2 minute read

3. Analysis of Nike’s the Supply Chain

3. Analysis of Nike’s the Supply Chain

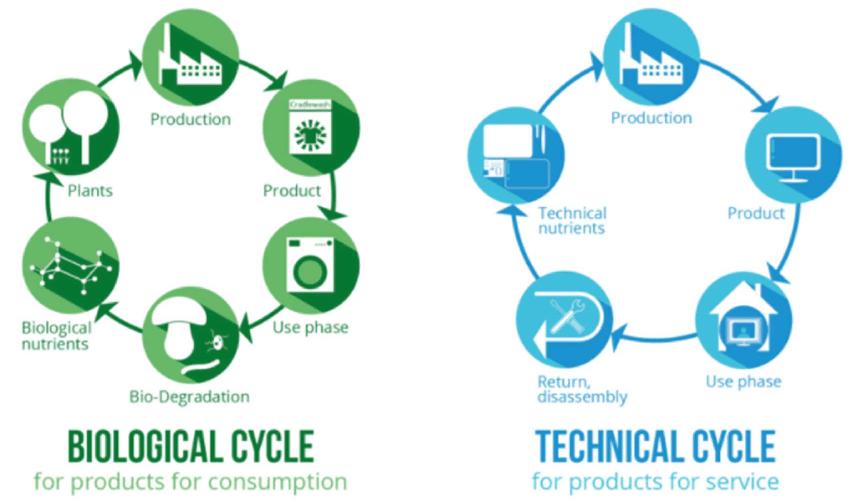

Majority of the garments found in landfills and incinerators are traditionally designed in a linear, cradle to grave model beginning with resource extraction, production, sales and eventually disposal (Gwilt and Rissanen, 2011). But these are very unsustainable models which impacts various resources, processes and people around the world. There is a requirement to move towards design strategies that not only focus on post purchase concepts of “Reduce, reuse and recycle” but also aim at lower resource utilization, and lower consumption of higher quality and durable goods at pre-manufacturing stage. One such approach could be through applying a cradle to cradle concept, which is a closed loop system inspired from nature. Here, products are classified as either biological components – which turn into food for the biological cycles or technical nutrients - that are absorbed into technical cycles for further production.(Sherratt, 2013) These cycles are illustrated in Figure 4 below and provide a guideline that could be used by Nike.

Advertisement

Figure 4. Cradle to Cradle cycle concept Image Source: (Wautelet, 2018)

Nike’s supply chain spans worldwide due to cost benefits. Majority of the manufacturing is outsourced to suppliers worldwide with most of the raw materials being sourced within the manufacturing host country by independent contractors. Therefore, embracing a robust supply chain management model would ensure standards of sustainability and quality of products are met.

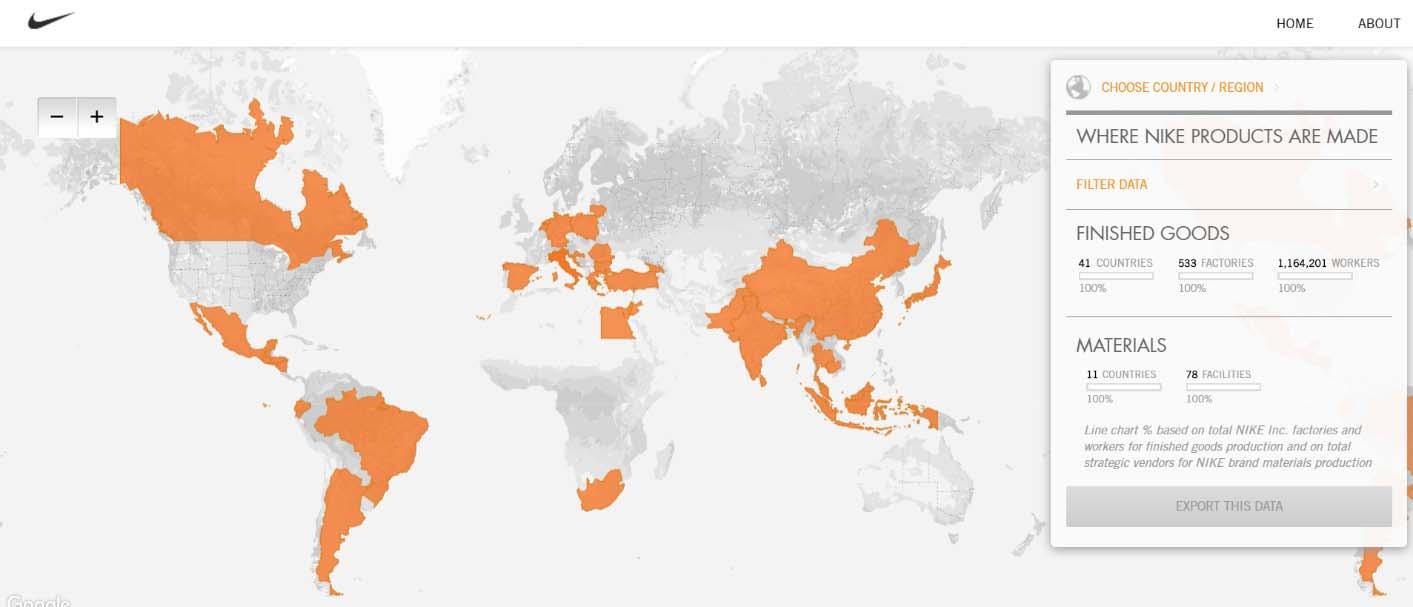

The below Figure 5 illustrates the size and span of Nike’s global supply chain. Its goods are produced in 41 countries at 533 factories with more than 1 million workers. Raw materials are sourced form 11 countries and 78 facilities.(Nike. Inc, 2019b). Nike sells its products through NIKE owned retail stores along with digital platforms and through independent distributors and licensees worldwide. These are supported by 6 primary distribution centres in the US and 67 distribution centres outside of the US.(Singh, 2019)

Figure 5. Nike Supply chain

Image Source: (Nike. Inc, 2019b)

Nike mas made major strides in establishing a good supply chain through long term supply with high quality and less number of factories that meet Nike’s stringent sustainability and corporate responsibility while minimizing environmental impact and creating a safe, valued, strong and engaged workforce. A similar commitment is shown at the highest level, through Nike’s Corporate Responsibility, Sustainability & Governance Committee of the Board of Directors who review and evaluate Nike’s sustainability practices and provide management oversight. In line with the cradle to cradle concept, Nike has committed to accelerate the implementation of circular economy and has published its 10 principles of circular design (Ref. Appendix. B)(Nike. Inc, 2019a). These principles consist of (1) low impact, upcycled and recycled materials, (2) designs with cyclability in mind, (3) waste avoidance in product creation process, (4) easy disassembly of products to preserve value, (5) green chemistry to eliminate hazardous wastes, (6) refurbishment through repair or components or materials, (7) versatility in products to adapt to changing styles and purposes, (8) durability through high quality production and materials, (9) recycled or biodegradable packaging, (10) establishment of new models to extend the product lifecycle.