AECI® Specialty Chemicals believes that everyone deserves good hair days without breaking the bank.

Introducing ground-breaking and budget-friendly hair food innovations that change your formulating experience…

• PJ free

• Reduced tackiness

• Moisturizing

Experience the difference with AECI® Specialty Chemicals and embrace the beauty of your hair, everyday!

www.pharmacos.co.za AFRICA Quarter 1 2024

news

Cosmetics & pharmaceutical process innovation

The quest for affordable hair nourishment

Engineering mannitol for optimal excipient performance

How to care for oily skin

www.pharmacos.co.za AFRICA

Quarter 1 2024 Cosmetics & pharmaceutical process innovation news NEXT

Pharmaceutical & cosmetic industry news

contents AFRICA

5 NEWS

Protect cosmetic formulations with Savelite HB

Epax launches first concentrated Omega oil

7 DIARY

What’s on in April, May & June

8 PHARMA FOCUS/TABLETING & ENCAPSULATION

Hemofarm reduces tablet press cleaning downtime

Engineering mannitol for optimal excipient performance

Ensure precision and efficiency in pharma production

15 SKINCARE

Symrise insights into how to care for oily skin

18 HAIR CARE

The quest for affordable hair nourishment

Functional waxes to elevate your formulations

Silicone co-emulsion delivers next level conditioning

Unlock the secrets to caring for textured hair

13 17 19

PREV NEXT

Trends and tech for advanced product development

Welcome to the latest edition of Pharmaceutical & Cosmetic Review Africa! Our content aims to empower brands and businesses with the tools to develop products that resonate with consumers across the continent.

In this issue, we take you to the forefront of process innovation, unveiling the latest trends and formulation technologies shaping pharmaceutical and cosmetic manufacturing. Our magazine is focused on equipping industry professionals with insights into enhancing production efficiency and product efficacy.

Quarter 1 highlights key themes vital to the advancement of tableting and capsule manufacturing. We explore pharma-specific ingredients and cutting-edge equipment tailored for tablets and capsules, providing invaluable knowledge on how to optimise these production processes.

For skincare formulators, we feature a natural active ingredient validated to normalise sebum production and enhance skin sensitivity.

If you’re looking for ideal ingredients to craft innovative and cost-effective hair care solutions, we’ve got your needs covered. Read about waxes and hair food additives tailored to addressing the diverse needs of the African market.

Enjoy this edition!

Natural and Organic Ingredients

• Natural & Organic

FROM THE EDITOR ADVERTISERS’ INDEX AECI SPECIALTY CHEMICALS 1 www.aeciworld.com/specialty-chemicals BRENNTAG SA 12 www.brenntag.com CHEMPACK INDUSTRIES 24 www.cpack.co.za/ CJP CHEMICALS 25 www.cjpchemicals.co.za IMCD SA 22 www.imcdsa.co.za NAUTICA ORGANIC TRADING 4 www.nauticaorganics.com ORISTOVISTA/NSI LABELS 5 www.labelandpack.africa ROMACO HOLDINGS ................................... 9 ........................www.romaco.com SAVANNAH FINE CHEMICALS ...................... 20 ......................www.savannah.co.za SENSETEK 6 www.sensetek.co.za SYMRISE SA 16 www.symrise.com VEGA CONTROLS 14 www.vega.com/radar n

4 QUARTER 1 2024 P&C AFRICA

Protect cosmetic formulations with Savelite HB

SYMRISE COSMETIC

INGREDIENTS has added to its portfolio of beauty ingredients. Savelite® HB is a multifunctional hydroxypropolyester, which can protect all types of cosmetic products targeting normal to sensitive skin. Based on well-known ingredients and harnessing innovative technology, the antimicrobial ingredient offers a range of key benefits to formulators and consumers.

As a clear, colourless and odourless liquid, Savelite HB enhances product protection by acting against microorganisms and oxidation. As a cold-processable ingredient, it also allows for easy handling, and saves time and energy during production. Offering the functionality of proprietary ingredients, Savelite HB builds on well-established propanediol and benzoic acid molecules. The introduction of this ingredient, 10 years after the launch of the revolutionary SymSave® H, sees Symrise broaden its toolbox for formulators.

While enabling the formulation of safer products, Savelite HB also acts as an efficient moisturiser. In vivo corneometer testing shows an increase of 10.9% after two weeks. It fully respects the skin microbiome. Further, it can help stabilise emulsions by reducing oil droplet size.

The ingredient also meets Symrise’s sustainability targets. Readily biodegradable, Savelite HB is produced via a sustainable manufacturing process aligned with the principles of green chemistry.

“Symrise has been leading the way on innovations in cosmetic product protection for more than 30 years,” says Sabrina Mizaël, senior global product manager, Cosmetic Ingredients at Symrise.

“Thanks to this new technology made from well-known ingredients, we are increasing the diversity of our product protection solutions. This enables us to support our customers in their formulation processes. We are also helping to minimise the impact of our industry on the environment.”

Symrise will introduce Savelite HB at in-cosmetics Global, taking place in Paris, France, from 16 to 18 April.

NEWS 5 QUARTER 1 2024 P&C AFRICA www

While enabling the formulation of safer products, Savelite HB also acts as an efficient moisturiser

REFERENCE:

1. Pilkington et al, 2011

Flavors & Fragrances

NEWS

THE TEAM

EDITORIAL

Editor: Abby Vorster

(0)71 359 4519

abby.vorster@newmedia.co.za

Layout & Design: Andipha Nkoloti

Contributors: Jan Clement, Graeme Macleod, Wayne Camarco, Léa Schmidt, Martina Herrmann, Roné Rudman

ADVERTISING

Key Account Manager: Carla Melless +27 (0)83 260 6060 carla.melless@newmedia.co.za

INTERNATIONAL SALES

Germany/Austria/Switzerland: Eisenacher Medien Erhardt Eisenacher +49 228 249 9860 info@eisenacher-medien.de

Italy:

Ngcombroker

Giacomo Rotunno +39 370 101 4694 g.rotunno@ngcombroker.com

Taiwan: Ringier Trade Media Sydney Lai +886 4 2329 7318 sydneylai@ringier.com.hk

CIRCULATION

Circulation Manager: Felicity Garbers felicity.garbers@newmedia.co.za

PUBLISHING TEAM

General Manager: Dev Naidoo

Group Account Director B2B Johann Gerber johann.gerber@newmedia.co.za

Production Manager: Mandy Ackerman

Group Art Director: David Kyslinger

JOHANNESBURG OFFICE

New Media, a division of Media24 (Pty) Ltd, Ground Floor, 272 Pretoria Avenue, Randburg, 2194

MANAGEMENT TEAM

CEO, New Media: Aileen Lamb

Commercial Director: Maria Tiganis

Strategy Director: Andrew Nunneley

Chief Financial Officer: Venette Malone CEO, MEDIA24: Ishmet Davidson

HEAD OFFICE

New Media, a division of Media24 (Pty) Ltd 8th floor, Media24 Centre, 40 Heerengracht, Cape Town, 8001 +27 21 406 2002

newmedia@newmedia.co.za

PO Box 440, Green Point, Cape Town 8051

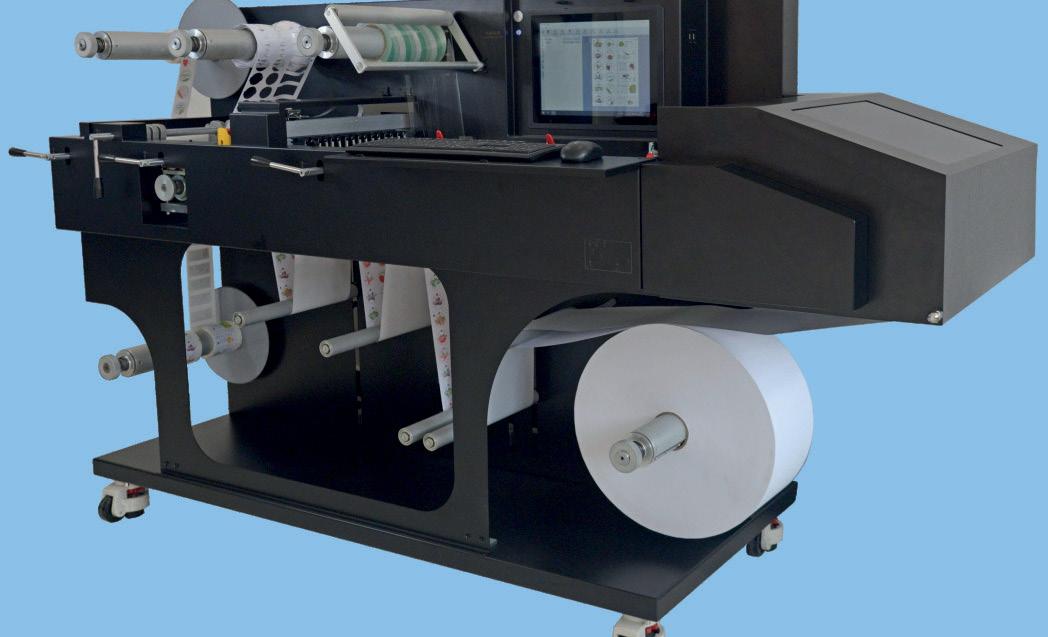

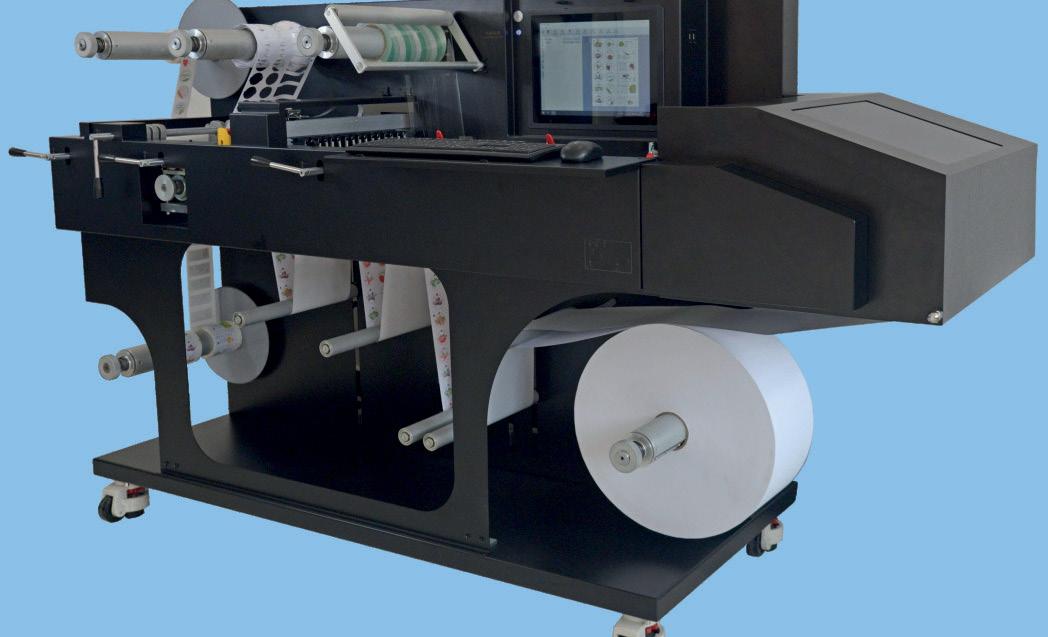

DIARY WHAT'S ON IN April May Natural & Organic Products Europe 14 to 15 April London, UK www.naturalproducts.co.uk in-cosmetics Global 16 to 18 April Barcelona, Spain www.in-cosmetics.com/global CPHI Japan 17 to 19 April Tokyo, Japan www.cphi.com/japan Pharma West Africa 8 to 10 May Accra, Ghana www.pharma-westafrica.com Vitafoods Europe 14 to 16 May Geneva, Switzerland www.vitafoods.eu.com Coschem JHB Supplier Day 15 May Joburg, South Africa www.coschem.co.za Propak China 19 to 21 June Shanghai, China www.propakchina.com Chemspec Europe 19 to 24 June Düsseldorf, Germany www.chemspeceurope.com June 2024 Pharmaceutical Cosmetic Review Africa is published by New Media four times year and circulates to manufacturers, packers and distributors of pharmaceuticals, health products, cosmetics, detergents, soaps, toiletries and allied products. The journal is an up-to-date source of reference for company directors, factory and production managers, marketing executives, engineers, import agents, buyers and research personnel. While precautions have been taken to ensure the accuracy of its contents and information given to readers, neither the editor, publisher, or its agents can accept responsibility for damages or injury which may arise therefrom. All rights reserved. © Pharmaceutical Cosmetic Review Africa No part of this publication may be reproduced, stored in retrieval system or transmitted in any form or by any means, photocopying, electronic, mechanical or otherwise without the prior written permission of the copyright owners.

by New Media, a division of Media24 (Pty) Ltd. Copyright: all rights reserved.

Published

+27

7 QUARTER 1 2024 P&C AFRICA

Hemofarm reduces tablet press cleaning downtime with Romaco technology

Serbia’s largest pharmaceutical company, Hemofarm has dramatically reduced the cleaning-related downtime of two KTP 420X and KTP 590X high-speed presses at its headquarters in Vršac. By Jan Clement, sales director, Romaco Kilian

Hemofarm has an extensive product portfolio, resulting in frequent product changes coupled with diverse production requirements within the manufacturing facility. This makes quick and easy cleaning of its tablet presses a necessity for the Serbian pharmaceutical manufacturer.

The generics producer relies on Romaco Kilian’s simple-to-clean machine design. By using quickchange parts and additional identical die tables, Hemofarm has heavily reduced the cleaning-related downtime of its KTP 420X and KTP 590X high-speed presses.

Hemofarm is a market leader in the Serbian pharmaceutical industry and the country’s largest exporter of drugs. It manufactures both proprietary drugs and pharma products for the STADA Group, many of them on its two KTP 420X and 590X tablet presses from Romaco Kilian. The KTP 420X achieves a maximum output of 360 000 mono-layer tablets per hour. With a maximum hourly output of 511 200 tablets, the KTP 590X was developed for fast changeover between mono- and bi-layer production, and for the high-speed production of effervescent tablets.

The demands placed on the tablet presses are exceptionally diverse – more than 200 pharmaceutical

products with very different formulations are manufactured in batch sizes from 100kg to 2 200kg. Compression forces between 5kN to 80kN are possible, and the ingredients can be either processed in the form of wet or dry granules or directly compressed. One or two product changes per week take place on the KTP 590X and about three or four on the KTP 420X, making intensive cleaning of the tablet processing areas and the productcontacted press parts a must. On top of this, partial cleaning is carried out between batches of the same product.

Did you know

Hemofarm produces more than 6.6 billion tablets and capsules annually. Since 2006, the manufacturer has been a part of the German STADA Group, which is one of the world’s biggest generic pharmaceutical firms.

8 QUARTER 1 2024 P&C AFRICA

Hemofarm is Serbia’s largest pharmaceutical company and part of the STADA Group (Image: Hemofarm)

PHARMA FOCUS/TABLETING & ENCAPSULATION

Hemofarm currently has eight Romaco Kilian tablet presses in total (Image: Hemofarm)

Less components than other presses

Romaco Kilian’s modern tablet presses have far fewer components than conventional models in compaction. Less components is decisive for cleaning and a major advantage in everyday production.

“The small number of productcontacted parts, optimised hygiene concept and various special features like the patented closed punch bellows turn

The Kilian presses have proven to be very versatile, robust and reliable in our day-to-day work

cleaning a KTP series press into child’s play,” explains Ivan Djokic, production manager at the Hemofarm site in Vršac. “The interchangeable parts are lightweight and can be dismantled without tools; resinserting them is also straightforward. Our machine operators say ‘it’s a pleasure working with the Kilian presses’.”

Even the fill shoe can be removed by a single person without any problem because the gearbox is located outside the compaction area. Apart from the die table, all the interchangeable parts of the Kilian presses weigh less than 15kg.

Hermetically sealed compaction area

The compaction and service areas on the Kilian KTP 420X and 590X presses are strictly separated, so that tablet dust is prevented from penetrating the machine cabinet. The compaction area is very small and reminiscent of a hermetically sealed, stainless-steel cage. The surface area for cleaning has been

reduced by about a third, resulting in significantly shorter cleaning times.

All presses in Kilian’s KTP series have a very small footprint owing

to their compact design and small window areas, for example 1 080mm x 1 115mm for the KTP 420X or no more than 1 230mm x 1 325mm for the KTP

M CM MY CY CMY 9 QUARTER 1 2024 P&C AFRICA

PHARMA FOCUS/TABLETING & ENCAPSULATION

A single machine operator requires just 10 to 15 minutes to install the interchangeable parts and the die table (Image: Hemofarm)

The use of identical die tables helps optimise the OEE and TCO of the tablet press (Image: Romaco)

590X. If the windows are opened, the KTP 420X measures a mere 2 303mm x 2 268mm while the KTP 590X measures 2 567mm x 2 472mm. Thanks to the economical use of space, energy consumption in the cleanroom is proportionally less, leading to sustainably lower running costs.

Cleaning in batch mode

Extra die table increases availability

To further reduce downtime during product changes, Hemofarm uses a second identical die table for each of the two tablet presses in addition to the quick-change parts.

The two sets of interchangeable parts used by Hemofarm for both tablet presses include the fill shoe, tablet scraper, upper punch cover, suction nozzles and cover between the pressure roller blocks. These parts are kept ready in a closed transfer trolley and are installed in the processing area of the tablet presses in the event of a product change. The parts removed following the previous batch are cleaned while manufacturing the next batch.

“People often underestimate the impact of an identical die table when it comes to optimising the OEE and TCO of a tablet press,” comments Gerd Heinen, Romaco Kilian’s area sales manager responsible for Hemofarm. “By investing in identical die tables, Hemofarm is demonstrating a pioneering approach.”

The die tables are cleaned by removing the upper cam track together with the upper and lower punches, while the lower cam track remains in the compaction area. To prevent dust from getting into the machine’s ‘grey’ area during cleaning, a blind cover is fitted after removing the die table. The punches, dies and other interchangeable parts are cleaned in an industrial washing machine. The die table itself is manually cleaned at Hemofarm. Only one Hemofarm employee is responsible for the complete product change cycle, including cleaning the interchangeable parts and the die table. Approximately six hours are needed for this change cycle.

Only 10 to 15 minutes are required to install the exchanged parts along with the die table. Between two batches of the same product, the tablet presses are partially cleaned using a vacuum cleaner as per the cleaning validation. The die table, dies, and punches as well as all other product-contacted parts remain in the compaction area, and only the fill shoe and inlet funnel are dismantled. This partial cleaning process can be completed in approximately one hour.

Versatile, robust and reliable Hemofarm has been using Romaco Kilian technologies since 2002, and currently has a

total of eight Kilian tablet presses operating at its five production sites. The KTP series single-sided rotary presses in Vršac run in three shifts, either five (KTP 420X) or seven (KTP 590X) days a week.

“The Kilian presses have proven to be very versatile, robust and reliable in our day-to-day work,” Djokic reports. “And if any service issues arise, we also benefit from the Kilian team’s short response times and competent support – with Romaco, the customer really is king, and that’s something we very much appreciate.”

Romaco Kilian – www.romaco.com/products/tableting

PHARMA FOCUS/TABLETING & ENCAPSULATION

The KTP 590X high-speed press is in use at Hemofarm 24/7 and is completely retooled and cleaned once or twice a week (Image: Romaco)

Hemofarm reduces cleaning time by using identical die tables, which are simply exchanged at the end of a batch (Image: Hemofarm)

Engineering mannitol for optimal excipient performance

Graeme Macleod and Wayne Camarco of SPI Pharma explore how the excipient manufacturer has engineered compendial mannitol to make it more suitable for orally dispersible applications.

Regulators continue to insist that formulators consider patient centricity during drug development. As such, the organoleptic properties of the final dosage form must be considered at the start of any project. There has been a significant increase in the number of patient-centric dosage forms reaching the market, with examples including orally dispersible (ODTs) and chewable tablets that meet the requisite targets of being ‘pleasant to take’. Despite the evolving requirements of patients and regulators alike, the introduction of excipients that enable formulators to meet these objectives has been minimal.

SPI Pharma was the first company to launch a co-processed excipient that, for the first time, enabled the formulation of a directly compressible blend of active pharmaceutical ingredients (APIs) and excipients, which met the requirements of ODT development. Pharmaburst could withstand downstream processing while disintegrating quickly in the mouth. It also imparts a positive patient experience. The utility of such excipients

could be further enhanced if formulators had access to a monographed compendial excipient with all the benefits of a co-processed system. With this in mind, SPI Pharma set about to develop such an excipient.

Innovating with mannitol

Mannitol is widely used as an excipient in oral dosage form development because of its low hygroscopicity and high stability or inertness.

It has extremely pleasant organoleptic properties, a mild sweetness and exerts a minor cooling effect as it solubilises in saliva.

These beneficial properties make it a preferred excipient in ODT formulations

many of the requisite attributes to support the move to patient-centric dosage forms, one barrier to its ubiquitous use is its relatively low ability to be tableted.

However, if the tabletability of mannitol could be enhanced, along with its inherent stability, inertness and pleasant organoleptics, the resultant product would be an ideal universal excipient for orally dispersed compressed tablets.

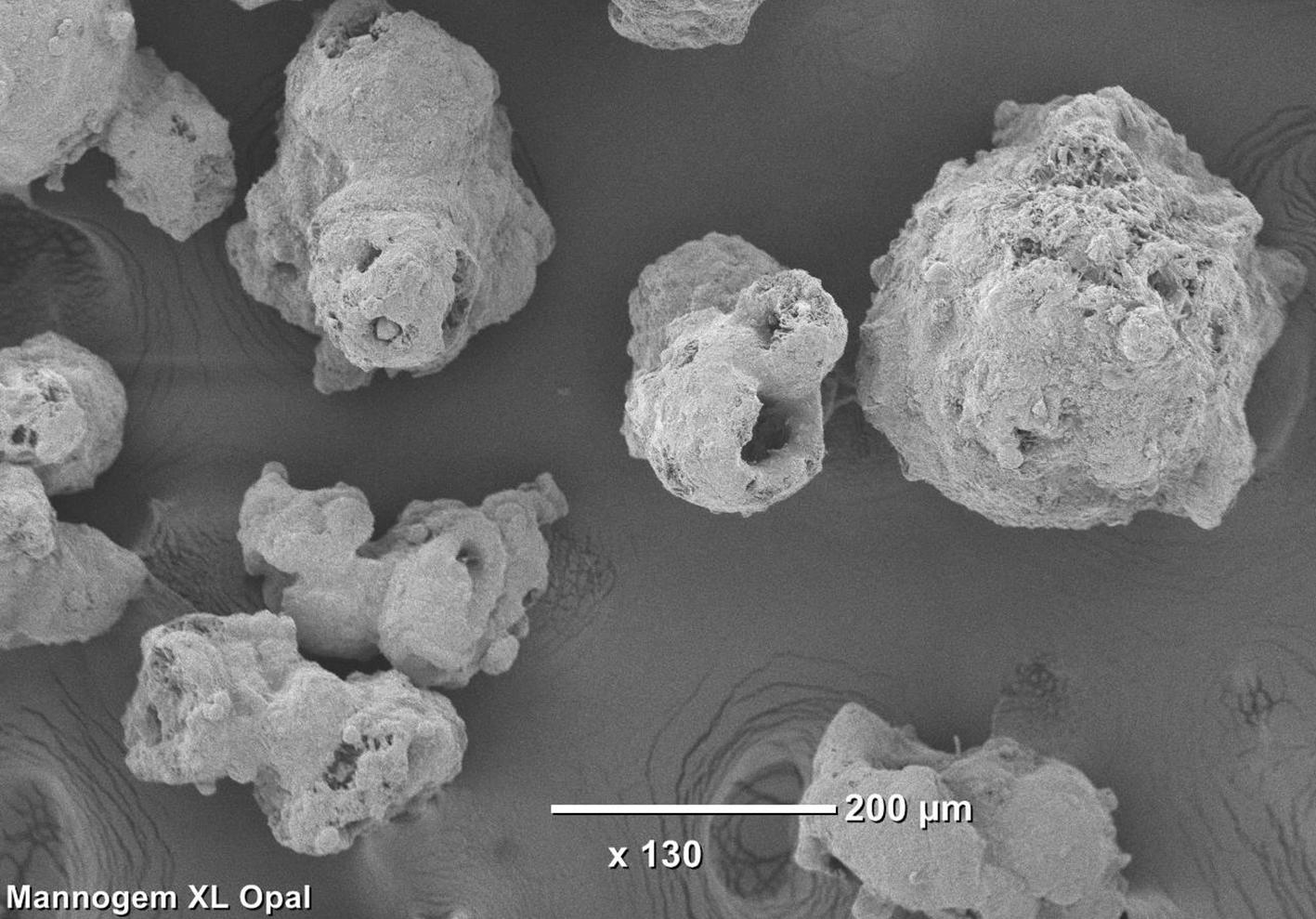

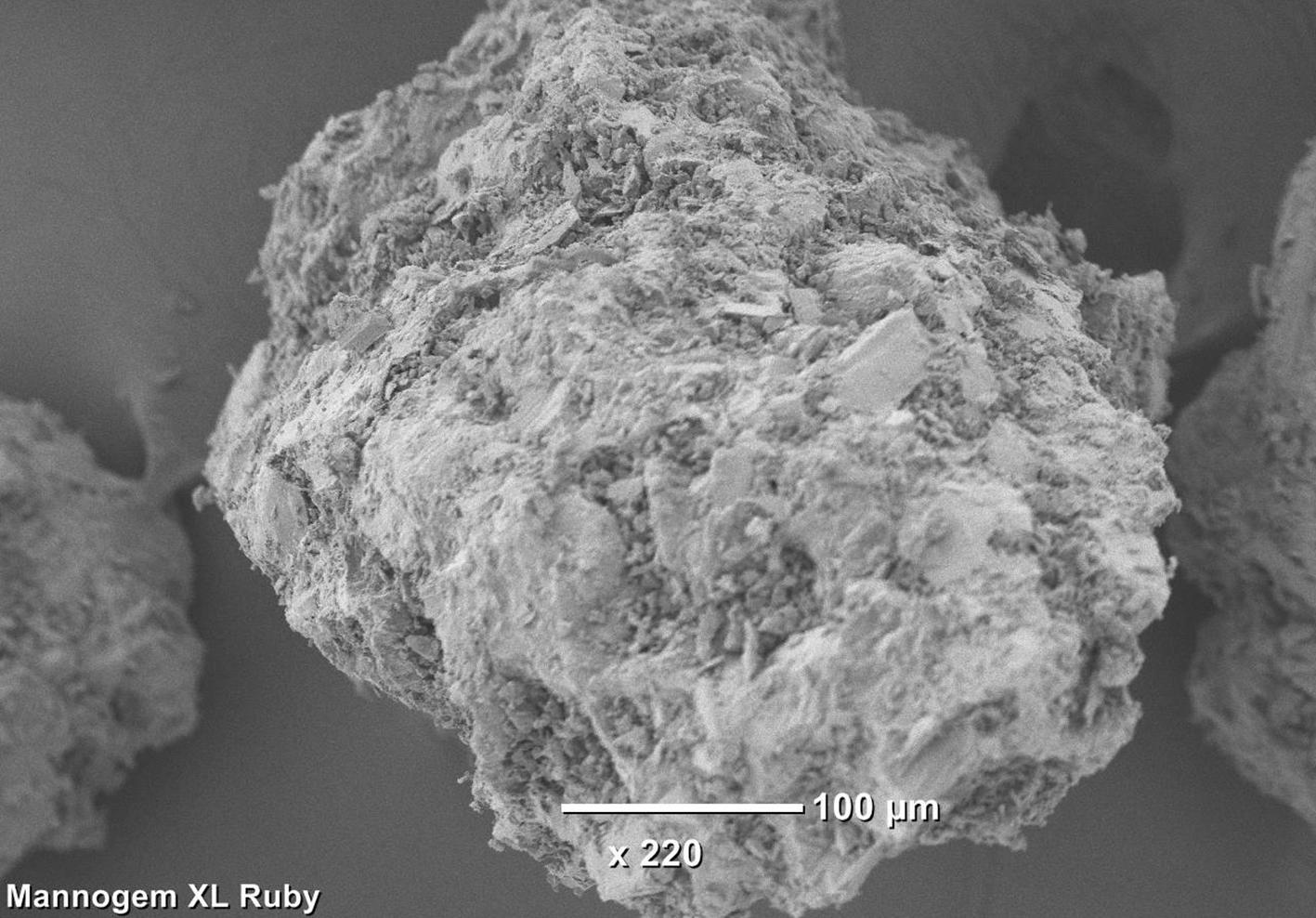

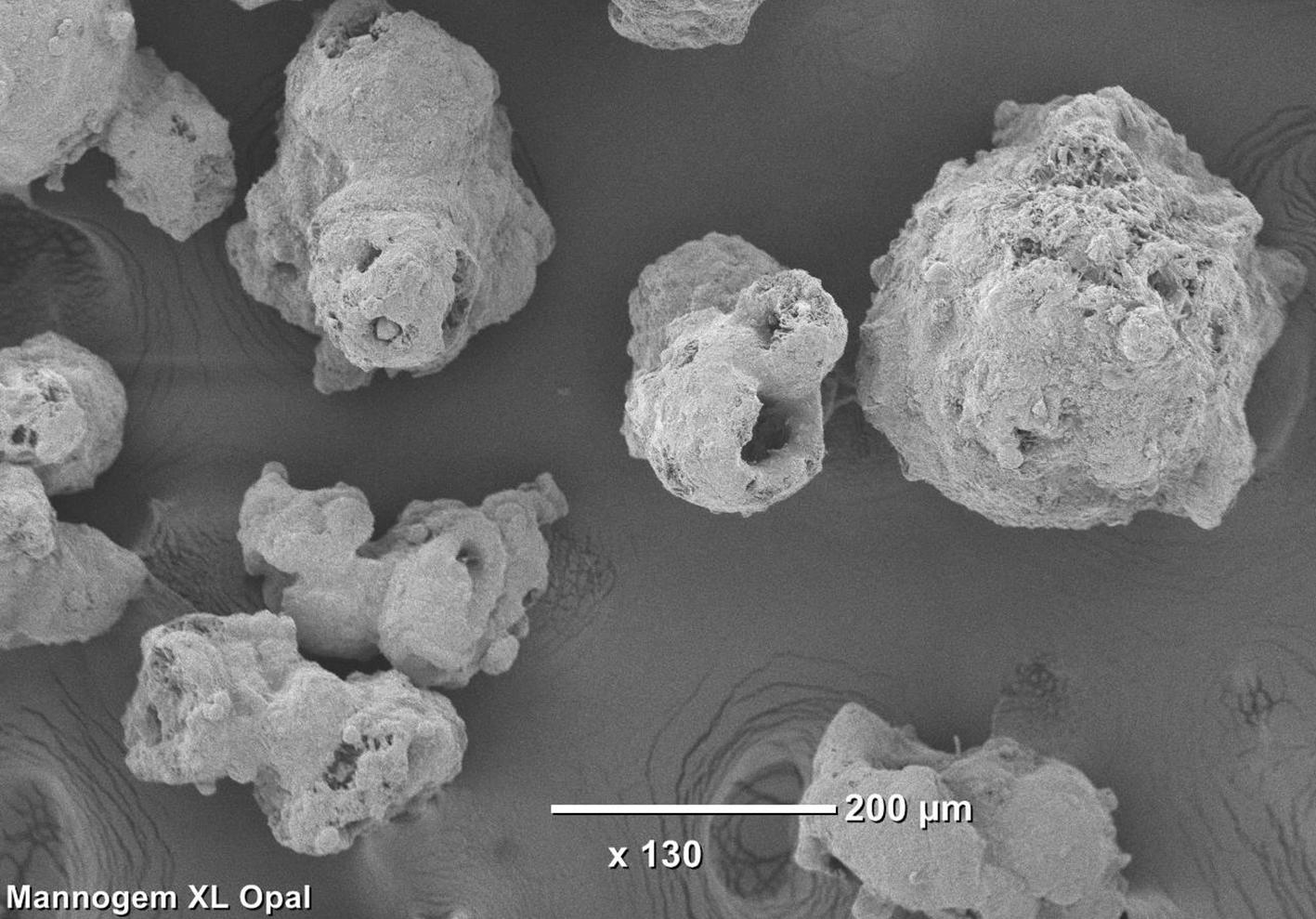

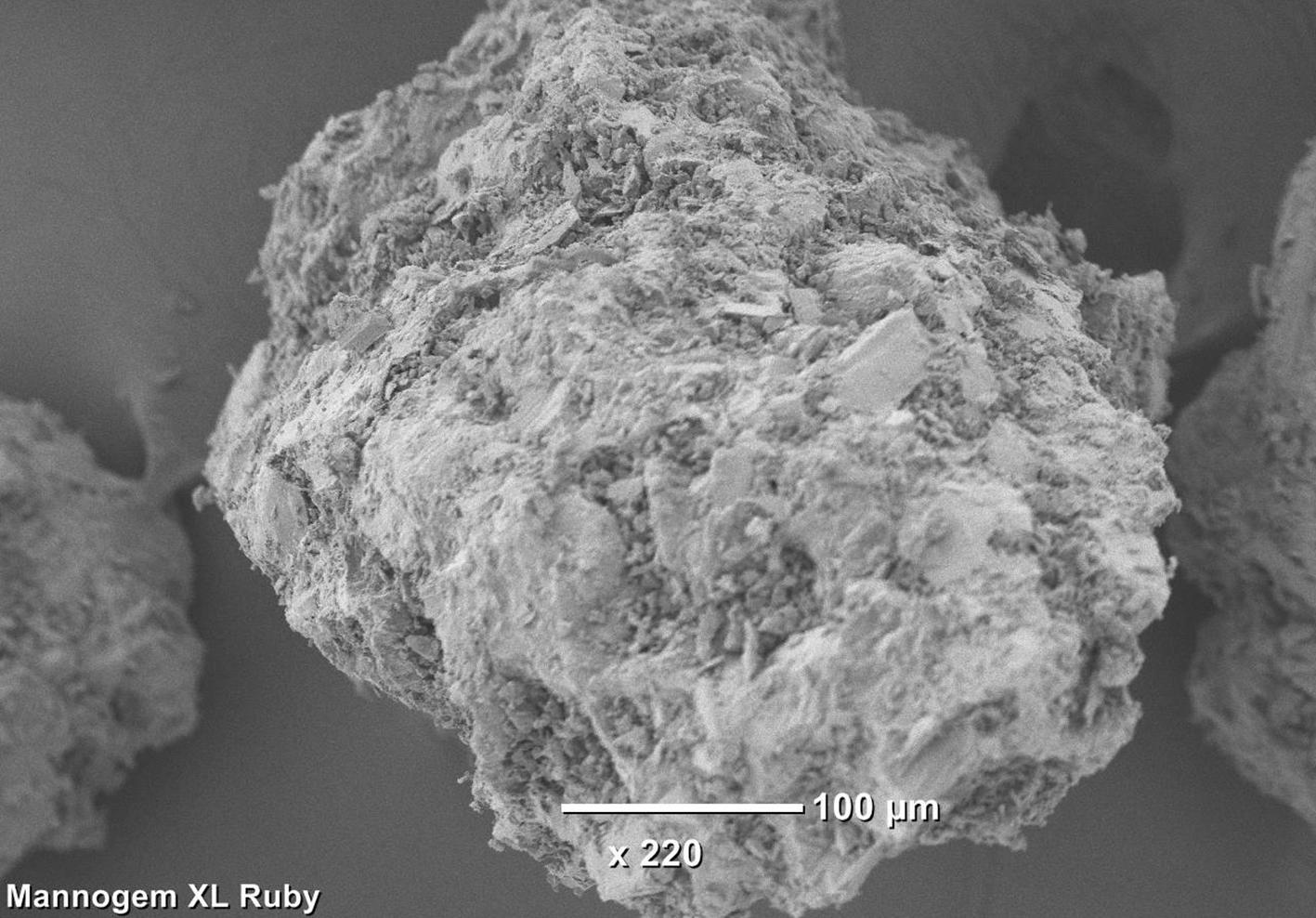

After extensive R&D, SPI Pharma scientists invented a technology known as Mannogem XL. From this, they recently launched two versions of

these new grades are the realisation of novel compendial excipients that have been developed with innovative drug development and patient needs in mind

11 QUARTER 1 2024 P&C AFRICA Product Main application d50 (µm) Bulk density (g/ml) Bulk density (g/ml) Mannogem XL Opal Direct compression ODTs, and swallowable and chewable tablets 160 0.52 0.45 Mannogem XL Ruby Direct compression ODTs, chewable tablets with larger MUPs, or taste-masked APIs where segregation is an issue 300 0.65 0.57

Figure 1

PHARMA FOCUS/TABLETING & ENCAPSULATION

Figure 1 illustrates the physical properties of Mannogem XL Ruby and Opal

Mannogem XL mannitol – Mannogem XL Ruby and XL Opal, which they believe offer formulators an excipient that not only meets existing monograph needs but has also significantly improved the applicability of mannitol.

Mannogem XL Ruby

Taste masking is an absolute must for certain APIs, which can be bitter or astringent in nature and would have a negative impact on patient centricity.

In most cases, the taste masking approach requires the application of a polymeric membrane to granules of the drug to help mask the unpleasant taste. As a result of these taste

masking techniques, the resultant particles can be quite large and dense, which can subsequently cause segregation of the active particles from the rest of the blend.

By matching the taste masked API particle with a larger particle-sized excipient with a higher density, it is possible to overcome segregation. Yet until now, such grades of mannitol where characterised by lower tabletability in comparison to the smaller particle-sized spray dried grades.

Overcoming this challenge, Mannogem XL Ruby combines the large particle size of a granular mannitol with the tabletability of a spray dried material.

Mannogem XL Opal

By extending the same XL functionality to a spray dried product, Mannogem XL Opal expands the utility of mannitol and makes it much more compressible.

The superior tabletability of Opal enables formulators to develop products with a drug loading capacity that was not previously possible. It also simplifies formulation by negating the need to use other binders, which can negatively affect organoleptics.

In conclusion, these new grades are the realisation of novel compendial excipients that have been developed with innovative drug development and patient needs in mind.

Mannogem XL Ruby and XL Opal are available in South Africa from Brenntag, the approved distributor of SPI Pharma.

Solving formulation challenges using superior functional materials

Distributor in South Africa natalie.macgregor@brenntag.com brenntag.com

SPI Pharma provides the innovative solutions our global pharmaceutical and nutritional customers need to succeed. We can help you solve even the most challenging formulation problems – efficiently, cost-effectively and with a focus on service. SPI Pharma – www.spipharma.com/en/ Brenntag South Africa – www.brenntag.com/en-za

12 QUARTER 1 2024 P&C AFRICA PHARMA FOCUS/TABLETING & ENCAPSULATION

Figure 3: Mannogem XL Ruby SEM

Figure 2: Mannogem XL Opal SEM

Ensure precision and efficiency in pharma production

VEGA, with its proven portfolio of instrumentation, is a trusted partner for plant operators worldwide, ensuring optimal performance even under the strictest regulations and harshest conditions.

The world of pharmaceutical production demands the utmost in reliability, accuracy and hygiene. From mixing and filling to autoclaving and cleaning, every step of the process hinges on precise monitoring and control.

VEGA introduced its new compact instrument series, specifically designed to address the needs of standard applications in the pharmaceutical industry. These instruments offer a perfect blend of compactness, flexibility, hygiene, and ease of use, without compromising on the renowned reliability and performance associated with the VEGA brand.

Hygienic sensors and switches

The VEGABAR series of pressure sensors and switches caters to various standard pressure measurement applications. Their compact size and flexible design make these sensors ideal for space-constrained environments, while their hygienic construction ensures product purity and simplifies cleaning procedures. Additionally, integrating IO-Link communication facilitates seamless data transfer and system integration.

The VEGAPOINT series of level switches offer adaptability and user-friendliness for diverse level measurement tasks. Their intuitive operation and clear status display enable operators to react quickly to process changes, while their robust design ensures reliable performance even during rigorous CIP and SIP cleaning processes.

The VEGAPULS 42 is an ideal sensor for non-contact level measurement of liquids and bulk solids in simple to moderate applications. The optional universal connection for hygienic adapters ensures reduced installation effort and leaner stockkeeping while fulfilling the requirements of hygienic processes in the pharmaceutical and food and beverage

industries. With IO-Link, it offers continuous digital data transmission.

Value-adding advantages

The benefits of VEGA’s new compact instrument series extend far beyond the instruments themselves. The advantages include:

• Increased process efficiency with reduced downtime and optimised production.

VEGAPULS 42 is an ideal sensor for non-contact level measurement of liquids and bulk solids

13 QUARTER 1 2024 P&C AFRICA

PHARMA FOCUS/TABLETING & ENCAPSULATION

With

its proven portfolio of instrumentation, VEGA is a trusted partner for plant operators worldwide

Additional features of Vega’s new instrument series:

• 360° switching status display to nsures quick identification of process changes from any direction.

• Wireless communication that simplifies setup and operation, particularly in cleanroom environments.

• Proven track record resulting from decades of experience gained in serving the pharmaceutical industry with reliable instrumentation.

cycles, which translate into significant cost savings.

• Enhanced product quality thanks to consistent and reliable measurements, which ensure adherence to strict quality standards.

• Simplified maintenance resulting from the easy installation, configuration and maintenance, minimising disruptions and resource allocation.

• Lower costs due to reduced spare parts inventory and operational expenses, which contribute to improved bottom-line performance.

Solutions tailored to your needs

VEGA goes beyond simply providing instruments. The supplier offers a modular platform that allows for tailored solutions to meet your specific needs, ensuring a perfect fit for your unique production environment.

Its complete offering encompasses both level and pressure measurement, eliminating the need to deal with multiple vendors. With experienced engineers available worldwide, VEGA provides unparalleled global support throughout the entire lifecycle of your instrumentation.

Partnering with VEGA means choosing a reliable supplier dedicated to your success in the demanding world of pharmaceutical production. Experience the positive impact VEGA’s expertise and innovative solutions can have on your operations.

Contact VEGA today to learn more about its complete solutions and how they can optimise your pharmaceutical production processes.

MINIMAL EFFORT FOR MAXIMUM PROCESS HYGIENE. THE 6X ®. FROM VEGA. For level applications with maximum hygienic standards, perfection can be achieved with extensive cleaning or, make it simple, just use a VEGAPULS 6X radar level sensor. Made for all media, all ambient conditions and, most importantly, for uncompromising levels of hygiene. VEGA. HOME OF VALUES. www.vega.com/radar

www.vega.com/en-za

VEGA –

various

PHARMA FOCUS/TABLETING & ENCAPSULATION

The

VEGABAR series of pressure sensors and switches caters to

standard pressure measurement applications

14 QUARTER 1 2024 P&C AFRICA

How to care for oily skin

Léa Schmidt and Martina Herrmann of Symrise unpack a natural active ingredient proven to normalise sebum production and improve skin sensitivity. SymControl® Care has been shown to influence the origin of sebum and skin sensitivity to support a reduction of sebum production in all skin tones, including the darker skins such as phototypes IV to VI.

The link between oily skin and skin sensitivity is not always well-defined. Yet oiliness is described as the second sign of skin sensitivity, after dryness. The sensitivity of oily skin has increased over the past few years. Both issues affect all skin tones, but darker skins are especially prone to oiliness and sensitivity.1

Oily skin and skin sensitivity are closely linked. Indeed, excessive sebum secretion can cause acne and increase skin sensitivity due to harsh skin treatments. A vicious cycle then takes place – the exposome increases skin sensitivity, leading to sebum overproduction. This and the oxidation of excess sebum creates skin inflammation.

In this article, we discuss the action of SymControl® Care (INCI: Water (and) Glycerin (and) Tetraselmis Suecica Extract), a natural and microbiome-friendly ingredient containing an extract of marine microalgae, Tetraselmis suecica. Originally isolated from the Mediterranean Sea, the microalgae are now sustainably cultivated under controlled conditions using outdoor solar energy.

The ingredient is a sebum and sensitivity normaliser for oily skin and helps to reduce COX-2 expression in sebocytes. It has been previously shown to support the reduction of sebum levels in an ex vivo skin model of human sebaceous glands, and to prevent pollution damage by strengthening the skin barrier.

MATERIALS AND METHODS –SymControl® Care

SCOX-2 expression reduction

In vitro modulation by the Tetraselmis suecica extract of prostaglandin-endoperoxide synthase 2 (PTGS2) – also known as cyclooxygenase 2 (COX-2) – gene expression was investigated using human sebocytes. This enzyme not only plays an important role in sebum production but also in skin sensitivity.

Primary human sebocytes were incubated with test products for 24 hours, followed by extraction, purification and reverse-transcription of total RNA.

Sebum level reduction of all skin tones

In vivo trials were performed on two groups of 15 volunteers with light skin (female and male, phototypes I to III, 19 to 60 years old, with slight to pronounced oily skin), and on one group of

SKINCARE

15 QUARTER 1 2024 P&C AFRICA

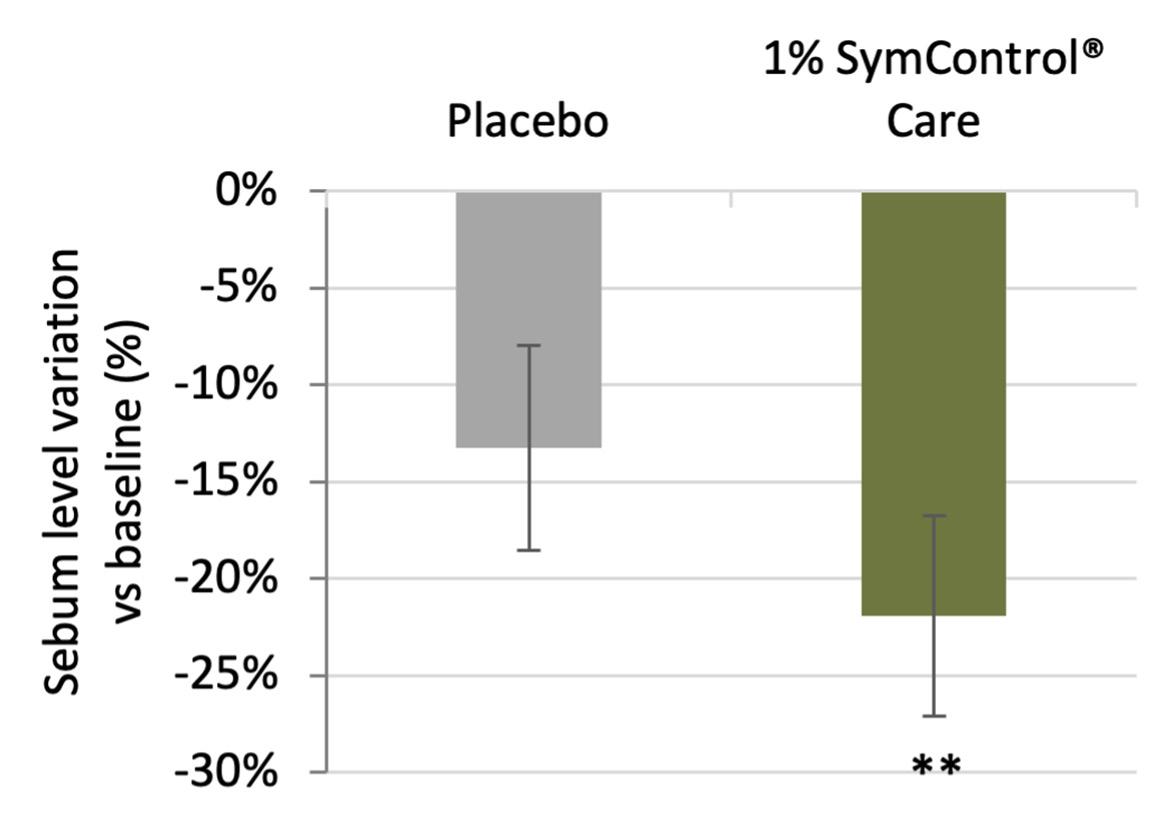

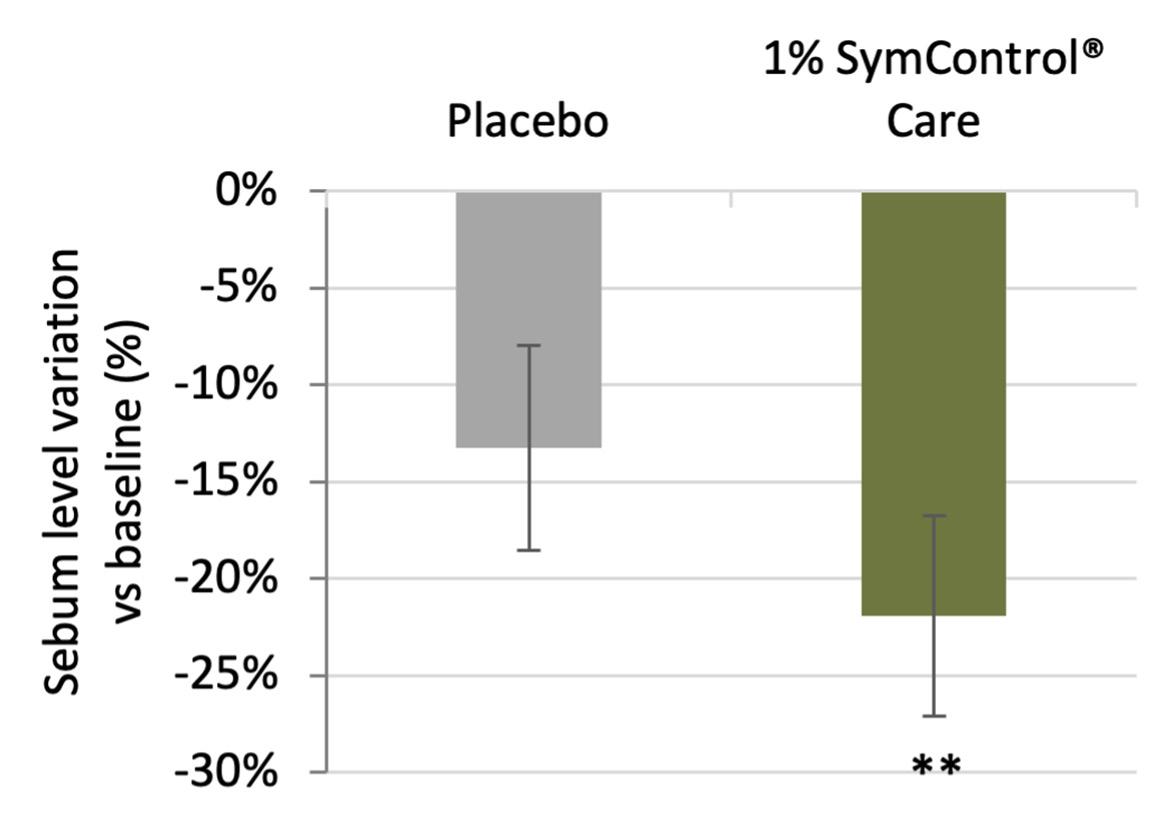

30 volunteers with darker skin (female and male, phototypes V to VI, 19 to 40 years old, with slight to pronounced oily skin).

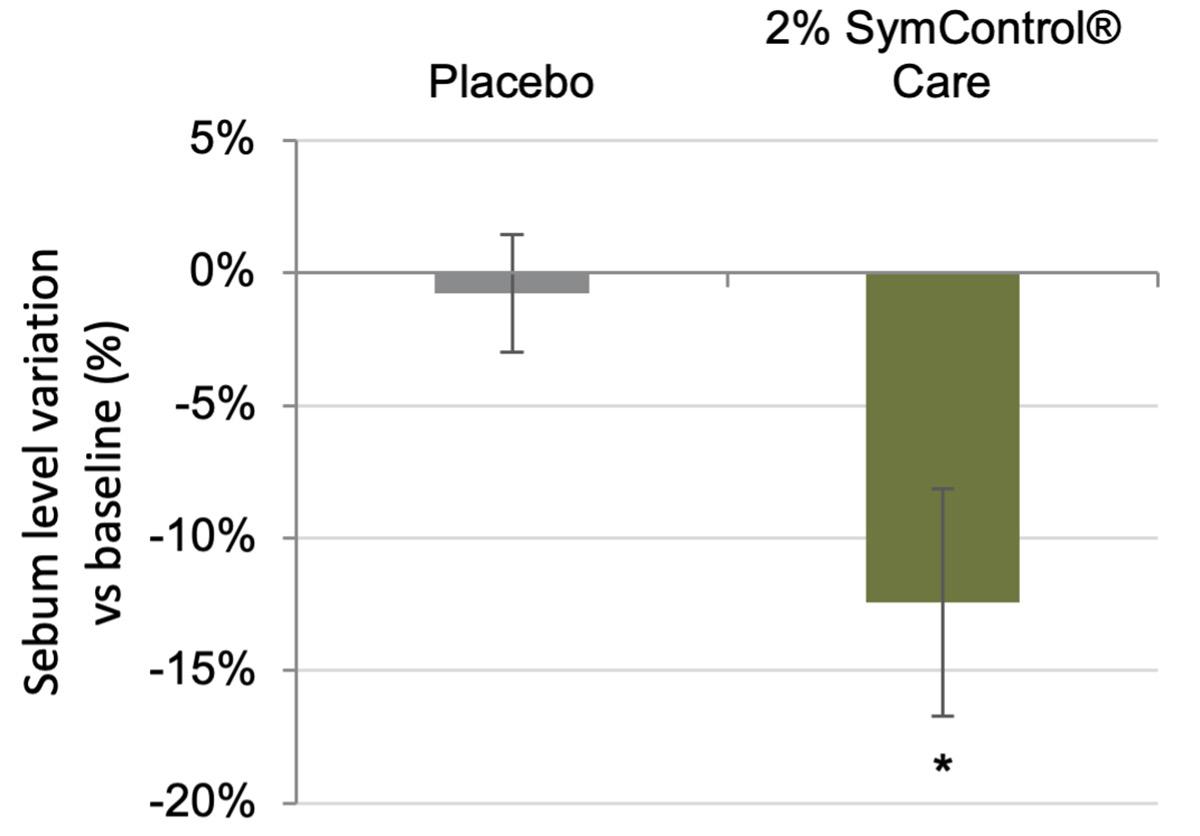

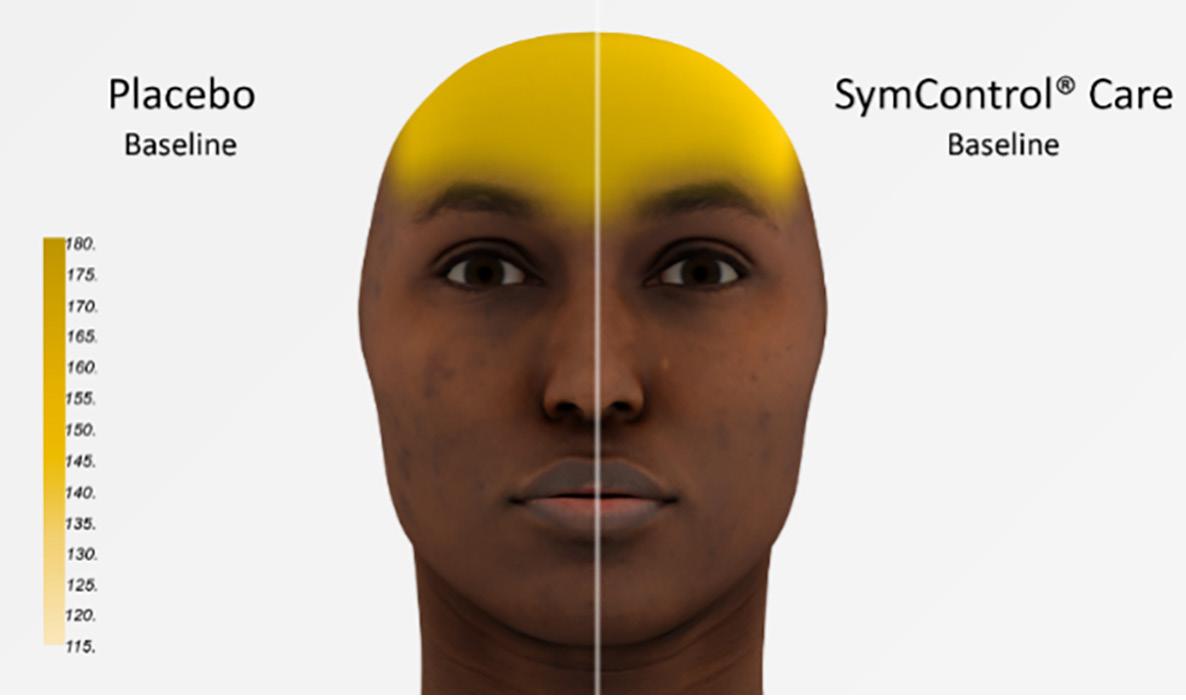

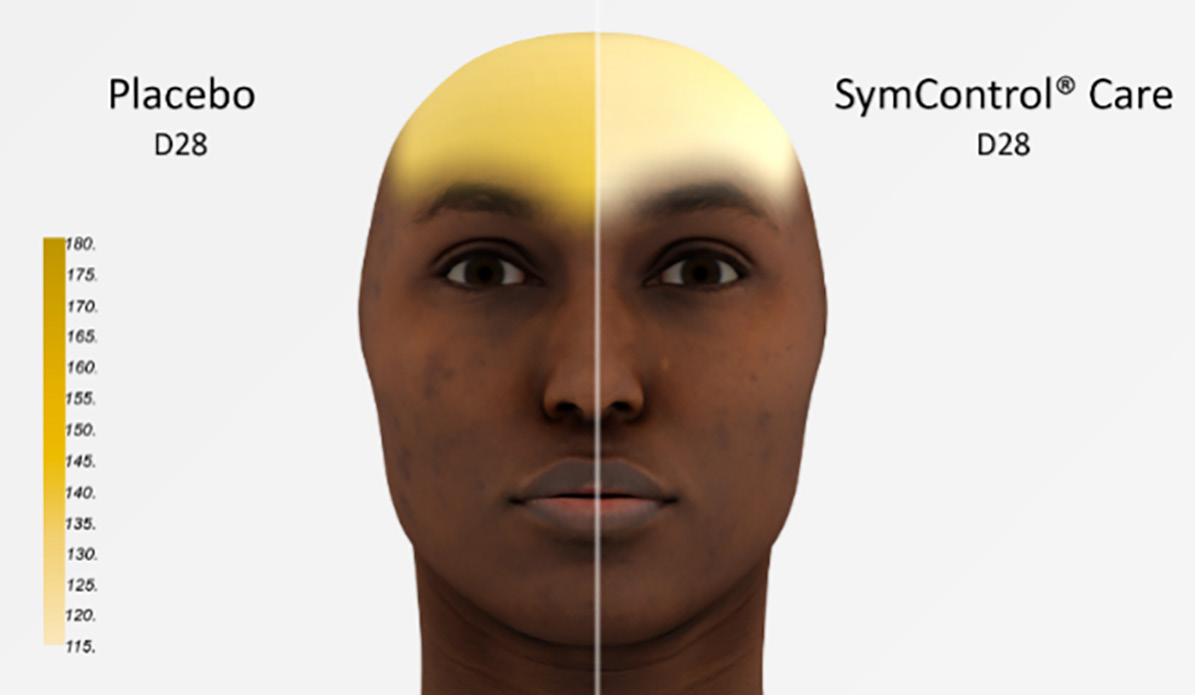

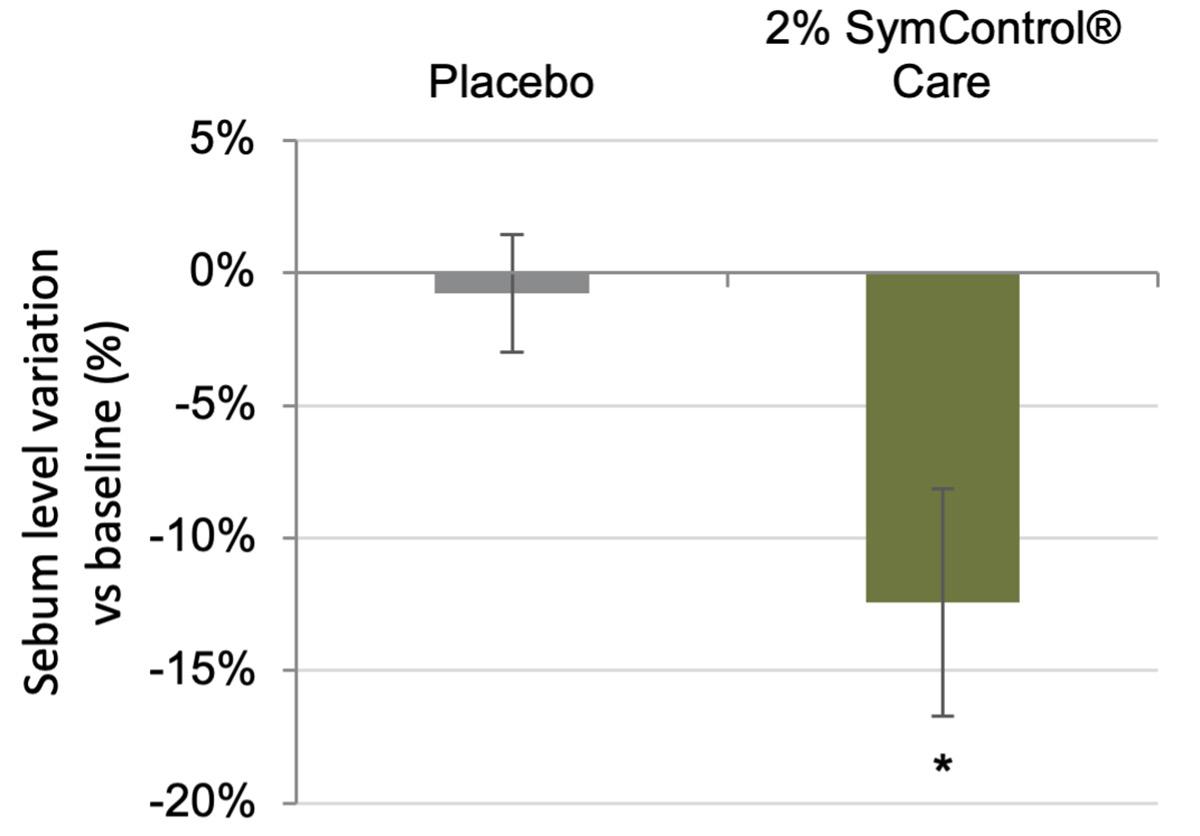

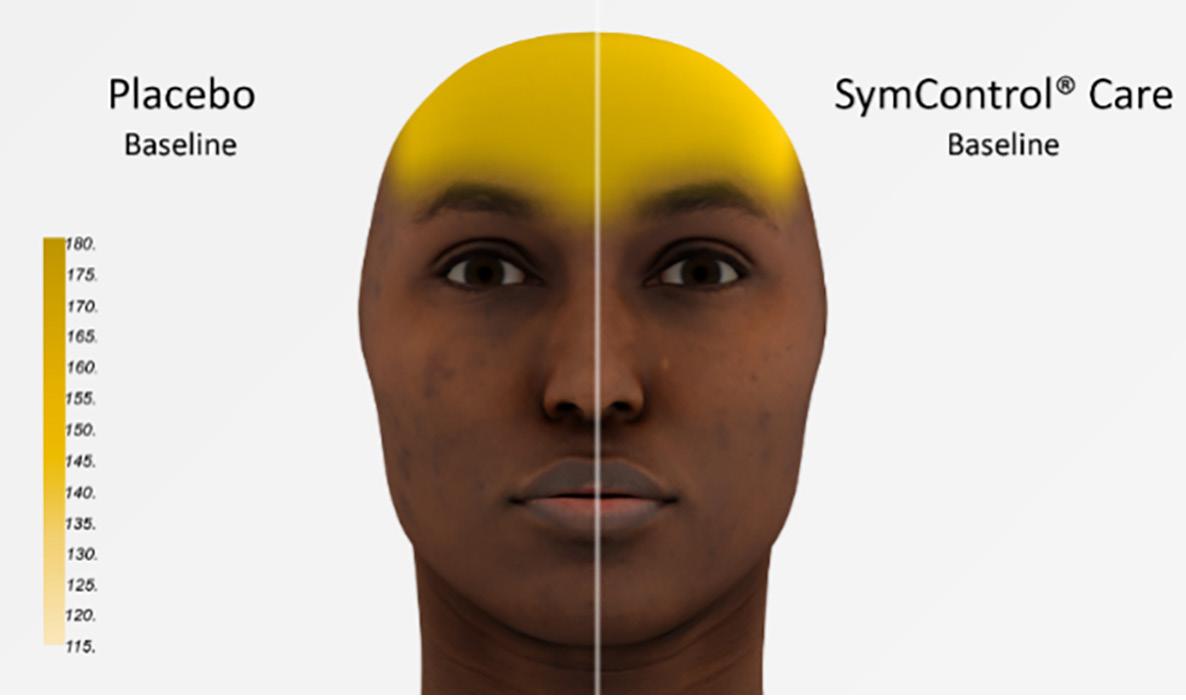

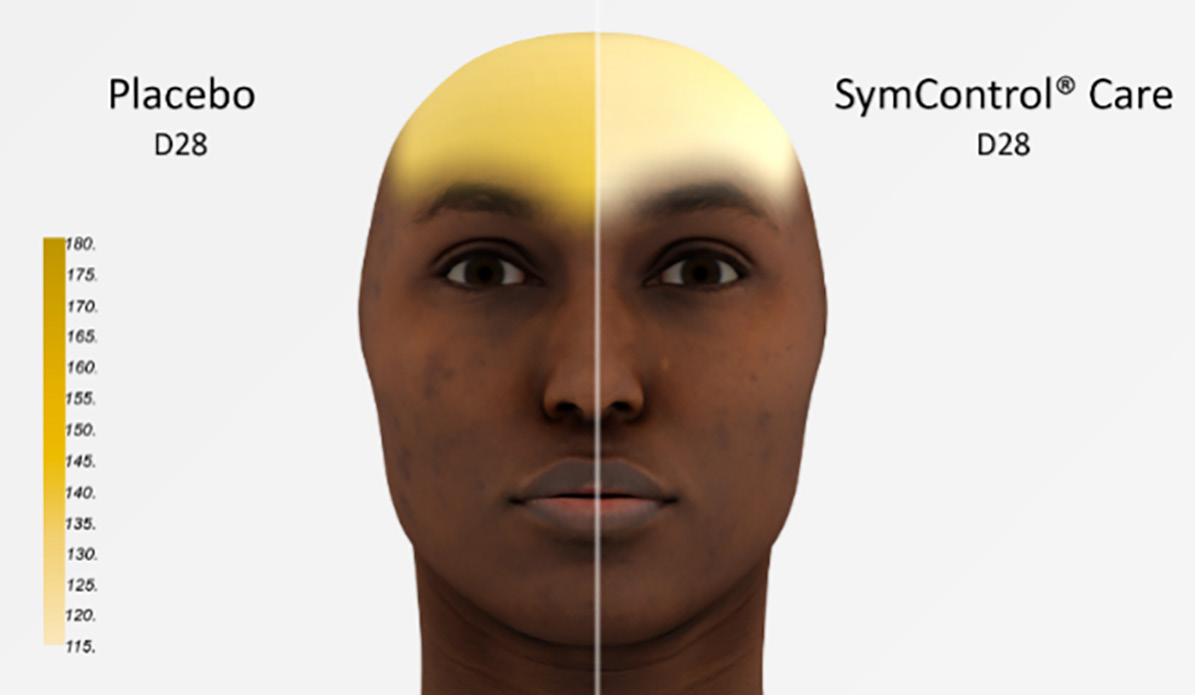

Two hydrodispersion gels were used for each study, a placebo and gels containing 2% and 1% SymControl® Care, for the studies on volunteers with light and darker skin respectively. The products were applied topically twice daily on the semi-foreheads of the volunteers. The sebum level was measured with a Sebumeter® at the start of the study and after four weeks of product application. During the study, colour mapping of the sebum evolution was carried out on darker skin, using a scale ranging from 115μg/cm2 to 180μg/cm2.

Balances pores activity

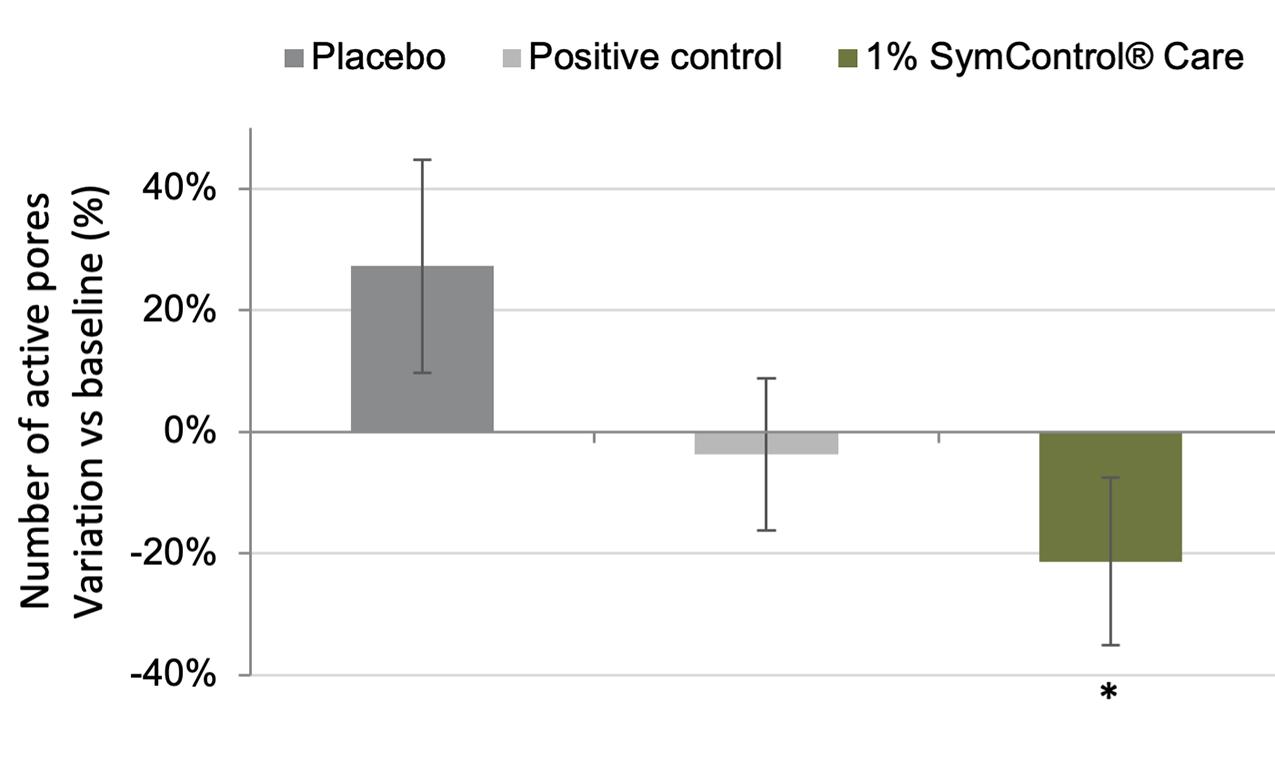

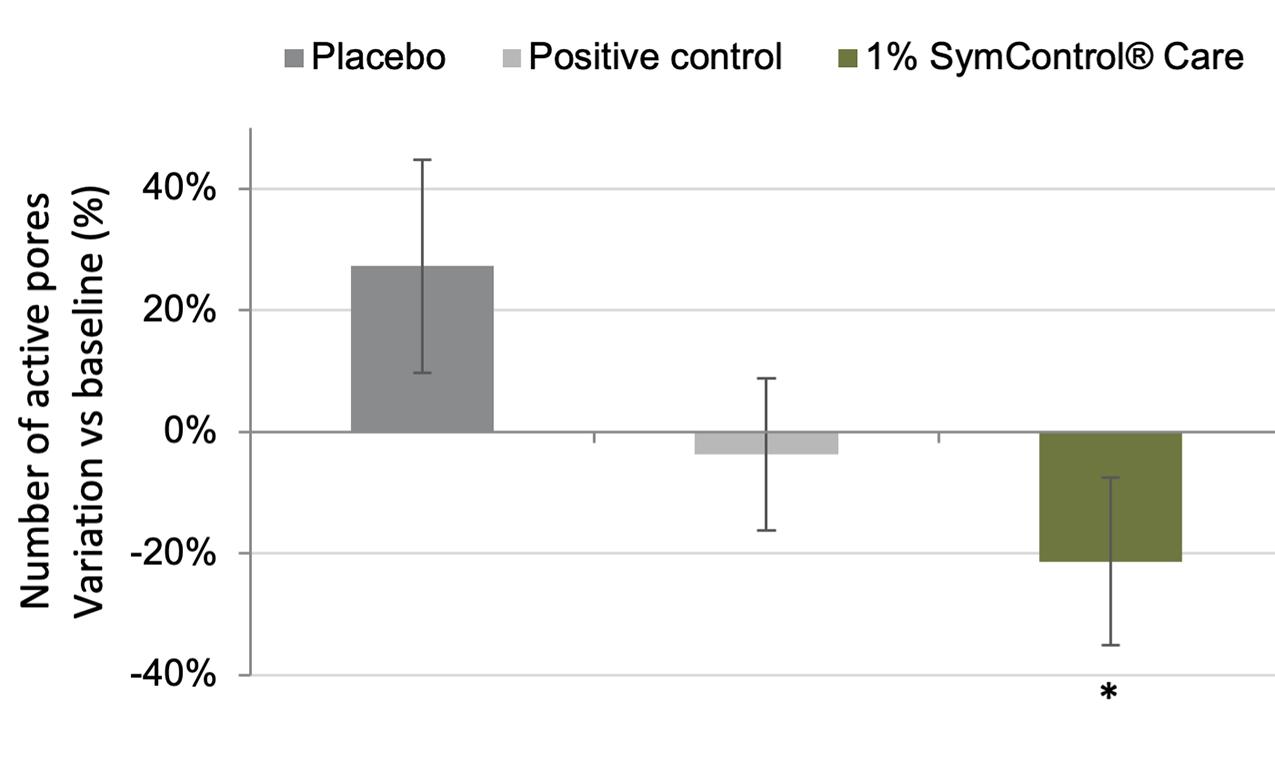

A proof-of-concept in vivo study was performed on two groups of 21 subjects (female and male, phototypes I to V, 16 to 59 years old, with slight to pronounced oily skin).

Hydrodispersion gels, which contained either 1% SymControl® Care or a combination of 2% niacinamide and 1% D-panthenol used as a positive control, 3 were applied topically twice daily on the semi-foreheads of the volunteers. Using a Visioscan® equipped with a Sebufix®

SymControl® Care helps to maintain a healthy balance of sebum production and skin sensitivity, enhancing the comfort of oily skin

Did you know?

COX-2 has been identified as a key enzyme in the origin of sebum production and skin sensitivity.

Obtained via blue biotechnology from a Mediterranean sea in Italy, Symrise developed SymControl® Care, a natural prebiotic that visibly reduces sebum & pores and decreases skin sensitivity to address oily skin at its true origin.

#SEBUM & PORES

#SENSITIVITY REDUCER #ANTI-POLLUTION

#MICROBIOME-FRIENDLY #PREBIOTIC #BLUE BIOTECHNOLOGY

COSMETIC INGREDIENTS BY SYMRISE always inspiring more ...

SKINCARE 16 QUARTER 1 2024 P&C AFRICA

www.symselect.com | www.symrise.com Follow us on Instagram @symrise.ci

SEBUM + SENSITIVITY Normalizer

SymControl® Care

foil, the number of actives pores were measured at baseline and after one week.

RESULTS – SymControl® Care

Universal sebum level reduction

A significant reduction of sebum is obtained after four weeks of product application in both studies (see figure 1). Reductions of 12% and 9% of sebum levels are shown for light skin (phototypes I to III) and darker skin (phototypes V to VI), respectively.

The colour mapping performed on darker skin visually highlights the reduction of sebum obtained with 1% SymControl® Care (see figure 2).

SymControl® Care effectively supports the reduction of sebum in all skin tones

This result also shows a better efficacy than the positive control (see figure 3).

Conclusion

SymControl® Care effectively supports the reduction of sebum in all skin tones and balances the activity of pores associated with oily skin. It also helps to reduce the expression of one of the key enzymes closely associated with sebum production and skin sensitivity.

The ingredient is both microbiome-friendly and COSMOS approved. It is obtained using blue biotechnology and is based on a sustainably sourced Mediterranean microalgae.

SymControl® Care helps to maintain a healthy balance of sebum production and skin sensitivity, enhancing the comfort of oily skin.

The authors would like to give special thanks to the Symrise Global Innovation Cosmetic Ingredients team, particularly Sandra Gaebler and Dr Dominik Stuhlmann for their expertise in ingredients and data development.

Balanced activity of pores

With SymControl® Care, a significant reduction of 49% in the number of active pores was obtained.

REFERENCES:

1.

2.

3.

Originally published in the SOFW Journal Symrise – www.symrise.com

SKINCARE 17 QUARTER 1 2024 P&C AFRICA

Figure 1: Variation in sebum level after four weeks of product application (compared to baseline). A: Sebum reduction of light skin (phototypes to III). B: sebum reduction of darker skin (phototypes V to VI)

*significant difference vs placebo (p<0.05)

**significant difference vs placebo (p<0.01)

Figure 2: Colour mapping performed based on the sebum level evolution measured at the start of the study and after four weeks of product application, during the study on darker skin

Figure 3: Variation of the number of active pores after one week of product application (compared to baseline)

*significant difference vs placebo (p<0.05)

CICS 2022 – 10 countries

M. Herrmann et al., Sebum and skin barrier normalizer from blue technology (2018), 30th IFSCC congress

Z.D. Draelos et al., The effect of 2% niacinamide on facial sebum production, J. Cosmet Laser Ther (2006), 8(2), 96-101 A B

A

B

The quest for affordable hair nourishment

AECI Specialty Chemicals is on a mission to ensure that all consumers experience fabulous hair days. The supplier’s personal care team has dedicated itself to crafting innovative and cost-effective formulations tailored specifically to the diverse needs of the African market.

n a world where hair care products often come with a hefty price tag, finding effective yet budget-friendly options is like discovering hidden treasure. Hair food is a good example. As a nourishing elixir, hair food promises to strengthen, revitalise and improve overall hair health without draining your wallet.

Different actives, oils and extracts can be added to a hair food formulation to meet African consumers’ hair care needs.

A basket full of benefits

Hair food offers various benefits for textured hair, including:

• Nourishment – hair food serves as a vital source of essential nutrients and moisture, enriching and

detangling and styling. With improved manageability, styling becomes effortless and hair looks smoother.

• Protection – a protective barrier formed by hair food helps shield the hair and scalp from environmental stressors like UV radiation, pollution and harsh weather.

• Styling aid and versatility – hair food functions as a versatile styling aid, offering hold, definition and shine to a range of hairstyles, including braids, twists and wash-and-go styles. Its versatility extends to different hair types and textures, from natural to chemically treated hair, providing nourishment and support across the spectrum.

• Daily maintenance – hair food helps maintain hair and scalp health.

Innovative formulas for inspiration

strengthening hair strands to promote overall hair health.

• Moisture retention – formulated with emollients and humectants, hair food plays a crucial role in retaining moisture within the hair. By creating a protective barrier that locks in hydration, it can also assist with scalp dryness.

• Hair growth – certain actives can be added to the formulation such as oils rich in vitamins and antioxidants that can assist with stimulation of the hair follicle. By nourishing the scalp and promoting healthy follicles, these ingredients can encourage optimal conditions for hair growth.

• Manageability – hair foods can assist with smoothing the cuticle, resulting in easier

Traditionally hair food formulations are developed using a high level of petroleum-based jelly. Other ingredients added to the formulation can include paraffinum liquidum (white oil), natural oils, butters, waxes and silicones. This type of formulation tends to be tacky and leaves a heavy feeling on the scalp. It can also easily attract dirt. Another disadvantage of a formulation like this is it can be expensive with the increasing cost of raw materials.

To overcome these challenges, AECI® Specialty Chemicals has developed innovative hair food formulations for the African market which are both costeffective and easy to manufacture. The distributor has also engineered the AECI Hair Food Concentrate, which can be used to simplify a hair food formulation. Table 1 features an example of a hair food formulation using the concentrate.

This is a simple, workable formulation that also offers a significant cost saving. The manufacturing process involves melting and stirring. Compared to traditional hair foods on the market, this hair food formulation provides a lighter feel and reduced tackiness. The formulation can be enhanced by adding in silicones, natural oil and/or butters.

The formulation in table 2 is more of an emulsionbased development. By adding in a water phase, the cost of the formulation decreases significantly. The addition of glycerine assists with increased moisturisation to the scalp.

AECI Specialty Chemicals can provide all ingredients for both formulations, as well as any other actives, silicones, extracts and/or oils and butters. Contact the team for more information.

I

HAIR CARE

18 QUARTER 1 2024 P&C AFRICA

Raw material 100% AECI Hair Food Concentrate 25 Parafinum Liquidum 74.5 Fragrance 0.5 Table 1: Hair Food Formulation 1

Phase Raw Material 100% A Deionised Water 52.2 Sodium Chloride 2.0 Urea 3.0 Glycerine 12.0 B Hydroxyethyldiethonium Polyisobutenyl Triethylaminosuccinate, C13-14 Isoparaffin, Polyisobutene, Sorbitan Oleate 2.0 Paraffinum Liquidum 16.0 Synthetic Wax 8.0 Dimethicone 1.5 C Phenoxyethanol and Ethylhexylglycerin 0.8 D Fragrance 0.5 Table 2: Hair Food Formulation 2 AECI Specialty Chemicals –Yurita.Boodhram@aeciworld.com, Ketul.Patel@aeciworld.com

Functional waxes to elevate your formulations

A leading specialists in natural waxes, Kahl has launched a new corporate identity, which includes fresh branding and a new website.

Kahl specialises in natural waxes, such as beeswax, carnauba wax, candelilla wax and many others. The company has a long tradition of refining and manufacturing waxes, functional ingredients, powders and emulsions. From its production site near Hamburg, Germany, Kahl ships its goods worldwide. The supplier’s in house laboratory researches and develops new products while providing extensive formulation assistance and technical support to customers.

In September 2023, the company launched its brandnew KAHL look, including a new Kahl World website, logo and corporate branding.

customers to easily find products that match their needs. In South Africa, Kahl’s products can be sourced from Savannah Fine Chemicals.

Waxes to enhance hair care

Waxes are a class of natural compounds that are malleable at room temperature. Typically, they are harder, less greasy and more brittle than fats, and show extreme resistance to moisture, oxidation, and microbial degradation.

The aim is to reposition the business as a manufacturer of specialty ingredients with a focus on quality, service and technical know-how. Kahl is shifting its focus from product-based to offering a solutions-based approach, which helps

Most hair conditioners or masks already contain waxy substances such as fatty alcohols, but only rarely contain actual waxes, because their melting point can be quite high, or their performance is unknown. In general, waxes can thicken products and bind high amounts of oils. This makes them very useful to improve and

HAIR CARE 19 QUARTER 1 2024 P&C AFRICA

regulate texture. Additionally, waxes also show interesting caring effects on hair.

Waxes deposit on hair and add softness. Yet unlike cationic conditioning actives, they do not attach firmly, which makes them easier to remove and less likely to cause build-up.

Depending on their chemical composition, waxes can add gloss, reduce combing force and detangle, have anti-static properties, and protect the hair against breakage and environmental stress. Some waxes can also provide slip and lubricity making the product easy to apply on wet hair, while others give more grip, which can be necessary for a good manageability.

example from the portfolio is KahlJelly 7038

Waxes can add gloss, reduce combing force, detangle, and protect the hair against breakage and environmental stress

Coco. This special blend is based on coconut oil, which is widely used in hair care and has been shown to be very effective in protecting hair. It also contains nourishing olive oil; low-melting berry wax, which provides a creamy texture and good spreadability; and upcycled sunflower seed wax for additional stabilisation.

KahlJelly 7038 Coco can be used in a variety of applications. It is easy to emulsify and ideal for use in cream conditioners and hair mask products. KahlJelly 7038 Coco has been shown to improve combability of wet and dry hair, without leaving a heavy residue.

Versatile and sustainable raw materials

Besides classic waxes like beeswax and natural speciality waxes like myrica and tea wax, Kahl also offers other functional ingredients that are perfectly suited for hair care applications. One

As solid cosmetics have become a booming trend in recent years, formulators are now looking for new ingredients to create highperformance cosmetic products that meet consumer’s expectations. KahlJelly 7038 Coco is an excellent ingredient for solid hair care formulations, where it acts as a binder for surfactants and as a caring ingredient. It is suitable for vegan, halal, and natural cosmetic formulations (ISO 16128: 100%), making it a perfect choice of raw material to use in both emulsion-based and anhydrous hair care products, like the solid shampoo featured in table 1.

IT‘S OFFICIAL: we rebranded! becomes

Welcome to the KAHL World!

On 1st of September 2023 we launched our brand-new KAHL look including a new website (www.kahlworld.com), new logo, and corporate design.

With our new brand KAHL we want to reposition ourselves as a manufacturer of specialty ingredients with a focus on quality, service, and technical know-how. We are shifting the focus from product-based to a solution-based approach which helps customers find the product that matches their needs more easily. We are more than just wax.

The new KAHL look is modern, minimalistic, and technical with a wide, strong, and self-confident logo. Our new claim “creating future standards” reinforces the logo: we are moving forward, leaving the competition behind.

In South Africa, Kahl is represented by www.savannah.co.za www.kahlworld.com

Kahl – www.kahlworld.com Savannah Fine Chemicals – www.savannah.co.za

Phase Ingredient INCI % A Lathanol LAL Coarse Lathanol LAL Coarse ad 100 Rice PO4 Natural 9031 Distarch Phosphaste 37.20 B KahlWax 6237 Rapeseed Hydrogenated Rapeseed Oil 4.50 KahlJelly 7038 Coco Cocos Nucifera Oil, Olea Europaea Fruit Oil, Rhus Verniciflua Peel Cera, Helianthus Annuus Seed Cera 20.00 C Coconut Beach Parfum 1.00

1: Solid Shampoo (vegan) Procedure: Mix phase A ingredients and preheat at 80°C. Melt phase B, add to A and mix until a paste is obtained. Add phase C and press into moulds. Let it set in a fridge for 30 minutes. HAIR CARE 20 QUARTER 1 2024 P&C AFRICA

Table

BELSIL® DADM 3240 E is highly effective, even at low concentrations

Silicone co-emulsion delivers next level conditioning

Shine, volume and manageability are key characteristics of attractive hair. Wacker already offers a broad range of silicone products aimed specifically at transforming a simple head of hair into a personal hairstyle and individual look. Building on this expertise, Wacker has developed an innovative silicone co-emulsion with outstanding conditioning properties. The product also protects hair and provides a silky, smooth finish.

BELSIL® DADM 3240 E presents distinct conditioning properties, even when used in small amounts. The emulsion, which consists of two silicones, works by forming a loose network structure around the hair to condition it and provide lasting protection.

In developing BELSIL® DADM 3240 E, Wacker succeeded with converting two silicones into an aqueous emulsion. The oil phase contains an amodimethicone cross polymer with an embedded conventional dimethicone. The cross polymer develops a protective polymer network around the hair, ensuring a lasting conditioning feel.

A winning combination

The combination of dimethicone and amodimethicone is extremely effective. It renders even rough, damaged hair soft and supple and makes it easy to comb when wet or dry. The conditioning properties are much longer lasting than other conditioning products on the market which are formulated with an un-crosslinked silicone fluid. As a result of the treatment, hair regains its natural, healthy appearance.

BELSIL® DADM 3240 E is suitable for formulating shampoos, conditioners and leave-in products. In shampoo systems, the new co-emulsion is compatible with a large variety of surfactant

systems employed in hair care. Its processing is straightforward. The co-emulsion can be admixed without lowering the viscosity of the formulation or impairing the foaming properties of the shampoo.

BELSIL® DADM 3240 E is highly effective, even at low concentrations. Shampoos formulated with mild, sulfate-free surfactants require just 0.8% silicone to boost hair suppleness by 35%, compared

HAIR CARE

BELSIL® DADM 3240 E has been developed for use in conditioners, hair treatments and leave-in products (Image: Wacker)

is better than one – the

Two

silicone co-emulsion BELSIL® DADM 3240 E consists of an amodimethicone crosspolymer (orange) and a dimethicone (yellow) (Image: Wacker)

21 QUARTER 1 2024 P&C AFRICA

to untreated hair. That is roughly 20 percentage points more than a reference formulation based on a standard market dimethicone emulsion. Conventional silicone emulsions cannot produce such effects.

Effective at a low concentration

With its broad palette of applications, BELSIL® DADM 3240 E brings benefits to damaged and stressed hair in shampoo formulations. It is well suited to rinse-off conditioners, hair treatments, masks and anti-frizz products, and it can be used as a conditioning aid in styling applications.

The recommended use level in a shampoo formulation ranges from 0.8% to 2.5%. In conditioner, treatment and mask formulations use levels may vary from 0.4% to 4.0%. The emulsion

should be formulated at temperatures below 35°C. It also needs to be stirred well before use.

Add silkiness to damaged hair

Shampoos containing BELSIL® DADM 3240 E achieve a more than twofold improvement in the silkiness of damaged hair compared to shampoos formulated with conventional dimethicones. The technology is truly advanced, especially because, unlike conventional silicone emulsions, the silkiness effect is produced with a mere 0.8% of the silicone emulsion in a mild, sulfate-free shampoo formulation.

Improved wet combing of damaged hair

BELSIL® DADM 3240 E improves wet hair combing. In fact, wet combability is enhanced by 16.5 percentage points when compared to commercial dimethicone emulsions. This increases to 25 percentage points when the comparison is made with silicone-free formulations.

Reduce surface friction after hair washes

Wacker’s combination of a dimethicone and an amodimethicone cross polymer yields compelling results. In particular, BELSIL® DADM 3240 E leaves bleached or dyed hair feeling silky-soft for longer. A mere 0.5% of BELSIL® DADM 3240 E in a conditioner formulation is enough to reduce surface friction on the hair and this easily observable effect keeps hair feeling great even after several washes.

BELSIL® DADM 3240 E is available throughout Southern Africa from IMCD, an approved distributor of Wacker’s products.

IMCD South Africa – www.imcdsa.co.za/en/ Wacker – www.wacker.com

CREATING TOMORROW’S SOLUTIONS INNOVATIVE STRENGTH FOR SILKY SMOOTH HAIR

Wacker Chemie AG , Hanns-Seidel-Platz 4, 81737 Munich, Germany www.wacker.com/contact, www.wacker.com/personalcare Follow us on:

Shampoos containing the novel co-emulsion BELSIL® DADM 3240 E improve the silkiness of damaged hair by more than twice as much as shampoos containing conventional dimethicones. This is a genuine technological advance, especially as just 0.8% silicone is enough to generate this e ect in mild, sulfate-free shampoos. Another benefi t: thanks to BELSIL ® DADM 3240 E, combs can slip e ortlessly through wet hair, thereby preventing further damage. Furthermore, we are sure that BELSIL® DADM 3240 E will become a favorite among hair products manufacturers. Firstly, because it is compatible with all conventional surfactant systems. Secondly, because it can be admixed without lowering the viscosity of the formulation or impairing the foaming properties of the shampoo. For more specifications visit www.wacker.com/personalcare

10 15 20 25 30 35 40 Shampoo without silicones Shampoo with dimethicone emulsion Shampoo with BELSIL® DADM 3240 E Improvement of Silkiness in % 6,03 7,90 0 5 10 15 20 25 30 35 40 Shampoo without silicones Shampoo with dimethicone emulsion Shampoo with BELSIL® DADM 3240 E Improvement of Wet Combing in % 0 20 40 60 80 Shampoo without silicones Shampoo with dimethicone emulsion Shampoo with BELSIL® DADM 3240 E Reduction in surface friction after hair wash in %

40 35 30 25 20 15 10 5 0 Base shampoo without silicone Base shampoo with dimethicone emulsion Base shampoo with BELSIL® DADM 3240 E

Improvement in silkiness [%] 40 35 30 25 20 15 10 5 0 Base shampoo without silicone Base shampoo with dimethicone emulsion Base shampoo with BELSIL® DADM 3240 E

Sulfate-Free Shampoo: Silkiness of Damaged Hair

Improvement in wet combing [%] 22 QUARTER 1 2024 P&C AFRICA HAIR CARE

Sulfate-Free Shampoo: Wet Combing of Damaged Hair

Unlock the secrets to caring for textured hair

Hair care continues to evolve. In this industry, brand owners are continually seeking a deeper understanding of market requirements and innovative approaches to offer consumers. In this article, Roné Rudman, Azelis personal care lab technician and technical support for South Africa & MEA, shares insights into how to care for textured hair.

Let’s delve into the complexities of hair structure, emphasising the trends of skinification and inclusivity, and highlighting innovative ingredients. There are also advanced care routines to analyse, tailored to diverse hair types, including the often underserved curly and kinky textures. A trend towards various home remedies and the use of traditional hair care treatments continues to grow worldwide. These insights can offer hair care professionals a comprehensive overview of current best practices in the market. Hair, in its simplicity, has a complex structure that determines its care requirements. Each of the three primary layers – the cuticle, cortex and medulla – play a pivotal role in hair health and appearance. The cuticle, the outermost layer, acts as a protective shield. Its health is crucial for preventing damage and retaining moisture. The cortex, which determines strength and colour, requires nourishment for resilience. Finally, the medulla, though not present in all hair types, impacts hair’s overall integrity.

Apart from the structure of the hair, it can be categorised into several types. In a basic classification, hair can be either straight, wavy, curly or coily and kinky, some with tighter curls and coils. While straight and wavy hair have their own challenges, curly and coily hair require a bit more TLC. With help of the André Walker scale we can focus some attention on mentioning the most abundant hair type in South Africa, which is curly, kinky and coily hair of type 4 a, b and c.

Unique challenges and needs

Type 4 hair presents a unique set of characteristics and challenges. This hair type is inherently fragile due to the twists and turns of each strand, which can lead to breakage and moisture loss. Although it appears robust, it is the most delicate hair type, requiring gentle handling and specific care routines. The primary concerns for type 4 hair include dryness, tangling and susceptibility to damage, particularly from heat and harsh styling practices.

The structure of type 4 hair is distinct, with densely packed curls that range from fine to coarse. It is the unique curl pattern that can create challenges in moisture retention, as it is quite difficult for the natural oils from the scalp to travel down the hair shaft when compared to straight and wavy hair as the base of the hair curls upwards. This can result in a lack of natural lustre and a propensity for dryness. Understanding this structure is key in addressing the specific needs of type 4 hair, which include enhanced hydration and protective styling.

Type 4 hair can thrive with protective styles that minimise manipulation and stress on the hair. Styles such as twists, braids and cornrows not only protect the hair but also celebrate its natural texture. However, it’s important to remember to limit stress on the scalp to avoid irritation and hair loss.

Gentle cleansing of the scalp is beneficial to type 4 hair to remove excess sebum. Other beneficial routines include very gentle cleansing of the extended hair, regular deep conditioning

23 QUARTER 1 2024 P&C AFRICA HAIR CARE

treatments, gentle detangling methods, and minimal use of heat.

Tailored hair care solutions

The hair care industry is increasingly focusing on innovative solutions specifically for type 4 hair. These include an array of products. Ultra-hydrating formulations like products rich in emollients, humectants, and oils such as shea butter, coconut oil, and glycerine provide deep hydration and seal in moisture. Strengthening treatments would include protein-based ingredients and products fortified with amino acids, which help to reinforce hair’s strength and combat fragility. Gentle cleansing agents, such as sulfate-free shampoos and cowashes, are essential to clean without stripping the hair of its natural oils and to maintain moisture balance. Detangling products are designed to ease combing and can help to significantly reduce breakage. Innovative styling products offer hold without flakiness or buildup, such as natural starch-

based gels and creams. They allow for versatile styling without compromising hair health. Scalp care treatments play a crucial role considering the challenges in natural oil distribution on the scalp. Products that nourish and stimulate the scalp help to maintain a healthy scalp while supporting hair growth and overall hair health.

In general, hair care is increasingly adopting a comprehensive approach, mirroring skincare practices. Ingredients traditionally found in skincare, like peptides, extracts and antioxidants, are now being incorporated into hair products. This reflects the growing recognition of the scalp as an extension of the skin.

Category advancements in formulation development

Innovation has seen significant advancements in the shampoo and conditioner categories.

Shampoos are no longer just cleansing agents. They're now formulated to address specific needs, from scalp health to texture enhancement. Conditioners, on the other hand, have evolved to provide targeted benefits, such as deep hydration for dry hair types and lightweight conditioning for fine hair. These products, when chosen according to hair type and concern, lay the foundation for effective hair care routines, complementing pre-

wash treatments, leave-in conditioners and styling aids.

The evolution of hair wash and treatment routines reflects the growing sophistication in hair care. Pre-wash treatments have gained popularity, especially for hair types prone to dryness, like type 4. These treatments involve applying nourishing oils or masks before shampooing to protect and hydrate hair.

Leave-in conditioners have become indispensable, particularly for maintaining moisture and manageability of curly and coily hair. They provide lasting hydration and help with detangling. Styling aids, evolving beyond the mere ‘hold’ function, now offer additional benefits like heat protection,

moisture retention, and enhancing natural textures, catering to the diverse needs of all hair types.

Essential ingredients for effective care

With an understanding of current hair care requirements, some ingredients are invaluable to include in any hair care set. Azelis is a key supplier to formulators looking to design innovative formulations and all-encompassing hair care products.

As mentioned before, sulfate-free surfactants are key in maintaining hair health, especially for curly and coily hair types. Another ingredient to consider is natural, high active sophorolipid surfactants, emerging as a superior alternative in sulfate-free products. These surfactants cleanse effectively

The evolution of hair wash and treatment routines reflects the growing sophistication in hair care

We supply raw materials to create innovative cosmetics and personal care products! High Quality Convenient Smaller Pack Sizes Cosmetics Consumables Chempack Industries Contact: Linda Thieme 083 600 0167 064 610 2736 Email: linda@cpack.co.za Website: www.cpack.co.za Chempack PCR half.indd 1 2024/03/07 14:32 HAIR CARE

24 QUARTER 1 2024 P&C AFRICA

The trend towards natural and inclusive hair care has led to a greater appreciation and understanding of type 4 hair

while being very respectful of skin and scalp and helping to preserve microbial balance.

Revolutionising the conditioning approach, guar hydroxypropyltrimonium chloride is particularly beneficial to type 4 hair, enhancing its natural texture without weighing hair down. Silicone alternatives, such as naturally derived oils and shea butter provide slip and smoothness without buildup. Using these ingredients in combination offers a sustainable and hair-friendly approach to managing frizz and enhancing shine while increasing moisture content of the hair.

Furthermore, the inclusion of natural starches in styling products, particularly for dry shampoos, allows for a lightweight and clean approach to hair styling and maintenance. Natural starches absorb excess oil without leaving residue, making them ideal for refreshing hair between washes, especially for oily or fine hair types.

A balanced approach to product protection

In the pursuit of effective and safe hair care formulations, the role of preservatives cannot be overstated. Preservative systems are essential to prevent microbial growth and maintain the integrity of products, especially those containing water and natural ingredients.

For hair care formulators, understanding the balance between efficacy and safety of these preservatives is key. Whether synthetic or derived from natural resources, these systems ensure that hair care products remain safe and effective over time for consumer use. They also cater to all hair types while respecting the increasing demand for natural and gentle formulations.

The trend towards natural and inclusive hair care has led to a greater appreciation and understanding of type 4 hair. Embracing hair’s natural beauty involves not only selecting the right products but also understanding the cultural and personal significance of its care. As the industry continues to innovate, all-inclusive hair care options are becoming more accessible, empowering individuals to celebrate their own style. At Azelis we have all the tools available, including a large range of key ingredients, technical lab support and innovative solutions.

25 QUARTER 1 2024 P&C AFRICA HAIR CARE

Azelis South Africa – www.azelis.com