that destroys the almond crop for the year will not be pleased with their winter sanitation effort in hindsight. To alleviate this risk, growers can consider enrolling in catastrophic crop insurance offered through USDA Risk Management Agency (RMA). This policy will reimburse growers for yield losses below 50% of the average yield for an orchard and only requires the grower to pay an administrative fee of $655 per crop per county (all premiums are subsidized by USDA for catastrophic coverage.) Such a policy is inexpensive and can help growers recoup input costs that occurred prior to the catastrophic weather event. Buy-up coverage is also available if the grower wishes to insure a higher portion of their average yield, but buy-up coverage is more expensive. Most of California’s almond acreage is already insured through federal crop insurance, but growers who are not currently insured can get information from a certified crop insurance agent. USDA-RMA provides an online crop insurance agent locator.

Varying pest pressure, weather conditions, and yield targets mean there is no “one-size-fits-all” strategy for profitable NOW IPM decisions. The same grower may even have different IPM programs across different almond orchards, depending on the characteristics of that year and orchard. It is important for growers to think critically about their NOW IPM program, remembering that maximizing long-term profitability of their almond orchard may not involve minimizing costs of NOW management.

IPM 2 Expected Rejection Rate at Handler $ 1.50 $ 2.00 $ 2.50 $ 3.00 2.1% -120 -120 -120 -120 2.0% -3 -1 1 3 1.9% 3 8 12 16 1.8% 10 16 23 29 1.7% 17 25 34 42 1.6% 23 34 44 55 1.5% 75 87 100 113 1.4% 81 96 111 126 1.3% 88 105 122 139 1.2% 95 114 133 152 1.1% 102 123 144 165 1.0% 131 154 178 201

ContinuedfromPage14

16 West Coast Nut July 2023

Table 3: Net economic benefit per acre from switching from IPM 1 to IPM 2 at varying almond prices and IPM 2 rejection rates at the handler (cost of mating disruption $120/acre)

References

2019 Cost and Returns Studies for Almond Production in Sacramento Valley, San Joaquin Valley North and San Joaquin Valley South: https://coststudies.ucdavis. edu/en/current/commodity/almonds/

Haviland, David R., et al. “Management of navel orangeworm (Lepidoptera: Pyralidae) using four commercial mating disruption systems in California almonds.” Journal of Economic Entomology 114.1 (2021): 238-247.

USDA RMA Crop Insurance Locator: https://public-rma.fpac.usda.gov/apps/ AgentLocator/#/

Wilson, H. et al. “Biology and management of navel orangeworm (Lepidoptera: Pyralidae) in California.” Journal of Integrated Pest Management 11.1 (2020): 25.

Zalom, F. et al. (2019) UC IPM Almond Pest Management Guidelines: Navel Orangeworm. UC ANR Publication 3341: https://ipm.ucanr.edu/agriculture/almond/ navel-orangeworm/

Comments about this article? We want to hear from you. Feel free to email us at article@jcsmarketinginc.com

Notes: All assumptions from analysis in Table 1. IPM 1 rejection rate at handler is constant at 2.10%.

IPM

at Handler $ 100 $ 110 $ 120 $ 130 2.1% -100 -110 -120 -130 2.0% 19 9 -1 -11 1.9% 28 18 8 -2 1.8% 36 26 16 6 1.7% 45 35 25 15 1.6% 54 44 34 24 1.5% 107 97 87 77 1.4% 116 106 96 86 1.3% 125 115 105 95 1.2% 134 124 114 104 1.1% 143 133 123 113 1.0% 174 164 154 144

2 Expected Rejection Rate

Table 4: Net economic benefit per acre from switching from IPM 1 to IPM 2 at varying costs of mating disruption and IPM 2 rejection rates at the handler (Nonpareil price $2.00/lb)

July 2023 www.wcngg.com 17

CARB Board Approves Expansive Truck Electrification Rule

By CHRIS MCGLOTHLIN | Director of Technical Services, Western Agricultural Processors Association

replace existing trucks within the fleet with comparable ZEV models starting in 2025.

The first impacts of this rule will be felt by the drayage industry. Within the rule, CARB specifically highlighted the priority to convert drayage equipment over to electric beginning in 2024. Additionally, no internal-combustion drayage vehicle with over 800,000 miles will be allowed to enter a California port beginning in 2025. CARB has also set the standard that all drayage trucks will be electric by 2035. This has significant implications for the industry that hauls imports and exports from some of the countries’ busiest ports.

In the beginning of 2023, many had to make difficult decisions on what to do with existing heavy-duty diesel trucks. With the conclusion of the Truck and Bus rule, many older diesel trucks were junked, scrapped or sold out of state and upgrades were made to existing fleets by purchasing 2010 or newer equipment to meet the requirements set by the rule. I fielded plenty of calls asking if this would be the last time the State would require equipment to be replaced. Unfortunately, the new rule was just passed.

In April of this year, the California Air Resources Board (CARB) met to hear two significant proposals on the electrification of equipment throughout California. The rules proposed by staff have a direct impact across various state agencies, local governments, fuel producers and biofuel generators, equipment manufacturers and Califor-

nia businesses. Board Members heard a lengthy presentation from staff on the Advanced Clean Fleets Rule. Dubbed the “Truck Rule 2.0” by staff early in the rulemaking process, the rule will require applicable fleets to upgrade specific equipment to comparable Zero Emission Vehicles (ZEV’s/electric) on an annual schedule. The rule specifically applies to fleet owners, operators and dispatchers of 50 or more Class 2b to Class 8 vehicles and applies to businesses with $50 million in receipts. Starting in 2024, applicable fleets would be required to begin converting predesignated internal combustion truck models with their electric counterparts once their useful life of 18 years has been reached or the equipment has reached a mileage threshold of 800,000 miles. Truck replacement and turnover is determined based on percentage amounts of fleets, with businesses having to

Prior to the hearing, CARB staff took several suggestions from industry and implemented them as part of the rule. Specifically, CARB staff included rule extensions to assist businesses most impacted by the requirement to electrify. Staff added a two-year extension in compliance if an equipment manufacturer is unable to fulfill an order by the required compliance date. Fleet owners must show a purchase order for the equipment prior to applying for the extension. A secondary exemption of up to five years is being provided for businesses experiencing interconnectivity delays. Businesses must show that a work order has been established by the utilities, and that the utilities have indicated the proposed project will be delayed for the foreseeable future. CARB is allowing for specialty vehicles with no comparable ZEV

ContinuedonPage20

18 West Coast Nut July 2023

Under the proposal, no internal-combustion drayage vehicle with over 800,000 miles will be allowed to enter a California port beginning in 2025.

model or manufacturer to be exempted from the rule, until a company begins manufacturing a ZEV specific model.

During the Board Hearing, after staff presented the recent updates to the rule, the Board took public comment. The Board heard public testimony from

over 120 commenters in the Byron Sher Auditorium in Sacramento. The unfortunate truth is that of those 120 comments, the Board only heard from three agricultural industry representatives on concerns about the implementation of this rule. Additional business representatives included drayage fleets, city rep-

resentatives, two truck manufacturers as well as many in the biofuel industry. Industry representatives were outnumbered 5-to-1 by environmental activists pushing the Board to approve this rule and, in some cases, make it more stringent. In a move that probably helped more than it hurt, the Board had moved the Advanced Clean Fleets item to an up-or-down vote on the proposal, meaning the Board could only accept the proposed regulation as-is, and no additional changes could be made. Several Board Members expressed support to environmental groups’ proposals to decrease applicable fleet sizes as well as expedite compliance requirements, but the up-or-down proposal held them to either accept or deny the regulatory proposal.

As one of the agricultural representatives to comment on the proposed rule, we at Western Agricultural Processors Association (WAPA) chose to focus on the current struggles the agricultural industry experiences with the major utility providers. The agricultural industry has long been the sector to be put on the backburner by utility companies, with several of our members waiting years before even being given a date to interconnect new projects to the grid. This rule will manufacture electrical demand throughout the state, and WAPA is confident that the utility companies are not ready to meet the demand of our industry in the areas of the state that our businesses inhabit. Throughout the workshopping process, and through several updates to the Board, the California Public Utilities Commission and the major utility providers have had opportunities to present to the Board. Those groups have consistently stated they have no concern whatsoever with being able to connect industry, which we consider a blatant fallacy or outright lack of awareness of what is required with this proposal.

WAPA presented various examples of long delays for various agricultural businesses. Examples included a farm that has waited six years for the utility provider to electrify a shop, a nut processor that has to rely on two permit-

ContinuedfromPage18 Cliff Beumel 559-531-7086 cbeumel@agromillora.com Main Office 530-846-0404 agromillora.com SUPER HIGH DENSITY OLIVES FOR OIL Your Best Orchard Crop for the Future!

CA -OLIVE OIL PRICES AT ALL TIME HIGH -FASTER ROI -GROWN, MILLED AND SOLD IN US -HIGHEST PROFIT IN ORCHARD CROPS -100% MECHANIZED FROM THE MOMENT OF PLANTING OLIVES REQUIRE THE WATER OF ALMONDS AND ¼ THE NITROGEN TO PRODUCE A FULL CROP 20 West Coast Nut July 2023

California Nursery Gridley,

ted natural gas engines to power their operation because of delays imposed by Pacific Gas & Electric, and lastly, another processor that is permitted as a “Major Source” who is unable to replace four internal combustion engines with comparable electric equipment because their service provider simply has too many other projects on the books. The last example drastically highlights how the pursuit of better air quality does not meet the priorities of the utility providers.

After public testimony ended, the Board reconvened the next day to make their formal vote. While several Board Members ignored concerns by industry, several other members of the Board echoed sentiments made by WAPA and incorporated a follow-up requirement by the utility companies to update the Board on the efforts to interconnect these businesses to help them comply with the rule. We do not expect the utility companies to be so open with these updates, so WAPA anticipates being as active as possible to shine a light on how bad it will continue to be for our industry.

Acting quickly on the heels of the Board Hearing, WAPA worked to bring together industry stakeholders, government agencies and utility companies as well as various other interested parties to demonstrate further how difficult the situation really is. In all, the meeting included state agency officials, industry representatives and the two major utility providers in the Valley. This gave industry the opportunity to explain to both CARB and the utility providers how bad the situation currently is, and how the new rule will further impact workload and equipment from the utility companies. The group concluded with a commitment to continue the dialogue in the coming months. We hope to have some impact in the future, but for now the clock has started.

Fast and Effective Broad Spectrum Control of Soft-Bodied Insects, Mites and Fungal Diseases

Gargoil® Insect, Mite & Disease Control targets pests including mites, aphids, thrips, whiteflies, psyllids and other soft-bodied insects. Gargoil® can also help control immature forms of larger insects such as worms and scale.

■ Apply throughout the season, even day of harvest, no PHI

■ No limits on the number of applications per year

■ Easy-to-use plant-based product

Gargoil® for the Control of Navel Orangeworm Adults in Almonds

Comments about this article? We want to hear from you. Feel free to email us at article@jcsmarketinginc.com

Call (760) 599-8855 or visit www.san-agrow.com

Arvin, CA 2020 Gargoil Grower Standard 28 3 14 13 51 7 0 1 2 2 Pre-treatment 16 13 9 6 60 50 40 30 20 10 0 Days After Treatment Number NOW Adults/Trap

ADVANTAGES

Gargoil® was applied at 3 qts/150 gallons of water per acre. All products were applied at the start of hull split. Grower standard was Bt/Burkholderia.

July 2023 www.wcngg.com 21

CARB’s proposed Advanced Clean Fleets Rule will require a phase in to zero emission trucks on an annual schedule.

ALMOND ACREAGE DECLINE PROMPTS INDUSTRY INTROSPECTION

By MITCH LIES | Contributing Writer

By MITCH LIES | Contributing Writer

The decline in California almond acreage last year, the first decline in more than 25-years, wasn’t unexpected, given a “trifecta of impacts,” according to Richard Waycott, president and CEO of the Almond Board of California.

Nevertheless, the decline from 1.65 million acres in almonds in 2021 to 1.63 million in 2022, according to figures from the USDA’s National Agricultural Statistics Service (NASS), is notable and has sparked an introspection of where the industry is today, where it has come from and where it may be headed in the future.

In one respect, after so many years of increased acreage, including a significant increase over the last decade, the decline was inevitable, according to ABC Board Member Mel Machado, Vice President of Member Relations for Blue Diamond Growers.

“We had a lot of acres planted in the last 10 years,” Machado said. “It just makes sense that that’s going to slow. It’s not a surprise that that acreage flattens. Not at all.”

“It was in line with most people’s

expectations,” Waycott said, “given the economic situations that have befallen agriculture in general, coupled with the drought that we’ve been experiencing and the logistical issues that caused the industry to have this backup of inventory, thereby influencing lower prices in the industry.”

Decline Marks a Milestone

In another respect, while the acreage decline from 2021 to 2022 marks a milestone of sorts, changes in growth patterns for California almonds are nothing new, according to Waycott.

“If you look over the past 20 years, you see these cycles we go through in terms of growth of acreage and then slowdowns,” Waycott said.

“But this one,” he added, “may be more profound and longer lasting than others. We’ve had a sort of trough of pricing that lasted much longer than it typically does. And thinking back over the years, I don’t think we’ve had the combination of factors occurring at the same time, where you have a low price for your product, you have the record costs at the same time, and you

have interest rates going up every day or inability to get loans to finance your operations. I don’t think we’ve had that happen to that extent before.”

Waycott also said the USDA’s May 12 estimate that the 2023 almond crop will come in at 2.5 billion pounds, 3% below last year’s 2.57 billion pounds, didn’t offer any surprises.

“A lower crop estimated was not unexpected considering all that growers dealt with last year and during this year’s bloom,” he said. “The cold, wet weather kept bees in their hives and reduced the hours they could pollinate orchards.”

Forecasted yield is 1,810 pounds per acre, down 90 pounds from 2022 and the lowest since 2005.

The Price Effect

Looking back, sources said that much of the acreage increases that occurred over the last two decades can be attributed to good prices. “When prices were good, a lot of acres got planted,” Machado said.

ContinuedonPage24

22 West Coast Nut July 2023

Industry observers expect a continued acreage decline in coming years, which is not necessarily a bad thing.

JOIN THE TABLE OLIVE RE V OLUTION

Musco Family Olive Co. – America’s largest olive company — is leading the transformation of the table olive industry, and we want you to grow with our family. Modern table olive orchards apply newly perfected, state-of-the-art planting and harvesting to one of the world’s most drought-tolerant tree crops for proven superior financial results. In today’s ever-changing environment, olive trees are the smart choice.

HIGH DROUGHT TOLERANCE & LONG LIFESPAN • FREE NURSERY STOCK FOR EARLY PIONEER PARTNERS • OLIVE CROPS ARE NOT RELIANT ON EXPORT SALES • TWENTY YEAR CONTRACTS AVAILABLE •

• MECHANIZATION GREATLY REDUCES HARVEST COSTS

• LOWER WATER USAGE THAN ALMOND & WALNUT ORCHARDS

• HIGH DENSITY PLANTING MAXIMIZES TONS PER ACRE

• PARTNER WITH AMERICA’S LARGEST OLIVE COMPANY

PROVEN MECHANICAL HARVESTING

PREMIUM MANZANILLA OLIVES BUILDING CALIFORNIA’S CROP OF THE FUTURE IN PARTNERSHIP WITH THE UC DAVIS OLIVE CENTER STEP 1: CHECK OUT THE WEBSITE STEP 2: CONTACT www.olives.com / million t rees DENNIS BURRESON DENNISB@OLIVES.COM (530) 624-4475 $3,800 $1,250 $600 ALMONDS WALNUTS AVERAGE GROSS PROFIT PER ACRE 4 YEAR PROFITABILITY OF OLIVES VS. WALNUT & ALMOND CROPS FREE NURSERY STOCK AVAILABLE Average gross profit source: Burreson Ranch actuals; other grower actuals; UC Davis; USDA FAS 2019 – 2022

OLIVES YIELD PROFITS OF 300% OR MORE*

MODERN TABLE

The high prices also allowed growers to keep older orchards in production longer. At the lower prices of today, growers couldn’t afford to do so, Machado said.

“Under higher prices, they could farm older orchards and make it work,” he said. “They were still making some money. But under the current pricing, that no longer works. That was one reason I’ve been hearing for why growers were pulling out orchards.

Barrett30: The Ultimate Nematode Control Solution

Barrett30 targets and eliminates nematodes leaving plants and soil unharmed. Growers benefit from controlling pests with our soft chemistry that is nonsystemic, uses minimal active ingredients and leaves zero trace of Barrett30 in the final product.

Say goodbye to nematode worries and hello to a successful harvest with Barrett30!

“The other reason I’ve been hearing, which is very ironic given this year’s water situation, is ‘I don’t have enough water to farm this thing. I don’t have enough water to sustain it,’” Machado said. “They are looking at their water allocations and deciding to move water onto younger, more productive orchards and taking out the older ones.”

In many cases, particularly in the southern part of the San Joaquin Valley, growers are not replacing almond orchards with new ones, he added, another factor that drew down acreage numbers.

“There are more pistachios going in than anything else in the southern San Joaquin Valley,” Machado said. “You have to look hard to find first-leaf plantings [of almonds] from about Madera south.

“Also, a lot of guys are taking a year off, which is a good thing. Some of these lands have been in almonds for 30, 40 or 50 years,” he said. “So, they are taking a break, doing something different, either letting it fallow or farming another crop, such as a forage if there is a dairy nearby or tomatoes, whatever is available.”

Varietal Changes

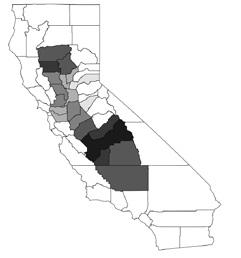

The acreage decline, which occurred despite a slight increase in bearing acres, has happened mostly in areas most affected by the drought, so areas like the west side of the San Joaquin and Sacramento valleys, according to figures from Land IQ and USDA-NASS, both of whom the Almond Board contracts with to compile acreage reports.

And the decline has occurred mostly in older varieties that have fallen out of favor because of performance reasons, such as Carmel, Butte and Padre. Butte and Padre, which combined for 11.4% of California almond production in 2014, accounted for just 7% in 2021. Carmel went from 8.5% of production in 2014 to just 4% in 2021.

Self-compatible varieties, conversely, have increased in acreage, particularly Independence, which has risen from less than 0.5% of California almond production in 2014 to 11.5% of the 2021 crop.

Nonpareil continued to be the leading variety in 2022, followed by Monterey and Independence. And Fresno, Kern, Stanislaus, Merced and Madera counties were the leading counties, accounting for 75% of the total bearing acreage.

Looking Ahead

One big question for the industry in light of the 2022 acreage decline is whether this will be but a blip in continued growth or the start of a longer trend.

(209) 409-2558

barrett30.com

chad@bpscience.com

“I think it will depend on the outcome of the implementation of SGMA as well as the profitability of the industry,” Waycott said. “And we’ve already seen prices improve since the beginning of the year. We’ve seen certain costs decline, such as freight rates and petroleum-based products, such

ContinuedfromPage22

ContinuedfromPage22

Secure healthier crops with Barrett30

Growth in international and domestic markets over the last 30 years will continue to drive interest in planting almonds.

24 West Coast Nut July 2023

as nitrogen. So, there are some good trends, or reversal-of-trends that are benefiting the industry. And, obviously, this year we will not have a shortage of water. So, that is a good thing.”

“I think we are going to continue to see [acreage] slip or slide down a bit,” Machado said. “I’ve said for many years that water will be our limiting factor for plantings in the future. And now with SGMA looming in the not-toodistant future, I’m sure that will have an impact.

“The question is to what degree and who will be impacted first and where those impacts will occur,” Machado added, “and those questions are largely unanswered, even though it is almost upon us.”

Asked whether last year’s acreage decline is in any way bad for the industry, Machado said, “No, I don’t think so at this point.”

Waycott, too, didn’t view the acreage decline as particularly significant.

“I think as long as almonds can retain long-term profitable outlook, growers will want to plant them,” Waycott said. “We’re obviously the best place in the world to grow this product, and that’s been proven over and over.

“And there are many advantages with almonds,” he said. “It is a low-labor industry. It’s not without its issues in terms of crop maintenance and crop protection and so on, but it’s relatively easier to farm than other things. And I think that the marketing machine that’s been developed over the last 30 years at the Almond Board has helped create a powerhouse of an industry that has transformed its product over the last 25 years. So, it’s very well positioned. And per-capita consumption in many parts of the world is still tiny, so there is a lot of room for growth.

“So, I think almonds have a good shot at continuing growth,” Waycott said, “even with the reduced agricultural footprint in California.”

Comments about this article? We want to hear from you. Feel free to email us at article@jcsmarketinginc.com

The decline has largely come through attrition of older varieties in drought ravaged areas.

The decline has largely come through attrition of older varieties in drought ravaged areas.

WE HAVE YOUR BACKS, BARNS AND BOTTOM LINES. *Rozol ground squirrel bait is a restricted use pesticide Ground squirrels distracting you from your daily to-dos? Minimize the squirrel moments with Rozol Ground Squirrel Bait.* REGISTERED FOR USE IN CALIFORNIA July 2023 www.wcngg.com 25

FIRST THING I’VE GOT TO DO IS SQUIRREL. AND THEN I’VE GOTTA SQUIRREL. AND AFTER SQUIRREL, I NEED TO SQUIRREL.

Land IQ Brings Accuracy to the Nut Industry With Crop Mapping and Ground Truthing

By MITCH LIES | Contributing Writer

In 2011, based on production levels, growers on the Almond Board of California (ABC) suspected acreage reports from the USDA National Agricultural Statistics Service (NASS) were too low. They asked Land IQ for a second opinion.

“Growers on the Almond Board came to us and said, ‘We can’t achieve the average yields that the USDA-NASS are reporting, and we think we’re pretty good growers,’” said Joel Kimmelshue, principal scientist and owner of Land IQ. “So, can you map some almonds for us.”

That request launched acreage reporting for a company that today provides mapping for more than 50 crops in California, representing the entirety of the state’s irrigated crop footprint.

Launched in 2007 by Kimmelshue and Mica Heilmann, Land IQ hadn’t done acreage reporting when ABC requested it do so. But it was using spatial data from satellite imagery for other work in agriculture. Kimmelshue proposed that Land IQ start with Madera County.

“I said, ‘Okay, sure. Let’s cut our teeth on Madera County,’” he said. “And we did that, took them the map, they went out and checked our work and said, ‘Okay, you did pretty well. But we think you might have got lucky, so do it again.’ And we did it another year, and they said, ‘Okay, fine, now do the whole state.’”

On behalf of ABC, California Walnut Board, California Prune Board

and the California Pistachio Research Board, Land IQ applied for and received a specialty crop block grant from CDFA, divvied up the cost according to acres and got to work.

“We did that a couple of years in a row. And then SGMA (the Sustainable Groundwater Management Act) hit and required the California Department of Water Resources to provide agricultural land use data set for the entire state of California, and we have been contracted with them ever since,” Kimmelshue said.

Today, Land IQ, which started in sublet offices with just five employees, has 40 employees between its Sacramento and Los Angeles offices. “And we’ve grown organically,” Kimmelshue

said. “We haven’t had any growth targets. We just grow in response to the need for the work, and we focus on delivering very accurate results centered on heavy ground truthing for calibration and validation.”

It was that need, incidentally, that initially prompted Kimmelshue and Heilmann to launch the company. At the time, in the mid-aughts, the co-owners were working for a large international consulting engineering firm.

“Normally, a big engineering job would come in the door and there would be a smaller ag component to

ContinuedonPage28

Joel Kimmelshue at Land IQ’s Sacramento office co-founded the company with Mica Heilmann in 2007 (all photos by M. Lies.)

26 West Coast Nut July 2023

A map of almond acres in California is displayed on a wall at Land IQ’s meeting room in Sacramento during a company meeting.

July 2023 www.wcngg.com 27 Sierra Gold Nurseries • (530) 674-1145 • sgtrees.com BEST CLONAL HYBRID ROOTSTOCKS PISTACHIOS WALNUTS ALMONDS CONTACT YOUR LOCAL FIELD REPRESENTATIVE PAUL SMITH Butte, Glenn, Tehama & Shasta (530) 517-9338 paul@sgtrees.com BOB FURMIDGE Yuba, Sutter, Colusa, Yolo, Solano, Sacramento & Placer (530) 755-7139 • bob@sgtrees.com RANDY FASANI San Joaquin, Stanislaus, Merced & Madera | (209) 988-7333 randy@sgtrees.com JOSH BERGMAN Fresno, Kings, Tulare & Kern (559) 260-6551 josh@sgtrees.com MATTHEW “BUBBA” HADDON Fresno, Kings, Tulare & Kern (661) 747-3967 • matthew@sgtrees.com Almonds · Walnuts · Pistachios EXPERIENCED ONSITE FIELD SERVICE TO HELP YOU AT EVERY STEP

that,” Kimmelshue said. “And we would touch base with irrigation districts and commodity groups a lot, and there was just a need we felt for detailed mapping, detailed water use and crop estimates. So we decided, ‘Let’s go take a stab at this ourselves.’”

Growth Drivers

Early on, Kimmelshue and Heilmann hitched their wagon to accuracy, Kimmelshue said, and today, between satellite data and ground truthing, Land IQ boasts a crop mapping accuracy rate of over 97%.

“Their expertise is second to none,” said Richard Waycott, president and CEO of ABC, which contracts with Land IQ to provide almond acreage data twice a year. “We have really benefited from the work they do.”

In developing its reports, Land IQ accesses spatial imagery from four sat-

ellite services, including three government services and a paid subscription service, and validates the data with ground truthing.

“We can create a digital fingerprint of almonds, which is different than a digital fingerprint of walnuts, which is different than a digital fingerprint of alfalfa, because when you look at it from the sky, the texture, color and temporal differences are different from one crop to another,” Kimmelshue said. “Then all the pieces are put together and you create a fingerprint by crop type.”

The ground truthing not only calibrates the remotely sensed models, but also confirms, or validates, the company is properly identifying the crop type from the multiple components provided by the spatial data from satellites.

“We drive about 17,000 miles of ground truthing each year,” Kimmelshue said. Ground truthing typically involves three people riding in a car documenting thousands of fields

by crop type and dropping points on an iPad. “We capture about 80,000 to 90,000 individual fields, or data points, a year.”

Expanded Portfolio

In addition to providing information on crop type, Land IQ can provide the age of an orchard and some climatic factors that may influence yields in an orchard. It can provide information on plant stress and on evapotranspiration (ET), which it does for approximately 40 Groundwater Sustainability Agencies each month. The ET data is used to determine groundwater pumping allocations in some cases or fee rates.

The expanded portfolio also has played a significant role in company growth, Kimmelshue said. “And there has been some luck involved,” he added.

Still, he said, none of this growth happens if the company doesn’t provide accurate results. And from its first acreage report, Land IQ has stood out for its accuracy, according to Waycott.

“The team that Joel and Mica have built there is top notch,” Waycott said. “And the data they provide is real-time data. And it is exact. So, that is something that has been very useful to us. And it has also been useful for USDA. We intentionally share the Land IQ data with USDA so they can take that data into consideration as they are going about their more traditional methodology of assessing acreage. And so, we are coming out with a better product at the end of the day.”

One other key Kimmelshue identified as instrumental to Land IQ’s expanding portfolio has been its vision. “The thing that we’ve been able to do is to be visionary,” Kimmelshue said, “to pay attention to what’s going on in the agriculture industry and see what the need is, and then moving quickly to address that need.”

Looking Back

Kimmelshue said he rarely takes the time to reflect on the success of the company he co-founded. When he does, he feels fortunate.

“I feel very blessed that I get to come and do the work that I do,” he said. “I

ContinuedfromPage26 28 West Coast Nut July 2023

can honestly say I’m happy to go work. I love my job.

“And I tell people that we’re doing stuff that is important,” he said. “And it’s never been done the way we do it, with accuracies that have never been achieved. And the most gratifying part is that the data we produce are being used in a hopefully objective, scientific manner to make tough decisions. ‘How much water can I pump?’ That’s a tough decision to make. But to have confi dence in the data that we deliver helps people make smarter decisions.”

Oh, and that acreage report that the Almond Board asked for in 2011? It showed USDA-NASS figures were about 10% below actual acreage, which, when considering production figures, was about what ABC members thought was the case.

Comments about this article? We want to hear from you. Feel free to email us at article@jcsmarketinginc.com

O ce: 559-686-3833 Fax: 5 59-686-1453 2904 E. Oakdale Ave. | Tulare, CA 93274 newerafarmservice .com

Since

Helping Farmers Grow NATURALLY

1974

July 2023 www.wcngg.com 29

Clockwise from left, Land IQ personnel Bradley Santi, Casey Gudel, Seth Mulder, Joel Kimmelshue and Adriana Delucchi discuss a mapping project during a meeting at company headquarters in Sacramento.

Diamond Foods Bets on Snacking and Product Innovation to Help Increase Walnut

and Pecan

Consumption

By BRIAN HUFF | President, Diamond Foods

Diamond Foods is on a mission to help grow North American walnut and pecan consumption with its continued investment in snacking and product innovation. The 110-year-old

handler launched the first-ever snack walnut line, Diamond of California Snack Walnuts, back in 2020 and this spring relaunched the original Santa Cruz trail mix brand, Harmony. We are

just getting started as we are on track to roll out a variety of new innovative products that focus on attracting new consumers and increasing occasions for walnuts and pecans.

Over the last century, Diamond Foods has made a name for itself with our extensive lines of Diamond of California “Made for Homemade” culinary nuts and ready-to-use nut pie crust products. While we have been a pioneer and leader in the culinary category for decades, it was vital for us to think about how we evolve and help increase the overall year-round consumption of walnuts and pecans.

While we’ve seen great success with our culinary nut line, the category has been traditionally limited to just one major consumption spike in Q4 for holiday baking and cooking. As such, shifting into the evergreen and fast-growing snack nut category was a natural progression for our brand to increase year-round consumption, especially with 94% of Americans snacking daily and 70% of consumers snacking at least twice each day. IRI data from April 2022 showed that in the last year the snack nuts category accounted for over $5 billion in retail sales, a 1.2% increase over the prior year.

We made our first foray into the

ContinuedonPage32

30 West Coast Nut July 2023

Diamond Foods initially launched Snack Walnuts with eight unique flavors, but four core flavors, Salted Dark Chocolate, Himalayan Pink Salt, Sweet Maple and Hot Honey, emerged as the clear flavors to prioritize (all photos courtesy Diamond Foods.)

snack nut category with the launch of our Diamond of California® Snack Walnuts line in 2020. March 2020 was not ideal timing to launch in the middle of a global pandemic, especially since the shopping experience was challenged by long lines, product shortages and shoppers looking for essentials and not new products. However, launching at that time allowed us to learn and grow from both retailers and consumers in the fast-changing snacking landscape. We initially launched Snack Walnuts with eight unique flavors, but our now four core flavors, Salted Dark Chocolate, Himalayan Pink Salt, Sweet Maple and Hot Honey, emerged as the clear flavors to prioritize. The success of those flavors confirmed the consumers’ demand for health-conscious yet indulgent snacks, but it also reminded us to keep flavors accessible. As we continue to innovate new products and flavors, we are leaning into our nutrient-dense walnuts as they are a great source of plant-based protein and better-for-you fats and complementing them with approachable flavor pairings that satisfy both the sweet and savory cravings.

Today, Diamond of California® Snack Walnuts are the No. 1 snack walnut brand in the U.S. with nearly three times more sold vs the next snack walnut brand in 2022 and sales up 61% per IRI data. We are proud of our success with Snack Walnuts thus far but know there’s still more room to grow, especially as overall domestic walnut consumption continues to be

stable. With increased walnut plantings over the last several years, the industry needs to be seeing growing consumption. With the growth of the snack nut category and our Snack Walnut line, we see snacking as a tremendous opportunity to help increase domestic demand as it will further deseasonalize walnuts and keep consumers coming back.

As part of our strategy to help increase domestic walnut consumption, we are focused on further developing our snack portfolio with innovative products that meet consumer needs and introduce walnuts in new ways to new consumers. In looking at IRI’s April 2022 data on the snack nut category, it was clear there was an upward trend of consumers purchasing trail mix. It showed the trail mix category saw a 9.1% increase vs the prior year, accounting for $1.26 billion in total retail sales. This was the rationale for relaunching Harmony, a 50-year-old Santa Cruz trail mix brand we acquired in 2006. The brand was originally founded by two surfers who made a delicious portable snack of nuts and dried fruit so they never missed the next big wave. Inspired by the original ethos of Harmony, “fuel your next adventure”, we gave the classic brand a fresh look and created a line of three tasty and nutritious trail mixes highlighting the benefits of walnuts paired alongside other complementary nuts, seeds, dried fruits and snacks.

Our reimagined Harmony launched earlier this year in three better-for-you varieties: Amped Omega-3, Colossal Keto and Mega Mountain. Amped Omega-3 is a functional blend of

Alpha-Linolenic Acid (ALA) Omega-3 superfoods, including our Diamond of California® Himalayan Pink Salt Snack Walnuts, almonds, pumpkin seeds, raw walnuts and dried cranberries, and each serving contains 1000 mg of ALA Omega-3 (62% of the recommended daily value.) Colossal Keto is a keto-friendly blend of good fats and low carbs with our Diamond of California® Himalayan Pink Salt Snack Walnuts, Sonoma Creamery Parmesan Cheese Crisps, roasted edamame, roasted almonds and roasted peanuts. Each serving contains 3g of net carbs, 7g of protein per serving, less than 1g of sugar and 0g of added sugar. Mega Mountain is a classic sweet and savory trail mix blend with Diamond of California Salted Dark Chocolate Walnuts, roasted peanuts, raisins, roasted almonds and coated chocolate candies. Each serving contains 4g of plant-based protein and is a good source of ALA Omega-3.

ContinuedfromPage30

32 West Coast Nut July 2023

Brian Huff, CEO of Diamond Foods

Diamond Foods relaunched Harmony®, a 50-year-old Santa Cruz trail mix brand acquired in 2006. The brand’s new trail mixes highlight the benefits of walnuts paired alongside other complementary

An additional phase of our strategy to increase walnut consumption domestically by further expanding our snacking portfolio is to serve another untapped market in the snack nut category: pecans. Domestic pecan consumption is up, and we see this as an opportunity to grow further by serving

opportunity by launching Pecan Pie Pecans along with an iconic seasonal flavor in Pumpkin Pie Spice Walnuts. Finally, we will also be launching an exciting co-branded product in our snack walnut line late in the year. While snacking and innovation are the keys to our strategy to increase

end benefits for the consumer. Food and drink flavors move faster in our more connected world, so we want to make sure we are being thoughtful and not just innovating for the next fad but creating timeless products that draw consumers in and keep them coming back for more.

References

IRI “Snack Sensations Around the World,” April 2022

Mintel – Snack Food, US (2018)

IRI MULO Market Advantage, Integrated Fresh, Total U.S., 52 Weeks Ending 04/17/22

IRI MULO Dollar Sales, 52 Weeks

July 2023 www.wcngg.com 33

PROGRESS BEING MADE ON EARLY WARNING SYSTEM FOR LEAFFOOTED BUG

By CECILIA PARSONS | Associate Editor

By CECILIA PARSONS | Associate Editor

Monitoring for leaffooted bug (LFB) invasions in almond and pistachio orchards is presently mostly a visual effort. Scouting orchards for signs of this large hemipteran pest begins when warm weather draws overwintering adults into orchards to feed. The trouble is damage to the developing crop may have already occurred before LFB are found. Or growers spend money on insecticide spray applications that may not be warranted.

Significant progress toward an ‘early warning system’ has been made in recent years with identification and synthesis of an aggregation pheromone. This attractant and an effective trap may give almond and pistachio growers a better picture of the potential for crop damage and justification for an insecticide spray.

Adult leaffooted bugs are large, measuring 0.75 to 1 inch in length and have large, strong mouthparts. The three main species of LFB in California have similar brown coloring with a narrow white band across the back. Their hind legs have an expanded appearance that resembles a leaf. Presently, the most common LFB species found in tree nut orchards is Leptoglossus zonatus, which can be identified by the two yellow spots on the plate-like structure that covers all or part of the thorax. UC Riverside Entomologist Jocelyn Millar said 20 years ago the LFB species Leptoglossus

clypealis appeared to be the most common species affecting California crops, but for reasons unknown, L. zona tus has now become dominant. L. clypealis does not have the yellow spots, but has a long, pointed feature on its head.