EXECUTIVE COMMITTEE

Bucky Pescaglia, Chairman Missouri-Pacific Lumber Co., Inc.

Stephanie VanDystadt, Vice Chairman Hull Forest Products

Jon Syre, Past Chairman 2022-2024 Cascade Hardwood, LLC

MISSION LEADERS

Sam Glidden, ITS and ITSEF GMC Hardwoods, Inc.

Ray White, Lumber Services Harold White Lumber, Inc.

Joe Pryor, Education Services Oaks Unlimited, Inc.

Rich Solano, Convention Pike Lumber Company, Inc.

Bill Courtney, Membership & Networking Classic American Hardwoods

Rob Cabral, Market Impacts UCS Forest Group

DEPUTY MISSION LEADERS

Chris Rider, Membership & Networking AHC Hardwood Group

Tom Coble, Market Impacts Hartzell Hardwoods, Inc.

Greg Fitzpatrick, Convention Fitzpatrick & Weller, Inc.

Tom Oiler, Lumber Services Cole Hardwood, Inc.

Trent Yoder, Lumber Services Yoder Lumber

Brant Forcey, ITS and ITSEF Forcey Lumber Company

George Swaner, Education Services Swaner Hardwood Co., Inc.

COMMITTEE CHAIRMAN

Sam Glidden, Rules GMC Hardwoods, Inc.

THE VOICE OF THE HARDWOOD INDUSTRY

National Hardwood Lumber Association PO Box 34518 • Memphis, TN 38184-0518 901-377-1818 • 901-382-6419 (fax) info@nhla.com • www.nhla.com

To serve NHLA Members engaged in the commerce of North American hardwood lumber by: maintaining order, structure and ethics in the changing global hardwood marketplace; providing unique member services; promoting North American hardwood lumber and advocating the interest of the hardwood community in public/private policy issues; and providing a platform for networking opportunities.

For advertising contact: John Hester j.hester@nhla.com or 901-399-7558

NHLA STAFF

Dallin Brooks, Executive Director dallin@nhla.com

John Hester, Chief Development Officer j.hester@nhla.com

Sam Leow, Chief Marketing Officer s.leow@nhla.com

Dana Spessert, Chief Inspector d.spessert@nhla.com

ACCOUNTING

Desiree Freeman, Controller d.freeman@nhla.com

Jens Lodholm, Database Manager j.lodholm@nhla.com

INDUSTRY SERVICES

Mark Bear, National Inspector m.bear@nhla.com

Tom Byers, National Inspector t.byers@nhla.com

Kevin Evilsizer, National Inspector k.evilsizer@nhla.com

Simon Larocque, National Inspector s.larocque@nhla.com

Benji Richards, Industry Services Sales Manager b.richards@nhla.com

Drew Snider, National Inspector d.snider@nhla.com

Marty Westeen, National Inspector m.westeen@nhla.com

INSPECTOR TRAINING SCHOOL

Roman Matyushchenko, Instructor of the Inspector Training School r.matyushchenko@nhla.com

MARKETING/MEMBERSHIP

Melissa Ellis Smith, Creative Director m.ellis@nhla.com

Brennah Hutchison, Content Strategist & Editor b.hutchison@nhla.com

Ashley Johnson, Convention and Events Director a.johnson@nhla.com

Darci Shannon, Communication & Outreach Specialist d.shannon@nhla.com

The RossiGroup has been helping customers navigate the global hardwoods industry for almost a century.

We have raised the bar with our new state-of-the-art Emporium Mill and kiln facilities, our long-term supply agreements, and our uniquely personal brand of customer service.

We deliver a world class selection of hardwoods – including the gold standard in cherry – all sorted, milled and dried to tolerances, consistencies, and yields that were not even possible five years ago. Visit us www.rossilumber.com or call 860-632-3505

In 1990, United Airlines aired one of the most unforgettable TV ads ever. For those of you too young to have seen it, the ad starts in an industrial conference room with the apparent CEO addressing his large staff. He says, “I got a phone call today from one of our oldest customers. He fired us! After 20 years, he fired us! He said he didn’t know us anymore.” He pauses momentarily and then says, “I think I know why. We used to do business with a handshake, face-to-face. Now, it’s a phone call or a fax. He says, “Well folks, things are going to change. We are going to set out for a face-to-face chat with every customer we have.” The narrator in the commercial then says, “If you’re the kind of business that still believes that personal service delivers a lot more than lip service, welcome to United.” Of course, the CEO then hands all his salespeople tickets to United Airlines to visit their customers. It finishes with one of the salespeople asking the CEO where he is going. He says, “I am going to visit that old friend who fired us this morning.”

To bring this 35-year-old ad into the more modern business era, we can replace the phone and fax with Zoom and email, but the same principle remains. If you want to establish a long-term business relationship, it is most essential to establish in-person relationships.

I am not suggesting that we buy dozens of airline tickets to visit our customers and suppliers tomorrow, as I know it isn’t realistic. What the ad reinforced to me was the importance of really getting to know each other’s needs. I suggest setting aside time to visit the top 10% of your customers or suppliers in the next few months. There is a lot to be learned by visiting your customer or supplier’s facility, and the return on investment is immense.

The simple act of visiting the customer or supplier shows them your commitment to the relationship. Most everyone is proud of their company and products and is excited to show off their unique

facilities. As a supplier, touring a customer's plant or warehouse can reveal processes or products you hadn’t noticed before. This insight may allow you to recommend a more suitable product for their needs or adjust your own processes to offer an even better solution

As a customer, visiting your supplier can also provide an opportunity to understand their processes and to see exactly how their products are being made. The more you know, the better decisions you can make for your business.

Just this morning, our sales manager left to visit two current customers and will stop at another potential customer while he is in the area. He is not expecting to bring back an entire book of orders, but we will continue to build on our personal relationships and possibly start a new one.

We all spend a lot of time and effort trying to increase our markets by searching for new clients or suppliers, but we also need to understand the importance of keeping our current ones. So don’t wait for one of your “old friends” to fire you. Make your plans to meet your business partners face-to-face right now. You won’t regret it.

Bucky Pescaglia NHLA Chairman | Missouri-Pacific Lumber Co., Inc.

Igrew up in a home where a strict father and a rigid Christian culture of rules shaped every aspect of life, with “My way or the highway” as the guiding principle. Most of my older siblings left home before age 18 because they found the family and church rules too constricting. They often struggled with curfews and other restrictions because of the bad company they kept and the rules they broke.

I saw things differently. I kept good company, stayed obedient, and over time, my rules became more of a guideline. The more I earned my parents’ trust, the more freedom I gained. By the time I was a teenager, I called home at 10:00 PM—before the era of cell phones—letting them know where I was, who I was with, and when I’d be home. I never lied, and in return, my curfew became flexible with their permission.

This wasn’t because I was spoiled—ask any of my nine siblings. As the middle child, I wasn’t given any special treatment. What set me apart was learning to work within the rules and understanding the principles behind them.

This lesson applies to the hardwood industry today. The current economic landscape presents a real opportunity to move beyond the “strict old rules” and bring the industry into the 21st century. I hear it all the time: “The NHLA Rules don’t apply to my business” because of variations in species, grades, or customer needs.

Tradition has its place, but why hold onto rules that no longer serve the future? If NHLA Grading Rules aren’t working for many businesses today, why not adapt them to fit modern needs? The fact that NHLA has been around for 127 years is an incredible testament to its legacy, but that doesn’t mean the rules from 127 years ago should remain unchanged.

The NHLA Rules shouldn’t be seen as rigid restrictions that limit manufacturers. They’re meant to be guidelines that provide flexibility to meet customers’ demands. But for them to remain relevant, adjustments are necessary. These could include introducing rustic grades, urban wood grades, or structural grades. The rules could also better reflect today’s dimensions, fixed widths, and lengths. Even

addressing issues like the 4% off-grade allowance—an outdated standard that neither customers accept nor businesses rely on— could make a meaningful difference.

Updating a standard isn’t the same as lowering it. Lowering a standard means intentionally reducing quality expectations. Updating a standard means aligning it with current realities to ensure its continued value and usability.

Of course, changes shouldn’t happen on a whim. That’s the beauty of having an association. Through debate and collaboration, the industry as a whole can determine what updates are needed and approve changes thoughtfully. But clinging to rules that are outdated or obsolete benefits no one.

As a parent, I never tell my kids, “My way or the highway.” Instead, I explain the rules and the principles behind them. I give them a choice: they can follow the rules for flexibility and freedom or fight them and face restrictions. I share lessons from my past and my siblings’ experiences to help them understand why the rules exist.

In the same way, the hardwood industry doesn’t need to discard its traditions or rules entirely. Instead, we can adapt them to reflect where we are today while honoring the principles they were built on.

So, I encourage you to take a close look at the NHLA Rules you’re using. If there are changes you believe would improve their relevance to your business, propose them. Chances are, you’re not the only one who sees the need for change—and by finding common ground, we can build a stronger foundation for the future of our industry.

Dallin Brooks NHLA Executive Director dallin@nhla.com

| 901-377-0182

Northeast Mill Services has provided sales, consulting, design, and engineering services to the Lumber Manufacturing Industry for over 40 years. NMS has recently been involved in the planning and completing of major improvement projects with multiple mills. We introduced Comact Hardwood AI/Vision Automated Grading to the US, selling 19 Hardwood TrimExperts to multiple companies, 16 of which are now in operation . . . Providing value to our customers!

Our Services Include:

• Mill Modeling

• Drawings

• Representation

• Optimization

• Coordination

• Commissioning

|

plan for the future?

|

The National Hardwood Lumber Association (NHLA) is currently accepting rules change proposals for the 2027 Hardwood & Cypress Lumber Grading Rules. This is your opportunity to shape the future of the hardwood industry and ensure the rules reflect the evolving needs of the market.

March 31, 2025 - Last day to submit Rules Change Proposals.

June 4, 2025 - NHLA Rules Committee meeting at NHLA School to discuss proposals for ballot.

Mid-June 2025 - NHLA Rules Committee results announced.

October 2, 2025 - Open Forum on Rules Proposals at NHLA Convention.

December 1, 2025 - Rules ballots mailed to Active members of NHLA.

December 31, 2025 - Poll closed and ballots counted.

Early January 2026 - Rules vote results announced.

January 2027 - NHLA Rules Book updated and released.

For more information and to submit your proposal, please email the NHLA Chief Inspector, Dana Spessert, @ d.spessert@nhla.com or mail to P.O. Box 34518 Memphis, TN 38184.

We are excited to announce the upcoming launch of Hardwood & Design, a biannual magazine dedicated to showcasing the exceptional role of hardwood in architecture and design. This publication aims to inspire architects, designers, and builders to integrate hardwood into their projects, emphasizing sustainable and innovative applications.

The inaugural issue, scheduled for release this May, will delve into various topics, including sustainability insights, versatile uses of hardwood, and the environmental benefits. By highlighting these aspects, Hardwood & Design seeks to drive demand and create new opportunities within the hardwood industry.

We are particularly proud to recognize the efforts of Brooke Pajkurich, our newly appointed Hardwood Technical Design Director. Brooke brings a unique combination of technical expertise and creative passion to the role. She thrives on connecting with architects, designers, and builders, advocating for hardwood as the ideal choice for sustainable, innovative design. Her background is as dynamic as her role. A licensed artist with experience in product design, carpentry, and home improvement, she has a hands-on appreciation for craftsmanship and creativity. Her curiosity and determination fuel her ability to tackle challenges, whether she's presenting the latest trends in hardwood applications or building meaningful relationships across the architecture and design community. Brooke's resourceful and adventurous spirit ensures that she'll be an inspiring advocate for the hardwood industry, helping to position our products as both sustainable and beautiful.

Together, we are redefining the future of hardwood in design and construction. Stay tuned for the first issue of Hardwood & Design this May!

In the hardwood industry, trust, quality, and reliability are essential. When you purchase hardwood products, you expect consistency, ethical sourcing, and a commitment to industry standards. NHLA members uphold these values, ensuring buyers receive precisely what they pay for and benefit from transactions built on integrity and expertise.

NHLA members adhere to the strictest grading rules in the hardwood industry, bringing uniformity and trust to domestic and international transactions. By following NHLA standards, members provide accurate product descriptions and consistent lumber quality. This ensures peace of mind for buyers, knowing they are receiving reliable products from companies committed to maintaining high standards.

The hardwood industry is constantly evolving with technological advancements, sustainability, and efficiency. NHLA members lead this evolution by embracing innovation and adapting to meet modern marketplace demands. When you work with an NHLA member, you partner with a company invested in continuous improvement and future-forward solutions.

Trust forms the foundation of every successful business relationship. NHLA members operate with transparency, ethical sourcing, and responsible forestry management. They prioritize sustainability and fair business practices, ensuring customers and partners can rely on them for reliable and trustworthy service.

NHLA membership connects companies with a network of trusted professionals, suppliers, and industry partners. This community fosters accountability and reliability, contributing to consistent product quality and dependable service. NHLA members leverage these connections to deliver exceptional results, building long-term relationships in the process.

NHLA members prioritize education and continuous improvement through training programs, workshops, and certifications. By investing in their teams’ professional growth, members stay at the forefront of industry knowledge and best practices. When you work with an NHLA member, you can trust that they are committed to excellence and expertise.

NHLA members are passionate advocates for the hardwood industry. They actively participate in efforts to protect the industry from harmful regulations, tariffs, and trade challenges. By supporting NHLA members, you are contributing to the sustainability and long-term success of the industry.

NHLA members are united by a commitment to upholding high standards of quality, service, and industry growth. Through active engagement in NHLA initiatives, events, and programs, they demonstrate their dedication to strengthening the hardwood industry and supporting its future.

When you choose NHLA members, you’re investing in quality, trust, and the long-term sustainability of the hardwood industry. NHLA members offer more than competitive prices or quick turnarounds—they deliver integrity, leadership, and accountability. In a marketplace where trust is everything, the choice is clear: partner with NHLA members for reliable, high-quality hardwood solutions.

John Hester Chief Development Officer

For sixty years, the industry has relied on Precision Husky Corporation to produce the highest quality, most rugged equipment. Today’s products are ready to lead the way for the next sixty years.

Our chippers are just one example. The spout design with a flat bottom and canted side gives 25% more anvil contact with the log. This provides absolute control of the log, preventing slapping and wood turning. Both horizontal and vertical anvils give additional life with less maintenance.

You can invest in our equipment with confidence, and know it will perform for many years to come. Call us today to discuss your needs, as well as the newest options available for our line of sawmill, logging and wood waste recycling equipment.

By DANA COLE, Executive Director of the Hardwood Federation

Since Inauguration Day, the U.S. Senate has been actively processing and confirming nominations for President Trump’s cabinet. While several appointments have received national media attention, the Hardwood Federation team wants to highlight a few lower-profile but equally important nominees who show promise in advancing our public policy priorities.

One key appointment is Secretary Sean Duffy, a former House lawmaker from Wisconsin’s 7th District who has been a strong advocate for the forestry and forest products industries. During his time in Congress, Duffy led the Safe Routes Act, a truck weight reform bill that allows trucks operating at the maximum gross vehicle weight on state roads to maintain that weight on federal interstate highways. This legislation is crucial for the logging sector, as current federal weight limits force log trucks onto narrow state roads that pass through small towns and residential areas.

Why is this important? Many states provide a weight tolerance of up to 10% for log trucks due to variations in raw timber moisture content, making precise weight estimation challenging. However, federal interstate highways impose a strict 80,000-pound weight cap, meaning that trucks carrying slightly over this limit must take less efficient and often more dangerous routes. Duffy’s bill proposes a commonsense reform that would allow fully loaded log trucks weighing up to 84,000 pounds to access the interstate when practical.

• Improves transportation efficiency

• Enhances road safety by reducing truck traffic through small towns

• Utilizes federal highways engineered for heavier loads

With his background in forestry policy and personal connections in the industry, Duffy is well-positioned to support truck weight reform in Congress and explore executive actions that could imple-

ment pilot programs within his department. Notably, his nomination was approved unanimously by the full Senate, demonstrating broad bipartisan support.

Another significant appointment is Lori Chavez-DeRemer, nominated as Secretary of Labor and scheduled for a Senate hearing next week. A former Representative from Oregon’s 5th District, she played a key role in workforce development legislation, serving as the Republican lead on the Jobs in the Woods Act, which funds workforce training programs in forestry and sawmilling.

Chavez-DeRemer worked closely with bipartisan lawmakers, including Rep. Marie Gluesenkamp Perez (D-WA), as part of the Congressional Problem Solvers Caucus, a group dedicated to advancing common-sense, bipartisan solutions. Her nomination will be closely

watched, as she is expected to receive support from both sides of the aisle. However, her previous support for the PRO Act, a pro-labor bill, may result in some Republican opposition.

Leadership at the EPA and USDA

Two other key appointments—Lee Zeldin as Administrator of the Environmental Protection Agency (EPA) and Brooke Rollins as Secretary of Agriculture—bring new leadership to critical departments that impact the hardwood industry.

• Lee Zeldin (EPA Administrator): A former New York Congressman, Zeldin was not known for environmental policy leadership but had a smooth Senate confirmation. The Hardwood Federation is optimistic about working with him to push for EPA recognition of biomass combustion emissions as carbon-neutral in federal air quality programs. His nomination passed 56-42, with some bipartisan support.

• Brooke Rollins (Secretary of Agriculture): Her nomination was unanimously approved (28-0) by the Senate Agriculture, Nutrition, and Forestry Committee, with expectations for full Senate confirmation soon. Rollins has engaged with lawmakers on trade policy, tariffs, and Farm Bill negotiations, signaling a willingness to support new trade agreements that could benefit the hardwood industry.

With the 119th Congress off to a fast-paced start, the Hardwood Federation team is actively engaging with key officials and their staff to ensure our industry’s priorities are heard. As more administration positions are filled, we will continue to advocate for policies that strengthen the hardwood sector and promote sustainable growth.

We look forward to working with these new leaders and keeping our members informed about developments that impact the industry.

"The Hardwood Federation team is actively engaging with key officials and their staff to ensure our industry’s priorities are heard."

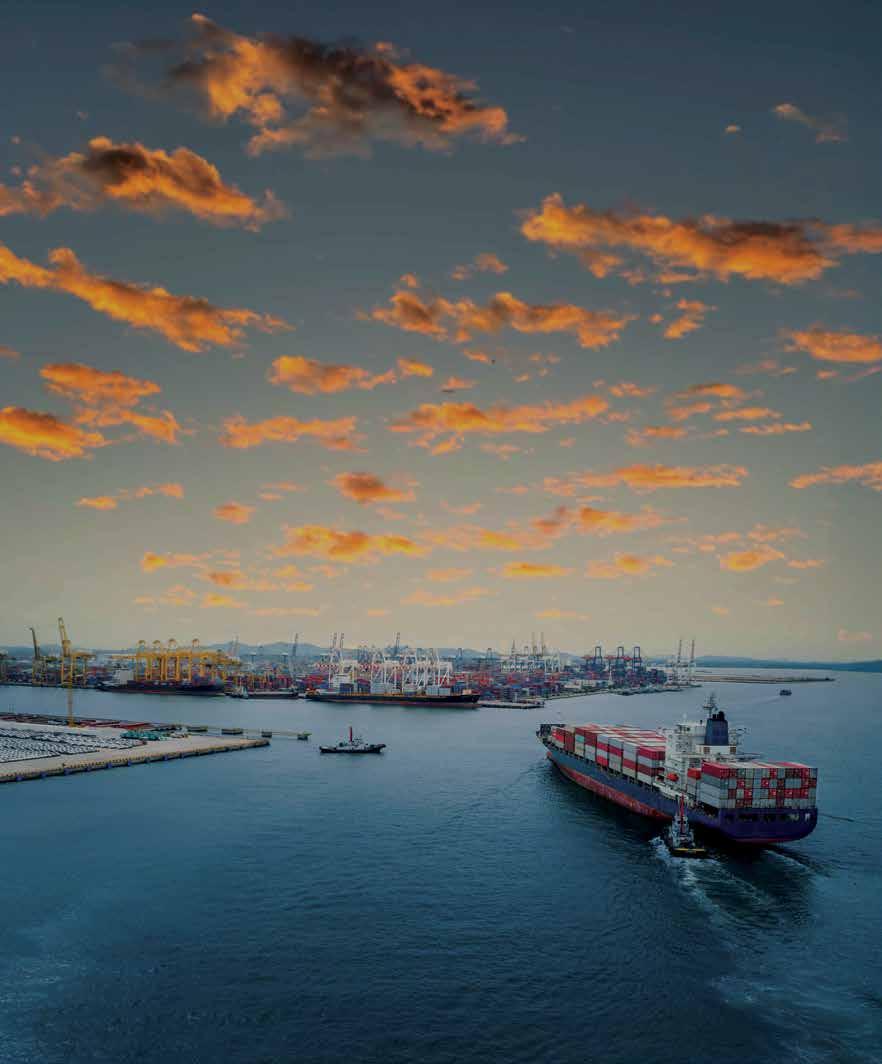

By RAY MOISTNER, Executive Director Indiana Hardwood Lumbermens Association

HAS EXPORTING BECOME TOO RISKY? With tariffs, trade wars, and EU procurement restrictions, the landscape for exporting remains uncertain. As offshoring slows and manufacturing returns domestically, questions about labor and automation loom large.

For Indiana exporters, inland shipping costs present significant challenges compared to competitors closer to ports. Since 2017, companies have seen dramatic reductions in export markets, resulting in a more cautious approach to re-entering global trade.

Logistics is more than moving goods; it’s the backbone of the supply chain, focusing on transportation and inventory management. Critical factors like warehouse capacity, labor availability, fuel costs, driver shortages, port delays, and tariffs can make or break success.

Decades ago, order processing was the most time-consuming part of logistics. With the advent of barcodes, real-time inventory tracking, and global logistics platforms, companies like Amazon redefined the industry. Transportation is the costliest part of logistics with significant efficiency potential. Freight alone accounts for two-thirds of logistics costs and plays a critical role in customer service.

Measuring logistics performance is essential to establish a baseline for improvement. Clear goals reduce costs and boost customer satisfaction. Key areas for improvement include:

• Increasing average order value.

• Reducing travel times and consolidating shipments.

• Localizing procurement.

• Investing in warehouse and transportation management systems.

• Embracing automation where it makes sense.

• Outsourcing logistical services for efficiency.

Mike Wagner, President of Jasper Group, has been navigating logistics challenges since 1876. The furniture industry is investing in re-shoring due to logistical uncertainties.

“Commercial and hospitality buyers are opting for more certainty of domestic manufacturing. Some of our hardwood suppliers have become so dependent on large container shipments to their Asian customers that many have diminished capabilities to deliver smaller, more frequent orders.”

Wagner adds, “In the coming years I suspect the automation in furniture manufacturing will sustain domestic production, and lumber supply chains will need to match the automation investments and realign their distribution strategies to serve a more diverse customer base.”

On the lumber side, Mike Powers of Maley and Wertz reports that their export business has declined by 90% compared to a decade ago. “We’ve replaced it with increased sales to domestic distributors and industrial markets,” says Powers. “We’ve always exported only

what we’ve produced in excess of our domestic demand,” he said adding that it’s better for market stability anyway.”

Powers reflects on the impact of tariffs during President Trump’s first term: “Overnight it seemed that most exports came to a grinding halt. Then those players that were heavy in exporting had no choice but to dump all their production in the US, crashing domestic markets.”

Tom Oilar, President of Cole Hardwoods, offers a positive outlook: “Exports are approximately 20% of our volume but we have seen more inquiries from China after the election. We assume it was them trying to get in front of the potential tariff. As of today we are seeing the freight rates to China unchanged over the last couple months. It appears the longshoremen have reached an agreement, which is good news for all.”

Oilar also notes, “Sawmills are reporting more activity from Chinese buyers sourcing logs. AHEC reports that in 2024, log shipments to China surpassed lumber shipments. While tariffs will impact the industry, I don’t expect them to be as severe as in 2018. We remain optimistic as we move into 2025.”

“I really expected our customers to be nervous with Trump talking tariffs, but it has been just the opposite,” said Brett Franklin of Tri-State Timber. “Log volume has been too low to get enough

(sawmill) sales, but new customers come in looking for logs. We keep raising our price and they keep buying. The last time Trump was in we lost a lot of export business, but so far we are not slowing down. Clear walnut seems to be hottest and white oak is still strong.”

Effective logistics leaders connect teams across all levels. They must excel in both data analysis and understanding global trends.

Logistics has a profound impact on profitability. With the right investments in technology, automation, and strategy, logistics is one of the most controllable costs in any business.

Effective logistics isn’t just about internal efficiency—it’s about how industries work together to overcome challenges and drive collective success. Collaboration between manufacturers, exporters, and industry organizations is critical to navigating trade restrictions, optimizing supply chains, and meeting market demands.

By leveraging partnerships, sharing best practices, and investing in forward-thinking strategies like automation and re-shoring, the hardwood industry can create a more resilient and sustainable future. When companies work together to adapt to global trends and logistical hurdles, the entire sector benefits—strengthening market stability and ensuring long-term growth.

By BRENNAH HUTCHISON, Content Strategist & Editor

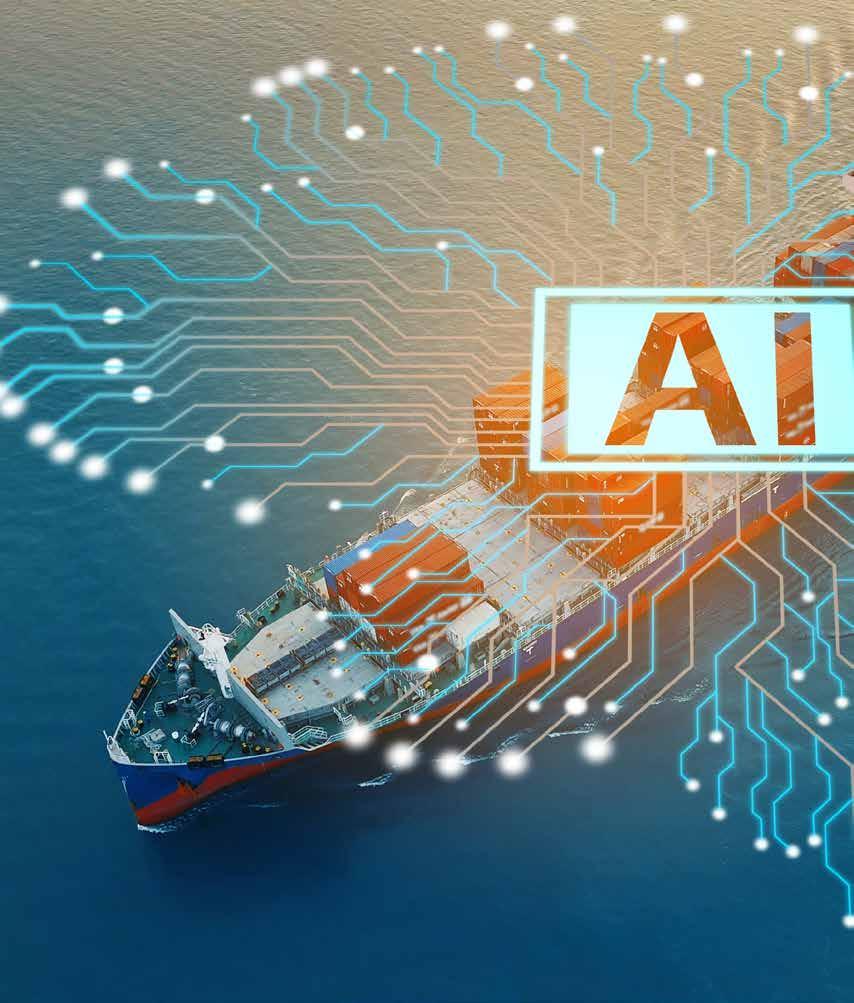

The U.S. hardwood industry is bracing itself against turbulent waves of uncertainty as recent tariff implementations threaten to disrupt trade and supply chains. Reflecting on past challenges, Executive Director Dallin Brooks noted, “During the 2017 trade dispute, [the hardwood] industry experienced significant challenges, including a 20-25% export decline. Several companies were forced to shut down, and many others struggled to recover.” Although my initial interview with Stephen Zambo, CEO and Founder of Ally Global Logistics (AGL Group), focused on AI’s role in global logistics, the recent tariff implementations prompted NHLA to explore whether AI-driven logistics might help mitigate some of these impacts.

In recent years, the logistics industry has shifted its focus from fraud prevention and visibility to integrating Artificial Intelligence (AI). Zambo explained, “We view AI, as an organization, as a tool to leverage, not to replace people, but to reduce a lot of the redundant manual work that takes place in the international logistics space.” AI-powered Transportation Management Systems (TMS) are increasingly being used to improve operational efficiency, particularly in automating document processing and tracking updates.

One area where AI is showing promise is in streamlining booking confirmation updates. Zambo described a common challenge, “For every booking confirmation a client requests, we might have eight updates on the back end from the steamship line. We’ve built out a tool where AI extracts the data and automatically updates and sends it to the client. That saves my team like 800 hours or something a month.”

“We view AI, as an organization, as a tool to leverage, not to replace people, but to reduce a lot of the redundant manual work that takes place in the international logistics space.”

Beyond operational efficiency, AI also offers potential solutions to tariff-related inefficiencies by reducing logistical bottlenecks and costs. Zambo noted, “When we do a shipping instruction for a client, we need several key documents—commercial invoice, tallies, packing list, and shipping instructions. Right now, that back-andforth can take five or six emails. With AI, that could be handled where that information is being checked and processed just by AI.” AI-driven optimizations have the potential to minimize tariff delays and costs, though many companies still rely on traditional systems that have served them well.

While AI-driven logistics offer efficiency gains, adoption remains uneven. Smaller businesses may struggle with implementation costs, and some logistics providers face challenges in integrating AI with existing infrastructure. “User adoption has always been one of the biggest challenges,” Zambo acknowledged. “We’ll introduce new software and change the process from steps 1-2-3 to 1-3-4, and sometimes getting everyone on board takes time.” He also pointed out the fragmented nature of the logistics industry, with many steamship lines owned by different countries, which can complicate integration efforts.

Despite these hurdles, AI-driven logistics offer a beginning to address some inefficiencies in the supply chain. In particular, AI-based routing is helping reduce empty truck hauls, contributing to more sustainable logistics. Zambo observed, “We’ve seen companies try

AI-driven logistics offer a beginning to address some inefficiencies in the supply chain. In particular, AI-based routing is helping reduce empty truck hauls, contributing to more sustainable logistics.

to match up an import move with an export move. And so that eliminates the amount of downtime in a truck so that a truck will be loaded from eighty to ninety percent of the time versus only fifty percent of the time.”

Looking ahead, companies are exploring AI advancements in predictive weather modeling to optimize shipment logistics. Zambo shared, “I just met with a company using a predictive weather model for import shippers. If a typhoon’s coming in, they might route it a different way or look to source from a different place based on that.”

In the context of current tariffs, AI-driven logistics can promote efficient, tech-enabled trade. The hardwood industry continues to navigate evolving logistical challenges, with AI emerging as one of many tools that could help companies adapt to future trade shifts. While AI adoption is still in its early stages, its long-term potential for the hardwood industry is immense. Zambo concluded, “I think we’re in like, you know, if you equate this to a football game, I think we’re in the second drive, you know, we’re not even out of the first quarter right now.”

Note: This article was drafted on February 11, 2025, and reflects the tariff situation as of that date.

UNLOCK THE FULL POTENTIAL OF YOUR SAWMILL OPERATIONS AND MAKE INFORMED DECISIONS FOR A MORE PROFITABLE FUTURE.

As an NHLA member, you have exclusive access to our Yield Analysis and Quality Control Services, designed to:

• Enhance Operations: Evaluate your process from log selection to the final product.

• Reduce Waste: Understand and minimize unnecessary loss.

• Increase Profitability: Determine the value of logs and make better business decisions.

• Boost Efficiency: Increase the volume produced from each log, raising production without increasing consumption.

• Promote Sustainability: Get the most out of your raw materials, contributing to sustainable practices.

IDEAL FOR:

• Members that are not regularly testing logs.

• Those considering new equipment for cost-benefit analysis.

“We participated in the NHLA Production Yield Analysis Program, and it was exactly what I had hoped for . . . We have improved our yields, and that has added to our bottom line! It’s been 8 months, and the NHLA National Inspectors that were on this team still call my managers just to see if they have any questions or concerns.”

— Kirkham Hardwoods, Inc.

To schedule your Yield Analysis Study or find out more information contact NHLA Chief Inspector Dana Spessert at 901-399-7551 or d.spessert@nhla.com. www.nhla.com

By DANA SPESSERT, Chief Inspector

One of the many challenges I face as the chief inspector of the NHLA is dealing with questions regarding the different stages in which lumber is inspected. In this month’s article, I would like to explain the rules for inspecting kiln dried lumber.

The rules were developed because the lumber is first inspected as air dried or green and then inspected again as kiln dried. So, when reading or studying the Rules Book, readers must be aware that the rules are written for inspecting green or air dried lumber, and shrinkage allowances are written for kiln dried lumber.

In the 2023 version of the Rules for the Measurement & Inspection of Hardwood and Cypress, on page 56; under the heading of Standard Kiln Dried Rule, it states:

Kiln dried lumber will be graded and measured as such; the grading rules for air dried lumber are to be applied in all respects unless otherwise specified. Rough kiln dried lumber specified 3/8” to 1-3/4” thick may be 1/16” scant of the nominal thickness; 2” and thicker may be 1/8” scant, and the 10% of scant quartered lumber admitted by Paragraph 36 may be 3/32” scant on one edge in 1” to 1-1/2” lumber and 3/16” on one edge in 2” and thicker. The minimum widths mentioned in all grades may be 1/4” scant in width. The 10% admitted by Paragraph 10 may be 1/2” scant in width. In other respects, the rules for grading air dried lumber shall apply.

Two different questions have been asked recently. The first was, what is the thickness of 5/4 walnut after kiln drying?

Green or air dried lumber that is cut 5/4 or 1 ¼” (31.75 mm) after kiln drying can be 1 3/16” (30.16 mm) thick at the thinnest cutting used in establishing the grade.

The second question was, is there any allowance for the minimum cutting widths after kiln drying?

The answer is complicated in that there are a couple of different areas we need to look at in the rules to explain.

If the board is of the minimum width for a particular grade, then the minimum sizes for the cuttings apply in all respects. If the board is below the minimum width and is covered under paragraph 10, Minimum Widths, on page 6, as written below, then you do have another option:

Ninety percent of the minimum widths mentioned in all grades of lumber shall be full width; the remaining ten percent may be up to 1/4” scant in width. This rule applies to each stock width and any specified width.

The option is listed under the grades of number 1, 2, and 3 common grades listed similar to the one standard cutting sizes as:

Minimum cutting: 4” wide by 2’ long or 3” wide by 3’ long, except that in pieces less than 3” wide, under the minimum width rule, Paragraph 10, cuttings the entire width of the piece are admitted.

The cutting sizes for boards that fall under the minimum board width and meet Paragraph 10 requirements allow for full-width cuttings; this would not allow a 2’ long cutting less than 4” wide to be scant. This would only apply to the 3” wide by 3’ long cuttings.

The allowances of thickness and width help compensate for the shrinkage that occurs during the drying process.

May 12-23

Spanish Language

Intro to Hardwood Lumber Grading

For Spanish speakers an Intro class to gain a basic understanding of the NHLA hardwood lumber grading rules and how the rules affect the value of lumber.

Housing and week-day meals are included.

Venue: NHLA Headquarters Location: Memphis, TN

Instructor: Roman Matyushchenko, NHLA ITS Instructor

June 16-19

Intro to Hardwood

Lumber Grading

Intro class to gain a basic understanding of the NHLA hardwood lumber grading rules and how the rules affect the value of lumber.

Host: Ohio Forestry Association

Venue: Yoder Lumber Co., Inc.

Location: Millersburg, OH

Instructor: Benji Richards, National Inspector

June 25-27

Lumber Drying Class

A 3-day course focused on Kiln Drying. You will develop an understanding of drying wood for value and defect reduction. Speakers include Dr. Adam Taylor, University of Tennessee Extension, Mr. Dana Spessert, NHLA Chief Inspector; as well as kiln drying expert Bob Pope from SII Dry Kilns. Yard personnel, kiln operators and supervisors should attend.

Venue: NHLA Headquarters Location: Memphis, TN

August 4-6

Walnut Grading Rules

Walnut is one of those species with a number of exceptions to the Rules. It is also one of the most highly valued species. Join us in Memphis for instruction on getting the most value out of your walnut production.

Who should attend: Experienced graders and inspectors, who grade walnut or will grade walnut.

Venue: NHLA Headquarters Location: Memphis, TN

August 11-21

Inspector Training School Online Program MODULE 1 Two weeks of hands-on training.

Venue: NHLA Headquarters Location: Memphis, TN

Module 2: Online study Module 3: Three weeks handson training and final testing at NHLA headquarters.

Instructor: Roman Matyushchenko, NHLA ITS Instructor

August 27-29

Intro to Hardwood Lumber Grading Intro class to gain a basic understanding of the NHLA hardwood lumber grading rules and how the rules affect the value of lumber.

Venue: NHLA Headquarters Location: Memphis, TN

Instructor: Roman Matyushchenko, NHLA ITS Instructor

Sept 8-Oct 31

Inspector Training School 210th Class

Traditional 8-week hands-on training to achieve a certificate of completion in Hardwood Lumber Inspection.

Venue: NHLA Headquarters Location: Memphis, TN

Instructor: Roman Matyushchenko, NHLA ITS Instructor

September 17-19

Lumber Drying Class

A 3-day course focused on Kiln Drying. You will develop an understanding of drying wood for value and defect reduction. Speakers include Dr. Adam Taylor, University of Tennessee Extension, Mr. Dana Spessert, NHLA Chief Inspector; as well as kiln drying expert Bob Pope from SII Dry Kilns. Yard personnel, kiln operators and supervisors should attend.

Venue: NHLA Headquarters Location: Memphis, TN

Here, you will find our current job listings. To see more details of the job or to post a job, visit www.nhla.com/resources/careers-center

LOS ANGELES, CALIFORNIA

Robinson Lumber Company is looking to hire a Hardwood Sales Representative. This is a newly created position based on our successful growth and development selling in the North American market. The ideal candidate will primarily be responsible for hardwood lumber and decking sales within North America. The more you contribute to sales, the more your earning potential increases!

Please send all questions, resumes and applications to melissa@roblumco.com.

GALETON, PA

Patterson Lumber Co., Inc. is a fourth-generation family operated hardwood sawmill producing 10 million feet annually. Its North Central Pennsylvania location is ideal for outdoor enthusiasts, making it a top destination for hunting, hiking, fishing and star gazing.

We are seeking to add a Lumber Grader for our kiln dried inspection line. The Hardwood Lumber Grader is a vital position in the lumber production process. They accurately inspect and properly grade hardwood lumber to the standards set by the NHLA and in-house standards.

Please send all questions, resumes & applications to plclbrpa@penn.com.

Woodgrain is looking for an experienced Hardwood Lumber Inspector for our Independence, VA sawmill to join our team! The Hardwood Lumber Inpsector is a vital position in the lumber production process. They accurately inspect and properly grade hardwood boards to the standards set by the NHLA and in- house standards. The Grader is responsible for sorting through the lumber on the grader chains and marks out the common boards, oversize, and any special trimming that is needed. Grader examines both faces of a board then assigns and marks a grade on the board so that correct trimming decisions are made to increase the value of each board.

Please send all questions, resumes & applications to michael.anderson@woodgrain.com.

Lebanon Oak Flooring Company is seeking a full time hardwood lumber grader/inspector position for incoming lumber at our plant in Lebanon, KY. The position will be primarily for grading green lumber and supervising a small crew.

Please send all questions, applications & resumes to don@ lebanonoak.com.

Here, you will find our current job listings. To see more details of the job or to post a job, visit www.nhla.com/resources/careers-center

BEACH LAKE, PA

Reining Forest Products is a family run sawmill that has been operating since 1944. We specialize in Softwood industrial and wholesale lumber but cut both soft and hard woods. We are seeking a sawyer with 3-5 years of experience cutting softwood or hardwood. Ownership of saw maintenance is a must. If interested, give us a call to discuss joining our team.

Please send all questions, resumes and applications to steph@reiningforestproducts.com.

SOUTH MILFORD, IN

We are seeking a skilled and detail-oriented Hardwood Lumber Grader to join our team. As a Grader, you will be responsible for inspecting and grading various hardwoods to ensure they meet quality standards. This is a critical role in our organization as it directly impacts the quality of our products.

Please send all questions, applications & resumes to dane@ wiblelumber.com.

Missouri Walnut Group is looking for a skilled Lumber Inspector with a high attention to detail, safety standards, who will help ensure lumber is examined properly to determine quality and assign grades. On the job training is a good way to discover how to do the job better, so you should have a willingness to learn and improve. Being a team player is essential, the goal is to ensure that production procedures are carried out smoothly in order to maximize efficiency and profits. This position participates in our monthly profit-sharing bonus which is based on profitability of the company.

Please send all questions, applications & resumes to awilkie@ missouriwalnutgroup.com.

The National Hardwood Lumber Association (NHLA) is seeking a motivated sales professional to promote advertising opportunities, exhibit booths for our annual convention, NHLA services, and membership benefits. This dynamic role offers the chance to build relationships, drive growth, and make an impact in the hardwood industry.

Please send all questions, applications & resumes to dallin@nhla.com.

Hardwood Markets Matter, and it is important for NHLA to share market details of the entire Hardwood Industry. We appreciate the support of allied associations and publishers in gathering and sharing this important market information that can help you understand the complete hardwood industry picture.

www.hardwoodreview.com

Poplar supplies have tightened recently, lifting KD 4/4 #2/Btr prices after they stalled or fell back slightly over the holidays. End-users started replenishing Poplar supplies in mid-January after purchasing little or none at year-end, and are increasingly concerned about supply shortages, potentially even before stronger spring homebuilding kicks in. With sawmill capacity contractions and log/labor shortages limiting production, upper-grade Poplar prices likely will continue to rise.

December Poplar exports to Vietnam and China were the lowest for any December since 2010 and 2000, respectively Yet, common-grade Poplar prices were largely stable in December, an indication of just how low production and supplies have fallen. Provided that no retaliatory tariffs are placed by China on U.S.

*Prices averaged across regions

lumber—and there were none as of this writing—Poplar demand from Asia should grow seasonally, further tightening availability. Inventories of KD 4/4 #2 Common Poplar have thinned as sawmills have left more of the logs in industrials, resulting in late-2024 price increases in Appalachia and more recent increases in the South. Two sawmills that didn’t want to hold any #2 Common Poplar last year now indicate it might be good to build a little inventory in anticipation of higher pricing in Q2.

www.hmr.com

The HMR Demand Index (HDI) is a feature in HMR Executive® that illustrates monthly trends in reported demand from 10 major domestic markets for hardwood lumber. Components of the index are color coded with various shades of blue when demand is slow, they transition to gray when demand is fair, and then to light red and deep red when demand moves from good to strong.

Index for January, which is published the first week of February.

Cabinets Residential

Upholst.

Wood

Moulding/Millwork

Wood Components

Board Road

Pallets

Railroad Ties

By Nate Irby, Ph.D., Railway Tie Association

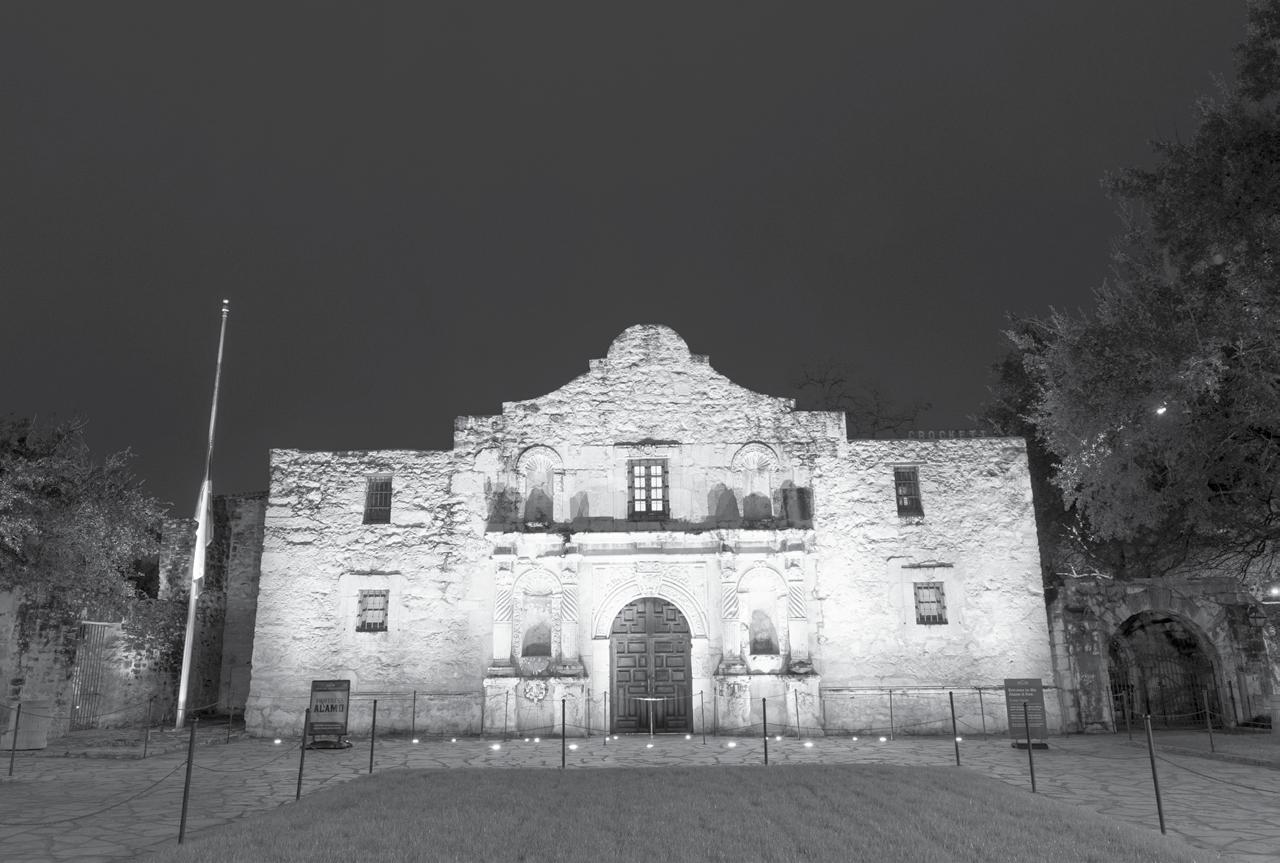

The Railway Tie Association’s (RTA) Tie Grading Seminar continues to break records, with the 2025 seminar overselling its capacity once again. To be hosted this year at the Koppers Inc. plant in Somerville, Texas, the seminar has grown steadily since 2021, reflecting its reputation as a cornerstone educational program for the wood crosstie industry.

Since its inception well over 30 years ago and having educated more than 1,200 students, the RTA Tie Grading Seminar has become an essential learning experience for sawmillers, producers, and railroaders, covering everything from wood tie sourcing to engineering. The event’s attendance has surged over the years, jumping from 41 participants in 2021 to a consistent 54 registrants in both 2024 and 2025.

“Our Tie Grading Seminar has grown into a must-attend event for our industry,” said RTA Executive Director Dr. Nate Irby. “The fact that we’ve oversold this seminar five years running is a testament to the quality of instruction, the commitment of our members, and the hands-on, real-world skills it offers to participants who then share their positive experience with the workforce.”

A standout factor in this year’s event is the participation of 10+ railroaders, a record-breaking number, further emphasizing the seminar’s relevance to all sectors of the wood tie industry, from tree to track.

The course has traditionally been designed for 40 students, ensuring a manageable group size for classroom learning, plant tours, and tie testing activities throughout the program. However, since 2021, attendance has consistently surpassed this target, driven by several key factors contributing to its success.

• Rescheduled Timing for Better Access: In 2023, the seminar moved from its usual early August timeframe to mid-March, a shift that better accommodates participants’ schedules encourages broader attendance. “Plus, especially in the U.S. south, March is a much more pleasant time to be outside compared to the heat of early August,” Irby added.

• Student-Driven Content Improvements: The seminar instructors continuously refine the course based on direct feedback from students. This includes one-on-one interactions during the course and formal evaluations completed at the end. These adjustments ensure the content remains relevant and impactful, empowering students and enhancing their sense of professionalism.

• Expert Instruction with Real-World Insights: Two of the instructors are former Class I railroad professionals who added a treated tie inspection component to the course in 2022. “The treated tie inspection segment has been overwhelmingly positively received and helps flush out the full spectrum of a wood tie from tree to track,” Irby said. “The seminar instructors are diverse and knowledgeable, from track-work experience, to academia, to plant operations, and quality assurance/conformance backgrounds.”

• The Power of Word of Mouth: Positive experiences from past attendees play a major role in attracting new participants. Many students report attending because coworkers shared glowing reviews about the seminar, describing it as a valuable and rewarding experience.

• First-Hand Experiences Shared by Instructors: Instructors recently introduced a tie grading booth presentation by a former professional wood tie grader and certified lumber inspector. This addition provides students with first-hand insights into grading practices in a real-world processing facility.

• Enhanced Curriculum on Railroad Engineering: The railroad engineering portion of the course has been revamped for improved flow, helping students better understand the critical role wood tie specifications play in determining tie usage in track and in keeping railroad workers safe and efficient.

• Simplified Wood Species Identification: Over the years, student feedback highlighted challenges in identifying 16-20 wood species during the three-day course. Instructors responded by aligning the training with real-world, state-of-the-art practices, categorizing species into three basic groups, improving test scores and student satisfaction and bolstering student confidence.

• Supportive Learning Environment: The instructors create a welcoming atmosphere where students feel encouraged to ask questions, seek clarification, and engage in one-on-one interactions. RTA staff also emphasize the rewarding nature of the wood tie industry, inspiring attendees to understand the broader scope of their work and to build on the knowledge and relationships they gain during the course.

Beyond the technical training, the seminar fosters relationships and provides a comprehensive view of the wood tie life cycle— from “tree to track.” Participants leave equipped with new skills, practical knowledge, and connections across the industry.

“We couldn’t do this without the incredible support of our members,” Irby said. “Their contributions—whether through hosting seminars, providing lunches, or sending personnel—are what make this program a success. We are deeply grateful for their dedication and reverence for what this seminar means to our industry.”

The Tie Grading Seminar remains a shining example of RTA’s commitment to education and workforce development. As the 2025 seminar approaches, attendees can look forward to another exceptional experience that blends industry expertise with practical application.

Planning is already underway for the 2026 Tie Grading Seminar, to be held March 16-18 at Stella-Jones Corp.’s Fulton, Ky., plant.

www.nwfa.org

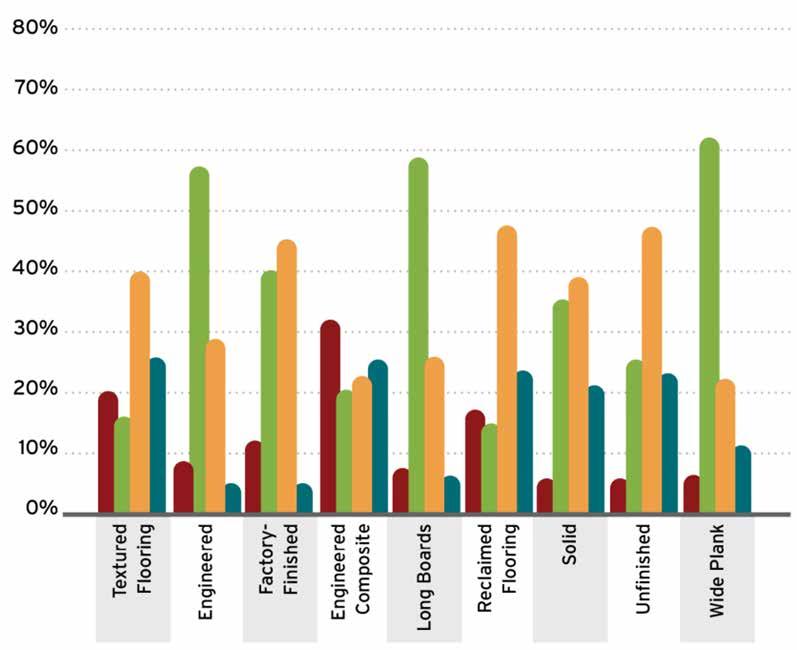

According to Hardwood Floors magazine’s 2025 NWFA Industry Outlook survey, longer, wider boards remain in high demand and engineered wood flooring continues to grow. Respondents say consumers are tending to avoid heavily distressed flooring.

eLIMBS | Agility | TallyExpress | Neural Grader

Ease the pain of staffing shortages with inventory management solutions made for hardwoods. DMSi is your one software partner from timber to consumer.

FRANK MILLER

LUMBER CO