13 minute read

Around the Yards

NORTHEAST

Maine shop seems to have a winner in 25-footer; magic has its place on the lobster boat racing circuit

By Michael Crowley

ast year, Jeff Eaton at

LEaton’s Boat Shop &

Fiberglassing in Deer Isle, Maine, finished off an Eaton Boat Shop 25 for a local lobsterman, and immediately it showed signs of being very popular. The 25-footer came out of a mold Eaton purchased six years ago that is about 20 years old and has gone through some name changes, from the Northern Edge 25 to the Northern Bay 25 when John Hutchins of Down East Boats and Composites had it, and now the Eaton Boat Shop 25.

This winter Eaton started building three 25s. Two are kit boats for tuna fishermen, one in New York and the other in Massachusetts. Each of those 25s will be powered by a 300-hp Yamaha outboard. The third 25 will be a pleasure boat with a head, V-berths and a settee.

The Eaton Boat Shop 25 with a 200hp outboard does 35 mph. Eaton says with the 300-hp outboard “we are looking for the higher 40s to 50 mph.”

There’s been enough interest for next year in the 25 that Eaton is seriously thinking of constructing an addition to his boatshop that will allow him to lay up a 25 hull and deck, then move those to the existing shop to be finished off, while laying up another hull and deck in the new shop.

Also in the cards for next year is the possibility of raffling off an Eaton Boat Shop 25. A thousand tickets would be offered at $20 a ticket. “We’d do a raffle and then split it up, $10,000 to the fire department and $10,000 to the ambulance volunteers. If there’s something they need, they can get it,” says Eaton. “It kind of helps the community out.”

In the meantime, Eaton is getting his own lobster boat ready for the coming season and the 2021 Maine Lobster Boat Races. Eaton’s La Bella Vita, a Northern Bay 38, is nine years old, and its 13-liter 750-hp Iveco has 11,000 hours and needs to be replaced. A new 16-liter Iveco is going in. “It starts out at 815, and we’ll see what we can get from there,” Eaton says when asked its horsepower. “You never know till you put her in.” He’s known of other boats that have replaced the 13-liter Iveco, and they’ve all gained speed, which he acknowledges would be good for racing. (La Bella Vita races in Diesel Class K 701 to 900 hp.)

Speaking of lobster boat racing, the first of Maine’s 2021 lobster boat races is set for Boothbay Harbor on June 19. One of the new boats bound to draw a lot of attention is Whiskey Tango Foxtrot, a 36 Crowley Beal designed by Calvin Beal, being built at Kennedy Marine Engineering in Steuben, Maine.

If the name is familiar to those who follow Maine lobster boat racing it’s because Whiskey Tango Foxtrot was written across the bow and transom of a 28 Calvin built by Kennedy Marine Engineering’s Roger Kennedy in 2014.

“It won every race that year — beat Wild Wild West. We were the boat to beat that year,” says Kennedy. After a season of racing, he sold her “to a fellow in

This Eaton Boat Shop 25 will be going to a tuna fisherman.

Continued on page 35

Jon Johansen

SOUTH

Omega trims Atlantic steamer fleet with conversion; pound-net skiff gets overhaul at Virginia railway

By Larry Chowning

ith the help of Ampro

WShipyard in Weems, Va., Omega Protein in Reedville is busy getting its menhaden fishing fleet ready for Virginia’s 2021 menhaden fishing season. The season opened in May.

Omega recently announced it’s cutting back on its Chesapeake Bay fishing fleet, as six boats will be fishing this season. Last year, the firm had seven menhaden steamers working Chesapeake Bay and the Atlantic Ocean. The Tideland, one of the largest and oldest vessels in the fleet, will leave the Larry Chowning fishing end of the business. It will remain in the fleet, however, as a carry-away boat. The 218-foot Tideland was launched in 1966. “She has caught a jag of fish in her lifetime,” said Omega’s Reedville Vessels Manager Harvey Hamm.

Tideland will require only a minor conversion to switch from fishing boat to carry-away boat. It will require installation of new pumps, modification of the hydraulic system and some new stainless steel piping.

The work will be done with the boat in-water at the Omega Reedville plant by way of a partnership between the Ampro work force and Omega’s boat maintenance crew. “We rely on Ampro to do a lot of our work,” said Hamm. “When we have a need we can count on them coming to our place to jump in and take care

The Calcasieu Pass is at Ampro Shipyard in Weems, Va., getting outfitted for the May start of Chesapeake Bay menhaden season.

of the problem.”

The F/V Calcasieu Pass is at the Ampro Yard in Weems. It’s there for upgrades to fish screens and to the refrigeration system. The yard is also replacing black iron piping with stainless steel pipe and rusted out ladder steps. “We are just trying to bring her back to life,” said Hamm. “If we take care of small problems at the start of seasons, it helps to eliminate larger problems in the future.”

Omega’s F/V Fleeton was at the Ampro yard before the Calcasieu Pass arrived. Ampro installed several new bridge wing doors, modified some of the hydraulics and replaced iron piping with stainless steel.

Over in Heathsville, Va., Chesapeake Bay pound net fisherman Fred Jett of Ophelia, Va., had his wooden pound skiff glassed at Cockrell’s Marine Railway. Built by George Butler of Reedville in 2000, the 23' 8" outboard-powered wooden skiff has been worked hard in the Potomac River pound net fishery, and it took a major overhaul to get her back on the waves. The old paint, inside and out, was power washed off with a 7,500-psi sprayer. And the outside was completely covered with two layers of DBM 1808 Knytex Biaxial matt and woven.

The ribs and chine are supported with 3/4"-thick sheets of Carbon Cove Honeycomb, fastened with stainless screws, and the inside of the skiff is totally encapsulated in fiberglass.

Jett uses the flat-bottom skiff as his main fishing boat for most of the season and has a larger deadrise boat for setting and dismantling pound nets at the start and end of seasons.

Butler’s boatbuilding records show he delivered the skiff to Jett in October 2000. “I can tell you one thing,” says Butler, “Fred works his boats hard, and I know she needed a lot of something to bring her back to life.”

Cockrell says the oak ribs along the inside of the skiff were about gone. Shoveling fish out of the bottom had just about shoveled the ribs away, he says. “There was hardly anything holding the chine to the sides. We got her back together and I guarantee she will last another 20 years.”

Moving south to the Gulf of Mexico and to Omega Shipyard in Moss Point, Miss., Omega Protein’s Vice President of Fishing Operations Monty Diehl reported that the yard has a $7 million refurbishing project about to start on the menhaden steamer Frosty Morn. The vessel is owned by Omega and used in the gulf menhaden fishery.

The 195-foot Frosty Morn was built in 1958 for the menhaden firm J. Howard Smith by Bellinger Shipyard in Jacksonville, Fla. Frosty Morn started life fishing

WEST

Oregon shrimper gets shafted — for the better; family tradition keeps going at California boatyard

By Michael Crowley

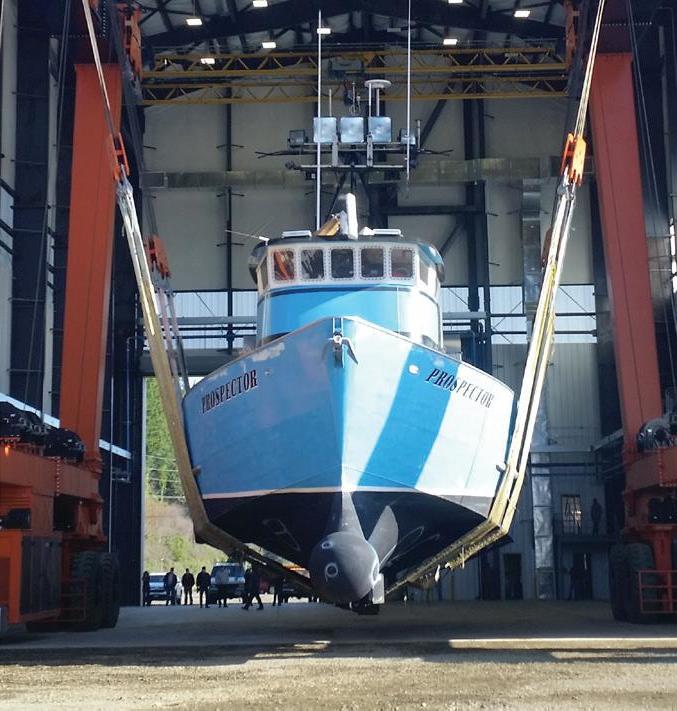

he Prospector, a 64' x 25'

Tshrimper and crabber built in 1973, was hauled out in March at the Port of Toledo Shipyard in Toledo, Ore., for a major overhaul. The 48-year-old Prospector had been sponsoned and lengthened in 2016, and then repowered with a 640-hp Cummins K-19 in October 2019.

When the Prospector was repowered, its 3-inch shafting wasn’t upgraded. Thus 4-inch shafting was being installed at the Port of Toledo Shipyard to allow for full use of the Cummins power. The Prospector is also getting larger cutlass bearings, larger Babbitt bearings and foundations, and new stuffing boxes at the stern tube and the engine room bulkhead. Plus the engine needed to be realigned, and at the end of that 4-inch shaft will be a new 58-inch, five-blade prop.

The “interesting thing about the shafting,” says the Port of Toledo Shipyard’s Mike Lee, is where it came from. Last year, the 78-foot dragger Miss Sue was hauled at the yard and repowered with a 750-hp Cummins QSK19 and given a new Nautican nozzle and triple rudder. More horsepower meant the Miss Sue’s 4-inch shafting would be replaced with 5-inch shafting.

That’s when the owners of the Prospector and the Miss Sue, who already knew each other, got to talking. The upshot was the Prospector’s owner ended up buying the Miss Sue’s old 4-inch shafting, which is now in the Prospector.

Work on the Prospector wasn’t limited to its powertrain. The pilothouse is being expanded and given a new interior, after the aft bulkhead was moved back 4 feet. Down below, the galley and stateroom areas are being stripped out and remodeled.

Shaft work was on the minds of a couple of other boat owners whose

Port of Toledo Shipyard

The 64-foot Prospector was the first boat in the Port of Toledo Shipyard’s new fabrication shop.

vessels were recently hauled out with the Port of Toledo Shipyard’s 600-metric-ton Travel Lift. They included the Northern Ram (ex-Blue Fox), an 85-foot dragger that had its shafting checked over and got a coat of bottom paint; the Pacific, a 75foot crabber and dragger whose tailshaft passed inspection but left with a new intermediate shaft and bearings, new cutlass bearings, new reduction gear and complete engine alignment.

In addition to its repair work, the Port of Toledo Shipyard had just about finished building a new sandblasting and fabrication shop in March. The shop will be 120 feet wide, 80 feet long and 100 feet tall.

Down in Fort Bragg, Calif., Howard Makela at Makela Boatworks completed work on the 72-year-old Sea Wolf in January. Makela’s father, Fred, and uncle Nick, who started Makela Boatworks, built the Sea Wolf in 1949. She is currently a salmon and albacore troller and crabber that needed new stern deck planking.

The 51-foot Ed Monk-designed Sea Wolf had been “well taken care of over the years,” says Howard Makela. But after seven decades “there weren’t any nails left” in the original Douglas fir decking, which was also turning “soft and starting to open up.”

New Douglas fir planking — 1 7/8 inches thick and 2 1/2 inches wide — went down over the original deck beams. The planking was fastened to the deck beams with cast, heavily galvanized, quarter-inch-square boat spikes that Makela says, are “a little heavier than a boat nail.”

Makela gets his boat spikes from Keystone Spikes in Lebanon, Penn., which, he says, “is the only place in the United States that makes them.” Speaking about working on older wooden boats, Makela adds, “you have to really search to find

Makela Boatworks

Around the Yards: West

Continued from page 44

Around the Yards: South

Continued from page 43

any materials these days.”

The seams of the new planking were caulked with cotton and then closed o with marine glue that expands and contracts with the weather while locking in the cotton. The planking was nished o with a coating of Log Oil.

Makela also replaced the coaming around the trolling pit. He gures the Sea Wolf “won’t need any other work in the near future.”

The Sea Wolf was the second boat built by his father and uncle. In March, Makela started work on the rst boat they built, the Condor. The 44-foot troller and crabber is getting new window frames and trim around the front of the wheelhouse. About 10 years ago, the Condor was at Makela Boatworks for extensive hull repairs, including new frames and refastening. “Basically it was a rebuild,” says Makela.

Fred and Nick Makela built 14 boats, all Ed Monk designs. Most of them are still shing o the California coast. for menhaden o the New Jersey coast and has spent the last 50 years in the Gulf of Mexico’s menhaden shery.

The yard also has a contract with its parent company, Cooke Aquaculture USA, to build a service barge to work in Cooke’s o shore Atlantic salmon aquaculture operations in Maine.

It takes three years for Atlantic salmon to grow to maturity. The rst 18 months are spent on land at a hatchery, and the next 18 months in ocean penstocks. The service barge will be used at sea.

Omega Protein is looking for a used o shore support vessel for potential conversion to a menhaden steamer. “We hope to do the conversion at Moss Point in 2022 to have the vessel ready for the 2023 (menhaden) shing season on Chesapeake Bay,” said Diehl.

Around the Yards: Northeast

Continued from page 42

BJ5000EX, ROLLERS, SQUID SYSTEMS, NET HAULERS, MACKEREL LINES

California.” Now Kennedy is getting back into racing with a di erent Whiskey Tango Foxtrot. FAST - FRIENDLY SERVICE - SAME DAY SHIPPING

The rst Whiskey Tango Foxtrot was powered by a 6.7-liter FPT. The new version has a 9-liter FPT that as a stock model should produce 589 hp. But as Kennedy is quick to say, “I’m going to get a lot more than 580 horses.” Asked how he was going to jack up the power, Kennedy replied: “Magic. I’ve got a couple of trick things I think will help it. Just going to massage it and play with it and see what we get. It won’t be earth shattering, but it will be a fun boat to watch.” Kennedy knows Whiskey Tango Foxtrot should hit at least 58 mph with enough power because, he says, that’s what Stevie Johnson achieved with a 36 Crowley Beal in the 1990s. email: gaskimarine@outlook.com

Keeping the weight down is key to building a fast boat, and phone: 902-701-8210 ∙ www.gaskimarine.com Kennedy is doing just that. He started out with a hull, top, and engine weighing 5,500 pounds. Since then, only cored and composite materials have been used as building materials. “There’s literally not one stitch of wood in it,” he says.

Speed is important to Kennedy, but so is safety. He says Whiskey Tango Foxtrot could go 100 miles o shore and its occupants would be safe. “I’m not building a lightweight race boat just for the sake Atlantic 37’ of going fast. I’m building a sturdy work- At Farrin’s, pride in our workmanship has been boat that as a byproduct could go fast.” continuously applied in over 45 years of building boats. Wayne Beal 40’ (Whiskey Tango Foxtrot will race in Our craftsmanship in construction will give your custom project the quality that has made Maine Custom building and finishing to 50’ Diesel Class J 551 to 700 hp.) famous in the boat building industry. Walpole, Maine 04573 • 207-563-5510 • FarrinsBoatshop.com