The new year is here, so what are we going to do differently? Every January, we sit down as a team and evaluate the previous year. We not only look at gross sales and gross profit percentage, but we look at our repair process, needed facility upgrades, marketing and – most importantly – our employees’ satisfaction. Does our team ‘like working here’? What can we do to offer them the best place in which to be successful? I have always believed the best way to achieve customer satisfaction is to empower everyone here to give them the tools needed to be successful, which will translate into the customer experience.

Of course, every business wants to do better. In the past, I would set high goals to achieve. Looking back at a lot of them, they were not realistic and unachievable. I’ve learned to set my expectations and work with my team. I’d spend hours writing all my goals and in the end, I’d look at the list and be completely overwhelmed; almost to the point of no action. I’ve learned to ‘eat the elephant one bite at a time.’ The important thing is to start in one place and move on from there. Whether it is blueprinting, SOPs, the repair process, estimating accuracy, OEM repair procedure integration, facility and equipment maintenance schedules, training calendars, etc., pick the top three most important things you bring to your team, present them, listen to their feedback and implement them.

PRESIDENT Kris Burton kris@rosslynautobody.com - 703-820-1800

VICE PRESIDENT Phil Rice price@bapspaint.com - 540-846-6617

TREASURER John Shoemaker john.a.shoemaker@basf.com - 248-763-4375

SECRETARY Barry Dorn bdorn@dornsbodyandpaint.com - 804-746-3928

IMMEDIATE PAST PRESIDENT Steven Krieps steve@gregclineauto.com 304-755-1146

Rodney Bolton (boltonconsulting61@gmail.com) 443-386-0086

Tom Brown (thbrown@ppg.com) 703-624-5819

Torchy Chandler (torchy.chandler@gmail.com) 410-309-2242

EXECUTIVE DIRECTOR

Jordan Hendler (jordanhendler@wmaba.com) 804-789-9649

WMABA CORPORATE OFFICE

P.O. Box 3157 • Mechanicsville, VA 23116

Kris Burton (703)-820-1800 kris@rosslynautobody.com

We hear the word culture all the time; to me, culture is everywhere around us. Do employees want to be there? Are they heard and supported? Does your facility provide the best working environment possible? Not everything costs a lot of money. There are simple things that can change ‘culture,’ many of which are the things we do not think about. Is the lighting in your building bright enough for techs to see what they are working on? Is your equipment up to date, is it in working order, are the restrooms clean, do all the electrical plugs work, are there adequate materials on hand, do techs spend time looking for parts and what to do next? These are all simple fixes that will change ‘culture.’

One of the things we strongly believe in is training. We are fortunate that there are so many opportunities available today as opposed to years past. Each person has different strengths and weaknesses. Send them to the training they will get the most value from, whether it’s OEM training, tool and equipment, paint companies, customer service, etc. Most importantly, it has to start somewhere, and little by little, it will get better.

Personally, the most value I’ve got is from participating with trade associations – not only with WMABA, but also SCRS and members of business performance groups. The first step is to show up. And there’s no better time to show up than in Richmond, VA on May 1 for the Southeast Collision Conference. H&D

HAMMER & DOLLY STAFF

PUBLISHER Thomas Greco thomas@grecopublishing.com

SALES DIRECTOR Alicia Figurelli alicia@grecopublishing.com

EDITORIAL DIRECTOR Alana Quartuccio alana@grecopublishing.com

SENIOR CONTRIBUTING Chasidy Rae Sisk EDITOR chasidy@grecopublishing.com

Tracy Dombrowski (tracy@collisionadvice.com) 571-458-0648 Bill Hawkins (hawkinswilliamjr@gmail.com) 510-915-2283

OFFICE MANAGER Donna Greco donna@grecopublishing.com

PRODUCTION Joe Greco COORDINATOR joe@grecopublishing.com

www.grecopublishing.com @grecopublishing

WMABA has worked hard to bring this opportunity, made for you. All that we do in preparation of the Collision P.R.E.P (Professional Repairer Education Program) series coming May 1-3 at the Southeast Collision Conference at the Greater Richmond Convention Center in Richmond, Virginia, is all arranged so that our industry can have opportunities to increase their knowledge, network and professionalism. In these modern times, getting yourself to industry events has never been more important to your professional health!

Both WMABA and the Carolinas Collision Association are excited to host the national Collision Industry Conference and Society of Collision Repair Specialists (SCRS) meetings in conjunction with SCC, also held in the same location. Several other national associations will also be holding board meetings or council meetings. It will bring another level of engagement, community and information to the repairers in our market regions.

Every person in the modern repair facility will be informed and challenged by a slate of nationally-known and recognized speakers. Folks like Mike Anderson, Danny Gredinberg, Mike Jones, Taylor Moss and more - in addition to a full panel discussion with OEMs - draw repairers from far and wide! With the education program, there will be classes

throughout the day Friday and Saturday for attendees to choose based on their interests and needs.

Every conference and meeting I attend is a testament to how gravely important it is for shops to be engaged – from management to technician to detailer – in the gathering of technological and structural advancements taking place in today’s vehicles and today’s business climate. When I say structural, I mean the vehicle and how you’ve structured your business model. Repairers who are adapting and changing are making headway, and it’s important that the entire industry do the same.

We are a skilled profession, not a trade. I don’t take credit for that realization; it goes to someone who’s a longtime owner who has always strived to repair vehicles by the OE procedure every time. But it’s high time we stand in a place of authority.

Much happens without you knowing, if you don’t leave your four walls. I give the analogy that it’s like our industry is suffering from perpetual “Covid shut-in syndrome”. What does that mean? It means you’re not getting out; many are only getting the education that comes to their doorstep or online. Trust me, ladies and gents, it’s not the same as being present, and in so many

ways you’re only cheating yourself of positive revelation.

When you come to education events in person, you get a greater sense of purpose, of industry, of community and of knowledge and it’s vital to every aspect of your day-to-da, no matter your position.

If you make one investment in your business this year, let it be the Southeast Collision Conference.

There’s too much at stake, both for you and your customers, to stick to the daily grind and not engage. I promise you will gain insight as to your own future and ways in which you can get to it, and people who will rally around and with you to see it happen.

The Conference isn’t just a conference; it’s our associations’ best weapon against the onslaught you face and we want to raise you into a leader who knows how to bring resources into power and light.

Get all the details by visiting southeastcollisionconference.com H&D

M A Y

1 6 - 1 8 GREENSBORO NORTH

F R I D A Y , M a y 1 7

8:30am – 10:00am |

Future-proof Your Shop: Tomorrow’s Success Starts with Today Mike Anderson, Collision Advice

11:30am – 1:00pm | LUNCH & LEARN

Efficiency Unleashed: Rethinking Roles in Collision Repair

Michael Bradshaw of K&M Collision, Barry Dorn of Dorn's Body & Paint, and Kris Burton of Rosslyn Auto Body

2:00pm – 3:00pm | Option 1 The Critical Steps Involved to Achieve

THURSDAY, MAY 1

Kick

FRIDAY, MAY 2

Tradeshow 10am - 5pm

Education 8:30am - 5pm

SATURDAY, MAY 3

S A T U R D A Y , M a y 1 8

Tradeshow 9am - 3pm

8:30am – 9:30am | Option 1

Education 8:30am - 4pm

100% Disassembly Mike Anderson

8:30am – 9:30am | Option 2

Do You Have Leaky Profit? Find Out Where

Profit Leaks from Your Collision Center and How to Fill the Holes!

Taylor Moss, OEConnection

11:00am – 12:30pm | LUNCH & LEARN

Repairer to Repairer: RTA’s and PRI’s, The Process & the Shop’s Role

Panelists: Adrian Mora, Collision Consumer Advocates, Billy Walkowiak, Collision Safety Consultants; Moderated by: Steve Krieps, WMABA Imm Past President / Collision Safety Consultants of WV

2:00pm – 3:30pm | Option 1

Nurturing the Goose That Laid the Golden Egg

Bruce Schronce, StrongLead’s Executive Partner and Leadership & Business Consultant

2:00pm – 3:30pm | Option 2

Increased Profitability through Proper Documentation: How communication, documentation and collision shop positioning must change in 2024 and beyond

Keith Manich, AMAM - Director of Collision Services, Automotive Training Institute

Audi Silver Spring

Direct: 301-890-3015

Fax: 240-471-6103

Email: wholesaless@mileone.com

Hours: M-F 7:30am - 5:00pm S 8:00am - 3:00pm

Mercedes-Benz Silver Spring

Direct: 301-890-3060

Fax: 301-890-5473

Email: mbsilverspring@mileone.com

Hours: M-F 7:30am - 5:00pm S 8:00am - 3:00pm

Porsche Silver Spring

Direct: 301-890-3015

Fax: 240-471-6103

Email: wholesaless@mileone.com

Hours: M-F 7:30am - 5:00pm S 8:00am - 3:00pm

Sprinter Silver Spring

Direct: 301-890-3060

Fax: 301-890-5473

Email: mbsilverspring@mileone.com

Hours: M-F 7:30am - 5:00pm S 8:00am - 3:00pm

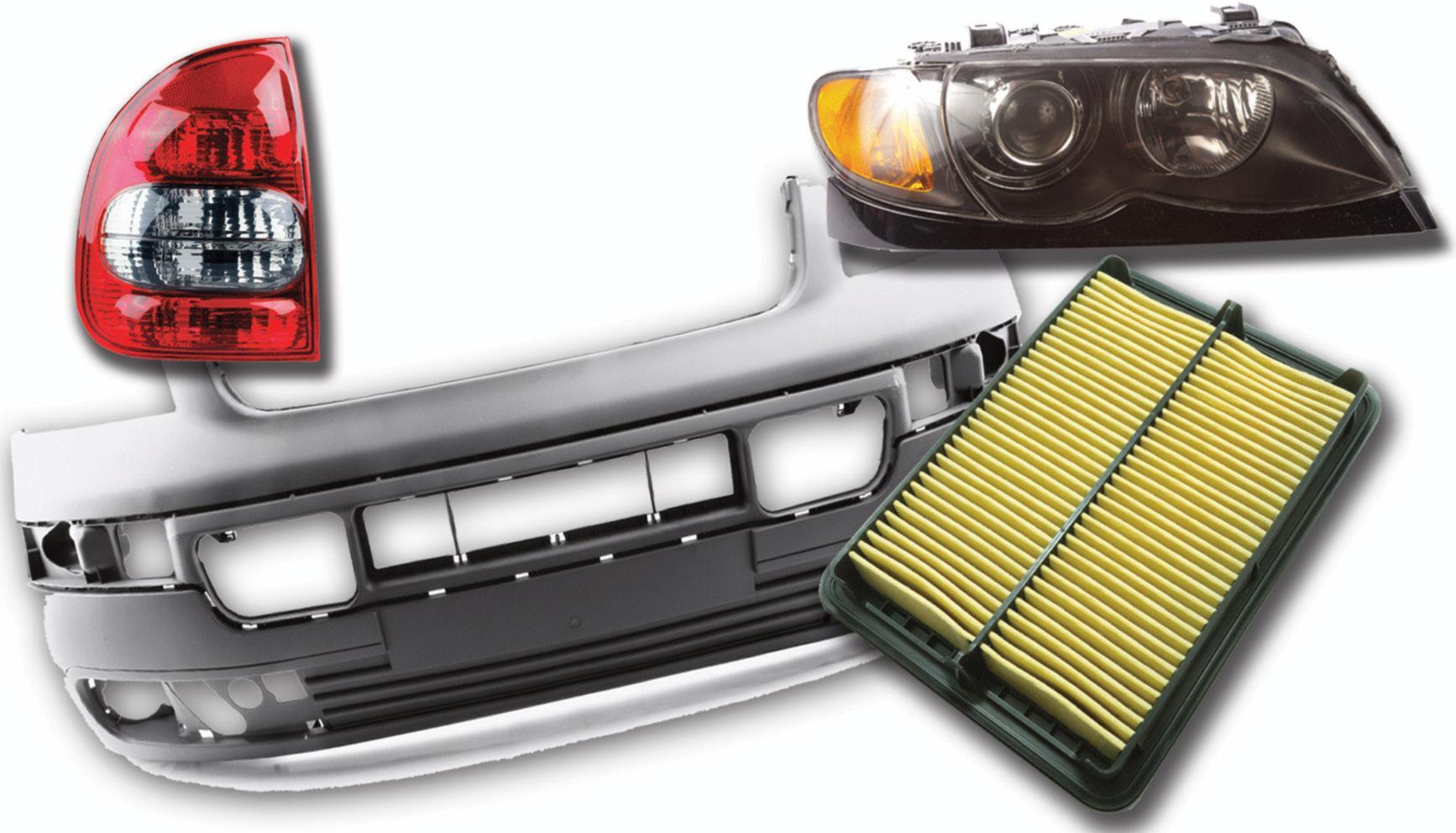

Free delivery on our fleet of 15 GPS-equipped delivery trucks - delivering all Silver Spring brands on the same truck throughout Maryland, D.C. and Virginia

We use IRF automotive systems including CCC, CollisionLink, OPSTrax, partslink24, PartsTrader & RepairLink

Highly knowledgeable, experienced and dedicated wholesale specialist team

Large inventory of OEM parts and tires

Contact our dealers for all your Genuine Parts needs!

BMW of Silver Spring

Direct: 301-890-3015

Fax: 240-471-6103

Email: wholesaless@mileone.com

Hours: M-F 7:30am - 5:00pm S 8:00am - 3:00pm

Herb Gordon Subaru

Direct: 301-890-3065

Fax: 301-847-2239

Email: herbgordonsubaruwholesaleparts@mileone.com

Hours: M-F 7:30am - 5:00pm S 8:00am - 3:00pm

Volvo Cars Silver Spring

Direct: 301-890-5456

Fax: 301-847-2239

Email: herbgordonvolvowholesaleparts@mileone.com

Hours: M-F 7:30am - 5:00pm S 8:00am - 3:00pm

Today’s students have many options when it comes to deciding their futures, and although the auto body industry offers a multitude of exciting career paths, many collision repair educational programs struggle to attract and retain those students due to an inability to show them that potential future; outdated tools, equipment and facilities leave them stuck in the past. That’s not the case at the Carroll County Career & Technology Center (CCCTC) in Westminster, MD – the school recently invested in its collision repair technology program by renovating the shop and classroom areas.

“The new shop and updated equipment have been a driver of new interest,” shares instructor Timothy Gisiner. “We have renewed energy and vision for the program that is paying off with more student interest.”

The two-semester program is open to students in the spring of their junior year and fall of their senior year. “Our current class consists of 18 students and one Research and Development student, a spring semester senior who is continuing their learning by assisting new students.”

Gisiner finds it particularly rewarding to “teach the very program from which I graduated in 1987 (in the renovated space that was my original classroom) to share my knowledge with the future of the industry. I am dedicated to restoring the program to its former glory from the ‘80s and beyond. We are adding state-of-the-art equipment each year to revitalize the program and ensure its students are learning the latest industry skills.”

“The program is run like a real shop but still has school requirements,” he explains. “After initial training, we take customer work on minor damage repairs. Students are in class for approximately three and a half hours each school day. School holidays, weather delays and special events are subtracted from those days. Then, time has to be allocated to

chapter work and testing, certification testing and special program events like industry presentations or career fairs. A typical fiveday job in another shop could easily take a month or more in our learning lab.”

Students enrolled in CCCTC’s collision repair technology program also learn skills that help them secure employment after graduation. “The program incorporates resume writing and job-hunting skills,” Gisiner reports. “Industry representatives visit the program during the career fair and other events. I work with shops in the area to get students jobs during the program. Most of the students were placed by the end of the first semester, and the rest should have offers by the end of the program. We continue to support our graduates when they reach out for references for jobs even years after they leave our walls.”

Like many other auto body program instructors, Gisiner faces budgetary constraints. “The administration provides as much of a budget as possible, but the cost of materials and equipment rises faster than program funding;” however, he overcomes

those obstacles through fundraising and applying for available grants. In 2024, CCCTC received a $5,000 Benchmark Grant through the Collision Repair Education Foundation that has helped with maintaining the program’s needs. “Donations of supplies from the industry and community are a tremendous help to supplement our budget.”

Support from the program’s advisory committee (PAC), which meets twice each year, also proves incredibly beneficial. Our PAC has been amazing at reviewing renovations, offering equipment purchase guidance, supporting audits and providing purchase justifications for larger equipment,” Gisiner praises. “We have a diverse PAC, currently led by a woman industry leader who has presented on diversity in the workplace and helps support our female students, as well. Half of our PAC members have already hired our students and graduates! The PAC members are present and involved. We welcome anyone interested in serving on our PAC, and I foresee it continuing to grow with the program.”

Gisiner also welcomes other collision industry professionals to visit the shop and speak to his students. “Each student is an individual, and there are many different facets of the industry. One size definitely doesn’t fit all! Visitors from different job functions within the industry would light the spark of interest in our students in these different industry jobs. Community involvement always creates more program interest for future students. I understand that not everyone has the time and ability to come during program hours, but we always need financial or donation

support. We try to stretch even the smallest donations as far as we can for our students and acknowledge all donors on our social media page.” He also recognizes the value of joining associations to expand his own knowledge, which is why his program decided to join WMABA this year. “We look forward to taking advantage of WMABA’s programs and offerings. So far, I have been passing the industry updates and information shared by WMABA to our students. A huge benefit of WMABA is that they are helping to keep me current in the quickly changing collision repair industry, so I can ensure our students are getting the latest-and-greatest industry updates!” H&D

ADAS calibration is the precise adjustment of your vehicle’s sensors and cameras, essential for the optimal functioning of advanced safety systems. This process is especially critical following significant repairs, part replacements, collisions, or windshield replacements, as these events can disrupt sensor alignment. It’s important to avoid driving without proper sensor calibration. Uncalibrated ADAS sensors can compromise your vehicle’s safety features, leading to potential malfunctions and driving hazards.

ADAS calibration is the precise adjustment of your vehicle’s sensors and cameras, essential for the optimal functioning of advanced safety systems. This process is especially critical following significant repairs, part replacements, collisions, or windshield replacements, as these events can disrupt sensor alignment. It’s important to avoid driving without proper sensor calibration. Uncalibrated ADAS sensors can compromise your vehicle’s safety features, leading to potential malfunctions and driving hazards.

The calibration of ADAS can be performed in two main ways: static and dynamic. Static calibration takes place in a controlled environment, ensuring accuracy and consistency. Dynamic calibration, on the other hand, involves driving the vehicle under specific conditions to fine-tune the sensors in real-world scenarios. This comprehensive approach ensures that your vehicle’s safety systems are

The calibration of ADAS can be performed in two main ways: static and dynamic. Static calibration takes place in a controlled environment, ensuring accuracy and consistency. Dynamic calibration, on the other hand, involves driving the vehicle under specific conditions to fine-tune the sensors in real-world scenarios. This comprehensive approach ensures that your vehicle’s safety systems are reliable and effective, providing peace of mind on the road.

THEY’RE CALLED “ORIGINAL BMW PARTS” FOR GOOD REASON. FOR UNCOMPROMISING PRECISION AND INCOMPARABLE QUALITY, YOUR BMW CENTER IS YOUR ONE-STOP SHOP FOR EVERYTHING BMW.

For Original BMW Parts, contact one of these authorized BMW centers:

BMW of Silver Spring 3211 Automobile Blvd

Silver Spring, MD 20904 866-737-8937

Direct: 301-890-3015

Fax: 301-890-3748

Email: wholesaless@mileone.com bmwofsilverspring.com

Passport BMW 5000 Auth Way Marlow Heights, MD 20746

301-423-0733

Fax: 301-423-2717 passportbmw.com

Richmond BMW 8710 West Broad Street Richmond, VA 23294

800-237-0130

Direct: 804-527-6860

Fax: 804-965-6254

Email: tdailey@crownauto.com richmond-bmw.com

BMW of Catonsville 6700 Baltimore National Pike Baltimore, MD 21228

855-996-2906

410-744-2000

Fax: 410-818-2600 bmwofcatonsville.com

Direct:

Communication is key in helping to better the industry. That is why the Society of Collision Repair Specialists (SCRS) brings the industry together at their Open Board Meeting multiple times per year to facilitate the right conversations geared toward the right solutions for the benefit of the entire collision repair industry.

Executive Director Aaron Schulenburg referenced the sense of community felt in the room filled with members from different facets of the industry during the Open Board Meeting held in Palm Springs, CA this past January.

“SCRS really is about the society, the community, the people it holds together,” expressed Schulenburg.

Reflecting on his his 18-year old son’s tendency to share quotes of stoicism on his social media platforms, Schulenburg noted the four virtues of wisdom, courage, justice and temperance and spoke of how they can apply to the work of the association, posing the following questions: “How do we embrace similar virtues? How do we do things that make a difference?”

It’s quite common to hear people speak about having a seat at the table in this industry, although Schulenburg pointed out it may really be more about surrounding oneself with others who share the same perspectives and, if they do not, to let that be known. It all comes down to “the opportunity to have a seat around the table and influence what our association does, how we do it and why we do the work we do.” But also to use the seat at the table to uphold the aforementioned virtues, rather than compromise them to gain the seat.

Having the right conversations has led to the development of great resources for SCRS members, such as the organization’s healthcare and retirement plans, which allows small businesses the opportunity to offer affordable benefits to their employees. Currently, 93 groups – a total employee count of about 2,500 – are participating in the SCRS healthcare program, which has an above average 58.9 percent participation rate.

“On average, most employers who come on the plan see 20-25 percent increase in participation in what they had noted with other plans,” shared Schulenburg. The program, developed via Decisely and Gravie, features zero dollar co-pays and other cost-saving benefits.

The retirement plan currently has $28.9 million in assets, and more growth is anticipated with new business in the onboarding process now. The plan allows employees to pay less in fees and therefore be able to save more for their future. SCRS meets quarterly to make sure the funds in

the plan and the investments made match what employees are looking for in order to ensure it’s meeting the needs of the industry as best as possible, Schulenburg relayed.

Keeping tabs on what is happening in the many states that make up the SCRS community is important to the work of the association. SCRS Board member Tony Adams (AkzoNobel) shared the Affiliate and Engagement Committee currently has 34 affiliates representing 40 states and a few areas of Canada who meet virtually several times a year to discuss common issues and other activities.

In relation to affiliate member California Auto Body Association, SCRS invited representatives from the California Bureau of Automotive Reports’ (BAR) Patrick Dorais (BAR chief) and Mathew Gibson (BAR program manager) to share the latest regulatory developments regarding tear down disclosure requirements and storage fees which are under public review, prompting an interactive discussion with members of the SCRS body.

BAR is a huge proponent of the tear down and disassembly process, according to Dorais. Consumer complaints have led to the reexamination of these regulations and a quest to clarify information to offer a more “descriptive description of that area to be repaired.”

“The new regulations, which are going through their process of public comment right now, will require an auto repair dealer

VISIT BOOTH #527 AT A AASP/NJ'S NORTHEAST® SHOW!

CUTTING TOOLS FUME EXTRACTION

DENT PULLING AND MUCH MORE!

continued from pg. 16

to record and provide additional information when adopting a third party payer estimate as the method of repair. Third-party payer is actually defined in this [proposed] package,” Dorais stated. Amended changes also will “require a clarification of the areas of the vehicle that are to be disassembled as part of a tear down.”

In addition to more accurately defining the areas of teardown in ways that “a person without professional or specialized knowledge in a particular subject would understand,” Dorais said, “These tear down regulations or disclosure regulations will also require that the auto repair dealer inform the consumer of the amount approved to be paid.”

The need to amend storage fee regulations stemmed from “disputes between insurers and automotive repair dealers or repair facilities [which] are harming consumers,” according to Dorais.

Gibson outlined some of the specific storage fee regulations, such as requiring “auto repair dealers that charge storage fees resulting from an accident or a theft recovery to report their maximum daily storage rate to BAR on the initial registration and on the renewal when they renew the registration.”

Repair shops that charge storage fees must post their maximum daily fees as they are reported to BAR. Reported maximum daily storage rates can only be changed by shops or auto repair dealers once per registration cycle. BAR’s website will host a search tool showing average daily storage rates per locale given by the rates reported to the Bureau.

Proposed regulations would clarify that storage fees cannot be assessed while a vehicle is undergoing repairs, including a tear down. “It will establish that an auto repair dealer must have obtained the customer’s authorization, generated an invoice after completion of the contract of repairs and notified the customer the repairs are completed prior to charging storage fees. It will require an itemized invoice of storage fees when they are charged,” Gibson outlined.

Dorais pointed to another aspect of the regulations intended to discourage “bandit tow operations” by putting in a “stop, do-notpass-go kind of provision” toward businesses posing as auto repair dealers, preventing them from “charging exorbitant storage fees from the moment they think that the vehicle dropped is off in an unbeknownst location to a consumer potentially.”

Kye Yeung (European Motor Works; CA) questioned when storage charge time begins pointing to how the proposed regulation states that one can’t charge while doing repairs on the vehicle. All too often, shops deal with vehicles sitting on their lot for two to three weeks at a time with no answer. “I don’t see anything there that holds that third party accountable,” stated Yeung.

Gibson said it’s up to the customer regarding whether or not repairs should continue, citing, “Once it’s a total loss, you can start charging storage because they have essentially severed your

contract with the customer.” He also pointed to the reason for tear down estimates. “If you have authorization to perform a tear-down estimate on the car and you have disassembled the vehicle to a condition where you can generate an unadministered estimate to restore it to a pre-loss condition and you notify your customer of that, they then have to either say they’re going to proceed with the repairs or they’re not going to proceed with the repairs. If they are not, then you have completed the contracted repairs, and you can start charging storage.”

On behalf of the Media Development Committee, Erin Solis (Certified Collision Group) reported the SCRS YouTube channel (available at youtube.com/scrscollision) has received more than 32,000 views and 1,200 hours of watch time since the last Open Board meeting held in July 2024.

Previously released videos have longevity as Solis reported that several continue to get views. For example, a quick tip video on EV isolation, released in August 2022, has been viewed just shy of 5,000 times with 749 views coming in just over the last 90 days.

Discussion included the work of the Database Enhancement Gateway (DEG) which received 2,300 inquiries last year with roughly 50 percent of those inquiries resulting in a time change.

Schulenburg commended the recently dissolved AASP National for contributing five years worth of funding to the DEG, continuing their commitment to the resource they helped build alongside SCRS.

He called it “a generous level of support from the organization to stand behind the programs that mean a lot to their members.”

SCRS will hold its Board elections at its April Open Board Meeting, which will take place in Richmond, VA. Three seats will be open for election as Solis, Robert Grieve (Nylund’s Collision Center; CO) and Dave Gruskos (Reliable Automotive Equipment) will not seek re-election. H&D

euroclassics.porschedealer.com

Mitsubishi now offers Genuine OEM parts through our new “Opt-OE” parts program at discounted prices. See Mitsubishi’s Ultra-Conquest parts and prices in the Optional OEM Suppliers category of popular collision estimating systems.

Ultra-Conquest Collision Parts Program Highlights:

• Discounted prices on quality new and unblemished OEM parts

• Automated price and part selection in collision estimating systems

• High parts availability

• Delivery to most major U.S. cities within 24 hours

To find out more about Ultra-Conquest pricing contact your local Mitsubishi dealer. For Genuine Mitsubishi parts, contact these authorized Mitsubishi Dealers.

Fitzgerald Mitsubishi

1930 West Street

Annapolis, MD 21401

Direct: 410-224-4636

Fax: 410-224-4264

E-mail: adamsf@fitzmall.com

Younger Mitsubishi 1945 Dual Highway Hagerstown, MD 21740

Direct: 800-296-1190

Fax: 301-733-5465 www.youngermitsubishi.com

Buy Genuine Mitsubishi Parts and get the perfect fit at the perfect price. 10% off on all parts orders when you mention this ad.

Safford Brown Mazda Fairfax 10570 Fairfax Boulevard

Fairfax, VA 22030

Toll Free: 800-234-8642

Phone: 703-385-3994

Fax: 703-591-5348

Fitzgerald Mazda 114 Baughmans Lane Frederick, MD 21702

Toll Free: 800-545-4745

Fax 877-696-1841

Email: parts@fitzmall.com www.fitzparts.com

Ourisman Mazda of Rockville 801 Rockville Pike Rockville, MD 20852

Parts Direct: 301-340-7668

Phone: 855-417-4511

Fax: 240-499-2488

Email: rockvilleparts@ourismanautomotive.com www.ourismanmazdaofrockville.com

Fitzgerald Mazda of Annapolis 1930 West Street Annapolis, MD 21401

Toll Free: 866-280-8022

Phone: 410-224-4636

Fax: 410-224-4264

www.fitzmall.com

This year, as Albert Kemperle Inc. celebrates its 83rd anniversary, BASF also celebrates its 158th anniversary. We are proud of our decades of partnership with BASF and years of serving the auto paint and body industry together. Kemperle’s founders would be proud of this relationship and the growth their company has experienced because of it.

Today, as we look forward to many more decades of service to our customers, we find ourselves filled with gratitude. The creativity, hard work, and sense of responsibility of the people working for our two companies have made us what we are today.

Thank you for your many years of loyalty.

626 E. Elizabeth Ave., Linden, NJ 07036 Phone: (908) 925-6133

(908) 925-4344 414-416 Madison Ave., Paterson, NJ 07524 Phone: (973) 279-8300

631 Clifton Ave., Toms River, NJ 08753 Phone: (732) 797-3942

(973) 279-9030

(732) 797-0774 100 Melrich Road, Cranbury, NJ 08512 Phone: (609) 860-2800

(609) 860-2801 4 Emery Ave., Randolph, NJ 07869 Phone: (862) 244-4818

(862) 244-4822 www.kemperle.com

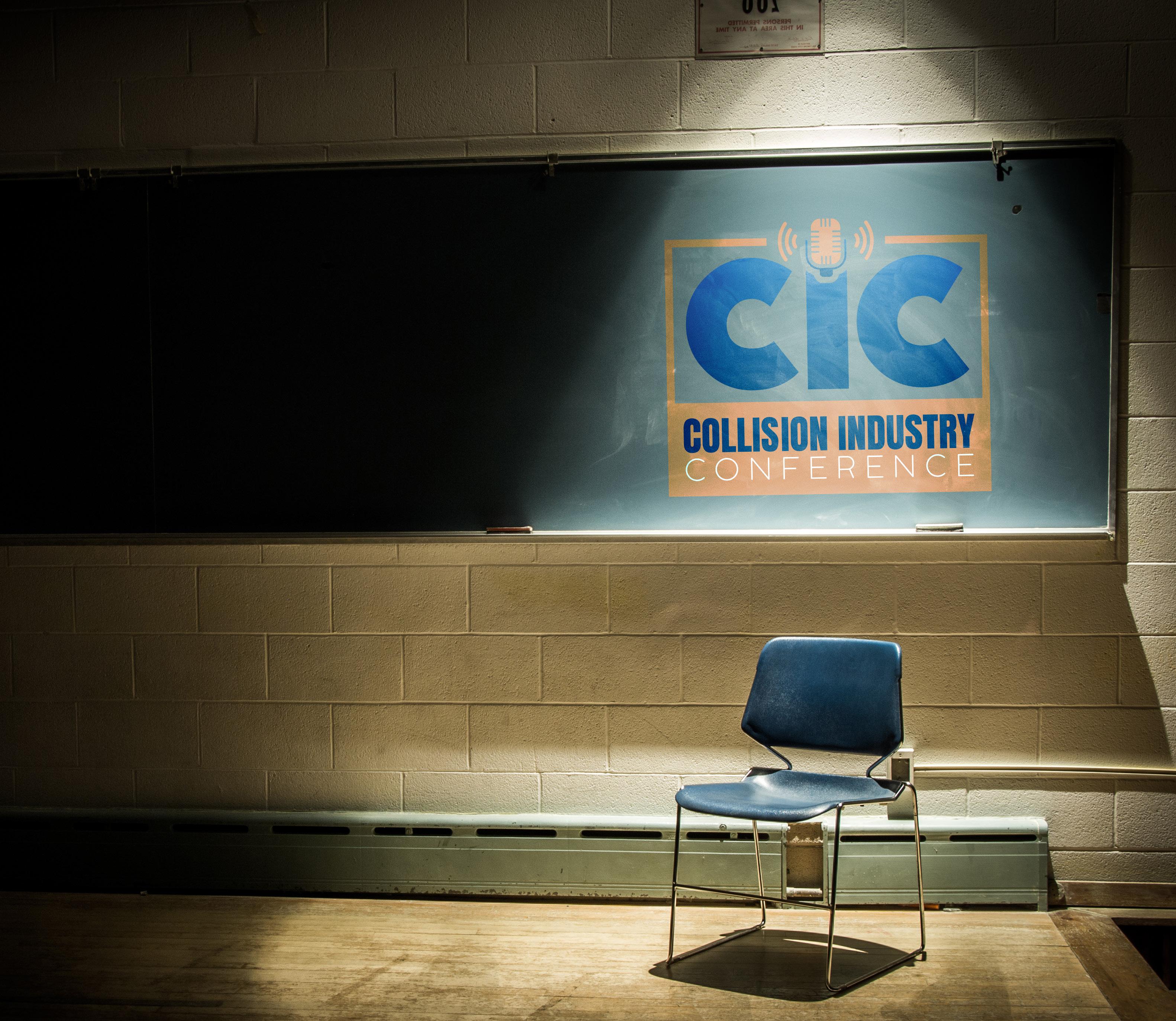

Industry professionals make their way to the Collision Industry Conference (CIC) multiple times a year for many reasons. But one thing is for certain – everyone who takes the time intends to serve the industry and ultimately, the “empty chair” – a symbol for the vehicle owners and families who this industry serves to protect.

CIC Chairman Dan Risley reminded the audience of that message as he kicked off the first event of 2025 in Palm Springs, CA in January.

“It’s a constant reminder to us that the consumer is the end-user,” he said of the “empty chair,” a shining symbol that has been the heart of this conference since former CIC Chairman Jeff Peevy hauled a chair onto the stage five years earlier to make that very point.

Risley set the tone of the day’s intention with conversations focused on doing things right, staying informed and educating the public by sharing two strong messages, “Be what works” and “We’re all here to serve.”

“I don’t think anybody specifically paid to be in this room because you’re getting something for it,” he stressed. “You’re here because you want to serve your industry. You want to serve your customer.”

“‘I’d love to have some intellectually stimulating story to tell you about how I strategically thought this was important to have a chair on stage, but the truth is, I don’t,” Peevy reflected, during a special presentation.

It was born out of a moment of frustration when it occurred to him that “nowhere in the conversation were the families who were riding in the vehicles our industry repaired ever mentioned. I just grabbed a chair, put it up on stage and said, ‘This is going to represent the families who ride in the cars our industry repairs. And we’re going to use this chair as a reminder to all of us of our responsibilities.’ Little did I know that five years later, it would still be up here, and I have been humbled over and over.”

The chair “represents our neighbors,” he continued. “Staying educated needs to be about making complete, safe and quality repairs so that we protect our neighbors.”

The sessions that followed were centered around educating for the sake of the “empty chair.”

Air quality management is a major concern to the south coast. As a result, the South Coast Air Quality Management District (AQMD) has proposed a two-part plan to phase out the use of specific solvents in low-VOC paint manufacturing in that area of California. Although it’s an issue specific to a local region, “this is something that everybody needs to understand,” Parts and Materials Committee Chair Aaron Schulenburg stated as he introduced a panel of experts to educate the audience on what these changes could mean for the industry.

Low-VOC products used in this region contain t-BAC and pCBtF, which means residents are exposed as a result of the 3,000 automotive body shops in the area, according to Heather Farr of the South Coast AQMD who shared the two-phase timeline for when coating manufacturers and the pCBtF are allowed to be sold and used through with both phases to be completely implemented by 2030.

Panelist Gene Lopez (Seidner’s Collision; West Covina, CA) painted a picture of what these changes could mean from a body shop owner’s perspective. He referred to the late ‘90s “when we were beginning to move toward lower VOC material and the heartburn that it created for a lot of the repairers and a lot of suppliers and, of

course, the big manufacturers. I see us going into that again.”

Lopez foresees that changing refinish technology will bring challenges and benefits. “There could be some issues around the equipment that we’re currently using, as much as on the spray gun and some of the spray gun technology.” He believes painters may have to relearn “how to use the higher VOC limit [materials]. But many of you may be happy because that material was really easy to spray.” Lopez expressed concern that 2030 isn’t very far off and the technology that will be used then is not available now.

As panelist Jeff Wildman (BASF) explained, “Paint companies do make different products for different parts of the country to meet the regulations, and that’s really what we focus on when we develop these products. We have to make sure they meet regulations for that country or that state. Because not only do we have different products by state here in North America, but we also have different products locally. We try to standardize those as much as possible,

but we have to meet the local regulations. So, as we see the changes coming in Southern California, we will have different products coming in. For phase one, we’re going to be able to use products that exist in other markets today – whether it be other parts of North America or those coming from Europe, we’ll bring them in just for Southern California. Phase two will bring all new products.”

Monitoring the regulations also poses challenges.

“We have a team of manufacturers who go out to local shops and trace where the product came from,” shared Farr.

“And that’s just one more thing that makes this difficult, because every distributor out there in southern California doesn’t just serve the South Coast Air Quality District,” Wildman added. “They serve customers in other areas, and the manufacturers have warehouses there that serve other areas. And the training centers serve customers coming from different areas. So, it’s a very complicated process to make sure that the right product goes to the right shop at the right time, with the right distributor and managing all that.”

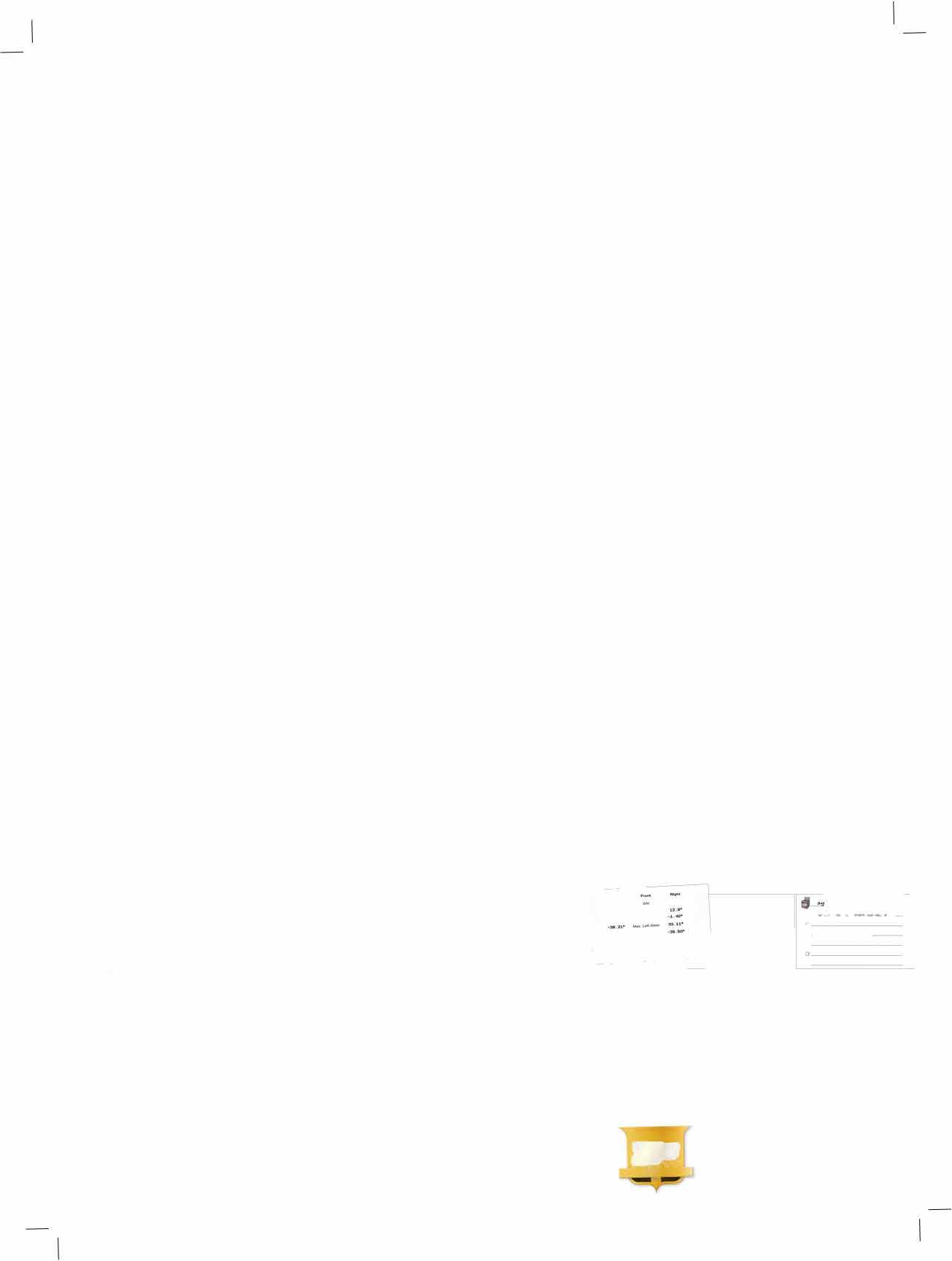

The Repair Process and Procedures Committee recognized the obstacles that lie in the way of measuring for liability, resulting in an engaging panel hosted by co-chairs Kye Yeung (European Motor Car Works; CA) and Barry Dorn (Dorn’s Body & Paint, VA).

Perhaps the largest challenge lies in the fact that people older than 45 still practice the imperial measuring systems, while many

continued on pg. 28

You’ve got the right tools, staff, technology and procedures to give your customers the best repair possible. The missing piece of the puzzle? Genuine Volkswagen Collision Parts. Contact an authorized dealer today and find your perfect fit.

Alexandria Volkswagen 107 West Glebe Rd. Alexandria, VA 22305

703-684-7007

Fax: 703-684-4138

e-mail: parts@alexandriavw.com

Karen Radley Volkswagen 14700 Jefferson Davis Hwy. Woodbridge, VA 22191

703-550-0205

Fax: 703-643-0081

Fitzgerald Volkswagen 114 Baughmans Lane Frederick, MD 21702

Toll Free: 800-545-4745

Fax: 877-696-1841

e-mail: parts@fitzmall.com www.fitzparts.com

“Volkswagen“ and

Fitzgerald Volkswagen of Annapolis 34 Hudson Street Annapolis, MD 21401

Phone: 410-224-4636 Fax: 410-224-4264 www.fitzmall.com

Ourisman Volkswagen of Laurel 3371 Ft. Meade Rd. Laurel, MD 20724

Phone: 301-498-6050

Fax: 301-498-0157 www.laurelvolkswagen.com

Ourisman Volkswagen of Rockville 801 Rockville Pike Rockville, MD 20852

Parts Direct: 301-340-7668

Toll Free: 855-417-4511

Fax: 240-499-2488

e-mail: rockvilleparts@ourismanautomotive.com www.ourismanvolkswagenofrockville.com

Wholesale Parts

under the age of 45 have embraced the metric system.”The problem that we see here is some of the older technicians have not adapted to the metric system,” stated Yeung. “There may be errors as a result of them not understanding the system.“ Rulers and measuring tape are extremely accurate and aid in repairing a car if used properly, but “there’s a huge amount of time savings and documentation” via the enhanced tools available today.

The issue isn’t just with having a proper way to measure; “one of the struggle points that we have is the pushback of compensation,” according to Yeung. “I find it amazing that all of a sudden the industry accepts pre-scanning, but they don’t embrace pre-measuring a vehicle. I’m encouraging all to understand that before you start a repair, it needs to be measured so you can comprehend what the damage is. That’s how you can ensure the ‘empty chair’ is taken care of.”

Technology has come a long way in assisting with this task, so there’s “really no reason a shop owner today does not document a measurement, whether it’s before or after the repair has been done,” according to Yeung.

Ensuring a proper repair gets done lies in pre-measuring, according to panelist Justin Lewis (Accurate Auto Body; WA) who suggested that OEMs consider issuing a position statement. “You might be disguising structural damage that you may not be aware of if you are going by the technician’s eyeball” and could potentially be returning an unsafe vehicle back to its owner.

Lucid Motors plans to make having a visual measuring system a requirement and will be issuing a position statement this May, according to panelist Matt Pitta. “It would be helpful to the shops to have some guidance in how to put things back to pre-loss condition,” adding that he hopes other OEs will follow suit.

Dorn continued to stress the liability factor. “I don’t think any of us want to be the cautionary tale. In order to fix [something properly], you have to know what the dynamic was and how we got there.”

Evolving ADAS continues to impact the industry in new ways. During the Emerging Technologies Committee, panelist Mike Muller (SEMA Garage) brought attention to the new standard ratified by the National Highway Traffic Safety Administration (NHTSA) last June that requires all passengers and light trucks weighing 10,000 pounds or less to have an automatic emergency braking system on board by September of 2029.

Muller spoke of the “pretty strict hard guidelines” OEMs will have to achieve to have the vehicle “avoid contact at up to 62 miles per hour. That means if the car is stopped in front of you and you’re going 62 miles an hour and approaching it, the car must brake and come to a complete stop without contact. If the vehicle is going 61 miles per hour and you recognize the car in front of you is braking and it’s going 62 miles per hour, you have to brake enough to stop and not contact the vehicle. You have to apply the brakes up to 90 miles per hour. So that difference of 90 minus 62 is 28 miles per hour. That’s a magic number as NHTSA determined that fatal accidents don’t occur below 28 miles per hour.”

Vehicles will also have to recognize a pedestrian, brake and avoid hitting the person when driving at 45 miles per hour in daylight and darkness.

Muller stressed this is going to pose a challenge for aftermarket members who must also be compliant by 2030. His team has been “collecting the data to be able to go to Washington, DC, to the OEMs, to the insurers and say, ‘We’re ready. We want to do this safely in the aftermarket. We’re with you. Help us out. What do you need in order to do this?’”

Data privacy has taken center stage at CIC countless times in recent years. On behalf of the Data Access, Privacy & Security Committee, Trent Tinsley (Entegral) spoke about the legislation and litigation taking place all around the country to protect consumer information and data privacy.

It’s becoming a source of revenue for states, Tinsley implied.

Google paid Massachusetts $9.3 million due to misleading customers about tracking information. Sephora paid $1.2 million in penalties to California for failing to disclose that it was selling their customers’ companies to data brokers all over the place. “New Hampshire has now actually created a data privacy union that is specifically going to go after businesses,” he shared.

He suggested shops implement best practices letting customers know they won’t sell their information to a third party and only use the data for the business purpose for which it was intended.

Attendees also learned about OEM certification updates from Kelli Doherty (General Motors), Ken Park (Volvo) and Christian Ruecker (DEKRA) courtesy of the OEM Industry Relations Committee, which was moderated by Liz Stein (Certified Collision Group).

The panelists all stressed that education is key toward getting it right in this industry. It all comes down to finding solutions together, Ruecker professed. “If we don’t talk and educate each other, there’s no common ground in mind. I think that’s just an important part of CIC.”

The next CIC is set for April 30- May 1, 2025 in Richmond, VA. Learn more about the next event and how to register at ciclink.com H&D

PROVIDING INDUSTRY LEADING PROVIDING INDUSTRY LEADING BRANDS AND PRODUCTS FOR YOUR BRANDS AND PRODUCTS FOR YOUR SSUCCESS! UCCESS!

In-house technical support with manufacturer-certified trained staff

In-house business development services

Provide, implement, and train on a variety of the industry’s leading replenishment and invoicing softwares

Provide a team approach to service with teammates who care about your business

ADAS solutions

The new VAS 843007 pneumatichydraulic riveting system is an optimal choice for repairers in need of a modular, high-performance system for riveting tasks. Designed for versatility and precision, its modular technology supports the use of various adapters, dies and tools, enabling a wide range of rivet types to be processed with just one tool for performance in various applications.

Vans. Born to run.

With the inclusion of the Premium Booster, rivets can be processed with impressive speed and setting force to improve efficiency and cycle time in the shop. One of the standout features of the premium booster is its patented function for controllable, force-free rapid advance; this “Smart Control” technology ensures precise and safe positioning of tools and maximum control, even during the most

sensitive of repair operations. The entire pressing or pulling process can be controlled with millimeter accuracy.

The system can be combined with different hydraulic cylinders and C-arms for enhanced functionality, and delivers precise control, ensuring accuracy regardless of the task at hand.

Get your customers back on the road faster with Genuine Sprinter Parts.

With OEM approvals from Audi, Porsche and Volkswagen, the VAS 843007 system is an excellent choice for repairers looking to perform accurate, precise rivets as recommended by the manufacturer.

Call our Sprinter Certified Parts Advisors today to get started.

Sprinter Silver Spring 3301 Briggs Chaney Rd. Silver Spring, MD 20904

301-890-3060 Fax: 301-890-5473

mbsilverspring@mileone.com

Hours: M-F 7:30am-5pm, S 8am-3pm

To learn more about the VAS 843007 system or to view Reliable Automotive Equipment’s full offering of products, services and support, visit raeservice.com

The VAS 843007 riveting system is a modular, high-performance system able to handle a variety of riveting tasks.

Contact our team of Mercedes-Benz Certified Parts Advisors today to get started.

Mercedes-Benz Silver Spring 3301 Briggs Chaney Rd. Silver Spring, MD 20904

301-890-3060 Fax: 301-890-5473

mbsilverspring@mileone.com

Hours: M-F 7:30am-5pm, S 8am-3pm

Quality Repairs Start With Volvo Genuine Parts.

mbsilverspring@mileone.com

For over eight decades, the

M-F

S 8am-3pm

PRESIDENT: Kris Burton kris@Rosslynautobody.com 703-820-1800

SECRETARY: Barry Dorn bdorn@dornsbodyandpaint. com

804-746-3928

VICE PRESIDENT: Phil Rice price@bapspaint.com 540-846-6617

TREASURER

John Shoemaker john.a.shoemaker@basf.com 248-763-4375

EXECUTIVE DIRECTOR: Jordan Hendler 804-789-9649 jordanhendler@wmaba.com

PAST PRESIDENT: Steven Krieps srkrieps@live.com 304-755-1146

Torchy Chandler

torchy.chandler@gmail.com 410-309-2242

Rodney Bolton boltonconsulting61@gmail. com 443-386-0066

Tracy Dombrowkski tracy@collisionadvice.com 571-458-0648

An association fostering the exchange of ideas and providing a voice and support for the collision repair professional.

Just like equipment and training, WMABA membership is not only a commitment to excellence, but also a valuable investment.

WMABA is recognized both regionally and nationally as the key forum for the exchange of ideas concerning the D.C., MD, VA and WV collision repair industry. It is the venue to discuss, learn about and impact evolving standards and policies in the technical, administrative and legislative fronts of our industry. Shops and industry supporters can best develop themselves and their employees by actively engaging in the association and its activities.

Tom Brown thbrown@ppg.com 703-624-5819

Bill Hawkins hawkinswilliamjr@gmail.com 510-915-2283

Automotive collision repair facilities in Maryland, Virginia, West Virginia and Washington, D.C. who are willing to adopt WMABA’s Standards of Membership and offer a guarantee to their consumers are encouraged to engage their business as an active member of the association. For over 40 years, the WMABA membership of professional collision repair businesses and affiliates have committed to operating at a higher standard on behalf of their industry and their consumers. Over the years, WMABA has proudly represented the collision repair industry at hearings on Capitol Hill, in Annapolis, MD, and Richmond, VA as well as almost every national collision repair event. While WMABA has a rich history of dedicated men and women serving the local collision repair community, WMABA also boasts numerous past and current accomplished Board members who represent our membership at the national level.

WMABA offers current and dynamic discussion forums on topics facing collision repairers, technical information and educational seminars, opportunities to network and discuss pressing topics with leaders of the collision repair industry, an arbitration program that works with consumers to help resolve issues they might have, apprenticeship programs, legislative representation and the ability to receive and contribute to one of the nation’s leading collision repair magazines, Hammer & Dolly

Contact Executive Director

Jordan Hendler to find out how WMABA can amplify YOUR voice in the collision repair industry.

This month, we “ASK MIKE” to share his thoughts on whether pursuing electric vehicle (EV) repair is still a viable option for independent shops. We at Hammer & Dolly hope you find the following exchange useful, and we encourage you to reach out to us if you have a question for Mike on this or any industryrelated matter that he can answer in a future issue.

Hammer & Dolly: Electric vehicles have been the talk of the town for years now, with ongoing discussions about their potential to reshape the industry. You have years of experience consulting with shops that have ventured into EV repairs. From your perspective, where do you see EVs’ current presence in the industry? Is it still the gamechanger that everyone thought it would be a few years ago?

Mike Anderson: It’s similar to the transition with aluminum. There was a lot of skepticism when it was first introduced. As people got educated, those myths were debunked, and the industry adapted. EVs are on a similar trajectory. While I don’t have a crystal ball by any means, it seems that political attention on EVs is shifting — Republicans don’t seem as focused on it as Democrats once were. EVs’ long-term impact on the industry depends on how quickly adoption rates rise. Based on how things stand today, it’s essential that shops stay proactive, research trends and stay updated on advancements, especially if they’re certified for specific brands. In areas with a high EV presence, continuing this research can give shops a competitive edge in the future. Shops that are wellpositioned with the right training and equipment stand to benefit as adoption rates grow, but staying flexible will be key as the market continues to evolve and diversify.

H&D: For your shop clients who’ve invested in EVs, how would you assess their current return on investment in terms of equipment, training and overall profitability? Are they seeing steady demand, or are there challenges in recouping their investment due to market fluctuations or customer volume?

MA: Some shops have seen a lot of work with certain EVs. The shops I’ve talked to that have invested in Rivian seem to be busy and are getting a lot of work sent to them. However, some other EVs haven’t generated as much work. Some shops are now rethinking their decision and questioning whether the investment has been worth it given the uneven demand and profitability.

There are two key factors to always consider: return on investment and return on objective. Some businesses might not be seeing positive ROI, but they continue to pursue EV work primarily to safeguard their market position. For them, the goal is to prevent competitors from capturing that business, ensuring they maintain a foothold. Many are viewing their involvement in EVs as a strategic move – not just a financial one. It’s a way of future-proofing their business, even if it doesn’t generate immediate profit.

H&D: You owned shops in the WMABA region. If you were on that side of the industry today, what would be your position on EVs? Would you make that investment?

MA: Absolutely. In the Washington DC/Maryland/Virginia area, there are enough EVs to support a move in that direction. Sometimes, you must hedge your bets. It’s like retirement –investing not for immediate returns but for long-term growth. If I were still operating a shop in the WMABA region, I would definitely focus on repairing EVs. Of course, starting out always carries risk, and you must weigh the odds against your investment carefully. However, if you already have most of the equipment, the investment is relatively minimal, and the potential for success is much higher. Ultimately, the key is

evaluating whether the venture has long-term growth potential. Take GM’s BrightDrop, for example, which could expand significantly in the future. Adapting to these trends early could position a shop for greater success down the road.

H&D: You mentioned aluminum earlier, and we all remember when that wave hit. A lot of independent shops made a mad dash to get as educated on it as possible, which is always a major concern whenever we’re hit with something new. Is the industry providing adequate, easily accessible information on EVs to the independents?

MA: I-CAR is certainly stepping in and trying to fill that void, and we have OEM-specific training. The OEMs are doing a good job of rolling that out.

H&D: Besides EVs, what are some other investment opportunities that may offer a clearer crystal ball at this point in time?

MA: Doing service work on the mechanical side is a very different business model, but it could be a valuable investment. Bringing your glass work, alignments and mechanical repairs in-house may be worthwhile for many shops. Back in the ‘60s and ’70s,

shops often sublet their frame work, but over time, everyone started bringing it in-house to have more control over costs, quality and turnaround times. I think it’s the same scenario with mechanical work today. While calibrations may not be the best option considering the amount of space needed to perform them correctly, there are many other services that shops could be performing in-house — things they’re often overlooking or underestimating. Expanding in this way could help increase overall efficiency and profitability.

Mike Anderson is an Accredited Automotive Manager (AAM) and the former owner of Wagonwork Collision Centers, two highly acclaimed shops located in Alexandria, VA. He has served as a member of many industry organizations throughout his career, including the WMABA Board of Directors, the Mitchell Advisory Board, the MOTOR Advisory Board, the ASE Test Review Committee, the National Auto Body Council, the Collision Industry Conference and the Society of Collision Repair Specialists. Additionally, he is a past Virginia SkillsUSA chairman, serves as a facilitator for Axalta Coating Systems’ highly recognized Business Council 20 Groups in both the US and Canada and facilitates numerous courses for Axalta Coating Systems’ Educational Series. He currently offers expert industry consulting via his latest venture, Collision Advice (collisionadvice.com). H&D

ADAS calibration is the precise adjustment of your vehicle’s sensors and cameras, essential for the optimal functioning of advanced safety systems. This process is especially critical following significant repairs, part replacements, collisions, or windshield replacements, as these events can disrupt sensor alignment.

It’s important to avoid driving without proper sensor calibration. Uncalibrated ADAS sensors can compromise your vehicle’s safety features, leading to potential malfunctions and driving hazards.

ADAS calibration is the precise adjustment of your vehicle’s sensors and cameras, essential for the optimal functioning of advanced safety systems. This process is especially critical following significant repairs, part replacements, collisions, or windshield replacements, as these events can disrupt sensor alignment. It’s important to avoid driving without proper sensor calibration. Uncalibrated ADAS sensors can compromise your vehicle’s safety features, leading to potential malfunctions and driving hazards.

The calibration of ADAS can be performed in two main ways: static and dynamic. Static calibration takes place in a controlled environment, ensuring accuracy and consistency. Dynamic calibration, on the other hand, involves driving the vehicle under specific conditions to fine-tune the sensors in real-world scenarios. This comprehensive approach ensures that your vehicle’s

The calibration of ADAS can be performed in two main ways: static and dynamic. Static calibration takes place in a controlled environment, ensuring accuracy and consistency. Dynamic calibration, on the other hand, involves driving the vehicle under specific conditions to fine-tune the sensors in real-world scenarios. This comprehensive approach ensures that your vehicle’s safety systems are reliable and effective, providing peace of mind on the road.