7

WHAT’S NEW

South Africa’s trendy food and beverage products

8 NEWS

Labotec Appoints New CEO I-MAK shifts gear with successful country road show

SOMIC opens new subsidiary in Asia

10

INDUSTRY TALK

Unveiling a state-of-the-art microbiology lab

Efficient DMSU22SA transmitter enhances sterile processes

12

COLOURS AND FLAVOURS

Meet Pantone’s Peach Fuzz Elevate visual appeal naturally

Refreshing drinks with plantbased hues

A pinnacle of innovation in micronized food colours

Expanding Isobionics with innovative flavours

Nurturing emotions with nature’s palette

28

CONVENIENCE FOOD

Spiral ovens insights

Standardised Solutions for creating QRS products

Detergent chemistry for food processors

34 BAKERY

Leading the way in bake belts & conveyor tech

Elevate sweet moments with premium ingredients

Seizing the sweet opportunity Plant – based boost for baked goods with faba bean

60 years of bakery expertise, innovation and sustainability Bread chemistry

44

FOOD SUSTAINABILITY

Feeding the future through innovation and sustainability

Championing food system transformation

46

FLEXIBLE PACKAGING

Transforming packaging perfection

Mould making for customisable and flexible packaging

Leading the evolution in packaging manufacturing

52

WATER PROCESSING

Handling the pressures of water treatment

The Food and Beverage industry is buzzing with the latest ingredient and product innovations that not only tickle the taste buds but offer functionality and delectable sensorial experiences, and it looks like the trend towards using flavouring and colouring from natural sources will continue well beyond 2024 as consumers move towards choosing healthier food and beverage options. The colour of food and beverage products extends far beyond just making a product look good. Colours evoke emotions and memories, enticing a person to choose a specific food or beverage item. Being able to tap into these feelings and personalise colours to appeal to a specific audience is essential in today’s world, read more on page (12) – (26). Food sustainability took center stage at the United Nations Climate Change Conference last year. This time the focus was on the environmental impact of food and specifically animal agriculture. This comes at a time where consumers are increasingly making choices that align with their values to preserve the climate, read more on page (45)

With the rate at which the world is moving, there is an increasing need for the production of fresh and frozen convenience food. Consumers are now on the lookout for prepared food that optimises ease of consumption, see page (28) where we look at new equipment on the market helping food and beverage manufacturers produce convenience food in a more efficient manner. Flexible packaging such as woven bags, pouches and tubes is also growing momentum due to its non-rigid qualities. By using these ecofriendly materials to package food, manufacturers are enjoying being able to customise the container to fit the product and the brand which presents unique marketing opportunities, see page(50)

Enjoy the read!

THE TEAM

EDITORIAL

Editor: Kelebogile Nondzaba

+27 (0)78 175 9632

Sub-editor: Gill Abrahams

Layout & Design: David Kyslinger, Tumi Kunene

ADVERTISING

Key Account Manager: Anita Raath +27 (0) 82 976 6541

anita.raath@newmedia.co.za

Key Account Manager: Càndida Giambò-Kruger +27 (0) 71 438 1918 càndida.giambò-kruger@newmedia.co.za

INTERNATIONAL SALES

Germany/Austria/Switzerland: Eisenacher Medien Erhardt Eisenacher +49 228 249 9860 info@eisenacher-medien.de

Italy: Ngcombroker Giacomo Rotunno +39 370 101 4694 g.rotunno@ngcombroker.com

Taiwan: Ringier Trade Media Sydney Lai +886 4 2329 7318 sydneylai@ringier.com.hk

CIRCULATION

Circulation Manager: Felicity Garbers felicity.garbers@newmedia.co.za

PUBLISHING TEAM

General Manager: Dev Naidoo

Head of Commercial B2B: Johann Gerber

Production Controller: Mandy Ackerman

Art Director: David Kyslinger

JOHANNESBURG OFFICE

Ground Floor 272 Pretoria Avenue Randburg, 2194

POSTAL ADDRESS

PO Box 784698, Sandton, Johannesburg 2146

Published by New Media, a division of Media24 (Pty) Ltd

MANAGEMENT TEAM

MANAGING DIRECTOR: Aileen Lamb

COMMERCIAL DIRECTOR: Maria Tiganis

STRATEGY DIRECTOR: Andrew Nunneley

CHIEF FINANCIAL OFFICER: Venette Malone

CEO: MEDIA24: Ishmet Davidson

HEAD OFFICE

@SA_FoodReview

@foodreview13 SA_FoodReview

New Media, a division of Media24 (Pty) Ltd 8th floor, Media24 Centre, 40 Heerengracht Cape Town, 8001

The

Copyright:

Readers

• Preparation & Processing

• Frying & Oil Management

• Batter & Breading

• Branding & Searing

• Cooking, Roasting & Drying

• Coating & Seasoning

• Product Handling

Across industries and applications, we design specialised solutions.

Bringing together leading brands in processing and packaging equipment for the value-added industry. Our fryers, ovens, branders, searers and breading/batter applications can prepare and cook the highest quality meat, poultry and seafood products. Whatever your product needs, we can meet it with precision and passion.

heatandcontrol.com

Hostex

Johannesburg, South Africa

3 - 5 March

www.hostex.co.za

14th SAAFI Seminar

Johannesburg, South Africa

11 - 13 March

www.saaffi.co.za

Propak East Africa Nairobi, Kenya

9 - 11 March

www.propakeastafrica. com

Anuga Foodtec

Cologne, Germany

19 – 22 March

www.anugafoodtec.com

Prowein

Dusseldorf, Germany

10 – 12 March

www.prowein.com

Organic and Natural Products

Cape Town, South Africa

27 – 28 April

www.

organicandnaturalportal. com

Propak Ghana

Accra, Ghana

23 – 25 April

www.propakghana.com

Analytica

Munich, Germany

9 – 12 April

www.analytica.de/en/

Organic & Natural Products

London,UK

14 – 15 April

www.naturalproducts. co.uk

Nampo Harvest Day

Bothaville, South Africa

14 – 17 May

www.grainsa.co.za

VitaFoods

Geneva, Switzerland

14 – 16 May

www.vitafoods.eu.com

IFAT

Munich, Germany

13 – 17 May

www.expobeds.com

Cibus

Parma, Italy

7 – 10 May

www.cibus.it/en/

While many of us use terms like bubbly, Champagne, MCC and sparkling wine interchangeably, Cap Classique is not to be confused with the rest. Typically, sparkling wine is carbonated using a gassy production method not too far removed from a household SodaStream. What distinguishes Cap Classique is the careful process of fermentation in the bottle and the long period of time needed – usually a minimum of 12 months – for naturally occurring bubbles to form.

Caroline van Schalkwyk, marketing manager for the Cap Classique Association, stresses the element of time in the making of fine South African Cap Classique: ‘It’s an important differentiator because it recognises the additional investment producers make in the pursuit of higher quality,’ she says.

In short, it takes a lot more work and technical ability to produce a Cap Classique, which is why wines in this category generally command higher prices than sparkling wine.

Cap Classique is produced in the traditional method employed by the French, although it is not to be confused with Champagne, which hails only from the Champagne region in France. The two share a preference for the same types of grapes: most South African Cap Classique is made from a blend of chardonnay and Pinot noir; a minority of winemakers include Pinot Meunier; and then there are those who choose to make a Cap Classique from nonChampagne varieties like chenin blanc or even Shiraz.

To read more, visit: www.foodreview.co.za

As the new year kicks off, it’s the perfect time to get into healthy habits and embrace positive changes for 2024. Arthur Ramoroka, Tiger Brands’ corporate nutritionist and Eat Well Live Well ambassador, shares advice on how South Africans can kick-start the new year in the best and healthiest way possible.

In South Africa, over 700 people die every day of noncommunicable diseases (NCDs) — a figure predicted to increase over the next decade. NCDs are a group of conditions that are not spread from person to person, but rather result from a combination of genetic, behavioural, environmental, and metabolic factors. Lifestyle choices such as unhealthy diets, lack of physical activity, tobacco use and excessive alcohol consumption contribute significantly to the development of NCDs. Some common examples include cardiovascular issues such as heart disease and strokes, cancer, chronic respiratory diseases and diabetes.

Over the past two decades, the mortality rate in South Africa has increased by 58,7%. This statistic is marked by an incredibly high prevalence of NCDs in the country, with diabetes as the country’s second biggest killer after TB.

Sugar-Free categories have set them apart in the market. The Vegan range utilises soy powder as a dairy substitute, while Xylitol and Sucrose sweeten their Sugar-Free products. The brand is now available in Checkers (Simple Truth) and are gearing up to launch a luxury ice cream under the Forage and Feast brand in March. Following closely, a Cashew Milk Vegan ice cream is set to hit shelves in April/May, marking their continuous expansion in response to evolving market demands. Images:

In response to the booming vegan market, Dolce Vita upgraded their packaging, introducing a variety of Dairy and Vegan options. Surprisingly, the vegan range quickly outpaced their dairy counterpart. The introduction of Elegance, Dipper and Waffler in convenient multipacks garnered interest from major retailers like Pick n Pay and Spar. The range expanded to include

sugar-free options such as Elegance and Italian Kisses, with Coney as the latest addition. Frootie, is a fruit-flavoured alternative that has become a sales powerhouse, featuring popular flavours like mango, Granadilla and berry. Their unique offerings in the Vegan and

In a strategic move to fortify its presence in South Africa, I-MAK, a premium brand under the umbrella of Bearings International (BI), executed an impactful Country Road Show.

Robert Sillis, the General ManagerProducts at BI, emphasised the initiative’s importance, stating: “The Country Road Show was not merely a product showcase; rather, it played a crucial role in unveiling I-MAK’s cutting-edge products across BI’s extensive local branch network. The Roadshow served as a gateway to introduce our value proposition, which is focused on enhancing customer uptime through value-added solutions. These solutions are expertly delivered by our internal technical advisors, ensuring a personalised local approach to customer service.”

Hosted at various BI branches, the Road Show proved to be a comprehensive undertaking, encompassing product training sessions and the distribution of sales enablement tools to managers and sellers. A key achievement was the unanimous commitment to focused pro-active initiatives, defining the strategic next steps for the

brand. This inclusive initiative involved extending invitations to all company managers and sellers, fostering a comprehensive and diverse spectrum of participation.

The focal point of the Road Show was the industrial sectors grappling with downtime challenges, specifically targeting mining, food and beverage, general industry, utilities, agriculture, as well as automotive sectors. I-MAK showcased a wide spectrum of products, prominently featuring the complete standard geared unit range, comprising inline, bevel, and shaft mount helical units to Bearings International representatives and senior managers in the geared units division. The event format included presentations on the features and benefits of brand and products and how it fits into the overall strategy of Bearings International and being in motion. The Road Show traversed the nation, making stops in cities and towns such as Klerksdorp, Witbank, Polokwane, Durban, Cape Town, Port Elizabeth, and Kimberly.

I-MAK boasts a remarkable legacy of over 50 years in developing and producing an extensive range of gearboxes and

Congratulations to Ambigai Naidoo on her appointment as Labotec Pty Ltd’s new CEO. It is always inspiring and motivating to see internal talents grow and take on leadership roles within the company. Her impact over the last 12 months has brought clarity, structure, focus, and a strong sales and customer-centric mindset to the organisation.

Ambigai is a strong believer in empowerment and ownership and has consistently demonstrated a commitment to building a positive and inclusive work environment. As CEO, she is ready to lead the company to new heights by leveraging

drive solutions. The company is guided by a vision to provide customers with unparalleled reliability and flexibility in their applications, fuelled by a deep-seated passion for its products.

Emphasising the global impact of I-MAK gearboxes, the company powers and propels hundreds of thousands of machines daily across diverse applications.

“The Road Show proved to be an invaluable experience for all stakeholders, as sellers underwent rigorous training conducted by internal product experts,” affirms Kobus Groenewald, Business Unit Leader: Industrial Geared Units. “Armed with this knowledge, they are now adept at presenting the product proposition to target customers and decision-makers, identifying winning factors, and delivering tailored solutions to enhance production uptime.”

“The I-MAK Country Road Show exceeded expectations, securing early wins and laying the groundwork for future successes. We eagerly anticipate extending these Road Shows to neighbouring countries in the near future,” Robert Sillis concluded.

her expertise, vision, and values. Ambigai is a highly accomplished and astute Executive Management

Professional, with nearly two decades of experience within the Science and Healthcare industry. She presents with significant career success in driving bottom-line delivery and expanding business footprints across South Africa and Sub-Saharan Africa.

To read more, visit: www.foodreview.co.za

Bangkok is ready to go! The packaging machine manufacturer SOMIC opened its new hub in Bangkok, Thailand, with a grand opening. With these sales and service location, the company is consistently developing its global presence. After entering the US market with the subsidiary in the USA in 2014, SOMIC is now continuing its expansion course towards the Asian markets with the new subsidiary SOMIC Packaging Asia Pacific Co. Ltd. The impressive event with a comprehensive program - including live operation of the new SOMIC 434 packaging machine and the presentation of the new CORAS collating and grouping system via a live link to Amerang in Germany - offered guests a deep insight into the philosophy of the German packaging machine specialists.

In addition to the high-ranking guests from 13 countries, Patrick Bonetsmüller, Chairman of the SOMIC Group, and Dr. Gerhard Huber, CEO of the SOMIC Group, also welcomed Mr. Hans-Ulrich Südbeck, Head of the Economic Department of the German Embassy in Bangkok. He was delighted that another German company will now be operating in Asia from Thailand. Lukasz Myszkowski, Managing Director of Sales SOMIC APAC, briefly outlined the background to the decision: “Foreign investors find Thailand an excellent location and operate in a stable

and mature economic environment. In addition, the Thai government’s economic development plan shows the country’s clear orientation towards digitalization and IoT.” In addition to these factors, there is also the availability of well-trained specialists in Thailand, which is essential for the development of activities in Asia.

SOMIC is one of the world’s leading companies for shelf-ready packaging machines and offers users in the food and non-food industry in Asia a customized and

future-proof concept for packaging products in one-piece or two-piece cardboard packaging. In particular, the development away from traditional RSC cartons towards wraparound cartons opens new opportunities for these markets. It offers new display options and simplifies the presentation of goods on the shelf. During the grand opening, guests were able to find out more about the SOMIC 434, the latest generation of packaging machine: In demo operation, the machine experts showed the high flexibility and performance of the modular platform concept for a wide variety of packaging.

Mérieux NutriSciences South Africa unveil the largest of their three state-of-the-art microbiology laboratories, in Cape Town. With a 100% increase in testing capacity, advanced features for sustainability, and a team of 50 expert Microbiologists, we solidify our position as a leading facility in South Africa.

We proudly announce the opening of our expansive new microbiology laboratory in Claremont, Cape Town, marking a significant milestone in the company’s commitment to advancing food safety and quality testing.

With a laboratory footprint spanning an impressive 1300 m2, which together with the supporting admin functions totals 2400 m2, this cutting-edge facility represents substantial growth from its previous 650 m2 footprint, solidifying our position as one of the largest microbiology testing facilities in South Africa. The size of the facility, staffed by 50 qualified Microbiologists, uniquely positions the Cape Town laboratory to handle very large sample volumes while delivering the highest quality results.

The facility boasts unique capabilities, including industry-leading testing turnaround times and the expertise to conduct large format testing on 375ml sample sizes for specified matrices. In response to escalating market demands, the expansion has resulted in a remarkable 100% increase in testing capacity, dedicated to processing samples for both Quantitative and Qualitative Analysis. The sample receival department has also been expanded to streamline the screening and verification of samples and documentation

before they are logged and processed. This optimisation not only enhances productivity but upholds the highest quality standards in the food industry.

Incorporating advanced features such as centralised climate control and a highly energyefficient lighting technology system, not only reduces electrical consumption but also reinforces our commitment to environmental, social, and governance (ESG) goals related to climate change. We are dedicated to making progress towards a BETTER WORLD through sustainable practices.

The building was inaugurated on 23 November 2023 by Nicolas Cartier (CEO) and Franck Capdevielle (VP MEA ASPAC & Corporate Development) both joining the occasion from the Mérieux NutriSciences Global office based in Tassin-la-Demi-Lune, France.

At Mérieux Nutrisciences, we leverage over 50 years of scientific and entrepreneurial expertise to answer food industry needs.

Today’s global challenges transform the way food is produced, marketed and consumed, which is why we know our clients need more than reliable analytical results; they need practical and innovative solutions that will contribute to make food

systems safer, healthier and more sustainable. From our initial expertise in microbiology and consulting, we have broadened our scope of scientific specialties into chemistry, education, certification, research, labelling, and sensory in order to offer a complete suite of services to meet our customers’ needs. Today, we offer comprehensive solutions to support our clients, from product development to market suitability, while contributing to consumers’ health worldwide. Present worldwide, we are more than 100 accredited laboratories and a team of over 8,000 committed employees.

In South Africa, Mérieux NutriSciences’ facilities are located in Cape Town, Midrand, Jeffreys Bay, George and Durban and offer SANAS-accredited microbiology and chemistry laboratory services that operate seven days a week, 365 days per year. We also provide services in food and non-food label compliance in accordance with South African regulations, auditing services and specialised testing services. We have a unique mix of capabilities that provides our clients with a complete safety and quality offer, allowing a strong partnership with businesses to ensure the safety and quality of their products in many stages along the product lifecycle. With a network of over 100 laboratories across Europe, North America, South America, Africa & Middle East, and Asia Pacific, we can support your global ambitions while ensuring you get rapid, reliable, repeatable, and impartial results from one location to another.

Less energy consumption, less cleaning effort and more safety:

As part of the pipeline, the new model DMSU22SA in-line process transmitter from WIKA helps to optimise sterile processes in the pharmaceutical and food industries.

The instrument communicates via HART protocol and is 3-Aand EHEDG-approved.

The heart of the transmitter is an elliptical tube sensor with a Wheatstone measuring bridge. Its hygienic design features very good flow behaviour when compared

“The instrument communicates via HART protocol and is 3-A- and EHEDG-approved.”

to a hygienic case, for example. The DMSU22SA therefore enables time- and cost-saving CIP and SIP processes. Operators also require less

energy to maintain process pressure. Depending on the requirements, the tube sensor is made of at least 0.45 mm thick stainless steel and is therefore many times more resistant than conventional in-line solutions. Should damage nevertheless occur, the user is informed, as it happens, via the alarm function. Active temperature compensation is also integrated into the transmitter, which makes process control more precise.

WIKA – www.wika.co.za

www.airproducts.co.za

DSM-Firmenich, leaders in nutrition, health and beauty, has unveiled Peach+ as the 2024 ‘Flavour of the Year’, drawing inspiration from Pantone’s Peach Fuzz, the Colour of the Year.

The selections are based on emerging trends and culture in the consumer landscape. The flavour and colour signals trends in kindness, community, goodness, and comfort. For more than 20 years, both companies have observed many of the same trend sources, drawing inspiration from a wide variety of influences, including culinary, fashion, hair and beauty, packaging and multimedia design, home decor and interior design, architecture, art, and cultural zeitgeist.

The peach is one of the oldest cultivated botanicals in the world, with a 4,000-yearold history that begins in China. Though China remains today the world leader in peach cultivation, varietals, and production export, this fruit is very synonymous with the South African consumer. Peach+ is an invitation to dsm-firmenich customers to innovate with this beloved flavour, to go beyond the traditional juicy sweet aspects to also consider softer, smoother, lighter, more refreshing, textural elements.

“Peach has many different meanings and evokes an incredible amount of emotion, according to our research, “added Dr Melanie Dennill, Sensory & Consumer Insights manager for Taste, Texture & Health at dsm-firmenich. “Having peach as a familiar fruit brings comfort to consumers and opens up a lot of opportunities for innovation.” According to Emotions 360™, a proprietary dsm-firmenich consumer study that

“The peach is one of the oldest cultivated botanicals in the world, with a 4,000-year-old history that begins in China.”

measures consumer emotions associated with ingredients, the peach is somewhat unique in that it has many innate qualities that contrast, such as being both indulgent and pampering, but also refreshing and revitalising, and youthful, but nostalgic.

Peach has been an evergreen fruit flavour in many categories for decades with a steady share of presence in innovations in most regions for decades. Today peach is growing in some regions and categories both as primary tonality and in combination with others. The most prevalent areas for growth are in carbonated soft drinks, nectars, candies, ready-to-drink teas, teas, flavoured alcoholic drinks, yogurt and fruit preparations, dairy drinks, juices containing peach, and fruit preserves. While some brands and some market maybe tapping into a new territory with peach, some will be reinventing and bringing peach back in a new way responding to those happy peach nostalgic memories consumers have.

“Now in its12th year, the announcement of the Flavour of the Year is an eagerly anticipated event,” said Maurizio Clementi, EVP for Taste, Texture & Health at dsmfirmenich. “The delicate and natural qualities of Peach+ call for diverse applications across multiple food and beverage industries, and we are excited to see the innovations of our clients upon receiving this news.”

Other areas showing promise for growth, according to dsm-firmenich trends data globally, are functional drinks and powdered soft drinks as well as side dishes, noodles, processed cheeses, and protein analogs. For those brands who are real leaders in innovation, the sky is the limit with peach+.

“We are really excited to elevate peach and explore with our customer partners the lesser celebrated aspects of the tonality and the emotions it can drive to unlock growth for their businesses through innovation.” said Lungie Mnyamana, marketing manager for Taste, Texture & Health at dsm-firmenich. Peach+ lands itself in a space to innovate with the flavour beyond the imagination. “We want brand custodians to consider the multi-layered composition of peach, from the juicy flesh, the velvet skin and the bitter, almond-like woody notes of the stone which takes peach beyond any category expectations.”

DSM-Firmenich - www.dsm-firmenich.com

As one of the oldest cultivated botanicals in the world, Peach has been delighting taste buds for decades. With today’s consumers increasingly seeking comforting food & beverage choices it is the perfect time to innovate with this timeless flavor and explore it’s softer, lighter and textural side!

Are you ready to explore the indulgent, refreshing and revitalizing possibilities of Peach? Then get in touch with us and try our variety of Peach+ flavours and functional benefits to find one that’s perfect for your brand and application.

www.dsm-firmenich.com

Savannah Fine Chemicals proudly showcases IFF’s revolutionary range of naturally sourced, clean - label and E-number free colours. Transform your products with these exceptional natural colours .

Savannah Fine Chemicals proudly represents IFF’s unique range of colours that are naturally sourced, clean label or E-number free, and designed to optimise visual appearance in a range of food and beverage products. These colour formulations are customised to fit each individual end use, in food and cosmetic applications.

Derived from natural sources we have two main ranges, manufactured by IFF,

THE RANGE OFFERS:

Water and oil soluble options

Available in liquid and powder form

Full strength concentrated and customised grades

Specific grades optimised for good heat and light stability.

the BRIGHT’N FREE & BRIGHT’N PURE portfolios, which provide you with an extensive pallet of colours.

EXAMPLE APPLICATIONS:

Beverages - The natural colour line offers a full palette of customised colour formulations for beverages, from juices and extracts to cloudy drinks and beyond. Explore our range of clear colour formulations for high-colour impact without cloudiness, as well as our allin-one cloud yellow to orange emulsion for cloudy drinks.

Culinary and plant-based – The portfolio offers a wide range of clean label colours and food colourings designed to mimic meat, such as red beet to replicate the pink colour of raw beef, turning brown when cooked.

Savannah currently represents IFF natural colours on the BRIGHT’N RED, red beet juice

powder and the BRIGHT’N YELLOW on beta carotene. Please don’t hesitate to contact us about your requirements.

Savannah Fine Chemical s –www.savannah.co.za

It’s the only one of its kind in the country to target decision makers in the manufacturing of food, beverages and their related industries. It o ers incisive and authoritative reports on all aspects of the process, from raw material sourcing, to manufacturing and packing, right down to the distribution and marketing of nished goods. FOOD REVIEW informs readers about the introduction of new ingredients, equipment, products and packing, and provides objective commentary on cutting-edge local and international market trends and issues.

To contribute editorially contact

Kelebogile (Lebo) Nondzaba

kelebogile.nondzaba@newmedia.co.za

+27 (0)78 175 9632

For advertising enquiries, contact

Anita Raath

anita.raath@newmedia.co.za

+27 82 976 6541 or

Candida Giambo-Kruger

+27 (0)71 438 1918

candida.giambo-kruger@newmedia.co.za

of additives to help create the taste, texture, performance and appearance you need for your food & nutritional products. We represent leading global manufacturers & our specialists can provide you with unrivalled sales support bringing the highest quality products to market:

Bakery ingredients: flavour, texture and fortification - Beverage ingredients for innovation - Confectionary: healthier & tastier alternatives to enhance your brandCulinary solutions for sauces, dressings and prepared meals that will innovateDairy & Desserts: texture and functionality - Flavour & fragrance creation - Health & sports nutrition.

+27 31 313 3338

+27 21 830 5306

Alison Donaldson, technical sales manager at EXBERRY by GNT, explains how plant-based colours can be used to send out all the right signals in beverages.

The health and wellness trends are becoming an increasingly important trend in the South African beverage market. Recent research shows a significant number of the country’s consumers now enjoy functional juices and waters (64%), chilled juices (58%), and smoothies (43%) at least once a month.ii In each of these product categories, the survey showed that overall consumption levels had risen over the previous six months. When creating healthy drinks, the choice of colour plays a key role in ensuring products send out the right messages. So, what strategies should brands consider to help their beverages stand out from the crowd?

Colour is a powerful storytelling tool that allows brands to connect with consumers on a deeper level. Subtle, earthy tones can signal a product’s naturality and authenticity. Bold, electric hues can be used to attract attention and add to the fun and excitement of consumption. Colourful ‘hero’ ingredients, meanwhile, allow brands to

showcase functional benefits. Products such as blue spirulina smoothies communicate their strengths in a striking yet intuitive way; in many of these drinks, branding or naming references are used to build up the connection between the colour and the active, healing ingredient.

Some functional beverages now use unusual, rich shades in both the product and the packaging to provide more abstract or thematic colour cues. A nootropic or gamer drink, for example, might use purple as part of a galactic theme that draws on elemental nature and science.

No-alcohol and low-alcohol beverages are also seeing growing demand. According to the IWSR No/Low Alcohol Strategic Study 2023, South Africa is among the top ten markets worldwide.iii The use of vivid colour shades can be used to help these beverages convey a message of fun, purpose, and adventure.

When selecting colours for healthy beverages, naturality is every bit as crucial as the choice of shade. An FMCG Gurus survey found that

68% of South African shoppers consider it important that colours used in food and drink are natural4. GNT’s plant based, sustainable EXBERRY® colours allow beverage brands to achieve strong visual appeal while tapping into consumers’ desire for natural ingredients. Our colours are made from fruit, vegetables, and plants, supporting clean label declarations while allowing for bright shades. The FMCG Gurus survey showed that 74% of shoppers in South Africa consider colours made from the concentrated juice of fruits, vegetables, and plants to be appealing.

EXBERRY colours are trusted by the world’s leading food and drink brands. Our portfolio features more than 400 shades from across the whole spectrum and they can be used in almost any application, including all types of beverages.

To ensure effective results with plantbased colours, it is important to consider applications’ individual characteristics. From smoothies to vitamin waters to protein shakes to mocktails, there can be dramatic differences in technical requirements.

Standard beverage processing is not a major challenge for EXBERRY colours as the range includes water-soluble and waterdispersible products as well as liquid and powder formats. They are also suitable for low pH levels and offer good heat stability.

However, some recipes have the potential for numerous ingredient interactions that can affect the performance of plant-based

The GNT Group is an independent, family-owned company focused on long-term success and the sustainable development of truly natural colouring solutions. This makes us a trusted partner to a growing number of food and beverage companies worldwide that want to meet the increasing consumer demand for visually outstanding natural products with clean and clear labels. Established 40 years ago, GNT started from humble beginnings in the German city of Aachen with one man’s vision to produce colouring concentrates in the most natural way possible. Our founder coined the term ‘Colouring Foods’: food concentrates used solely for the purpose of delivering colour to food and beverages. Colouring Foods are now becoming the industry standard in many markets.

colours. There are many vitamins, minerals, and botanicals that can have an impact. For example, colours made from raw materials containing carotenoid pigments may benefit from ascorbic acid to support performance. With anthocyanin-based red colours, though, ascorbic acid may have a negative impact on performance.

It is therefore essential to identify a raw material combination that delivers the desired colour shade and performance in the given beverage system. Doing so requires the supplier to be able to select from a wide range of raw materials and to have a deep understanding of their individual properties.

GNT has been working with plant-

based colours since 1978 and offer a comprehensive toolbox of solutions made from more than 30 different raw materials. We support our customers through every step of the product development process, from concept innovation and colour selection to stability testing, regulatory support, and quality documentation.

We’re not just a colour supplier; we’re a partner in your innovation journey. In a world where visual appeal and clean labels matter more than ever, our plant based EXBERRY colours can help ensure beverages match up to consumer demands.

*References available on request

Carst & Walker - www.carst.co.za

EXBERRY by GNT – www.exberry.com

ROHA has recently introduced ChromaFine, an innovative range of ultrafine micronized food colours, to its extensive collection of natural food colourants.

Micronized food colours undergo a meticulous micronisation process that reduces particle size to the micron level, enhancing dispersion, solubility, and brightness. Derived from carefully sourced natural ingredients, ChromaFine adds rich, authentic colours to seasoning blends, particularly excelling in oil-based applications. Its commitment to clean label and natural solutions aligns seamlessly with consumer preferences, ensuring that seasoning products stand out for their natural appeal and original qualities. ChromaFine’s ease of blending and spreading creates intensely vibrant colour hues, maintaining high standards of quality in culinary offerings.

Deliver vibrant, intense colour shades: ChromaFine is designed to impart vivid and striking colour shades to food products. Its micronized particles ensure that colours stand out vibrantly, enhancing the visual appeal of the final product.

Custom colour blends: With ChromaFine, users have the flexibility to create custom colour blends according to their specific requirements. Whether it’s achieving bold reds, earthy greens, or any other desired hue, ChromaFine allows for personalised colour creations.

“With ChromaFine, users have the flexibility to create custom colour blends according to their specific requirements.”

Evenly coat the food application: ChromaFine’s ultrafine particles enable smooth and even coating of food applications. This ensures that colours are distributed uniformly throughout the product, enhancing its overall appearance. Homogeneous colour effect: The micronised nature of ChromaFine guarantees a homogeneous colour effect. This means that the colour is evenly dispersed throughout the product, resulting in a consistent appearance without any streaks or uneven patches. No specking in fat-based creams, compound coating, and tablets: ChromaFine is specifically formulated to prevent specking in fat-based creams, compound coatings, and tablets. Its fine particles blend seamlessly with these formulations, eliminating any undesirable specks or inconsistencies.

Clean label natural colourants: ChromaFine is derived from natural ingredients, aligning perfectly with the clean label trend in the food industry. It provides manufacturers with a natural colouring solution that meets consumer preferences for clean and transparent ingredient lists.

Stability characteristics: ChromaFine offers excellent stability characteristics, ensuring that colours remain vibrant and consistent throughout the shelf life of the product. Its stability in various food applications makes it a reliable choice for food manufacturers.

ROHA started out in India and has since grown into a global power in the food colours and ingredients, and the industrial dyes & pigments markets. This has been achieved through a consistent pursuit of natural alternatives, technology, intensive research, sustainable sourcing and staying ahead of the latest trends to develop futureready solutions for clients. It has its beginnings in the Roha district of Maharashtra, India. The company was founded as a manufacturer of synthetic colours for industrial applications in 1972 and has always held clients at the center of what it does. This has shaped how the company does business and managed to evolve over the years. The company has led a revolution in the food colours industry through unmatched quality standards. In its present avatar, ROHA is a multinational giant dealing with natural food ingredients, food colours, pharmaceutical and cosmetic pigments, dried ingredients, and industrial colours & dyes.

In conclusion, micronized food colours, with their advantages of solubility, dispersion, and colour intensity, continue to play a significant role in the culinary world. ROHA’s ChromaFine leads the innovation, offering transformative possibilities in the realm of micronized food colours.

As ROHA remains at the forefront of tailormade food color solutions, customers are invited to explore the vibrant possibilities of ChromaFine and embark on a transformative journey in micronized food colours.

ROHA - www.roha.com

Images: Shutterstock.

Isobionics®, a brand of BASF Aroma Ingredients, is launching two new natural products on the flavour market. Isobionics Natural alpha-Bisabolene 98 and Isobionics Natural (-)-alpha-Bisabolol 99 are the latest additions to its Isobionics’ portfolio as proof points of its commitment to developing natural flavours driven by customer needs.

“We are delighted to introduce the two new products, which are natural flavours and produced with our cutting-edge fermentation technology. Therefore, they are independent from harvest conditions and pesticide free,” says Toine Janssen, CEO of Isobionics. “This is a major milestone for us and for the flavour industry, as it is the first time that two natural flavours are being launched and marketed together. Building on our cutting-edge fermentation technology we can constantly expand our natural flavour portfolio beyond our well-established citrus products to address further customer and market demands.”

Breaking new ground beyond the citrus portfolio, Isobionics is unlocking a world with new possibilities for food, beverage, and flavour enthusiasts and is proud to introduce the following two products:

• Isobionics Natural (-)-alpha-Bisabolol is a known product, traditionally derived from natural sources and with a complex and captivating aroma profile. Renowned for its delicate floral notes, it offers a subtle hint of chamomile, along with hints of sweet, woody undertones, resulting in a truly unique flavour experience. This groundbreaking innovation allows culinary professionals and beverage creators to boost other flavours such as

Vanillin and Nootkatone to add a distinctive twist to their creations.

• Isobionics Natural alpha-Bisabolene 98 is a breakthrough in the flavour industry as its purity improves better flavour development. Moreover, with its creamy milky flavour, it makes a major contribution to the expansion of the Isobionics’ portfolio.

One of the most exciting aspects of the two new flavour ingredients is their great versatility. These flavour ingredients, produced at very high concentration via fermentation technology can be found not only in citrus essential oils, but also in several

”This is a major milestone for us and for the flavour industry, as it is the first time that two natural flavours are being launched and marketed together.”

other natural oils, such as chamomile, ylangylang, black pepper, and basil oils. The very high quality of our natural flavours opens a world of possibilities for flavour enhancement in a variety of applications. Whether it is adding crispness to mild flavours, complexity to your beverages and confectionery formulations, or a savoury punch to culinary creations, the new products offer limitless potential for creating memorable taste experiences. These natural products, use only renewable raw materials and they are produced via fermentation technology, which makes them independent from harvest conditions and seasonality and free from agricultural residues, thus ensuring a constant quality in your products.

Steffen Götz, vice president of Aroma Ingredients at BASF, highlights the dedication to customer-centric innovation: “Isobionics’s new flavour solutions embody our ongoing commitment to providing sustainable and high-quality ingredients. These new product launches complement and expand the existing portfolio an answer the need for fermentationbased natural flavours. Dedication to providing natural and sustainable flavour solutions forms the core of our new product developments. Our biotech platform plays a significant role in developing future ingredients to deliver exceptional flavour profiles that are geared to consumer preferences.”

The new natural flavours Isobionics Natural alpha-Bisabolene 98 and Isobionics matual (-) – alpha-Bisabolol 99 have now been officially launched. Customers can already reach out to their designated sales contact and schedule an exclusive presentation of the new flavours to experience these extraordinary flavour innovations first hand.

At Isobionics, we offer you access to high-quality, natural aroma ingredients. Our product range is the ideal choice for anyone looking for innovative, cutting-edge ingredients based on fermentation technology.

Our products in a nutshell:

< Premium quality

< Reliable availability, independent of weather or harvest conditions

< EU and US Natural, Kosher and Halal

< Fermentation based from renewable resources

< Pesticide free

In recent years, there has been a distinct shift in consumer preferences towards natural ingredients in the food and beverage industry. This trend is driven by a growing awareness of the potential health risks associated with artificial additives, such as synthetic colours. However, the focus on natural ingredients goes beyond mere health concerns. An emerging consumer trend is the use of natural colours and colouring foods to tap into positive emotions and address mental health awareness.

tranquil blues and greens may evoke a sense of calmness and relaxation.

By deliberately selecting colours that align with positive emotions, product developers aim to create a sensory

experience that promotes mental health awareness. This approach not only attracts consumers seeking natural alternatives but also appeals to those searching for products that support their emotional well-being.

available through the Barentz network globally we can always offer a better solution to our clientele.

SK Chemtrade, Oterra’s distributors in South Africa explain how, natural colours can both support consumer demand for naturality and align with the positive effects of active ingredients that promote mental health benefits through the association of specific colours and postive emotions. Images:

Colours have a profound influence on human emotions and can evoke various psychological responses. Recognising this, food and beverage companies are incorporating specific colours to target positive emotions and enhance mental well-being. For instance, bright, vibrant hues like yellow and orange are associated with feelings of happiness and energy, while

We are a distributor with in-depth knowledge about our suppliers’ products, including application and cost-in-use benefits. We supply these ingredients to manufacturers of food, beverages, pharmaceuticals and dietary supplements in South Africa and its neighbouring countries. We can also combine our suppliers’ ingredients with other ingredients to develop customer specific food and beverage compounds in our laboratory in Cape Town. Our Cape Town facility is FSSC 22000 certified and with our team of Food Scientists we can take a brief from Concept to Launch. By further tapping into the application laboratories

We are the largest provider of natural food colours worldwide. Since our first food colour launch in 1876, we’ve continued to offer the power of nature’s true colours to the food and beverage industry. With Oterra, you have access to the widest portfolio of natural food colours in the industry. And our commitment to R&D, our world-class application expertise, and our control of each raw material’s value chain are why we lead the industry.

In response to the consumer trend, innovative products that combine natural colours and mental health awareness have emerged. Drinks infused with vibrant beetroot extracts are marketed as a ‘natural pick-me-up’ to energise consumers and boost mood. Similarly, teas infused with soothing chamomile and lavender offer a calming effect on the mind. These product developments highlight the industry’s commitment to incorporating natural ingredients and leveraging colour psychology to create holistic experiences for consumers.

The consumer trend towards natural ingredients, particularly regarding natural colours and colouring foods, reflects an

“By deliberately selecting colours that align with positive emotions, product developers aim to create a sensory experience that promotes mental health awareness.”

increasing emphasis on mental health awareness. As consumers become more conscious of the relationship between their diet and emotional well-being, food and beverage companies are harnessing the power of natural colours to create positive sensory experiences. By continually innovating and educating consumers, the industry can support mental health awareness while meeting the demand for natural and authentic products.

DID YOU KNOW?

Colours have a profound influence on human emotions and can evoke various psychological responses.

SK Chemtrade – www.skchemtrade.co.za

Oterra – www.oterra.com

Proud partners helping you do great things with natural colors

Kerry, a global leader in taste and nutrition unveils its 2024 Taste Charts, offering a comprehensive exploration of future tastes across 13 regional markets, providing key insights into flavour trends and innovations shaping the food and beverage sector.

The culmination of Kerry’s year-long research is a series of incisive, interactive charts created separately for 13 individual regional markets, including some 30 countries in Asia Pacific, Middle East & Africa (APMEA).

The charts list mainstream, key, up-andcoming and emerging tastes across five food and beverage categories, provide an in-depth analysis of the flavours, ingredients and trends that will shape innovation in the food and beverage sector in the year ahead, and inspire product and menu developers worldwide.

To illustrate today’s incredible pace of innovation, Kerry researchers conducted a deep dive into the lifecycles of two longpopular flavours — orange and chocolate — and examined how these mainstream ingredients are evolving into all manner of inventive tasty product offerings around the world. These two case studies demonstrate how popular and traditional tastes worldwide are fusing into new, innovative applications as brands source, combine and recombine flavours and ingredients from other places.

Commenting on the 2024 Asia Pacific (APAC) Taste Charts, Avinash Lal, Market Research and Consumer Insights director, Kerry Asia Pacific, Middle East & Africa (APMEA), said: “The APAC flavour scene is a vibrant tapestry, constantly evolving and influenced by diverse cultural traditions, emerging trends, and evolving consumer preferences. Consumers are rediscovering

“Think Sichuan peppercorn ice cream in China, Calamansi-infused yogurt in the Philippines, or black sesame latte in Japan.”

the magic of their own culinary heritage, seeking out unique regional ingredients and flavour profiles. Think Sichuan peppercorn ice cream in China, Calamansi-infused yogurt in the Philippines, or black

are getting a modern twist, leading to innovative dishes like charcoal-grilled skewers with fermented chilli paste in Thailand and turmeric latte macarons in India.

• Young consumers are craving bold and unusual flavour combinations, driven by social media’s influence and a desire for novelty. This opens opportunities for sweet-savoury pairings like bacon milkshakes, coffee infused with black garlic, and chocolate bars with wasabi.

• The plant-based revolution is taking off, leading to new demand for creative flavour solutions in meat and dairy alternatives, such as jackfruit rendang in Indonesia, mushroom jerky in Australia, or chickpea falafel with a Middle Eastern twist.

OTHER TOP INSIGHTS FOR 2024 FLAVOUR INNOVATION ACROSS ASIA PACIFIC, MIDDLE EAST & AFRICA:

• Fruits such as Yuzu are gaining popularity across multiple markets and applications, with recent launches including Yuzu Gose beers in South Africa, Yuzu and pepper mayonnaise in China, and Yuzu low ABV wines and alcoholic beverages in Australia. In South Africa, authentic local flavours such as Chicken Dust, creative combinations the likes of chilli lemon/lime, and global culinary influence (jalapeno atchar) reflect the nation’s cultural diversity. Sweet flavour pairings are also gaining popularity, from sweet & salty, sweet & spicy, to sweet & smoky.

• Traditional spices and cooking techniques

• Passionfruit: considered a niche fruit, this cold beverage flavour appeared in all thirteen different global regions as analysed by the charts. It’s a mainstream ingredient in New Zealand but still only an early-stage emerging flavour in the Middle East.

Soumya Nair, Global Consumer Research and Insights director at Kerry, observed: “Consumers want tasty new innovations or flavours they may have experienced while travelling. We are seeing many unique flavour intersections in foods and beverages. Although rapidly changing times can present great challenges, they also provide an unparalleled opportunity for brands to catch a trend on the rise. The Kerry 2024 Taste Charts are a valuable tool for the food and beverage industry to navigate the new taste environment for products.”

Q.What products are cooked in the spiral oven?

A. Engineered for high volume, spiral ovens are used to cook a multitude of foods. Meat, poultry, prepared foods, bakery items, breakfast cereal, and even dehydrated fruit and vegetables are all cooked using the spiral oven. This oven can partially or fully cook a product and even facilitates dehydration before further downstream processing. They can develop and enhance product colour and are suitable for products requiring a long residence time. An alternate solution to tunnel ovens the spiral oven provides maximum baking capacity with a small footprint.

Q.What type of operations are spiral ovens suitable for?

A .Generally speaking, they are suited to medium and large-scale producers.

Q.Explain the single drum vs twin drum options?

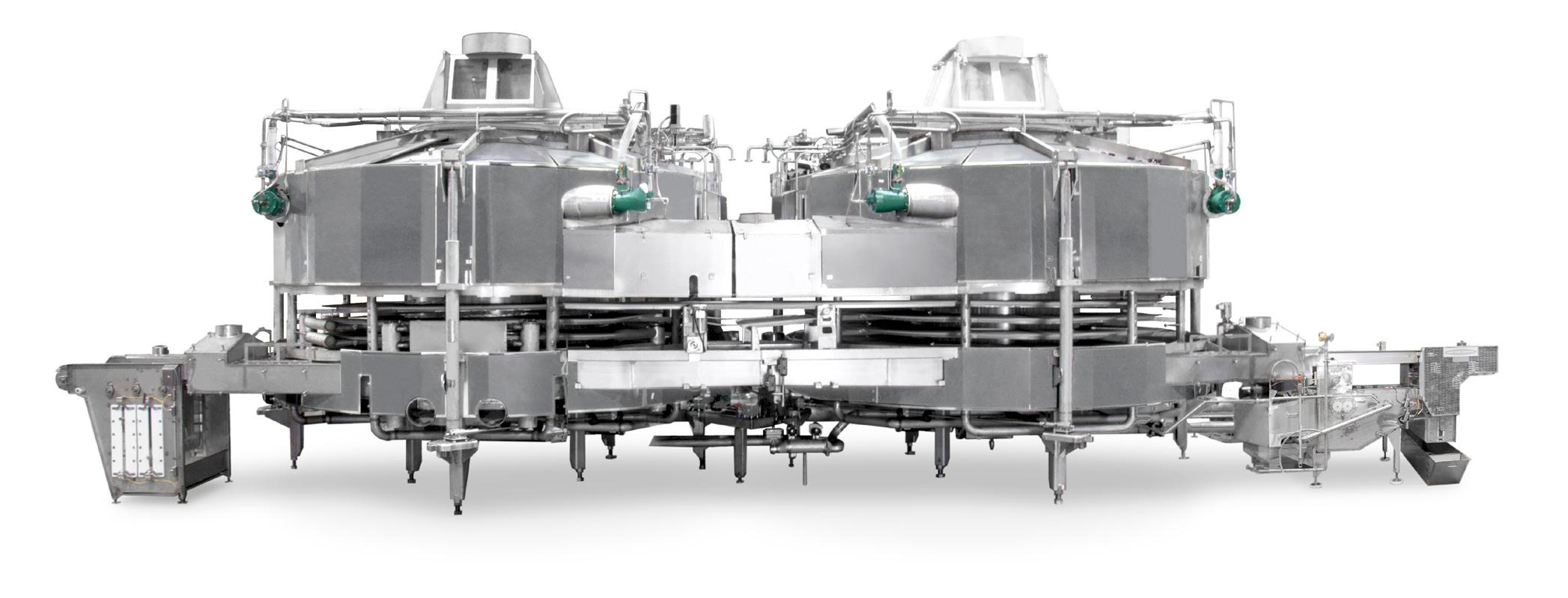

Explore the world of spiral ovens with Heat and Control. From cooking versatility to unique design features and discover how these ovens cater to diverse food processing needs. Image:

A .A single drum has one heating zone. All the product inside this oven is exposed to the same cooking environment. This can result in lower yields compared to the same product cooked in a twin drum. The twin drum has the advantage of setting two very different cooking environments within the one system. The ‘up-drum’ can be set with high humidity to cook but not dry out a product, while the down drum can be set with a drier environment, often used to develop product colour. This results in less moisture loss

from the product and reduced loss of yield. Available factory space often determines which oven is chosen.

Q.Where in the processing line does the spiral oven fit? What other equipment is it used with?

A.The spiral oven is typically placed downstream from a frying system and up-stream from a freezer. The fryer sets up the coatings and then the spiral oven is used to further cook the product and develop its colour.

Q.The spiral oven is versatile in its ability to use dry heat, steam only or a combination. Provide an example of how these options may be used by a food processor?

A .Dry heat is used to develop and enhance product colour. The downside of this method is that moisture evaporates from the product resulting in smaller yields. Moisture loss from the product also affects texture and palatability. By reducing moisture loss, a producer ensures higher product weights and a better tasting product, which leads to increased profitability. A food processor may use the steam option for a 100% steamed product that doesn’t require any colour development. This method transfers energy to the product with little or no moisture loss. By using a combination of both steam and dry heat, a processor gets the best of both worlds. Steam helps to reduce moisture loss and combines with dry heat to create a premium finish with high product yields.

Patented Moisture Control System

Developed over 40 years ago, this system was originally used in our MPO oven. It is easy to use and maintain with proven reliability and doesn’t use expensive sensors requiring frequent calibration.

Water spray and belt brushes ensure that the oven’s belt is kept clean during operation. A soak tank prior to the belt wash softens and loosens baked on grime making the job of the belt brushes much easier.

The structure of this oven doubles as pipework for a CIP system. CIP spray balls are placed to ensure all internal surfaces are sprayed during CIP. Nozzles on the cantilevers spray directly onto the belt to assist with cleaning. The CIP system has a continuous filter that reduces the risk of spray balls and nozzles being blocked and this reusable filter element is easily removed for cleaning. Settings can be saved for every recipe and there is no need to change the settings every time. Options for automatic dosage of cleaning chemicals are also available.

The spiral oven allows processors to use the entire width of the oven belt allowing for higher capacity outputs.

Heat and Control - www.heatandcontrol.com

In the realm of quick service restaurants (QSR), precision is paramount. Marel, a pioneering force in the processing industry has unveiled standardised solutions to meet the stringent demands of QSR industrial standards.

The market for portioned products can be very diverse, mostly depending on the type of product. The QSR industrial standards formulate the strictest demands. The product must be uniform, standardised, consistent and repeatable. In the QSR market, cooking time is also important, but the highest priority is given to the fact that products are ‘always the same’. Marel has developed standardised production processes that comply with such precise specifications.

In the QSR market, products such as chicken burgers, chicken tender strips, skewer meat, nuggets and popcorn are all standardised. They have one thing in common: their production requires multiple cuts or multiple processes. Single machines can’t meet the requirements anymore, so complete solutions are necessary. Marel can support processors in making the right product-market combinations by implementing its dedicated standardised solutions.

If the end products should be QSR cubes, Marel can offer a standardised process and can also advise

on the raw material. For making a fast-food cube, a calibrated product is preferable. That’s because a weight-calibrated product gives a better uniformity of the end product and a better control of the process. However, purchasing calibrated raw material is more expensive than uncalibrated product. And the availability could sometimes be an issue.

If the raw material is uncalibrated, it’s the exact opposite. The process can’t be controlled properly, meaning that it will be more difficult to produce the cubes just as nice as the QSRs want them to be. So the impact of the raw material must not be underestimated.

This standardised configuration can

“Marel can support processors in making the right productmarket combinations by implementing its dedicated standardised solutions.”

produce high volumes of in-spec cubes. Marel knows exactly how to produce the strips with the required characteristics and the right quality and avoid making them look like French fries. Irrespective of what kind of raw material is brought in, it is always possible to create a high-quality strip and cube. This solution is very flexible. Processors who don’t produce cubes day-in-day-out, want

to make other types of products too.

That can be done by adding a SensorX, a RoboBatcher or even another component to the line. In this way, the same portioning line setup can produce burgers, tenders, and schnitzels.

The preparation of the fillets before portioning, such as height calibration, is also very important.

Marel’s SmartSplitter performs horizontal slicing, with its knife set at a fixed position.

Lying on the conveyor belt, the fillet enters the SmartSplitter and anything that is above the height of the knife will be cut away.

The end result is a piece of trim and a nice, calibrated piece of breast meat.

The cubing process needs the heightcalibrated breast fillet as its input. First, the I-Cut 122 TrimSort portion cutter cuts the fillets into strips. After this, the additional process makes the same I-Cut 122 cut the strips into cubes. The recipe for this process is easy to program via the HMI display of the I-Cut 122. It is controlled by internal machine

DID YOU KNOW?

This standardised configuration can produce high volumes of in-spec cubes.

A dicing machine isn’t useful for QSR fixed-weight fixedshape cube cutting. If you take all the fillets and simply cut as many cubes out of them as possible, you’ll get some smaller and some bigger pieces, all with different shapes and different weights. You have no control over this process, and that’s what we call dicing. Those dices typically go to supermarkets into bags of 500 gram, and you’ll use them for goulash or stir fry. It is true that you’ll get more dices than cubes out of a fillet, but this presumable yield win isn’t valid for QSR purposes.

Fixed-weight cubing for QSRs requires a specific procedure, with an analysis of each individual fillet or strip. Therefore, cubing needs more processes and intelligent software to make it work, it is not simply cutting squares. The uniformity and consistency of the production process for every single cube are crucial. Meeting these strict requirements is an absolute necessity, because QSR chains only accept 18-22 gram or 15-20 gram fixed-weight cubes that have the same shape and dimensions. The challenge is to achieve the highest yield out of every fillet, with the lowest possible giveaway.

Fixed-weight cubing for QSRs requires a specific procedure, with an analysis of each individual fillet or strip. Therefore, cubing needs more processes and intelligent software to make it work, it is not simply cutting squares. The uniformity and consistency of the production process for every single cube are crucial.

Meeting these strict requirements is an absolute necessity, because QSR chains only accept 18-22 gram or 15-20 gram fixed-weight cubes that have the same shape and dimensions. The challenge is to achieve the highest yield out of every fillet, with the lowest possible giveaway.

software, which can be combined with overarching Innova process control software.

NEW CRISPY BURGER PATTIES

A relatively new product in the core menu of one of the biggest QSR chains is the crispy burger. It is the company’s first new permanent chicken burger menu item in 15 years. It is a 70-gram teardrop design whole muscle burger, in fact a crunchy breaded fillet, and it will be on equal terms with the other fast movers of this QSR chain. Marel already knows how to produce this crispy burger patty and has solutions available.

According to Branson Chemicals, food processors frequently spend substantial amounts of money on cleaning and sanitising chemicals and this article will equip them to make informed decisions about their purchases.

With few exceptions, water is the universal cleaning agent, but pure water does not exist in nature and water itself is not a particularly good cleaner.

The hydrological cycle consists of several key stages, beginning with evaporation, where heat transforms liquid water into vapour rising into the atmosphere. Condensation follows, as water vapour cools and forms liquids. Precipitation occurs when clouds release water in the form of rain, snow, sleet or hail. Water percolates through deposits of limestone, chalk or gypsum, which are largely made-up of calcium and magnesium carbonates, bicarbonates, and sulphates. These impurities are called water hardness, which can pose critical problems in industrial settings and can have a serious deleterious effect on the performance of detergents. Hard water often manifests itself in the formation of different types of scales, such as water scale, beer stone, wine stone and milk stone which frequently represent significant cleaning challenges and often require the use of powerful detergents, especially acids. Where high water hardness is encountered, water softening and/or high detergent concentration may be used to reduce hard water’s adverse effects.

Before embarking on any cleaning and sanitation program, various questions need to be answered:

What type of surface are we cleaning –stainless steel, aluminum etc.?

What type of soil are we trying to remove –milk residues, beer stone etc.?

ARE:

0-60ppm Soft water

61-120ppm Moderately Hard

121-180ppm Hard

>180ppm Very Hard

What kind of detergent will work best, and do the least damage?

How can we enhance the effectiveness of the detergent solution? By adjusting the concentration and/or heating.

Fats, oils, and greases, which may be difficult to remove, especially if they have been burned or baked on. This is typically not a problem in beverage plants unless there is a heating stage in the process.

Carbohydrates such as lactose which are typically water soluble unless they have been heated and caramelised. Once again this is not typically a problem unless there is a heating stage in the process.

"With few exceptions, water is the universal cleaning agent, but pure water does not exist in nature and water itself is not a particularly good cleaner. "

Proteins, such as casein, are large complex molecules and can be hard to remove, especially if they combine with hard water salts of calcium and magnesium. All food plants should check their water hardness. Scales, which manifest as beer stone, milk stone or hard water scale and are usually removed by a strong acid detergent.

Alkaline detergents are the workhorses of most cleaning programs and come in a variety of different forms powder or liquid; caustic or non – caustic and high foaming or non- foaming, depending on the application. Caustic detergents are mostly used for CIP applications and are always

non – foaming. However, some alkaline detergents used for foam cleaning may contain a percentage of caustic.

Alkaline detergents are the workhorses of most cleaning programs and come in a variety of different forms powder or liquid; caustic or non – caustic and high foaming or nonfoaming, depending on the application. Caustic detergents are mostly used for CIP applications and are always non – foaming. However, some alkaline detergents used for foam cleaning may contain a percentage of caustic.

Broadly, detergents fall into their groups:

• Alkaline

• Acid

• Neutral

Sources of Alkalis

Sodium Carbonate (Soda Ash) Mild alkali is commonly used in manual cleaners, and laundry detergents

• Corrosive to Aluminum

• Sodium Hydroxide (Caustic Soda) Strong alkali commonly used.

• Corrosive to Aluminum

• Potassium Hydroxide (Caustic Potash)

Strong alkali expensive not widely used

• Corrosive to Aluminum

Sodium Metasilicate Mild alkali is widely used in manual cleaners and provides corrosion protection.

Sequestrant

All alkaline detergents will contain sequestering agents, such as sodium tripolyphosphate. Sequestrants enhance the performance of detergents by controlling

Emulsification

One of the primary functions of surfactants is emulsification, which involves dispersing and stabilizing one immiscible substance (e.g. oil) within another (e.g. water).

Detergency

Surfactants are the key ingredients in many cleaning agents, as they help to loosen and remove dirt, grease, and other contaminating from surfaces. Their hydrophilic head attracts water molecules, while the hydrophobic tail binds to the dirt, allowing it to be washed away.

water hardness and preventing and preventing mineral deposits. Sequestrants, ‘Tie up’ or sequestrate water hardness ions, preventing them from reacting with surfactants and forming insoluble salts, by binding to ions. Sequestrants ensure that the surfactants can perform their cleaning action more effectively. As mentioned, sodium tripolyphosphate is by far and away the commonly used sequestrant, but there are other agents such as EDTA and the phosphonates that are used for specific applications. Phosphonates are a class of organic compounds known for their versatility in various applications, such as water treatment and liquid detergent manufacture. Phosphonates play a vital role in preventing mineral deposits and corrosion. They are widely used in highly alkaline liquid detergents, such as bottle washing compounds. One group of phosphonates are chlorine stable and are used in liquid chlorinated alkaline detergents.

Surfactants are compounds that possess unique chemical properties, allowing them to interact with both water and oil-based substances. They consist of molecules with a hydrophilic (water attracting) ‘Head’ and a hydrophobic (water repelling) ‘Tail’. This dual nature grants them the ability to reduce surface tension, enabling them to mix substances (such as oil and water) that would otherwise remain separate.

Surfactants can be categorised into four main groups based on the charge of their hydrophilic head.

Foaming and wetting

Surfactants are responsible for creating foam in shampoo, hand soap and detergents. They also reduce the surface tension of liquids (water) making them penetrate and spread more easily.

Stabilisation

Surfactants are used to stabilise a variety of systems, including suspensions, emulsions, and foams. They prevent particles from clumping together or liquids from separating.

Anionic surfactants

These are typically high foaming and have a negatively charged head. They are commonly found in detergents and cleaning products. Dodecyl benzene sulphonic acid is the most widely used anionic detergent.

Cationic surfactants

These have a positively charged head and are not generally effective cleaners. They are often used in fabric softeners and hair conditioners. In the food industry the best known are the quaternary ammonium compounds, (QAC’s) which are effective sanitisers.

Non-ionic surfactants

These lack a charged head and are widely used in both personal care and industrial detergents. Some are high foaming, some are low foaming, and some are de- foaming at elevated temperatures.

Amphoteric surfactants

These can carry either a positive or negative charge, depending on the pH, they are seldom used in industrial detergents. Acid detergents are widely used in applications where ‘stones’ or mineral deposits are an issue. Typical examples are milkstone, beerstone, winestone and hard water scale.

Phosphoric Acid - Widely used

Hydrochloric Acid - Corrosive – Not used

Sulphuric Acid - Occasionally used

Nitric Acid - Very Strong – widely used

Sulfamic Acid - Occasionally used

Hydroxy Acids - Seldom used

Email:

IPCO is the world’s largest manufacturer of solid and perforated steel bake oven belts, supplying OEMs and end users alike.

The key qualities of an IPCO bake oven belt include outstanding thermal properties for efficient baking; the inherent ease of cleaning of a belt compared with mesh; and the attractive return on investment when considering overall lifetime cost.

Belts are available in widths from 800 mm to 3500 mm, and are suitable for products as diverse as bread, biscuits, brownies, crackers, pastries, sponges, all-butter cookies and pizza bases.

Steel belts offer several distinct advantages in terms of performance in the oven, primarily due to their excellent heat transfer and thermal conductivity. As the heated steel belt surface is in direct contact with the underside of the product, this delivers the crisp, chewy base that represents much of the appeal of many products.

A flat, smooth surface ensures clean release at the end of the oven with minimal risk of damage to fragile products.

Several factors combine to make steel belts a more sustainable choice than other belt types. Their strength results in exceptional

“IPCO produces a range of belt alignment solutions, including an upgraded version of its widely used Compact Belt Tracker (CBT), a versatile, tilt roller tracking system that can be retrofitted to existing conveyors.”

durability, which means a 20 year working life is not unusual. Secondly, solid steel belts are inherently lighter than mesh belts and perforated belts even more so. A belt has to be reheated every time it enters the oven and a lighter belt means less metal to heat. This means that significantly less energy is required – and these savings are continuous. This weight advantage also means less energy is needed to ‘drive’ the belt through the oven.

The quality of the belt – its straightness and flatness – is central to its long term performance but bake oven belts also require effective tracking systems. IPCO produces a range of belt alignment solutions, including an upgraded version of its widely used Compact Belt Tracker (CBT), a versatile, tilt roller tracking system that can be retrofitted to existing conveyors.

While the existing CBT uses a physical edge sensor, a new, contact-free model features an optical sensor that continuously monitors the belt edge. Any unwanted movement instantly triggers the necessary corrective action in the tilt roller, and smooth, straight running is immediately restored.

The new contact-free Compact Belt Tracker is just one of a comprehensive range of IPCO conveyor components. These include rolling supports, sliding supports (e.g. skid bars and graphite stations), frames, end stations, pulleys, cleaning devices and more.

Complementing the company’s expertise in belts, IPCO can also support bakeries with belt cleaning using an innovative system based on high power industrial laser technology.

The laser is installed above the belt and as the belt travels beneath the beam, deposits are burnt off and collected by a vacuum system. Once the strip has been cleaned, the laser head is moved across to the next section.

The key benefit is speed; depending on belt size and level of build-up, a typical bake oven belt can be cleaned in a day. It is an entirely contact-free cleaning process – the structure of the belt is unaffected by the laser. Laser cleaning is a completely dry treatment that uses no water, detergents or aggressive chemicals such as caustic soda (NaOH), making it a far more environmentally-friendly solution than traditional methods.

IPCO has been involved in bake oven conveyor design for decades, often working hand in hand with oven builders to ensure that an oven reaches its full potential. This extends to ongoing partnerships with bakeries and the company has a Special Engineering team who can provide expert technical support.

This experience has resulted in an indepth understand of how a belt behaves in an oven and how it interacts with the many other component parts that make up the system. As a result, IPCO can deliver inspection and maintenance services that go beyond the belt, with investigations encompassing the entire line to understand how the system is performing IPCO recommends that customers take advantage of Preventative Maintenance Agreements (PMAs). In this way, risks of failure can be identified before they have chance to disrupt production.

Our solid and perforated steel belts have helped bakeries produce premium quality products for almost 100 years.

Flat, straight, durable and easy to clean, they provide a baking surface that’s ideal for everything from rich, chewy all butter cookies to traditional biscuits and crackers.

We can also support you with a wide range of conveyor components covering everything from tensioning, drive stations and drums to tracking systems, break points and graphite stations. Talk to your local IPCO service team and we’ll work with you to improve the performance, productivity and reliability of your oven through process enhancement and system upgrades.

High productivity wide belts up to 3500 mm.

Maximum versatility – bake more on an IPCO steel belt.

Energy efficient – lighter belt means lower carbon footprint.

High power laser cleaningfaster, cleaner and greener than traditional cleaning.

Installations, upgrades (mesh replacement), repair, maintenance and spare parts.

Indulge in the art of confectionary with FAMASONS culinary excellence, the exclusive importer and distributor of fine chocolate, and locally manufactured coatings and inclusions in South Africa.

Get ready to celebrate the upcoming Valentine’s Day and Easter festivities with FAMASONS Premium Ingredients. We have a diverse range of compound and coverture coatings that will transform your creations into works of art. We offer a wide range of specially manufactured imported and local, nontempering and easy to use products, ensuring that your business has access to a diverse and exceptional selection, engineered for multiple uses and applications such as, coating – enrobing – moulding –panning – filling – inclusion – topping. Our

Twenty years ago, a distinctive energy emerged within the Bakery Ingredient supply industry.

FAMASONS was established in 2003, by a dynamic duo and a skilled, master baker, who in earlier years, were directly involved in Bakery and Confectionary businesses.

With just three main product categories and a handful of customers we knew we started something special. Despite the risks, we set off on a path to establish a business built on the principles of Trust – Integrity – Passion – Commitment –Service – Teamwork – Innovation, all of which are active in a family driven atmosphere.

When you step into our offices, you’ll be greeted by the unmistakable presence of these core values proudly displayed on our walls. Although they may sound cliché to some, we can assure you that for two decades, our company has remained steadfast in upholding these principles. We have earned our respect and built our reputation as a committed and successful team, rising above all challenges, while supplying the food industry with professional Bakery Ingredients and Solutions. The success we see today is built on the effort and dedication of all our employees, and the unconditional loyalty of our valuable customers and trading partners.

“Our expertise extends beyond chocolate, FAMASONS proudly supplies a wide range of premium ingredients that are meticulously sourced and chosen to meet the highest standards.”

team is here to elevate your creations to new heights of culinary excellence, unlocking your business’s full potential.

With Valentine’s Day and Easter on the horizon, FAMASONS understands the pivotal role your business plays in sweet crafting memories and spreading joy to customers young and old. Allow us to tempt your taste buds with our exceptional range of premium ingredients and our delectable chocolate variety.