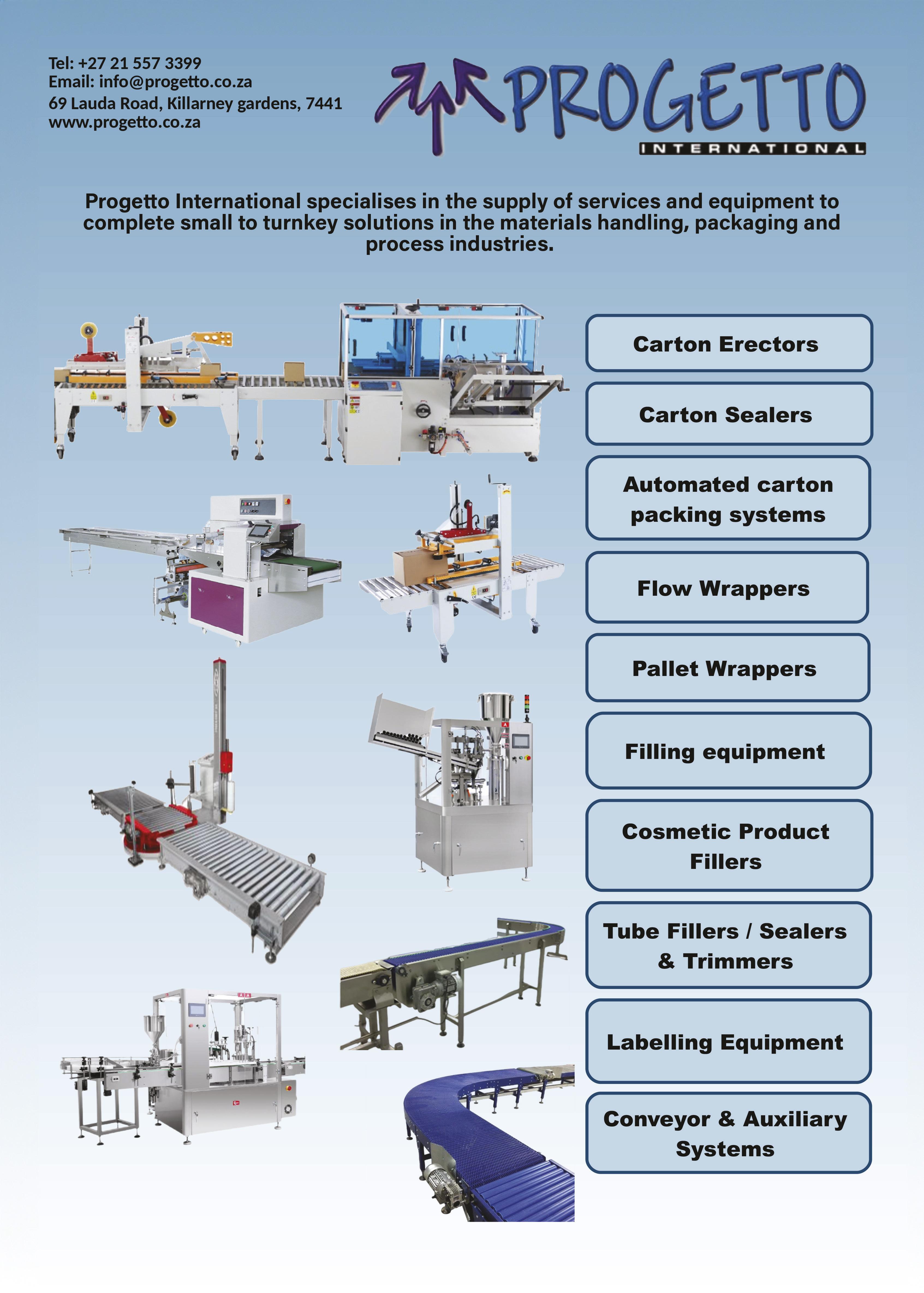

Conveyor Systems for a Flawless Flow

We understand the intricacies of your franchise business and look at it holistically across the value chain to offer innovative solutions that promote business growth.

This enables us to provide your franchise business with a seamless, end-to-end funding process that supports the purchase of additional sites, and funds any new opportunities that may arise.

So, do you want just any financial partner, or a partner that thinks bigger to help your franchise business grow?

7 WHAT’S NEW

The latest product innovations on the South African food and beverage shelves

8 NEWS

Döhler announces key expansion of Paarl Plant

9 INDUSTRY TALK

From taste to tech

Leading the way with sustainable metal packaging

Peak pump performance Coatings in alternative meat products

Leibinger’s IQ Jet wins gold

A winning partnership in high-tech packaging

10 COMPANY FOCUS

SA’s leaders in sustainable conveyor components

12

CONVEYOR SYSTEMS

Reliable high-volume pumps

Boosting efficiency in baking and chocolate forming

Conveyor lubrication systems Hygienic, energy efficient food conveyors

Leading the way in conveyor and process belts

26

INSPECTION, CODING & MARKING

Embracing digitisation

Perfect quality croissants using X-ray inspection

Product safety and inspection systems

Unveiling the next generation of print inspection

AI & machine vision

34 FLAVOUR INSPIRATIONS

Reflecting on a year of collaboration and innovation

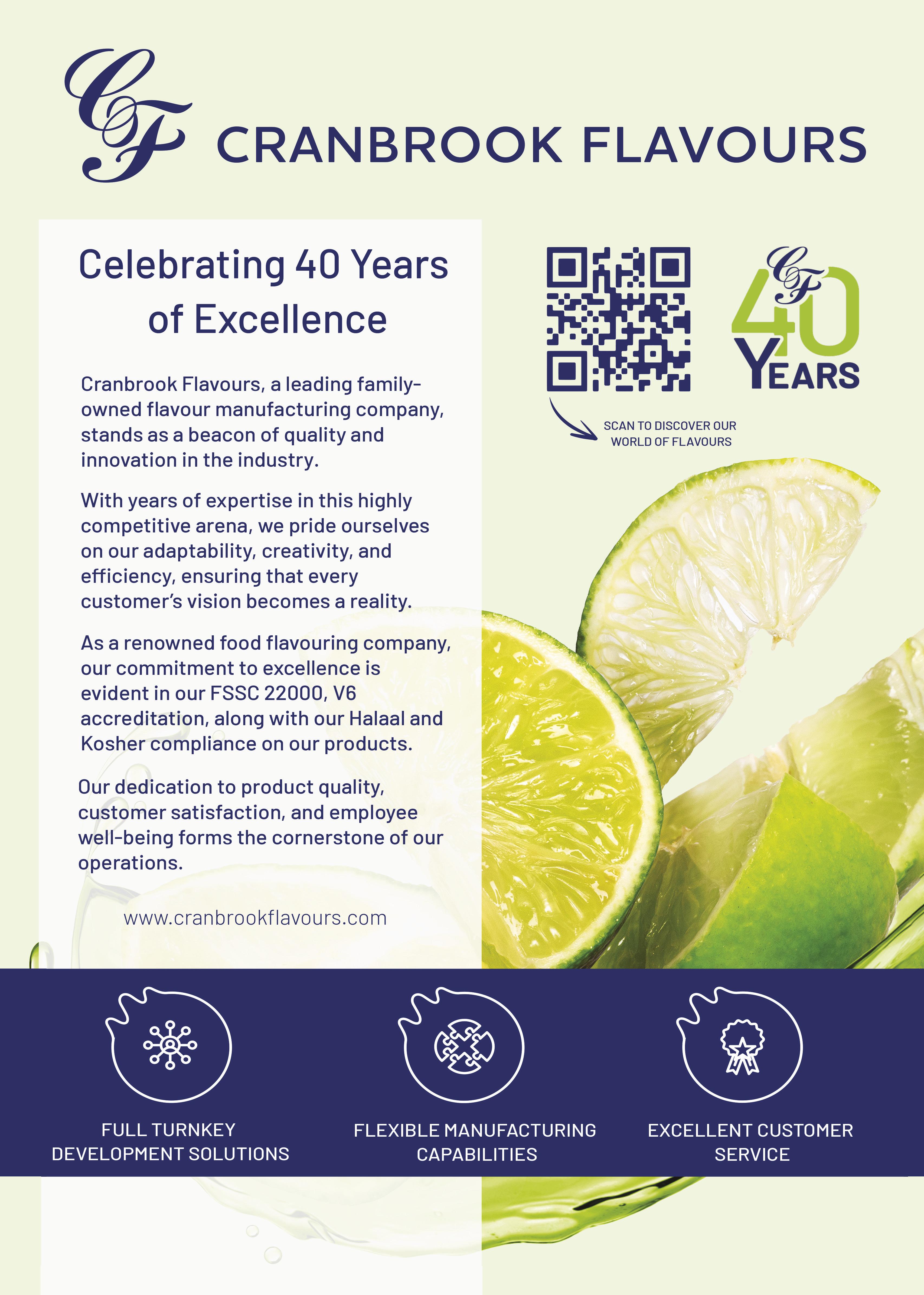

Celebrating 40 years of flavour inspirations in Africa

Microencapsulation for superior flavour

40 READY TO DRINK

Recycling light-sensitive packaging

Welcome to this edition of Food Review magazine and this issue we kick off with a focus on conveyor belt systems. Learn how these innovations boost efficiency, enhance hygiene with self-sanitising surfaces, and promote sustainability through energy-saving designs and eco-friendly materials. IRP Engineering showcase their new 3800 square meter factory, completed in November 2023. The facility strengthens their position as the largest local manufacturer of conveyor components in the Southern Hemisphere. Read more about their bright future on page 10. Congratulations to Leibinger’s gold award win! Read more about this magnificent achievement on page 24. In our Inspection, Coding and Marking section on page 27, Ishida continues to shine, thanks to their IX –EN – 2493 X –ray inspection systems that maximises food safety and help ensure a consistent quality of filled croissants for their customers. For some flavour inspirations, dsm firmenich reflected on a year of collaboration and innovation with their team in South Africa on page 34. Another company with reason to celebrate is Cranbrook Flavours who have been in the industry for more than 40 years! This South African owned business has grown from a small snack seasoning manufacturer to market leaders in flavour creations. Read more on page 36. While the ready-to-drink (RTD) beverage market is booming, sustainability is also a growing concern and on page 40, we highlight RTD brands embracing eco-friendly practices, featuring innovations in recyclable packaging. CCL Label, one of the global leaders in speciality label security and packaging solutions, have introduced a new version of its proven EcoFloat low- density polyolefin sleeve material: EcoFloat WHITE.

Don’t forget to turn to page 6 for the latest industry trade/ exhibition show events!

Enjoy the read! Kelebogile (Lebo) Nondzaba

THE TEAM

EDITORIAL

Editor: Kelebogile Nondzaba +27 (0)78 175 9632

kelebogile.nondzaba@newmedia.co.za

Sub-editor: Gill Abrahams

Layout & Design: Tumi Kunene

ADVERTISING

Key Account Manager: Anita Raath +27 (0) 82 976 6541 anita.raath@newmedia.co.za

Key Account Manager: Càndida Giambò-Kruger +27 (0) 71 438 1918 càndida.giambò-kruger@newmedia.co.za

INTERNATIONAL SALES

Germany/Austria/Switzerland: Eisenacher Medien Erhardt Eisenacher +49 228 249 9860 info@eisenacher-medien.de

Italy: Ngcombroker

Giacomo Rotunno +39 370 101 4694 g.rotunno@ngcombroker.com

Taiwan: Ringier Trade Media

Sydney Lai +886 4 2329 7318 sydneylai@ringier.com.hk

CIRCULATION

Circulation Manager: Felicity Garbers felicity.garbers@newmedia.co.za

PUBLISHING TEAM

General Manager: Dev Naidoo

Head of Commercial B2B: Johann Gerber

Production Controller: Mandy Ackerman

Art Director: David Kyslinger

JOHANNESBURG OFFICE

Ground Floor 272 Pretoria Avenue Randburg, 2194

POSTAL ADDRESS PO Box 784698, Sandton, Johannesburg 2146

Published by New Media, a division of Media24 (Pty) Ltd

MANAGEMENT TEAM

MANAGING DIRECTOR: Aileen Lamb

COMMERCIAL DIRECTOR: Maria Tiganis

STRATEGY DIRECTOR: Andrew Nunneley

CHIEF FINANCIAL OFFICER: Venette Malone

CEO: MEDIA24: Ishmet Davidson

HEAD OFFICE

New Media, a division of Media24 (Pty) Ltd 8th floor, Media24 Centre, 40 Heerengracht Cape Town, 8001

Smart and flexible conveying that keeps your line running smoothly. We provide a wide variety of innovative and dependable conveying and product handling systems to move product through the line as efficiently as possible.

Ideal applications: Everything you need to move your product from A - Z

• Snack foods

• Prepared foods

• French fries

• Fresh produce

• Pet food

• Nuts & Trail Mix

• Crackers

• Confectionery

LOOKING BACK. PRESSING FORWARD. ALWAYS INNOVATING.

Organic & Natural Expo Africa

Sandton

12 – 14 September www.organicandnaturalportal.com

Food Show Africa

Johannesburg, South Africa

5 – 7 August www.foodshowafrica.com

Morocco SIEMA

Casablanca, Morocco 27 – 29 August www.siemamaroc.com

Plant

It’s impossible to talk about Mexican culture and not think of the rich and vibrant colours punctuated by geometric shapes that make up the medley of Mexican heritage.

These vibrant colours go beyond the elaborate prints, bold hues and tones that are synonymous with Mexico and its people, but trickle down to the food and beverages alike. With bold flavours that awaken the senses to simple sophistication of Mexico’s vibrant landscape, it is only befitting that iconic cocktails like the Margarita and Paloma are Mexico born.

For over 94 years, KFC’s iconic blend of 11 herbs and spices has delighted taste buds in over 140 countries worldwide. To prove the strength of its iconic taste, KFC South Africa introduced the ultimate taste test. The result? A first-of-its-kind interactive activation that allowed KFC’s fans to experience the KFC taste in wildly unexpected ways. A real world in-store taste demonstration, powered by audience ideas, nationwide.

“Over the years, we’ve had some interesting requests from customers looking to add flavour to their favourite South African food,” explained Grant Macpherson, KFC South Africa’s CMO. “This made us wonder what other dishes people wanted to improve with our famous secret recipe,” he continued.

Food and beverage giant Döhler is bolstering its presence in Africa with a significant expansion of its Paarl plant in South Africa.

The expansion of Döhler South Africa’s plant in Paarl introduces new, state-ofthe-art production lines for compounds and emulsions as well as powdered and liquid flavours. In addition, it substantially increases the company’s capability for processing bulk juice concentrate. From now on, customers will have direct access to the complete portfolio of compounds, which shows Döhler’s commitment to being at the forefront of the food, beverage and life science and nutrition

industry in the region.

2024 promises to be a groundbreaking year for Döhler South Africa following notable achievements and the establishment of strategic partnerships in the last year. The Paarl plant expansion sets the stage for future advancements. The addition of cutting-edge production lines and state-of-the-art R&D labs will further strengthen Döhler’s ability to deliver high-quality products and product solutions directly to the African market.

So in February, KFC South Africa broke all the traditions of KFC history, by opening its doors for a real-world, experiential taste demonstration, dubbed “Make it KFC.”

Prior to this, through a series of social media polls, the brand invited its audience to submit suggestions for unique food items they’d love to be a little more KFC. Customer suggestions ranged from household staples like brussels sprouts and grapes to sweet indulgences like birthday cake. Fan favourites also included some classic South African delicacies such as biltong, mopani worms and milk tart.

When customers arrived in store and ordered their favourites, they were surprised not only by the great tasting results, but also by bespoke packaging for the different items.

Akram Sabbah, General Manager for Southern & Eastern Africa, emphasizes the strategic significance of the expansion, stating, “The Paarl plant has been an integral part of Döhler’s success in Africa. This expansion reflects our dedication to meeting the evolving needs of our customers, and it positions us for even greater accomplishments in the future.”

Jochen Bitzel, a member of the Executive Board, expressed enthusiasm about the expansion’s potential, adding, “We are excited about the potential this expansion brings. It significantly increases our production capacity. This strong boost in capability enables us to better serve our customers across Africa and solidify our position as industry leaders.”

The expansion of Döhler’s plant in Paarl was officially inaugurated in May with a ceremony attended by prominent industry figures, the Drakenstein Executive Mayor and the Consul General of the German Consulate, emphasising Döhler’s commitment to deepen its engagement with the African food, beverage and life science and nutrition industry.

Food scientists & technologists! Master food analysis techniques with Anton Paar’s workshop at UP. Explore viscosity, shelf life & more.

From determining the viscosity and mouthfeel of chocolate to the analysis of particle size of food powders to measuring the oxidation stability of packed products to investigate shelf life. With our

AGENDA:

• 09h00 to 10h00: Registration

• 10h00 to 11h00: Density and Refractometer – presentation and theory

• 11h00 to 11h10: Break

• 11h10 to 12h10: Viscosity - presentation and theory

• 12h10 to 12h40: Light lunch

• 12h40 to 13h40: Rheology - presentation and theory

• 13h40 to 14h00: Break and mini expo

• 14h00 to 15h00: Guest speaker -

measuring solutions, overcome the various challenges in food processing, storing, mixing and fully control your production as well as your product with our vast instrument portfolio.

Professor Eric Amonsou

• 15h00 to 15h10: Break

• 15h10 to 16h10: Particle Characterization

- presentation and theory

• 16h10 to 16h20: Break

• 16h20 to 17h20: Solid densitypresentation and theory

• 17h20 to 17h40: Oxidation Stability

• 17h40 to 18h00: Networking

• 18h00 to 20h00: Three Course Dinnerpresented by the University of Pretoria’s Consumer Science department

In collaboration with SAAFOST (South African Association for Food Science & Technology) and the University of Pretoria join us and our guest speaker, Professor Eric Amonsou from Durban University of Technology; on Thursday, 19 September 2024 where we will delve in the various food analysis techniques presented by Anton Paar’s portfolio.

LOCATION INFORMATION:

Venue: University of Pretoria Department: Faculty of Natural and Agricultural Sciences Room: 2-33, Old Agriculture Building.

Anton Paar – www.anton-paar.com

19 September, 2024: Register now

In the ever-evolving world of waste management, MetPac-SA stands out as a champion for sustainable practices, particularly when it comes to metal packaging.

In the dynamic landscape of waste management and recycling, MetPacSA stands as a beacon of success, particularly in the realm of metal packaging. As the Producer Responsibility Organisation (PRO) focused on metal packaging in South Africa, MetPac-SA has achieved significant milestones in promoting the collection and recycling of metal packaging materials, ranging from aerosol canisters to aluminium beverage cans and ferrous food packaging. MetPac-SA’s commitment to understanding the material flow of aluminium beverage containers through a Material Flow Analysis (MFA) exemplifies its dedication to informed decision-making. By updating the MFA annually, MetPac-SA gains crucial insights into the local market dynamics, identifying areas for improvement and optimizing recycling processes.

In addition to data-driven initiatives, MetPac-SA has invested in educational outreach through the “Plant the Seed” video series, emphasising the importance of recycling and metal recovery. These videos serve as catalysts for raising public awareness and fostering a culture of sustainability.

MetPac-SA, a leading advocate for sustainable metal packaging solutions, is thrilled to announce its pivotal role as the lead sponsor of the innovative new series of videos about recycling and the importance of creating a circular economy that was developed by “Plant the Seed” – an organisation and social enterprise that assists businesses, schools and communities with their recycling and waste management solutions.

Explains Thomas Chevallier, Director at Plant the Seed: “Our brand-new and dynamic series of four videos are not just about waste and recycling – it’s a journey towards empowerment where every citizen learns to be a steward of the environment

"MetPac-SA’s commitment to understanding the material flow of aluminium beverage containers through a Material Flow Analysis (MFA) exemplifies its dedication to informed decision-making. "

right from their home. The videos are engaging and informative and aim to create a blueprint for a sustainable tomorrow”.

Kishan Singh, CEO of MetPac-SA, says the Producer Responsibility Organisation (PRO) for the metals packaging industry felt strongly about supporting the Plant the Seed videos, as education is key to driving positive change towards a more sustainable future.

“This project aligns seamlessly with MetPac-SA’s dedication to contributing significantly to the circular economy, sustainable development, and the creation of resilient ecosystems. Ongoing education is key and this series of videos succinctly explain the ‘what, why, and how’ of recycling in a way that is timeless and easy

to understand by audiences of all ages and backgrounds,” Singh says.

Each video will offer practical insights and actionable tips for incorporating recycling into daily routines. From understanding the importance of segregating waste to exploring innovative recycling technologies, the series will cover a diverse range of topics designed to empower viewers to make informed choices that benefit both the environment and society at large:

• Episode 1 – Waste hierarchy

• Episode 2 – Separation at Source

• Episode 3 – Plastic

• Episode 4 – Tin and Metal

The video series will officially be launched on various platforms (Instagram, LinkedIn and Youtube) throughout the month of May 2024. Although only one of the videos focus specifically on the recycling of metal packaging, MetPac-SA felt it was important to support the making of all the videos in an effort to encourage individuals and communities alike to adopt environmentally conscious behaviours and embrace the principles of the circular economy.

– SA - www.metpacsa.org.za

For nearly four decades, IRP Engineering has been a trusted name in South Africa’s food, beverage, and packaging industries. Their unwavering commitment to local manufacturing, exceptional customer service, and environmental responsibility has seen them become a true industry leader.

For 38 years, IRP Engineering has been a cornerstone of the South African food, beverage, and packaging industries.Situated in Lanseria Corporate Estate, the company has carved a niche for itself by prioritising local manufacturing, exceptional customer service, and a commitment to sustainability.

IRP Engineering’s core value is to be a reliable and trusted partner for its customers. This commitment manifests in several ways. First, the company prioritises on-time delivery, ensuring production lines stay operational. Second, they produce high-quality conveyor components locally, eliminating reliance on overseas suppliers and offering competitive pricing. Finally, IRP Engineering fosters personal relationships with its clients, providing expert advice and ensuring their needs are met promptly.

Cassidi Kibble, marketing manager at IRP Engineering, emphasizes the importance of these relationships: “They [customers] know that they can rely on us when it comes to advice, delivery, and quality. This is what sets us apart from our competitors.”

The company’s dedication to local manufacturing has been a significant driver of growth. Over the years, they have continuously invested in state-ofthe-art CNC machinery, injection molding equipment, and tooling. This commitment allows for high-quality production

components competitively, passing the cost savings on to their customers.

A testament to this dedication is IRP Engineering’s new 3800 square meter factory, completed in November 2023. This facility strengthens their position as the largest local manufacturer of conveyor components in the Southern Hemisphere. “We really encourage and would like to invite as many of our customers as possible to come and visit our new facility to showcase how we manufacture,” says Kibble, director at IRP Engineering. “A picture speaks a thousand words.”

The company understands the importance of environmental responsibility and has

“Situated in Lanseria Corporate Estate, the company has carved a niche for itself by prioritising local manufacturing, exceptional customer service, and a commitment to sustainability.”

IRP is SA’s most preferred AMM (Alternative Material Manufacturer) for reversed engineering solutions.

implemented several initiatives to minimise their carbon footprint. The new factory boasts a solar system comprised of 340 panels and 2 x 100kWh batteries. This system allows the workshop to run entirely off the grid, significantly reducing energy consumption and the company’s carbon footprint. Their molding division also benefits from 45% solar power, ensuring continued production efficiency.

Furthermore, IRP Engineering actively promotes water conservation through their innovative Dry Running NGE (Next Generation Engineering) product. This system allows customers to significantly reduce water usage during conveyance, potentially saving them up to 90% on water costs and consumption. This product is a win-win for both businesses’ bottom lines and the environment.

IRP Engineering’s future looks bright. The company remains focused on providing competitive pricing and fast delivery by continuously investing in local manufacturing and innovative product development. “Our main focus is to continue to provide our customers with competitive pricing and delivery by continuing to invest in our local manufacturing capabilities and new product development,” says Kibble.

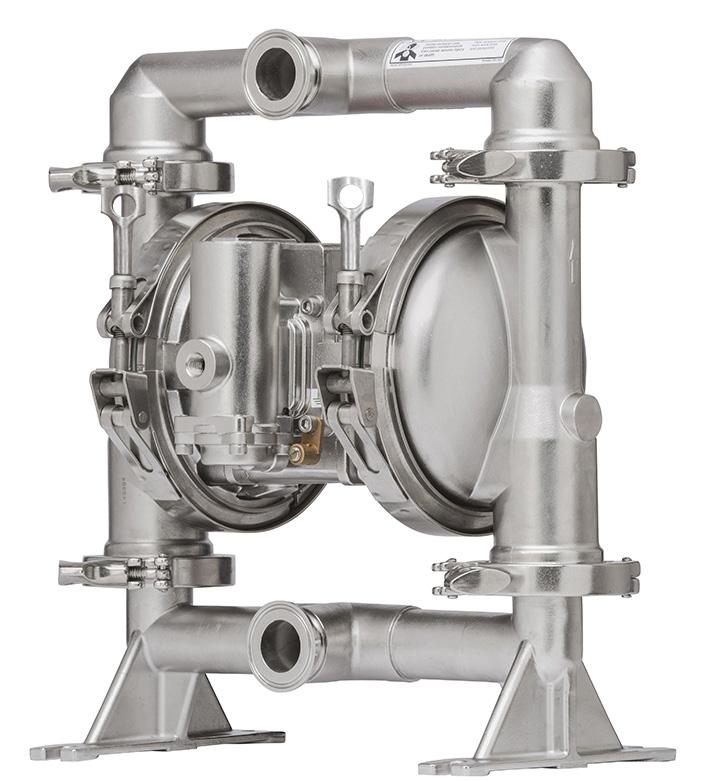

BMG’s range of Ingersoll Rand ARO® fluid management equipment comprises FDA-compliant air operated diaphragm pumps that provide dependable solutions for the food and beverage sector, as well as in pharmaceutical and cosmetic pumps applications.

FDA compliant ARO sanitary pumps not only enhance product purity and ensure easy clean-out in environments that require the highest standards of cleanliness, but these pumps also enable safe operation at elevated temperatures.

“The ARO Expert (EXP) line of FDA approved air operated diaphragm pumps, which has been designed to transfer fluids for the food, beverage and pharmaceutical industries efficiently and safely, ensure high reliability and typically yield about 30% better flow rates than similar pumps. Since fluids are transferred efficiently and gently by ARO air operated diaphragm pumps, shelf life of the liquid (such as beer) is often extended. The gentle pumping action will not froth or separate fluids, thus improving end-product quality,” explains Joe Pinheiro, BMG’s National Product Manager, Pumps. “These robust ARO pumps, have been designed with the capacity to handle high volume transfer and dispensing applications, also optimising total cost of ownership for users.

can pass even large shear-sensitive solids without degradation or heat build-up and are also designed to run dry, eliminating the risk of pump damage. The gentle pumping action will not froth or separate fluid, improving endproduct quality.”

As an expansion to the standard double diaphragm pumps, BMG now offers plant managers and maintenance engineers a reliable choice of two pump ranges for sanitary applications.

Centre bodies available in Stainless Steel provide a durable construction that is compliant in FDA environments, while Polypropylene centre bodies are lighter and chemically compatible for most caustic environments. In the SD series, flow rates are optimised for improved overall performance, the electro-polished Stainless Steel 316L construction is FDA compliant and these robust pumps have a higher temperature capability.

“All ARO EXP pumps feature a patented unbalanced air valve design, which prevents stalling issues associated with conventional pumps. Exhaust valves effectively divert cold exhaust air from ice-prone components, to prevent freezing and minimise downtime. These pumps

An optional single piece composite PTFE diaphragm minimises the number of collection points for the fluid being pumped, which speeds up disassembly, cleaning and re-assembly. The optional electronic interface integrates easily with PC or PLC systems and the ARO controller helps to

reduce waste and increase productivity.

BMG’s ARO PM series diaphragm pumps are also constructed from electro-polished 316 Stainless Steel but feature a bolted construction with all stainless-steel hardware. Centre sections are available in aluminium, polypropylene, or Stainless Steel.

In a recent ARO case study at a leading brewery, electric powered centrifugal pumps were replaced with ARO FDAcompliant air operated diaphragm pumps, which resulted in an increase in production capacity of between 10 and 15%. According to the customer, key to the success of maintaining the quality of beer and accelerated speed to market, has been in the careful pump selection.

Although the electric powered centrifugal pumps previously used by the brewery provided high power, these pumps required operation on a continuous cycle. The constant pumping of the beer with an impeller pump, introduced more oxygen into the beer, causing foam that affected the flavour. ARO fluid handling products are engineered to deliver high performance and serviceability, enabling users to achieve the best cost of ownership. Factory-installed options enable customisation of these sanitary pumps to specific application requirements. .

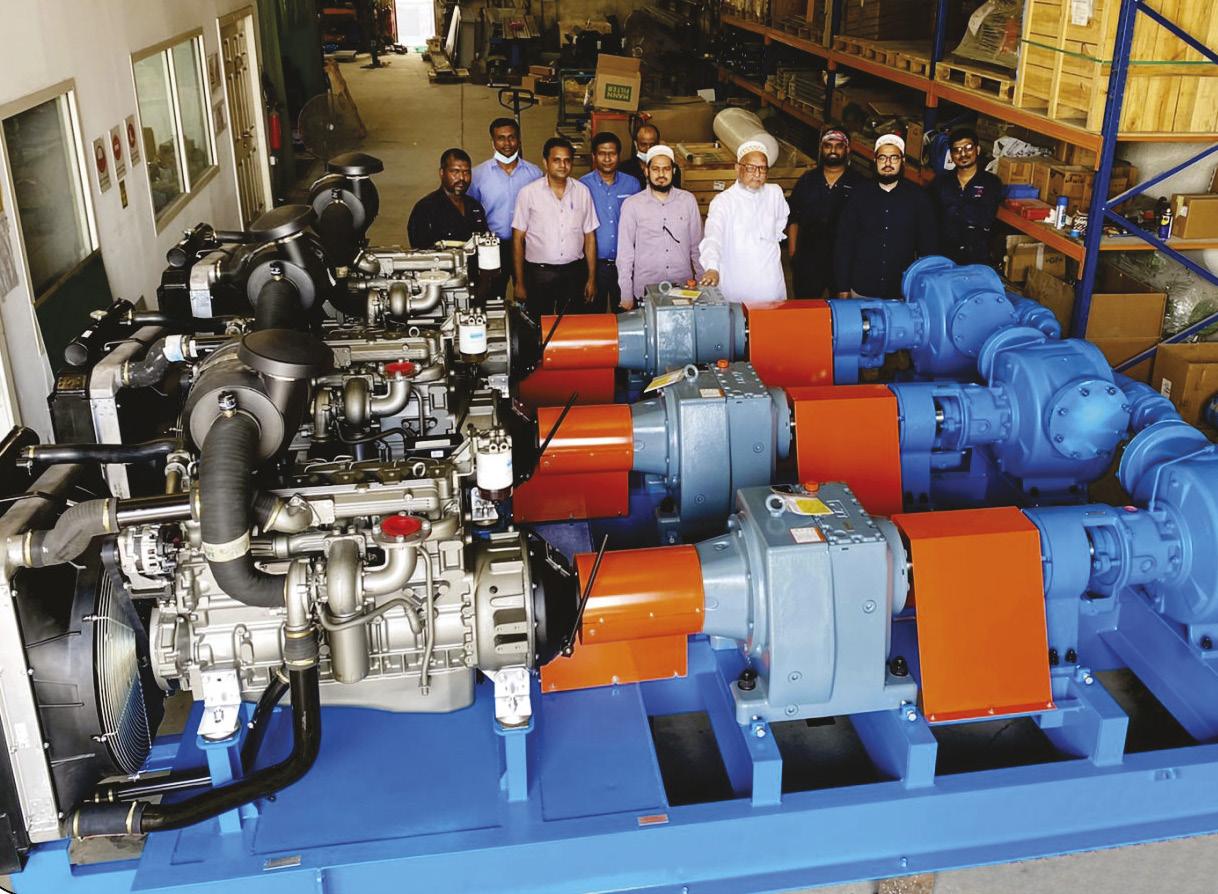

As global populations rise and environmental concerns mount, industries must adapt. I-MAK, a leading provider of gearbox solutions, is at the forefront of this shift.

Given burgeoning global populations and the rapid depletion of resources, industry has a prominent role to play in protecting the environment in a bid to save the planet. A key focus area is waste which has become a precious resource that can add value through reformation, recycling and re-use. Municipalities are subsequently switching from burying and burning waste to an environmentally friendly business model of processing and value addition. Global gearbox and drive solutions specialist, I-MAK, one of Bearing International’s (BI) premium brand offerings to Southern African mining and industry, is a pioneer in the development and supply of geared motor solutions that are widely used in domestic and industrial water treatment, recycling, and solid waste disposal applications around the world,

contributing to reduced energy consumption and process optimisation.

Life cannot exist without water so it is critical that projects address the concerning global escalation of poor water quality and hydric stress (lack of water) must be ramped up. The water and wastewater treatment industry is part of this important value adding green mind-set of preservation and recycling and is steadily moving to more efficient and optimised processes. “This is a key sector for I-MAK and the company is actively contributing to the optimisation of water treatment stations and the reduction of their impact on the environment,” notes Robert Sillis, General Manager: Product

Management at BI. I-MAK designs and develops bespoke and innovative products, advanced technologies and engineering solutions for key applications from primary to secondary water treatment, in close collaboration with customers and end-users. I-MAK’s IR (Helical bevel), ADS (Aerator), YP (Parallel shaft) and M (Monobloc) series of gearboxes feature specific gear, housing and mounting position configurations to meet the requirements of various applications in water and chemical treatment plants including conveyors, sorting facilities, shredders, compactors, agitators, mixers, rotating discs, pumps and clarifiers.

Bearings International –www.bearingsinternational.co.za I-MAK – www.imakreduktor.com

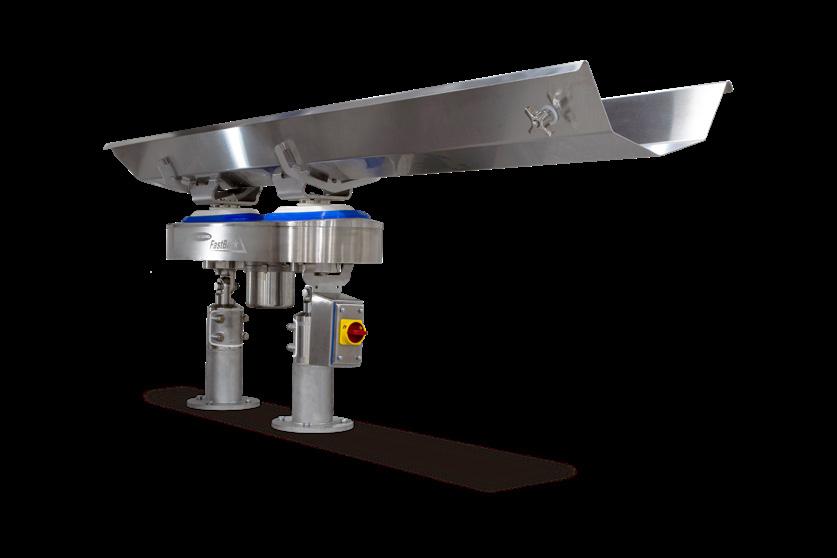

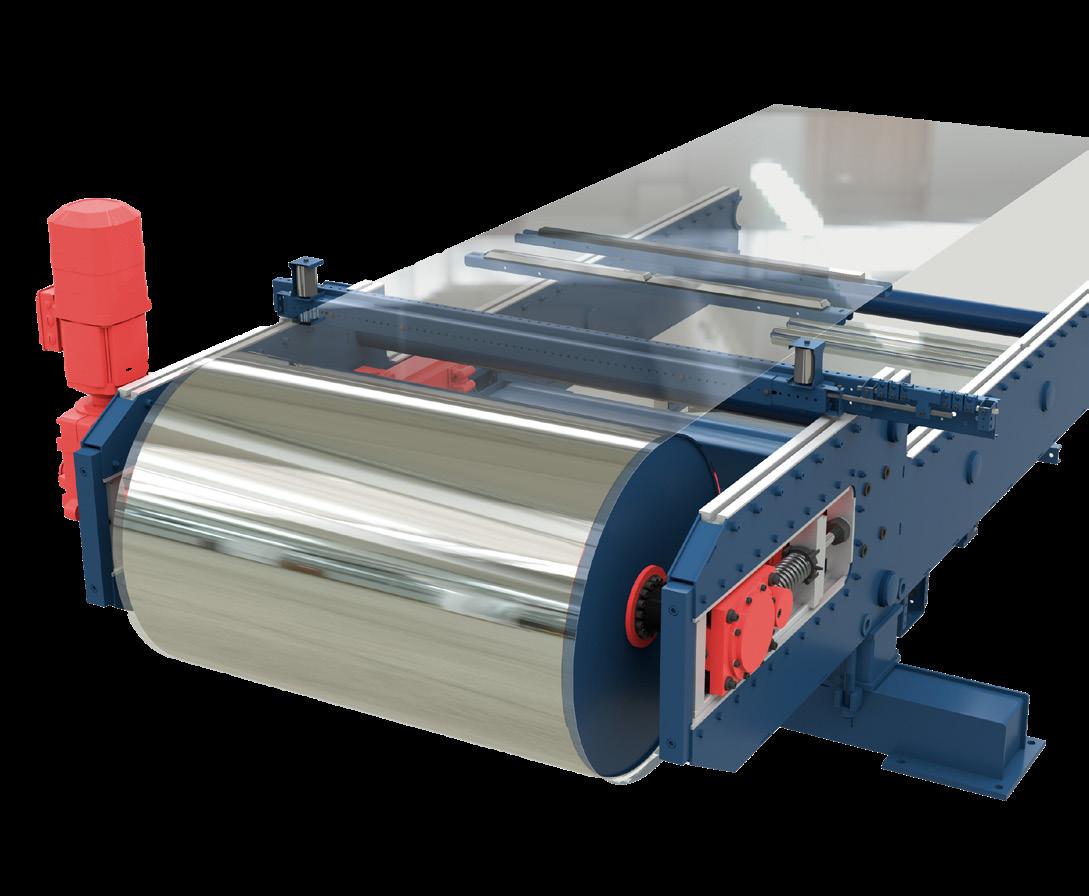

Leading manufacturer IPCO is gearing up to showcase its innovative solutions from highperformance steel bake oven belts to advanced chocolate forming systems, IPCO’s offerings promise efficiency, sustainability, and top-notch quality for businesses of all sizes.

IPCO, one of the world’s leading manufacturers of steel bake oven belts and chocolate forming systems, will be showcasing the productivity benefits that can be achieved using its systems, including demonstrations of its market-leading Rotoform chocolate chip depositor.

The company will also have details of the latest addition to its range of conveyor components – a new belt tracking solution – and will be highlighting the benefits of wraparound service support that’s available to all customers.

IPCO is a world-leading manufacturer of steel belts to the bakery and confectionery

IPCO innovates, manufactures and services steel belts and advanced highperformance processing equipment: Thermopress double belt press systems - Double belt presses for applications such as pressing, lamination, impregnation, and cooling offer a versatile solution for a wide range of industries. IPCO’s ThermoPress systems integrate these processes into one continuous production line, facilitating efficient and environmentally friendly lamination press solutions. Steelbelt solutions for every industry - For over 120 years, IPCO has led innovation in steel, combining precision engineering with expert craftsmanship. As a global leader in steel belt technologies, we specialise in producing high-quality steel belts and steel belt systems for high-performance applications across various industries.

industries, supplying both OEMs and end users. IPCO bake oven belts offer outstanding thermal properties for efficient baking; inherent ease of cleaning, a high degree of sustainability due to low heating costs; and an attractive return on investment.

High-capacity chocolate forming systems: IPCO also is a major supplier of chocolate forming/moulding equipment, with systems designed for the production of industrial ingredients – chips, chunks, drops and blocks – and decorative products such as shavings, rolls, pencils, blossoms and many more.

These include the market-leading Rotoform HP (High Performance) chocolate forming system, a high-capacity rotary drop depositor that that can be used to form chips

“IPCO also is a major supplier of chocolate forming/moulding equipment, with systems designed to produce industrial ingredients –chips, chunks, drops and blocks – and decorative products such as shavings, rolls, pencils, blossoms and many more.”

IPCO offers high productivity solutions for baking and chocolate forming.

kg – by simply changing the shell. Conveyor component ranges expanded with new tracking device: IPCO has expanded its range of conveyor components with the introduction of an innovative new Compact Belt Tracking system, CBT 2G. Featuring a contact-free optical sensor that continuously monitors the position of the belt, the device immediately corrects any belt deviation to deliver fast, precise tracking and an extended belt life.

The CBT 2G is the latest addition to a range of conveyor equipment encompassing everything from sheaves and shafts to bearings and breakpoints.

Global service support: IPCO has sales and se rvice offices in more than 30 countries, with trained and equipped service teams on the ground and available to provide a quick response to any service or repair requirement.

Mobile: +2772 780 0213

Email: maanda.mafunisa@ipco.com www.ipco.com/bake

In the fast-paced world of beverage production, conveyor systems operate under constant pressure. Here’s why proper conveyor lubrication is crucial for maintaining efficiency, safety, and longevity of your production lines.

In the fast-paced world of beverage production maintaining a clean, efficient and reliable conveyor system is crucial for meeting demands and ensuring smooth operations, conveyor lubrication plays a pivotal role in achieving this by reducing friction, preventing wear and tear, and extending the lifespan of conveyors. Conveyors are the backbone of beverage production lines, transporting bottles, cans, and packaging materials from one stage of the production process to another. These systems are subjected to continuous motion, high speed operations, and various environmental factors. Without effective lubrication, the friction generated during these processes can lead to increased energy consumption, bottle scuffing, breakages, down time due to maintenance and even equipment failure. One of the primary benefits of conveyor lubrication is the reduction of friction between bottles and cans, and conveyor itself. This results in decreased energy consumption, contributing to overall energy efficiency in the plant. Energy–efficient operations not only align with sustainability goals, but also lead to cost savings, making lubrication systems a valuable investment. Moreover, conveyor lubrication plays a crucial role in preventing wear and tear on conveyor components. The constant movements of materials and the exposure to contaminants can accelerate the deterioration of belts, chains and rollers. Lubrication acts as a protective barrier, minimising the impact of friction and extending the lifespan of these

components. This reduces the frequency of maintenance interventions and enhances the conveyor system’s overall reliability. Selecting the right lubricant is paramount in ensuring the effectiveness of a conveyor lubrication system. Early lubes were all soap based and had certain inherent problems. They were very sensitive to water hardness, often produced excessive foam and supported the development of microbial slimes.

Today, most lubes are based on synthetic organic compounds. They have high tolerance for water hardness, eliminating the need for water softeners. This brings cost savings by obviating the cost of running and maintaining softeners. Synthetic lubes generally do not support microbial growth on the conveyors and some formulations are antimicrobial and do not allow any bacterial or fungal slimes to form and build up on the conveyors. The floor under the conveyors is therefore clean and slime free, which

contributes to personal safety and plant hygiene. Another positive feature of synthetic lubes is that conveyor spray nozzle blockages are greatly reduced or eliminated entirely, which saves manpower for the time to unblock the nozzles and reduce conveyor wear. Various factors, such as the type of conveyor, operating conditions, and the type of beverage being processed influence the choice of lubricant. Implementing an effective lubrication strategy involves more than just applying lubricant to moving parts. Regular inspections, monitoring systems, and proper maintenance schedules are essential elements of a comprehensive approach. In addition to the mechanical benefits, proper conveyor lubrication contributes to a cleaner and safer working environment. Over–lubrication can lead to spillage, creating slippery surfaces that pose safety hazards for plant workers. A well-maintained lubrication system minimises the risk of spills, contributing to a safer workplace and reducing the potential for accidents and contributing to efficiency and longevity of conveyor systems .

Swiss material-handling equipment supplier Interroll offers a Special Hygienic Conveyor (SHC), a conveyor platform consistently designed in accordance with hygienic product design guidelines.

The modular SHC platform, manufactured based on stainlesssteel construction, enables zeropressure accumulation and particularly energy-efficient transport of E2 standard crates in the food sector. With the Special Hygienic Conveyor, Interroll is taking on the responsibility as a technological leader in the material-handling sector. In doing so, it is pushing ahead to advance the Groupwide platform strategy. The platform’s modularity means that it can be flexibly put together from proven products and expanded as a plug-and-play solution based on the LEGO principle. System integrators can use it to handle both simple and highly demanding tasks in the automatic conveying of packaged food or other hygiene-sensitive products. The SHC platform includes both roller and belt conveyors that transport all kinds of packed food.

Automated flow of goods can be controlled flexibly: Automation is crucial for further improving productivity in the food industry. With the IP 55 MultiControl, a multiprotocol control system from Interroll, the flow of goods on conveyors can be controlled flexibly and as required. A further advantage is that sensors and the drives, such as the proven RollerDrive, can be integrated directly into the field bus level, without need for an additional sensor/actuator level with extra gateways. In addition, the solution enables precise positioning of transported goods on the conveyor. This important feature enables the easy integration of labelling machines, for example, into the automatic flow of goods after packing without complex sensor installations.

The drive concept of the SHC is a decisive factor in achieving the highest possible energy efficiency. Today, a central drive concept for zero-pressure accumulation with 400V drives operating continuously with additional pneumatics technology for zone control is not the most energyefficient solution available. Interroll’s compact low-voltage drives - the 24/48V RollerDrive - offer energy savings of up to 50 percent. The reason for these savings is that the decentralised drives only activate the conveyor zones in which goods need to be moved.

“The drive concept of the SHC is a decisive factor in achieving the highest possible energy efficiency. ”

Cleanability is key: Cleanability is one key criterion for hygienic applications. You need to ensure that everything that can influence food safety and quality can be cleaned effectively and efficiently to prevent microbiological contamination. That’s why the SHC platform for the food industry was developed from the beginning according to the principles of hygienic product design. Therefore, one of its distinguishing features is that the SHC has been structurally designed for unobstructed drainage of

cleaning liquids. All available components of this plug-and-play conveyor, which include electrical products such as RollerDrive, i.e. motorised rollers, and corresponding controls (IP 55 MultiControl), are certified to at least IP 55 and protected against splashing water. This allows simple cleaning procedures with low water pressure to be carried out. In addition, liquid residues— which can compromise function and hygiene—are prevented from remaining in the conveyor afterward.

Thanks to a special transition module (transfer), which is characterised by an extremely small deflection radius, the SHC can also be connected to existing conveyor systems without any major technical adaptation effort. With the Interroll Layouter, system integrators can design, plan and virtually commission complete system concepts on the computer. Presentations and decision-making processes for end users will become more meaningful and significantly easier. At the same time, preparation for smooth installation and commissioning of the solution is improved. Depending on customer requirements, conveyors based on this platform are driven by stainless steel drum motors or RollerDrive. At the same time, the SHC improves the working environment by generating less noise and reduces wear when conveying E2 standard crates or any other plastic crates.

Interroll – www.interroll.com

With the SHC, Interroll launches a proven modular platform specifically for packed food applications. Therefore we are offering a stainless steel platform that is easy to integrate and a solution for where basic hygiene standards are required.

Modular plug and play platform

Easy interfaces to existing applications

Stainless steel construction

Water proof: all components are at least IPX5 certified

Energy savings up to 50% possible with ZPA

Suitable for dry to moist packed food applications

Chiorino’s commitment to research, development, and technology ensures they deliver highquality, custom-designed solutions that meet the strictest environmental and international standards.

Chiorino, founded in 1906 in Biella by Lorenzo Chiorino is today a leading international company in the manufacturing and distribution of conveyor and process belts, flat transmission belts and other technical solutions for many different industries. Research, development and technology are the successful pillars of a Group that has been globally recognised for its ability to anticipate the market trends through highly engineered tailored solutions that guarantee outstanding quality performances with respect for the environment, the natural resources and the most rigorous international standards. Thanks to an extensive distribution and

UNIQUE FEATURES AND BENEFITS:

• Superior release properties

• Excellent cleanliness

• Enhanced food safety & hygiene

• Increased efficiency

• Highest reliability

• Optimised cost of ownership

Hyper Clean is available in the Chiorino exclusive solution Antimicrobial, X-Ray &

“Thanks to an extensive

distribution and service

network, Chiorino is able to meet the specific needs of OEMs and endusers operating all around the world in the food, packaging, intralogistics, airport, paper & printing, textile, raw materials and many other industries.”

Metal detectable. It is the ideal solution for processing sugar/starch-based food that can stick on the belt surface, such as Chocolate, Honey, Caramel, Sticky dough, Sticky rice / Sushi, Nougat.

Its superior release properties prevent the sticky food from adhering to the surface, making cleaning easier, faster and more effective.

service network, Chiorino is able to meet the specific needs of OEMs and end-users operating all around the world in the food, packaging, intralogistics, airport, paper & printing, textile, raw materials and many other industries.

Polyolefin (TPO) food conveyor belts are the ultimate solution for sticky food, confectionery and chocolate processing. The range is ideal for cooling tunnels thanks to the excellent resistance to low temperatures.

HYPERCLEAN® is perfectly smooth and even surface guarantees excellent release, reducing cleaning operations and increasing hygiene & efficiency.

• Enhances food safety

• Improves process efficiency

• Optimises the total cost of ownership

VALUE PROPOSITIONS

Superior release: The perfectly smooth and even HYPERCLEAN® Polyolefin surface guarantee an excellent release of any sticky food. HYPERCLEAN® belts allow waste

To access video, check out the Food Review Digimag.

reduction when processing chocolate, dough, granola bars, stuffed rice, honeybased confectionery.

Excellent cleanliness: Cleaning is easier, faster and more effective thanks to the smooth surface, the superior release properties and resistance to hydrolysis. More efficient cleaning operations reduce water & energy consumption and extend the belt service life.

Enhanced Food Safety & Hygiene: A perfectly clean and smooth surface strongly reduces the prescence of microbes on the belt, enhancing food safety & hygiene. Available in the Chiorino exclusive solution Antimicrobial & Dual Detectable (X-Ray & Metal)

Increased Efficiency: Faster and more efficient cleaning operations prevent belt surface crackings, improving operational processes and reducing machine downtime.

Highest Reliability: HYPERCLEAN®

Polyolefine (TPO) excellent performances guarantee the highest resistance to hydrolysis, chemicals, aggressive oils & fats, knife edges, increasing belt reliability and service life.

To protect Consumer’s health, CHIORINO process and conveyor belts comply with the latest european and international Food Regulations:

• Regulation EC 1935/2004 and amendments

• Regulation EC 2023/2006 and amendments

• Regulation EU 10/2011 and amendments

• FDA (Food and Drug Administration)

Chiorino operates all over the world through Group companies and more than 100 distributors.

Optimised cost of ownership: HYPERCLEAN®’s superior performances allow a total cost of ownership reduction, reducing waste, water, energy and maintenance, offering a longer service life.

Chiorino –www.chiorino.com

You partner for food safety

Belts for a sustainable food processing efficiency

Polyolefin (TPO) food conveyor belts are the ultimate solution for sticky food, confectionery and chocolate processing. The range is ideal for cooling tunnels thanks to the excellent resistance to low temperatures.

unique features and benefits: Superior release properties

Excellent cleanliness

Enhanced food safety & hygiene

Increased efficiency

Highest reliability

perfectly smooth and even surface guarantees excellent release, reducing cleaning operations and increasing hygiene & efficiency. is available in the Chiorino exclusive solution Antimicrobial, X-Ray & Metal detectable.

Johannesburg | T: +27 (0)11 397 1268 | andrew@chiorino.co.za Cape Town | T: +27 (0)21 510 1361 | sh@chiorino.co.za Durban | T: +27 (0)31 792 5500 | sr@chiorino.co.za www.chiorino.com

As the global market for prepared foods expands, the demand for meat-free alternatives is on the rise. To meet this demand, processors must create high-quality products that replicate the taste and texture of traditional meats. Discover how Heat and Control’s coating technology can help you achieve this and elevate your products to new heights.

As the global market for prepared foods expands rapidly, the demand for meat-free alternatives is on the rise. Driven by health consciousness, ethical considerations, and environmental sustainability, consumers are increasingly seeking plant-based versions of their favorite prepared foods. In response to the demand, processors are faced with the challenge of creating high-quality meat alternative products that will replicate the taste, texture, and overall experience of their traditional prepared foods lines.

When you’re in the process of selecting equipment for your meat and plant-based products, there are numerous factors to consider. With Heat and Control’s extensive experience in developing food processing lines, we’re here to assist you in creating all the trending products your consumers love. Beyond perfecting your recipe, we’re also committed to helping you achieve higher yields, better efficiency, and more safety than ever before.

Challenge #1 - Replicating the sensory experience: A key challenge in producing meat alternative prepared foods lies in replicating the sensory experience of meat. Achieving the juicy tenderness and crispy exterior your consumers crave is pivotal for the success of your meat alternative products. Essential for the success of your meat alternative products — coatings are your secret weapon in enhancing the taste and texture of

“With Heat and Control’s extensive experience in developing food processing lines, we’re here to assist you in creating all the trending products your consumers love.”

prepared foods, whether they’re meat-based or plant-based proteins. What’s more, the same equipment used to apply coatings to traditional beef, pork, chicken, turkey, and fish based prepared foods can also be utilised to coat meat alternative prepared foods.

Challenge #2 – Mouth feel and flavour: From creating a crispy exterior reminiscent of fried chicken to achieving a juicy texture in your meat alternative ‘burger’ — coatings help replicate the mouthfeel and flavor of meat to make plant-based alternatives more appealing to consumers. Image 2.

Challenge #3 – Visual appeal: Many processors utilise coatings to enhance the visual appeal of their prepared foods lines, whether achieving a golden-brown crust or a glossy glaze. While enhancing attractiveness, coatings also serve practical purposes. They can act as a barrier to moisture loss during cooking or storage, ensuring product freshness and quality over time. Ultimately, the success of prepared foods hinges on the quality and consistency of their visual appeal

and final presentation. To ensure success, it’s crucial to employ the right equipment and processes for meat alternative products. An adaptable coating system solution that caters to both traditional meat and meat alternative protein-based foods is essential for achieving optimal results and meeting consumer expectations.

The coating process can be executed in single or multiple stages. An example of a multi-stage coating system is the two-stage method, where a liquid ingredient, such as oil, is first applied as a tack agent, followed by a dry seasoning application.

Chicken nuggets and plant-based alternatives often made using mycoprotein, soy protein, pea protein, wheat protein, and then flavored with oil and garlic powder are examples of products utilising a two-stage coating system. (Image 1).

Other coating system solutions utilise a slurry spray system, which applies a mixture of oil or water and dry seasonings. This method is chosen when a processor is aiming to impart a complex flavour profile, and particularly when the seasoning and oil need to penetrate the product. Marinated chicken or marinated tofu ‘chicken’ products utilise this type of coating system.

Alternatively, there is another seasoning application known as ‘dry seasoning only’ which requires no liquid application. This method is used when your product has either sufficient surface moisture or can

retain residual surface moisture to hold the seasoning, for example herb seasoning.

The function of the coating drum is to gently lift and fold the product repeatedly to allow each product piece exposure to gradually build-up liquid and dry coatings. A key component of a successful coating system is a properly engineered coating drum. Image 3. Product throughput, bulk density, shape, and other characteristics all factor into the drum’s length, diameter, and design.

Coating system design principles remain the same regardless of the spray system utilised. By utilising an effective spray design with multi-nozzle manifolds, you maximise the coating zone within the drum. This, coupled with precise nozzle placement, directs targeted sprays onto the product moving beneath the spray nozzles within the drum. This approach facilitates a gradual accumulation of applied liquid onto the base product, ensuring a more uniform coating overall.

A variety of spray system options from “airless” pulsing oil spray applicators to airassist or high-volume oil spray systems are available, as well as slurry spray systems for applying emulsions, solutions, liquid-solid slurries, or other high-viscosity liquids.

In a continuous coating system, applying dry seasoning to products requires both an auger-based powder feeder and a scarf plate distributor. For instance, a powder feeder meters the dry seasoning or salt at a consistent and accurate rate onto a scarf plate feeder, which then evenly distributes it onto the product.

The scarf plate distributor is a fixed-speed, vibratory conveyor featuring a narrow, mirrored finish, bias-cut tray. It’s user-friendly, easy to clean, and compatible with most dry seasonings, salts, and other granular products, ensuring a consistent curtain of the applied dry product.

Deliver unparalleled inspection with extremely high detection sensitivity for metals - whether ferrous, non-ferrous, or stainless steel - for all manner of food products, anywhere along the line.

LEIBINGER’s innovative industrial printer, the IQJET, has been recognised for its excellence by the German Design Council.

The interdisciplinary expert jury of the German Design Council awarded IQJET in the category “Excellence in Business to Business: Machines & Engineering” with the Gold German Innovation Award. The award is based on criteria such as sustainability, quality, and economic efficiency for outstanding products, projects, and pioneering achievements. About 300 guests from politics, business, and media attended the festive event at the Berlin Futurium.

“ The interdisciplinary expert jury of the German Design Council awarded IQJET in the category “Excellence in Business to Business: Machines & Engineering” with the Gold German Innovation Award.”

Wherever production and packaging occur, marking plays a crucial role. Printed information ensures reliable compliance with legal requirements, enables seamless traceability along the entire value chain, and creates transparency as well as user interaction opportunities for consumers. With the new industrial printer, IQJET, LEIBINGER revolutionises continuous

The industrial printer IQJET from LEIBINGER impressed the expert jury and users with its high performance, quality, reliability and sustainability.

inkjet printing (CIJ) and offers users from numerous industries an optimal solution for marking their products. IQJET, for instance, prints texts, logos, and codes on a variety of surfaces such as metal, plastic, glass, and paper. The device guarantees high performance, exceptional print quality, and efficiency with reliable continuous operation and no need for cleaning. Users benefit from the unique “Plug&Print” performance, easy

ABOUT PAUL LEIBINGER GMBH & CO. KG (LEIBINGER)

LEIBINGER is a globally operating specialist in coding & marking systems with headquarters in Tuttlingen, BadenWürttemberg (Germany). The thirdgeneration family-run company, founded in 1948, develops and produces industrial inkjet printers as well as inks for various applications – with a workforce of close to 300. Innovative technologies and an exceptionally high standard of quality are what distinguish LEIBINGER’s advanced coding & marking solutions.

operation, and five years of maintenance free operation. Compared to conventional printers, IQJET reduces operating costs by up to 30 percent. Furthermore, companies optimise their ecological footprint through the low consumption of energy, ink, and solvents. Christina Leibinger, CEO of LEIBINGER, and COO Jan van het Reve personally accepted the award. Leibinger summarises, “We have set a goal to continuously optimise industrial CIJ printing and take a leading role as a provider of innovative coding & marking technology. We are proud that our innovative strength has also impressed the jury.” Van het Reve adds, “Our developments are always focused on benefiting the customer, meaning that with the LEIBINGER printers we aim to make a significant contribution to operating cost optimization, sustainability, and efficiency in manufacturing and packaging lines worldwide.”

ALSO

The nomination committee also recognised LEIBINGER as Innovator of the Year 2024. Renowned business, science, and media experts consider LEIBINGER to be the pioneer in its field. The award is the largest audience award in German business, honoring companies of every size and industry as well as innovative ideas from all areas of business. Over 70,000 entrepreneurs, CEOs, and other business enthusiasts also choose the winners of the audience awards online in various categories.

Leibinger – www.leibinger-group.com

Fit-for-purpose packaging machinery that meets the needs of the product.

From horizontal and vertical form-fill-seal-machines and boxing systems to customized transfer and flow systems that provide efficiency and traceability. Fuji is the industry leader in automated packaging machinery technologies.

Though digital technologies are still young; they are already improving operational efficiencies and have the power to help improve profitability in other ways too. Felix Flemming, head of Digital at TOMRA Food and Recycling, explains.

Some food processors and packhouses might think that ‘digital transformation’ has nothing to do with them. That it’s something for higher-tech businesses or for a time that hasn’t yet arrived. But the reality is changing fast. In fact, digital transformation is already taking place in processing and packing and delivering competitive advantages.

But what, exactly, is digital transformation? Why is it a mistake to ignore it? And how can it improve day-to-day operational efficiencies and higher-level decision-making?

When we talk of digital transformation, we mean the process of using digital technologies to change the way business is done. And when we speak of digital technologies, we mean electronic tools or automated systems that generate, store and process data. These technologies are developing so quickly that a ‘second wave’ of digital transformation is currently sweeping through industries, bringing robotics, big data, artificial intelligence, and machine learning.

These technologies are transformational because they can change business processes, business agility, customer relationships and –of greatest immediate value to processors and packhouses – production efficiency.

There is more to digital transformation, however, than technology. It’s also a cultural change. A mindset. A willingness by businesses to recognise that they could be doing some things better and openmindedness to digital technologies to enable the targeted improvements.

It is also important to understand that digital transformation is a journey. Because technologies and solutions are constantly evolving, progress never ceases. Many digital solutions, for example, will periodically benefit from software updates. This means that digital transformation continually helps businesses futureproof themselves.

As the use of digital technologies widens, food processors face a moment of change.

The industry is poised to take its biggest step forward since automated sorting machines replaced manual sorting. Once again, it is automated sorters that are making the leap possible. These machines routinely collect masses of data about the product they are sorting and grading. This machine data was previously buried, but digitalisation makes it accessible and useable, producing useful information about a wide range of factors such as equipment availability, machine uptime, predictive maintenance requirements, throughput, and product quality.

Product quality is of most interest to food processors because this is where their greatest operational challenges are. As well as the headaches caused by significant quality variations from one batch of infeed product to another, there can also be variations within the same batch. Manual sampling methods can misread true batch quality because they only examine a tiny part of the product flow, sometimes missing imperfections and defects clustered in hotspots – but the sorter sees everything and reports precisely on what it finds.

The industry leader in sorting, grading, and packing solutions, TOMRA Food, has been on its digital transformation journey for five years. Knowing that digital solutions will be a key enabler of efficient food production –and that reducing food waste is becoming

increasingly important, both for economic and environmental reasons – TOMRA has committed considerable effort to build the foundations of its first digital technologies to support customers. This has resulted in TOMRA’s Digital Operations Center; TOMRA Remote Assist for technical support; the TOMRA Visual Assist Augmented Reality tool; and the TOMRA Insight customer portal and data platform. This foundation also serves as the basis to offer artificial intelligence and deep learning solutions for TOMRA Food’s sorting and grading equipment.

The TOMRA Insight customer portal and data platform are cloud-based and available by subscription. This automatically extracts data from sorting machines and presents it in easy-to-understand graphics. Information about materials passing through the machines can be seen and responded to in real-time on the machine user’s touchscreen, enabling instant improvements in line efficiencies and product consistency. More detailed data can be viewed retrospectively in reports – and by analysing this, TOMRA and customers can work together to find further efficiency gains, not only on the line but also in the supply of raw materials. Businesses that rely on precise, objective data – rather than merely depending on experience and instinct – make better-informed operational and strategic decisions.

Slovakia’s largest croissant producer, Frost a.s., has implemented Ishida’s IX-EN X-ray inspection systems to maximise food safety and ensure consistent quality for their filled croissants.

An innovative approach to quality control at Frost a.s. Prešov, Slovakia’s largest croissant manufacturer, has been achieved through the installation of three Ishida IX-EN-2493 X-ray Inspection systems that maximise food safety and help ensure a consistent quality for filled croissants.

Frost Prešov supplies a diverse range of fresh and frozen baked goods to the central European market. Popular product lines are are croissants containing a variety of fillings such as chocolate, apricot or marmalade which are individually wrapped in 60g pillow packs.

T he requirement for a capable quality control solution for these products prompted Frost to approach Ishida for a solution. The company supplied three IXEN-2943-S

X-ray inspection systems which are working across three lines to inspect approximately 18,000 packs of croissants per hour in a 24/7 operation. In order to handle such high volumes, the X-ray systems incorporate a high-capacity belt system that is capable of speeds up to 75 metres per minute.

Established in 2013, Frost a.s. Presov produces a wide range of sweet and savoury baked and frozen pastries, sold throughout Slovakia, Poland, Hungary and the Czech Republic. The company’s factory in Presov in Eastern Slovakia features the largest and most technologically advanced production process for pastries in Slovakia. Frost frequently changes its ranges of pastries in line with customer demands, with innovations continuously developed to meet diverse consumer requirements.

“The requirement for a capable quality control solution for these products prompted Frost to approach Ishida for a solution. ”

The IX-EN models are performing two different but equally essential quality control checks. Firstly, they carry out vital foreign body detection for companies, with the ability to identify and reject packs containing metal, rubber and other contaminants even at these high inspection speeds.

Equally important to Frost is the missing item feature of the IX-EN range which can detect croissants with missing or defective fillings. This helps to maintain the highest product quality and consistency in order to protect and maintain Frost’s premium brand image.

Before delivery, Ishida’s technical team worked closely with Frost to maximise the effectiveness of the missing item feature. A range of samples was sent to Ishida Europe’s UK headquarters where a series of tests took place to ensure that croissants with out-of-spec fillings were

reliably rejected from the line. Central to this capability is Ishida’s unique Genetic Algorithm (GA) image processing feature which optimises product inspection for greater sensitivity to specific contaminants and quality issues.

“The Ishida X-ray systems are easy to use and to clean, making staff training straight forward,” said Vladimir Varga, Technical Manager at Frost. “Of particular benefit to us is that we don’t have to adjust settings when changing fillings, so this greatly simplifies our production planning.”

The installation marks another milestone in the relationship between the two companies with Frost already using Ishida X-ray inspection systems for other product lines.

“We are really pleased with the level of service we have received from Ishida over the years,” continued Vladimir Varga. “In particular, the company was a huge help in enabling us to solve some technical production issues, working directly with us to ensure that the solution met our exact needs. For that reason, we have a lot of confidence in both the equipment and in Ishida as a brand.”

Following the success of this latest quality control solution, Frost intends to continue to invest in Ishida X-ray equipment for future product lines.

Karel Šmakal, Regional Sales Manager at Ishida commented: “Our long-standing relationship with Frost is a great example of our customer-centred approach.”

Tel: 011 976 2010/11

Email : melika.seiderer@ishidaeurope.com www.ishidaeurope.com

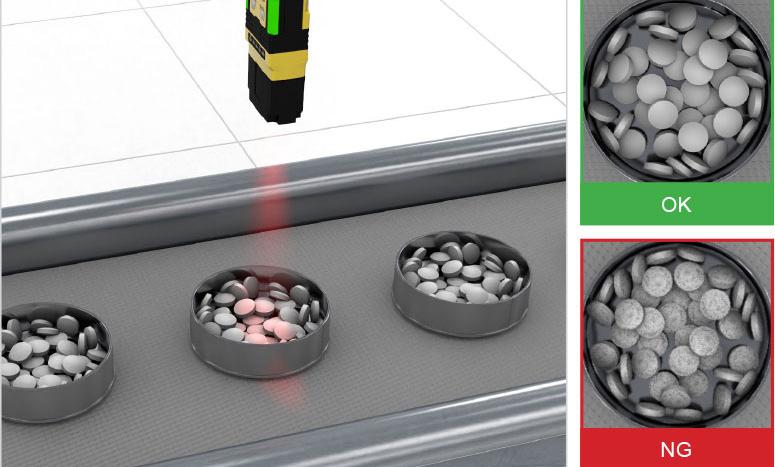

Ensuring food safety is paramount. In Europe, over 3,000 product recalls occur annually due to contamination or mislabeling. This is more than a logistical headache for manufacturers; it can damage brand reputation and consumer trust.

Inspection systems help manufacturers to prevent such a situation from happening in the first place. Digital solutions by Bizerba offer 100 % product reliability and complete tracking. Only food of perfect quality is supplied to the market: Free from foreign bodies, hygienically packaged, labelled with ideally positioned labels containing the right information which is easy to read.

WHAT DO INSPECTION SYSTEMS DO?

They detect products that do not meet the standard (quality or safety and since food producers are responsible for the

safety of products, inspection systems help them comply with legal requirements. There is no manual work required since the devices are more accurate and reliable than humans, inspection solutions precisely detect foreign objects or product defects during production process and conspicuous products can be removed. Inspection systems also increase productivity, less costs and promote sustainability. Less giveaway and downtime since devices work precisely in detecting faulty goods which means there is no need to throw away a whole batch. As a business, you earn your customer’s trust because of safe

and flawless products that don’t need to be recalled. Your business stays competitive due to flawless product quality.

WHAT DOES BIZERBA OFFER?

We offer hardware and technology for the inspection of food in the products line. Different technologies may be used, for example, metal detectors, X-ray systems and camera inspection systems. This results in various systems with manifold functions, possibilities and properties, even for complex products or packaging.

Bizerba – www.bizerba.com

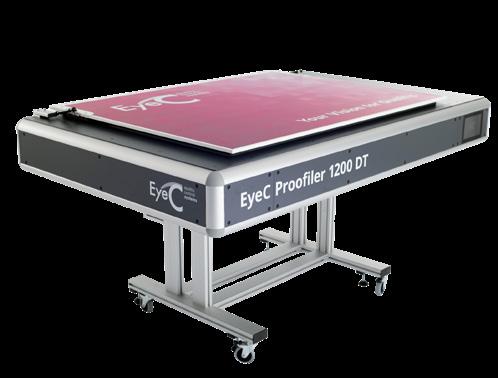

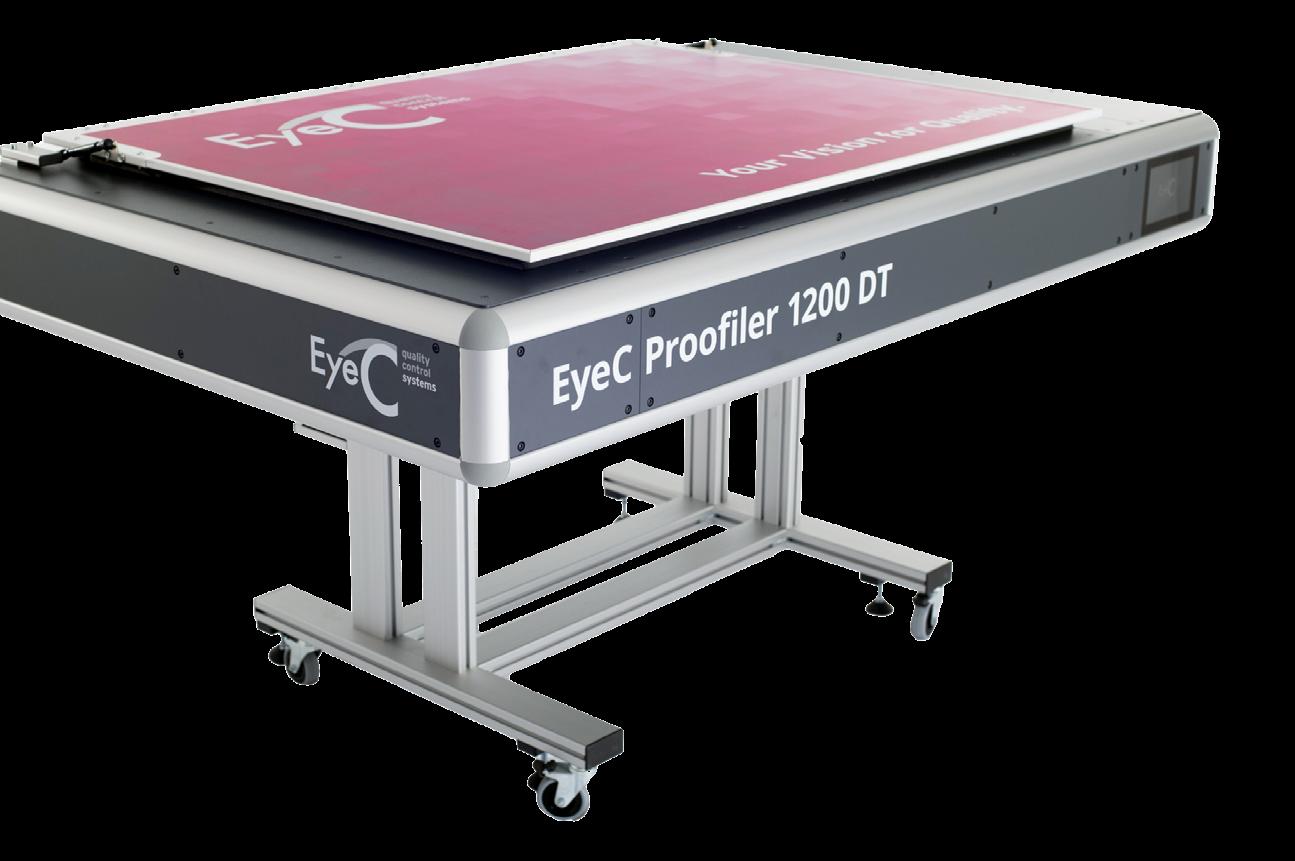

In line with its slogan “Sharper, Quicker, Better: Revolutionise Your Inspection with the New EyeC Proofiler 1200 DT”, the new EyeC Proofiler 1200 DT delivers improved scanning technology. As part of EyeC’s extensive DT product line, the system offers scan formats up to 1,778 x 1219 mm. The Proofiler 1200 DT sets new standards in terms of speed. Thanks to the further developed camera box with optimised lamps and a PC box with a 10Gbit network interface, the inspection system enables a scanning process of only 12 seconds at a resolution of 600 dpi. The redesigned scanner lid not only offers better and easier handling for the user but is also aesthetically

EyeC GmbH, a leading provider of automated artwork verification and print inspection systems, has announced the launch of the innovative EyeC Proofiler 1200 DT.

pleasing thanks to its modern design.

The EyeC Proofiler 1200 DT is also characterised by further improved robustness. The use of high-quality glass reduces the number of air pockets that can affect the scan result; two coupled motors reliably prevent problems with the camera box. Optimised camera cable routing also ensures a longer cable service life and protection against cable breakage. The sealing of the side walls minimises potential dust ingress to ensure trouble-free operation even in production environments. The EyeC Proofiler 1200 DT has been equipped with special service flaps to make maintenance easier and less complicated. A newly

developed transport packaging also ensures safe and reliable delivery of the system with reduced resource consumption. “With the new EyeC Proofiler 1200 DT we offer a pioneering solution in the quality control of print samples. We are proud that our most popular inspection system is continuously evolving to meet the increasing demands of our customers and to take printing and packaging processes to a new level,” says Nico Hagemann, director of product management at EyeC.

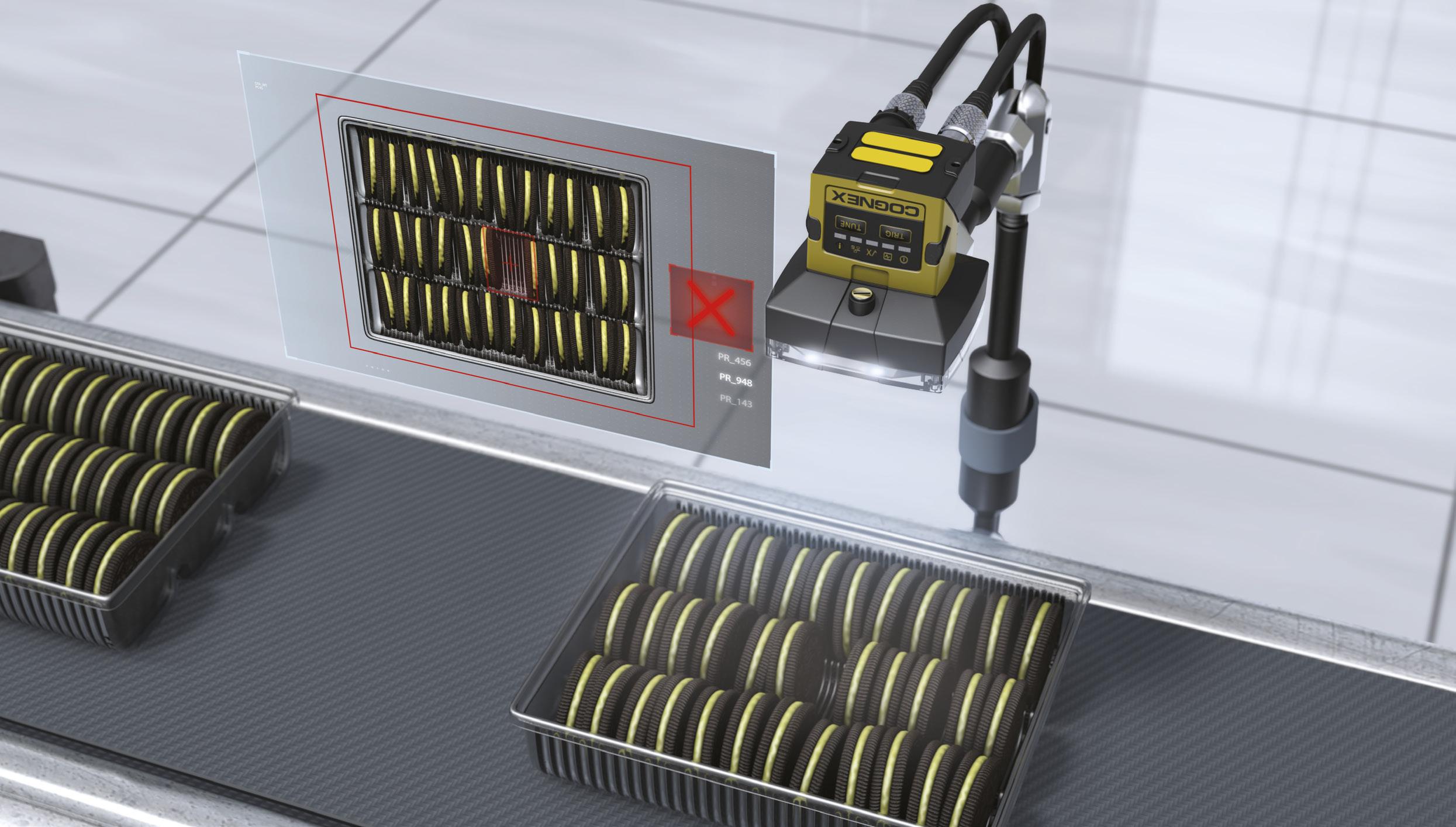

TracePack’s vision systems leverage AI to ensure consistent quality, accurate packaging, and FSMA compliance.

In the fast-paced world of food and beverage manufacturing, maintaining high levels of quality and accuracy is crucial. With the increasing demand for product variety and the need for error-free packaging, companies are turning towards advanced technologies to streamline their operations. One such technology revolutionising the industry is vision inspection using machine vision and AIbased technologies.

Advanced machine vision systems enable real-time product quality assessment, reducing defects and ensuring consistency. Examples include 3D Final Product Packaging Inspection, Assorted Chocolate Box Quality Inspection, Automated Meat and Poultry Inspection, and Chewing Gum Inspection. These inspections verify the

" Advanced machine vision systems enable real-time product quality assessment, reducing defects and ensuring consistency."

integrity and uniformity of packaging materials, detect anomalies in meat products, and check for defects in gum packaging.

Vision systems accurately verify primary packaging details, including labelling, sealing, and cosmetic defects. Examples include Aluminium Can Inspection, Glass Jar Neck Inspection, Code Reading on Chicken Parts Packaging, and Tea Bag Carton Inspection. These inspections ensure proper can sealing, verify jar neck integrity, read product codes accurately, and detect defects in tea bag packaging.

Consistent assembly verification: At the heart of precision in production are verification solutions that ensure consistent quality. TracePack’s vision systems play a key role in this process, with applications such as Bottle Cap Inspection, Chocolate Assembly Verification, Cookie Counting Verification, and Fill Level Inspection. These inspections are crucial in ensuring proper cap placement, validating chocolate product assembly,

guaranteeing accurate cookie counting, and verifying fill levels in containers.

Food Safety Modernisation Act (FSMA) Compliance: Our technologies facilitate end-to-end food traceability, a critical requirement under FSMA. By capturing data at various stages of production, manufacturers can ensure compliance and respond swiftly to any safety concerns.

Edge Learning, an AI-powered machine vision technology, addresses inaccuracies, difficult optical character recognition (OCR), and production slowdowns caused by conventional cameras. It adapts to complex scenarios, improving inspection accuracy.

Cross-packing is simply putting the wrong product in the wrong pack/carton. It is one defect that should be eliminated in every manufacturing process as it is a common contributor to market recalls and can sometimes cause severe fatalities. Crosspacking is simply a mix-up or error in the endto-end supply chain but can lead to incorrect product claims, undeclared allergens, consumer confusion and dissatisfaction, damage to brand reputation/brand image, product recall/ Withdrawal from trade, regulatory sanctions from SON and NAFDAC, reduced Sales opportunities. TracePack’s vision system and OCR technology ensure the right product is in the carton or pack.

Scanning labels and blister packs for defects, errors, and omissions minimises the risk of incorrect product placement.

Machine vision systems are pivotal in ensuring accurate labelling and coding on food packaging. These systems inspect labels by checking that lids and containers match each other and accurately reflect the package contents. They also confirm that product labels comply with in-house procedures and quality standards imposed by regulatory bodies.

Optical Character Recognition (OCR) and Optical Character Verification (OCV)

technologies read and verify printed information on each package, including lot codes and expiration dates. This eliminates manual errors, ensures correct labelling, and prevents potential recalls and compliance issues.

Implementing our machine vision and AI-based technologies in food and beverage

manufacturing processes provides several advantages. These systems operate rapidly, ensuring inspection and verification processes do not slow production lines. This allows manufacturers to maintain productivity while guaranteeing the quality and accuracy of their products.

Additionally, these technologies minimise human error in the inspection process, providing consistent precision. By automating the inspection process, manufacturers can always rely on objective and reliable results.

In conclusion, vision inspection using our Cognex machine vision and AI-based technologies has revolutionised the food and beverage industry.

Tel : 010 020 7221

Email: sales@tracepack.co.za www.trackpack.co.za

It’s the only one of its kind in the country to target decision makers in the manufacturing of food, beverages and their related industries. It o ers incisive and authoritative reports on all aspects of the process, from raw material sourcing, to manufacturing and packing, right down to the distribution and marketing of nished goods. FOOD REVIEW informs readers about the introduction of new ingredients, equipment, products and packing, and provides objective commentary on cutting-edge local and international market trends and issues.

The success story of how the Cama Group and B&R overcame the challenges to co-create a solution combining machinery, technology and augmented reality. The future is right here, right now.

Operating in a high-tech niche market means overcoming the most difficult and demanding challenges. It means recognising our own value and identifying the positive scenarios which can drive business forward. The “co-creation” between Cama and B&R arose in this context. Founded in 1981, Cama has since become a leader in its field. Specialising in producing and engineering secondary packaging machinery with integrated robotics for the Food and NonFood sectors, the Cama Group currently has six subsidiaries worldwide and invests 5% of its annual turnover in technology; B&R has been producing technologies and solutions for machine and factory automation since 1979, and is responsible for machine automation within the Robotics & Discrete Automation Business Area at ABB, offering a full portfolio of robotics, automation and software.

In merging these trajectories and specialisms, a reciprocal partnership formed between these two companies, enabling both to profit from their combined expertise in machines, processes and products, to create highly innovative solutions.

“Finding the right partners is no mean feat,” explains Cama CEO Daniele Bellante, “because you need to share the same values and objectives. Sustainability is

our watchword at Cama. Not so much in terms of environmental sustainability, as we don’t produce any polluting emissions and we’re not energy-intensive, but rather sustainability in terms of durability. We offer added value by perpetuating shared values over time, and this requires a strong focus on people. At Cama we produce machines, but we also produce people: investing in our personnel to sustain the

"At Cama we produce machines, but we also produce people: investing in our personnel to sustain the company over time."

company over time. This is the only way to consolidate market leadership. It is people who make the difference, and all partnerships are established with people”.

With B&R, we seem to have found a winning solution: an ergonomic, flexible and modular machine designed to integrate the MTL Monoblock Top Loading system; this latest-generation equipment features a transparent guard for maximum visibility and optimal hygiene. Intuitiveness is a key design pillar: this is fundamental because the product’s target markets have diverse skills and, potentially, a high staff turnover.

“This is a very interesting and complex solution” explains Cama Sales Group Director, Alessandro Rocca. “It also makes use of augmented reality to access maintenance, changeover and spare parts, which can be ordered directly via a tablet, also enabling predictive maintenance. As a result, this solution requires less human intervention, thereby reducing the potential for human error. Remarkably, this solution also saves time, cutting the changeover time from 30 to 12 minutes! Our technologies offer real added value and our approach is holistic and customer focused. This means that we pay great attention to our customers’ needs.”

And B&R’s offering truly helps us deliver a customer-focused solution, successfully overcoming certain challenges posed by the MTL Monoblock Top Loading system, namely to create a monoblock

which can serve three or more upstream feeds for similar products with different synchronisations and to manage buffers automatically thanks to B&R’s ACOPOStrak magnetic track system. The result is increased productivity with a reduced footprint. The solution allows to decouple the process stations, optimising the flow of products and cycle times; processing times were also optimised and the control panel was simplified, making commissioning and maintenance quicker and easier.

Wlady Martino, B&R Global Industry Manager, Packaging explains the issue: “The challenge was the high throughput and the distance that the products have to travel –up to 14 metres. In this sense, speed and dynamics become important. We proposed ACOPOStrak in this case for several reasons: it is an extremely highperformance magnetic shuttle solution: each shuttle can reach a speed of 4 m/s and an acceleration of 50 m/s2. The system is modular which encourages machine

scalability; it also has a clean design enabling easy maintenance with tool-free shuttle removal. To achieve the customer’s objectives, we used simulation, native to the B&R programming system, to optimise the layout, the number of shuttles and the work cycle. At this stage, the customer can make any changes even before the hardware is available. So, we have what we call a “co-creation” process. Impressively,

the simulation delivers a result that match the real behaviour on the final hardware. The co-creation process is made possible by combining a variety of skills and that is why, in the end, it really is the people who make the difference.

USS Pactech - www.usspactech.co.za CAMA - www.camagroup.com

COMPASS takes food sorting in a new direction by combining the latest intelligent technology with simple, highly intuitive operation. It has never been easier to sort accurately through every production run and maximise your product quality, yield and line profits. COMPASS reduces maintenance costs and sanitation requirements, while providing access to usable performance data and reports that help you improve your production process.

A year after their successful merger, dsm-firmenich reflects on a year of collaboration and innovation.

Celebrations around the world have been underway throughout the month of May and June, marking a year since the successful integration that solidified its position as a category of one within the industry.

“In South Africa, our team gathered to commemorate this special occasion in the true South African way. Braai meat, potjie pots with chakalaka, delicious sides, salad and of course a rainbow cake, representative of our diverse rainbow nation. An afternoon of celebrating was indeed thoroughly enjoyed by all!” said Imaan Gaffore, Country Lead of dsm-firmenich for South Africa.

This past year has been testament to the power of collaboration. Taste. Texture. Health. At dsm-firmenich, we bring it all together, because we believe today’s consumers shouldn’t have to choose between what tastes good, what feels good, and what’s good for them. That’s why we help deliver the products that sustain us all –but healthier. More delicious. And better for people and the planet.

As innovators in nutrition, health, and beauty, dsm-firmenich has embraced new ideas, fostered innovation and leveraged opportunities from the partnership to bring significant advancements towards its purpose.

We’re proud of our broad portfolio – of ingredients, flavours, and expert tools. This includes one of the largest natural flavours library in the industry, sugar reduction tools, cultures, enzymes, vitamins, hydrocolloids, yeast extracts, nutritional premixes and so much more. It’s our ability to combine our