We understand the intricacies of your franchise business and look at it holistically across the value chain to offer innovative solutions that promote business growth.

This enables us to provide your franchise business with a seamless, end-to-end funding process that supports the purchase of additional sites, and funds any new opportunities that may arise.

So, do you want just any financial partner, or a partner that thinks bigger to help your franchise business grow?

7 WHAT’S NEW

South Africa’s trendy food and beverage product innovations

8 NEWS

Ishida Revolutionizes X-Ray Inspection for Flow Wrapped Packs

Meet the Markem-Imaje SmartLase® Coder F250

10 INDUSTRY TALK

Bühler Southern Africa aims for food security

12 COMPANY FOCUS

Setting industry standards in hygiene management

14

EMBRACING THE WHITE PEACH TREND IN DAIRY

A fresh approach to dairy processing

Pectin’s potential in dairy Innovative nutritional cheese concepts

Enhancing diary with natural colours

Energy solutions in the cheese industry

28

VEGAN INGREDIENTS & PROCESSING

Coatings in meat alternative products

A sweet vegan treat

Natural colours for plant-based meat

Unpacking Coperion’s new MeGAtexR90

Optimising vegan and vegetarian nutrition

A natural citrus fiber for clean label

38

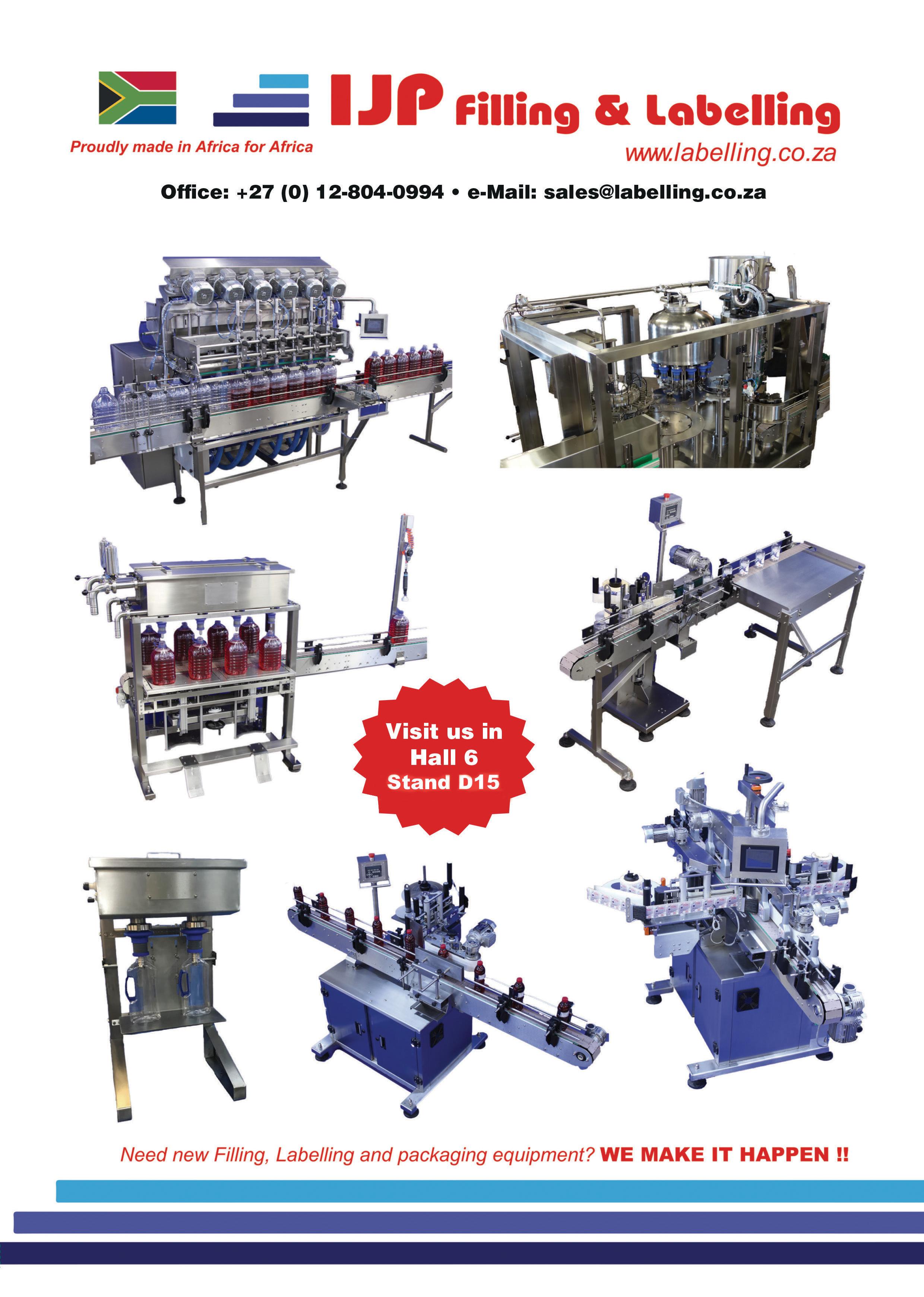

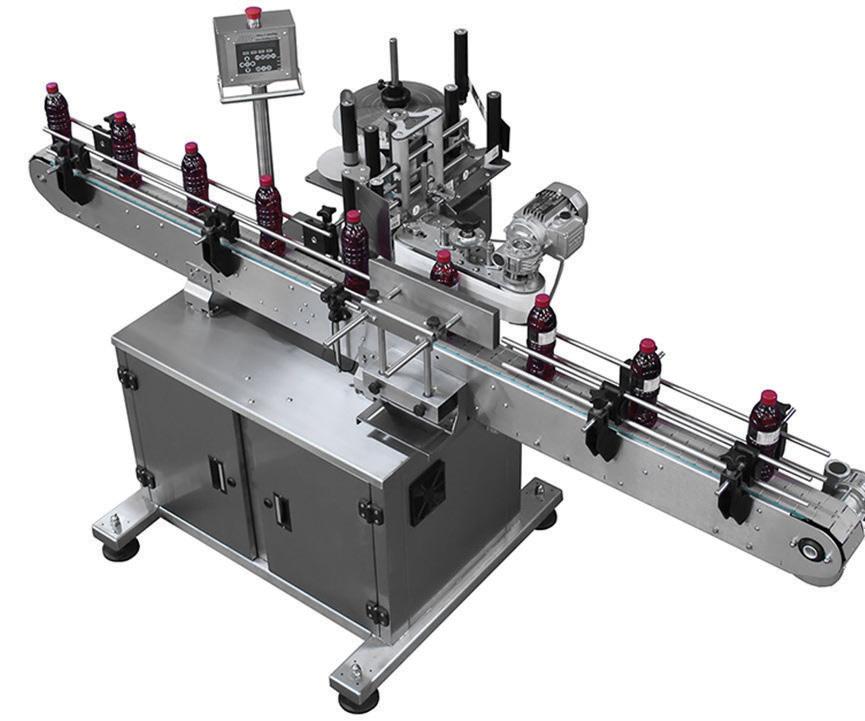

BOTTLING & FILLING TECHNOLOGY

EvoFill PET: Efficiency redefined

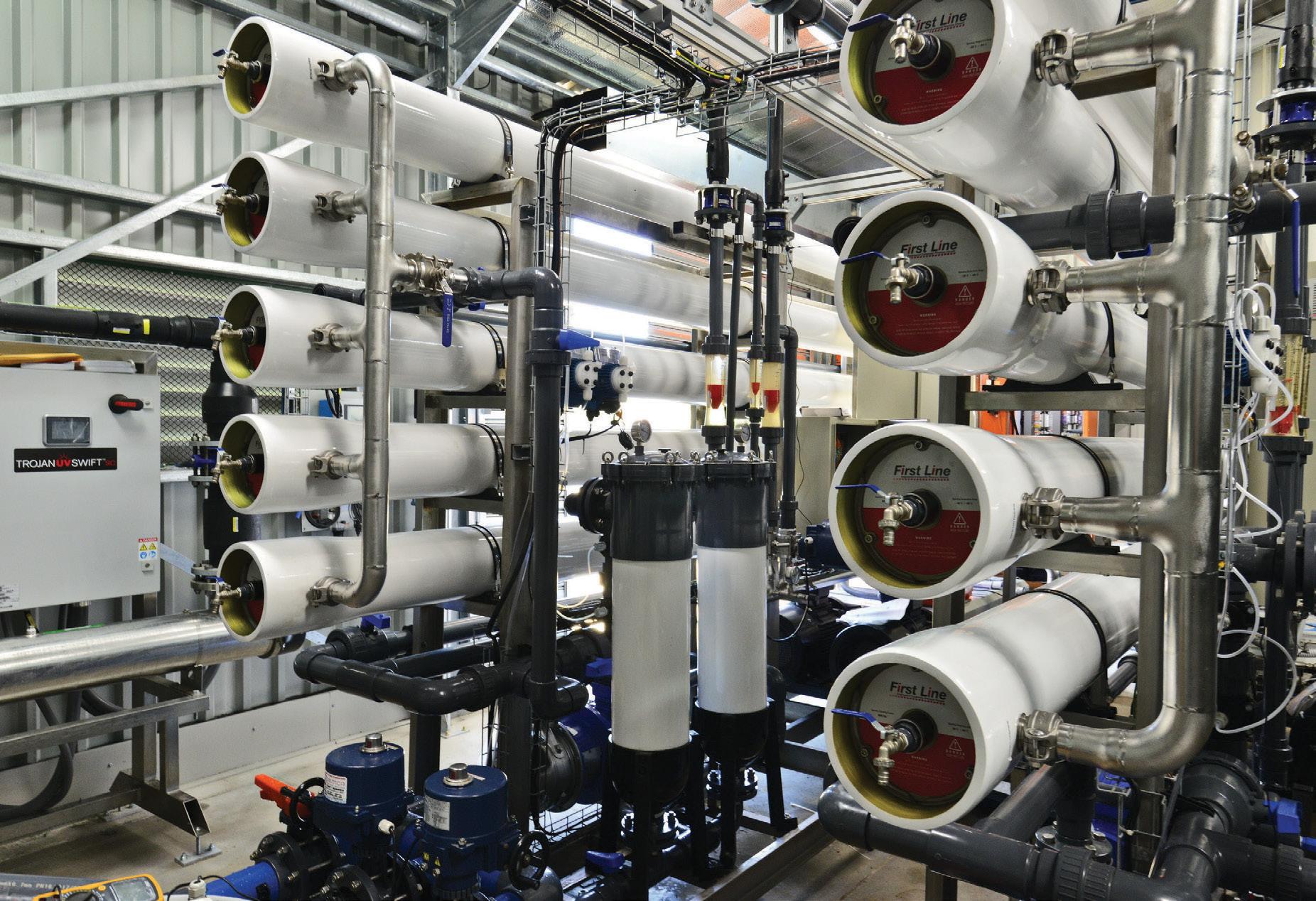

The future of bottled water in Africa

Moo-ving forward into energy efficiency

Beverage packaging for a greener future

48

LABORATORY & TESTING SERVICES

Quality control in food manufacturing

Nutritional labelling and quality testing

Making test results work

Elevating food safety standards

Cutting-edge packaging solutions

56 SAFETY, HYGIENE & QUALITY ASSURANCE

Tailored solutions for food and beverage surfaces

As consumer demands continue to evolve, food and beverage manufacturers are facing unprecedented challenges and opportunities. From shifting dietary preferences to increasing sustainability concerns, the landscape of the industry is constantly evolving. However, with change comes innovation, and we are witnessing remarkable advancements across various aspects of food production. Welcome to the latest edition of Food Review ! In this issue we shine the spotlight on the following sectors: There is a rising interest in functional dairy products that offer additional health benefits beyond basic nutrition. These products may contain added probiotics, prebiotics, vitamins, or minerals to support digestive health, immune function, or overall wellness. On page, 14 AGRANA SA embrace the white peach trend dairy and plant-based products. Vega focuses on a fresh approach to dairy processing and share insight on how to ensure good quality and safety of milk throughout the production process in order to guarantee optimal storage conditions, see page16. Moving on to vegan ingredients and processing, Heat and Control on page 28, highlight the consumer’s drive for health consciousness, ethical considerations and environmental sustainability by demanding plant-based versions of their favourite foods. On page 36, Savannah Fine Chemicals unpacks how Herbafood Ingredients Gmbh, a company that has been at the forefront of sustainable practices with its production of multifunctional citrus fibers is boldly this trend. Read more about how this movement is currently shaping the food manufacturing industry. Filmatic is shaking things up in the future of bottled water in Africa with its cost-effective solutions playing a crucial role in addressing the growing demand for bottled water by providing efficient and hygienic solutions to fulfil customer expectations, see page 40. Other sectors in this issue: Safety Hygiene & Quality Assurance, on page 54 as well as Laboratory & Testing Services on page 46.

THE TEAM

EDITORIAL

Editor: Kelebogile Nondzaba +27 (0)78 175 9632

kelebogile.nondzaba@newmedia.co.za

Sub-editor: Gill Abrahams

Layout & Design: Tumi Kunene

ADVERTISING

Key Account Manager: Anita Raath +27 (0) 82 976 6541 anita.raath@newmedia.co.za

Key Account Manager: Càndida Giambò-Kruger +27 (0) 71 438 1918

càndida.giambò-kruger@newmedia.co.za

INTERNATIONAL SALES

Germany/Austria/Switzerland:

Eisenacher Medien

Erhardt Eisenacher +49 228 249 9860 info@eisenacher-medien.de

Italy: Ngcombroker

Giacomo Rotunno +39 370 101 4694 g.rotunno@ngcombroker.com

Taiwan: Ringier Trade Media

Sydney Lai +886 4 2329 7318 sydneylai@ringier.com.hk

CIRCULATION

Circulation Manager: Felicity Garbers felicity.garbers@newmedia.co.za

PUBLISHING TEAM

General Manager: Dev Naidoo

Head of Commercial B2B: Johann Gerber

Production Controller: Mandy Ackerman

Art Director: David Kyslinger

JOHANNESBURG OFFICE

Ground Floor 272 Pretoria Avenue Randburg, 2194

POSTAL ADDRESS PO Box 784698, Sandton, Johannesburg 2146

Published by New Media, a division of Media24 (Pty) Ltd

MANAGEMENT TEAM

MANAGING DIRECTOR: Aileen Lamb

COMMERCIAL DIRECTOR: Maria Tiganis

STRATEGY DIRECTOR: Andrew Nunneley

CHIEF FINANCIAL OFFICER: Venette Malone

CEO: MEDIA24: Ishmet Davidson

HEAD OFFICE

New Media, a division of Media24 (Pty) Ltd 8th floor, Media24 Centre, 40 Heerengracht Cape Town, 8001

Our value-added systems prepare and cook consistently superior beef, pork, chicken, turkey, fish and other meat products including other Meat Alternative Products to create a distinctive quality that stands out in the marketplace.

• Preparation + Processing

• Battering + Breading

• Frying + Oil Management

• Branding + Searing

• Cooking, Roasting + Drying

• Coating + Seasoning

• Product Handling

LOOKING BACK. PRESSING FORWARD. ALWAYS INNOVATING.

Nampo Harvest Day

Bothaville,South Africa

14 – 17 May www.grainsa.co.za

Food Pack Africa

Kampala, Uganda

6 – 8 May www.mxmexhibitions.com

IFAT Munich, Germany

13 – 17 May www.ifat.de

Cibus Parma, Italy

7 – 10 May www.cibus.it

SIAL Shanghai, China

28 - 31 www.sialchina.com

Africa’s Big 7 Johannesburg, South Africa 11 – 13 June www.africabig7.com

Food & Beverage W/Africa Lagos, Nigeria 11 – 13 June www.fab-westafrica.com

AFMAS Food EXPO Eastern Africa 12-14 June www.afmass.com

Dairy Manufacturing Africa Expo

Co-located with Afmas Food Expo 12 – 14 June www.dairymanufacturingafrica.com

Africa Meat & Poultry Expo

Co-located with Afmas Food Expo 12 – 14 June www.africameatpoultryexpo.com

Moedi Wines, a new female-owned African wine brand, is set to make waves at ProWein 2024 in Düsseldorf, Germany. Founded by Lesego Serolong Holzapfel, Moedi not only showcases premium South African wines globally but also emphasises sustainability, African heritage, and community empowerment through the craft of beekeeping.

This year, South Africa commemorates 30 years of democracy and 365 years of its wine industry, which now employs over a quarter million people in its value chain.

“Amid our challenges, there is much to celebrate,” Holzapfel reflects. “In 1994, it was nearly impossible for any black wine producers to participate in ProWein, and yet here we are.”

Growing its wine exports from only 50 million litres in 1994, South Africa ranked as the sixthlargest wine exporter globally in 2022, at 440 million litres. Despite a dip to an estimated 306 million litres in 2023, Holzapfel envisions the industry’s potential to expand its wine exports and further increase the value per litre.

To read more visit, www.foodreview.co.za

Make this Easter a feast for the senses by elevating your celebrations with a decadent Rooibos and chocolate tasting.

Pairing tea or herbal tisanes with chocolate is a culinary delight, which can help to unlock the more subtle flavours and aromas that you might not pick up when you enjoy tea or chocolate on its own.

Adele du Toit, spokesperson for the SA Rooibos Council (SARC), says Rooibos and chocolate make excellent Easter companions. “Both Rooibos and chocolate are associated with comfort, indulgence and reflection, which align with the spirit of Easter. Enjoying a cup of Rooibos and chocolate together can enhance these sentiments.

“They also share many similar characteristics – from the fruity, floral and nutty aromas to the slight levels of astringency, making them an ideal match.”

In addition to Rooibos being used in chocolate bars and truffles, innovative chocolatiers from around the world are also experimenting with the tisane in chocolate drinks, which

UPM Raflatac has received RecyClass recognition for PE Films with its Multipurpose UV acrylic adhesive technology - making UPM Raflatac the first ever pressure sensitive laminate producer to receive technology approval in this category. The granted recognition expands UPM Raflatac’s portfolio of RecyClass approved PE (polyethylene) label materials. These materials are recognized to be recycling compatible with coloured and natural PE flexible films. Today’s consumers and brand owners demand product solutions

where the sustainability aspects including packaging recyclability are carefully considered. As a significant trend which is only going to get bigger, UPM Raflatac is well positioned to cater for the growing market demands with its labelling solutions for fastmoving consumer goods (FMCG) products which are by default designed to support recycling compatibility.

“We are working towards a more sustainable and circular future. One big part of this is making plastic packaging

appeals to consumers looking for alternatives to traditional hot chocolate or coffee-based drinks.

Du Toit says Rooibos-based chocolate drinks vary widely, incorporating different blends, such as matcha and chai, and combining them with chocolate in various forms, such as cocoa powder, chocolate syrup or chocolate chips. “These drinks can be found in specialty cafés, tea shops and artisanal chocolate shops, catering to consumers interested in exploring new and exotic flavour combinations.”

Milk chocolate is the most versatile for pairing with Rooibos. It’s creamy, milky consistency can help to balance the flavour of various blends. Plain Rooibos, Rooibos Cinnamon, Rooibos Berry and Rooibos Vanillaall pair beautifully with milk chocolate Rooibos’ smoky undertones complement the nuttiness of milk chocolate, while its smooth, sweet caramel notes naturally match and balance the flavours of the chocolate. These blends also work well with sponge cakes, custard and other sweet tarts.

recyclable. Labels not only serve as a carrier of information on flexible packages and packaging films, but also offer a functional purpose for example as closure systems. We are proud to be the first ever selfadhesive label company to provide RecyClass approved recycling compatible labeling.

The challenge of carrying out comprehensive foreign body and quality checks on small lightweight flow wrapped confectionery and bakery packs on high-speed packing lines has been overcome with the introduction of Ishida’s latest X-ray inspection system.

The new Ishida IX-EN-2493-Compact combines an ultra-compact design, which can fit easily into existing lines, with speeds of up to 120 metres per minute. This is double the speed of a typical standard X-ray inspection system.

Key to achieving these high speeds is the IX-EN-2493-Compact’s unique split conveyor design. Traditional X-ray systems have a single conveyor with protective curtains that contain the X-ray beam within the machine. However, these curtains can interfere with the movement of lightweight flow wrapped packs, causing them to be destabilised and creating product jams. With the Ishida solution, the curtains are raised above the conveyor so as not to

impede the movement of the packs. The X-ray beam is therefore projected through the pack as it passes over the gap in the conveyor where it is captured within two large metal plates to ensure any X-ray emissions are contained within the machine.

“Our new compact X-ray inspection system enables manufacturers to check primary packs, whereas before the fast speed of line prevented inspection at this stage,” explained Glen Oxborough, Quality Inspection Control Sales Specialist, Ishida Europe. “Prior to this, therefore, the only effective solution was to carry out the inspection in the secondary packaging, either when the packs were part of a multipack or in their outer case ready for onward delivery.

“However, this meant that if a substandard pack was detected, the entire pack or box would need to be rejected, leading to unnecessary – and expensive – product and packaging waste.”

The IX-EN-2493-Compact features Ishida’s proven Genetic Algorithm (GA) technology

that enables operators to optimise the X-ray inspection process for greater sensitivity to specific foreign bodies. As well as reliably detecting items including steel, aluminium, tin, glass, stones, dense rubber and Teflon, the machine can also identify quality issues such as broken or mis-shaped items.

Another special design feature of the Ishida X-ray system are the two separate bins for foreign bodies and quality issues, both of which can be accessed from one side of the conveyor for maximum operator convenience. This also helps to minimise the overall footprint of the machine to enable easy integration into packing lines.

“Food quality and safety are key issues that can adversely affect brand image and consumer loyalty,” said Glen Oxborough.

“Our new IX-EN-2493-Compact delivers peace of mind for manufacturers with a solution that can handle the fast line speeds of flow wrappers to enable primary packs to be inspected.”

To read more visit, www.foodreview.co.za

As technology advances, so do how we print and code our products.

In particular, the laser coder has revolutionized how we approach industrial coding solutions, setting a new standard in the world of manufacturing. This coder available from Pyrotec PackMark is a wonder in the realm of laser coding. It’s not just faster, it’s also more accurate and substantially more reliable than conventional coding machines.

The reason behind this efficiency is the high precision of lasers used by the SmartLase® Coder F250, enabling it to etch complex codes onto products without causing any damage. This

coder saves manufacturers from unnecessary product loss, while significantly improving the overall look and quality of the codes.

And let’s not forget about versatility - the SmartLase® Coder F250 comfortably adapts to a range of industries, seamlessly integrating into automotive laser coding, extrusions and electronics laser coding, and cable laser coding. With its performance and adaptability, this laser coder is a game-changer in the world of industrial coding solutions.

Small Character Inkjet 9040 Contrast: The Preferred Coding Machine

Moving on, let’s touch on the ideal coding machine for these industries. Cue the Pyrotec’s Small Character Inkjet 9040 Contrast. This machine is uniquely

designed for industrial coding solutions, offering a wide range of ink colors, fast drying times, and easy operation, making it a hit in sectors requiring small, precise, and contrasted codes. Its superiority shines through in the quality of codes it produces, its efficiency, and its adaptability to different production lines.

• Automotive Industry: The need for precision and permanence is catered to by laser coders. They provide accurate, long-lasting codes on a variety of materials, including plastic, glass, or metal.

• Extrusions and Electronics: This sector requires high-contrast, intricate codes. Laser coders meet this need effortlessly, creating clear, indelible codes capable of withstanding high temperatures, humidity, and time.

• Cable Industry: The cable industry also benefits from the capabilities of laser coders. They offer precise, sharp codes that are easily readable, even on the smallest diameter cables, enhancing traceability and reinforcing brand identity.

These points demonstrate the revolutionary impact of Pyrotec PackMark’s laser coders. They are reshaping industries, setting new standards for industrial coding solutions, and paving the way for a more efficient, high-quality coding process.

The food and mobility issues confronting the region demand innovative solutions, technologies, process solutions and business models, explains Bühler Southern Africa.

Bühler Southern Africa is deeply committed to addressing food security, both a regional and continent – wide concern. “We are actively participating in various discussions, highlighting the importance of this issue and our dedication to finding solutions,” comments managing director, Marco Sutter. As a result, the company has started off 2024 in full swing. “Our mission is innovation for a better world. The food and mobility challenges we face demand innovative solutions, technologies, process solutions, and business models,” highlights Sutter. “We want to contribute to a sustainable world that affords the next generation the same chance to live and develop as today’s society. The digitalised world we live in requires higher flexibility and agility to be successful and as a result, a culture based on self-responsibility and collaboration, “says Sutter.

Values are the basics of any company culture, and Sutter highlights that Bühler Southern Africa cares equally for its customers and colleagues. “Our mission is innovation for a better world. What does that mean for us in our region? We have a huge responsibility. We create solutions for safe and affordable food and feed for everyone. Sutter affirms that Bühler is the technology leader in the industry and sets new trends

with its advanced solutions. “We develop new process solutions and business models for the industry and nurture fresh talent for the region. The world we currently inhabit requires more flexibility and agility to achieve success. Therefore, we need to inculcate a culture of high self-responsibility and collaboration, “says Sutter.

Buhler has been operating in South Africa since 1972 and has over 220 employees at present. Its Johannesburg operation provides

sales and service, project execution and manufacturing and logistics. In addition, it has service stations in Cape Town, Lusaka and Maputo, offering its extensive client base spares and wear parts, roll refluting, and die refurbishment. “We offer a strong and trusted local presence in Africa, with a state-of-the-art workshop and local spares stockholding,” highlights Sutter.

Every day, billions of people encounter our technologies to cover their basic needs for food and mobility. We strive for innovations for a better world, with a special focus on health, safe, and sustainable solutions. We contribute significantly to feeding the world’s population, while setting the focus on food security and safety. Our solutions and technologies enable efficient and clean mobility. We are a leader in processing grains, rice, cocoa, coffee and other raw materials. Also, we are a leading solution provider of die-casting and surface-coating technologies in high-volume application

areas, such as automotive, optics and inks. As a leading technology group, We invests up to 5% of its turnover every year in research and development. In 2024, its

roughly 12, 700 employees in over 140 countries generated a turnover of CHF 3.0 billion. The globally active Swiss familyowned company is particularly committed to sustainability. We want every human being to have access to healthy food. We want to protect the climate with energy-efficient cars, budlings and machinery.

Bühler Southern Africa – www.buhler.co.za

AUTOMATION DOESN’T HAVE TO BE COMPLICATED.

WHAT WE STAND FOR

Why we do, what we do:

We want our customers to be successful

We want every human being to have access to healthy food

We want to protect the climate with energy-efficient cars, buildings and machinery

We give you – our employees – all the support and freedom you need to make a difference

We want to remain independent as a company by achieving sustainable success.

What we do:

To achieve this, we develop the best food & feed processing solutions –focusing on food security and food/feed safety.

We develop the best material processing solutions – focusing on energy efficiency and optimal end-products. We provide skills, services and knowledge transfer to enable our employees and customers to be successful.

COMPASS takes food sorting in a new direction by combining the latest intelligent technology with simple, highly intuitive operation. It has never been easier to sort accurately through every production run and maximise your product quality, yield and line profits. COMPASS reduces maintenance costs and sanitation requirements, while providing access to usable performance data and reports that help you improve your production process.

| heatandcontrol.com

Since 1994, NutroChem has grown from a local chemical supplier to a top manufacturer and distributor of specialty chemicals in Southern Africa. With a focus on quality, innovation, and customer service, NutroChem offers a comprehensive range of hygiene management solutions tailored to various industries, explains Geoff Bayman, national sales director.

The company has garnered a stellar reputation for excellence and innovation, specialising in producing and distributing detergents, disinfectants, and essential raw chemicals catering to various sectors. These include the food and beverage industry, agriculture, laundry, hospitality, industrial, commercial, and water treatment industries. NutroChem’s dedication to quality is underscored by its ISO 9001:2015 certification, ensuring manufacturing processes that meet stringent international standards such as SANS1828, EN1276, and EN1656. Clients can trust in our rigorously tested products that consistently adhere to the highest quality and safety standards. At the core of our operations is a commitment to research-driven product development and exceptional customer service, positioning NutroChem as a reliable partner in hygiene management and food safety. Embracing a challenge-driven, results-oriented philosophy, we operate under the guiding principle of “Making a Difference of Value,” constantly refining our services with innovative hygiene management solutions.

Our dedicated team of Hygiene Specialists conducts regular workplace audits, identifying and acting on opportunities to enhance hygiene practices through both manual and automated cleaning protocols. After these audits, any necessary remedial actions are promptly implemented, including comprehensive training programs tailored to the nuances of chemical handling, cleaning protocols, and safety procedures.

Our extensive local and international network ensures a robust, result-focused approach to hygiene management. This approach is augmented by advanced tools like CIP-X and Smart CIP, which provide essential data to maintain exceptional hygiene standards in food production facilities. Our rigorous monitoring and verification practices help ensure

"Our rigorous monitoring and verification practices help ensure cleanliness, offering quality controllers vital peace of mind"

cleanliness, offering quality controllers vital peace of mind.

We support these efforts with top-tier equipment designed with expert industry knowledge to help manage cleaning teams effectively and maintain high hygiene standards within budget constraints. Our after-sales support is equally comprehensive, offering customisable solutions to keep customer facilities audit-ready at all times through meticulously crafted Master Cleaning Schedules, complete with detailed SOPs and training records.

Continuing from the robust framework of services NutroChem offers, our valueadding services are designed to enhance operational efficiency and effectiveness further. Chemical Supply and Application Management, Optimisation of Chemical and Cleaning Protocols, and On-Call 24/7 Support are pivotal to our commitment to service excellence.

Our Chemical Supply and Application Management service ensures that all chemicals are delivered on time and applied in the correct quantities, using precise methods tailored to each client’s specific needs. We also provide detailed usage reports and conduct regular reviews to optimise consumption and reduce waste, ensuring our clients maximise their investment.

Our expertise extends into the meticulous optimisation of chemical use and cleaning protocols, wherein our specialists work closely with clients to review and refine their existing procedures. This process enhances the effectiveness of cleaning efforts and significantly reduces unnecessary chemical use, promoting environmental sustainability and costefficiency. Through ongoing training and updates in cutting-edge chemical application technologies, we keep our clients at the forefront of industry standards, ensuring they always operate at peak efficiency.

Our clients can access expert advice whenever needed, whether it’s a need for additional supplies or an urgent consultation on unexpected hygiene issues. Our team is equipped to respond promptly, helping to resolve problems efficiently and minimising any potential disruption to operations.

Nutrochem – www.nutrochem.co.za

Chemical Supply and Application Management

On-Site Hygiene Audits and Reports

Workplace Best Practice Training

Optimisation of Chemical and Cleaning Protocols

On-Call 24/7

Drawing inspiration from the rich culinary heritage of Asia, particularly China and Japan, the white peach trend has emerged as a tantalising addition to the world of dairy and plant-based products. In the past year alone, the region has witnessed a surge in the introduction of 34 yoghurt variants.

For ‘feel good’ we observe a ‘back to the essentials of dairy’ approach with focus on protein, probiotics and an overall stronger emphasis on functional products. The product offerings for women in menopause and for seniors are extended. Protein and probiotics: High protein yoghurt is still booming and keeps consumers engaged. Consumers globally want high-protein yoghurt. Besides protein, many brands leverage probiotics in fermented dairy products for better health. Good for breakfast: Dairy has been part of the breakfast routine for many consumers already, it gets a new twist with more focus on energy in the morning and throughout the day. On top, it is also perfect for calming night-time snack. Menopause-targeted offer: The audience of senior women is critical to dairy but avoid to overly target products to their age or life stage. Rather highlight the dairy-inherent benefits that can help with the challenges ageing women face like good quality sleep, eating healthy and avoiding brain fog. Dairy products can help fight symptoms like slower digestion and bone loss. Dairy needs to position itself with consumers for active ageing, especially related to protein needed for muscle mass. The senior generation are devoted

dairy consumers but are often neglected by brands. Although it can be a win-win: seniors need dairy as a source of protein and dairy needs seniors as their loyal consumers.

Functionality and nutritional values are key for plant-based innovation. Consumers look for similar functional ingredients as in dairy products: protein, probiotics, antioxidants. Nutrition Focus: Often dairy alternatives are considered inferior to dairy products when it comes to their nutritional values. A lot of innovations activity in the plantbased space is tackling this now; added protein, probiotics, antioxidants. Often dairy alternatives are considered inferior to dairy products when it comes to their nutritional

values. A lot of innovation activity in the plant-based space is tackling this now: added protein, lower cholesterol or added functionality around immunity are some of the hot topics.

Probiotics and Antioxidants: Dairy alternatives should focus more on nutrition and health. As they contain nuts, fruits and spices, some products can be positioned as antioxidant foods. Antioxidants are perceived to slow down ageing. Besides antioxidants, many products focus on their probiotics content. Kefir Format: Kefir is one of these heritage dairy products booming for years already. No wonder that now plant-based versions of kefir products are emerging on the market.

1 in 3 consumers globally are proactive in preventing health issues.

" Dairy products offer consumers the opportunity for affordable healthy nutrition."

TREASURE WORLD IN DAIRY

Technological advancements allow for more sustainable forms of dairy production with precision or biomass fermentation. But not just technology plays a role, locally sourced ingredients are another avenue for more sustainable solutions in the dairy space.

Lab-grown dairy: Precision fermentation is advancing, and many new products are developed. The aim is to replicate the taste and texture of diary in a more environmentally friendly manner. Consumer opinion about cell-cultured dairy is polarised.

17% of dairy yoghurt launches in 2023 have a high/added protein claim.

Hybrid blend products: Hybrid dairy products with blends of animal and plantbased ingredients have potential, but the innovation activity is limited as many brands as possible struggle to position products with ‘the best of both worlds. The potential should not be overlooked though as most plant-based consumers are flexitarians and thus consuming both. Local ingredients: Not new, but still a topic for consumers around the world is the high rate of globalisation. Many brands counter that with locally sourced ingredients. For dairy it is mainly about the milk, but also the sugar and fruits used start to be more local in premium products.

TREASURE WORLD INNOVATION CONCEPT

New plants emerging: The variety of what plant-based alternatives are made of is expanding: mushrooms, tigernut, peas, chickpeas are just some of the new products emerging on the market. Plant-based alternatives focus with their position more on the resourcefulness and sustainability advantages over dairy products. They do so by calling out the climate footprint, using upcycled ingredients or locally sourced plantbased ingredients regeneratively grown. In control in dairy: Dairy products offer consumers the opportunity for affordable healthy nutrition. Dairy products are reclaiming their position of healthy and nutritious food and highlight positive ingredients like fiber or honey in this journey.

Real dairy fighting back: As a response to the plant-based boom, dairy products are fighting back re-claiming their position of the ‘real deal’. The focus is on the nutritional values and taste of dairy products. Highlighting the fermentation process can

help underpin this position of great taste and texture. Especially for Gen Z for whom dairy competes with many other product categories, it needs to become more exciting again.

High fiber and oatmeal in yoghurt: Most consumers do not get enough fiber in their nutrition. Added fiber yoghurts are an easy and convenient way to add fiber to your daily nutrition. Oats are an all-time consume favourites here in many formants: overnight oats, porridge or crunchy cereal toppings. Honey as a star ingredient : A main trend for 2024 is calling out certain ingredients on products with positive consumer association. Honey is one of these start ingredients for the dairy space. It adds a touch of balanced sweetness and great taste.

“In control” for plant-based means finding the right balance. It plays out in form of shorter ingredients lists, highlighting the advantages of shelf-stable and powder formats and natural sweetness from fruits. Cleaner labels: Shorter and simpler ingredient lists are imperative for dairy alternatives’ future growth. Many brands are innovating in this direction now. Shelf-stable and powder format: One advantage of many plant-based alternatives compared to chilled dairy products is the shelf - stable storage possibility. Powder format dairy alternatives are emerging currently. Sweetened with fruit: No added sugar dairy alternatives yoghurts are on the rise. They take their well-balanced sweetness from fruits and partially from the plant source like oats o similar.

Although dairy products are inherently associated with health and nutrition, indulgence and enjoyment play an essential role as well. Nostalgic vibes, guilt-free indulgence, layers and texture inclusions are some of the hot topics.

Nostalgia and retro: Nostalgic and retro products have been trending for some years already, but that does not make them less appealing to consumers. Known recipes with a new twist transport consumers back to their childhoods and remind them of simpler times creating a cosy feeling. Often well-known desserts or sweets brands are tapped intro for inspiration.

Permissible Indulgence: Dairy products are inherently perceived as healthy and nutritious products, but they can be also a nice indulgent treat. Dairy desserts satisfy your cravings for something sweet, but without the guilt.

‘Treasure world’ is the main trend driver for plant-based products. Although the plantbased sector has been experiencing some slow-down, we expect it to be there in the long run and the offer continues to expand.

Enjoy and experienced in plant-based: Plant-based dairy alternatives can be indulgent. More dessert products are launched, and vegan chocolate inclusions add to an outstanding multi-sensory experience.

Plant-based desserts: Plant-based desserts with and without live cultures are booming – in both variations; with fruity brown flavour combinations. Full-blown indulgence in vegan format.

Vega shares insight on how process instrumentation ensures safe and efficient storage in the dairy industry.

Ensuring the quality and safety of milk throughout the production process is of the utmost importance in the dairy industry. This is especially relevant during storage, where raw milk is held at a cool temperature before further processing. Process instrumentation plays a vital role in this stage by providing accurate measurements of level, pressure, and point level to guarantee optimal storage conditions. Maintaining milk quality through precise measurement: In the heart of dairy operations lies the critical process of raw milk storage. Here, the incoming milk is kept chilled at 4°C and continuously stirred to prevent spoilage. Three key measurements are essential for this process to run smoothly namely level measurement, pressure measurement and point-level detection. Monitoring the level of milk in the tank is essential to prevent overflows and ensure there’s enough product for processing. Maintaining a slight overpressure within the tank safeguards the milk from contamination with external elements, whereas a point-level detection system acts as a failsafe, preventing the tank from overfilling or dry-run.

The dairy industry poses specific challenges when it comes to selecting suitable process instrumentation in the form of stringent hygienic requirements. All equipment in contact with milk must comply with strict hygiene regulations to prevent bacterial growth and contamination. This necessitates the use of certified materials that meet FDA and EC 1935/2004 standards. Ensuring reliable and hygienic milk

storage: The VEGABAR pressure transmitters are suitable for hygienic applications. They are an asset in the dairy industry and have been used with success for measuring the milk level and the process pressure in storage tanks. These instruments are constructed with FDA and EC 1935/2004-compliant materials and guarantee a hygienic operation. The diaphragm can easily handle high pressures and is resistant to the vacuum that is created during the tank cleaning cycles. The VEGABAR 83 offers universal use due to the welded measuring cell. It is ideal for maintaining hygiene as the seal-less design eliminates the risk of contamination from milk contacting the seal. Traditional pressure

" Maintaining a slight overpressure within the tank safeguards the milk from contamination with external elements, whereas a point-level detection system acts as a failsafe, preventing the tank from overfilling or dry-run."

measurement often relies on complex capillary lines, which can be challenging to install and difficult to maintain.

The VEGABAR series takes a simpler approach by utilising electronic differential pressure measurement, eliminating the need for capillaries. For point level detection, the VEGASWING 61 is a versatile vibrating level switch that offers several advantages in the form of reliable detection, with a universal application and low maintenance costs. This switch precisely detects the limit level of the milk with millimetre accuracy, regardless of mounting position and is suitable for various liquids, maximising process control. It can function as an empty or full detector, ensuring proper overfill protection, and dry run prevention in the storage tanks and pipelines.

The VEGASWING 61 is adaptable to each dairy’s individual needs, as it offers various process fittings, housings and approvals. It can be configured to fit specific application requirements with ease. Process instrumentation is a crucial aspect of ensuring the safe and efficient storage of raw milk in dairy production. To achieve this goal, dairy producers rely on advanced tools such as the VEGABAR 83 and VEGASWING 61. These instruments provide highly accurate and reliable measurements of critical parameters, as well as detect any potential issues such as overfilling or leakages. By using these instruments, dairy producers can optimise their processes and ensure that the milk is stored hygienically, which ultimately leads to the production of high-quality dairy products. The VEGABAR 83 and VEGASWING 61 are indispensable tools for dairy producers who want to maintain the highest standards of safety, efficiency, and quality in their production processes.

Vega – www.vega.co.za

Explore how pectin improves the quality of yoghurt, sour milk drinks, and fruit preparations, while also simplifying ingredient lists and meeting consumer demands for healthy, high-quality products.

The range of established and innovative dairy products finds itself on a worldwide expansion course. From the texturisation of fruit preparation, to protein stabilisation: Pectin enjoys a positive positioning within the consumer’s perception as a natural, plant-based ingredient. The use of pectins in dairy products is hugely diverse. The functional properties of pectins offer perfect, practice-oriented starting points for optimal results.

The importance of yoghurt as a healthy and delicious component of any diet has significantly increased dairy sales globally. A large number of consumers around the world buy yoghurt on a regular basis. The use of apple or citrus pectin improves the texture of yoghurt, reduces whey separation and gives sour milk products and dairy desserts the desired texture.

are offered, thereby giving the fruit preparations the necessary rheological properties. Above all, pectins ensure uniform fruit distribution and reliable reproducibility of fruit preparation. Whereas in conventional yoghurt fruit preparations, for example, the use of calcium salt is necessary to prevent the fruit preparation from reacting with the white mass, innovative pectins texturize the fruit preparation alone. Thus, it is possible to label only with the words “fruit, sugar, pectin”. The fruit preparation can be stirred in or layered. The fruit preparation’s texture is smooth, shear thinning and not gelatinous.

OF STANDARDIZED, LOW METHYLESTER PECTIN FOR YOGHURT FRUIT PREPARATIONS WITH 35 - 50 °BRIX:

“The use of apple or citrus pectin improves the texture of yoghurt, reduces whey separation and gives sour milk products and dairy desserts the desired texture.”

The popularity of dairy products as part of a balanced diet continues to grow.

Another area of application is in sour milk drinks. For example, high methylester citrus pectins in drinking yoghurt with a low pH value protect the protein against heat denaturation during heat treatment. This prevents sedimentation and flocculation. A stable product with optimal sensory properties is guaranteed, without loss of quality – even during longer storage periods.

Especially with regard to fruit preparations for dairy products, standardised, low methylester pectins or amidated pectins

• No addition of calcium salt required

• Suitable for organic products

• Smooth homogeneous texture, not gelatinous

• Appealing surface gloss

• Low tendency to syneresis

• Excellent fruit retention due to low cooking viscosity

• Uniform fruit distribution due to the yield point at filling temperature

• Good stirring characteristics into the yoghurt

• Short ingredient list. Declaration: Pectin

For many decades, Pectin has been safely and widely used by food manufacturers for the formulation of recipes. As with the use of food and beverage ingredients, pectin is strictly regulated around the world. Consumers can therefore rely on the safe production and high quality of APECX pectin’s in their products. The consumer market is more attentive and focused on healthy, high quality products making pectin a very appealing product for the simple labelling possible on products.

The use of pectin in dairy products is extremely diverse. The functional properties of OBIPEKTIN provide the perfect starting point for achieving optimal results. OBIPEKTIN improves the texture of milk drinks, yoghurts and milk-based desserts.

Advantages of OBIPEKTIN from APECX

Flexible pectin with versatile use

Perfect texture and mouthfeel for dairy products

Plant-based, suitable for vegetarians and vegans

Halal, kosher, non GMO, FSSC 22000 certified

Arla Foods Ingredients, a leading supplier of dairy ingredients, has introduced two cheese recipe concepts aimed at enhancing the nutritional profile of cheese products.

The first concept is a cream cheese formulation that contains 50% less fat than standard recipes while still delivering a creamy texture and delicious taste. According to the company, enriched with high-quality whey proteins, the cream cheese formulation offers all essential amino acids, appealing to health-conscious consumers seeking flavourful, nutrient-rich choices. In addition, Arla Foods Ingredients has developed a low-fat solution for individually wrapped cheese slices, utilising fat-mimicking proteins to reduce the need for skimmed milk cheese. “The formulation, enhanced with milk mineral concentrate, provides the same calcium content as a large glass of milk in a single cheese slice.” Arla noted that the innovative concepts aim at providing nutritious yet indulgent options for consumers.

“As our new concepts demonstrate, the right ingredients can give a cheese product a major nutrition boost, creating opportunities for health claims without sacrificing taste or texture.”

nutritional quality with indulgence. In a market where consumers are highly focused on value, health concerns remain a powerful purchase driver. In the US, 51% of cheese consumers are attracted to products with on-pack health claims, while 38% of those in Spain and Italy say they would buy a product that offers a nutritional benefit.1 With 42% of consumers globally saying that protein is the most important ingredient2, boosting its content in cheese is one of the best strategies to improve nutritional status and allow health claims.

Arla Foods Ingredients is a global leader in improving premium nutrition. Together with our customers, research partners, suppliers, NGOs and others, we discover and deliver documented ingredients and products that can advance lifelong nutrition for the benefit of consumers around the world.

By incorporating high-quality dairy ingredients to replace milk fat with healthy milk proteins, the company noted that the concepts significantly boost the protein and calcium content of cheese products.

Arla Foods Ingredients is demonstrating how manufacturers can meet demand for high-protein cheese products that combine

We serve leading global brands in early life nutrition, medical nutrition, sports nutrition, health foods, and other foods and beverages.

Five reasons to choose us:

• We’re passionate about improving nutrition

• We innovate by connecting the best

• We master both discovery and delivery

• We build strong, long-lasting partnerships

• We are committed to sustainability Headquartered in Denmark, Arla Foods Ingredients is a 100% owned subsidiary of Arla Foods.

Arla Foods Ingredients - www. arlafoodsingredients.com

Claus Bukbjerg Andersen, senior category manager, Cheese at Arla Foods Ingredients, noted the importance of addressing consumer demand for nutritional value in cheese products.

He emphasizes the company’s commitment to developing solutions that offer a major nutrition boost without compromising taste or texture, thereby creating opportunities for health claims in the market. “Cheese consumers are highly focused on nutritional value, in particular protein content. At the same time, they still want indulgent taste and texture,” he said. “While this has posed challenges for manufacturers, it has also opened up new opportunities. As our new concepts demonstrate, the right ingredients can give a cheese product a major nutrition boost, creating opportunities for health claims without sacrificing taste or texture.” Meanwhile, beyond product innovation, Arla Foods Ingredients has taken steps towards carbon reduction goals by investing in an electric heat pump facility at its primary processing plant in Denmark. The initiative marked the company’s largest single investment in net-zero initiatives to date, aiming to reduce greenhouse gas emissions by 22% compared to 2023 levels. Scheduled to commence operations in 2025, the electric heat pump facility will convert electricity into heat, reducing reliance on fossil fuels and contributing to Arla’s overarching goal of reducing CO2 emissions from production by 63% by 2030.

Arla Foods Ingredientswww.arlafoodsingredients.com

Natural colours elevate dairy products offering hues while aligning with clean-label trends. Explore Oterra’s CapColours range for visually stunning, stable and eco-friendly solutions, meeting consumer demands for both beauty and sustainability.

Natural colours play a pivotal role in enhancing the visual appeal of dairy particularly fruity yoghurts and creamy desserts. In a day and age where visual appeal is so important in influencing consumer choice, vibrant colours derived from natural raw materials can help a product stand out from the crowd, not only on shelf, but also at the dining table. Additionally, the utilisation of natural colours in dairy products aligns with the ever-relevant industry trend towards clean-label formulations. Consumers are

It’s the only one of its kind in the country to target decision makers in the manufacturing of food, beverages and their related industries. It o ers incisive and authoritative reports on all aspects of the process, from raw material sourcing, to manufacturing and packing, right down to the distribution and marketing of nished goods. FOOD REVIEW informs readers about the introduction of new ingredients, equipment, products and packing, and provides objective commentary on cutting-edge local and international market trends and issues.

To contribute editorially contact Kelebogile (Lebo) Nondzaba kelebogile.nondzaba@newmedia.co.za

+27 (0)78 175 9632 For advertising enquiries, contact Anita Raath anita.raath@newmedia.co.za +27 82 976 6541 or Candida Giambo-Kruger +27 (0)71 438 1918 candida.giambo-kruger@newmedia.co.za

“Consumers are increasingly mindful of the ingredients used in the foods they consume, preferring natural alternatives over synthetic additives and artificial colours.”

increasingly mindful of the ingredients used in the foods they consume, preferring natural alternatives over synthetic additives and artificial colours. By including colours from natural sources in their recipes. dairy manufacturers can cater to these preferences while meeting the demand for visually appealing products.

Produced with the latest encapsulation technologies, Oterra CapColours products come in a variety of shades and are stable across an array of applications.

The use of natural colours in dairy products addresses the growing concern over sustainability in food production. By sourcing colourants from renewable botanical sources, manufacturers minimise their carbon footprint. This shift towards sustainability resonates well with eco-conscious consumers

role in enhancing the visual appeal of dairy products such as yoghurts, dairy desserts, milkshakes and fruit preparations. Oterra’s CapColuors® offer a more vibrant and stable solution in dairy application, with no reduced risk of migration at a competitive cost in use in the production of dairy products. By embracing natural colourants, dairy manufacturers can create products that not only delight the senses but also reflect a commitment to quality, authenticity, and sustainability.

Oterra – www.oterra.com SK Chemtrade – www.skchemtrade.co.za

Oterra’s CapColours range is the perfect solution for multi-layered or marbled dairy products, featuring

• Minimal colour migration

• Great stability

• Improved brightness They are an easy-to-use solution for adding a vibrant colour for all dairy product developments. With a high tinctorial strength, they also maintain a reasonable cost in use. All in all, a fantastic solution.

SMC shares insight on how to gain competitive advantage and discover simple and effective ways to ensure operational savings and improve productivity.

We are being urged to save energy and reminded of the need to reduce our carbon footprint to achieve a greener lifestyle. It is an important issue and one we ignore at our peril. Growing customer expectations and increasing legislation also mean that businesses can no longer afford to ignore green issues.

By adopting an energy saving strategy as part of your business efficiency programme, not only will you save money, but you will help make a sustainable lifestyle for future generations. As worldleaders in pneumatics, our experts have developed some of the most innovative ranges of energy saving products and activities for compressed air systems across all industries which will help you save money.

If this sounds too good to be true, we will be happy to share our energy efficiency knowledge and technology with you.

At SMC we recognise that an ability to fully understand the requirements and issues of any manufacturing process is the key to our future success.

CHEESE MANUFACTURING

CHEESE MANUFACTURING

In the case of the cheese industry our experts know the stringent requirements that need to be met and all have extensive knowledge of both your production process and your business needs.

Our experts recognise that maximum operator health and safety is a MUST and with energy costs increasing at an

alarming rate, even the smallest saving can have a real impact on a business’s bottom line as well as the environment.

In today’s food manufacturing industry, ensuring the highest standards of hygiene and safety is paramount. SMC, a leader in pneumatic technology, introduces a gamechanging solution with its HF2-BF series of antibacterial filters. These filters not only meet but exceed expectations in terms of performance, durability, and reliability.

One standout feature of the HF2-BF series is its unparalleled antibacterial effectiveness. Utilising FDA compliant materials and cutting-edge technology, these filters inhibit bacterial growth on their surface, ensuring that your compressed air remains pristine and free from contaminants. Unlike conventional filters, which merely

"Growing customer expectations and increasing legislation also mean that businesses can no longer afford to ignore green issues."

capture foreign particles, our antibacterial filters actively work to maintain hygienic conditions, crucial for industries where food safety is non-negotiable.

Moreover, our commitment to innovation is evident in the HF2-BF series’ ability to exceed rated flow rates by approximately 10% compared to equivalent products from competitors. This means not only do you get superior antibacterial protection, but you also enjoy enhanced efficiency

and productivity, giving you an edge in a competitive market.

Furthermore, we understand the diverse needs of our customers. Whether you require a filter for wetted parts with NSF H1 food-grade grease (HF1) or FDA compliant materials with antibacterial properties (HF2), SMC has you covered. The versatility of these filters ensures that they seamlessly integrate into various applications, providing peace of mind and exceptional performance across the board.

And we don’t stop at delivering exceptional products but also prioritise our customer’s satisfaction and support. With a comprehensive understanding of industry requirements, SMC offers guidance on replacement periods and installation, ensuring optimal performance and longevity of its antibacterial filters.

In conclusion, SMC’s HF2-BF series represents a leap forward in food safety technology. By combining cutting-edge antibacterial properties with superior performance and reliability, and empower food manufacturers to uphold the highest standards of hygiene and quality. In an era where consumer trust and safety are paramount, SMC’s antibacterial filters stand as a testament to innovation and excellence in the food manufacturing industry.

For more information contact SMC Corporation South Africa, +27 10 900 12 33, zasales@smcza.co.za

Discover how WeightPack’s innovative net-weight rotary filling system is transforming industries worldwide with precision, speed, and versatility.

Caltech is proud to have partnered with Weightpack, who are industry leaders in the design of bespoke net-weight filling, capping, and special application packaging machinery for food and non-food liquids and powders. The company was founded in 2002 by Carlo Corniani in Italy, who gained international recognition for being the inventor of the very first netweight filler with electronic control in 1979. Their mission is to become designers of custom-made machines, aiming at research, innovation, quality and reliability.

WeightPack has earned significant positions in the European, United States, and the Middle Eastern industries of:

• Food and beverage

• Dairy (aseptic)

• Edible Oil

• Home and personal care

• Chemicals and motor oils

• Pharmaceuticals

WeightPack’s Net-Weight rotary filling system is an advanced solution designed for industries that require precise and efficient filling processes.

Precision: The system uses load cells at each weight station to check the empty container weight, auto correct the filling weight, and zero the load cell on each filler rotation. This ensures each container is filled with an exact amount of product.

Speed: The rotary design allows for high-speed filling without sacrificing accuracy, making it ideal for high-volume production lines.

"WeightPack’s NetWeight rotary filling system represents a significant advancement in filling technology, offering precision, efficiency, and adaptability to a wide range of industries."

Versatility: It can handle a wide range of product viscosities and is suitable for various container types and sizes.

Integration: The system is designed to be integrated with capping solutions, providing a seamless filling to capping transition.

BENEFITS ACROSS INDUSTRIES:

Food and beverage: Ensures consistent product quality and helps in maintaining flavour consistency by precise ingredient filling.

Pharmaceuticals: Meets stringent regulatory requirements for accurate dosing and helps in reducing product giveaway.

Chemicals and Detergents: Allows for safe handling of potentially hazardous materials with minimal human intervention.

Automotive: Ideal for filling motor oils and lubricants with precision to avoid wastage and ensure proper packaging.

Personal care: Can fill a variety of products, from shampoos to creams, with the exact amount needed, preserving product integrity and consumer trust.

ADDITIONAL ADVANTAGES:

Product savings: The precise dosing reduces product waste, leading to significant cost savings over time.

Customisation: WeightPack specialises in customising machinery to meet specific

industry needs, ensuring that the filling system aligns perfectly with the production requirements.

Data utilisation: Equipped with numerous sensors, the machinery provides a wealth of data that can be used for efficiency improvements, predictive maintenance, and more.

The complex process of keeping our sensitive foods safe from the cow to the consumer requires layers of hygiene control throughout their preparation and distribution.

Weightpack’s highly developed food safety techniques ensure the consumer always receives wholesome and satisfying food, no matter the supply chain length. Get in touch for more details on our high-performace Aseptic fillers.

As the global market for prepared foods expands, the demand for meat-free alternatives is on the rise. To meet this demand, processors must create high-quality products that replicate the taste and texture of traditional meats. Discover how Heat and Control’s coating technology can help you achieve this and elevate your products to new heights.

As the global market for prepared foods expands rapidly, the demand for meat-free alternatives is on the rise. Driven by health consciousness, ethical considerations, and environmental sustainability, consumers are increasingly seeking plant-based versions of their favorite prepared foods. In response to the demand, processors are faced with the challenge of creating high-quality meat alternative products that will replicate the taste, texture, and overall experience of their traditional prepared foods lines.

When you’re in the process of selecting equipment for your meat and plant-based products, there are numerous factors to consider. With Heat and Control’s extensive experience in developing food processing lines, we’re here to assist you in creating all the trending products your consumers love. Beyond perfecting your recipe, we’re also committed to helping you achieve higher yields, better efficiency, and more safety than ever before.

Challenge #1 - Replicating the sensory experience: A key challenge in producing meat alternative prepared foods lies in replicating the sensory experience of meat. Achieving the juicy tenderness and crispy exterior your consumers crave is pivotal for the success of your meat alternative products. Essential for the success of your meat alternative products — coatings are your secret weapon in enhancing the taste and texture of

“With Heat and Control’s extensive experience in developing food processing lines, we’re here to assist you in creating all the trending products your consumers love.”

prepared foods, whether they’re meat-based or plant-based proteins. What’s more, the same equipment used to apply coatings to traditional beef, pork, chicken, turkey, and fish based prepared foods can also be utilised to coat meat alternative prepared foods.

Challenge #2 – Mouth feel and flavour: From creating a crispy exterior reminiscent of fried chicken to achieving a juicy texture in your meat alternative ‘burger’ — coatings help replicate the mouthfeel and flavor of meat to make plant-based alternatives more appealing to consumers. Image 2.

Challenge #3 – Visual appeal: Many processors utilise coatings to enhance the visual appeal of their prepared foods lines, whether achieving a golden-brown crust or a glossy glaze. While enhancing attractiveness, coatings also serve practical purposes. They can act as a barrier to moisture loss during cooking or storage, ensuring product freshness and quality over time. Ultimately, the success of prepared foods hinges on the quality and consistency of their visual appeal

and final presentation. To ensure success, it’s crucial to employ the right equipment and processes for meat alternative products. An adaptable coating system solution that caters to both traditional meat and meat alternative protein-based foods is essential for achieving optimal results and meeting consumer expectations.

The coating process can be executed in single or multiple stages. An example of a multi-stage coating system is the two-stage method, where a liquid ingredient, such as oil, is first applied as a tack agent, followed by a dry seasoning application.

Chicken nuggets and plant-based alternatives often made using mycoprotein, soy protein, pea protein, wheat protein, and then flavored with oil and garlic powder are examples of products utilising a two-stage coating system. (Image 1).

Other coating system solutions utilise a slurry spray system, which applies a mixture of oil or water and dry seasonings. This method is chosen when a processor is aiming to impart a complex flavour profile, and particularly when the seasoning and oil need to penetrate the product. Marinated chicken or marinated tofu ‘chicken’ products utilise this type of coating system.

Alternatively, there is another seasoning application known as ‘dry seasoning only’ which requires no liquid application. This method is used when your product has either sufficient surface moisture or can

retain residual surface moisture to hold the seasoning, for example herb seasoning.

The function of the coating drum is to gently lift and fold the product repeatedly to allow each product piece exposure to gradually build-up liquid and dry coatings. A key component of a successful coating system is a properly engineered coating drum. Image 3. Product throughput, bulk density, shape, and other characteristics all factor into the drum’s length, diameter, and design.

Coating system design principles remain the same regardless of the spray system utilised. By utilising an effective spray design with multi-nozzle manifolds, you maximise the coating zone within the drum. This, coupled with precise nozzle placement, directs targeted sprays onto the product moving beneath the spray nozzles within the drum. This approach facilitates a gradual accumulation of applied liquid onto the base product, ensuring a more uniform coating overall.

A variety of spray system options from “airless” pulsing oil spray applicators to airassist or high-volume oil spray systems are available, as well as slurry spray systems for applying emulsions, solutions, liquid-solid slurries, or other high-viscosity liquids.

In a continuous coating system, applying dry seasoning to products requires both an auger-based powder feeder and a scarf plate distributor. For instance, a powder feeder meters the dry seasoning or salt at a consistent and accurate rate onto a scarf plate feeder, which then evenly distributes it onto the product.

The scarf plate distributor is a fixed-speed, vibratory conveyor featuring a narrow, mirrored finish, bias-cut tray. It’s user-friendly, easy to clean, and compatible with most dry seasonings, salts, and other granular products, ensuring a consistent curtain of the applied dry product.

Heat and Control –www.heatandcontrol.com

As a powerhouse developer and manufacturer of cutting machinery, Urschel delivers targeted results to meet processing goals and optimise profits. Rugged slicers, shredders, dicers, and milling machinery built to exceed expectations.

Step into the captivating world of plant-based confectionery and snacks, where every bite is a delightful journey into sweet satisfaction.

Finding appropriate sweets was difficult

restricted when it came to classic desserts because these contained ingredients that come from animals, such as milk powder, gelatin, or beeswax. Today, vegan candies come in a wide variety of forms, from chocolate bars to fruity gummies.

vegan confectionery, everyone’s taste varies. We select our snacks taking into account our mood, health, and surroundings. The vegan industry has grown over the years and now

vegan confectioneries come in various flavours

cheeky bag of chips between meals or a few pieces of vegan candy after dinner. There is something for everyone – the

Vegan sweets are made with 100% plant-based ingredients and at the heart of these ingredients is Gum Acacia. Harvested solely from the acacia tree in the southern Sahel region of

organic, and vegetal ingredient by nature. Gum Acacia, also referred to in the food

“Gum Acacia, also referred to in the food and beverage industry as Acacia Fibre, Gum Arabic or simply E414 is an additive that has been used for centuries.”

and beverage industry as Acacia Fibre, Gum Arabic or simply E414 is an additive that has been used for centuries. Acacia gum is a texturing and coating agent in numerous confectioneries and sweets. The functional property of gum acacia is to enhance texture, add thickness, and prevent

Bragan Ingredients is the most resourceful and competitive distributor of highquality ingredients to the Food and Beverage industries. Supplying ingredients throughout sub-Saharan Africa. We achieve customer satisfaction through our excellence in service delivery. With warehousing and distribution branches in Johannesburg, Cape Town, Durban & Port Elizabeth, we can serve all our customers within the sub-Saharan African region. Proudly all our branches are ISO 9001:2015 certified. We’ve distributed Food & Beverage ingredients to over 40 cities since 2006. We have established a market and network within all the food manufacturers in South Africa.

crystallisation when combined with glucose and sugar in confectioneries. The traditional and common use of acacia gum is coating, particularly for sweets that need to have a gumming operation of their centres and chocolate panning.

Leading French based Gum Acacia supplier, Alland & Robert conducted studies

on the different specifications/grades of Gum Acacia and have found that Instant Soluble Gum Acacia offers more effective stabilisation of oil in water emulsion for longer periods, compared to other Gum Acacia grades. It therefore offers the best protection against external conditions, including light and oxygen, to avoid aroma deterioration. This grade of Gum Acacia is odourless, colourless, tasteless and extremely soluble in water. This vegan ingredient contains no gluten and is allergenfree and GMO-free. It is rich in fibre, organic, halal and kosher certified.

Innovations such as these are the reason you don’t have to deprive yourself of sweet streets when you are following a vegetarian or vegan diet. Manufacturers worldwide are finding new ways to create new products and expand their confectionery offerings with healthier alternatives and Gum Acacia will be at the forefront of this innovation for years to come.

Bragan Ingredients –www.braganingredients.co.za

Alland & Robert –www.allandetrobert.com

New Coperion MEGAtex R90 Cooling Die allows flexible adjustments to meat substitute texture at high throughputs

The new MEGAtex R90 texturising unit achieves throughputs of up to 500 kg/h and is optimally matched to Coperion’s ZSK Food Extruders in sizes ZSK 43 and ZSK 54. Used in vegan ground meat substitutes and chicken analogues among other products, HMMA is manufactured using plant proteins. The MEGAtex cooling die provides HMMA with its fibrous and meat-like textures.

Coperion has designed its MEGAtex series texturising units especially for use with the ZSK food extruder. The ZSK twin screw extruder and the MEGAtex cooling die are the core technologies within the high moisture extrusion process that generates meat analogues from plant proteins with a dense, fibrous structure that closely resembles lean animal meat.

The new MEGAtex R90 cooling die builds upon the principle of a round cooling die. Following discharge from the ZSK food extruder, the protein mass passes through a round channel in which the product is cooled to the desired temperature and the meat-like texture is formed to specification. For HMMA manufacturers, the cooling die opens up a broad spectrum of possible ingredients and textures –from smooth to loose, dense, foamy, large-pored and all the way to long- and short-fibered. The machine operator can precisely target process parameters such as temperature, pressure, shear rates and mass flow.

The central element of the MEGAtex R90 is its rotating, cooled core. This core is provided

with a pitch to influence the texture and the nozzle flow. This in turn affects the pressure in the upstream extrusion process and alters the HMMA’s texture, form, colour and surface.

To operate HMMA production machinery at very high efficiency, Coperion’s main objective in developing the MEGAtex R90 was to achieve very good and fast cleanability. All the cooling die’s surfaces

Coperion is a global industry and technology leader in specialised equipment for the food and health industries. Coperion develops, produces, and services plants, machinery, and components for the food, pet food, baking, pharmaceutical, and cosmetics industries. Its brands – Baker Perkins, Bakon, Coperion K-Tron, Diosna, Gabler, Kemutec, Peerless, Shaffer, Shick Esteve, Unifiller, and VMI – are experts in ingredient automation, pre-dough systems, mixing, and depositing technologies. Coperion employs more than 5,000 people in its three divisions Polymer, Food, Health & Nutrition, and Aftermarket Sales & Service, and in its over 50 sales and service companies worldwide. Coperion is an Operating Company of Hillenbrand (NYSE: HI), a global industrial company that provides highly engineered, mission-critical processing equipment and solutions to customers serving a wide variety of industries around the world.

are easily accessible. With just a few manual adjustments, the die core including the drive section, can be retracted out of the cooling barrel on linear guide rails. The product channel is then fully accessible and can be cleaned in no time at all. Retracting the die core also makes the ZSK food extruder’s process section directly accessible. Its twin screws can then be removed as needed to easily clean the process section without moving the MEGAtex R90.

“Following the MEGAtex S7, the new MEGAtex R90 is the logical expansion of our cooling die line. It allows manufacturers of meat substitutes to produce HMMA with consistently very high product quality. Even at the high throughputs that the MEGAtex R90 achieves, this cooling die offers the operator the ability to modify the texture very precisely and with great variety. Thus, in combination with our ZSK Food Extruder, it fulfills important success factors for manufacturing high quality meat substitutes”, said Stefan Huber, project engineer in research & development, Extrusion at Coperion.

Colour plays a crucial role in the success of plant-based products. Consumers instinctively judge food and drink based on whether it matches up to expectations and looks appetising. It’s therefore essential that meat alternatives look like the real thing to give a positive first impression of product quality.

In the modern market, it is also important to reassure consumers that products are safe and healthy. Manufacturers now rarely use artificial colours in plant-based meat for this reason. Some use spices to deliver colour, but their impact on flavor limits the possibilities to achieve the desired shade and visual appeal. As such, many opt for natural colours such as paprika oleoresin and betanin to achieve the colour effects they want. We offer hundreds of plant based

Theresa Wilms, technical sales manager at EXBERRY by GNT, explains how colours made from fruits, vegetables and plants can maximise the appeal of meat alternatives.

EXBERRY® colours that can deliver excellent results in all types of meat substitutes. Our portfolio also includes a full spectrum of EXBERRY® Colouring Foods. Based on the concept of colouring food with food, they are made from edible fruits, vegetables, and plants using physical processing methods like chopping and boiling. Due to the way they’re made, they offer the ultimate clean label colouring solution, allowing for simple declarations such as “Concentrate (carrot and beetroot).”

Plant-based colours can be used to deliver excellent results in all types of food and drink, but they are not a plug-andplay solution. There are many technical considerations to bear in mind as the

concentrates have varying characteristics, including their colour hues and temperature and pH sensitivities. The colour of the base will also have an impact. For example, pea protein is more yellow than soy so the dosage recommendations will be different.

Selecting the right colours will depend on the desired functionality. There are three main categories of meat and fish alternatives according to the process technology used. Products such as plantbased burgers, meatballs, minced meat, and salmon fillets rely on mincing and mixing. Sausages, cold cuts, ham, and smoked salmon use emulsification. Products such as tuna and chicken pieces

EXBERRY by GNT – www.exberry.com

> extruders > feeders > components > pneumatic conveying > complete systems

+ Highly flexible dual use extruder for TVP and HMMA

+ Plant based ingredient material handling equipment from source to packaging

+ Proven industry leader with installed TVP and meat analogue systems globally

+ Strict adherence to cGMP guidelines and standards

+ High accuracy loss-in-weight feeding of powders and liquids

+ Worldwide service network

Coperion`s ZSK Mv PLUS food extruder for plant-based proteins in a hybrid design allows dual use for manufacturing meat substitute products. Both TVP and HMMA can be produced on the same extruder, realizing maximum flexibility and profitably react to changing market demands. www.coperion.com/food-extruders

In recent years, the rise of vegetarian and vegan lifestyles has been nothing short of remarkable. However, while these dietary choices offer numerous health and environmental benefits, they also present unique challenges, particularly in meeting essential mineral needs.

The vegetarian and vegan lifestyle has become more and more important in recent years. But this form of nutrition is not without risk. Enriching vegetarian and vegan foods with Minerals can help to minimise the risk of a mineral deficiency.

Animal products often have higher contents of various Minerals. These amounts are difficult to achieve with a purely vegetable diet.

For example, it can be difficult for vegans to obtain an adequate supply of Calcium, since they do not consume the main sources

of Calcium, milk and dairy products. The daily requirement of Calcium (1000 mg/day for adults) is therefore difficult to cover.

Iron is present in plant foods as Fe3+, which is difficult to absorb. In contrast, Iron is more easily absorbed by the body as Fe2+ from meat. The same applies to Zinc, which can be better absorbed from animal products such as meat or fish.

In addition, besides the low mineral content, the absorption of Minerals such as Calcium, Iron and Zinc is also inhibited by various components of plant foods, for example by dietary fibres, oxalic acid or phytic acid.

Vegetarian or vegan meat and milk substitute products enriched with Minerals offer a good possibility of a balanced mineral supply. Meat substitutes based on soya or other vegetable proteins are highly processed products that are ideally suited for enrichment with Minerals during the manufacturing process. They represent a diverse matrix which can be refined as needed.

According to the Health Claims Regulation (EC) No. 1924/2006, highly enriched foods can be labelled with a health claim for the corresponding Mineral. This makes it easier

for the consumer to identify foods with added health value.

The regular intake of food supplements as part of the normal diet can also ensure a sufficient supply of Minerals even if animal products are completely avoided.

With our expertise in the chemical and physical modification of Mineral Salts and our customer-oriented corporate philosophy, we are the ideal partner to turn your ideas into reality.

OUR FORTIFICATION RECOMMENDATION:

Nautilus Chemicals (Pty) Ltd. was formed in April 2019 by the Warren Brothers, whom

“For example, it can be difficult for vegans to obtain an adequate supply of Calcium, since they do not consume the main sources of Calcium, milk and dairy products. ”

have combined experience in this business for over 35 years, science and commercial backgrounds, and most importantly a passion for the products as well as the industry.

The company specialises in high quality ingredients for the food & beverage, pharmaceutical & veterinary and dietary & sports supplements industries in South Africa.

Our company represents quality and service, but are also an evolving company bringing innovative products to the market and striving for perfection.

Nautilus Chemicalswww.nautiluschemicals.co.za

Nautilus Chemicals (Pty) Ltd. was formed in April 2019 by the Warren Brothers, whom have combined experience in this business for over 35 years, science and commercial backgrounds, and most importantly a passion for the products as well as the industry.

The company specialises in high quality ingredients for the food & beverage, pharmaceutical & veterinary and dietary & sports supplements industries in South Africa.

Our company represents quality and service, but are also an evolving company bringing innovative products to the market and striving for perfection.

◆ Highly bioavailable Minerals designed for your plant-based products

Iron for blood formation

Zinc for a vital immune system

Calcium for strong bones

T: +27 21 140 0308

E: info@nautiluschemicals.co.za www.nautiluschemicals.co.za