www.foodreview.co.za SOUTH AFRICAN JOURNAL FOR FOOD AND BEVERAGE MANUFACTURERS MAY 2024 Vol. 51 • No. 4 From Dough to Delight Smart Solutions for Storage & Logistics Tech Trends Shaping Your Food The Future of Functional Food COVER PRICE: R85.00 Photo credit: Shutterstock.com

7 WHAT’S NEW

South Africa’s trendy food and beverage product innovations

8 NEWS

Celebrating 25 years of joy!

Turnkey agriculture solutions

One-stop lab testing solutions.

10 BAKERY

Baking powder rises to the occasion.

Sugar reduction made possible.

Egg replacement solutions.

Offering quality at every step.

Bake belt conveyor tech.

Healthy snacking with beta-glucans.

22 FOOD PROCESSING TECHNOLOGY

Tailored food processing software.

Innovative convenience food production.

ProxxD, the new benchmark.

Tomra Neon shines.

32 FUNCTIONAL

INGREDIENTS

Mind the gap: Fibre the true superfood

A higher state of consciousness

38

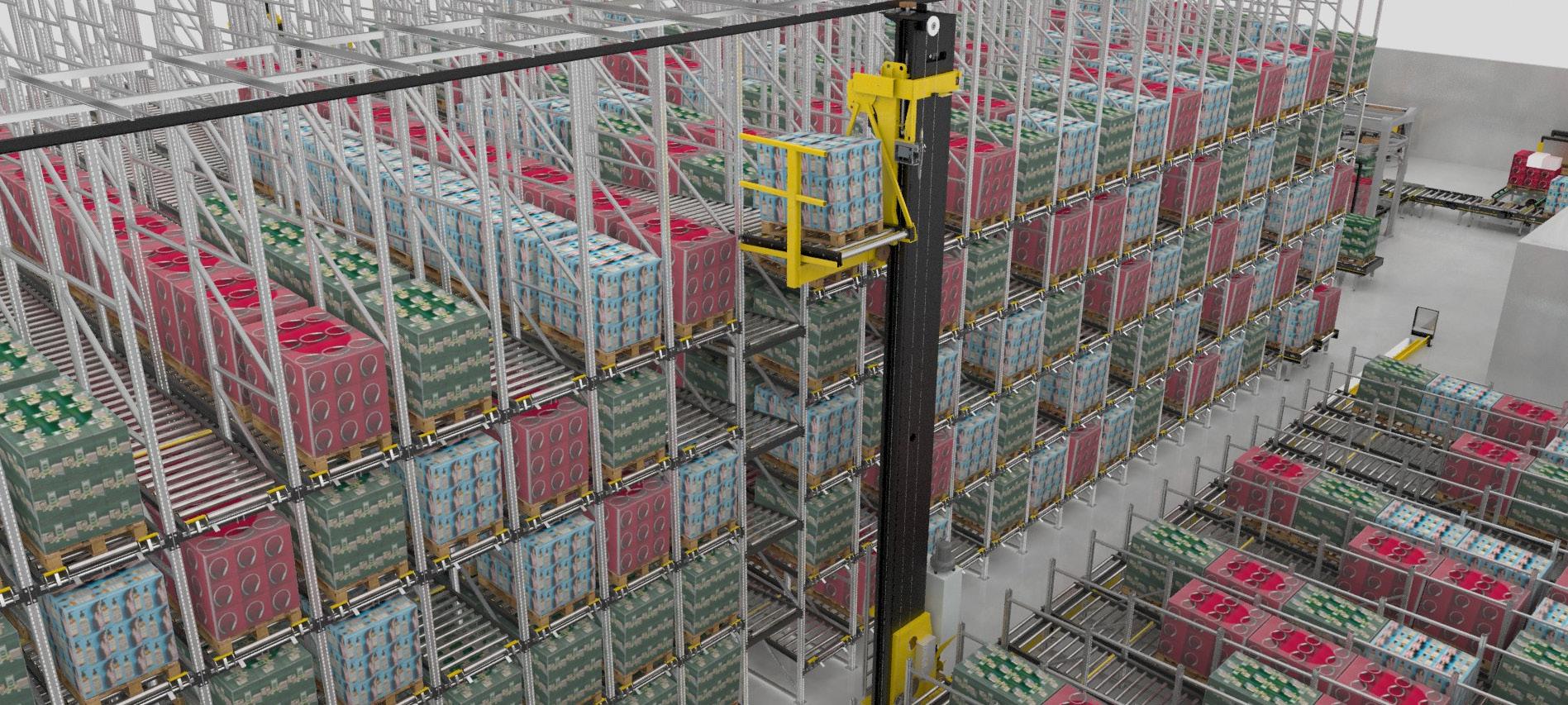

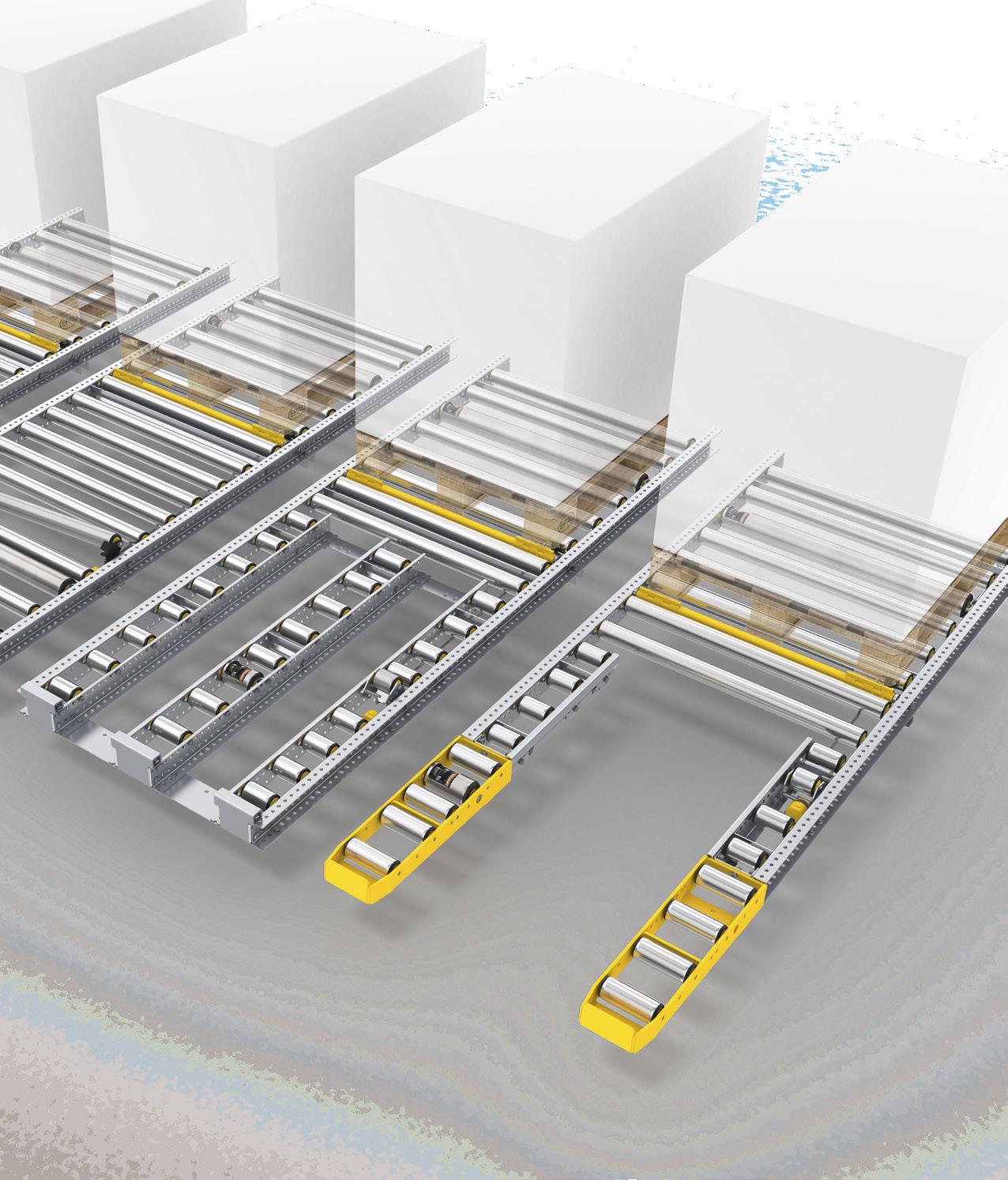

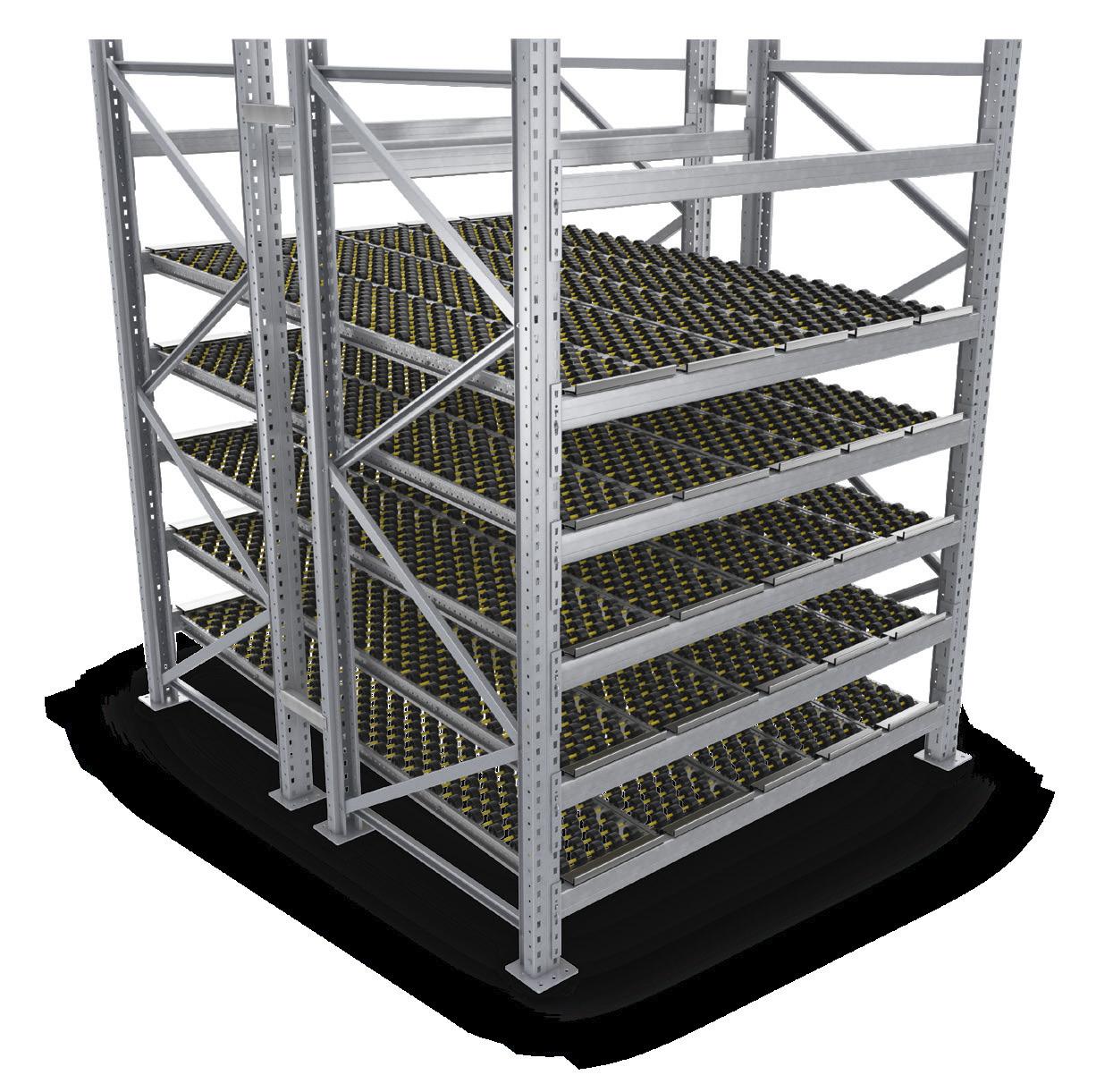

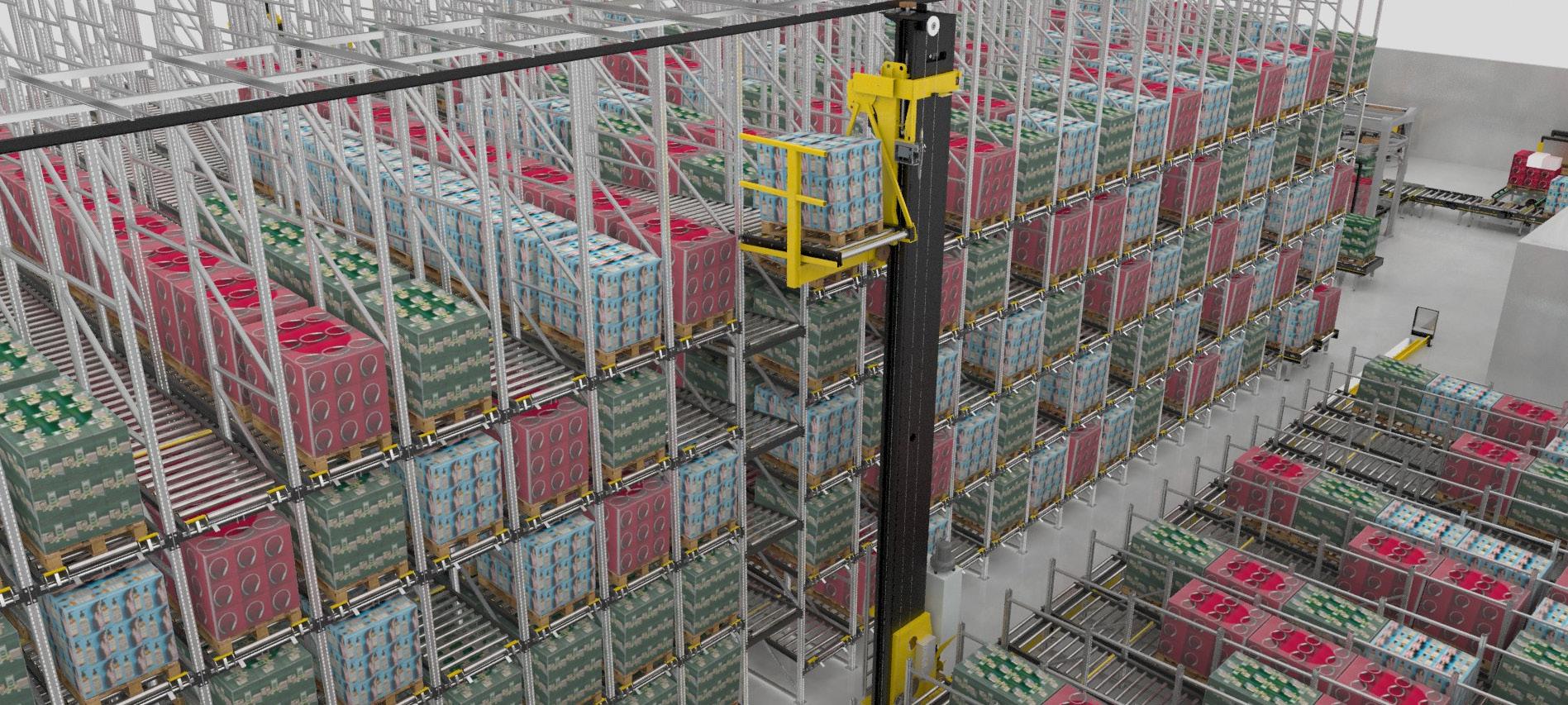

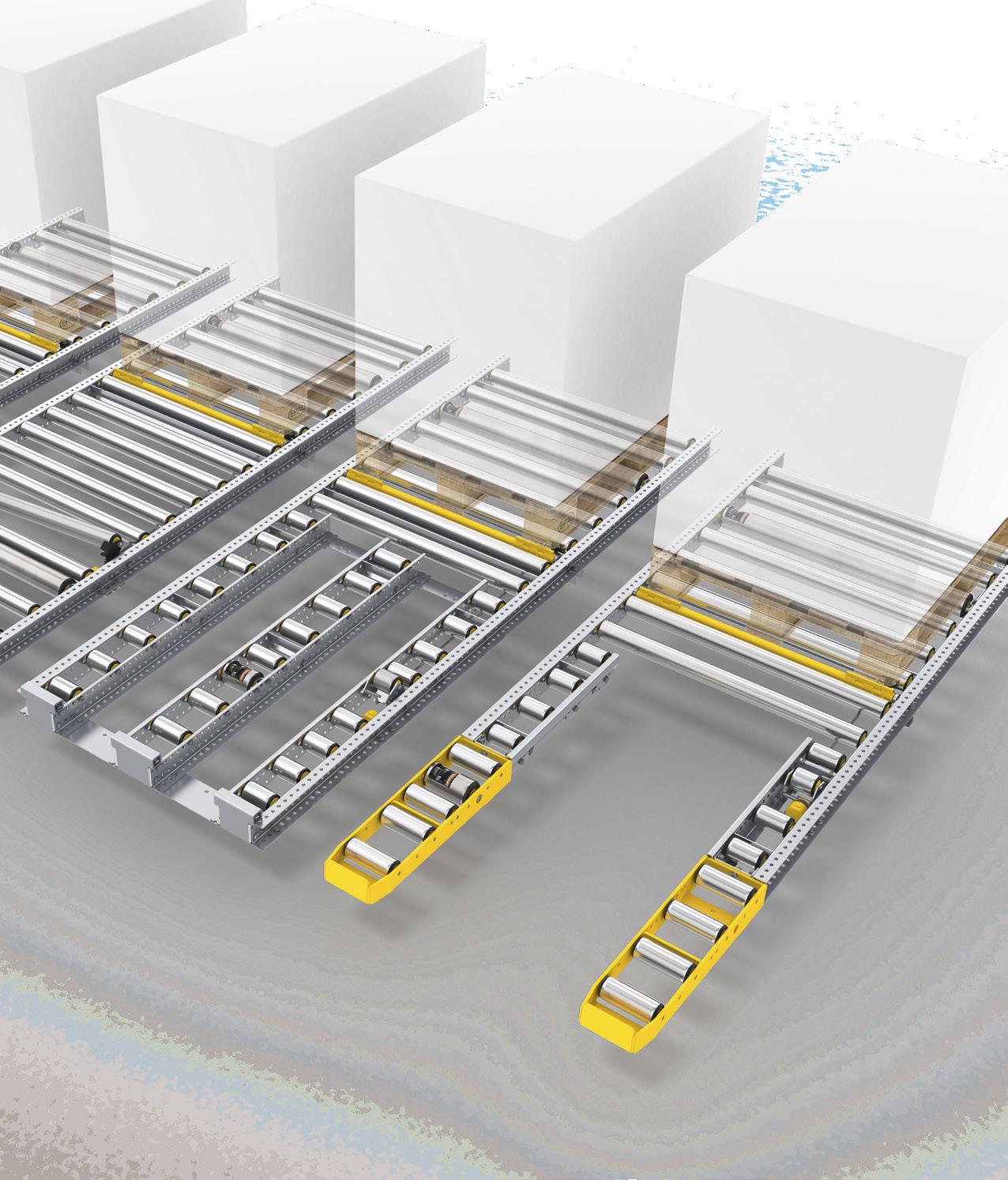

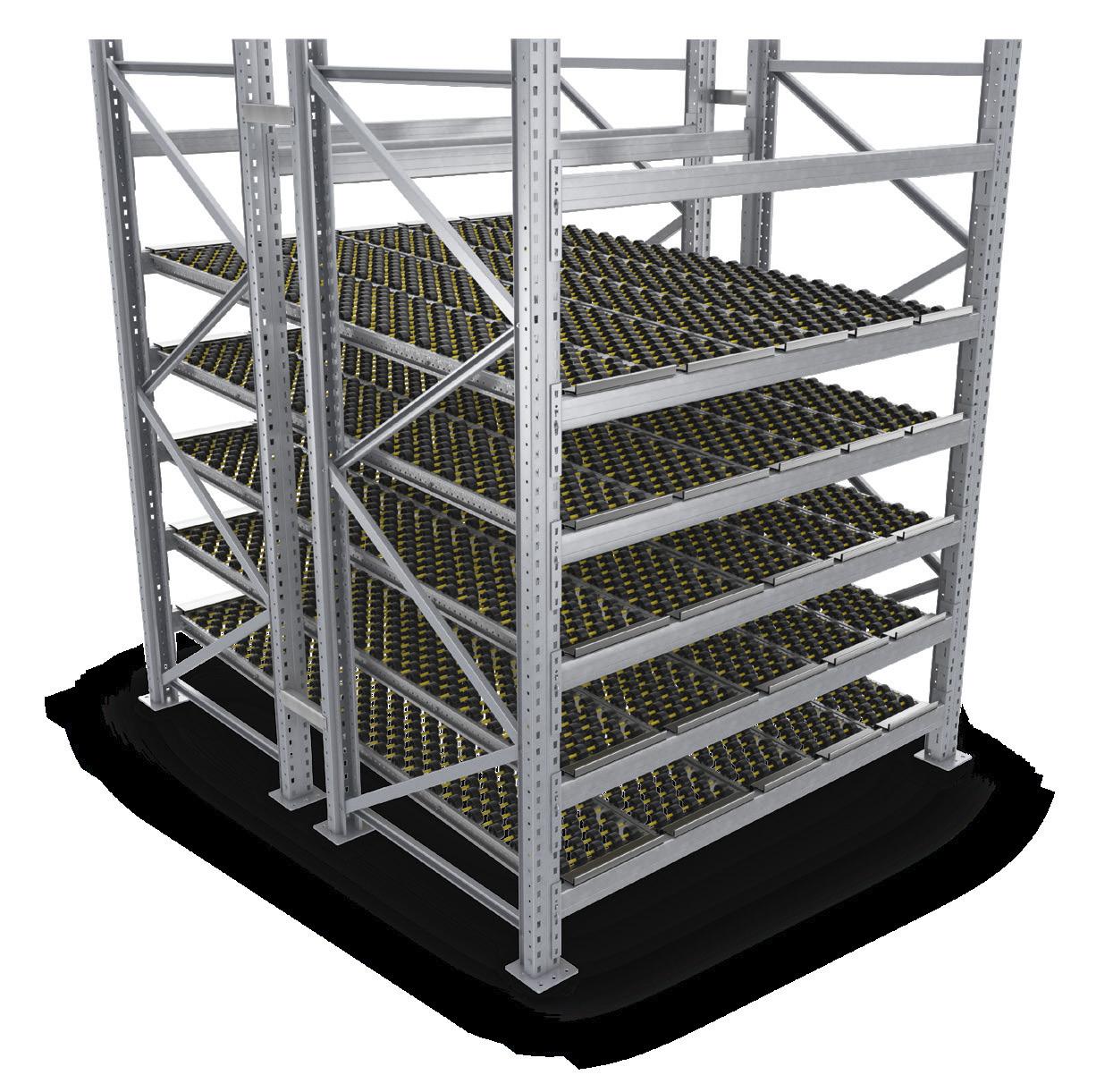

MATERIALS HANDLING, STORAGE & LOGISTICS

Faster, Safer, Smarter: Warehouses Go Dynamic

A legacy of sweetness.

FOOD REVIEW | MAY 2024 3

www.foodreview.co.za CONTENTS MAY 2024 Vol. 51 • No.

5

Baking inspirations and beyond

Welcome to another exciting edition of Food Review. The humble bakery is no stranger to reinvention. We unpack the world of baking powder, a well-known raising agent with Synercore’s senior R&D technologists in baking, see page 10.

The recent egg shortage and rising costs had many bakers scrambling for substitutes. Fear not! We’ve got you covered on page 13; we explore how milk proteins can be successfully used as a partial or complete egg replacement.

Need a recipe refresh or some inspiration for your next baking project? Flip to page 14 for a treasure trove of ingredients and recipes to satisfy your sweet tooth.

And the innovations don’t stop there! We’ll also be showcasing the latest conveyor bake belts on page 16, designed to streamline your baking process.

Looking beyond the bakery, we unpack the exciting world of food processing technology. Matrix Software, a leading provider in this space, is offering customised solutions to optimise your production, see page 22 . Discover how these advancements can boost efficiency, ensure consistent quality, and minimise waste.

Speaking of health, we turn our attention to the power of functional ingredients. With a focus on prebiotics and probiotics and look into the science behind gut health. Carien Schoeman, Savannah’s technical manager, highlights a startling statistic: less than 10% of the global population gets enough fiber! page 32 . But fear not, the good news is that consumer awareness is growing, with many seeking convenient food and beverage options packed with this essential nutrient. Learn more about the incredible health benefits of fiber and how to incorporate it into your diet.

Join the action at Africa’s Big 7 this June at the Sandton Convention Center in Johannesburg, South Africa. Discover more industry events on our diary page 5

Happy reading!

THE TEAM

EDITORIAL

Editor: Kelebogile Nondzaba +27 (0)78 175 9632

kelebogile.nondzaba@newmedia.co.za

Sub-editor: Gill Abrahams

Layout & Design: Tumi Kunene

ADVERTISING

Key Account Manager: Anita Raath +27 (0) 82 976 6541

anita.raath@newmedia.co.za

Key Account Manager: Càndida Giambò-Kruger +27 (0) 71 438 1918 càndida.giambò-kruger@newmedia.co.za

INTERNATIONAL SALES

Germany/Austria/Switzerland: Eisenacher Medien

Erhardt Eisenacher +49 228 249 9860 info@eisenacher-medien.de

Italy: Ngcombroker

Giacomo Rotunno +39 370 101 4694 g.rotunno@ngcombroker.com

Taiwan: Ringier Trade Media

Sydney Lai +886 4 2329 7318 sydneylai@ringier.com.hk

CIRCULATION

Circulation Manager: Felicity Garbers felicity.garbers@newmedia.co.za

PUBLISHING TEAM

General Manager: Dev Naidoo

Head of Commercial B2B: Johann Gerber

Production Controller: Mandy Ackerman

Art Director: David Kyslinger

JOHANNESBURG OFFICE

Ground Floor 272 Pretoria Avenue Randburg, 2194

POSTAL ADDRESS PO Box 784698, Sandton, Johannesburg 2146

Published by New Media, a division of Media24 (Pty) Ltd

MANAGEMENT TEAM

MANAGING DIRECTOR: Aileen Lamb

COMMERCIAL DIRECTOR: Maria Tiganis

STRATEGY DIRECTOR: Andrew Nunneley

CHIEF FINANCIAL OFFICER: Venette Malone

CEO: MEDIA24: Ishmet Davidson

HEAD OFFICE

New Media, a division of Media24 (Pty) Ltd 8th floor, Media24 Centre, 40 Heerengracht Cape Town, 8001

4 MAY 2024 | FOOD REVIEW

Kelebogile

@foodreview13 SA_FoodReview Anita Raath Key Account Manager +27 (0)82 976 6541 Càndida Giambò-Kruger Key Account Manager +27 (0)71 438 1918 @SA_FoodReview EDITOR’S COMMENT Food Review is published by New Media Publishing (Pty) Ltd 11 times a year and circulates to executives in the food and beverage industries. Views expressed in this journal, other than where specifically stated, are not necessarily those of the publisher. The editor welcomes for publishing consideration news items, press releases, articles and photographs relating to developments in the food and beverage industries. No responsibility is accepted should contributions be lost. Food Review is printed and bound by CTP Printers. Copyright: all rights reserved. ISSN 0257-8867 Readers are prohibited from using the contact details displayed in any advertisement or editorial within the pages of this publication to generate and/or distribute unsolicited bulk emails or other forms of mass marketing correspondence.

(Lebo) Nondzaba

2024 DIARY

June

Africa’s Big 7

Johannesburg, South Africa 11 – 13 June www.africabig7com

Food & Beverage W/Africa Lagos, Nigeria 11 – 13 June www.fab-westafrica.com

AFMAS Food EXPO

Eastern Africa 12-14 June www.afmass.com

Dairy Manufacturing Africa Expo

Co-located with Afmas Food Expo 12 – 14 June www.dairymanufacturingafrica.com

Africa Meat & Poultry Expo

Co-located with Afmas Food Expo 12 – 14 June www.africameatpoultryexpo.com

July

Organic & Natural Expo Africa Sandton Convention Center 12 – 14 September www.organicandnaturalportal.com

August

Food Show Africa Johannesburg, South Africa 5 – 7 August www.foodshowafrica.com

Morocco SIEMA Casablanca, Morocco 27 – 29 August www.siemamaroc.com

FOOD REVIEW | MAY 2024 5

WHAT'S NEW

INNOVATIVE INSTANT SPORTS NUTRITION INGREDIENTS

Ingredients specialist Loryma is expanding its Lory® Crumb portfolio with two new varieties made from rice flour and milk protein. The extruded flakes can enhance both the texture and nutritional profile of instant products such as porridge or pudding. Thanks to excellent swelling properties, the end product has a homemade texture and is ready in just a few minutes, depending on the temperature of the liquid added. The extrudates are available in different variants and can be used on their own or in combination. This makes it possible to achieve targeted nutritional profiles with a focus on protein or carbohydrate content, or both. The extrusion process gives the ingredients a rapid swelling capacity. This allows for easy preparation with an authentic texture. Both versions are suitable for clean label products. Furthermore, consumers can flavour the end products as desired, and add other ingredients such as dried fruits. Valuable source of carbohydrate and protein Rice-based Lory Crumb is an ideal source of carbohydrate, while the milk protein and potato starch variant offers a high protein content of 48.5 per cent. Read more on, www.foodreview.co.za

EMBRACING WELLNESS WITH KELLANOVA’S NEW GRANOLA RANGE

Cereal giant, Kellanova introduced its latest breakfast innovation, Kellogg’s Granola Wellness Range. Launched through an exhilarating wellness event, The Kellogg’s Flourish Fest, the wellness festivities, Hosted by television presenter and awardwinning content creator Naledi Mallela, the event took place on the 18th of April 2024 at The Ground Venue in Muldersdrift. Guests were treated to the ultimate fitness and wellness escape where yoga instructor extraordinaire Drake Selwe provided some exciting yoga exercises for the fitness enthusiasts in attendance. Award winning fitness experts Sibongiseni “Sybo” Ndwandwe and Zinhle “Zee” concluded the day’s workout activities with an exhilarating fitness bootcamp to commemorate Kellogg’s new Granola Cinnamon Crunch and Cocoa Delight variants.

The fun continued as the day progressed, with a surprise performance by award winning singer Shekhinah, followed

WOODLANDS DAIRY WINS BIG AT 2024 BLOEM SHOW CHEESE AWARDS!

Woodlands Dairy triumphed at this year’s Bloem Show Cheese Awards, the only show in South Africa where a dairy product competition is still presented. With diverse categories including butter, gouda cheese, cheddar cheese, continental cheese, specialty cheese, and exotic cheese, along with a wide array of milk and goat milk products, the company secured thirteen awards for their First Choice products and those of clients. The company’s own brand, First Choice,

earned awards for its Amazi, Baby Gouda, UHT Low Fat Milk, UHT Pouring Cream, and Velvet Dairy Desert (Butterscotch). Award-winning products produced specifically for Spar include Butter Spread, Rindless Gouda, Rindless Cheddar, Matured Cheddar Gouda Processed Cheese Slices, and Vanilla Custard. Woolworths walked away with top honours for their UHT Full Cream Milk and UHT Whipping Cream, manufactured by Woodlands Dairy.

by a mouth-watering Kellogg’s Granola inspired lunch prepared by Chef Thero. The Flourish Fest menu included Flavourful Cinnamon Crunch stuffed crepes, a delectable chicken salad filled with bulgur wheat, harissa, smoked chicken, pomegranate, pickled cucumber, grilled courgette, Cocoa Delight Granola, shallots, curry roasted eggplant, mint and lemon dressing bursting with flavour from every crunchy bite.

Amongst some of the notable guests in attendance were former Miss SA Ndavi Noreki, music sensation Holly Rey, Media Personality Tshego Koke, Radio and TV personality Jamie-Lee Domburg and reality tv star Libhongelethu Geza.

Whether you’re a gym junkie seeking the rush of adrenaline or prefer the serene embrace of a morning yoga session, Kellogg’s Granola Wellness Range eagerly awaits to nourish you best, so you can flourish on your wellness journey.

6 MAY 2024 | FOOD REVIEW

Images: Supplied by clients

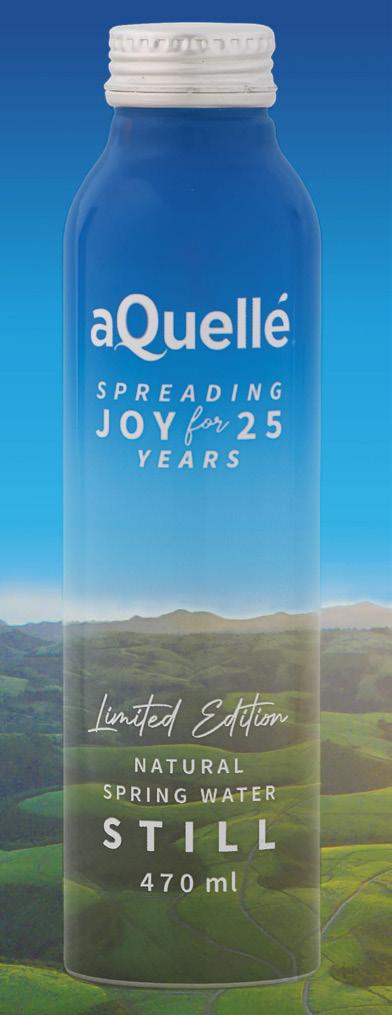

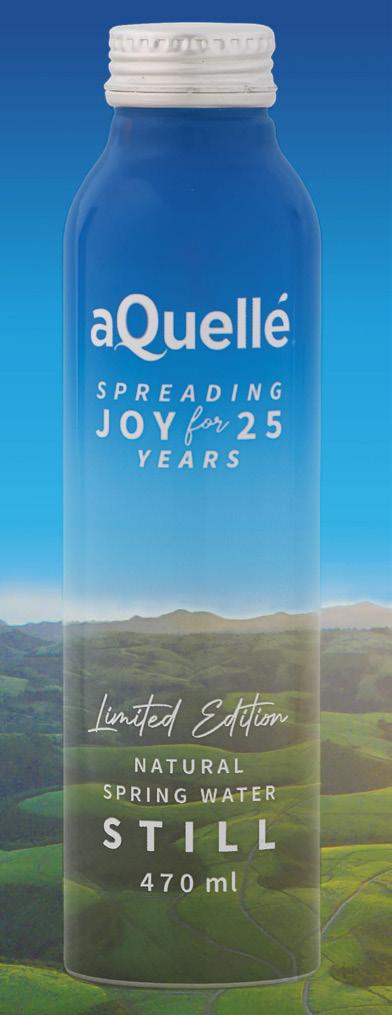

AQUELLÉ’S JOURNEY: CELEBRATING 25 YEARS OF JOY

As aQuellé commemorates its 25th anniversary it marks a significant milestone, acknowledging twentyfive years of refreshing households across Mzansi. This year, aQuellé celebrates with a distinct Limited Edition aluminium bottle. Gratitude in Every Drop The specially designed aluminium bottle highlights the natural purity of their spring water source. Not merely a container, but a symbol of appreciation for everyone who has been part of their journey. This Limited Edition bottle signifies more than a celebration, it’s a commitment to spreading joy. Celebrating 25 Years

aQuellé’s journey began in a modest 360m2 space. Through dedicated efforts, they have achieved substantial success, presently managing three cutting-edge bottling facilities totalling over 50,000m2. aQuellé has grown to be South Africa’s no. 1 water brand, thanks to God’s wondrous grace and Mzansi’s incredible support. Giving Back aQuellé’s dedication to communities and sustainability shines through their Limited Edition aluminium bottle. Each bottle purchased contributes to water security in needy communities and will see 25 water tanks installed all over South Africa. aQuellé is committed to making a tangible difference where it is needed most, including various community upliftment programs such as “Together let’s beat Diabetes” and “aQuellé Khula Clean ups” around the country.

aQuellé’s Journey aQuellé gives God all the glory for reaching this milestone. They consider His grace to have carried them through all these years, constantly inspiring them to continue their mission of spreading joy and refreshment to South Africans.

TURNKEY AGRICULTURE SOLUTIONS FROM THE GROUND UP FROM BEARINGS INTERNATIONAL

As a trusted partner to South Africa’s agricultural sector for some 66 years, Bearings International (BI) supplies integrated product and service solutions that ingrain the entire agriculture supply chain. “From soil preparation, fertilizing, ploughing and planting to irrigation, harvesting, processing and packaging – we’ve got it covered,” says Andrew Altree, BI Agriculture Segment Lead. “We essentially have products for all seasons.”

The primary differentiating factors of BI’s agriculture offering are quality of products, competitiveness of pricing, standard of service and expanse of footprint. BI’s comprehensive agriculture product solutions include bearings, hubs and units, coulter discs, planting and fertilizing coulters, plumber and pillow blocks, sprockets, belts, motors, gearboxes, chain, lubricants, PTO’s, accessories,

parts and spares. These products operate on a wide variety of farming machinery, equipment, and irrigation systems as well as in agriculture product processing and packaging environments.

Agriculture is fundamental to cultivating economic growths and food security and, on these grounds, it is one of BI’s primary segments. “In order to meet our objective of optimising our customers’ operations through the provision of customised, quality product and service solutions, it’s imperative that we, first and foremost, have a good understanding of their respective segments, giving rise to our segment approach,” states Christian Chipamaunga, GM End-User Markets at BI. “In line with this strategy, we place a deliberate focus on key industries to gain in-depth knowledge and insights that enable us to deliver on-point solutions to our customers.”

FOOD REVIEW | MAY 2024 7

NEWS

Images: Supplied by clients

One-Stop Lab Testing for Food Safety

The food industry demands speed, but never at the expense of safety. One-stop lab testing providers like AssureCloud are streamlining the process, offering comprehensive solutions from testing and inspection to certification and training.

From staple crops to animal feed and irrigation water, food safety testing is essential for ensuring product quality and safety within the dynamic and consumer-driven food market.

As businesses rapidly advance their products from farm to market, maintaining robust testing and compliance often poses significant challenges.

One-stop lab testing solutions can streamline the microbiology testing industry and enhance market growth for enterprises.

Testing maintains product integrity: The acceleration of food products to market can be challenging, an area that thorough lab testing cannot be overlooked. With heightened awareness on food safety, there is a demand from the public for accountability from producers. Minor errors can result in product recalls, reputational damage, and legal consequences.

Testing reaches beyond regulatory compliance as it enables producers to detect potential problems early in the production cycle and enhances consumer confidence and brand trust as products reach the market.

By adopting a one-stop shop approach, businesses can achieve greater levels of efficiency, reliability, and expertise throughout their production processes.

ONE-STOP SHOP APPROACH

Testing service provider AssureCloud, which has the largest footprint of laboratories and inspection services in Southern Africa, is transforming all labs into one-stop testing facilities, to service clients’ growth strategies by helping them mitigate food safety risks.

AssureCloud offers food safety testing, inspection, certification, and training solutions, and is one of SA’s few Biotoxinaccredited laboratory for seafood, the country’s first Asbestos Accredited Laboratory, and a specialist in Salmonella

"As businesses rapidly advance their products from farm to market, maintaining robust testing and compliance often poses significant challenges."

Serotype Testing.

Presently, all labs situated in Western Cape, Johannesburg, Oudtshoorn and Zambia are being refreshed and upgraded to meet international standards. Changes include optimising physical workflows to enhance turnaround times on reporting results. Changeover rooms, pathogen rooms, process and reading rooms have also been reorganised into separate functional spaces for ease of work.

Etienne van Zyl, laboratory manager at AssureCloud Oudtshoorn, said the upgrades came at an opportune time when food and water testing was high on the public agenda.

“Getting products to market faster can be a constant struggle, but lab testing cannot be compromised. We live in a world where the public is highly aware of the importance of food and water testing and is not shy to hold manufacturers accountable. This is where AssureCloud plays an important role in food safety testing to enable enterprises to offer a tested product,” said van Zyl.

Food industry landscape: Testing food products for harmful microorganisms such as Aflatoxin, Salmonella, E. Coli, and Listeria is crucial before they can be distributed to the market. As the sector evolves, so do its food safety regulations, enforced by authoritative bodies to ensure adherence. A one-stop shop partner, who also evolves with the industry, can effectively support clients’ needs.

Testing, therefore, builds consumer trust and brand reputation. This requires a joint effort by lab and client, to ensure the delivery of safe, high-quality food products to the market.

8 MAY 2024 | FOOD REVIEW Image: Supplied by AssureCloud INDUSTRY TALK

AssureCloud – www.assurecloud.co.za

Your One-Stop lab food testing partner

Support your business growth with full testing services from AssureCloud – and access Southern Africa’s largest footprint of laboratories and inspection services.

Testing

We offer a broad range of services for microbiological testing of swabs, water samples for all the major pathogenic, indicator and spoilage microorganisms.

Other analysis conducted by the microbiological laboratory include (but not limited to):

• Bacteriology (raw milk and dairy products, ready to eat/reheat, fresh produce, fruits. Nuts, dried cereals, etc.)

• Pathogens

• Viruses (salmonella, staphyloccus aureus, e-coli)

• Water testing (potable, river and bottled)

• Dalrode-approved for meat import testing

AssureCloud offers complete food safety testing, inspection, certification, and training solutions.

• We conduct GLOBAL G.A.P. certification for farmers only (for fruit and vegetables)

We will find a solution for your food safety testing requirements. Contact us on +27 87 330 3792

Email: enquiries@assurecloud.co.za

Baking powder 101: Rising to the occasion

This article by Karla Pretorius-Verneel, Synercore’s senior R&D technologist in baking, unpacks the world of baking powder – a key ingredient for achieving those light and fluffy baked goods.

Baking powder is a well-known raising agent used in a wide variety of baked goods including cakes and muffins and the development thereof has been recorded as early as 1843 in England, and 1850 in America. It is typically used in confectionery baked items where the flavour of yeast and fermentation is undesirable. Baking powder can be defined as a dry chemical leavening agent which typically consists of three main components including a base (sodium bicarbonate; NaCHO3), an acid (such as cream of tartar) and starch which acts as a buffer to prevent premature reaction between the base and acid components (corn starch most commonly used).

THE SCIENCE BEHIND THE RISE

When baking powder is added to a recipe, the main object is for liberation of carbon dioxide (CO2). The CO2 produced is subsequently entrapped in a batter or dough to create a desired voluminous, fluffy texture in the baked product. For the chemical reaction where CO2 is released to take place, water needs to be added to baking powder. Addition of water allows the acid and base components to react, leading to release of CO2 from the sodium bicarbonate which in turn inflates the dough. More CO2 is produced when heat is introduced as NaCHO3 undergoes thermal decomposition at temperatures in excess of 80°C, producing one molecule of CO2 for every two molecules of NaCHO3. Although sodium bicarbonate, commonly known as baking soda, can be used on its own, it is generally only used in recipes where an acid component such as lemon juice or buttermilk is already used in the recipe allowing the NaCHO3 to undergo an acid-base reaction. In this case a single CO2 molecule is released for every one NaCHO3 molecule, which implies that half the amount of baking soda is required to get the same amount of volume and fluffiness obtained when using baking powder. Recipes that do not contain

an acidic component will generally use baking powder, which consists of one or a combination of acid components as discussed above.

Baking powder is classified by its rate of reaction (ROR) which represents the percentage of CO2 released by the acidbase reaction and can be grouped into three different classes. Firstly, and most commonly, double acting baking powder contains a mixture of leavening acids which reacts immediately when liquid is added, and again when heat is introduced. Double acting baking powder only reacts partially at low temperatures to form a smooth batter, but typically requires higher temperatures to complete the reaction. Secondly, fast-acting baking powder releases most of its potential gas volume during the first few minutes of contact with liquid, creating the need to process the batter or dough relatively quickly. Thirdly, in contrast to fast-acting baking powder, slow-acting baking powder releases no gas when a liquid is added and requires heat to enable and complete the reaction.

BEYOND LEAVENING

Apart from its function as leavening agent, baking powder can also significantly influence crumb structure, moisture absorption and crust formation in baked goods. Crumb structure is influenced by the air pocket arrangement created by

the CO2 gas produced by baking powder, which will affect the distribution and size of the air pockets leading to a more fine or more coarse crumb structure. Moisture absorption in baked goods can be negatively affected when too much baking powder is added, causing quick dry-out which will lead to a crumbly texture. Adding the optimal amount of baking powder generally yields a light and fluffy texture. However, when too much baking powder is added the batter or dough will overexpand, resulting in a cracked and uneven crust. Furthermore, adding too much baking powder, or using a baking powder with incorrect composition, can also affect the flavour of baked goods resulting in a bitter aftertaste.

The addition of baking powder to baked confectionery items such as sponge cakes, biscuits, muffins, and scones is crucial as it will ultimately not only act as raising agent, but will also influence physio-chemical, textural, sensory, and aromatic properties of baked goods. The correct usage level of baking powder will result in tender and moist baked goods and by understanding the chemical reaction of baking powder and the interaction thereof with other ingredients, it can aid baking consistently high-quality products.

Synercore – www.synercore.co.za

10 MAY 2024 | FOOD REVIEW

Images: Sutterstock.com

BAKERY

FOOD REVIEW | MAY 2024 11

High reliability and flexibility

The metal detector entry level model iMD basic with integrated conveyor belt and its robust design is ideally suitable for the food sector. Rely on safe detection of enclosed contaminations such as steel, stainless steel or non-ferrous metals like aluminium for packaged and non-packaged products.

FOOD SAFETY

Product recalls are a nightmare for food producers – and not just because they can become extremely expensive. They may result in health risks for consumers, a loss of image with bulk purchasers and end customers, and additional work due to batch tracing. Furthermore, there may be no upper limit to potential costs, whether these are contract penalties, fines, compensation or damages. Serious sanctions and systematic resolution are required to protect the lives and health of people as unsafe food can have dramatic consequences.

IMD BASIC

For a reliable inspection performance, the

compact metal detector works with highest search sensitivity. Thanks to its robust stainless steel conveyor belt construction the iMD basic is suitable for piece goods of up to 20kg. The short metal-free zone (MZ) ensures interference-free and reliable detection. The flexibly adjustable height of the metal detector guarantees reliable detection of contaminations. Optional casters allow flexible set-up away from or within a production line. The system adjusts to your needs via conveyor belts having a variable belt width. You may choose between the following standard sizes: 150, 300 and 400mm.

Bizerba – www.bizerba.com

Distributors of Rondo equipment in

South Africa

Polyline

equipment in South Africa

The Polyline is Rondo’s starting point for automatic pie production. In addition to pies you can produce folded, rolled, filled, decorated, cut and even stamped out products with the Polyline.

Distributors of Rondo equipment in South Africa

Polyline production. decorated, Polyline.

Rondostar 4000

The Rondostar 4000 can produce dough bands and blocks easily and gently. It can also produce very thin dough bands and process the more difficult dough types like shortcrust pastry.

Tel: +27 11 462 3224/5 Fax: +27 11 462 3226 E-mail: foodequip@arbonia.co.za

Tel: +27 11 462 3224/5 Fax: +27 11 462 3226 E-mail: foodequip@arbonia.co.za

produce dough bands and blocks easily and gently. thin dough bands and process the more difficult shortcrust pastry.

12 MAY 2024 | FOOD REVIEW BAKERY

half page.indd 1 2023/05/09 11:32

Arbonia

Image:

Supplied by

Bizerba

Whey to go: Replacing Eggs in Baking

Eggs in baking? Not always! Whey protein offers a reliable, functional alternative for bakers. Discover its benefits for batters, structure, and shelf life.

The baking industry has a long tradition of using eggs in baked goods. From time to time however, bakers and the entire baking industry experience disruptions in supply due to circumstances that cannot be planned for, like avian flu.

The consumer’s demand for products that are consistent in quality but also price stable, has necessitated the increasing introduction of egg substitutes to the bakery industry to meet the demand.

When eggs are unavailable or are undesirable due to cost, food safety concerns, special diets or allergens or even just ethical reasons, milk proteins can be utilised successfully for partial or complete replacement of eggs in bakery formulations.

Milk proteins, especially whey proteins, are highly versatile ingredients that can be used for their many functionalities across the food industry. In the baking industry

milk proteins can be used for egg reduction of up to 50% or total replacement. The functionality of milk proteins allows for stabilising of cake batters, creation of excellent cake structures, improvement of shelf life and freshness as well as reduction of crumbliness in muffins.

WHEY PROTEINS BENEFITS

Bakers can achieve the desired protein

levels using whey protein instead of egg and the functional properties of whey make it an effective egg alternative. Whey protein provides browning, improves texture, volume and consistency while also extending the shelf life of the final product. This makes whey protein the preferred ingredient for egg replacement in sponges, muffins and pound cakes.

The fact that whey proteins are natural, is also something that is appreciated by both customers and producers. Protein concentrations range from 34% to 85% in whey protein concentrates (WPCs) while whey protein isolates (WPIs) contain 90% protein which is useful for formulations that aim to achieve high protein and low carbohydrates in the final product.

CHEMPURE’S EGG ALTERNATIVES

Chempure represents renowned manufacturers such as BaltMilk, Hilmar Ingredients and Milk Specialities Global in their ranges of MPC85s, WPCs and WPIs for our customer’s convenience.

Chempure – www.chempure.co.za

FOOD REVIEW | MAY 2024 13 BAKERY

Images: Shutterstock.com

Quality at Every Step

At Design Baking Ingredients, we understand the pure joy of creating delicious baked goods. Founded in 2007 by passionate food enthusiasts with over 30 years of industry experience, our mission is simple: to be the premier supplier of the nation’s favourite baking and confectionery ingredients.

We offer a comprehensive portfolio of top-notch baking and confectionery solutions to satisfy your every need. Whether you’re a professional baker, a home-based entrepreneur, or simply someone who enjoys whipping up a batch of cookies for family and friends, we have the ingredients to help you bring your baking dreams to life. We are driven by an unwavering commitment to quality and a desire to empower bakers of all levels to achieve success in the kitchen.

" We offer a comprehensive portfolio of top-notch baking and confectionery solutions to satisfy your every need."

OUR WIDE RANGE OF PRODUCTS OFFERINGS:

Premixes and bread mixes: Save time and ensure consistent results with our convenient premixes and bread mixes. From classic white bread to flavourful multigrain options, we offer a variety of choices to suit your taste and baking goals.

Fruit toppings and pie fillings: Elevate your pies, pastries, and desserts with our delicious selection of fruit toppings and pie fillings. Made with high-quality ingredients and bursting with flavor, our fillings are sure to become a staple in your baking repertoire.

Chocolate, chocolate spreads, and truffles: Indulge your sweet tooth with our decadent chocolate products. We offer

a variety of chocolates, from rich dark varieties to creamy white chocolate, perfect for baking, decorating, or simply enjoying on their own. Our chocolate spreads are a delightful addition to toast, waffles, or even enjoyed straight from the jar, while our truffles offer a luxurious taste sensation.

Chocolate fillings: We are particularly proud of our popular chocolate fillings. These fillings are guaranteed to take your baked goods to the next level. Our white truffle filling offers a smooth and creamy texture, while the dark chocolate truffle filling provides a rich and decadent flavour experience. And for those who crave a truly unique taste sensation, our caramel chocolate filling is simply out of this world!

UNWAVERING COMMITMENT TO QUALITY

At Design Baking Ingredients, quality is not just a word; it’s the cornerstone of everything we do. We source our ingredients from top South African suppliers renowned for their dedication to excellence. Our commitment extends beyond the ingredients themselves; we implement rigorous food safety protocols to ensure the safety and consistency of our products.

We understand that food safety is paramount to customer satisfaction and the success of your baked goods. That’s why we take every step necessary to ensure that our products meet the highest safety standards. We are dedicated to providing exceptional customer service and building long-lasting partnerships with our clients. Our team of technical experts is always available to answer your questions, offer guidance, and help you find the perfect ingredients for your baking needs. We encourage you to “task us with your needs” – no challenge is too big or too small!

Whether you’re a seasoned baker or just starting out, we are here to support you on your baking journey. With our extensive product range, unwavering commitment to quality, and dedication to customer service, Design Baking Ingredients is your one-stop shop for all your baking and confectionery needs.

DRIVING INNOVATION AND EFFICIENCY

Our passion for food extends beyond simply providing ingredients. We are constantly striving to innovate and develop new products that meet the evolving needs of our customers. We are also committed to helping our clients achieve factory efficiency and cost reduction. By offering high-quality, consistent products that minimise waste, we can help you streamline your operations and minimise your profits .

14 MAY 2024 | FOOD REVIEW Design Baking Ingredients –www. designbaking.co.za Images: Shutterstock.com

BAKERY

Our mission is to establish Design Baking Ingredients as the premier supplier of the nation’s preferred baking and confectionery ingredients, unwavering in our principles of quality.

Images: Shutterstock.com

Fruit Pie Fillings & Toppings

Doughnut Dips

Whipping Creams

Confectionery Products

Glaze Products

Fats, Margarines & Oils

Chocolate Spreads

Bread, Rolls & Imporvers

Shelf Life Extenders

Aroma Paste

Colour Range

Chocolate Range

Bakers Choice Range

Cake & Sponge Products

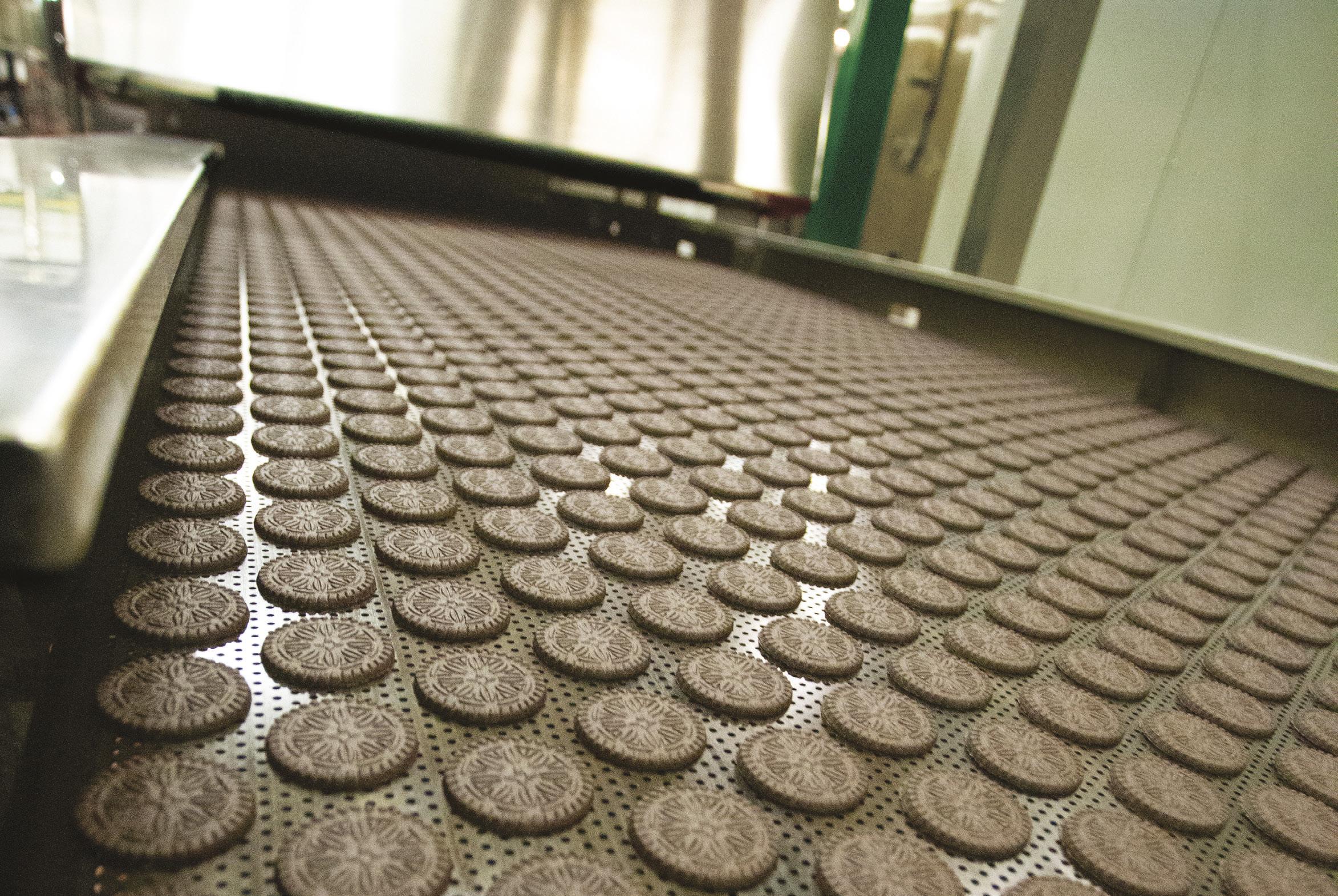

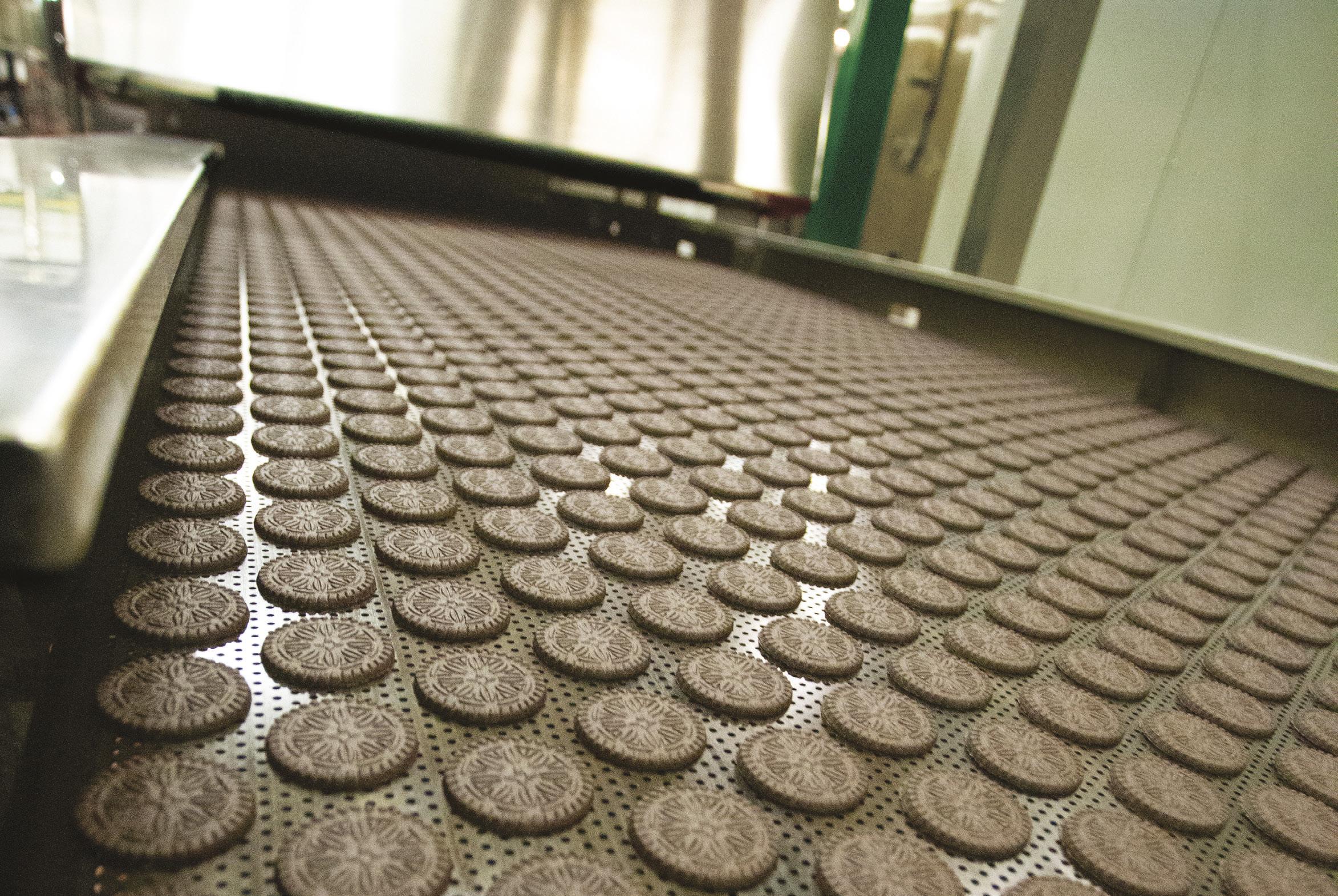

Leading the way in bake belts and conveyor tech

IPCO is the world’s largest manufacturer of solid and perforated steel bake oven belts, supplying OEMs and end users alike.

The key qualities of an IPCO bake oven belt include outstanding thermal properties for efficient baking; the inherent ease of cleaning of a belt compared with mesh; and the attractive return on investment when considering overall lifetime cost.

Belts are available in widths from 800 mm to 3500 mm, and are suitable for products as diverse as bread, biscuits, brownies, crackers, pastries, sponges, all-butter cookies and pizza bases.

Steel belts offer several distinct advantages in terms of performance in the oven, primarily due to their excellent heat transfer and thermal conductivity. As the heated steel belt surface is in direct contact with the underside of the product, this delivers the crisp, chewy base that represents much of the appeal of many products.

A flat, smooth surface ensures clean release at the end of the oven with minimal risk of damage to fragile products.

BAKE OVEN BELTS WITH BUILT-IN SUSTAINABILITY

Several factors combine to make steel belts a more sustainable choice than other belt types. Their strength results in exceptional durability, which means a 20 year working life is not unusual. Secondly, solid steel belts are inherently lighter than mesh belts and perforated belts even more so. A belt has to be reheated every time it enters the oven and a lighter belt means less metal to heat. This means that significantly less energy is required – and these savings are continuous. This weight advantage also means less energy is needed to ‘drive’ the belt through the oven.

UPGRADED BELT TRACKING SYSTEM WITH OPTICAL SENSOR

The quality of the belt – its straightness

and flatness – is central to its long term performance but bake oven belts also require effective tracking systems. IPCO produces a range of belt alignment solutions, including an upgraded version of its widely used Compact Belt Tracker (CBT), a versatile, tilt roller tracking system that can be retrofitted to existing conveyors.

While the existing CBT uses a physical edge sensor, a new, contact-free model features an optical sensor that continuously monitors the belt edge. Any unwanted movement instantly triggers the necessary corrective action in the tilt roller, and smooth, straight running is immediately restored.

The new contact-free Compact Belt Tracker is just one of a comprehensive range of IPCO conveyor components. These include rolling supports, sliding supports (e.g. skid bars and graphite stations), frames, end stations, pulleys, cleaning devices and more.

“IPCO produces a range of belt alignment solutions, including an upgraded version of its widely used Compact Belt Tracker (CBT), a versatile, tilt roller tracking system that can be retrofitted to existing conveyors.”

HIGH POWER LASER CLEANING –FASTER, CLEANER, GREENER

Complementing the company’s expertise in belts, IPCO can also support bakeries with belt cleaning using an innovative system based on high power industrial laser technology.

The laser is installed above the belt and as the belt travels beneath the beam, deposits are burnt off and collected by a vacuum system. Once the strip has been cleaned, the laser head is moved across to the next section.

The key benefit is speed; depending on belt size and level of build-up, a typical bake oven belt can be cleaned in a day. It is an entirely contact-free cleaning process – the structure of the belt is unaffected by the laser. Laser cleaning is a completely dry treatment that uses no water, detergents or aggressive chemicals such as caustic soda (NaOH), making it a far more environmentally-friendly solution than traditional methods.

CUSTOMER SUPPORT THROUGH SERVICE AND SPECIAL ENGINEERING

IPCO has been involved in bake oven conveyor design for decades, often working hand in hand with oven builders to ensure that an oven reaches its full potential. This extends to ongoing partnerships with bakeries and the company has a Special Engineering team who can provide expert technical support.

This experience has resulted in an indepth understand of how a belt behaves in an oven and how it interacts with the many other component parts that make up the system. As a result, IPCO can deliver inspection and maintenance services that go beyond the belt, with investigations encompassing the entire line to understand how the system is performing IPCO recommends that customers take advantage of Preventative Maintenance Agreements (PMAs). In this way, risks of failure can be identified before they have chance to disrupt production.

IPCO – www.ipco.com/bake

16 MAY 2024 | FOOD REVIEW BAKERY

Image: Supplied by IPCO

------BAKE MORE, BAKE BETTER WITH IPCO STEEL BELT TECHNOLOGY

Our solid and perforated steel belts have helped bakeries produce premium quality products for almost 100 years.

Flat, straight, durable and easy to clean, they provide a baking surface that’s ideal for everything from rich, chewy all butter cookies to traditional biscuits and crackers.

We can also support you with a wide range of conveyor components covering everything from tensioning, drive stations and drums to tracking systems, break points and graphite stations. Talk to your local IPCO service team and we’ll work with you to improve the performance, productivity and reliability of your oven through process enhancement and system upgrades.

High productivity wide belts up to 3500 mm.

Maximum versatility – bake more on an IPCO steel belt.

Energy efficient – lighter belt means lower carbon footprint.

High power laser cleaningfaster, cleaner and greener than traditional cleaning.

Installations, upgrades (mesh replacement), repair, maintenance and spare parts.

ipco.com/bake

Innovative and healthier snacks with beta-glucans

Plant-based beta-glucans can add dietary fibre and heart health benefits to successful snacks with approved health claims, explains Beneo.

The vast majority of consumers (82%) around the world recognise the link between “heart health” and their overall health.1 Coronary heart disease (CHD) is the leading cause of death worldwide. Choosing to eat whole grains and fibre as part of a healthy diet, can lower the risk of CHD. Including such ingredients in your product offering and stating their health claims are an effective way to help consumers make better nutritional choices.

Incorporating beta-glucans from barley into recipes is an easy and affordable way to achieve this. Barley beta-glucans are viscous, soluble, fermentable dietary fibres with scientifically proven benefits for heart health, while also allowing for fibre enrichment and corresponding claims.

Beta-glucans generate a high viscosity, which makes the food thicker and slows its passage through the gastro-intestinal tract. This delays the uptake of glucose from food, lowering the blood glucose response. 2 In addition, the high viscosity lowers the uptake of bile acids and thereby reduces blood cholesterol concentration3, helping to cut the risk of coronary heart disease.

When it comes to snacks enriched with these functional ingredients, there are benefits for producers, as well as for consumers. There are more than 120 scientific studies demonstrating the health effects of beta-glucans from cereals, and official bodies including EFSA, the FDA and Health Canada have approved corresponding health claims.4

As a leading producer of functional ingredients, BENEO offers barley betaglucans in the form of Orafti® β -Fit, a clean label, non-GMO, vegan-friendly wholegrain barley flour with a beta-glucan content of 20% on dry matter. Orafti® β -Fit is available at an affordable price and can be used in a wide variety of snacks, including baked goods like muffins, cookies, cakes and biscuits as well as extruded cereals. It can also serve as a clean label texturiser – for example in dairy and dairy alternatives.

The BENEO-Technology Center developed,

“Dependent on the amount of Orafti® β-Fit included in your product, on-pack messages can range between “source of fibre”, “high fibre” or “increased fibre”. Communicating on “wholegrain” is another way to draw consumer attention.”

for example, a recipe for multigrain cookies with beta-glucans that can carry high fibre and EU health claims, like “Barley betaglucan has been shown to lower/reduce blood cholesterol. High cholesterol is a risk factor in the development of coronary heart disease”. This claim can be used for foods that provide at least 1 g of barley betaglucan per quantified portion, which can be easily fulfilled with the cookie recipe. The beneficial effect is obtained with a daily intake of 3 g barley beta-glucan. The cookies also have a great taste and a crunchy texture. Adding Orafti® β -Fit to a meal is a way to deliver fibre enrichment to consumers daily diet. As such, it can support people’s ambition to increase their fibre intake for an overall improved digestive wellbeing. Dependent on the amount of Orafti® β -Fit included in your product, on-pack messages can range between “source of fibre”, “high fibre” or “increased fibre”. Communicating on “wholegrain” is another way to draw consumer attention.

BETTER FOR YOU’ MULTIGRAIN COOKIE WITH FIBRE & HEART HEALTH BENEFITS

Minor ingredients (e.g. milk powder, salt, raising agents, flavour, emulsifier) q.s

*References available on request

Savannah Fine Chemicals –www.savannah.co.za Beneo – www.beneo.com

18 MAY 2024 | FOOD REVIEW Image: Supplied by Savannah

BAKERY

INGREDIENTS (% w/w) Test recipe Oat & rye flakes 30 Sugar 17 Wheat flour 15 Beta-glucan

barley flour 14 Vegetable fat

Water

rich

11

11

Beta-glucan rich barley flour can be used in place of traditional flour in snacks like cookies.

The faba fix for a greener, tasty future. Replacing eggs and saving costs.

Our answer to stricter rules around egg production is a sustainable one. We source faba from a region in which irrigation is not necessary, while improving soil structure and biodiversity. Dive into a delicious future with our faba bean protein –a revolutionary solution to replace or reduce eggs, ensuring stable ingredient costs, and good functionality in your recipes. Crafted by our experts, BENEO’s plant-based recipes open new doors in the bakery segment, featuring faba bean protein for impeccable texture and taste. www.beneo.com

Want to know more about BENEO? Scan here! Our

Sales Network Partner in South Africa: www.savannah.co.za

Smooth Sailing for Peanut Butter Filling

Peanut butter production demands precise filling. Discover how VEGA’s VEGAPULS 42 radar sensor tackles challenges like changing viscosity and condensation, ensuring consistent batches and happy customers.

Peanut butter as a kitchen staple in South Africa has evolved into a highly industrialised product in today’s commercial market. As manufacturers strive to meet growing demands while maintaining quality and consistency, the need for precise level measurement in batch filler vessels has grown drastically.

The production of commercial peanut butter involves a blend of factors, from roasting peanuts for the flavour to incorporating additives like sugar, salt, and oils for taste and shelf life. These variations in ingredients and processing methods create complexities that demand great attention to detail, especially during the filling and packaging stages.

ABOUT US

With a legacy of innovation spanning decades, VEGA stands as a global leader in providing cutting-edge measurement technology. Through dedication to precision and reliability, VEGA has redefined the landscape of industries worldwide. VEGA’s customised solutions have empowered businesses to optimise processes, enhance efficiency, and ensure the highest quality standards.

Driven by a commitment to excellence, sensors and instruments continue to set new benchmarks for accuracy, durability, and performance.

KEEPING PEANUT BUTTER PRODUCTION SMOOTH

In response to these challenges, the use of advanced instrumentation for level measurement has emerged as a critical aspect of peanut butter production. With production challenges like the changing product density and viscosity, condensation in the vessels and the presence of agitators, the task of ensuring optimal filling levels becomes both essential and intricate.

VEGA offers a tailored approach to address the specific needs of peanut butter and similar products. The VEGAPULS 42 radar sensor stands out as a compact yet powerful tool for continuous level measurement in vessels of varying sizes. Designed to operate reliably in challenging environments, the VEGAPULS 42 utilises 80 GHz radar technology, providing accurate readings even in vessels with limited space. Its noncontact operation minimises the risk of contamination and ensures maintenance-free performance, crucial for food processing applications.

THE VEGAPULS 42: A RADAR HERO FOR BATCH TANKS

One of the key advantages of the VEGAPULS 42 is its versatility in handling changing product densities and temperatures. Whether dealing with peanut butter, chocolate spread, or other viscous substances, this sensor delivers consistent results, contributing to efficient production processes. The integration of IO-Link functionality enables seamless connectivity with existing control systems, facilitating smooth operation and monitoring. This capability enhances overall efficiency and enables real-time adjustments to optimise filling levels and minimise waste.

In addition to addressing technical challenges, the VEGAPULS 42 offers practical benefits for manufacturers, such as easy installation and setup. Its compact design allows for flexible placement within production facilities, ensuring compatibility with various equipment configurations. The accurate measurement of peanut butter levels in filler vessels is crucial for maintaining product quality, maximising efficiency, and minimising downtime. With innovative solutions like the VEGAPULS 42, manufacturers can meet these demands with confidence, ensuring consistent results and customer satisfaction in every jar.

“Designed to operate reliably in challenging environments, the VEGAPULS 42 utilises 80 GHz radar technology, providing accurate readings even in vessels with limited space.”

20 MAY 2024 | FOOD REVIEW Image: Supplied by Vega BAKERY

Vega Instruments - www.vega.com

The future of instant noodles

Indulgence redefined: discover the trends shaping the future of this global phenomenon, explains Berlinda de Broize RD&A Culinary Manager.

In the fast-paced world of modern cuisine, instant noodles have long been a pantry staple, offering convenience without compromising on taste. However, as consumer preferences shift towards indulgent experiences, quick family meals, and all-in-one solutions, the landscape of instant noodles is undergoing a remarkable transformation. According to the Instant Noodles Global Market Report 2024, the instant noodles market size has grown strongly in recent years, and it’s showing no signs of slowing down. It’s projected to grow from $55.77 billion in 2023 to $59.16 billion in 2024 at a compound annual growth rate (CAGR) of 6.1%. This growth is not without reason. Factors like convenience, affordability, and cost have all fuelled this remarkable rise. As we delve into the future of instant noodles, we uncover a culinary revolution that is set to redefine the way we perceive this beloved staple.

CONVENIENCE MEETS CULINARY ARTISTRY

From simplicity and convenience to culinary finesse instant noodles have come a long way from their role as a quick and easy meal to a canvas for culinary creativity. From truffle-infused noodles to creamy coconut curry varieties, the options are expanding. Even trends like the spicy noodle challenges popular on TikTok have influenced the market, with consumers seeking bold and fiery flavours that excite their taste buds. As more consumers prioritise nutrition, the

“From simplicity and convenience to culinary finesse, instant noodles have come a long way from their role as a quick and easy meal to a canvas for culinary creativity.”

industry has also responded with options that are lower in sodium, gluten-free, and made with wholesome ingredients. These alternatives provide guilt-free indulgence for those seeking a nutritious option without compromising on flavour. In recent years, we’ve witnessed the rise of gourmet noodles that rival the flavours found in upmarket restaurants. Spicy miso ramen is an example of an indulgent option now available. These gourmet flavours are not only satisfying to the taste buds but also offer a differentiated touch to everyday meal experiences.

TRENDS SHAPING THE FUTURE OF NOODLES

Indulgence and all-in-one solutions

Indulgence is a key theme driving the future of instant noodles. Consumers are no longer satisfied with basic flavours; they crave restaurant-quality experiences in the comfort of their own homes. At the same time, the demand for all-in-one solutions is on the rise.

Busy lifestyles mean that consumers are looking for meals that are not only quick to prepare but also nourishing and delicious. The appeal of all-in-one solutions lies in their ability to provide a complete meal in a single package noodle which often comes with protein-rich toppings, vegetable blends, and flavourful sauces, making them a satisfying and convenient choice for busy individuals and families alike. Interestingly, instant noodles are also pivoting and disrupting the traditional snack market, offering a fresh and innovative experience beyond the usual potato chips, popcorn, etc. With flavours ranging from savoury to spicy and everything in between, noodle snacks are becoming the go-to choice for those seeking a satisfying crunch with a twist. Whether it’s ramen-inspired crispy noodles, crunchy noodle sticks infused with gourmet seasonings, or even noodle-based chips with bold flavours, these options are redefining what it means to snack.

Kerry GroupTaste & Nutrition Ingredients and Science

Tel : +27 31 344 0071

Email address: ccsouthafricalocal@kerry.com

Kerry Group - www.kerry.com

FOOD REVIEW | MAY 2024 21

ADVERTORIAL Image: Shutterstok.com

Tailored Food Processing Software

Matrix Software isn’t your average software company. They build custom solutions for the food processing industry, tackling specific challenges like traceability and cost control. This clientcentric approach empowers businesses like Cape Deli to achieve success.

Matrix Software’s philosophy is simple: start where the problem is and work from there. They’re a software solutions company specialising in the food processing industry that was started in 2006 from the ground up, because they wanted to be close enough to the problem to gain the specific knowledge and experience needed to solve it. Today, this approach continues to serve them well as they truly understand their clients’ challenges. Matrix Software meets clients where they’re at and journey with them to develop innovative and fit-for-purpose solutions that elevate their business and truly make a difference.

“Relationships build our foundation and people drive our progress. Our clients are at the heart of all we do and through our handson approach, we have developed a wide range of solutions to meet their evolving needs. With our team’s technical support and consulting expertise, we engineer success by dismantling obstacles and nurture the successful operations of our own business and that of our clients,” says Dewald Carelse, Matrix Software CEO.

“At Matrix Software, we don’t sell software, we solve problems.”

An example of a successful client partnership is Cape Deli, a Cape Town based biltong and dried meat manufacturer, which caters for local and international markets.

TRACEABILITY TAKES CENTER STAGE

Cape Deli found that Matrix Software was the right fit for them as an ERP provider to help them overcome specific challenges relating to the traceability of their products. Traceability of meat and food products has long been under the industry spotlight with the two main drivers being food safety and authentication. As competition increases globally, it is critical that technologies help safeguard manufacturers against, among others, non-compliance with industry standards and inadequate quality control.

Says Louis Myburgh, systems developer at Cape Deli, “When it comes to the specific challenges that the industry faces, traceability

is at the top of the list due to the sheer complexity of the supply system. Meat cutting and the cost of that process is also a critical factor for us. Stockholding and gathering accurate information regarding product ageing was cumbersome and problematic before partnering with Matrix Software.”

With every step meticulously tracked and managed within the Matrix Software ecosystem, Cape Deli will now be able to confidently trace the journey of each product from raw materials to finished goods, to final destination. This not only ensures compliance with regulatory requirements but also instils trust and confidence among consumers, strengthening Cape Deli’s reputation for quality and integrity.

“Cape Deli achieved 99.5% in its most recent FSA audit result, and Matrix Software’s traceability solution certainly contributed to making information more easily available to help us obtain this result, highlights Myburgh.”

MATRIX SOFTWARE DELIVERS: A TRACEABLE JOURNEY

A tailor-made system consisting of a wide

22 MAY 2024 | FOOD REVIEW

FOOD PROCESSING TECHNOLOGY

FOOD REVIEW | MAY 2024 23

variety of configurations ensure that clients such as Cape Deli have accurate job costing, complete stock control, fit for purpose quality control, and complete process traceability, equip food manufacturers with the tools necessary to navigate the industry’s nuances effectively. Furthermore, the Matrix Software system integrates the latest technology, including Android-based mobile scanners, integrated RFID solutions, automated weighers and easy-to-use label designers.

The complexities inherent in the food processing industry demand robust solutions that go beyond standard off-theshelf software. Matrix Software’s solution, powered by Microsoft’s SQL Server and running on standard Microsoft Windows machines, offers our clients a cost-effective and scalable option tailored to their needs.

Their proven track record shows that they have the knowledge and know-how to meet the requirements of the meat processing industry and their system can be easily adapted to other perishable processing industries. Many clients in the

seafood, dairy and fresh produce industries have tangibly benefited from their solutions to increase profitability.

The software is developed in South Africa specifically for the South African and African markets, so it’s designed to be cost-effective and easy to support. The systems are leased

on a month-to-month basis, which makes it simpler for businesses to get started without a large capital investment.

Matrix Softwarewww.matrixsoftware.co.za

Buyer’sguide

24 MAY 2024 | FOOD REVIEW FOOD PROCESSING TECHNOLOGY

Available online: www.thebuyersguide.co.za 2023/2024

THE The directory for manufacturers of food, beverages, pharmaceuticals, cosmetics, toiletries, packaging and the printing industry TBG 2024.indd 1 2024/02/16 11:49

Software

Images: Supplied by Matrix

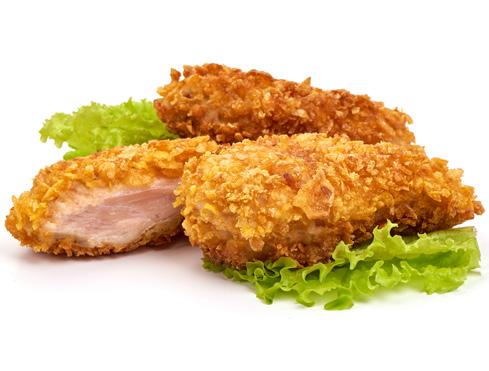

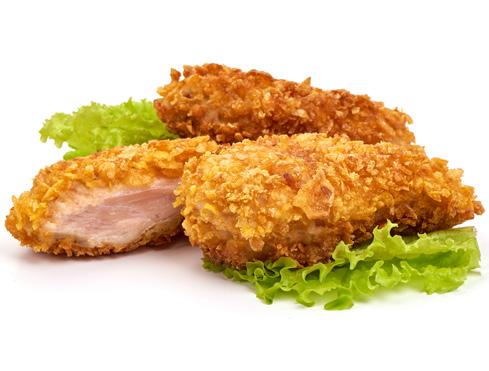

Convenience food production

By developing By developing an in-depth understanding of your end-product requirements, we can create a complete solution to meet your needs at every step in the processing chain, from raw material preparation all the way through to the packing of your convenience end products. We partner up with you to develop together the route towards the perfect convenience product. Our expert technologists have in-depth process knowledge to provide all the support you need to get the best possible results, increasing automation and food safety to ensure the highest quality, on-spec products every time.

WHOLE MUSCLE OR FORMED

Schnitzels may be created from whole muscle breast fillet meat. In this case, they need to

be sliced in the TSM Profiler or SmartSplitter to present a consistent thickness and weight to the Schnitzel convenience line. It is also possible to create formed schnitzels from meat mass with a RevoPortioner. the meat mass must be prepared by Marel’s Meat Preparation solutions to achieve the right consistency and viscosity for RevoPortioner to form it into consistent products with uniform shape and weight. The first step of coating will be done in the Active Flour Applicator. A layer of flour, also called predust, is applied in this stage. The fine layer of flour serves as an adhesive. It also supports the juiciness of product and adds yield. Now the schnitzel is ready for the wet coating. The Active Batter Applicator apply an even layer of batter on the top and bottom side, for the dry coating to stick to the product later.

CRUMB MANAGEMENT

The final step in the coating process is to apply crumbs. Depending on the customer’s wish, the schnitzels can be covered by fine breadcrumbs or coarse product such as cornflakes, depending on product requirements. The crumbs are applied gently, so large pieces remain intact. Spreading of the crumbs on top and bottom is very important, which is why RevoCrumb works with an innovative crumb management system to control the distribution of larger and smaller pieces on the schnitzel. Now the schnitzels are ready to be par-fried, so they only stay in the GoldFryer for a limited amount of time, while their juiciness remains optimal.

It’s the only one of its kind in the country to target decision makers in the manufacturing of food, beverages and their related industries. It o ers incisive and authoritative reports on all aspects of the process, from raw material sourcing, to manufacturing and packing, right down to the distribution and marketing of nished goods. FOOD REVIEW informs readers about the introduction of new ingredients, equipment, products and packing, and provides objective commentary on cutting-edge local and international market trends and issues.

To contribute editorially contact Kelebogile (Lebo) Nondzaba kelebogile.nondzaba@newmedia.co.za

+27 (0)78 175 9632

For advertising enquiries, contact Anita Raath anita.raath@newmedia.co.za

+27 82 976 6541 or Candida Giambo-Kruger

+27 (0)71 438 1918

candida.giambo-kruger@newmedia.co.za

FOOD REVIEW | MAY 2024 25 FOOD PROCESSING TECHNOLOGY Images: Supplied by Marel, Shutterstock.com

solution to help you transform your processing.

Whether you’re producing burgers, nuggets, schnitzels or chicken wings, Marel have a state- of-the-art

Marel – www.marel.com

www.foodreview.co.za New Media, Ground Floor 272 Pretoria Avenue Randburg, 2194 SA_FoodReview www.facebook.com/FoodReview13

South African journal for food and beverage manufacturers FRV 1-2.indd 1 2023/08/02 14:01

ProxxD, the new benchmark in processing technology

More speed, more efficiency, more capacity – the ProxxD from ProXES takes the production of homogenised and dispersed food products to the next level.

If you are in the business of processing mayonnaise, ketchup, dressings, spreads or other food products, you have probably come across the MaxxD, FrymaKoruma’s successful vacuum processing system. For more than two decades the MaxxD has been the processing industry’s go-to system for the production of high-quality products with guaranteed reproducibility. Based on the proven design of the MaxxD, manufacturer ProXES developed its successor, the ProxxD, to significantly increase production advantages.

“Versatile, powerful and reliable – the ProxxD takes the production of homogenised and dispersed food products to the next level.”

CO-CREATION TO MEET CUSTOMERS’ NEEDS

In close collaboration teams from ProXES brands FrymaKoruma, Stephan and Terlet joined their innovative spirit and longstanding expert knowledge. FrymaKoruma, as engineering lead, worked with close involvement and feedback from leading food producers. Their R&D team developed a future-proof processing system that lives up to the requirements of manufacturers today: the ProxxD.

New homogeniser, higher capacity: The ProxxD’s high performance and efficiency originates from the new, improved FrymaKoruma homogeniser. With the help of the latest simulation tools and market

feedback, the well-known rotor-stator homogenizer design underwent a thorough examination. The result: a perfected flow profile while maintaining equal shear energy transfer. The oil emulsification rates in mayonnaise production have been revolutionised while all other applications benefit as well. The new homogeniser enables a serious increase of production capacity at highest product quality. Lower environmental impact and lower production cost for achievable capacities make the ProxxD stand out.

NEW TECHNOLOGY BASED ON A PROVEN DESIGN

The functional principle is an evolution of the proven MaxxD system. Mounted underneath the vacuum-rated conical bottom, it introduces controlled shear energy into the product and drives the product flow. The improved flow dynamics of the frontal ingredient inlets as well as the product outlets, coupled with the external recirculation processing principle, ensure highest production consistency of each batch.

PROXXD HIGHLIGHTS AT A GLANCE

The new technological advance of ProxxD enables higher production volumes by lower energy use per kg of product such as mayonnaise and other emulsified products:

• Increase of production capacity

• Highest product quality

• Fastest oil dosing on the market

• Ecology and economy in sync

• Reduction of noise emissions

• Faster return on investment

• Intuitive operation with ProUI

Highly efficient vacuum processing: The robust ProxxD provides superior oil dispersion at high precision, rapid outflows, and effective processing of the ingredients. First, the scraper agitator supports the top-down material flow produced by the recirculation line (macro-mixing). Secondly, it reliably prevents the product mass binding to the interior wall of the vessel. The vessel temperature is controlled automatically through the double walled insulating jacket – the product can be heated or cooled as you require.

FLEXIBILITY ENABLES OPTIMISED PROCESSING TIMES

The unit’s integrated vacuum system allows the adjustment of the vacuum at any time to individual operations. Thus both liquid and powdery ingredients can be fed directly into the homogeniser. Optimised processing times, processes running simultaneously where possible, as well as low running costs (due to its energy efficiency) make the ProxxD an outstanding choice for your production.

PROXES – QUALITY EQUIPMENT MADE IN EUROPE

With roots in Germany and Switzerland, ProXES unites three leading process technology brands under one roof: FrymaKoruma, Stephan and Terlet. Together, ProXES combines innovative and long-standing expert knowledge as a manufacturer of machines, plants as well as process lines and solutions in the food, pharmaceutical, cosmetics and advanced materials industries.

PMD – www.pmdpackaging.co.za

26 MAY 2024 | FOOD REVIEW

Images: Supplied by PMD.

FOOD PROCESSING TECHNOLOGY

PMD

Systems (Pty) Ltd Suppliers of Packaging and Processing Machinery www.pmdpackaging.co.za l sales@pmdpackaging.co.za l (011) 795 1994

Packaging

To access video, check out the Food Review Digimag.

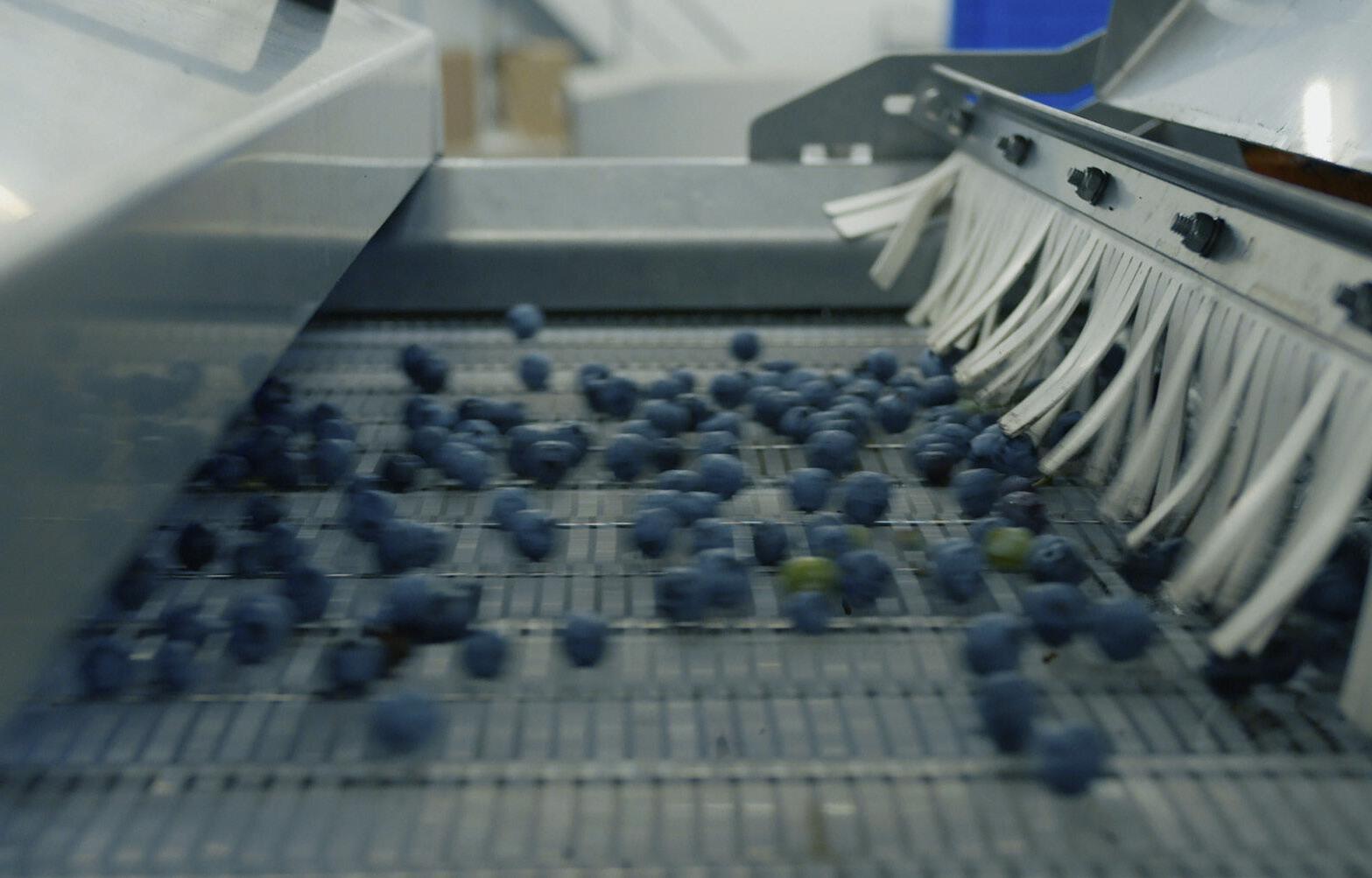

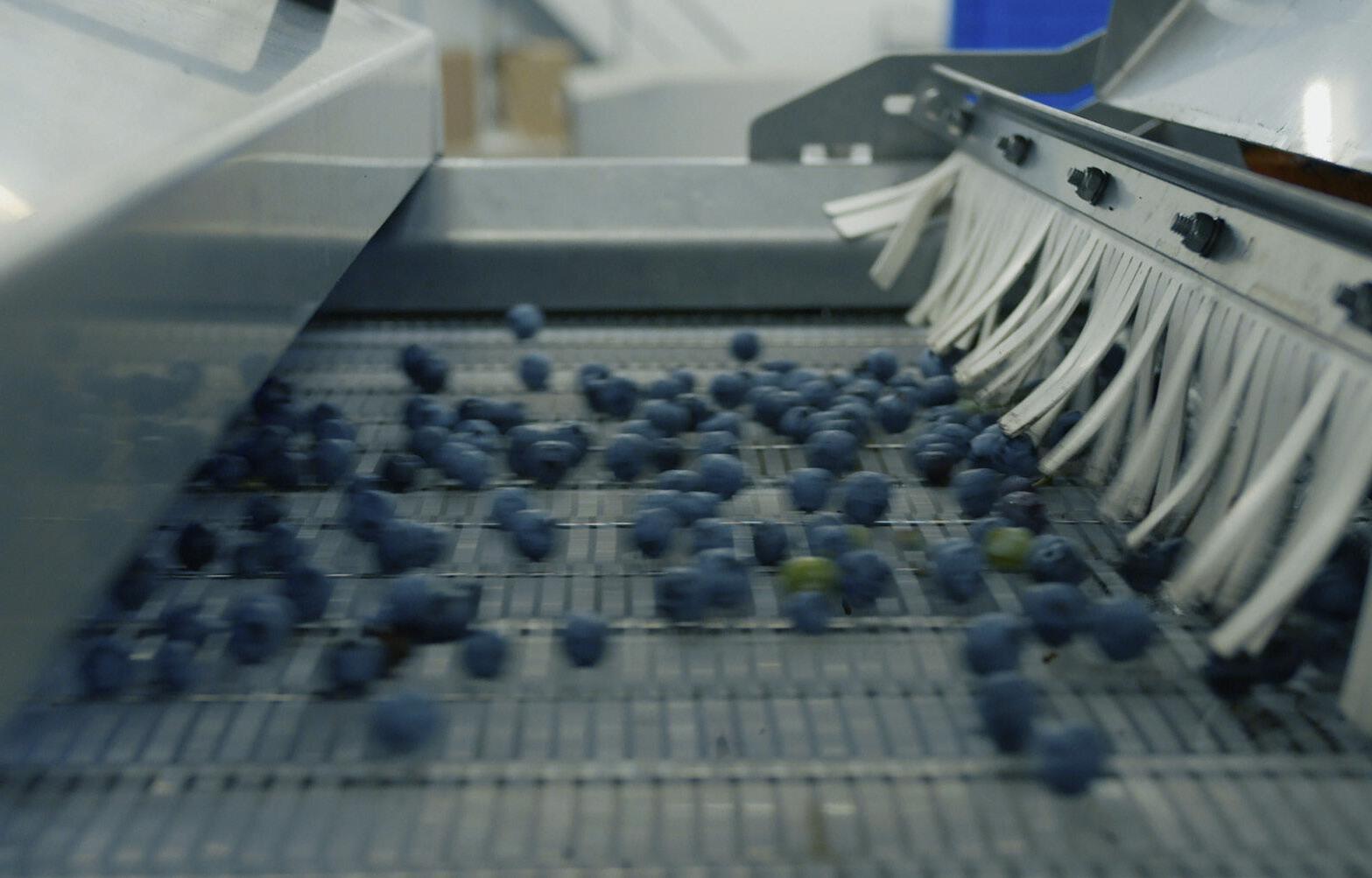

TOMRA Neon Makes Machine-Harvested Blueberries Shine

Blueberries are a delicious and popular fruit, but machine harvesting can present challenges for quality control. TOMRA Neon tackles this problem by pre-grading machine-harvested blueberries, ensuring a smooth and efficient packing process.

The global trend towards the machine harvesting of blueberries has brought challenges. Although machine harvesters are faster and less costly than manual picking, they also harvest debris and fruit clusters which cause disruption on packhouse production lines. Machines also harvest unwanted green and red berries which unnecessarily reduce pack-out from grading lines. The new TOMRA Neon allows Blueberry growers to automatically process machine harvested blueberries for the fresh market.

TOMRA Neon pregrades machine-harvested blueberries before transferring the fruit directly onto TOMRA’s KATO260 optical sorter and sizer. By employing artificial intelligence modelling, this detects clusters with unrivalled accuracy. Because it is compact, durable, and easy to clean, it fits perfectly into any processing and packing line

“The new TOMRA Neon allows Blueberry growers to automatically process machine harvested blueberries for the fresh market.”

RECOGNISING THE CHALLENGE

Manual blueberry harvesting is labor-intensive and requires pickers to spend long hours in the field. This is exactly the kind of tediously repetitive, physically tiring work that people no longer want to do. As a consequence, it is becoming increasingly difficult for growers to recruit and retain seasonal harvesting staff, which has accelerated the adoption of automated harvesting.

Another good reason for harvesting mechanically is the need for speed. Machines work much more rapidly than people. But machines cannot see or judge blueberries on the bushes in the same way that

people can. As well as harvesting good fruit, machines also pick fruit that’s unripe or grouped in clusters. By working closely with blueberry growers and packhouses, TOMRA Food recognised the need to help customers move to machine harvesting, adding value by reducing labour requirements, while still delivering the highest quality product to the consumer.

TOMRA Food’s knowledge of blueberry sorting, grading and packing goes back well over 20 years as it includes the specialised knowledge possessed by the New Zealandbased businesses Compac and BBC Technologies, which TOMRA acquired in 2016 and 2018. Detailed conversations with customers led to TOMRA setting itself the task of designing and developing a blueberry pre-grader that is technically sophisticated, robust, easy to maintain, easy to clean, and yet also price sensitive.

To achieve the necessary technical sophistication, TOMRA’s engineers drew extensively on their experience developing the company’s LUCAi AI technology, an optional add-on for the KATO260 which classifies and grades fruit with unrivalled accuracy. LUCAi employs Deep Learning, which uses pre-trained models to teach computers how to process data, such as complex patterns in photos – a principal which TOMRA will extend to other applications.

28 MAY 2024 | FOOD REVIEW

FOOD PROCESSING TECHNOLOGY

IMPRESSIVE RESULTS

TOMRA Neon was tested and validated over two-and-a-half years in varied machineharvested conditions in North America and New Zealand. These trials culminated in the controlled, early release and sale of 10 machines during the 2023 season to TOMRA customers. This made it possible to fine-tune TOMRA Neon’s software, AI algorithms, and mechanical set-up based on millions of kilos of machine-harvested blueberries in commercial environments.

These extensive validation tests have shown that TOMRA Neon optimises optical grader efficiency by removing more than 95% of clusters and more than 90% of green and red berries. And thanks to its unique ejection manifold, TOMRA Neon runs with a throughput capacity of up to 500 berries per second. Even when fruit removal is as high as 40%, an output speed of up to 280 berries per second can be

maintained to keep the KATO260 running at full capacity.

TOMRA Neon was launched to market in October 2023. Its introduction means there is now turnkey integration between TOMRA’s Harvest Cleaner, Small Fruit Eliminator, TOMRA Neon, and KATO260 – a suite of solutions that empowers packhouses to process machine-harvested blueberries easily and effectively to the highest level.

TOMRA Food designs and manufactures sensor-based sorting machines and integrated post-harvest solutions transforming the global food production to maximize food safety and minimize food loss, by making sure Every Resource Counts™.

FOOD REVIEW | MAY 2024 29 Images: Supplied by Tomra

– www.tomra.com

TOMRA

FOOD PROCESSING TECHNOLOGY

learn more visit:

tomra.com/food To

How metal detectors work

Food manufacturers rely on metal detectors to ensure safety. But what causes false alarms?

This article explores the culprit: environmental and product factors, plus the different metal detector technologies available. Discover how to minimise downtime and ensure the best possible detection.

There are several types of metal detectors, and each uses a different detection method to operate. In the food industry, metal detectors usually apply the balanced coil method. These metal detectors are equipped with a transmitter coil, which generates an electromagnetic field, and two receiver coils. The receiver coils have an equal but opposite output, creating a balanced state.

When a conductive object passes through the detector, it interrupts the balanced state of the electromagnetic field and causes a signal that is detected by the receiver coils. The electronics unit in the metal detector then analyses this signal, evaluates it, signals a metal detection, and either activates the automatic reject units that separates the contaminated product from the production line or alerts the operator.

FACTORS THAT LEAD TO FALSE DETECTIONS

There are two main factors that can lead to false positives in metal detection: environmental factors and product factors:

Environmental factors: Most food manufacturing and packaging lines involve the movement of products via conveyors, and the metal detectors are often installed close to the conveyors and often other electromechanical equipment. The preference today for the use of variable frequency drives, mainly to maximise energy efficiency, means that there is an increased potential for electromagnetic interference across a wide spectrum of frequencies. Such interference can often lead to disruption of the field of the balanced coils in a typical single-frequency or multi-frequency metal detector, leading to false detection.

Product factors: Some food products contain salt, iron, and moisture — each of which can alter the detector’s field and can trigger a false detection. This effect increases with higher inspection frequencies that are typically used to detect smaller particles and can lead to significant levels of wasted product and downtime.

Types of metal detectors: There are three main types of metal detector technologies: single-frequency, multi-frequency and

multi-spectrum metal detectors.

Single frequency detectors: Most metal detectors on the market use only one frequency when inspecting food products. The selected operating frequency depends primarily on the product being inspected. This is satisfactory when the product is dry and non-conductive. Single frequency metal detectors have limited abilities to work with different products and are difficult to optimise for varying conditions of temperature, water content, and packaging types.

" There are two main factors that can lead to false positives in metal detection: environmental factors and product factors."

MULTI-FREQUENCY DETECTORS

Using a metal detector that offers more detection frequencies can result in more sensitive metal detection and fewer product effect errors, as well as being able to use the machine on products with differing characteristics.

Multi-frequency metal detectors can only use one of the available operating frequencies at a time, however. The operator may need to switch from one frequency to another when changing products, or in more advanced multi-frequency systems, the metal detector will switch back and forth between two or more frequencies in rapid succession. However, only one frequency (one electromagnetic field) can be on at any time, and to prevent false rejections on more difficult products, reducing the sensitivity typically is still required.

Multi-spectrum metal detectors

Developed by Italian company CEIA, these metal detectors operate over an entire spectrum of frequencies that are simultaneously analysed and applied to eliminate product effects and interference, allowing for an improved inspection of the product.

Equipped with advanced computer technology and patented algorithms, CEIA’s multi-spectrum metal detectors can not only eliminate false positives, but can ‘learn’ the product being scanned, and perform automated testing to ensure correct detection, minimising false negatives.

TRUSTED EXPERTISE

CEIA was founded in 1961 in Turin, Italy –initially to produce electronic components and systems for industrial automation. In 1971 the company began developing metal detectors, their products first gaining recognition in the security industry. They developed advanced walkthrough metal detectors for high-security applications, such as airports, government buildings, and public venues.

Heat and Control –www.heatandcontrol.co.za

30 MAY 2024 | FOOD REVIEW Images: Supplied by Heat and Control INDUSTRY TALK

Our value-added systems prepare and cook consistently superior beef, pork, chicken, turkey, fish and other meat products including other Meat Alternative Products to create a distinctive quality that stands out in the marketplace.

• Preparation + Processing

• Battering + Breading

• Frying + Oil Management

• Branding + Searing

• Cooking, Roasting + Drying

• Coating + Seasoning

• Product Handling

LOOKING BACK. PRESSING FORWARD. ALWAYS INNOVATING.

FOOD REVIEW | MAY 2024 31 Meat your standards for meat

foods info@heatandcontrol.com I heatandcontrol.com

and plant-based

Mind the gap: Fibre the true superfood

Less than 10% of people globally get enough fibre, leading to a host of health woes. But there’s good news! Technical manager, Carien Schoeman from Savannah discusses the health and technical functionality of fibre.

Globally less than 10% of people are getting enough fibre in their diet. That amounts to a global populationwide deficiency, what nutritionists are calling the “fibre gap.” Diets low in fibre are associated with gastrointestinal health problems, increased risk of heart attacks, high cholesterol, obesity, strokes, and type 2 diabetes to name but a few. Fortunately, when it comes to the importance of dietary fibre intake, public awareness has been steadily growing over the last decade. Many consumers are already actively asking for convenient food and drinks that include higher amounts of fibre.

Fibre is the closest thing we have to a true superfood or super nutrient, as it has immense health benefits for consumers as well as technical advantages for food manufactures. Fibre can be broken up into two different types: soluble and insoluble fibre. With the right type of fibre at hand, food manufacturers can only benefit from answering the consumer demand on increase fibre products and resolve technical challenges at the same time.

UNDERSTANDING THE TWO TYPES OF FIBRE

Both soluble and insoluble fibres are from plant origin and are important for wellness and their technical functionality in products. Soluble fibre, as the name indicates, are fibres that are soluble in water. There are many different soluble fibres but only 3 have proven to have a prebiotic effect, two of which are Inulin and Oligofructose. The

prebiotic effect of chicory root fibre gives selective increase of bifidobacteria that has been linked to the following health benefit: improved bowel function, blood glucose management, stronger inner defence, improved bone health and body weight management. Prebiotics are valuable for all age groups from infants to the elderly and every stage in between. Savannah offers both these soluble fibres in the Orafti range from Beneo, which are extracted from the chicory root. Not only are these proven prebiotics that aids in a healthy gut microbiome, but they can also be used as technical functional tools in sugar and fat reduction which will also lead to a lower caloric effect on the final product.

content by 30%, giving a more pronounced creamy taste. High performance inulin can be used in sugar free applications with ease to give structure and mouthfeel. Orafti Inulin can also be used in savoury applications for mouthfeel, texture and as a fat replacement in soft cheeses, spreads, and sauces.

ORAFTI: REDUCING SUGAR AND FAT WITH FIBRE